Flat seal having a deformation limiter

A gasket and waveform technology, applied in the field of metal layers, can solve the problems of bead rupture, reduction of bead strength and elastic potential energy, reduction of bead elastic characteristics, etc., to achieve the effect of saving bead and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

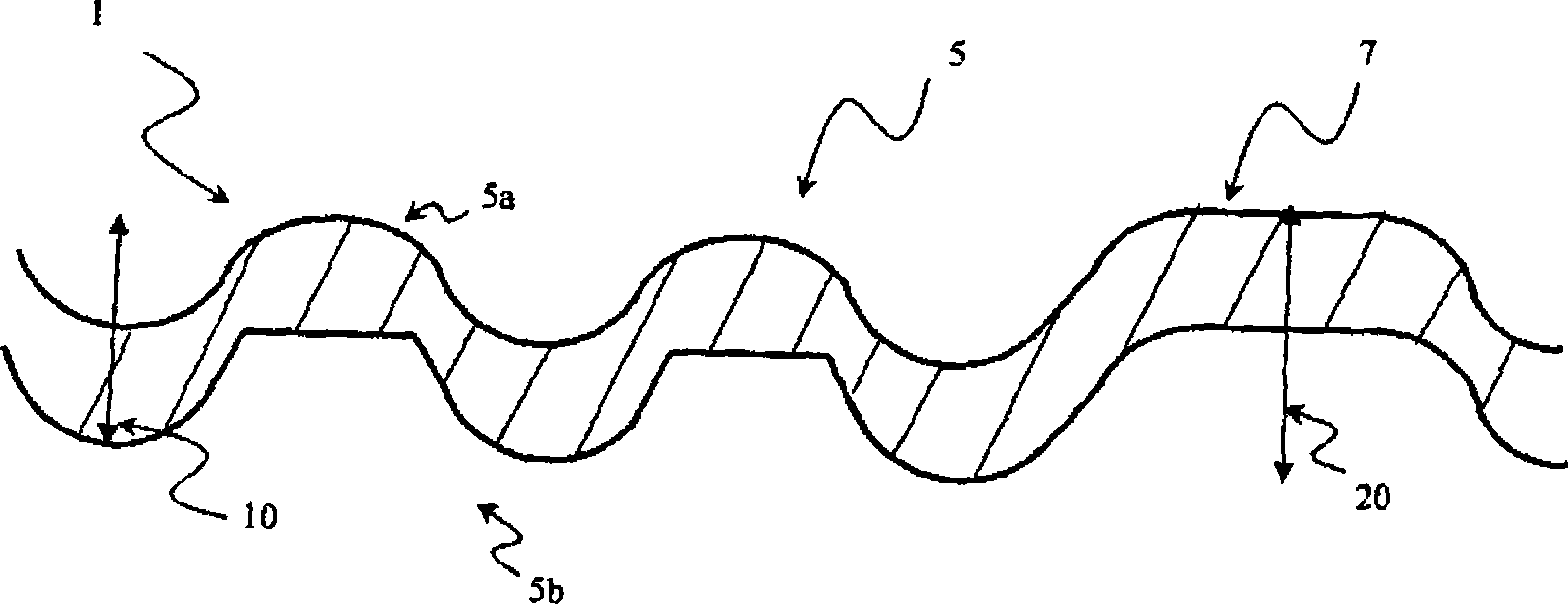

[0029] figure 1 Details of the metal layer 1 within the flat gasket are shown. A profile 5 is embossed as a detent on the metal layer, which profile has a corrugated structure 5a on one side and a contour 5b consisting of a corrugated structure with flat bottoms on the other side. The height 10 of the profile extends between the amplitude of the undulating structure and the amplitude of the peaks of the profile. A bead 7 is arranged close to the brake, the bead 7 having a height 20 . The height 20 of the bead is greater than the height 10 of the profile. The bead does not necessarily have to be imprinted onto the metal layer in the same direction as the wave structure, it can also extend in the direction of the profile.

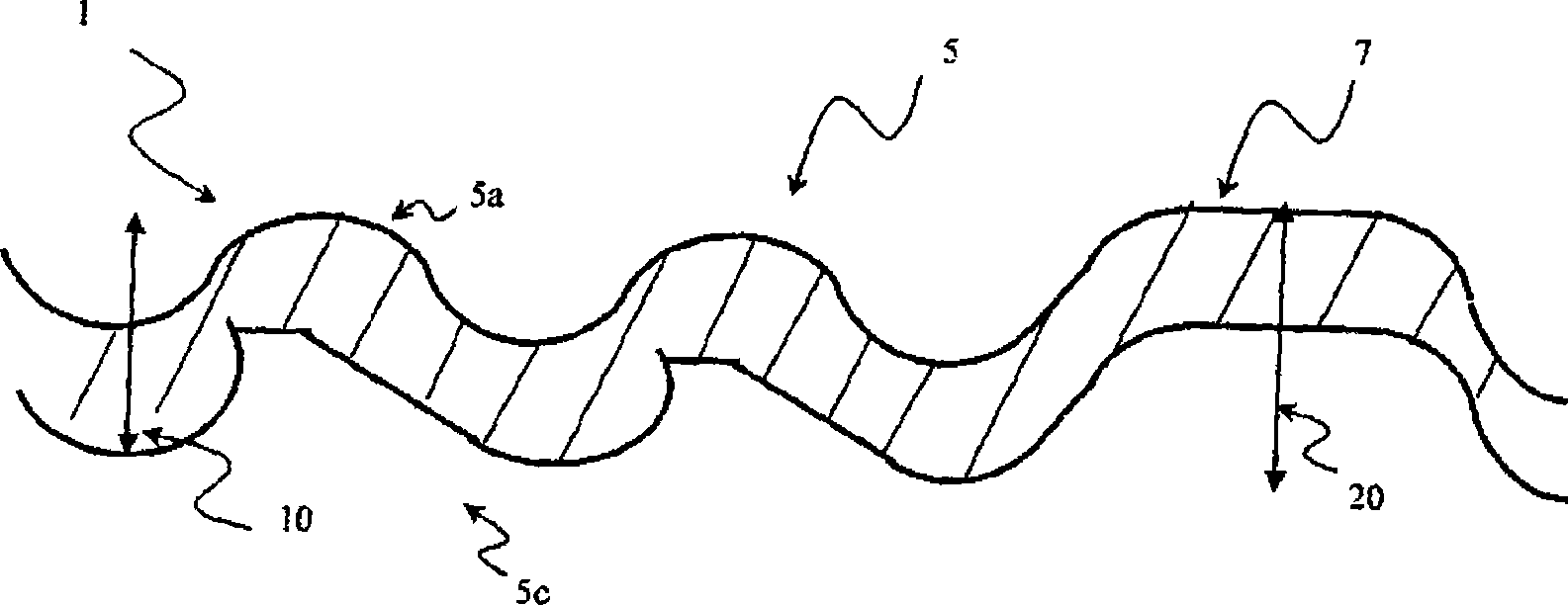

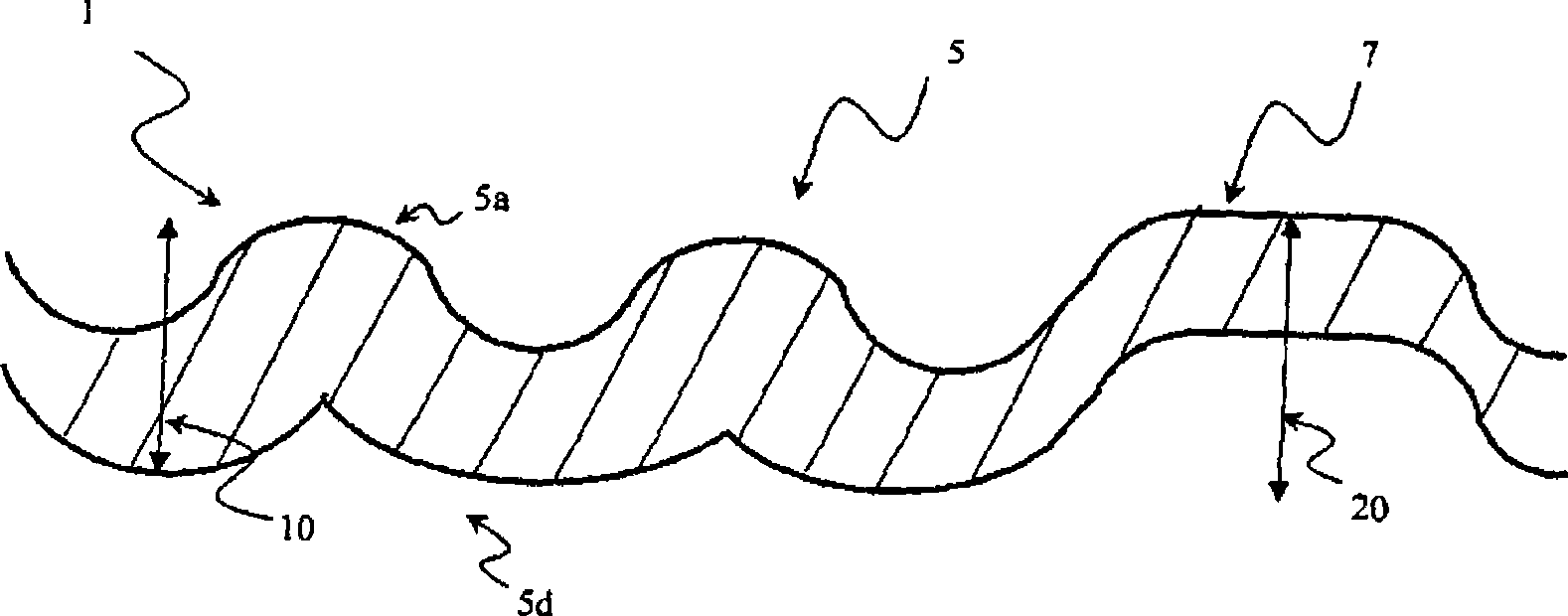

[0030] figure 2 A schematic side sectional view of a part of a flat gasket with another embodiment of the profile according to the invention is shown. The metal layer 1 of the flat gasket has a contour 5 . The profile 5 includes a corrugated structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com