Preparation method for preparing polyurethane marble-imitated decorative material from industrial saponification waste residues

A decorative material, polyurethane technology, applied in the field of architectural decorative materials, can solve the problems of small amount of addition, high cost, etc., and achieve the effect of light weight, low density and easy breakage

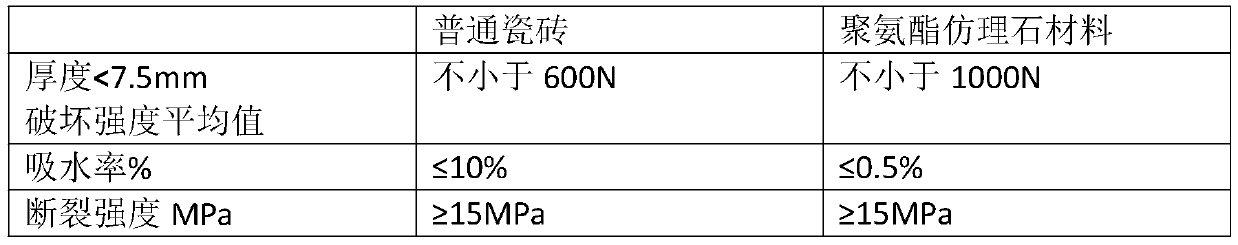

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Heat up polyether triol with a molecular weight of 5000 and a functionality of 3 to 120°C for dehydration for 2 hours, then add polyphenyl polymethylene isocyanate (PAPI) after cooling down and react in a reactor at 70°C to 80°C 2h, generate NCO=25% polyurethane prepolymer; dry and grind the saponification waste residue of filler industry at 200 mesh to 600 mesh, use polyether diol with molecular weight of 2000 and functionality of 2 to heat up to 120°C for dehydration Standby, take 107 grams of dehydrated polyether glycol, 54 grams of 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA), and mix MOCA in polyether glycol at 100°C Melt, add 261 grams of industrial saponification waste slag after drying and grinding, add 0.8 grams of dibutyltin silicate, 7.8 grams of 3-glycidyl etheroxypropyl trimethoxysilane (KH560) and mix well as a chain extender Components: Mix 100 grams of polyurethane prepolymer and 431 grams of chain extender components evenly at room temper...

Embodiment 2

[0029] Example 2: Heat up the polyether triol with a molecular weight of 3000 and a functionality of 3 to 120°C for dehydration for 2 hours, then add modified diphenylmethane diisocyanate (Hunsman 2412) to react at 70°C to 80°C after cooling down React in the kettle for 1 hour to generate NCO=20% polyurethane prepolymer; dry and grind the filler industrial saponification waste residue at 200 mesh to 600 mesh, use polyether diol with a molecular weight of 2000 and a functionality of 2 to heat up to Dehydration at 120°C for later use, take 91 grams of dehydrated polyether diol, 43 grams of 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA), and heat the polyether diol at 100°C Melt MOCA in the medium, add 234 grams of dried and ground industrial saponification waste residue, 0.7 grams of stannous octoate, and 7.3 grams of 3-glycidyl etheroxypropyl trimethoxysilane (KH560) and mix well as a chain extender group point. Mix 100 grams of polyurethane prepolymer and 376 grams of chain...

Embodiment 3

[0031] Example 3: heat up polyether diol with a molecular weight of 1000 and a functionality of 2 to 120°C for dehydration for 2 hours, add polyphenyl polymethylene isocyanate (PAPI) after cooling down, and react in a reactor at 70°C to 80°C 2h, generate NCO=15% polyurethane prepolymer; dry and grind the saponification waste residue of filler industry at 200 mesh to 600 mesh, use polyether triol with a molecular weight of 3000 and a functionality of 3 to heat up to 120°C for dehydration Standby, take 80 grams of dehydrated polyether triols, 36 grams of 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA), and dissolve MOCA in polyether triols at 100°C After melting, add 216 grams of dried and ground industrial saponification waste residue, 0.6 grams of stannous octoate, and 6.5 grams of 3-glycidyloxypropyl trimethoxysilane (KH560) and mix uniformly as chain extender components. Mix 100 grams of polyurethane prepolymer and 340 grams of chain extender components evenly at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com