Shale reservoir post-fracturing seepage microscopic model, manufacturing method and experimental device

A shale reservoir and microscopic model technology, applied in the field of shale oil and gas reservoir research, can solve problems such as difficulty in observing seepage and inability to simulate shale reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Experimental device Experimental operation process:

[0082] 1) Inhale the fluid to be injected with a Luer sampler and place it on a Harvard PHD 22 precision syringe pump;

[0083] 2) Use a 1 / 16-inch outer diameter peek pipeline to connect the Luer sampler to the joint port 11 of the micromodel;

[0084] 3) Place the microscopic model on a Lecia DM2700 M upright metallurgical microscope;

[0085] 4) Connect the CYYZ35 intelligent pressure transmitter to the 1 / 16-inch outer diameter peek pipe in step 2), and observe the pressure change;

[0086] 5) Adjust the flow rate, start the Harvard PHD 22 precision syringe pump, so that the fluid flows into the micromodel joint port 11 through the 1 / 16-inch outer diameter peek pipeline;

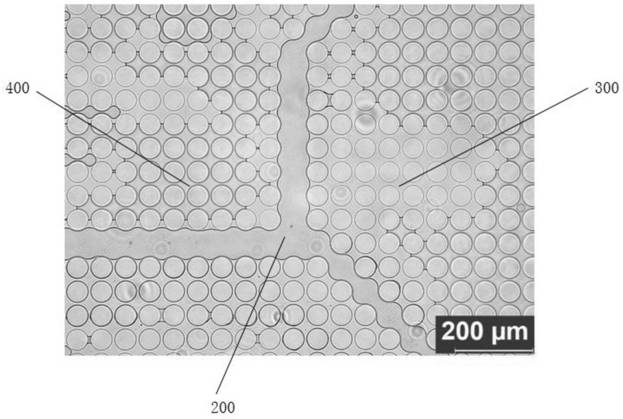

[0087] 6) Open the Leica imaging software LAS EZ in the computer, adjust the eyepiece and objective lens multiples of the Lecia DM2700 M upright metallurgical microscope, so that the internal structure of the microscopic model can be clearly im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Crack width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com