Extra-heavy casement window sliding support hinge

A technology of sliding brace hinges and casement windows, which is used in building fastening devices, wing sash fastening devices, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

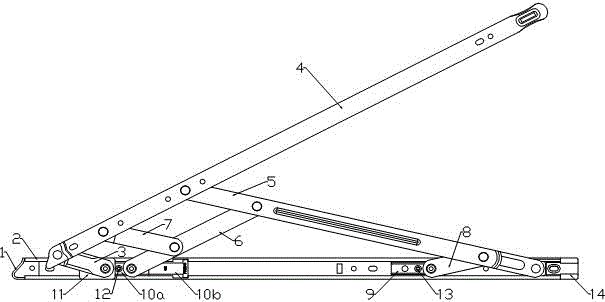

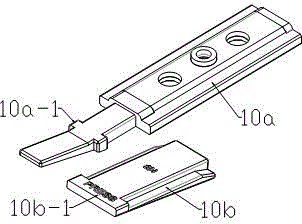

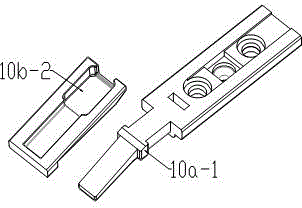

[0027] refer to figure 1 , Figure 9 , the overweight casement window sliding stay hinge of the present invention is composed of a slide rail 2, a first slider 10, a second slider 9, a movable support gasket 11, a first short support cantilever 3, a second short support cantilever 8, a long support cantilever 5. The top support cantilever 4, the reinforced support cantilever 7 and the sixth support cantilever 6 are assembled: one end of the second short support cantilever 8 is hinged with the second slider 9 through a rivet 171 and then loaded into the slide rail 2; the first short support cantilever 3. The support cantilever 6 is articulated with the movable supporting spacer 11 and the first slider 10 through rivets 172, 173 and then loaded into the slide rail 2; one end of the support cantilever 5 is hinged with the nylon spacer 161 and the slide rail 2 through the rivet 174; The middle part of the long support cantilever 5 is hinged with the other end of the nylon spacer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com