Hammer disk structure for single-segment hammer crusher

A single-stage hammer type and crusher technology, applied in the direction of grain processing, etc., can solve the problems of uneven force on the hammer shaft, wear, and short life of the hammer plate, so as to save the use cost, improve the service life, and increase the force face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

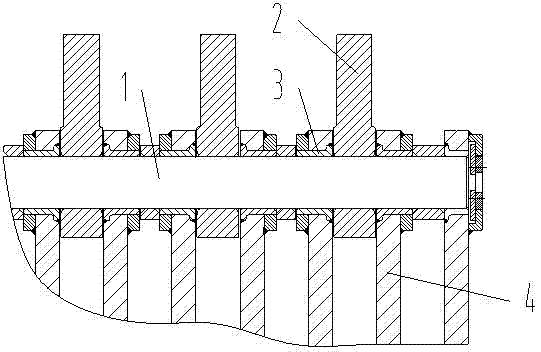

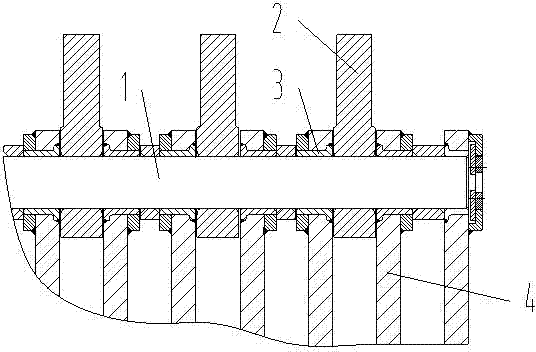

[0010] see figure 2 In the hammer disc structure of the present technology shown, the hammer head 2 is connected to the hammer shaft 1, a wear-resistant alloy bushing 3 is arranged in the hammer shaft hole on the hammer disc 4, and the hammer shaft is rotatably arranged in the bushing. The hammer shaft forms a rotating pair with the hammer shaft hole through the bushing 3 . The hardness of the bushing is 268-296HB.

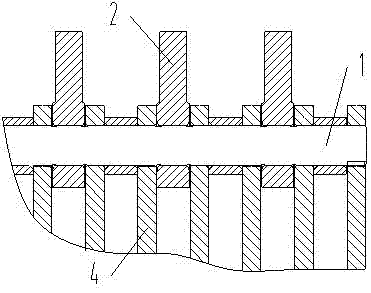

[0011] see figure 1 In the hammer-disc structure shown, the hammer head 2 is connected to the hammer shaft 1 , and the hammer shaft 1 is arranged in the hammer shaft hole on the hammer plate 4 . The hammer shaft and the hammer shaft hole directly form a rotating pair.

[0012] This technology is a structural improvement for the rotor hammer disc. On the basis of the original hammer disc, a wear-resistant alloy bushing is added to the hammer shaft hole of the hammer disc. The alloy bushing is made of high-quality wear-resistant alloy forgings, quenched and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com