Patents

Literature

111results about How to "Change elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

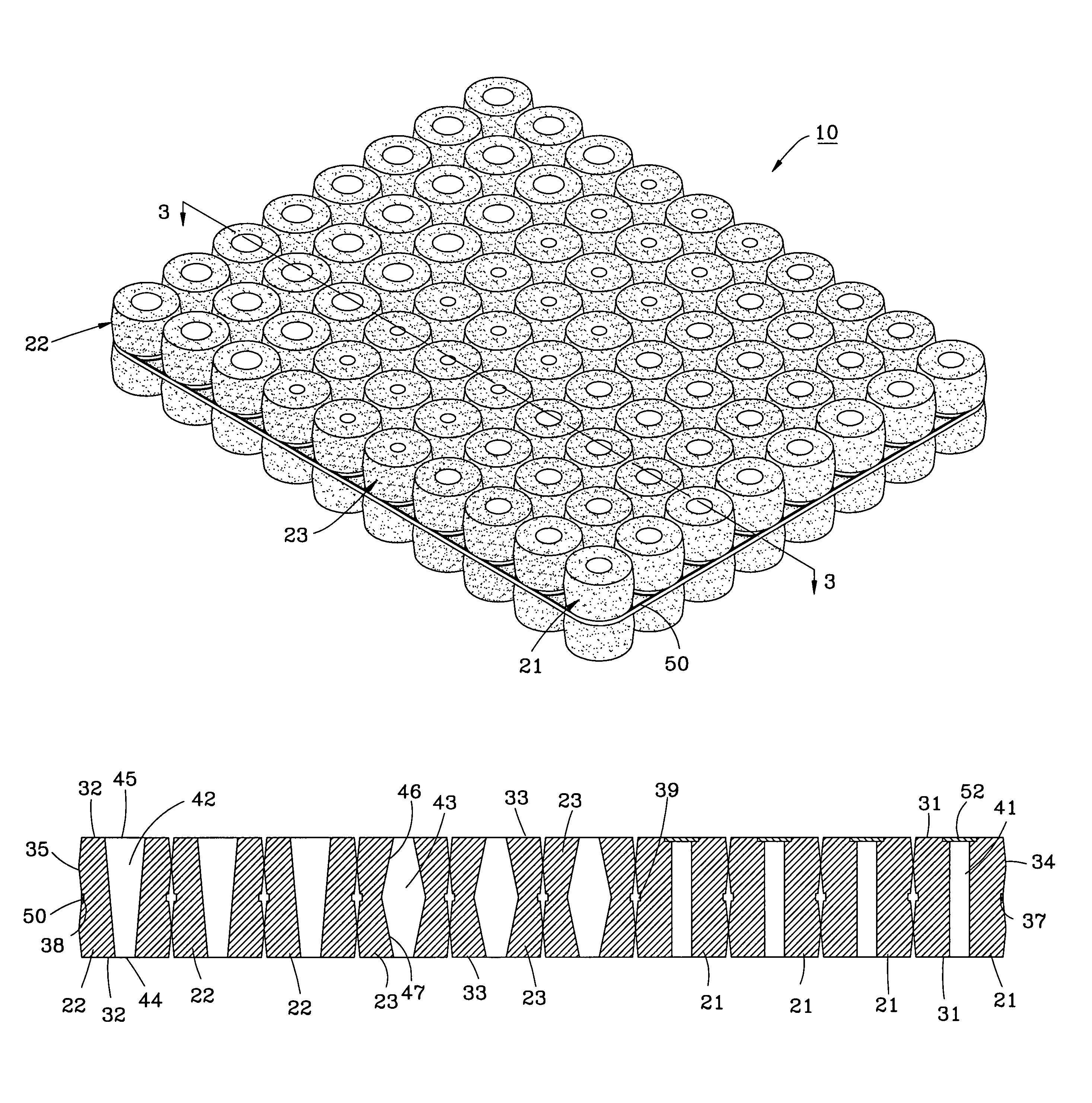

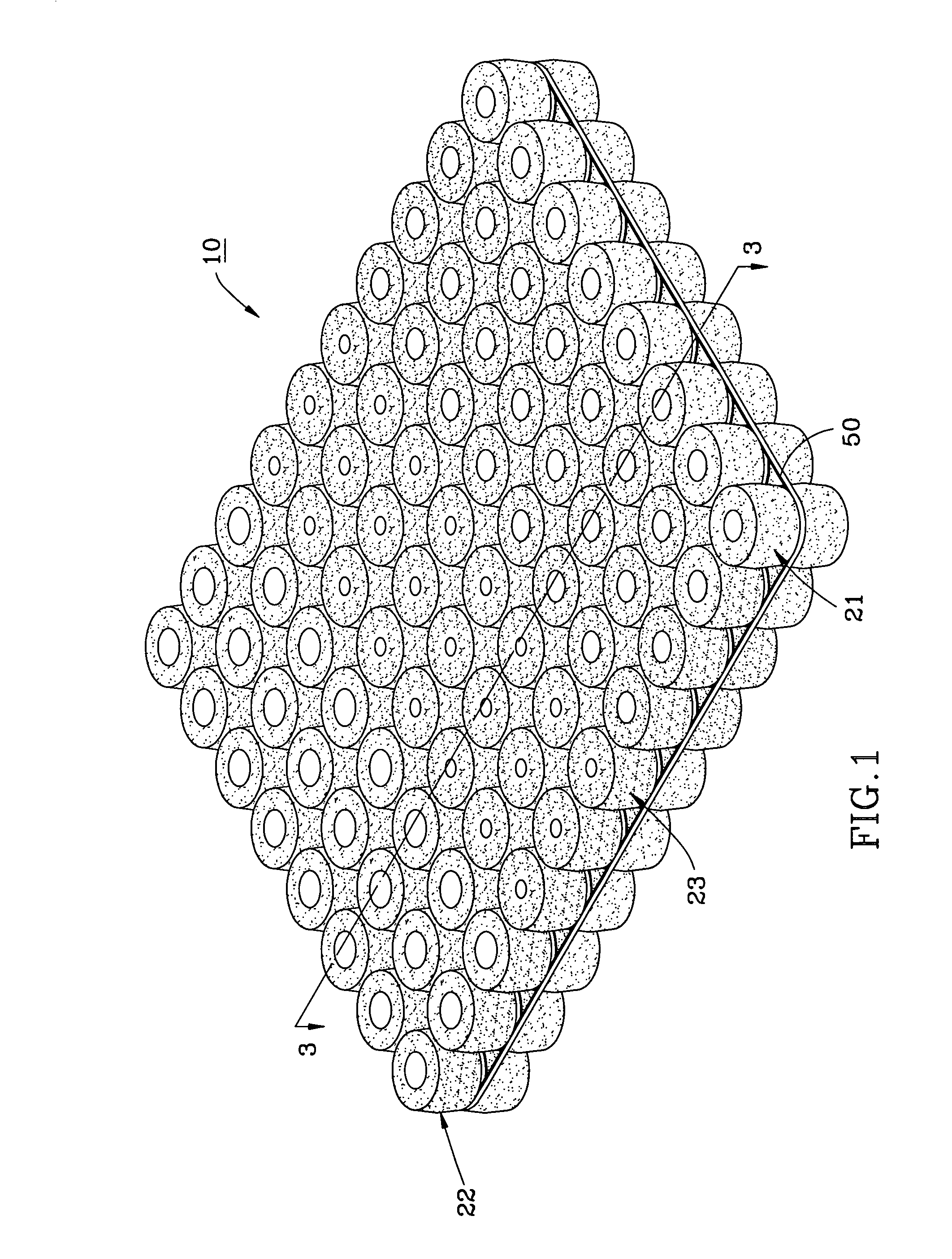

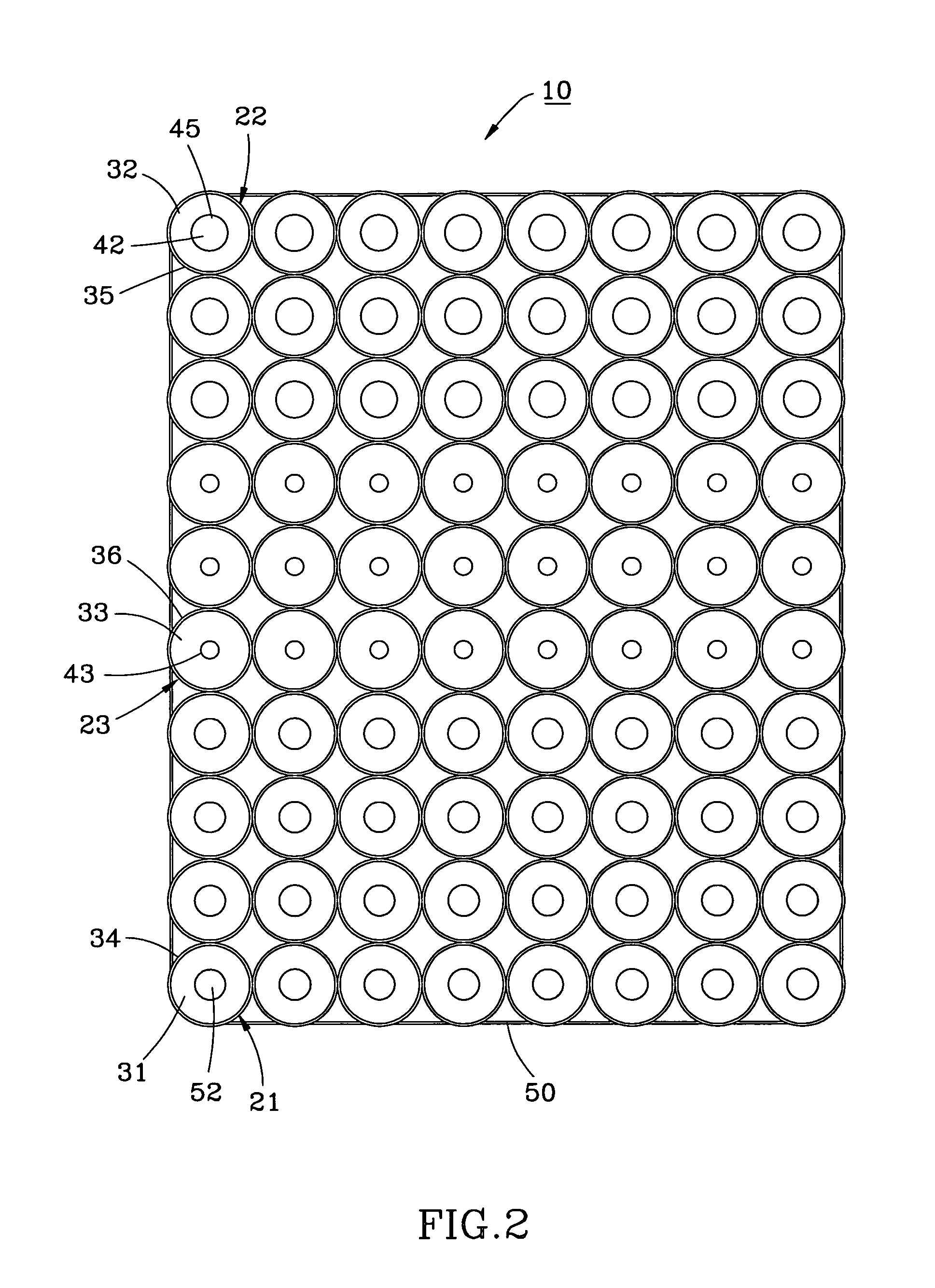

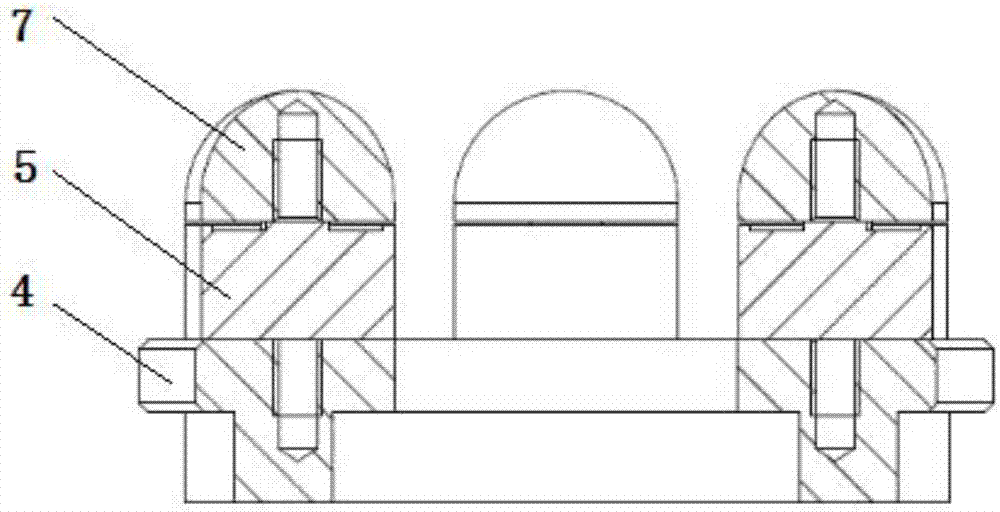

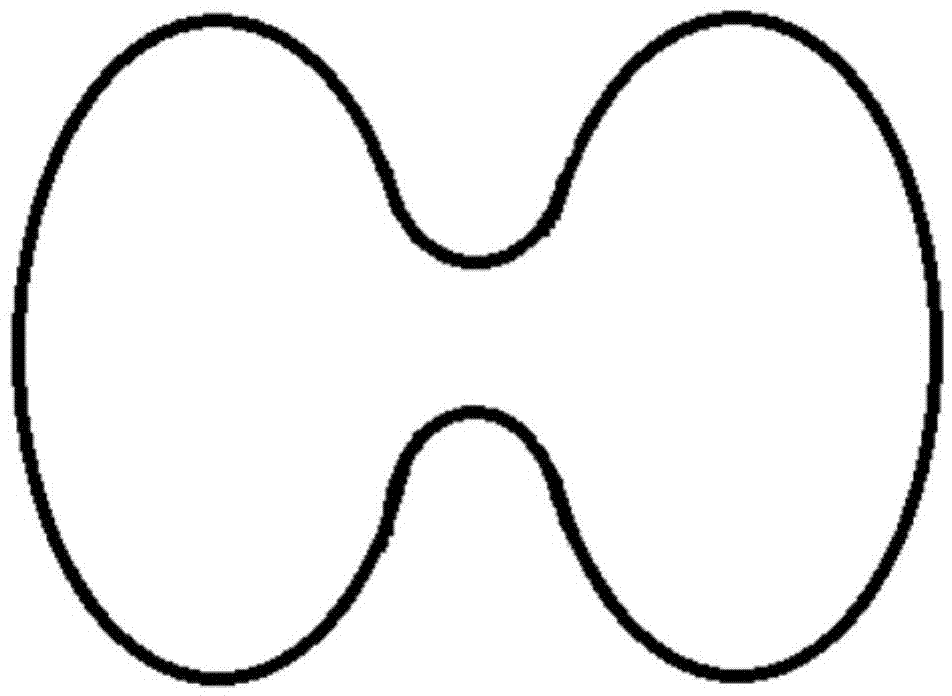

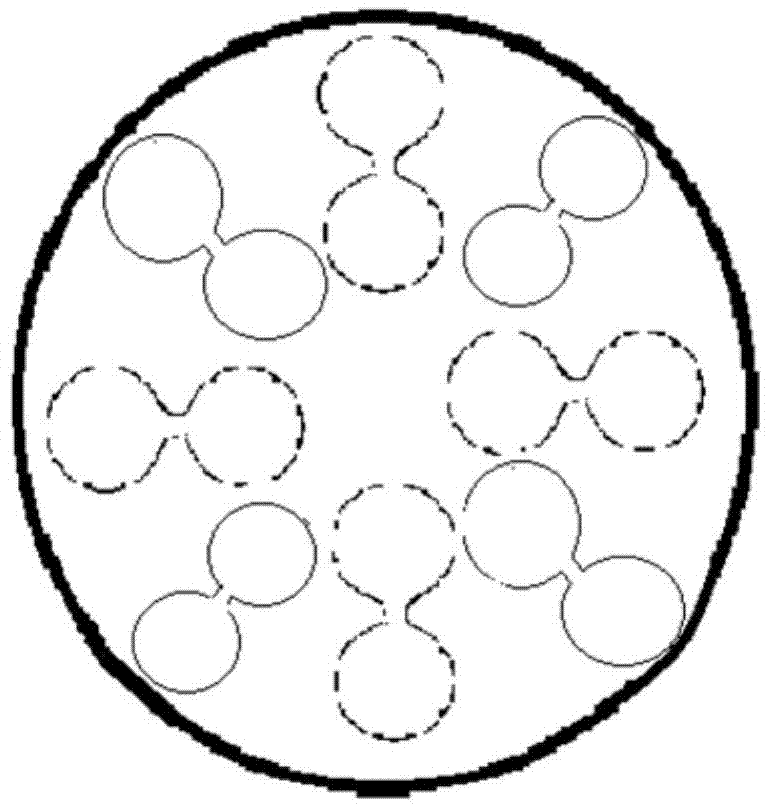

Combination mattress

A combination mattress includes a plurality of independent barrels each having two resting faces and an outer peripheral face extending between the two resting faces. Each independent barrel has a recess extended through the two resting faces. The independent barrels are combined together with the outer peripheral faces abutting mutually.

Owner:LIAO HSIU CHEN

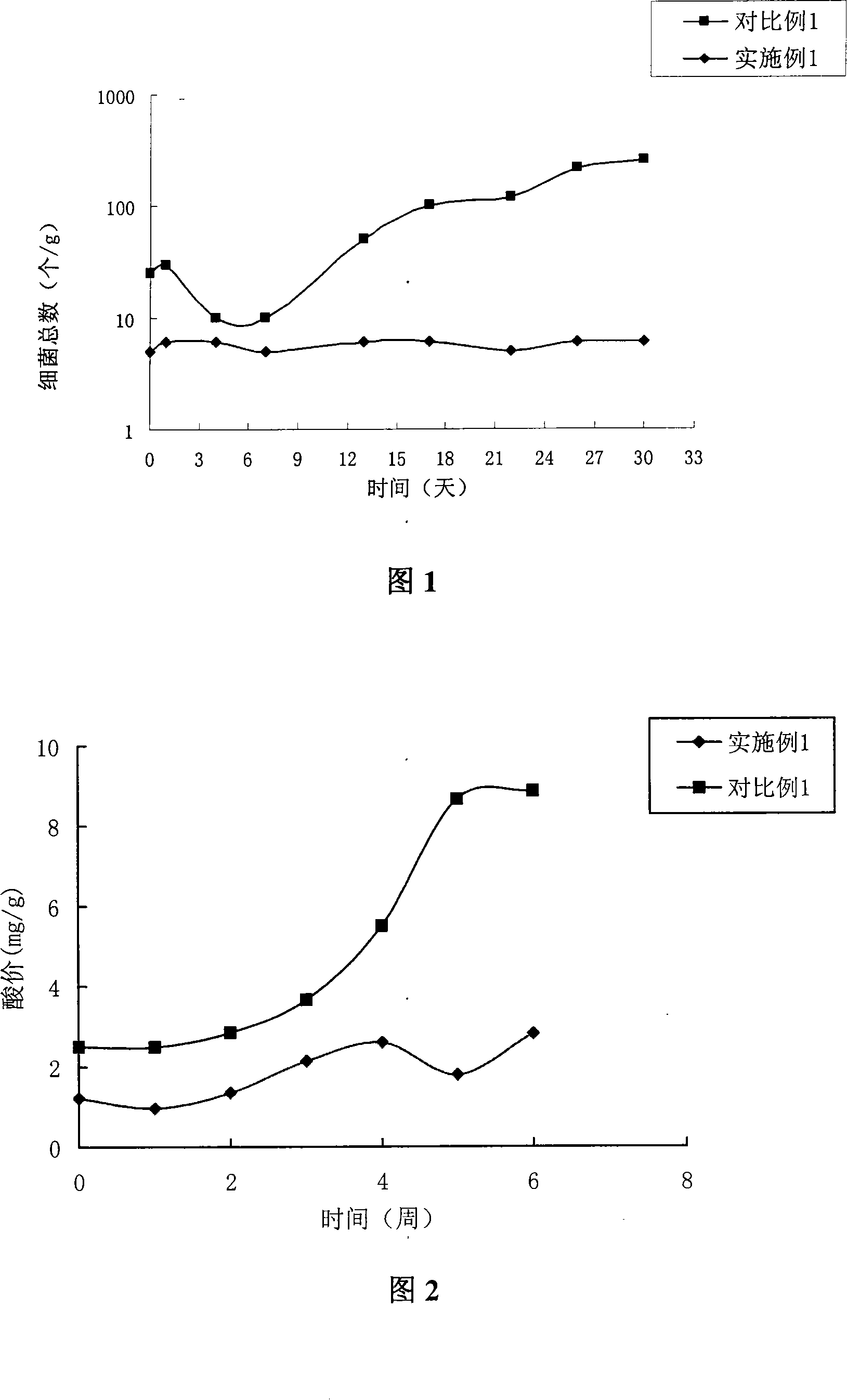

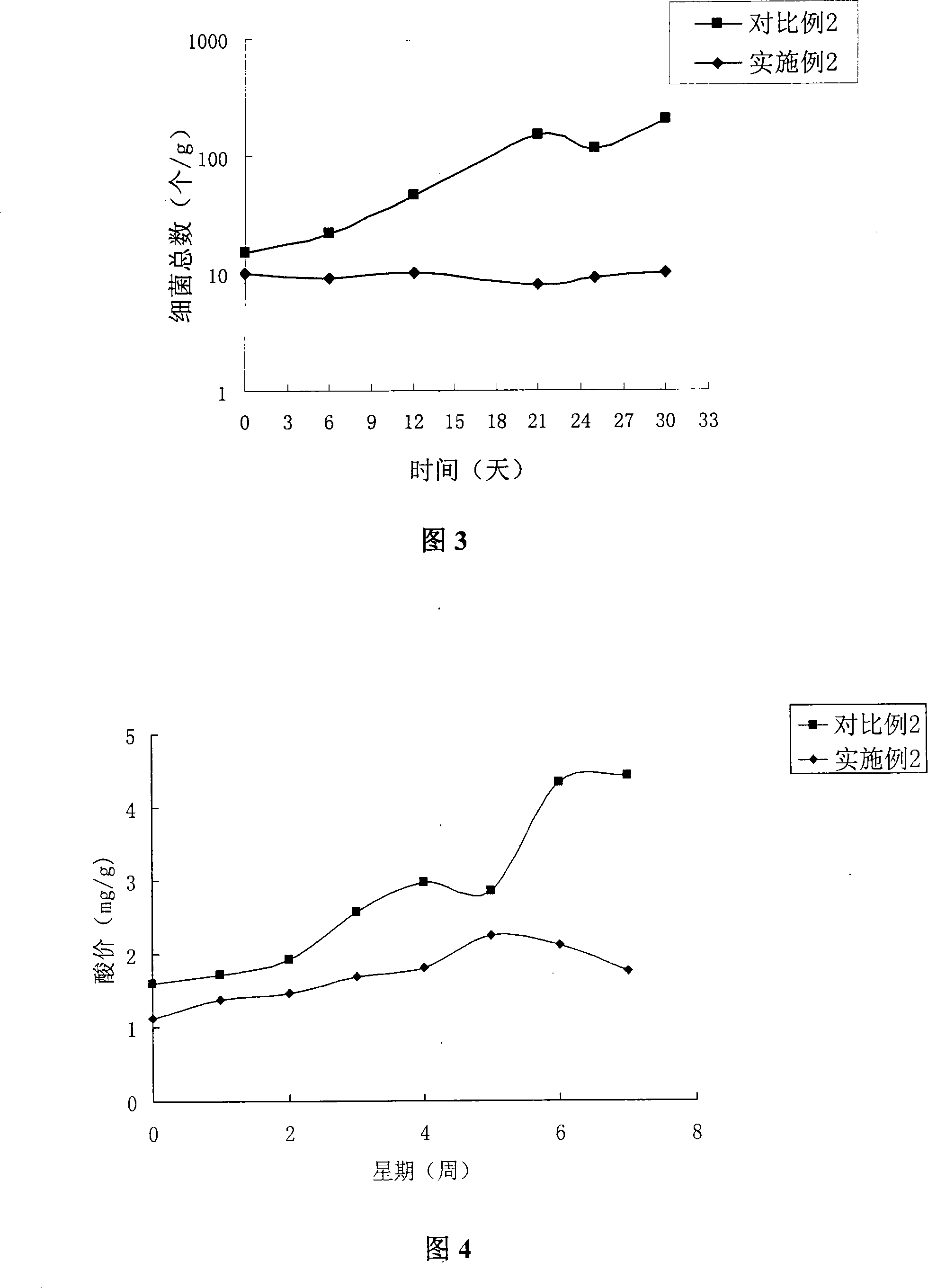

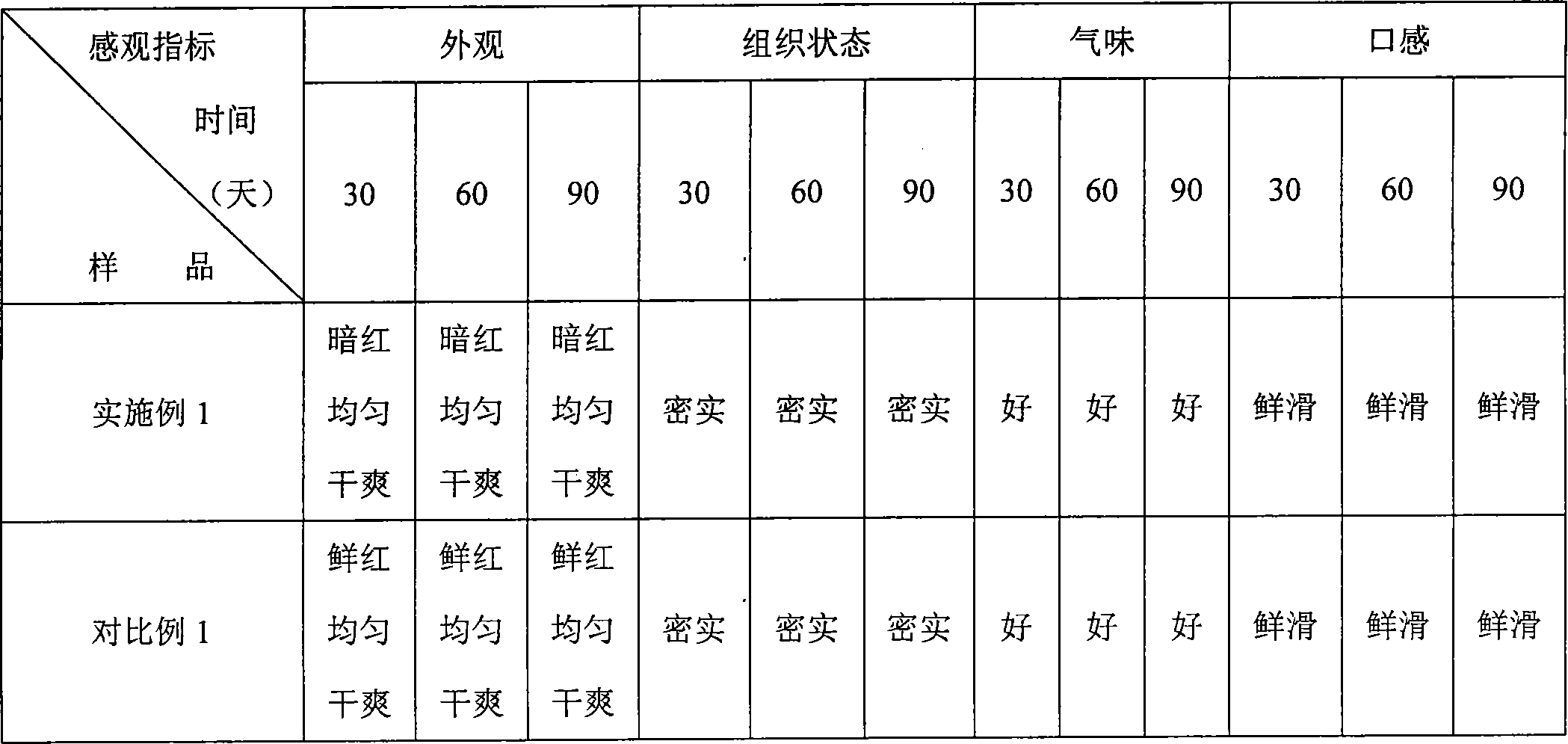

Fresh-keeping method for pickle cured meat product

InactiveCN101156616AWon't taste badThere will be no serious problems such as the destruction of nutrientsMeat/fish preservationCyclic processVacuum pack

The invention discloses a fresh keeping method for salted and preserved meat products. The fresh keeping method is realized by putting the vacuum-packed salted and preserved meat products in liquid pressure medium in the super-high pressure container under 20-60 DEG C for 1-3 times of cyclic processes of pressurizing, pressure keeping, and pressure discharging, the freshness date of the high-pressure processed salted and preserved meat products can be prolonged to one year in the normal temperature. The fresh keeping method for the salted and preserved meat products of the invention can effectively prolong the freshness date of the salted and preserved meat products, can be used in various salted and preserved meat products, such as sausage, preserved ham, preserved duck, and preserved beef.

Owner:GUANGDONG FOOD IND INST +2

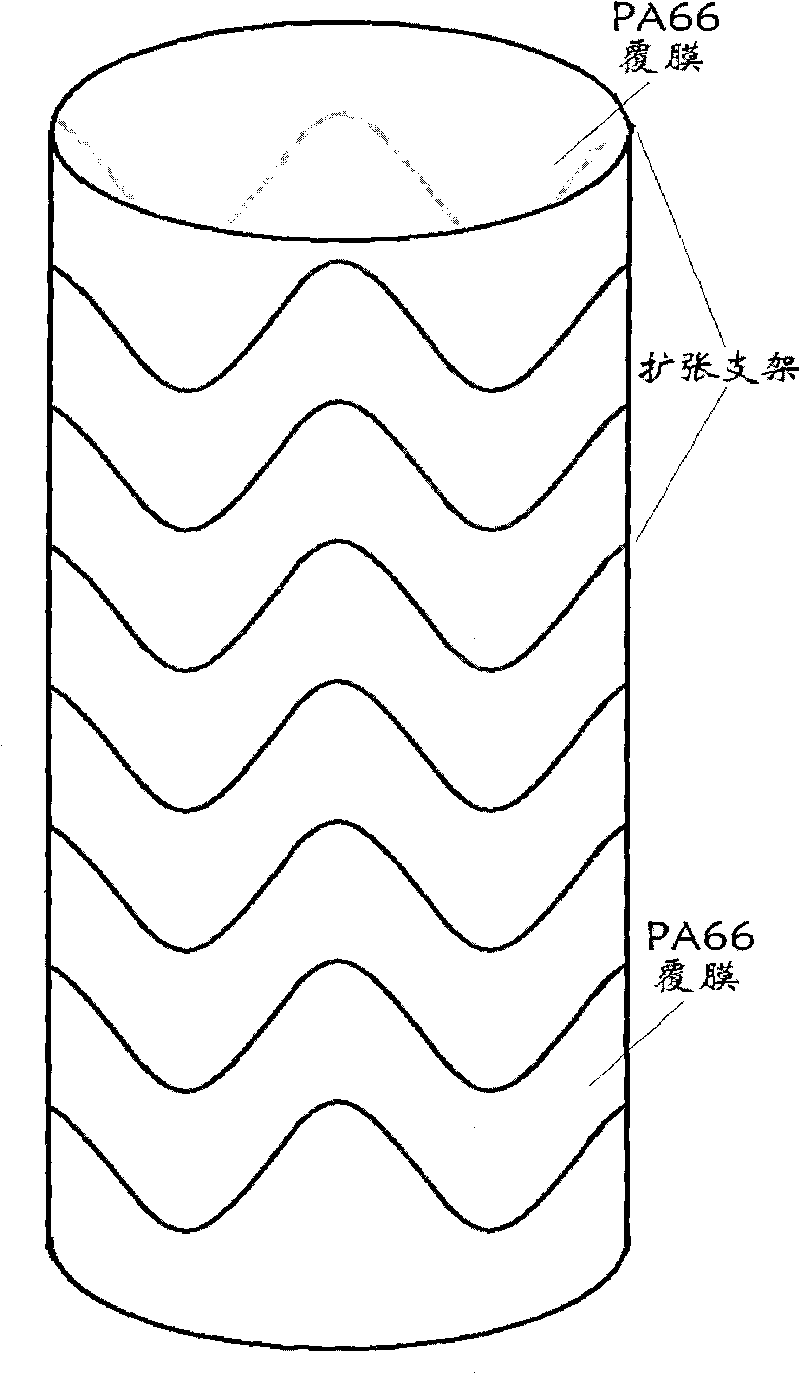

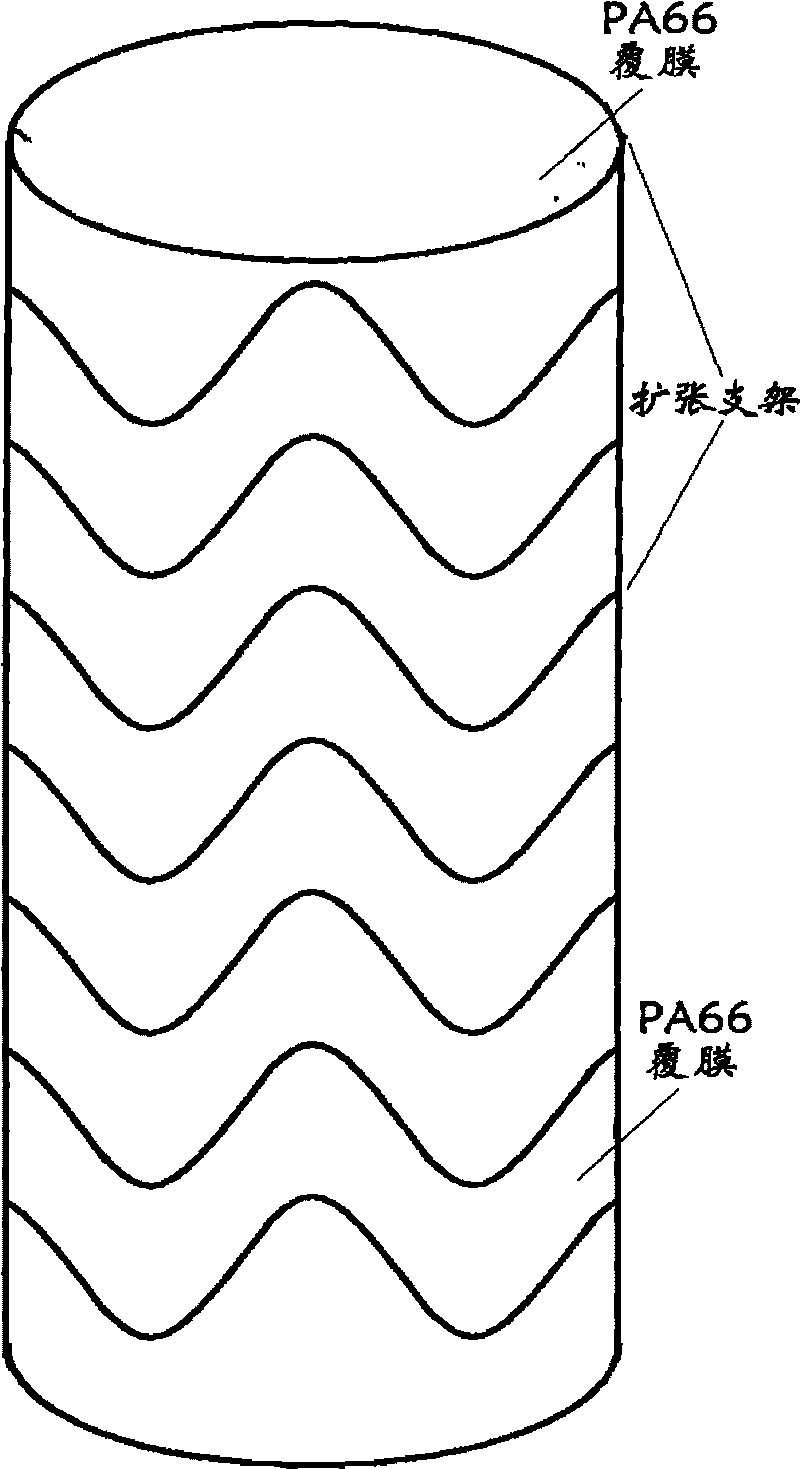

Polyamide 66 membrane covered nickel-titanium alloy intravascular scaffold and preparation method thereof

InactiveCN101703812AImprove impact toughnessExcellent formabilityLiquid surface applicatorsSurgeryNitinol stentPolyamide

The invention relates to a polyamide 66 membrane covered nickel-titanium alloy intravascular scaffold and a preparation method thereof. The intravascular scaffold comprises a nickel-titanium alloy scaffold and a polyamide 66 membrane, and is provided with a tubular blood vessel shaped structure or a cylindrical blood vessel shaped structure, wherein the surfaces of an inner wall and an outer wallof the scaffold are covered by thin membranes with the thickness between 0.2 and 5 millimeters. The preparation method comprises the following steps of: preparing 1 to 20 percent of polyamide 66 solution by using formic acid as a solvent; coating a layer of the polyamide 66 solution on a glass rod and volatizing the solvent; sleeving a nickel-titanium shape memory alloy expanding scaffold on the glass rod; coating another layer of the polyamide 66 solution on the glass rod and volatizing the solvent; and peeling off the polyamide 66 membrane and the nickel-titanium alloy intravascular scaffold from the glass rod, and performing vacuum drying to obtain the polyamide 66 membrane covered intravascular scaffold. The intravascular scaffold prepared by the method has a stable structure, good mechanical property, transportability and anti-seepage property, overcomes the performance defects of a single material, and has a simple preparation process.

Owner:DONGHUA UNIV

Novel high-resilience foamable rubber shoe sole material and preparation method thereof

The invention discloses a novel high-resilience foamable rubber shoe sole material and a preparation method thereof. The material is characterized of being prepared from, by mass, 10-15% of chloroprene rubber, 8-12% of natural rubber, 10-15% of ethylene-vinyl acetate copolymer, 20-25% of butadiene rubber, 6-12% of butadiene styrene rubber, 5-10% of ethylene propylene diene monome, 5-12% of white carbon black, 3-6% of naphthenic oil, 0.5-1.5% of resin, 1-3% of an active agent, 1-3% of a foaming agent, 1-3% of a modified flowable agent and 0.5-1.5% of a bridging agent. The preparation method comprises the steps of material compounding, banburying, mixing, open milling, stamping and vulcanization, so that a finished product is obtained. According to the novel high-resilience foamable rubber shoe sole material and the preparation method thereof, the characteristics that compatible and complementary elements exist among all types of rubber raw materials are utilized, the novel foamable rubber shoe sole material having the mechanical properties such as high resilience, high abrasion resistance and low weight is obtained, and the material is widely applied to the field of rubber shoe sole manufacturing.

Owner:JINJIANG XINQIDA SHOES MATERIALS CO LTD

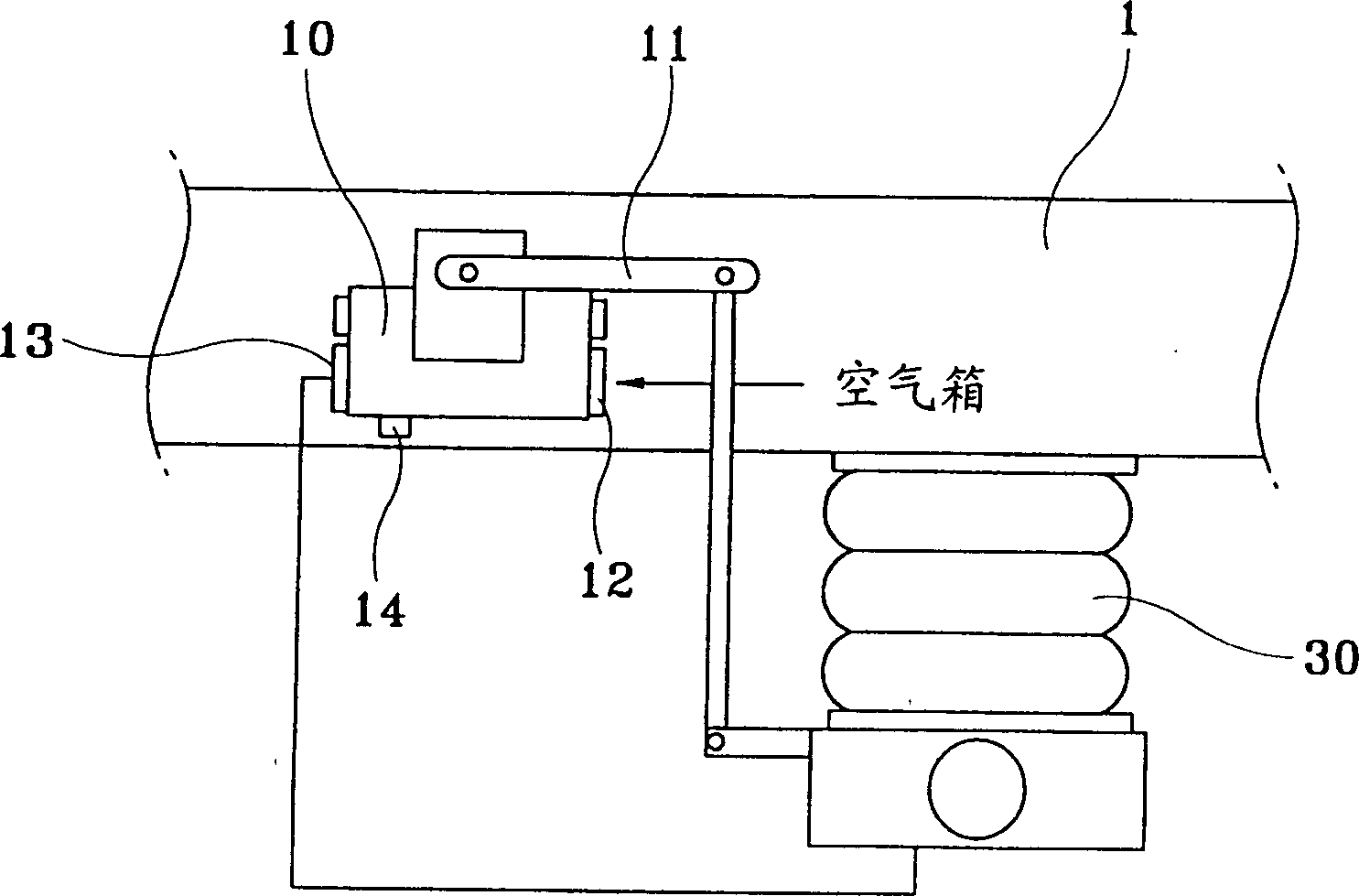

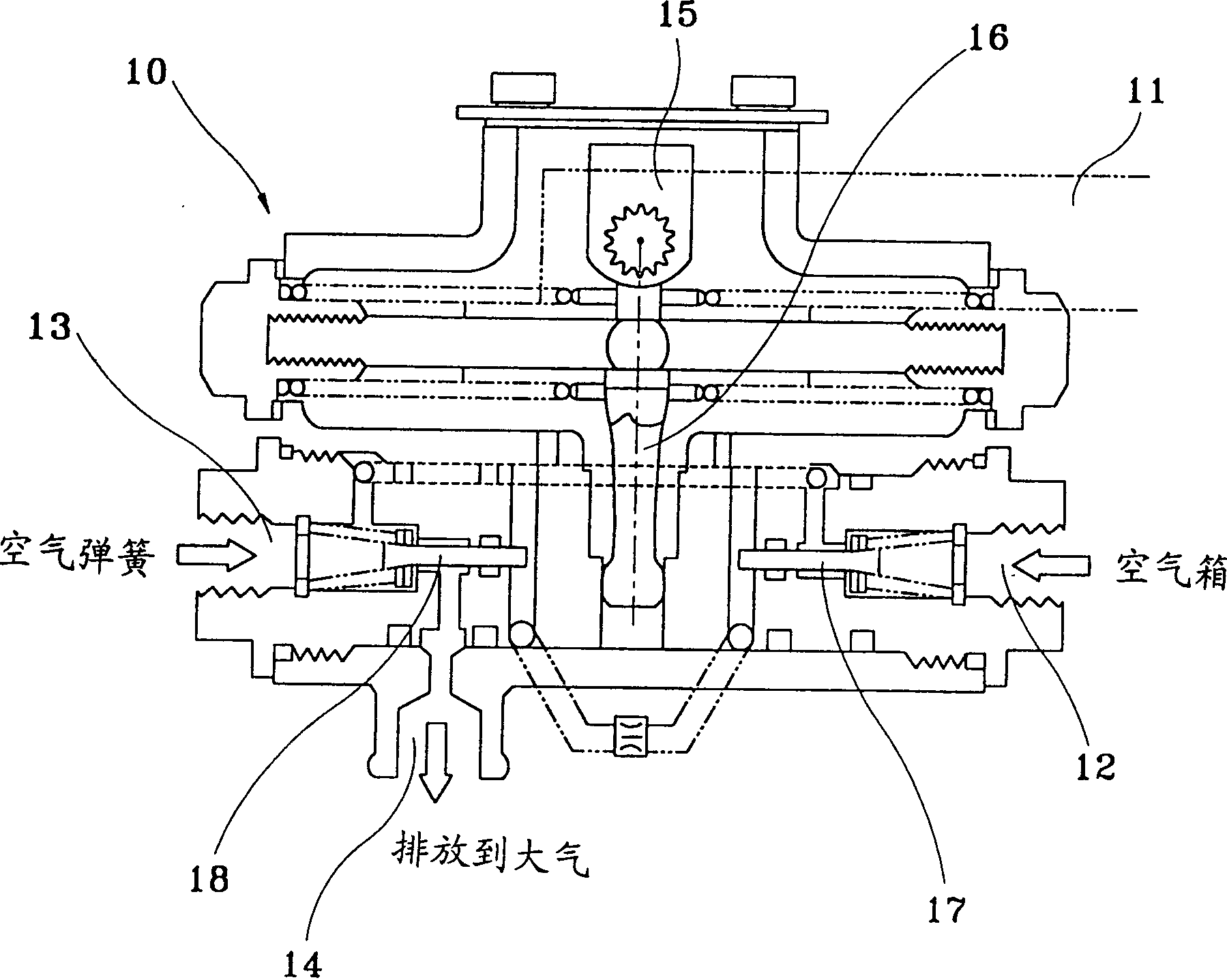

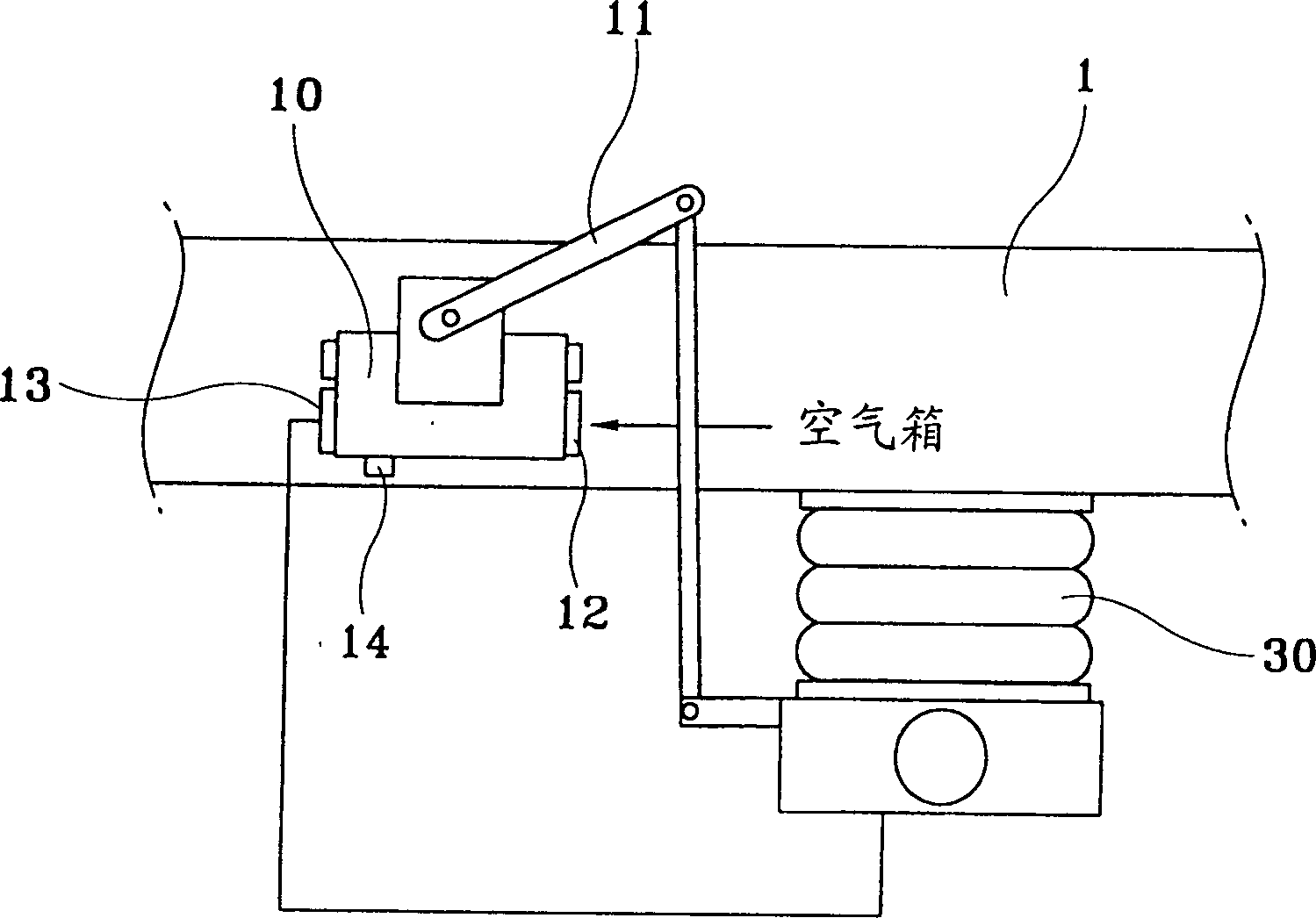

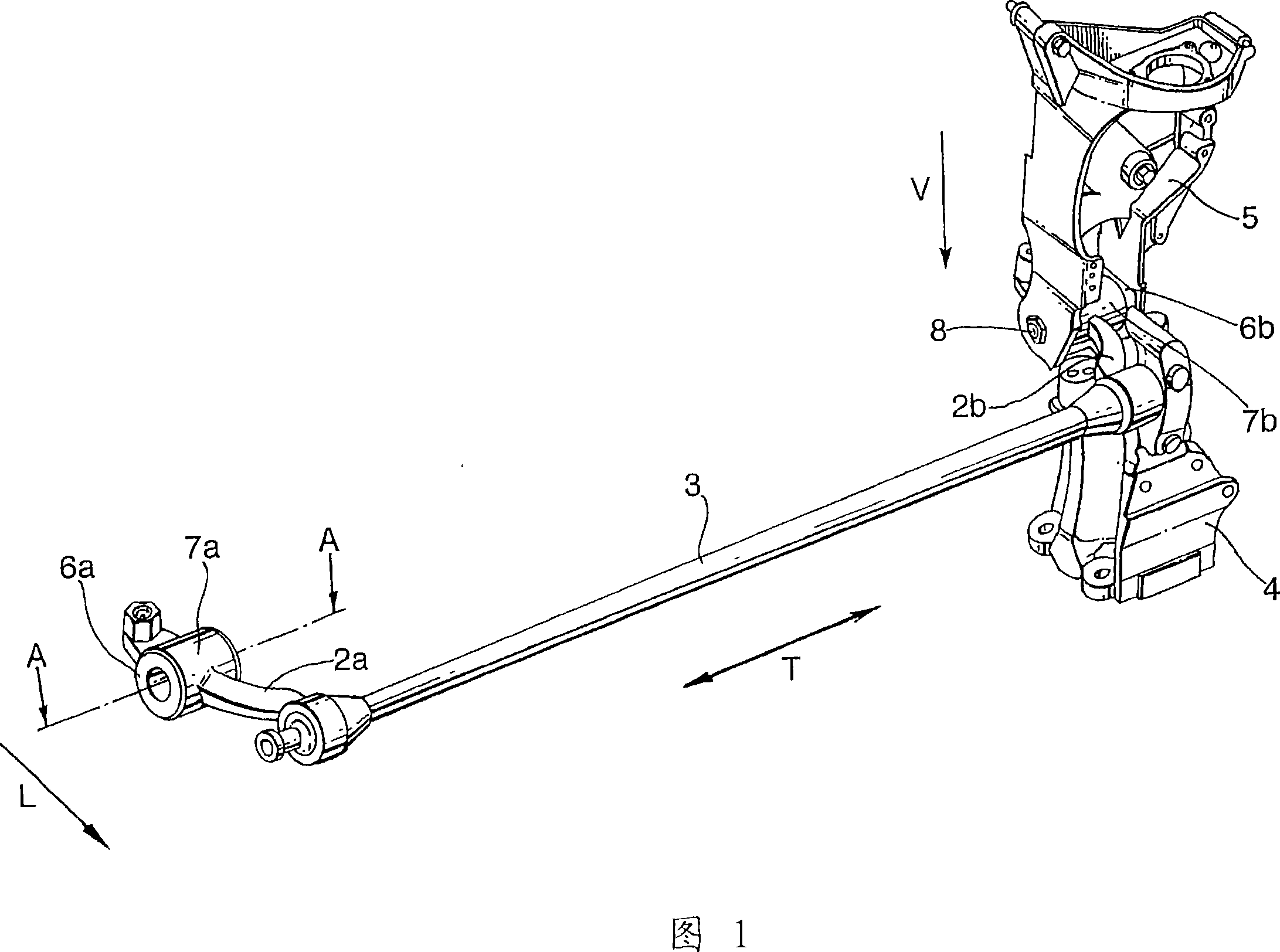

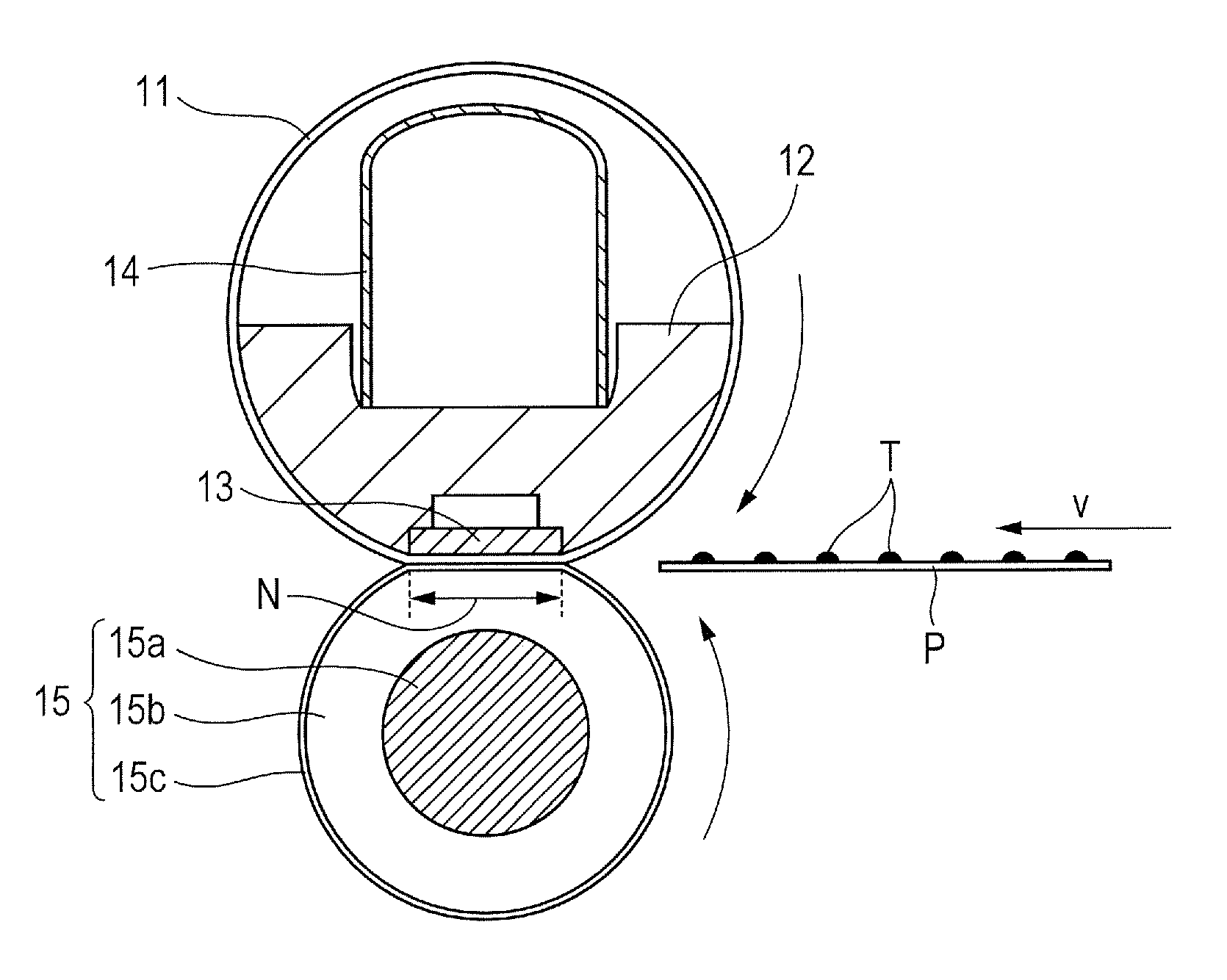

Air suspension system for vehicle

InactiveCN1410287ASave installation spaceChange elasticitySpringsResilient suspensionsVehicle frameAir spring

An air suspension system for a vehicle wherein a valve means for varying the resilience of an air spring in response to changes of vehicle height is integrally formed with an air spring to be mounted on the vehicle frame such that the installation space of the air suspension system can be minimized. As a result, cumbersome processes involved with the manufacture of the vehicle can be eliminated to provide an improved convenience for workers. A conventional lever used for connecting a leveling valve and an air spring is dispensed with to reduce the number of parts constituting the air suspension system and lower the manufacturing cost.

Owner:HYUNDAI MOTOR CO LTD

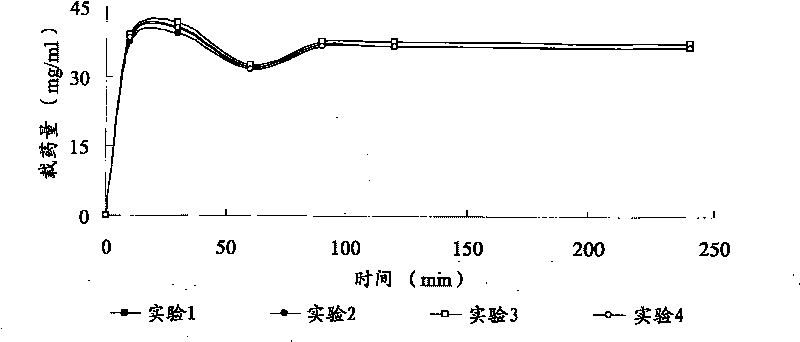

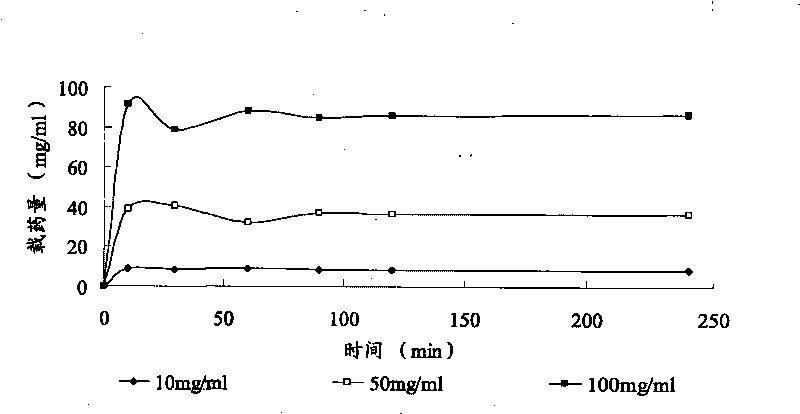

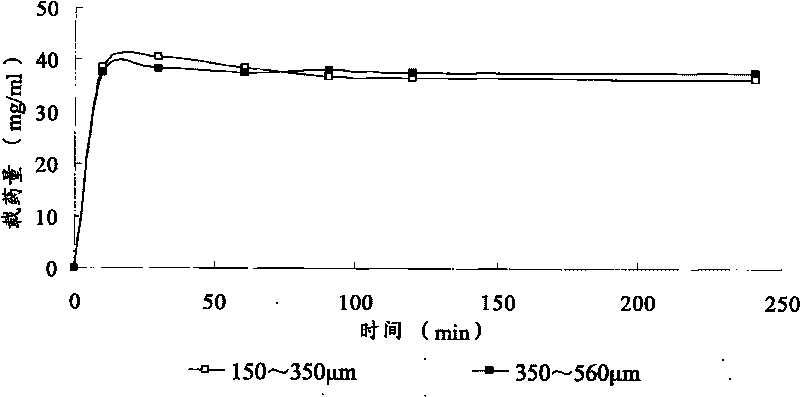

Medicine composite used for embolotherapy and acesodyne and preparation method thereof

ActiveCN101716349ALower drug concentrationSmall side effectsAntipyreticDigestive systemLidocaine HydrochlorideDouble bond

The invention provides a medicine composite used for embolotherapy and acesodyne and a preparation method thereof. The medicine composite comprises a biocompatibility macromolecular compound containing hydroxy, a monomer containing unsaturated double bond and anion group, a polymer, and local anesthetic containing amino group, wherein the polymer is generated through a polymerization reaction of an optional vinyl monomer and the polymerization reaction is initiated by free radicals, and the local anesthetic is combined to an anion group of the generated polymer. In the invention, lidocaine hydrochloride is combined to a polymer carrier; which can give full play to the acesodyne effect of the local anesthetic in the embolotherapy; the anion part of the polymer can properly combine with the local anesthetic containing the amino group, which can both realize higher medicine loading capacity and enable the medicine in an emboliaztion agent to be exchanged by cations in vivo and then slowly released. Moreover, the polymer emboliaztion carrier has simple technology, low cost, and suitability for large scale industrial production.

Owner:HYGEA MEDICAL TECH CO LTD

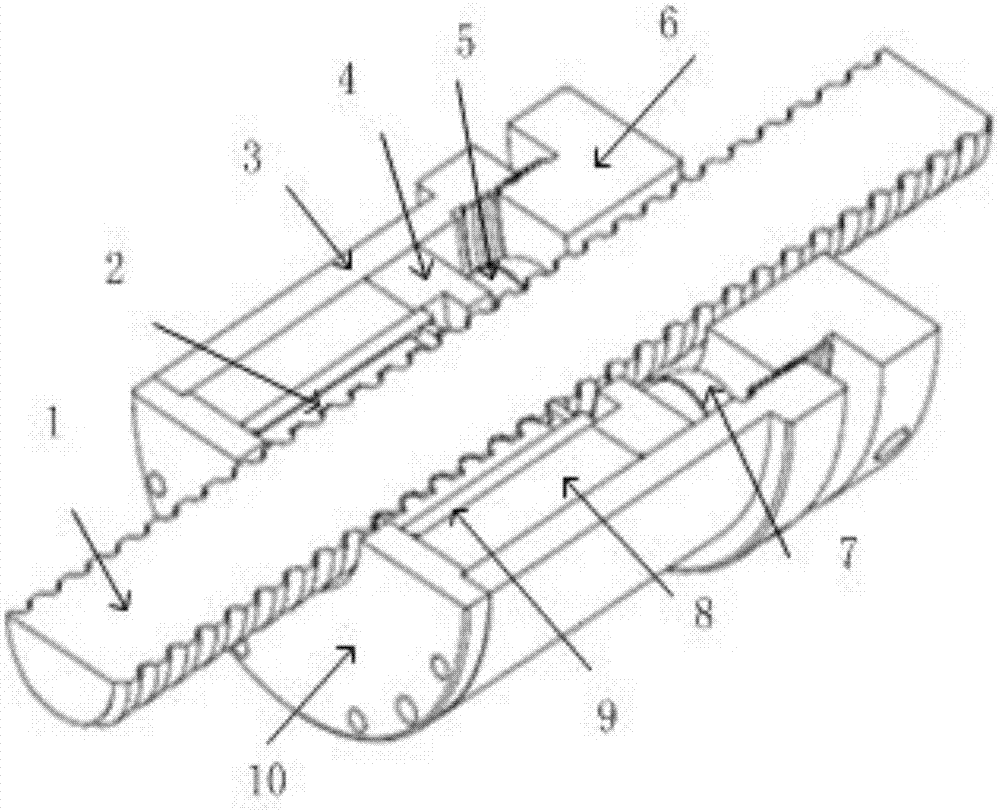

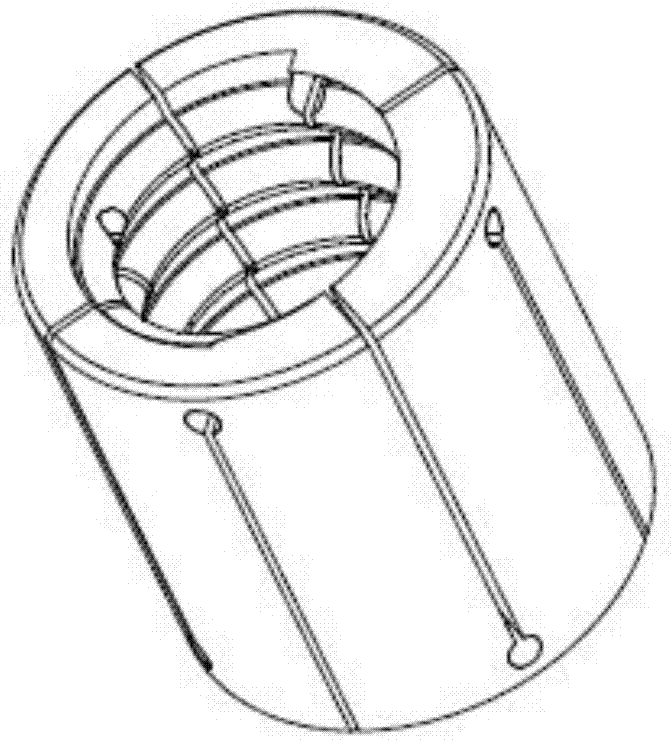

Tool for ball screw pair outer raceway grinding and grinding force loading

InactiveCN107322418AChange hardnessChange elasticityGrinding feed controlGrinding machinesPolyurethane elastomerAxial pressure

The invention provides a tool for ball screw pair outer raceway grinding and grinding force loading. The tool comprises a flexible nut, a grinding outer cover, a sensor assembly, a thread end cap, a polyurethane elastic body, a polyurethane buffering body and an outer cover base. The outer cover base is arranged at the front end of the grinding outer cover and forms a grinding cavity with the grinding outer cover, a first lead screw through hole is formed in the outer cover base, and the flexible nut is arranged in the grinding cavity and connected with a lead screw in a matched mode. The flexible nut is sleeved with the polyurethane buffering body, and the polyurethane buffering body is sleeved with the polyurethane elastic body. The inner wall of the polyurethane elastic body and the outer wall of the polyurethane buffering body are tightly matched, and the outer wall of the polyurethane elastic body and the inner wall of the grinding cavity are tightly matched. The thread end cap is provided with a second lead screw through hole and extends into the grinding cavity to be fixed from the rear end of the grinding outer cover, the sensor assembly is arranged between the thread end cap and the polyurethane elastic body and provided with tension and pressure sensors, and the pressure sensors measure the axial pressure of the thread end cap on the polyurethane elastic body.

Owner:NANJING UNIV OF SCI & TECH

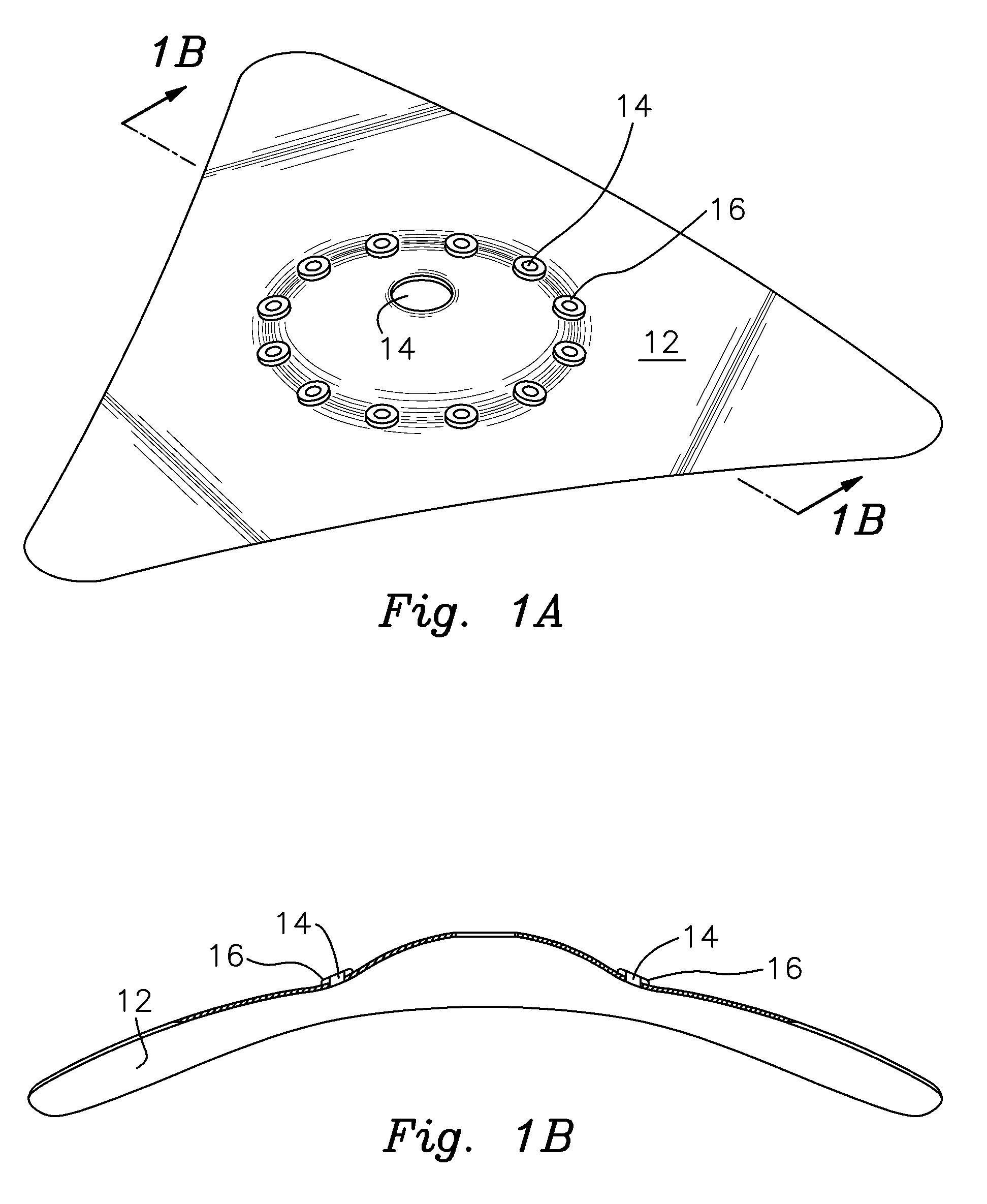

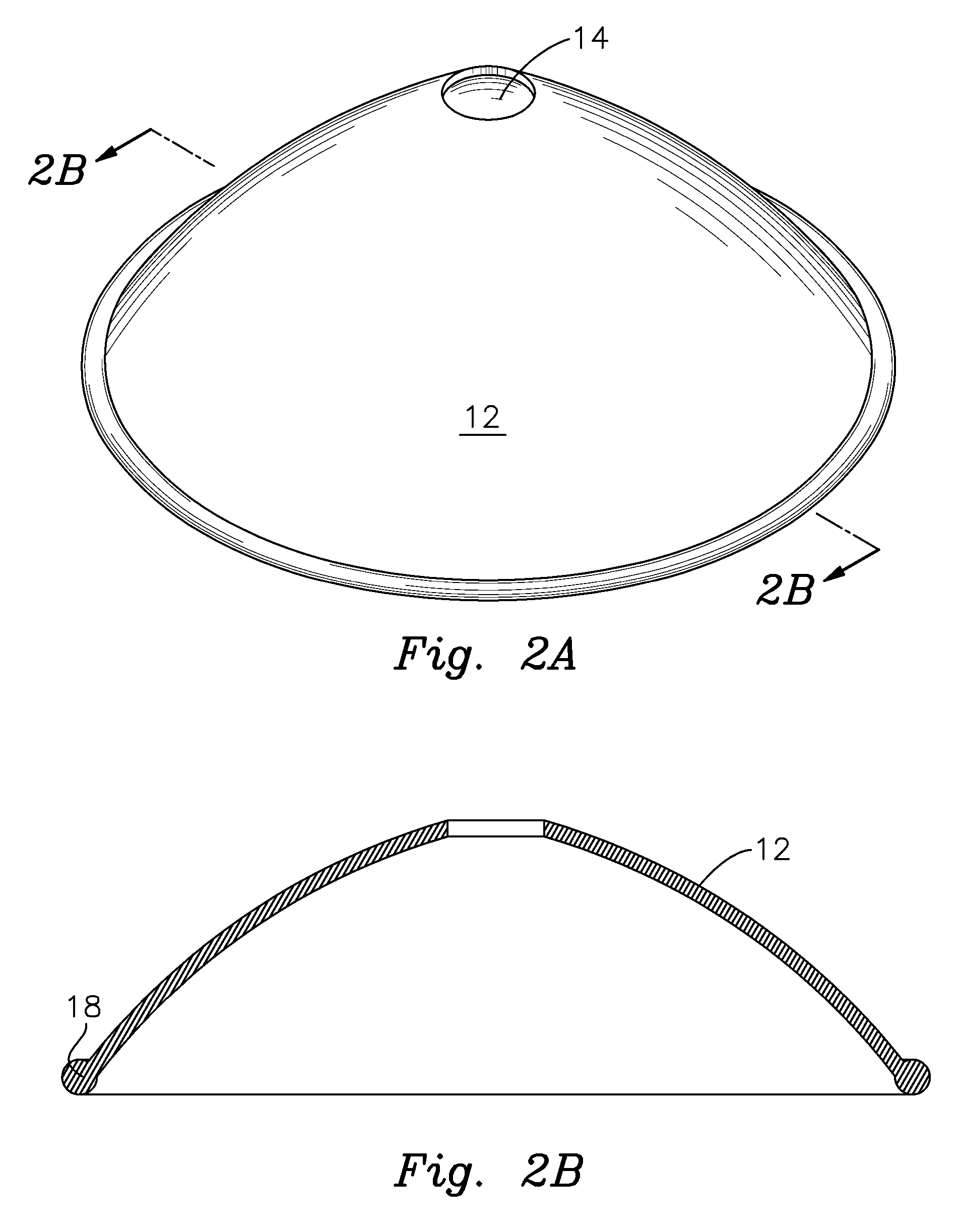

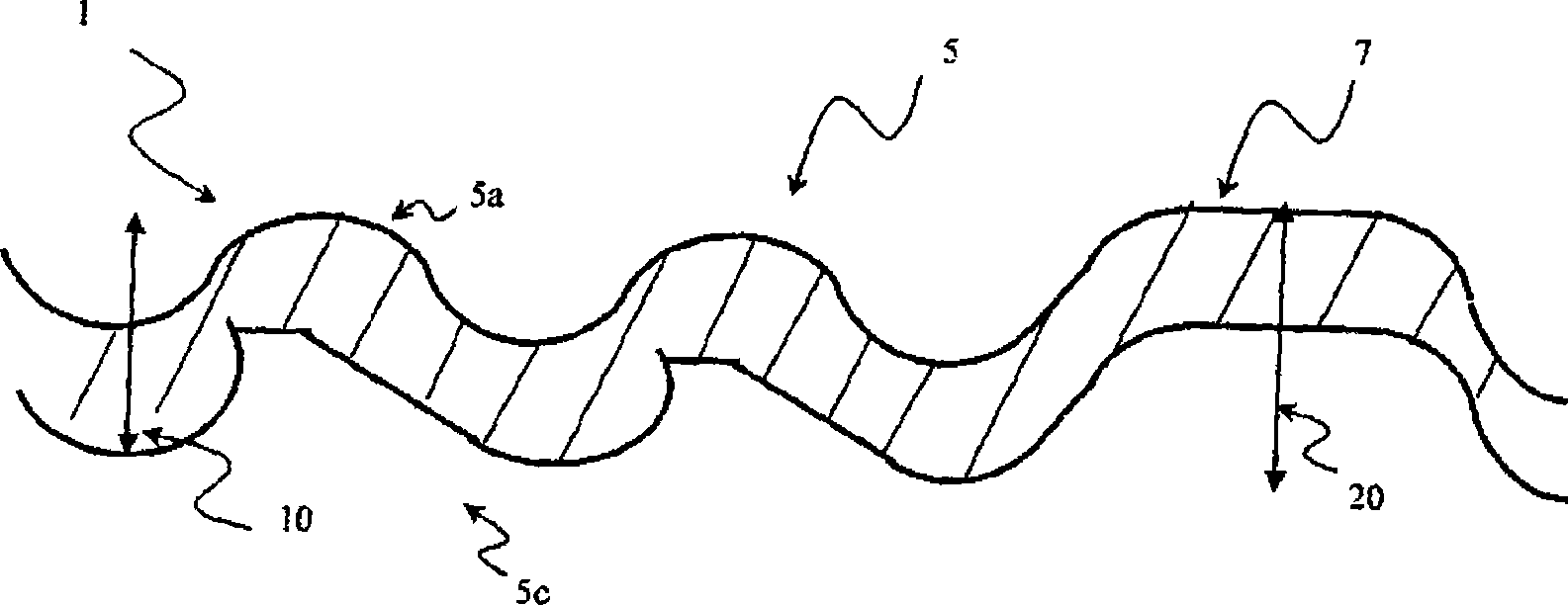

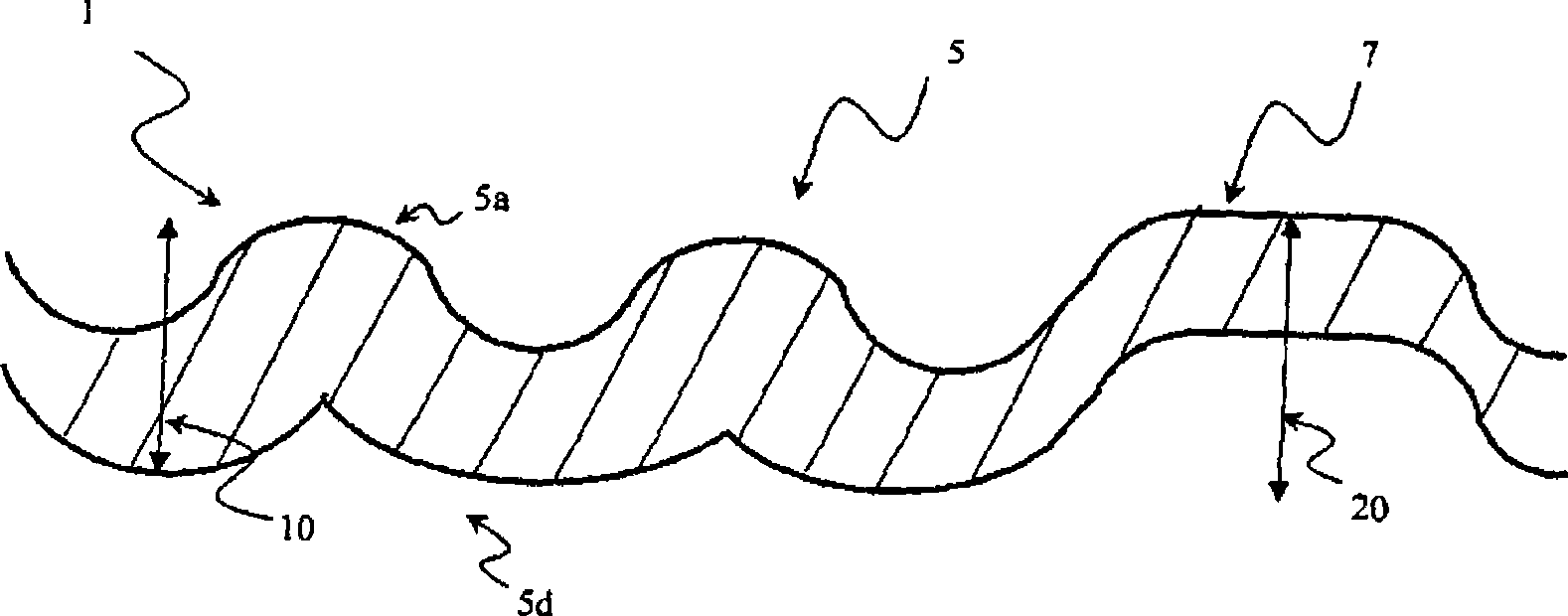

Percussion instruments using molten or plasticized metal

Cymbals and generally flat sheet instruments, as well as compound instruments, are formed using welding process and metal melting processes to form holes and edges with thickened edges from the melting processes, to join sections of metal, to add metal by creating beads at desired locations, to join sections with differing hardness and / or thickness, to create compound cymbals and compound flat sheet instruments by joint welding cymbals or sheet instruments together. The invention also includes cymbals and bells and various combinations and shapes thereof and the unique overtones attained thereby.

Owner:STANNARD JOHN

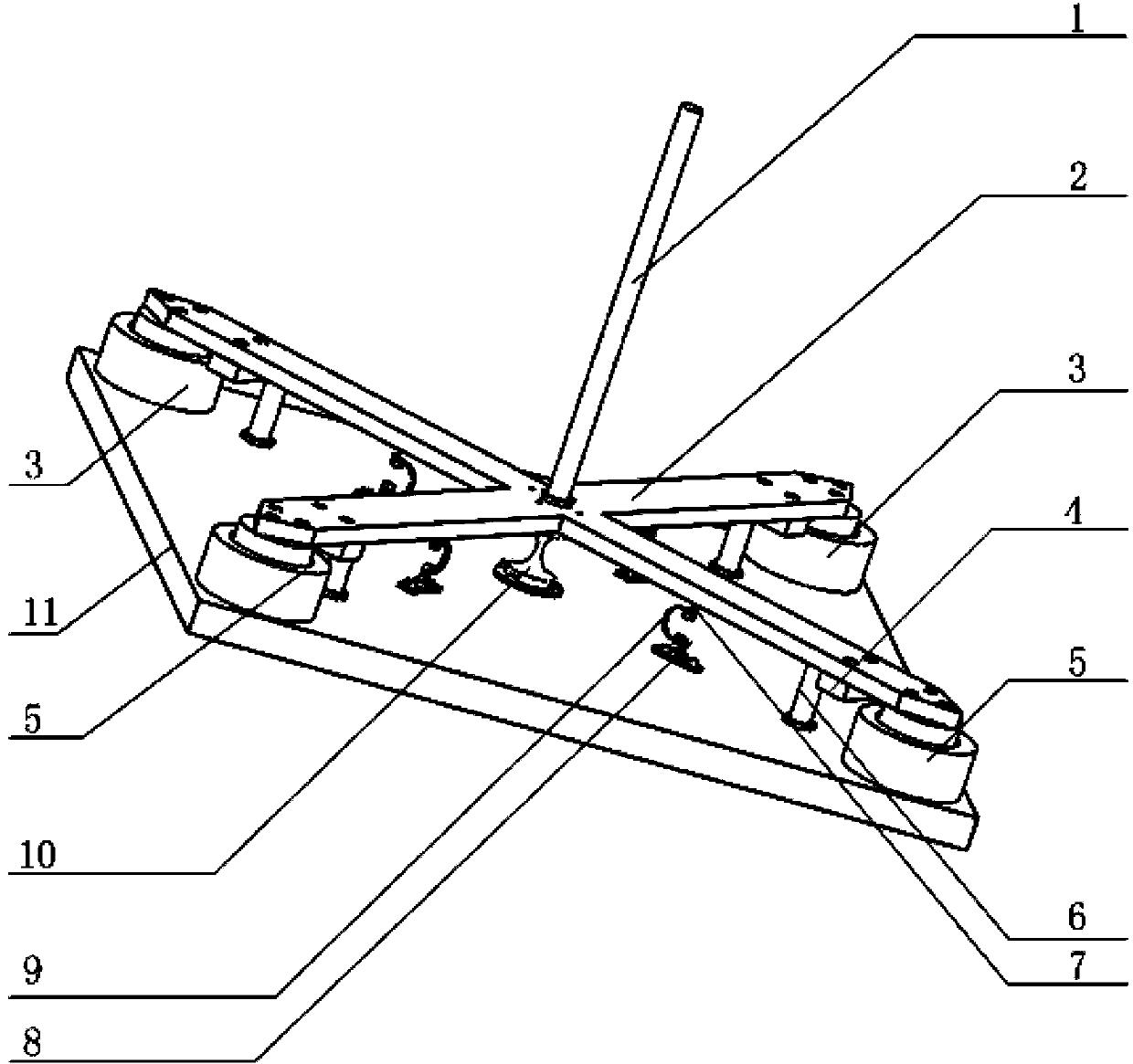

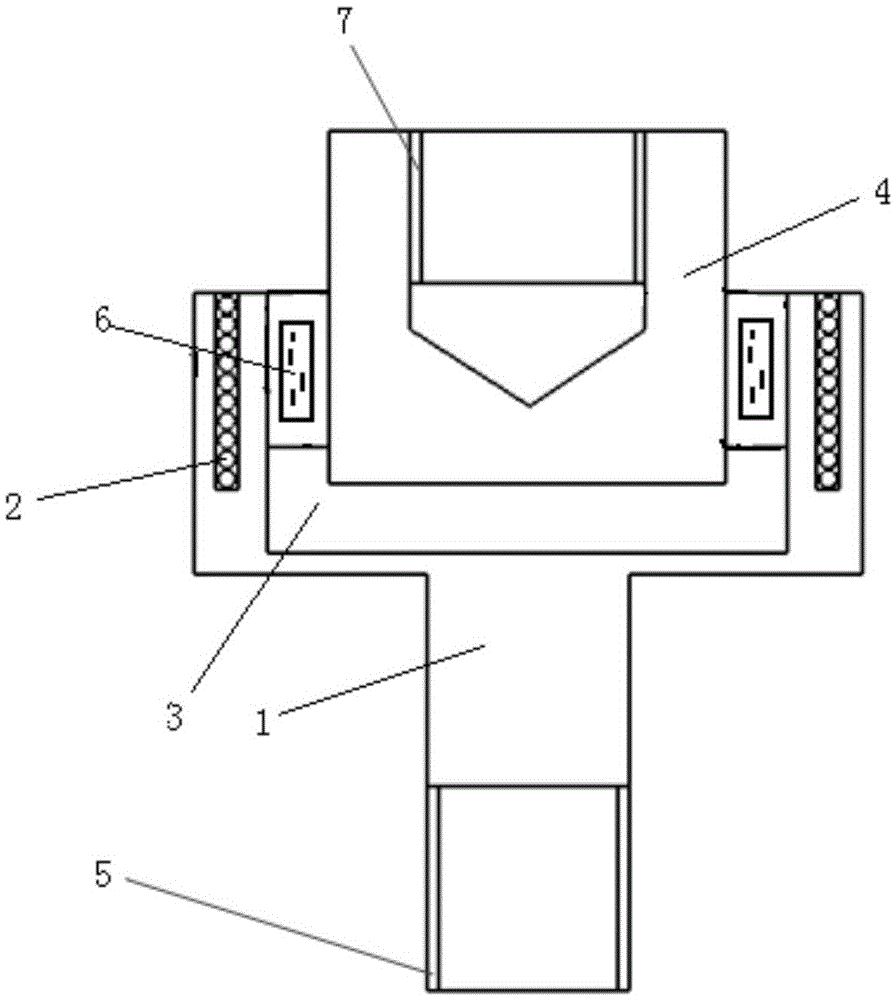

Damping-rigidness-controllable double-freedom-degree vibration active control platform

ActiveCN103398138AGood linearitySmall vibration rangeNon-rotating vibration suppressionCounterweightsEngineeringActuator

A damping-rigidness-controllable double-freedom-degree vibration active control platform comprises a cross-shaped beam frame and a square base which are connected through a flexible hinge. A cross-shaped beam of the cross-shaped beam frame is distributed in the diagonal directions of the square base. A structure column is arranged at the center of the cross-shaped beam frame. Sensors and actuators are connected between the lower portions of the diagonal top ends of the cross-shaped beam frame and the square base respectively. Four limiting columns are arranged between the cross-shaped beam of the cross-shaped beam frame and the square base respectively. Prearranged gaps are reserved between the limiting columns and the cross-shaped beam frame. Four balancing weights are fixed on the lower portion of the cross-shaped beam frame between the sensors or the actuators and the limiting columns respectively. Twisting limiting spring pieces are arranged at the symmetrical positions on the lower portion of the cross-shaped beam frame between the limiting columns and the flexible hinge. The electromagnetic type sensors and the electric-damping electric-rigidness actuators are used to achieve detecting of angular speed and actuating, the flexible hinge and the spring piece with changeable thickness are combined to achieve controllable damping and rigidness in a quantifying mode, and double-freedom-degree vibration active control in the x direction and the y direction of the structure is achieved.

Owner:XI AN JIAOTONG UNIV

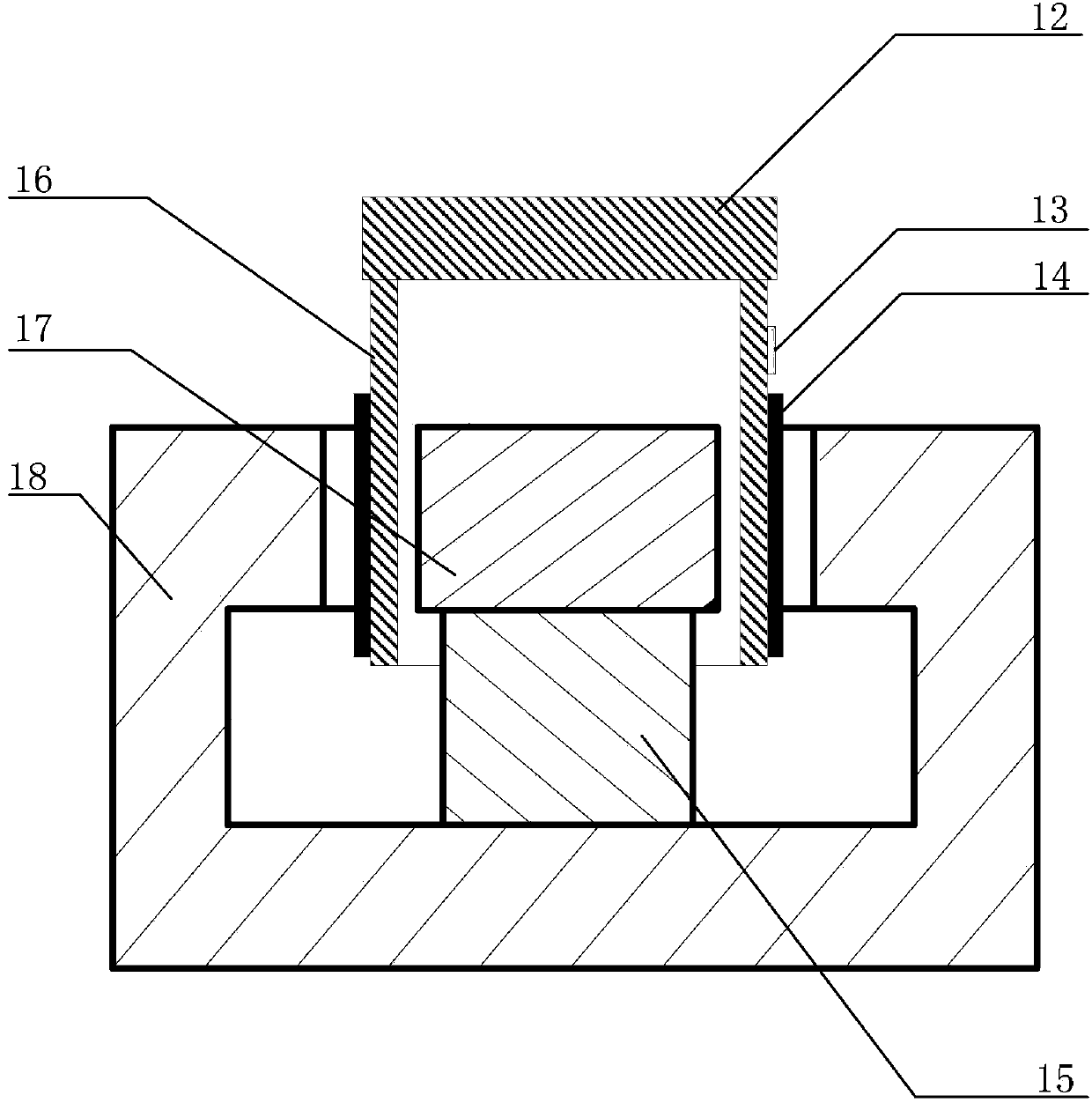

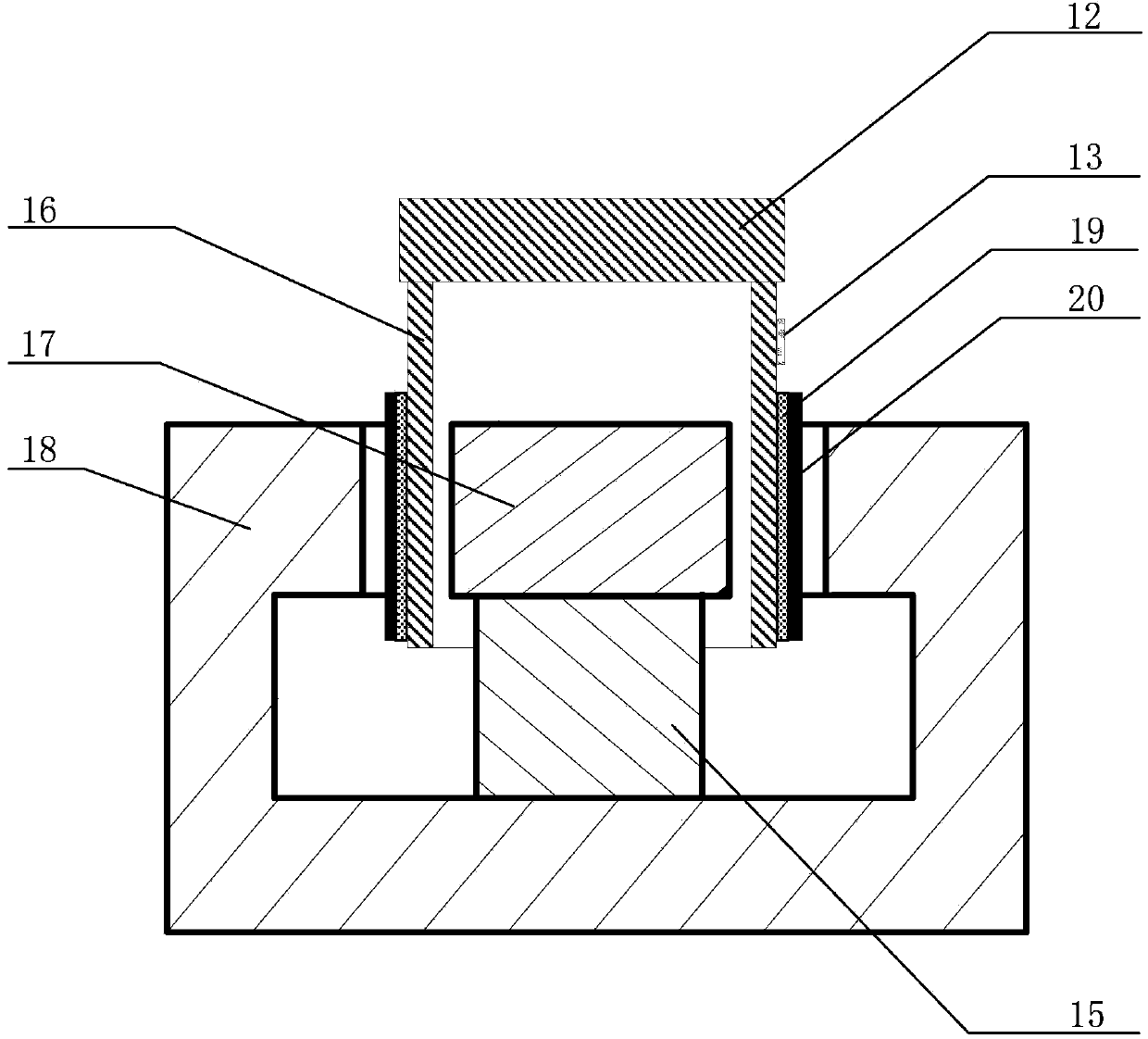

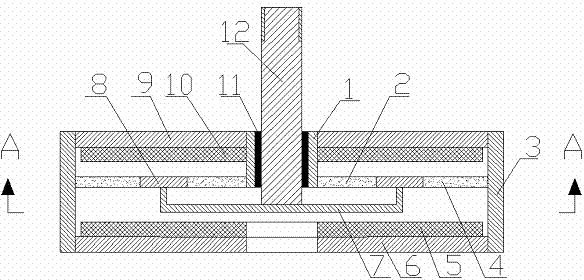

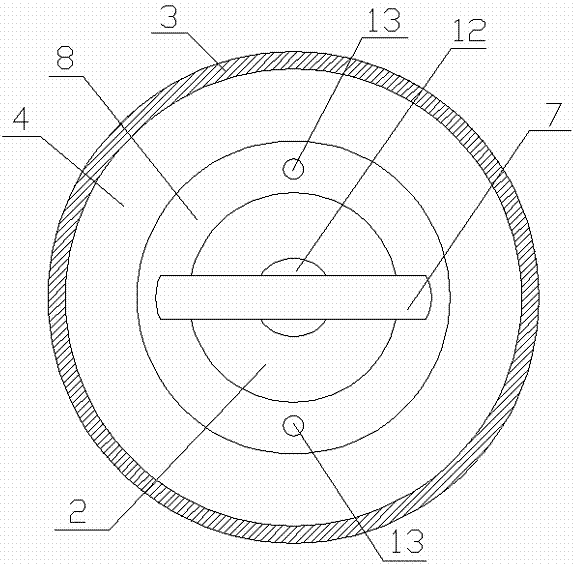

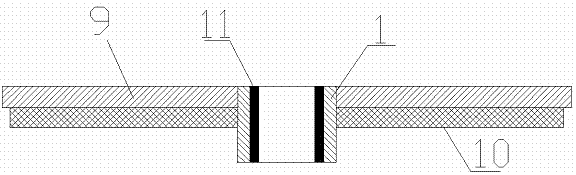

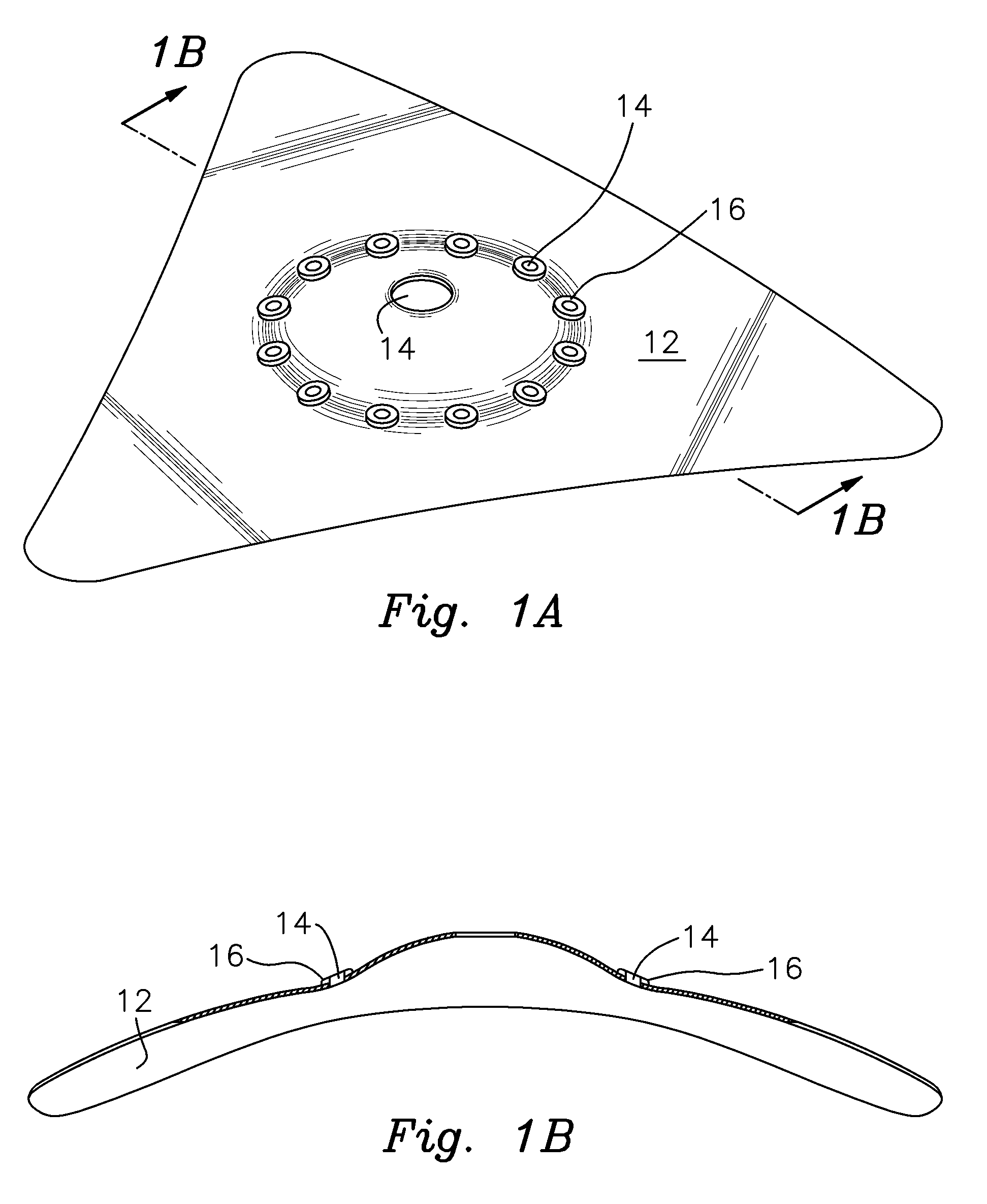

Magneto-rheological elastomer double-annular-membrane damper

InactiveCN103671687AEnhance the strength of the electromagnetic fieldHigh strengthSpringsShock absorbersElastomerArchitectural engineering

The invention discloses a magneto-rheological elastomer double-annular-membrane damper which comprises a work cylinder, a damping rod, large annular damping membranes, small annular damping membranes, an annular damping washer and two single-face annular electromagnets. The work cylinder comprises a drum and the two single-face annular electromagnets, the two single-face annular electromagnets are fixed to the two ends of the drum, and opposite poles of the two single-face annular electromagnets are opposite in direction. The large annular damping membranes and the small annular damping membranes are respectively composed of a magneto-rheological elastomer, the inner circumferences of the small annular damping membranes are fixed to outer circumferences of the tops of inner circular tubes, the inner circular tubes are fixed into center holes of the single-face annular electromagnets, the outer circumferences of the small annular damping membranes are fixed to the inner circumference of the annular damping washer, the outer circumference of the annular damping washer is fixed to the inner circumferences of the large annular damping membranes, and the outer circumferences of the large annular damping membranes are fixed to the inner circumference of a work cylinder circular tube. One end of the damping rod is fixed to the annular damping washer through a support, and the other end of the damping rod extends out of one end of the work cylinder through sliding bearings in the circular tubes, at one end of the work cylinder, of the single-face annular electromagnets.

Owner:谭苹

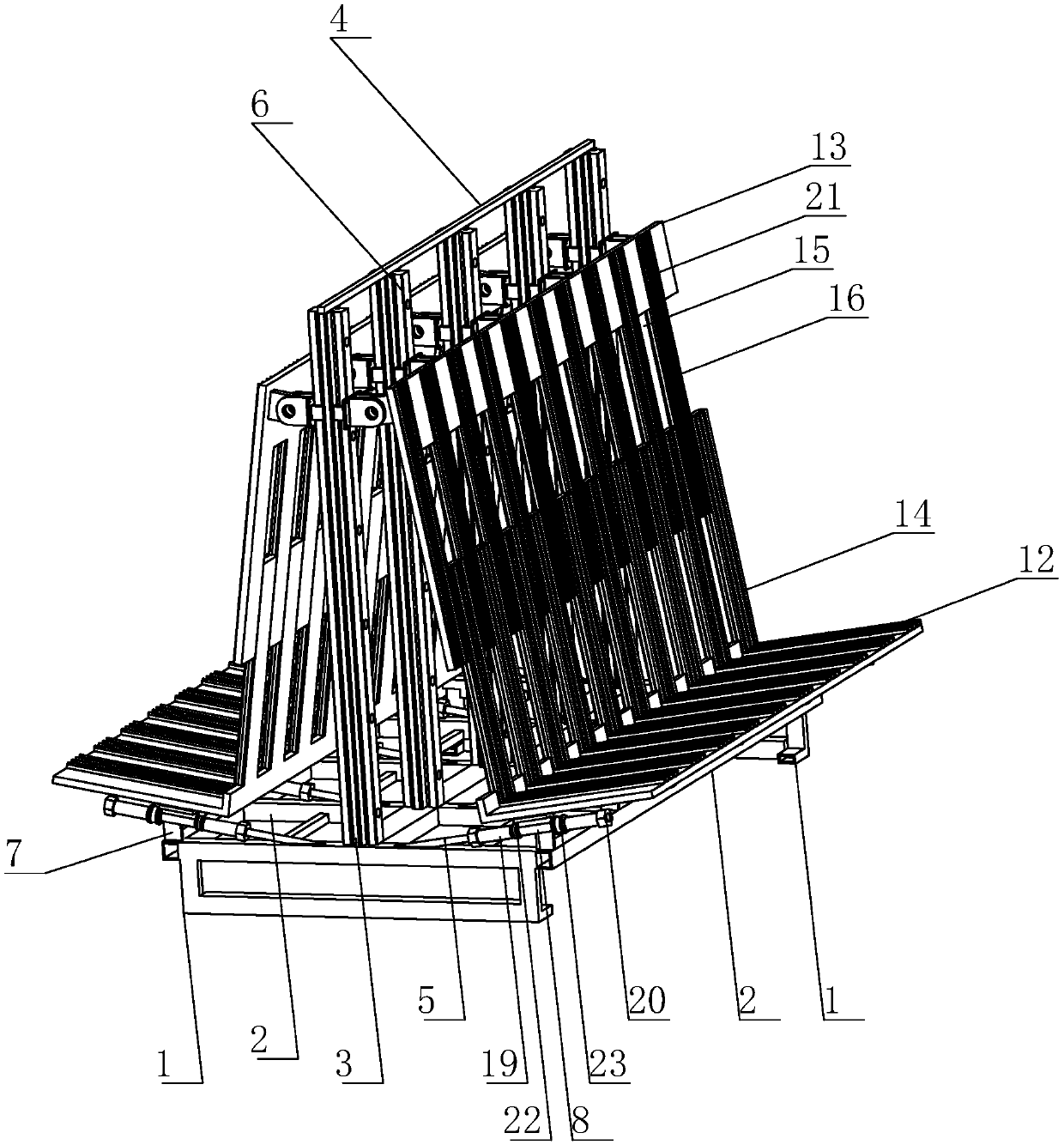

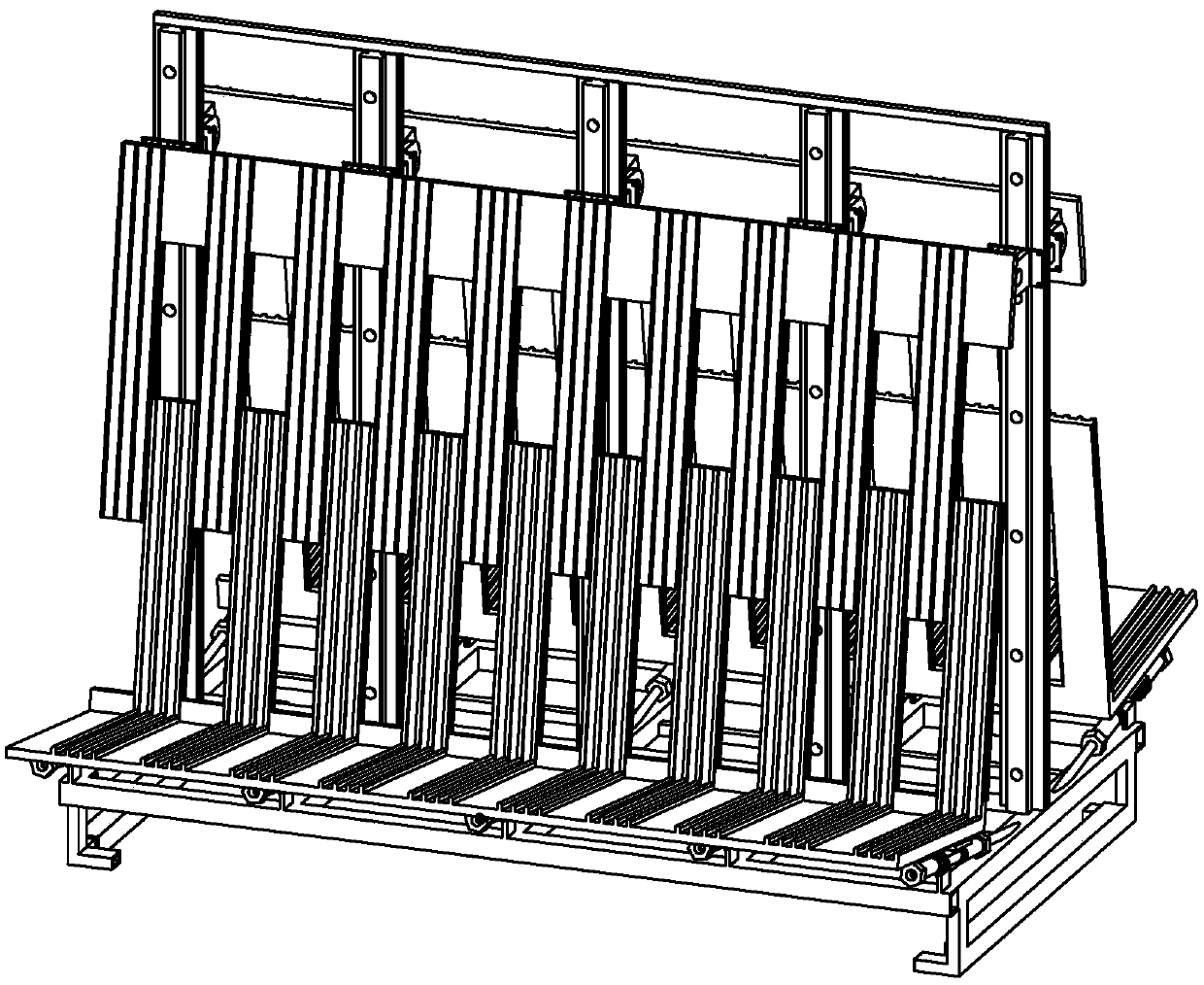

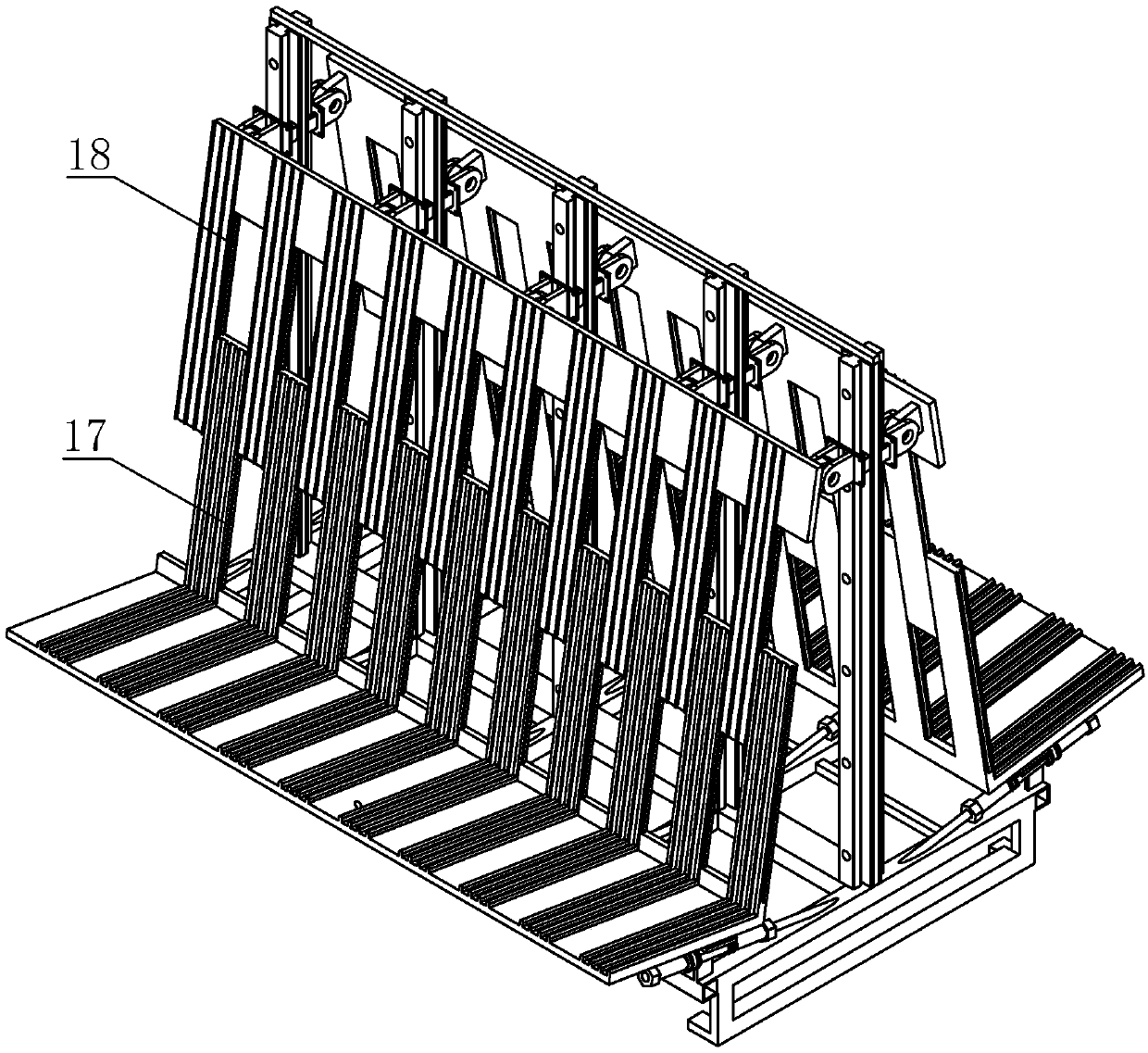

Fixing bracket for glass transportation

ActiveCN108674990AEliminate transportation lossDistribute the load evenlyCharge manipulationConveyor partsEngineeringResource utilization

The invention discloses a fixing bracket for glass transportation, mainly relates to the field of construction equipment transportation. The fixing bracket for glass transportation comprises a main bracket body, a guide rail mechanism, a glass supporting mechanism, a limiting assembly and a buffering piece. The glass supporting mechanism achieves L-shaped extension adjustment by the bidirectionalguide rail mechanism, and achieves fixing and limiting by the limiting assembly; and the buffering piece achieves rigid shock absorption of glass. The fixing bracket has the beneficial effects of being capable of adapting to different conditions on site according to the glass with different sizes and characteristics to fix and transport the glass, significantly lowering transportation losses and improving resource utilization rate.

Owner:王盼

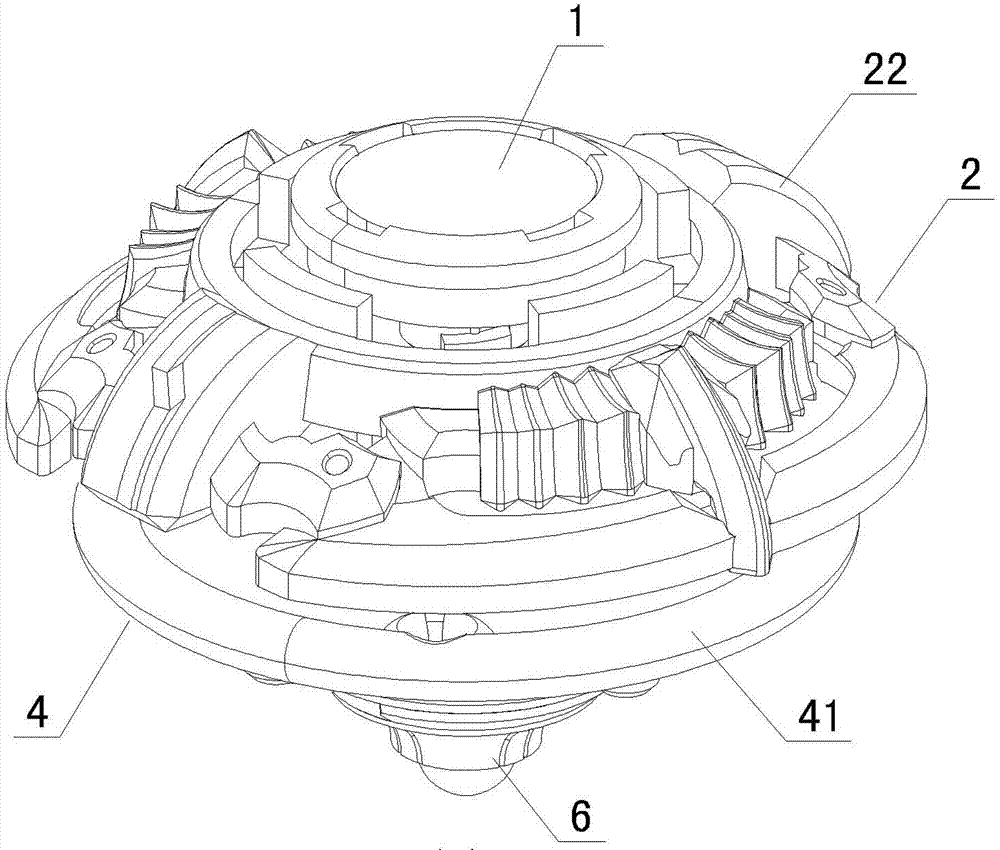

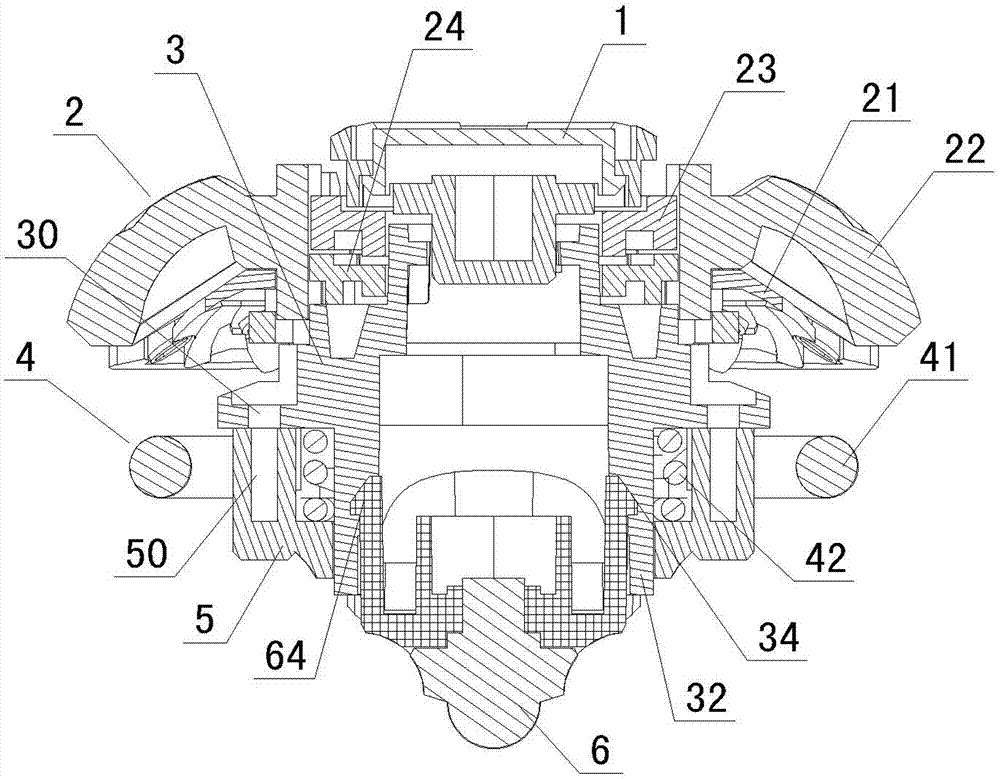

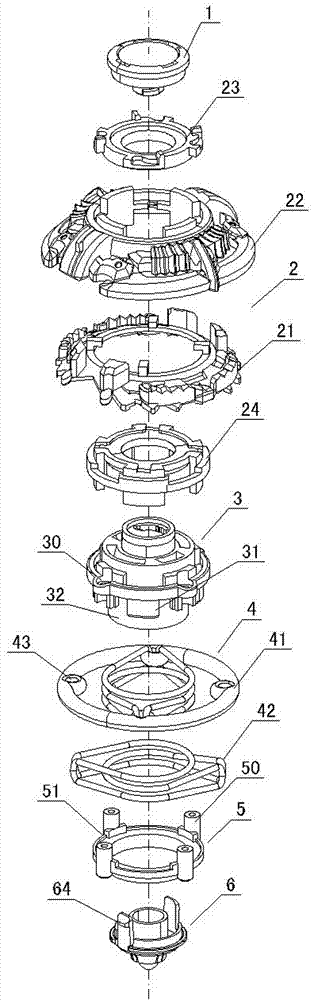

Toy gyro good in defensiveness

The invention provides a toy gyro good in defensiveness. The toy gyro comprises a spiral cover, a spiral sheet, a spiral base and a hillock point, and is characterized by further comprising an elastic shock absorption piece for buffering impact force when the gyro is impacted. The shock absorption piece is provided with an elastic part used for resisting impact and a connection part fixedly connected with the spiral base. The elastic part is located on the periphery of the spiral base through fixed connection of the connection part and the spiral base, and therefore when the gyro competes with other gyros and the other party impacts on the elastic part, impact force will be reduced due to elastic deformation of the elastic part; thus, the shock absorption effect is achieved to make the gyro rotate stably, anti-impact force is produced and returned to the other party at the same time to interfere the other party, and accordingly the win rate of the gyro is improved. The toy gyro is strong in interestingness, the elastic property of the elastic shock absorption piece can be changed by a player according to judgments so as to achieve a better anti-impact effect, the method to play the toy gyro is novel, the toy gyro can attract more players, and manipulative ability and competitive ability of children can be trained at the same time.

Owner:ALPHA GRP CO LTD +2

Percussion instruments using molten or plasticized metal

Cymbals and generally flat sheet instruments, as well as compound instruments, are formed using welding process and metal melting processes to form holes and edges with thickened edges from the melting processes, to join sections of metal, to add metal by creating beads at desired locations, to join sections with differing hardness and / or thickness, to create compound cymbals and compound flat sheet instruments by joint welding cymbals or sheet instruments together. The invention also includes cymbals and bells and various combinations and shapes thereof and the unique overtones attained thereby.

Owner:STANNARD JOHN

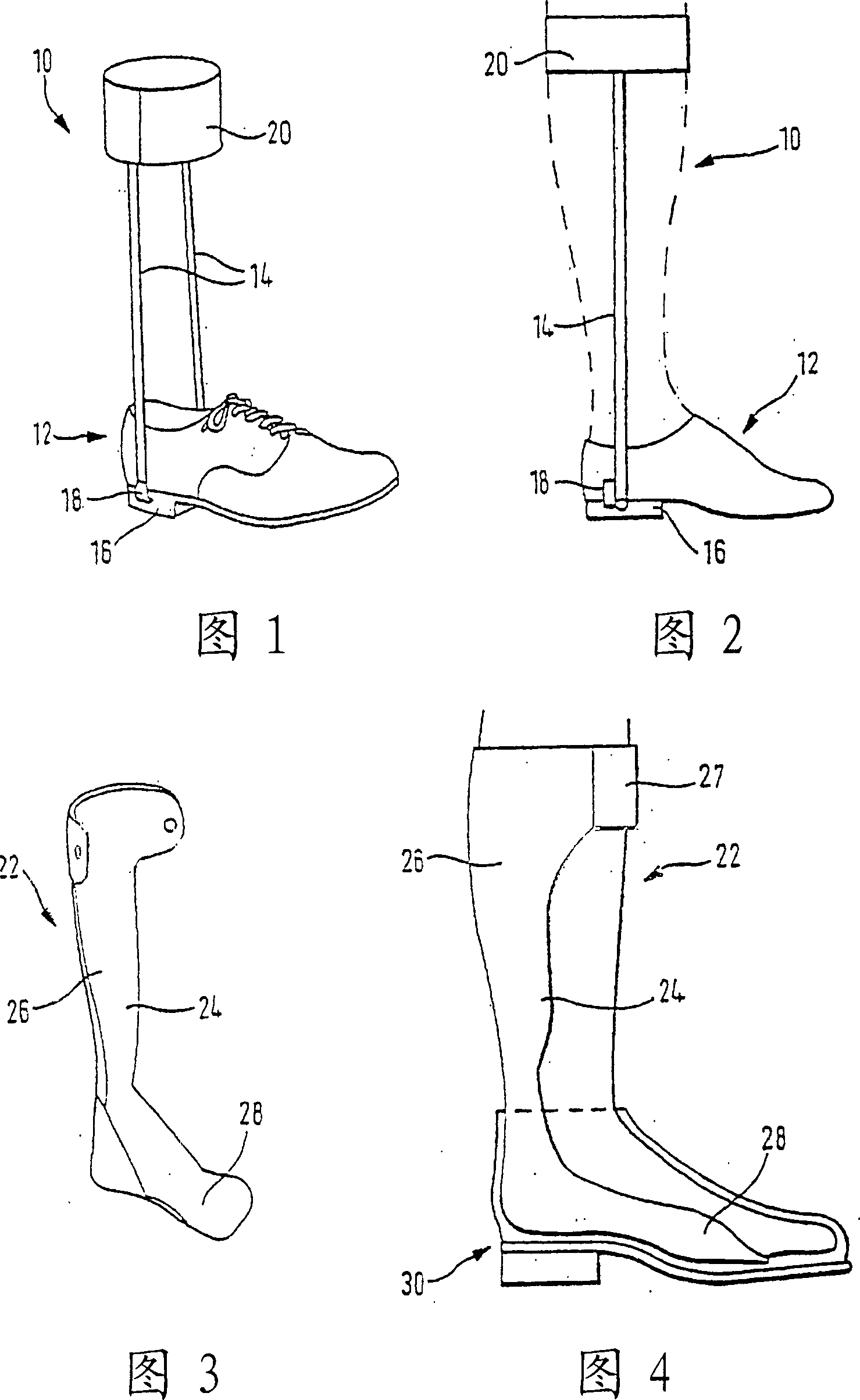

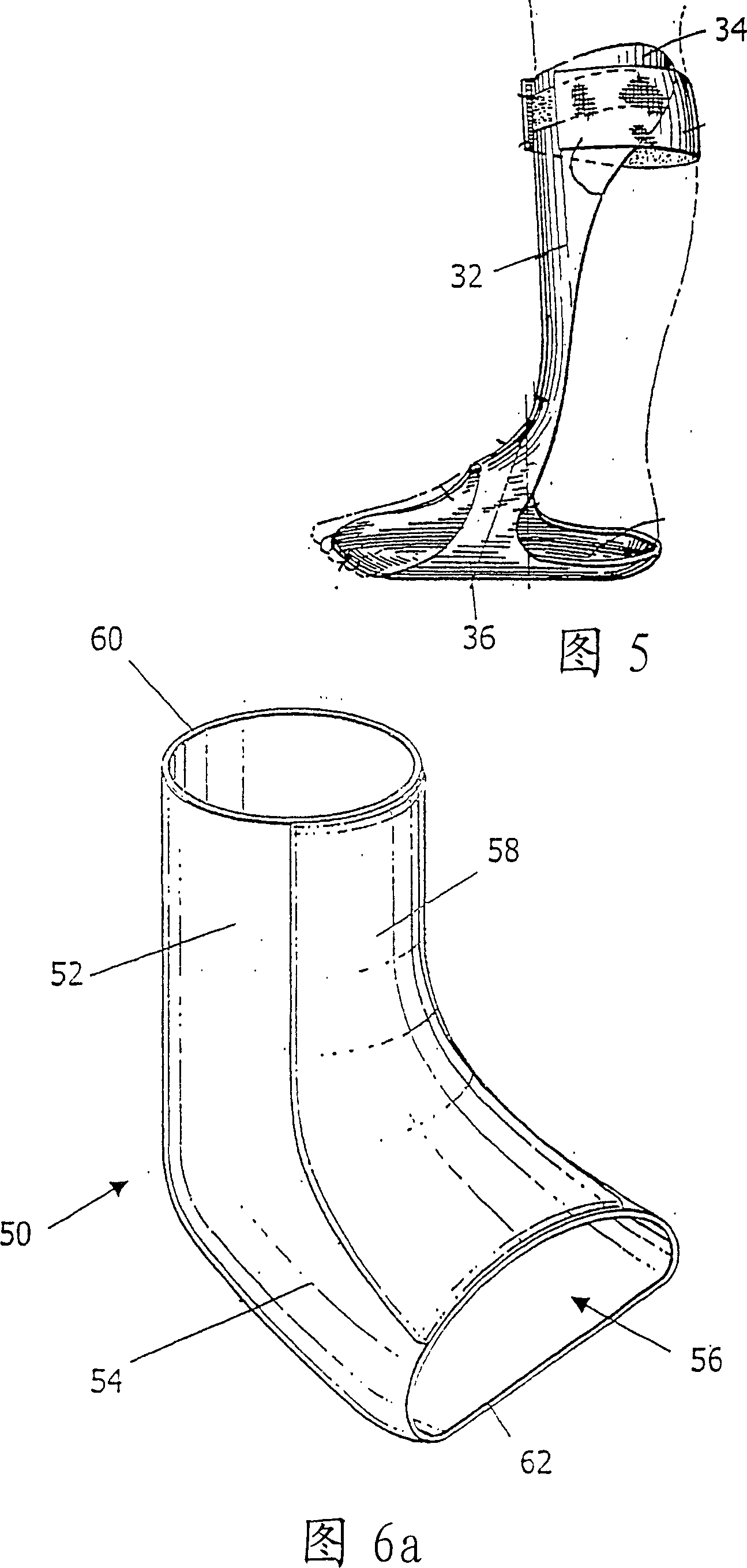

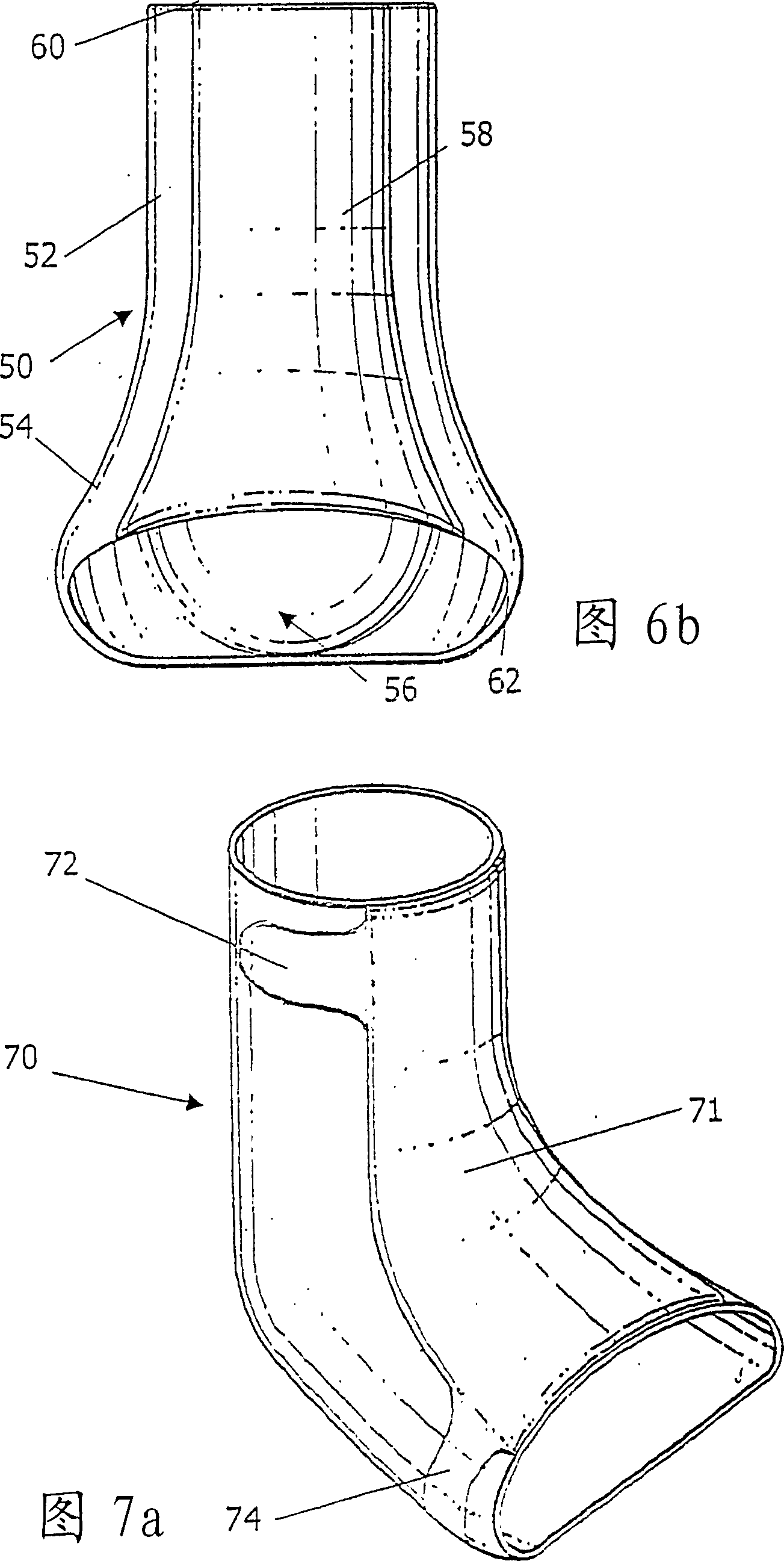

Ankle-foot orthosis

InactiveCN100361639CSuitable for commercial retailLess expensiveFeet bandagesNon-surgical orthopedic devicesMedicineKnee orthosis

Owner:罗伯特·约翰·瓦特

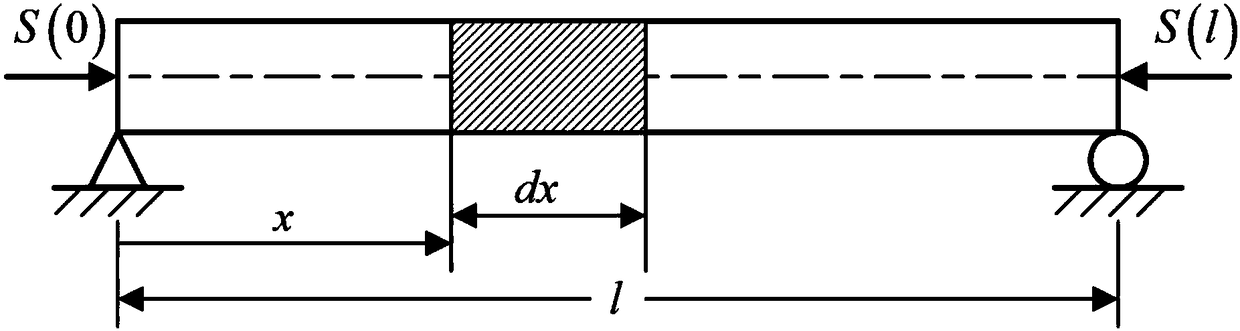

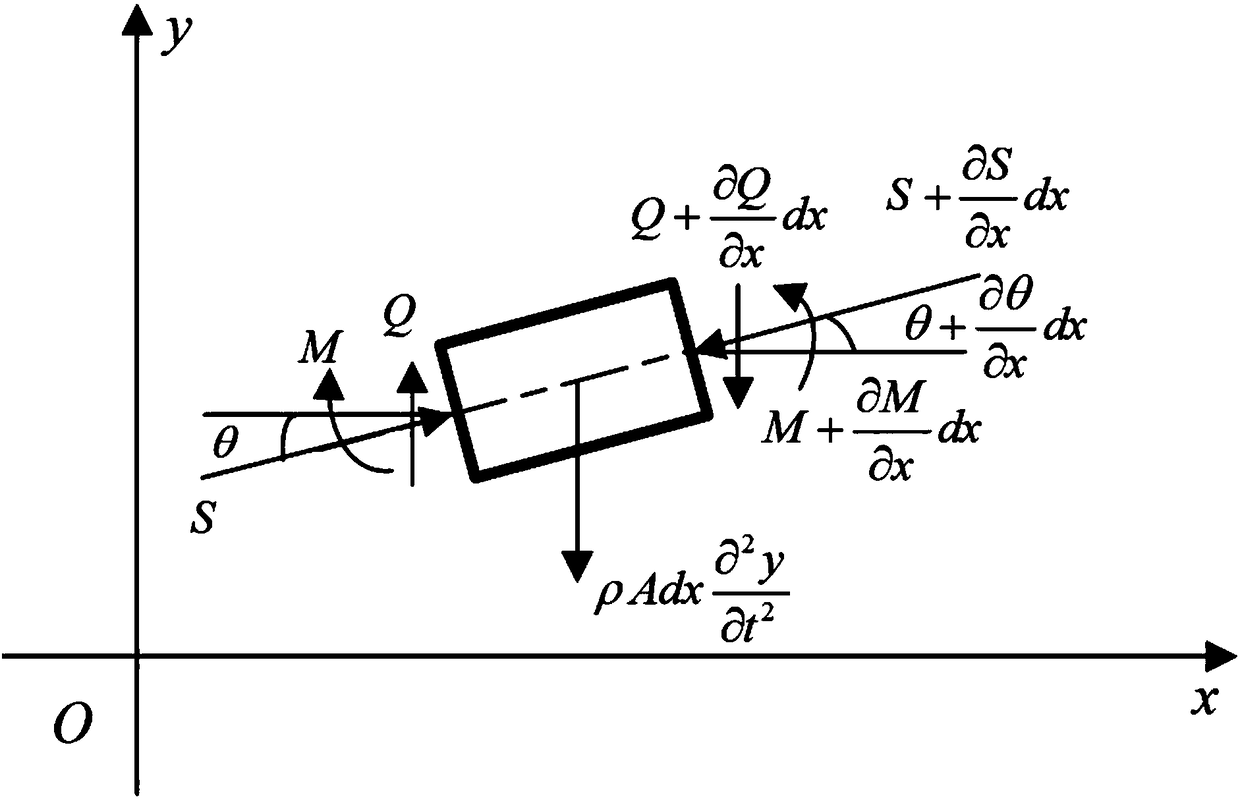

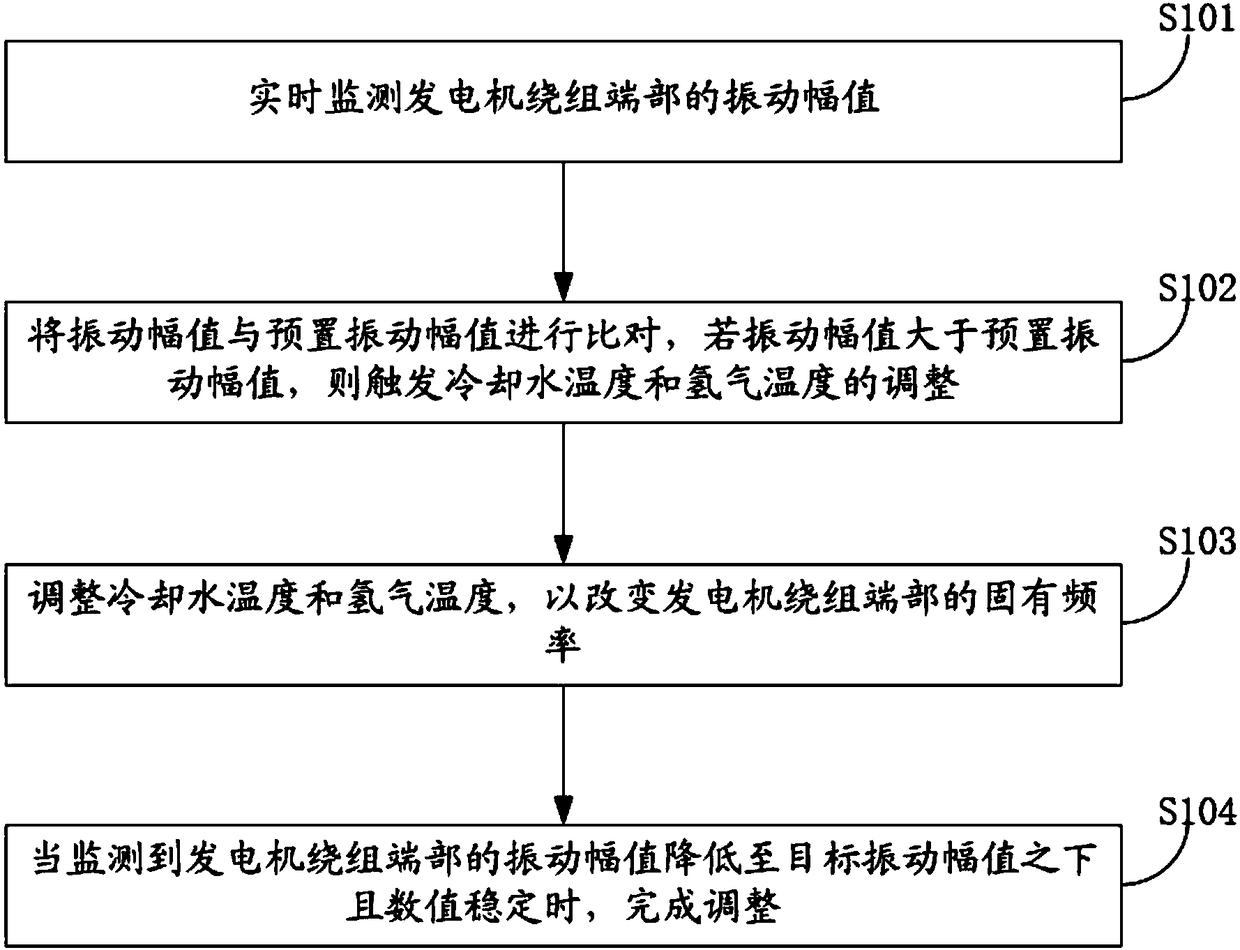

Method and system for controlling end portion vibration of generator winding

InactiveCN108181944AChange elasticityChange natural frequencyMechanical oscillations controlVibration amplitudeForce frequency

The invention discloses a method and system for controlling end portion vibration of a generator winding. The method comprises: a vibration amplitude of the end portion of a generator winding is monitored in real time; the vibration amplitude is compared with a preset vibration amplitude; if the vibration amplitude is larger than the preset vibration amplitude, adjustment of the temperatures of cooling water and hydrogen is triggered; the temperatures of cooling water and hydrogen are adjusted to change the inherent frequency of the end portion of the generator winding; and when the vibrationamplitude of the end portion of the generator winding is monitored to be reduced to be below a target vibration amplitude and the value is stable, adjustment is completed. According to the invention,on the basis of a relationship between a generator temperature field and a modal frequency of the winding end structure, the temperature field inside the generator is changed based on the temperaturesof cooling water and hydrogen, so that the material structural force and elasticity modulus of the end portion of the generator winding are changed and thus the inherent frequency of the end portionof the generator stator winding is changed. Therefore, the excitation force frequency is avoided and the vibration amplitude is reduced.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

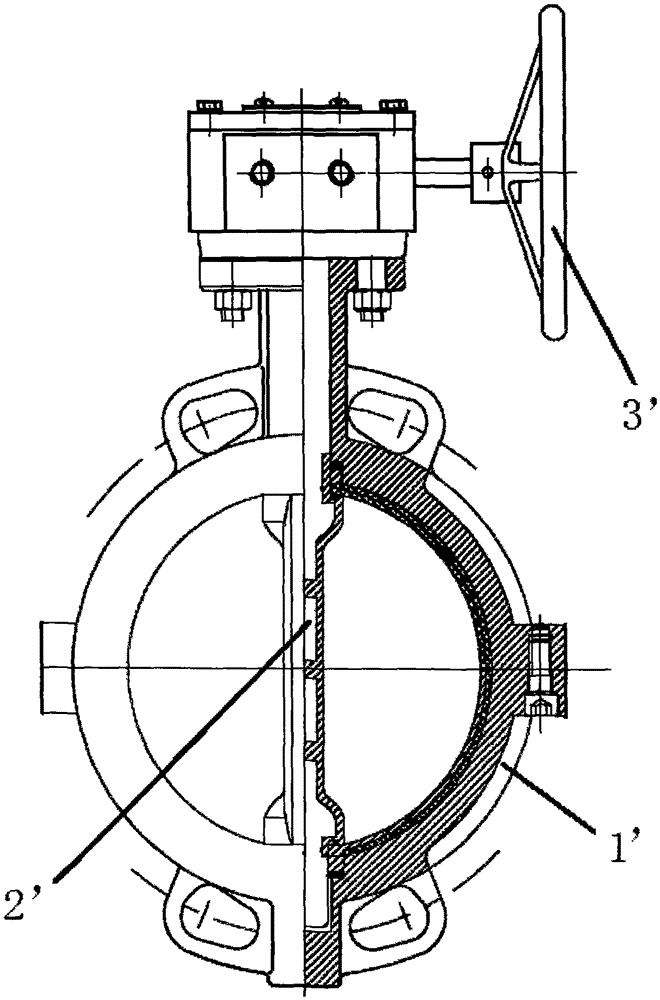

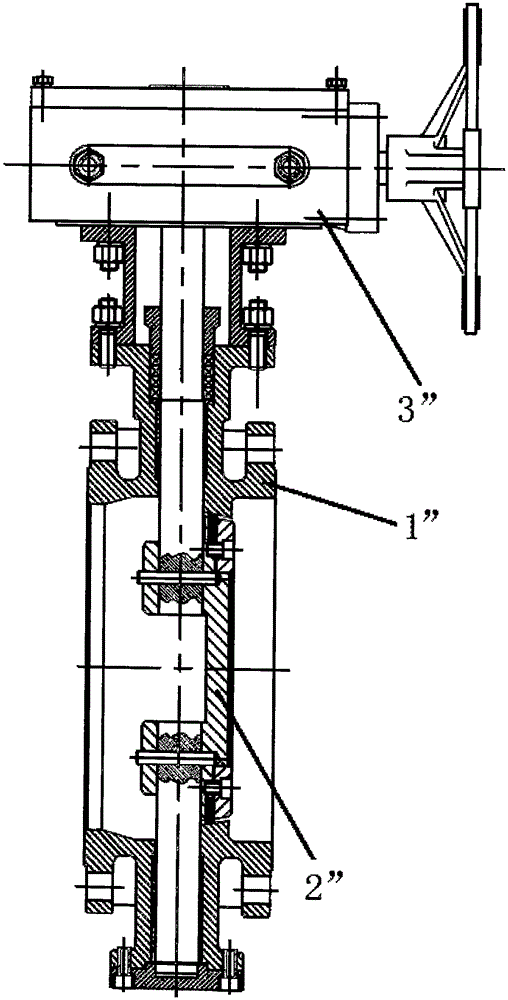

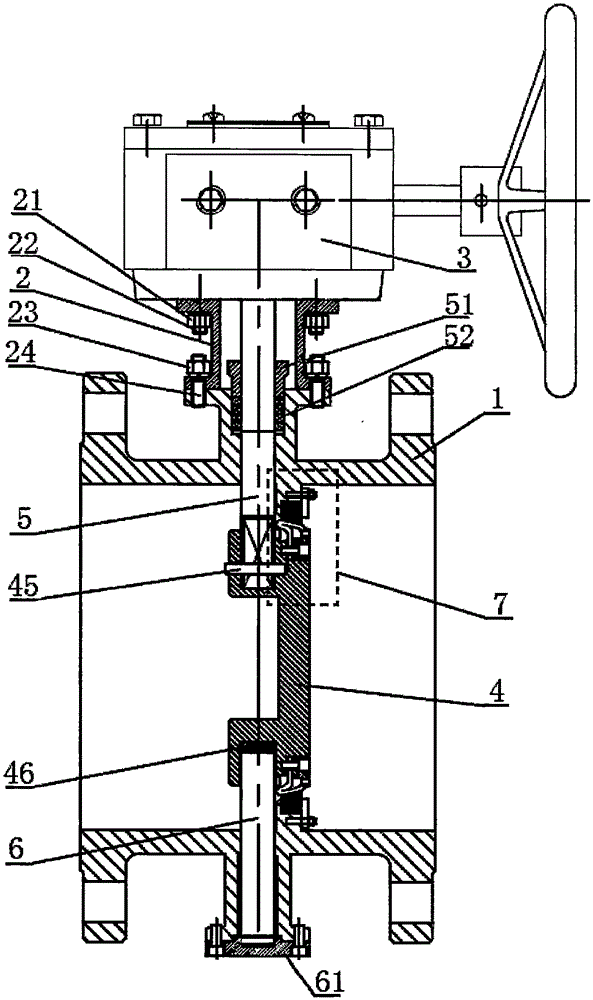

Double-scraper diaphragm butterfly valve

PendingCN105587869AChange the tightnessChange elasticitySpindle sealingsLift valveCompressive resistancePrism

The invention discloses a double-scraper diaphragm butterfly valve. The double-scraper diaphragm butterfly valve is characterized in that a valve body, a support and an execution mechanism are included, and the support and the execution mechanism are sequentially connected with the valve body; a butterfly plate is arranged in the valve body; a tetragonal-prism-shaped groove ring lug and a cylindrical groove ring lug which are parallel to the plane of the butterfly plate are arranged above and below the rear end of the butterfly plate; a tetragonal-prism-shaped upper valve rod is arranged in the tetragonal-prism-shaped groove ring lug; a cylindrical lower valve rod is arranged in the cylindrical groove ring lug; the butterfly plate is further connected with a sealing structure, and the sealing structure comprises a valve seat pressing plate, a valve seat, a diaphragm ring, a pressing plate ring, a butterfly plate sealing pad, a front pressure cavity and a rear pressure cavity; and a diaphragm front end thrust groove, front through-flow holes and pressing plate bolt holes are formed in the pressing plate ring. The elastic diaphragm pressure self-sealing structure is adopted, the diaphragm front end thrust groove and a diaphragm rear end thrust face achieve the function of scrapers, and special connection of the upper valve rod and the lower valve rod and locking prevention are achieved; low twisting force and the small structure are achieved, and compressive resistance is high; and the butterfly valve has the beneficial effects of being reliable in performance and long in service life.

Owner:天津自阀流体控制有限公司

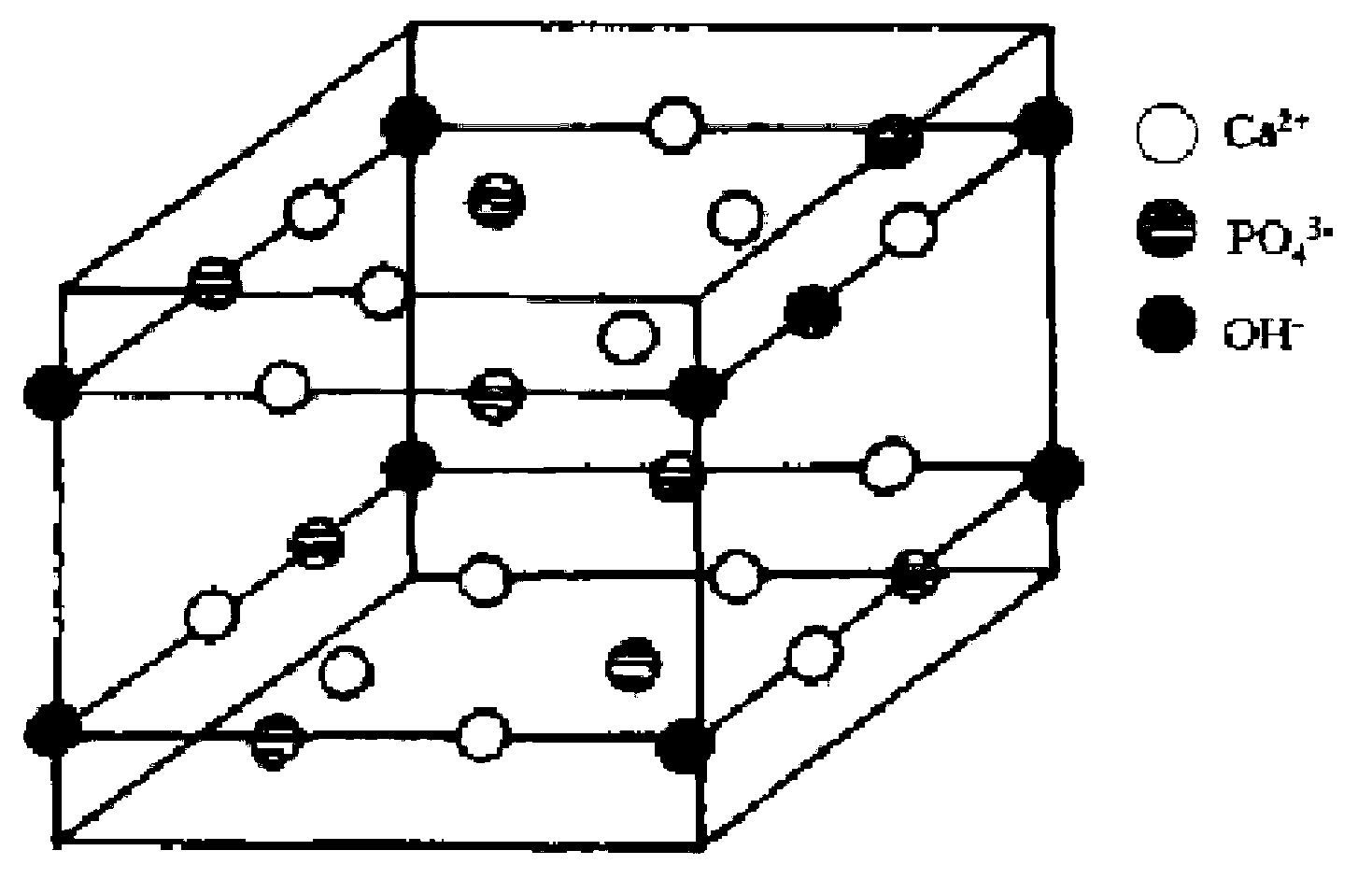

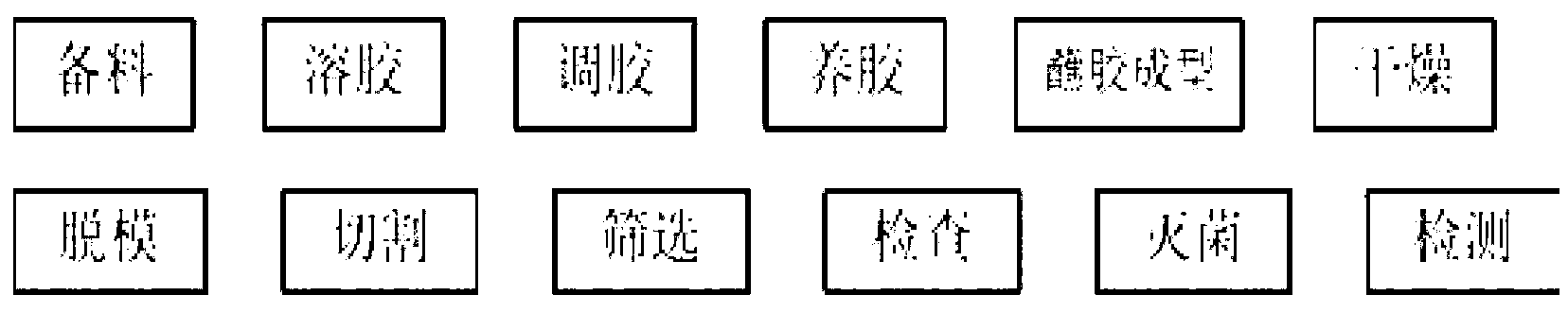

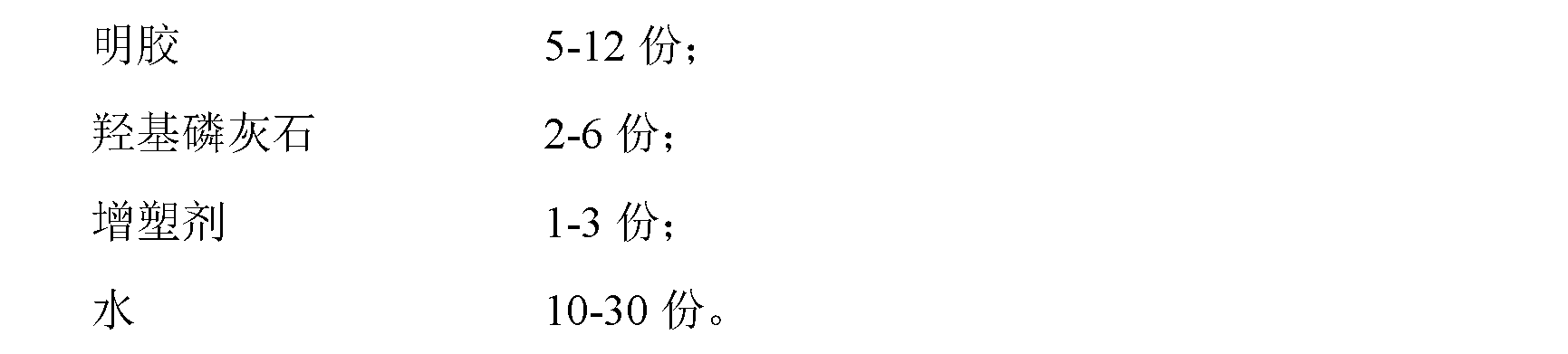

Bone capsule shell with functions of supplying calcium and building strong bones and preparation method thereof

InactiveCN103071158ATake advantage ofSolve the problem of difficult entryMetabolism disorderCapsule deliveryPlasticizerDrug product

The invention relates to a bone capsule shell with the functions of supplying calcium and building strong bones. The bone capsule shell comprises the following components in part by weight: 5-12 parts of gelatin, 2-6 parts of hydroxyapatite, 1-3 parts of plasticizer and 10-30 parts of water. According to the invention, the bone capsule shell not only has the functions of medicine slow-releasing and medicine effect improvement the same as the conventional capsule shell, but also has the efficacies of supplying calcium and building strong bones, and has favorable physiological activity, so that the capsule shell is fully utilized; the materials and the manufacturing method of the bone capsule shell completely conform to the requirements of medicine and food; and the bone capsule shell can be used in the field of medicine, healthcare food and the like.

Owner:TIANJIN UNIV OF SCI & TECH

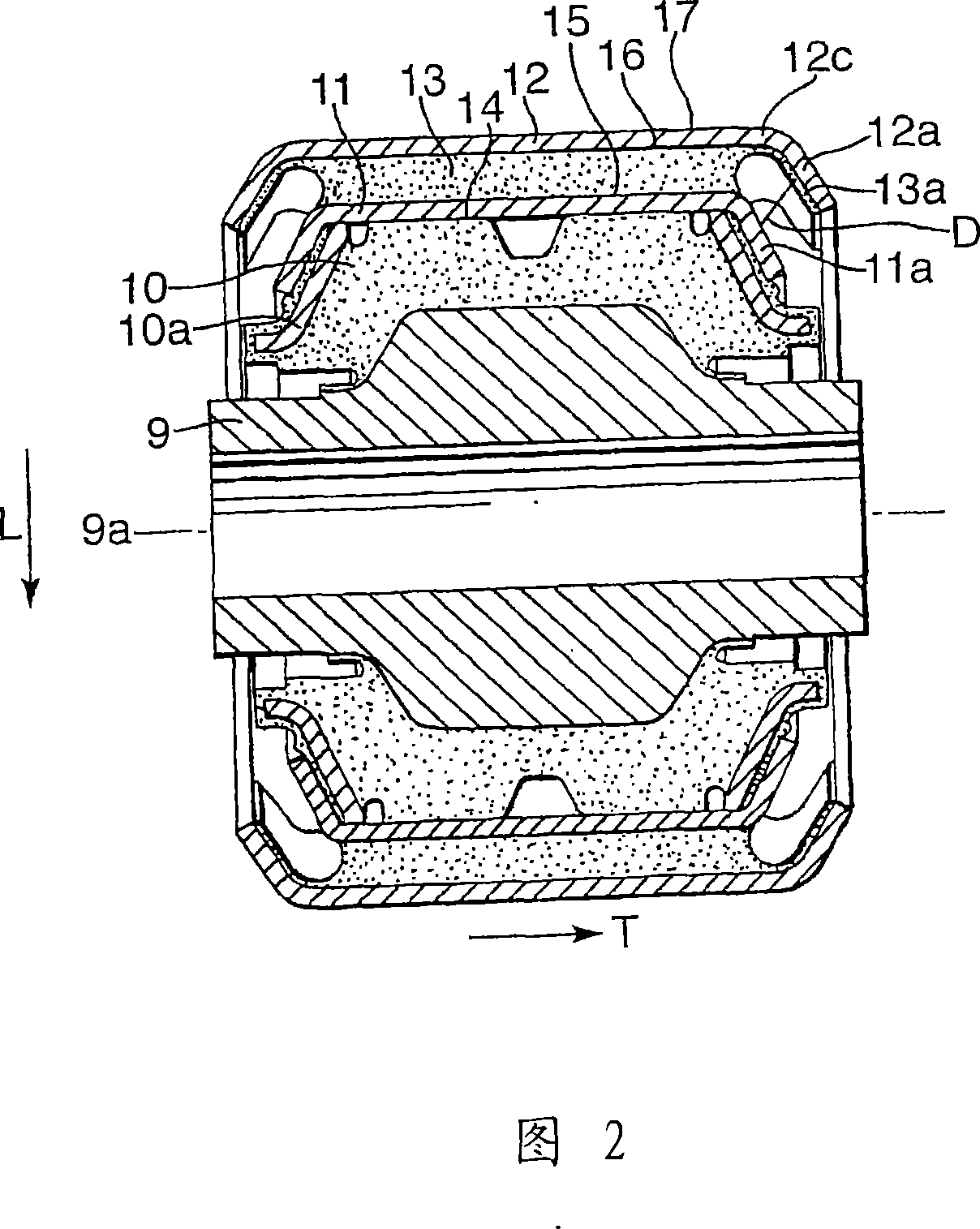

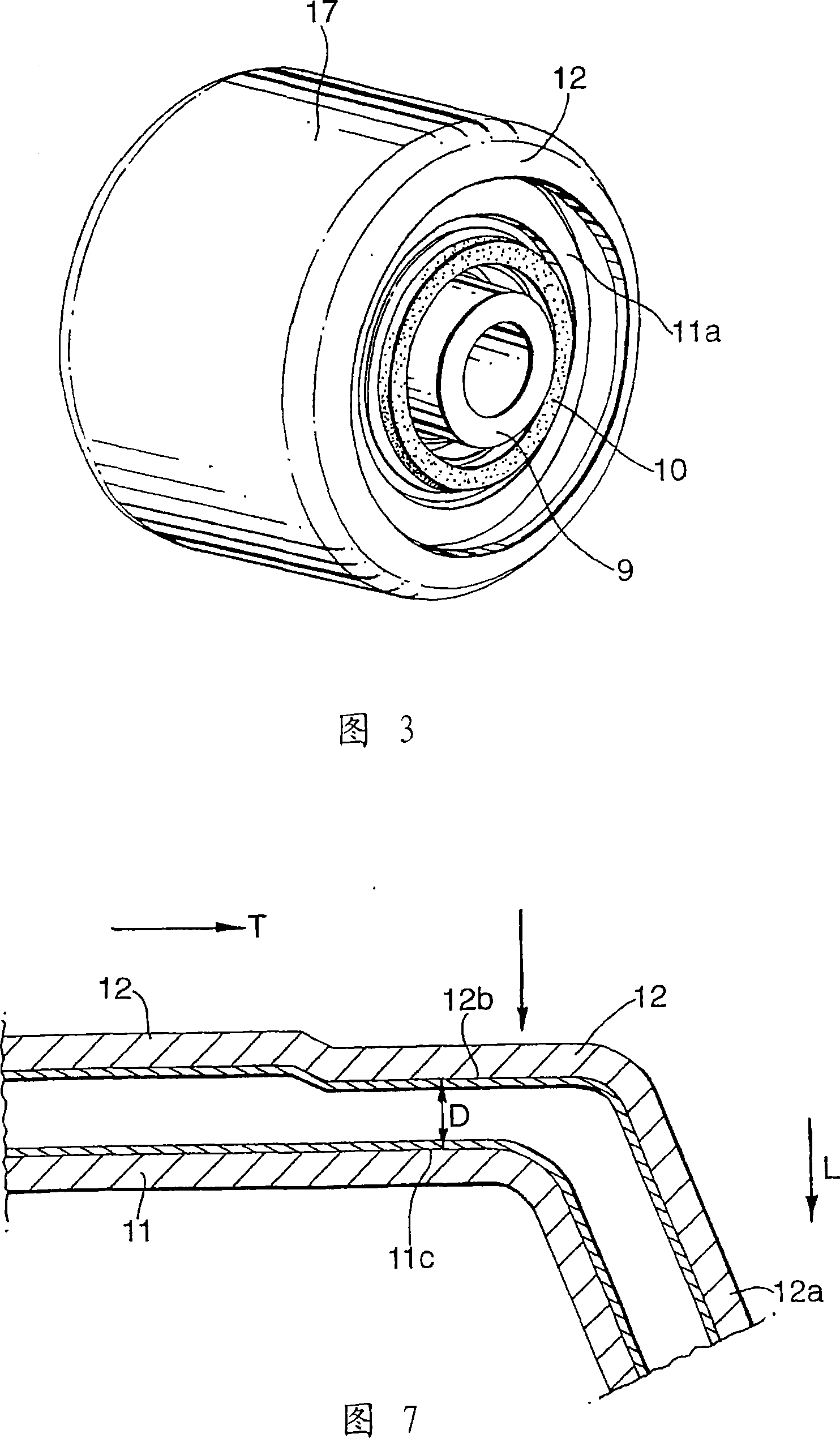

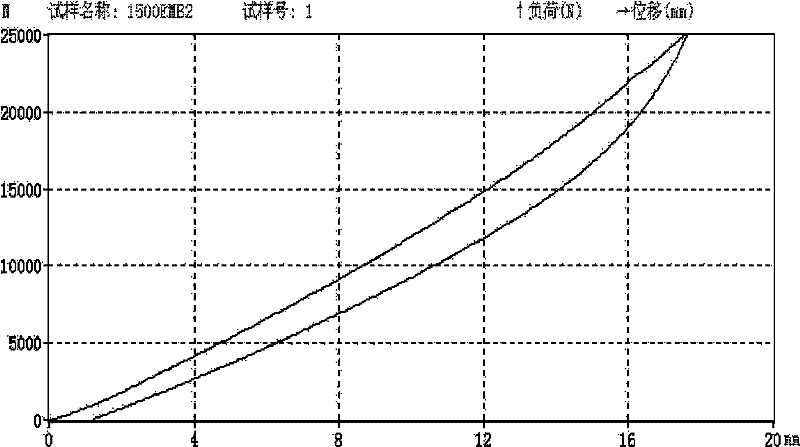

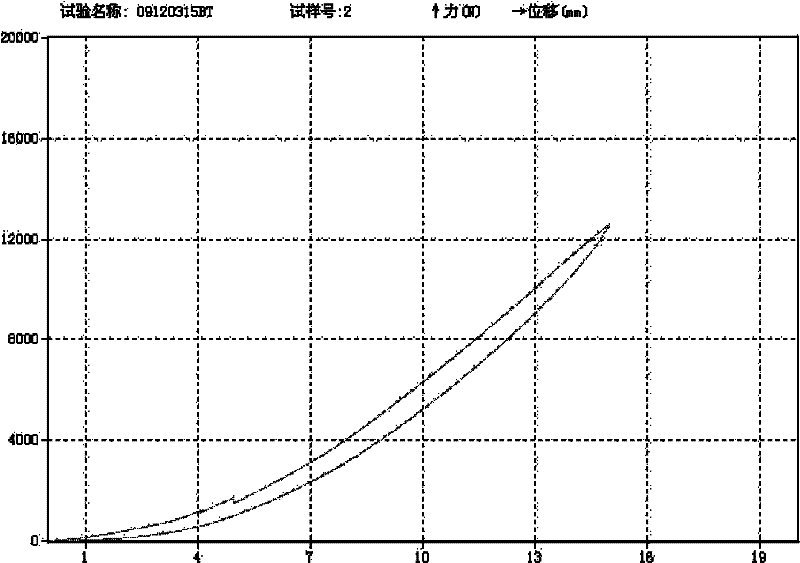

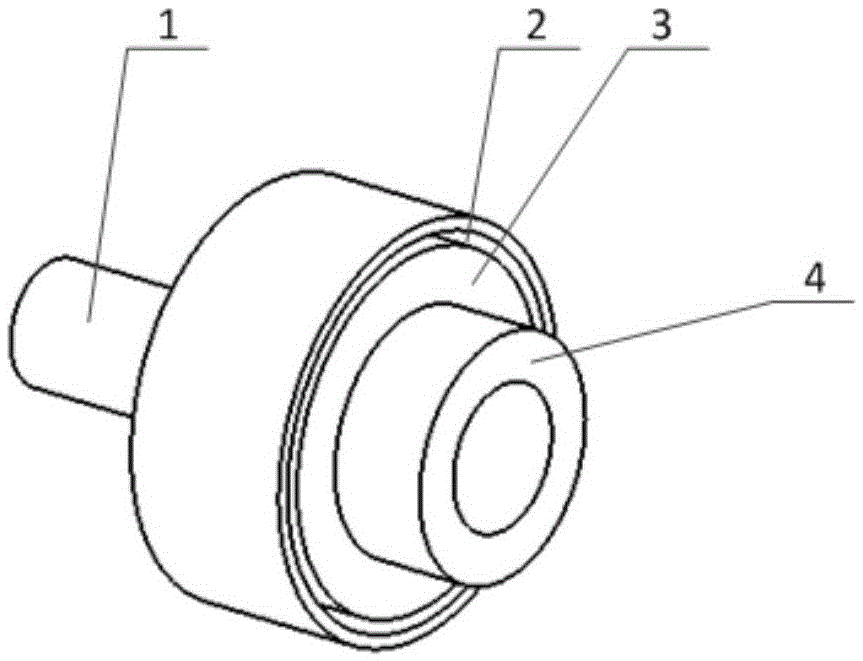

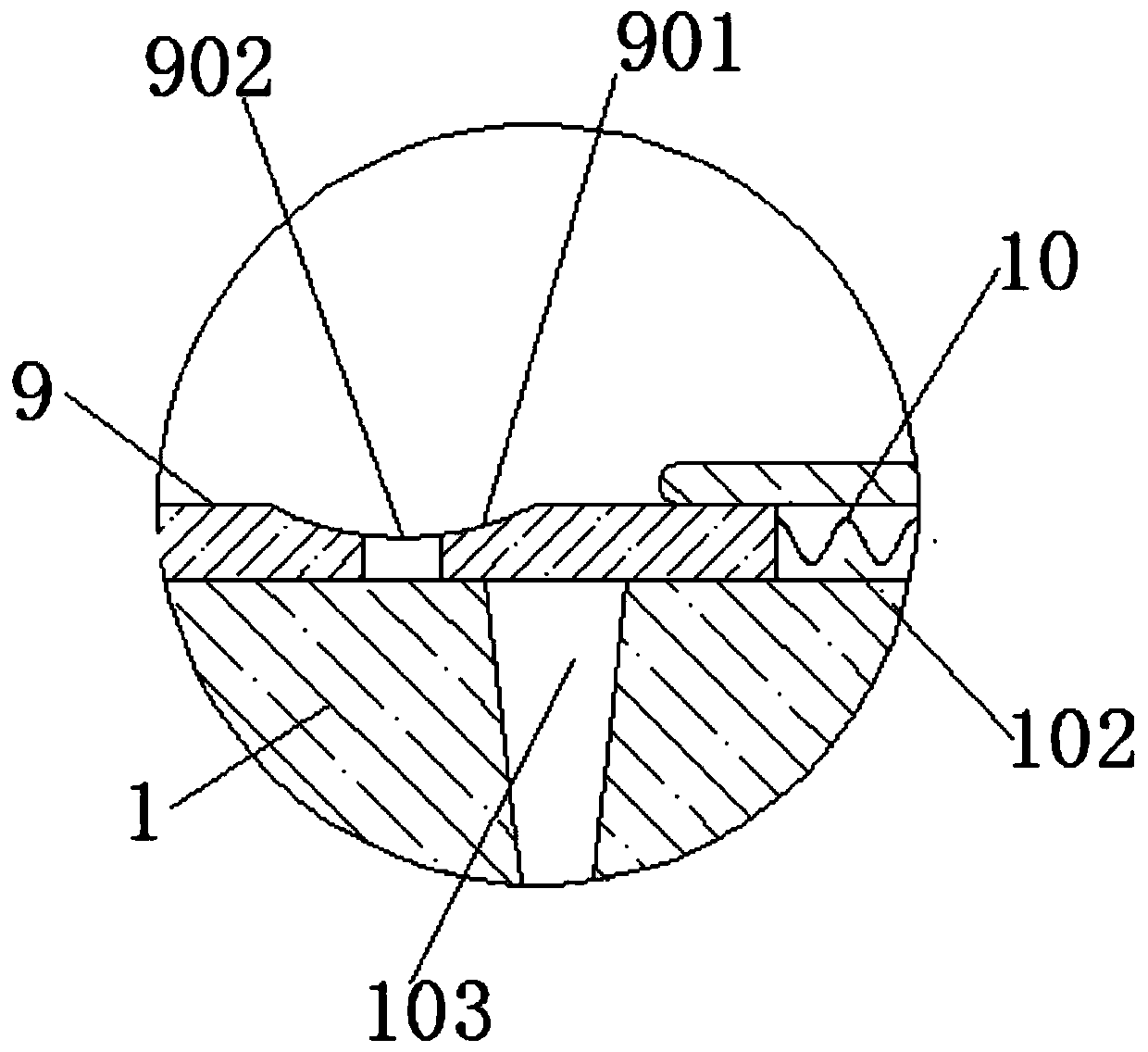

Tuneable bushing

ActiveCN101203696AChange elasticityReduce dissonanceMultiple spring combinationsSprings/dampers design characteristicsAnti-roll barRadial position

A bushing device used for the connection between the cab and the vehicle chassis. The anti-roll bar consists of a torsion bearing and two connecting arms. Each link arm has a first end connected to the torsion bar and a second end connected to the core (9) via a first sleeve element. The first sleeve element includes a first rigid sleeve (11) arranged concentrically with the core and a first elastic element (10) located between the first rigid sleeve and the core. The bushing device further includes a second bushing element arranged concentrically with the first bushing element and at a position radially outward or inward relative to the first bushing element. The second sleeve element includes a second rigid sleeve (12) and at least one second elastic element (13), wherein at least a portion of the radially inner surface of the second rigid sleeve is in contact with the radially outer surface of the second elastic element . The second elastic element is more elastic than the first elastic element. The second sleeve element is provided with at least one adjustable braking device, which includes a braking portion (12a) contained in the second sleeve element.

Owner:孔斯贝格汽车公司

60-degree natural rubber and production process thereof

The invention discloses a 60-degree natural rubber and a production process of the 60-degree natural rubber. The raw materials of the 60-degree natural rubber comprise 48%-65% of raw natural rubber, 1%-2.5% of vulcanizator, 5%-21% of high wear-resistant furnace black, 8%-28% of spraying carbon black, 5.5%-17% of active agent, 0.1%-0.6% of accelerator, 0.55%-3.2% of anti-aging agent and 0.5%-3% of plasticizer, and the natural rubber is produced by processes of plasifying and mixing. The 60-degree natural rubber has the advantages of good ageing resistance, good elongation at rupture, excellent wear resistance, good rebound value, good load compression amount and natural frequency; meanwhile, the rubber is low in production cost.

Owner:北京市长城机床附件有限责任公司

Automobile seat

InactiveCN102673450AImprove comfortComfortable surfaceBack restsThigh restsDriver/operatorMuscle fatigue

The invention provides an automobile seat. The automobile seat is manufactured by filling sponge with a slow rebound mechanical property, and comprises a seat cushion where a passenger sits, and a back and a head pillow which support the back of the passenger. With the adoption of the automobile seat provided by the invention, the riding experience and the comfort of the user can be improved; the conditions of muscle fatigue and unsmooth circulation of bloods of four limbs and the back, caused by long-distance driving of a driver, can be reduced; and the experience sense that important passengers sit on a back row of a high-grade luxury automobile can be improved. Furthermore, the automobile seat can bring the better rest experience to the passengers, so that the passengers enjoy tour time, and the discomfort caused by bumping and shaking of an automobile can be removed.

Owner:SUZHOU FEIYU PRECISION TECH

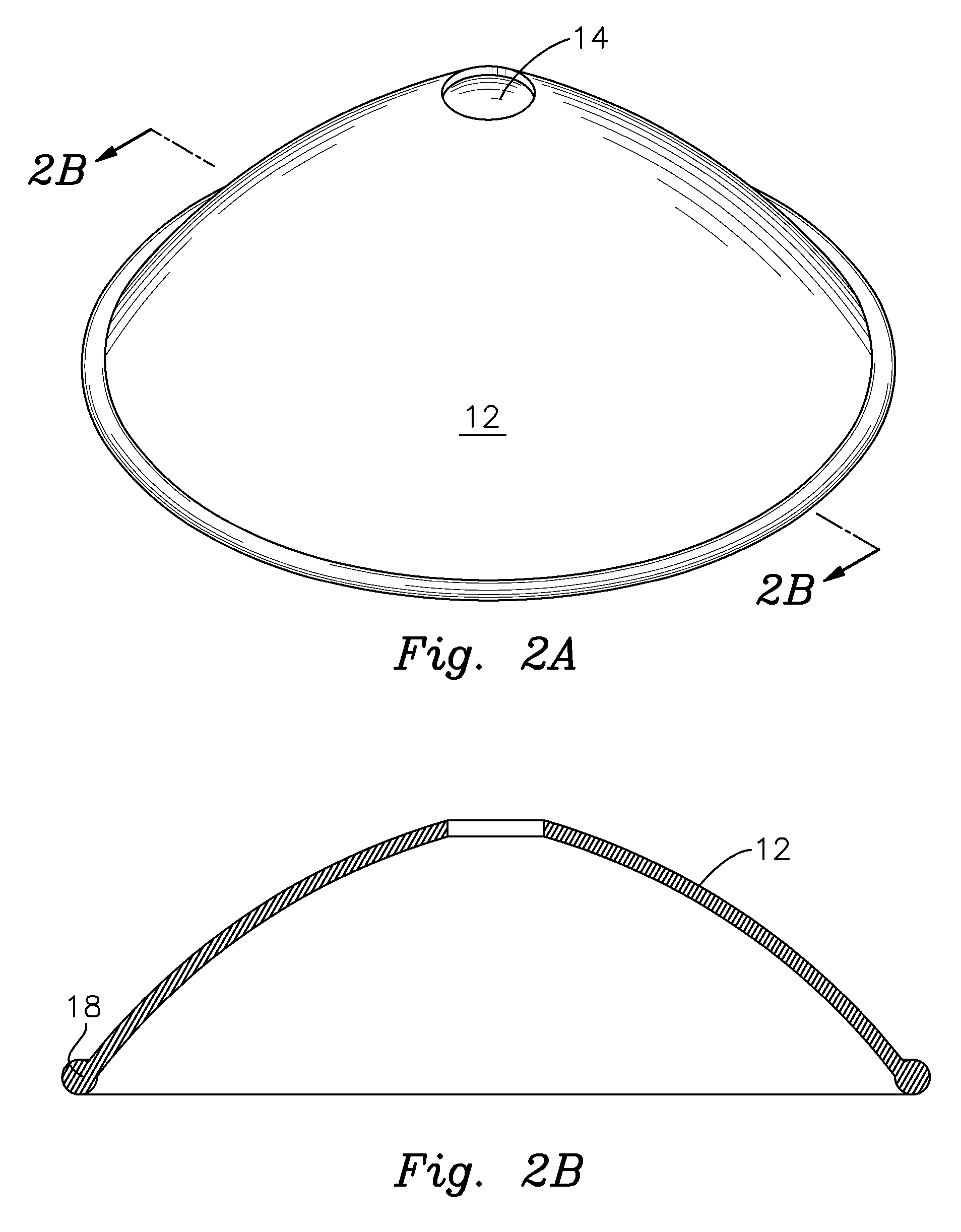

Flat seal having a deformation limiter

Owner:FEDERAL MOGUL SEALING SYST GMBH (DE)

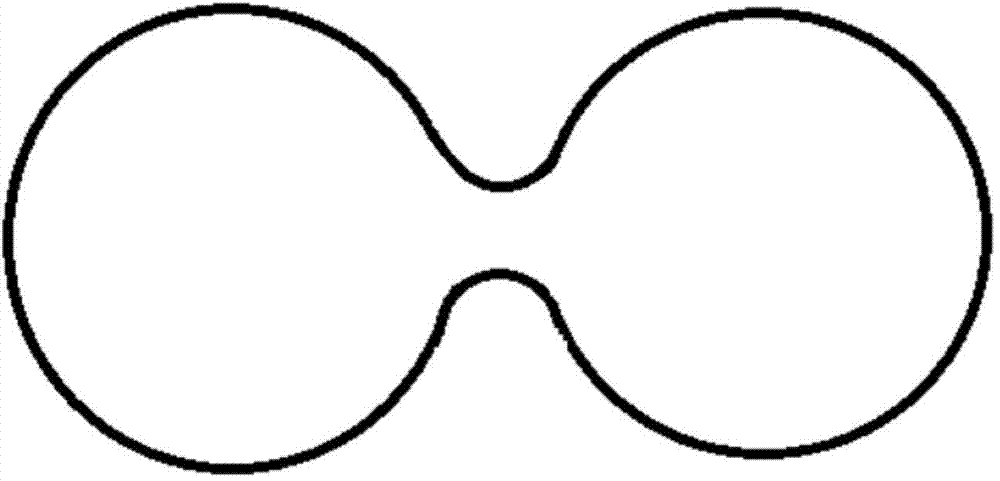

Three-dimensional elastic rotating color changing fiber and spinneret plate thereof

ActiveCN103924310AGood discoloration effectImprove moisture wicking functionFilament/thread formingConjugated synthetic polymer artificial filamentsEngineeringFiber

The invention relates to a three-dimensional elastic rotating color changing fiber and a spinneret plate for manufacturing the three-dimensional elastic rotating color changing fiber. The specific rotating color changing effect of the three-dimensional elastic rotating color changing fiber is ensured through the dye-uptake difference between two components of the three-dimensional elastic rotating color changing fiber and a three-dimensional spiral crimp structure of a parallel composite fiber. The three-dimensional elastic rotating color changing fiber and the spinneret plate are characterized in that each micropore of the spinneret plate for producing the three-dimensional elastic rotating color changing fiber is shaped like the Arabic numeral eight; a composite spinning assembly and a specially-shaped spinneret assembly are adopted; moisture absorption and sweat releasing performance of the three-dimensional elastic rotating color changing fiber can be improved due to grooves in the surface of the three-dimensional elastic rotating color changing fiber. The three-dimensional elastic rotating color changing fiber has the stable crimp resilience and is simple in manufacturing process, the elastic range of the three-dimensional elastic rotating color changing fiber can be adjusted according to the heat treatment technology, and the three-dimensional elastic rotating color changing fiber can be widely applied to sports wear, underwear, woven tapes and the like.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

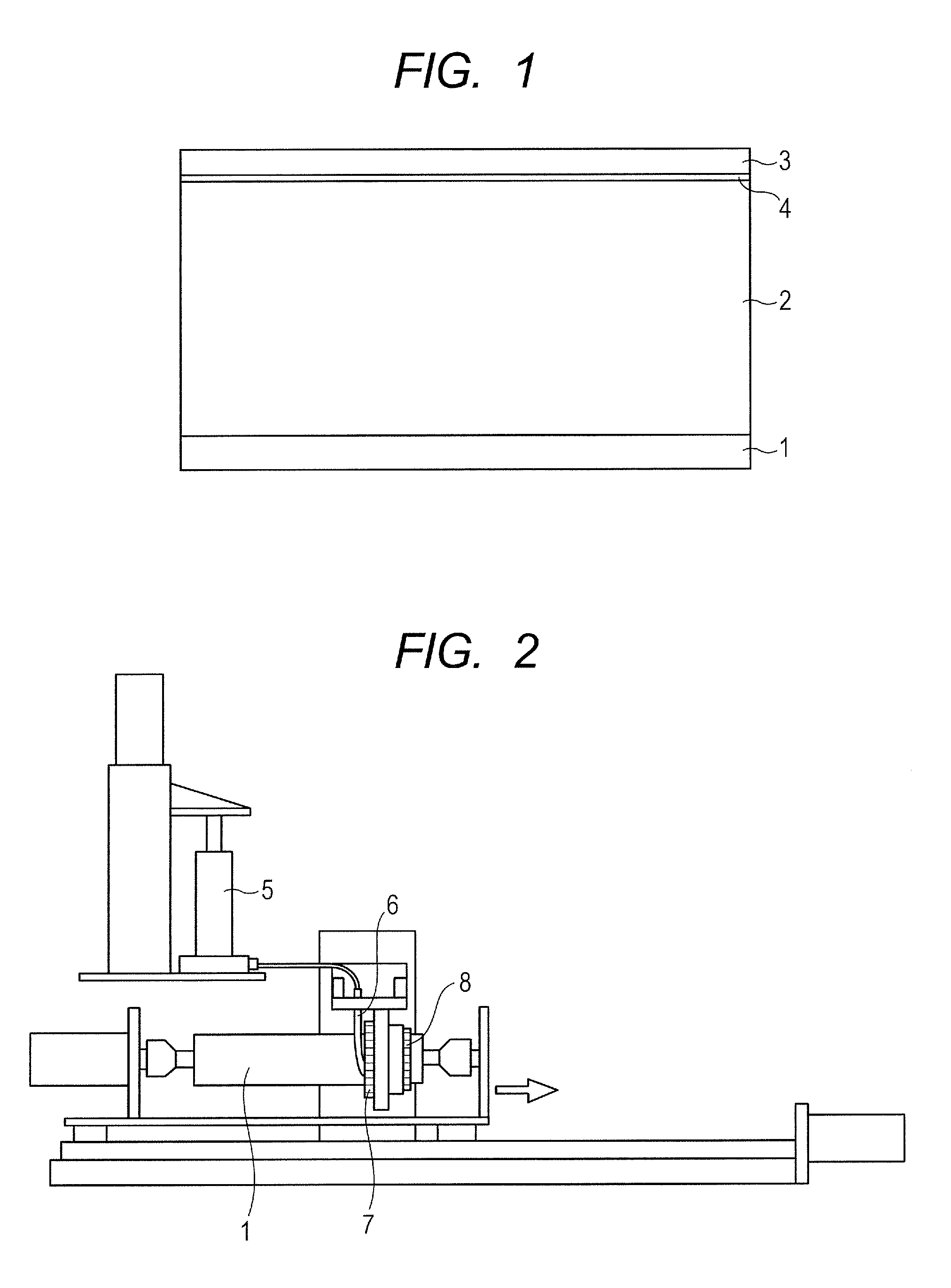

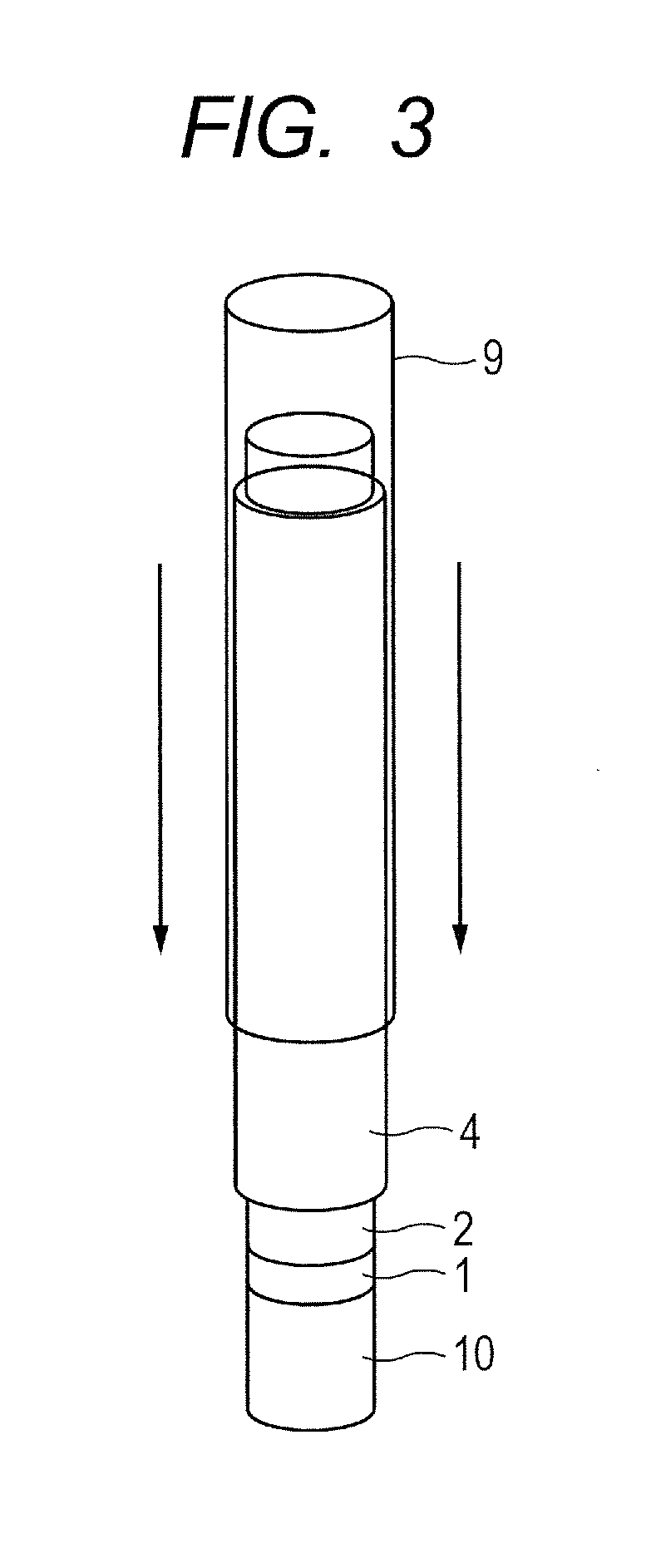

Electrophotographic fixing member, fixing apparatus and electrophotographic image forming apparatus

ActiveUS20150098739A1Elasticity can be deterioratedAvoid changeElectrographic process apparatusPolymer scienceHydrogen

An electrophotographic fixing member includes a substrate, a cured silicone rubber layer and a fluorine resin layer bonded onto the cured silicone rubber layer, wherein a micro hardness of a cured silicone rubber constituting the cured silicone rubber layer is designated as Hμ0, and a micro hardness of a rubber obtained by soaking the cured silicone rubber in a methyl hydrogen silicone oil for 24 hours and then further curing the cured silicone rubber, is designated as Hμ1, Hμ1 / Hμ0 is 1.5 or more and 5.0 or less, and the cured silicone rubber layer comprises a titanium oxide crystal having an anatase type structure.

Owner:CANON KK

Magneto-rheological damper used for installation and debugging of helicopter high-definition camera

ActiveCN105626758AHigh structural reliabilityCompact structureAircraft componentsSpringsHigh definitionMagnetic current

The invention discloses a magneto-rheological damper used for installation and debugging of a helicopter high-definition camera, comprising a base, a coil and a magneto-rheological fluid; the base comprises a first connecting part connected with the camera and a second connecting part fixedly connected with a helicopter; the first connecting part comprises a first containing part used for containing the coil and a second containing part used for containing the magneto-rheological fluid; and the first containing part surrounds the periphery of the second containing part. The magneto-rheological damper is compact in structure, high in reliability and light in weight.

Owner:EAGLES MEN AERONAUTIC SCI & TECH GRP

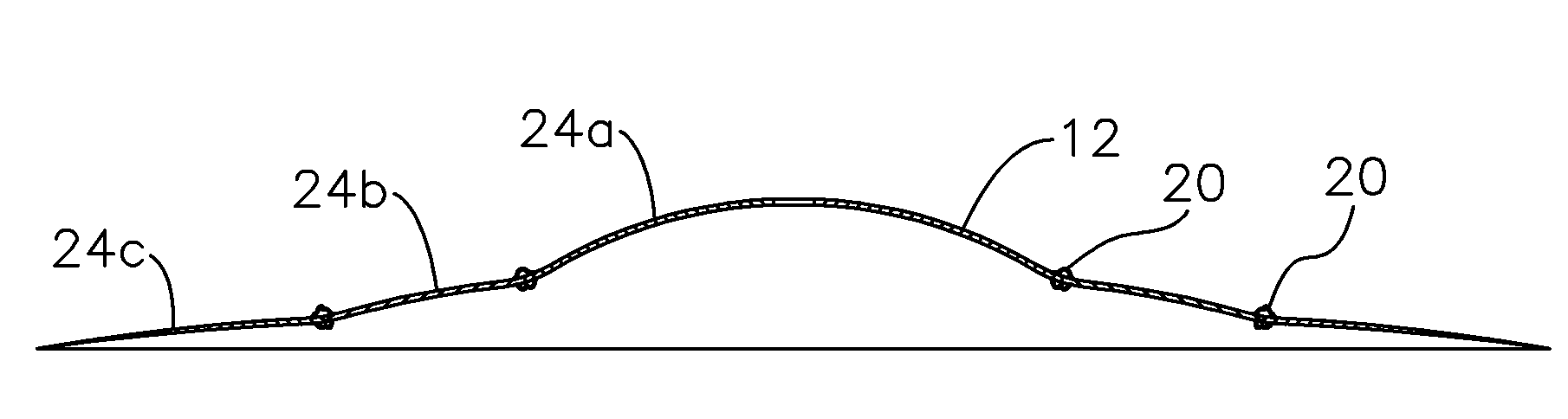

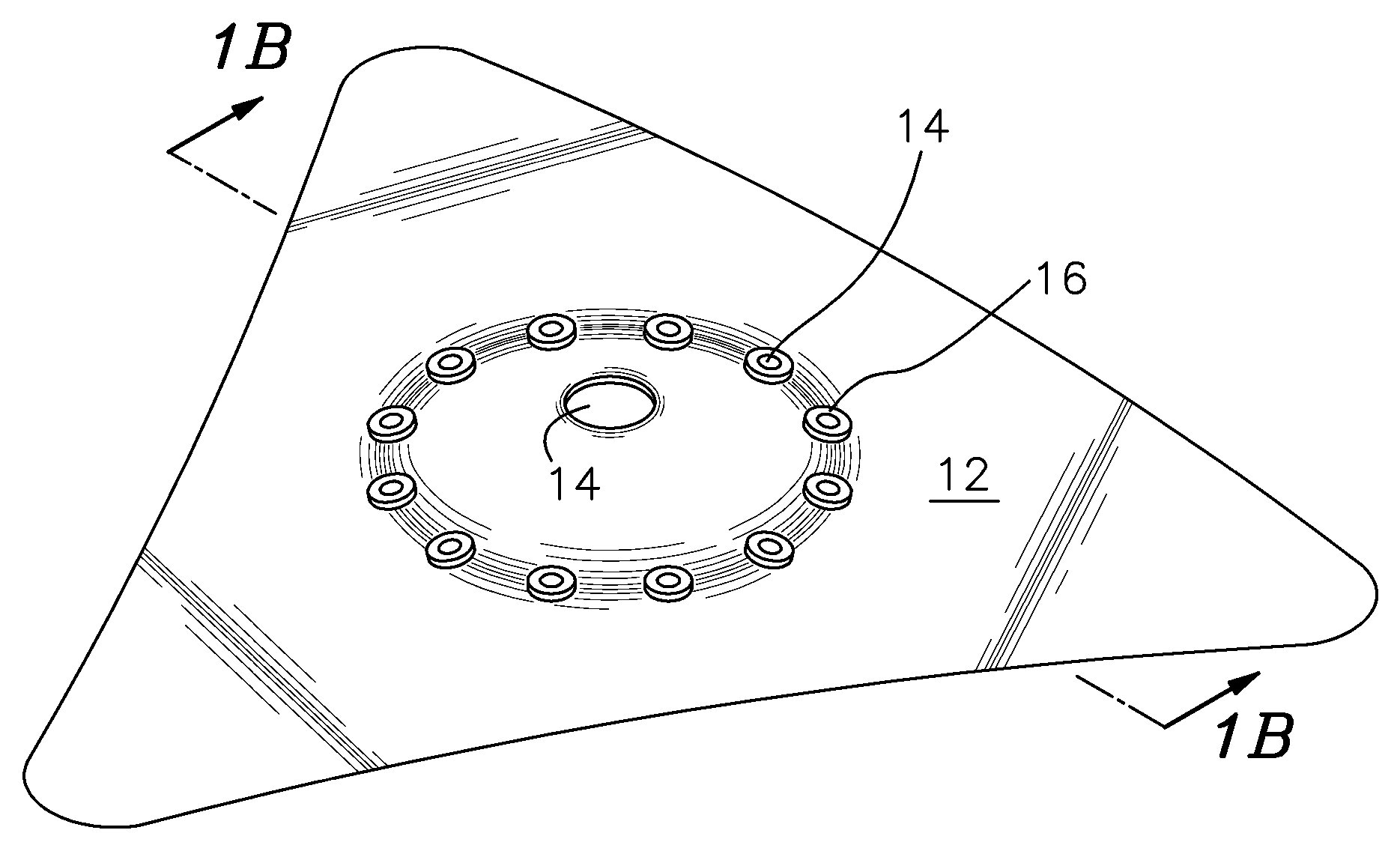

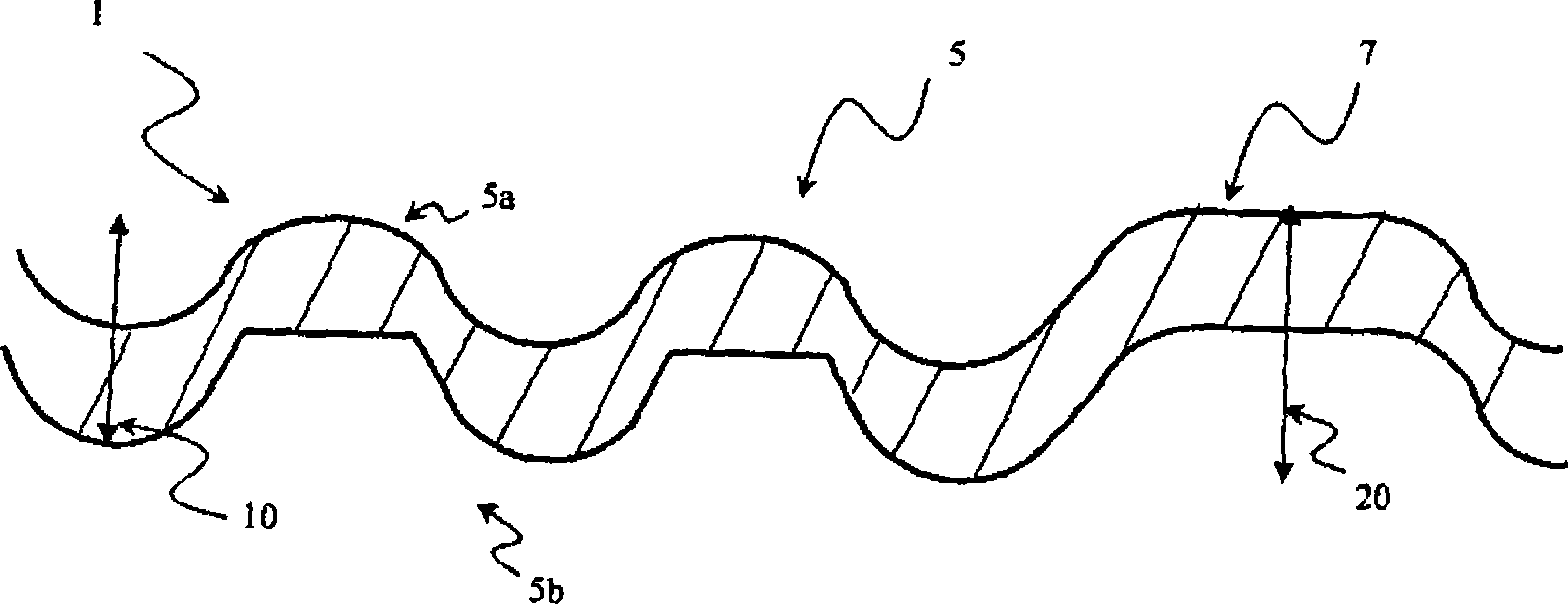

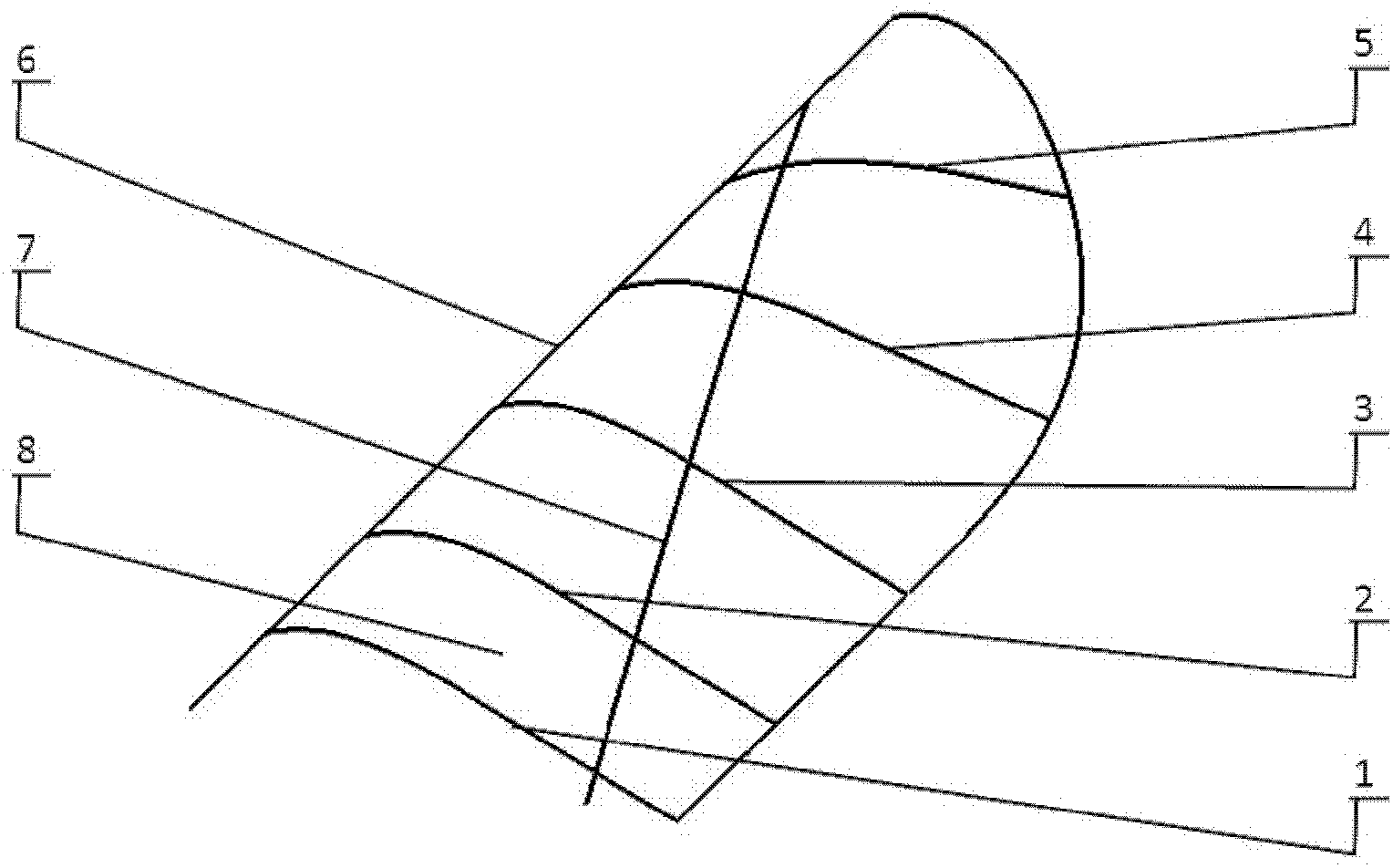

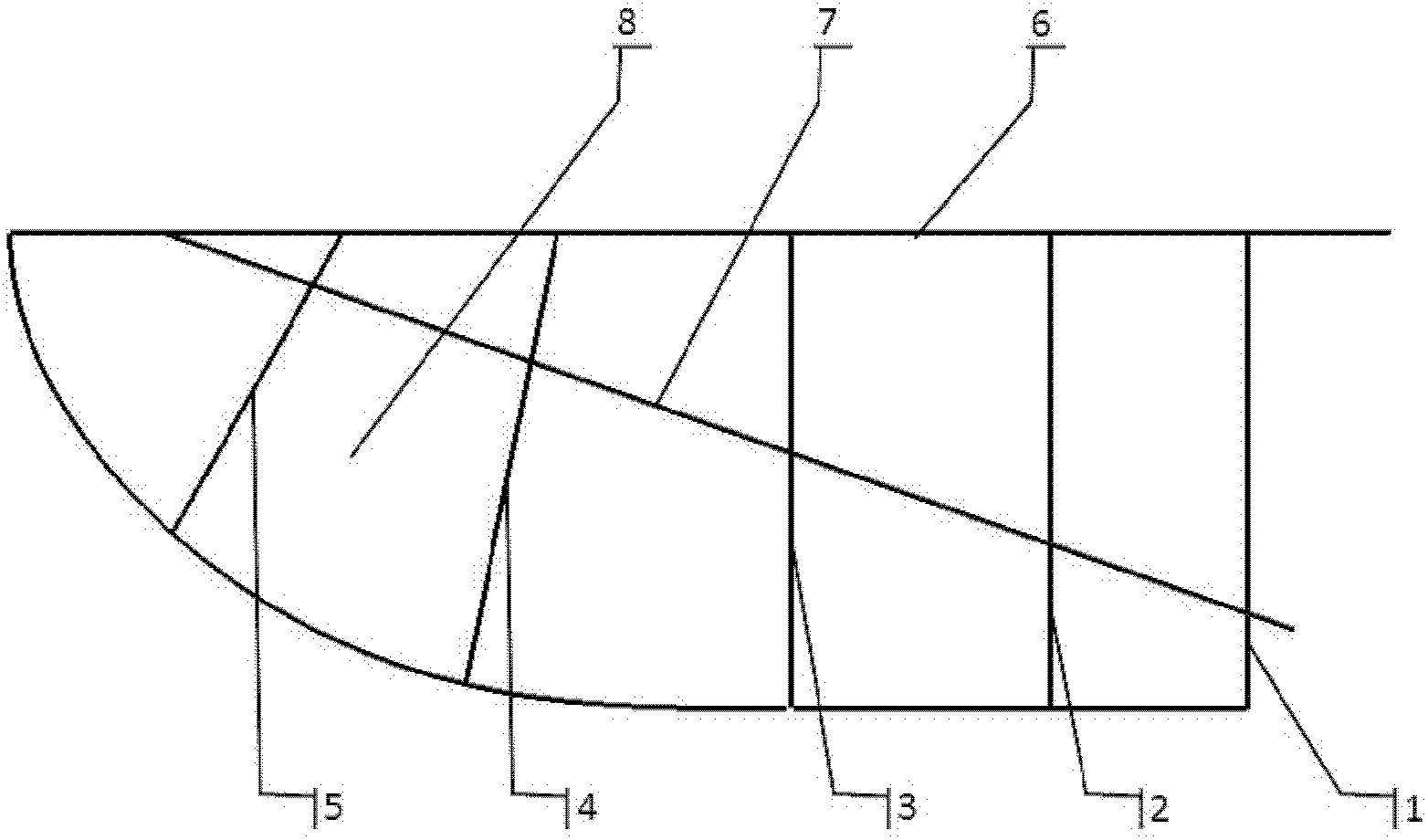

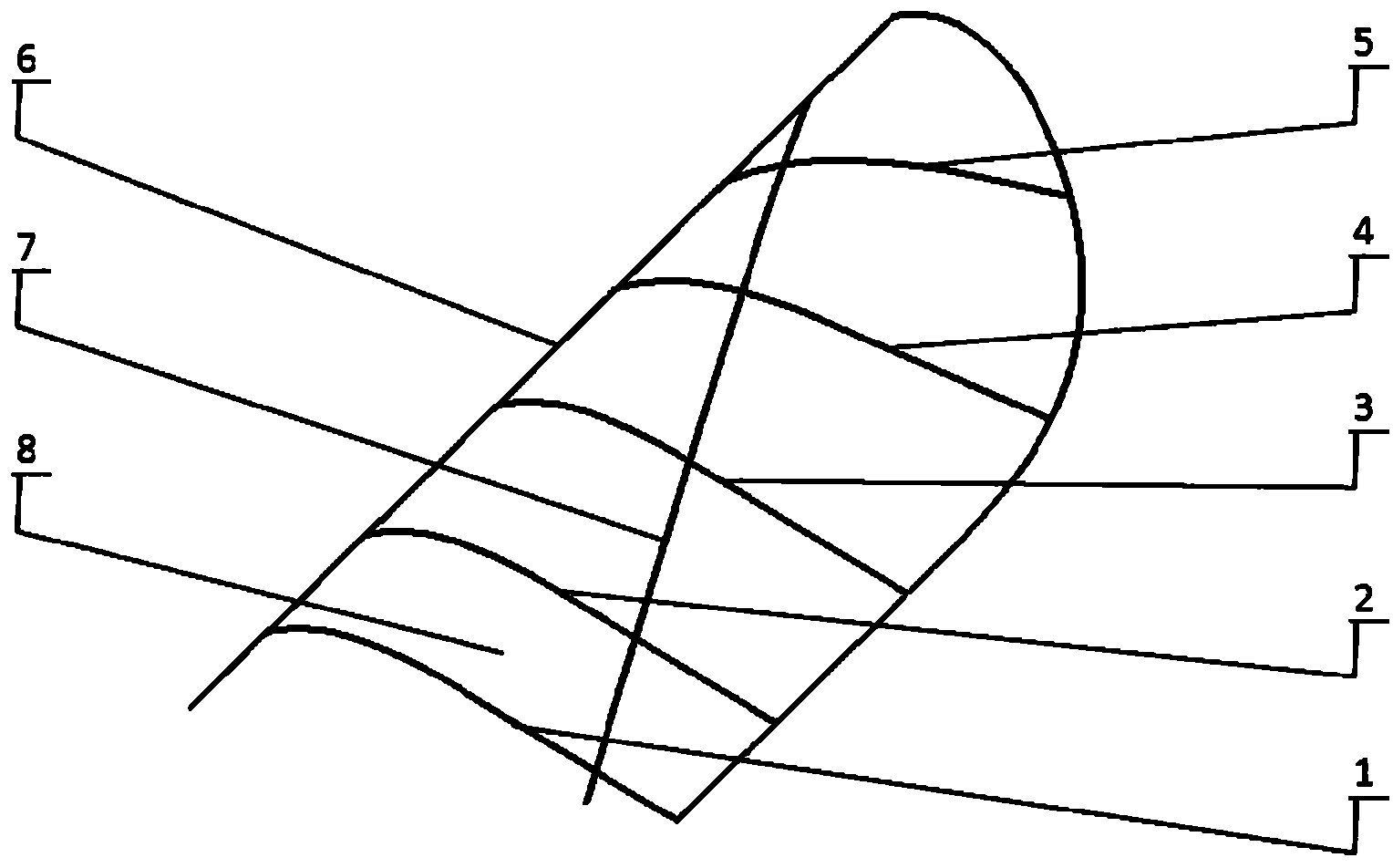

Wing of micro ornithopter

ActiveCN102501972AFlat stiffness distributionSmooth transition of stiffness distributionOrnithoptersAcute angleFront edge

The invention discloses a wing of a micro ornithopter. According to the present invention, a main beam is level and straight; the front edge points of five wing ribs are fixed on the main beam; the wing rib No.1, the wing rib No.2 and the wing rib No.3 are perpendicular to the main beam; the wing rib No.4 and the wing rib No.5 form acute angles with the tip part direction of the main beam; the chord lengths of the wing rib No.1, the wing rib No.2 and the wing rib No.3 are the same; the chord length of wing rib No.4 and the chord length of the wing rib No.5 are sequentially reduced, and are shorter than the chord length of the wing rib No.1; an assistant beam is an arc structure; the outer edge point of the assistant beam is fixed on the main beam between the end point of the tip part of the main beam and the rear edge point of the wing rib No.5, the root part of the assistant beam passes through the rear half part of the wing rib No.1, the assistant beam contacts the positions corresponding to the five wing ribs and is fixed with the positions corresponding to the five wing ribs; the main beam, the assistant beam and the wing ribs form a wing structure frame, and a skin is adhered above the frame to form a complete wing. With the present invention, the stiffness distribution of the whole wing flatly transits, the structure continuity is good, the good force loading property is provided, the structure is simple, and the wing of the present invention is convenient to manufacture.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

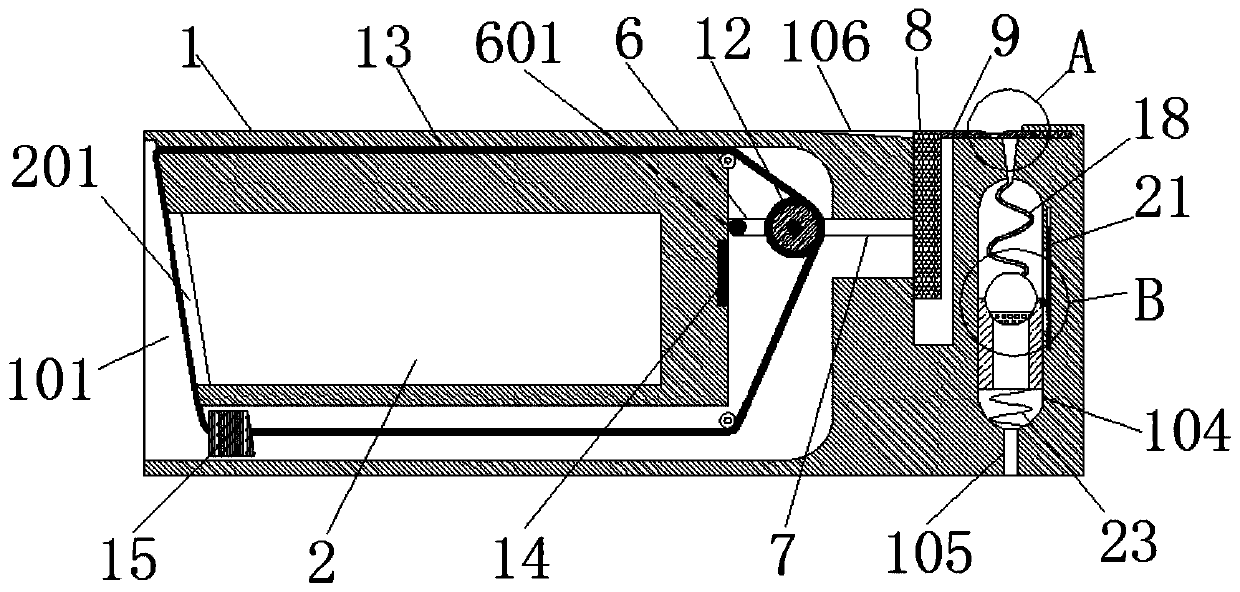

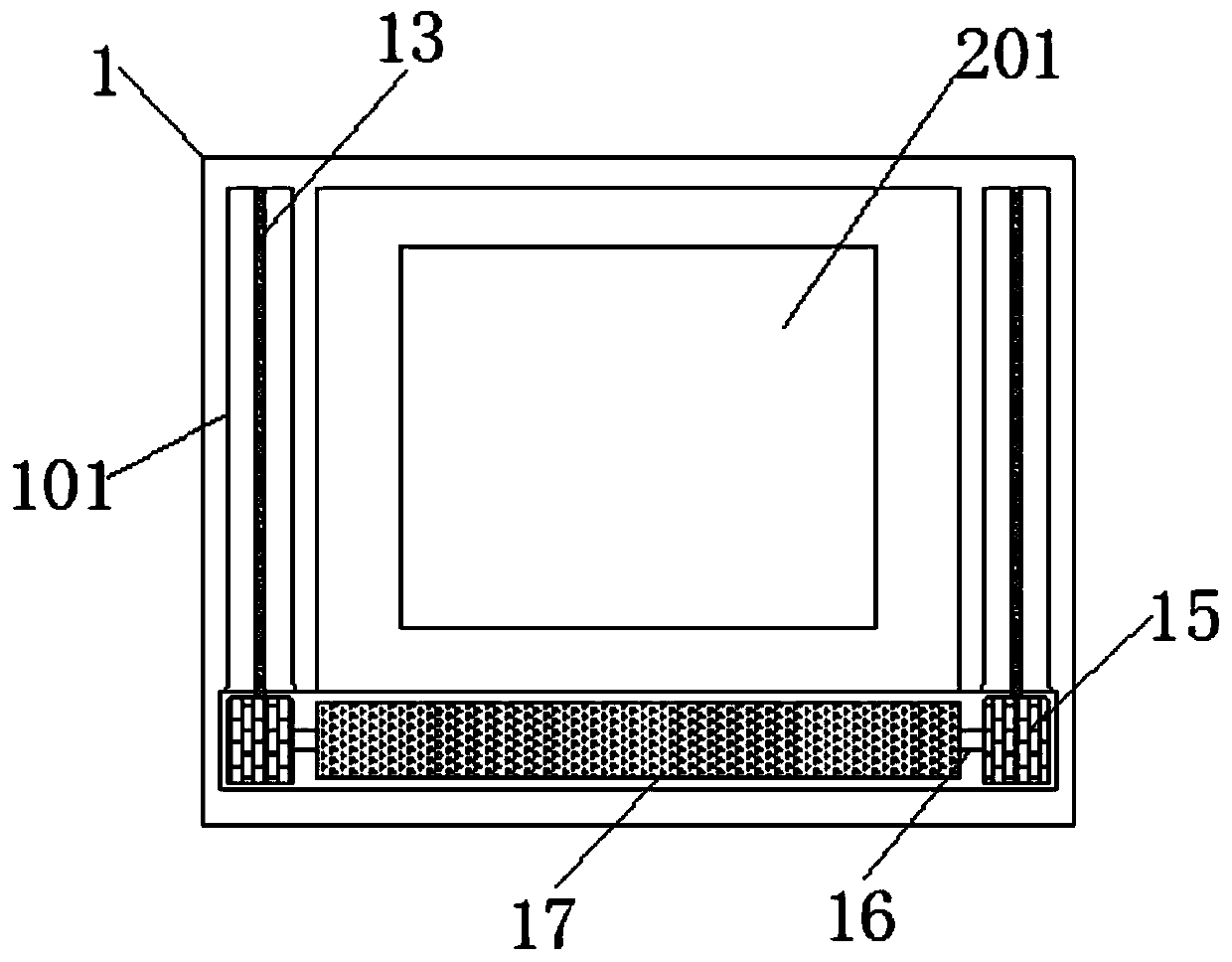

Outdoor self-erasing camera for mobile internet

ActiveCN110971802ASolve the problem of not automatically adjusting the cleaning outputSolve the problem of inaccurate cleaning frequencyTelevision system detailsColor television detailsInternet usersMetal sphere

The invention relates to the technical field of photographic equipment for the Internet. and discloses an outdoor self-erasing camera for mobile internet. The camera comprises a photography body. Anintermittent structure is connected to the interior of a movable frame; a first metal ball is connected to the left end of a fixing rod, an expansion strip is connected to the right end of a connecting rod, a cable is arranged on the outer side of a wire coil, a metal sheet corresponding to the first metal ball is arranged in the photographing body, a water bag is connected to the lower end of tahose, a second metal ball is arranged on the upper portion of the supporting sliding block, and a variable resistor is arranged on the right portion of the photographing body. A sliding rod is pushedto move rightwards through the upper end of an expansion strip; rainwater flows into the water bag through a conical groove and the hose. A supporting sliding block drives the second metal ball to slide on the variable resistor, the size of the rainwater can be indirectly detected through the weight of the water bag, and therefore the output size of the driving shaft is changed, and the structuresolves the problem that an existing internet camera cannot automatically adjust, clean and output during photographing.

Owner:徐正才

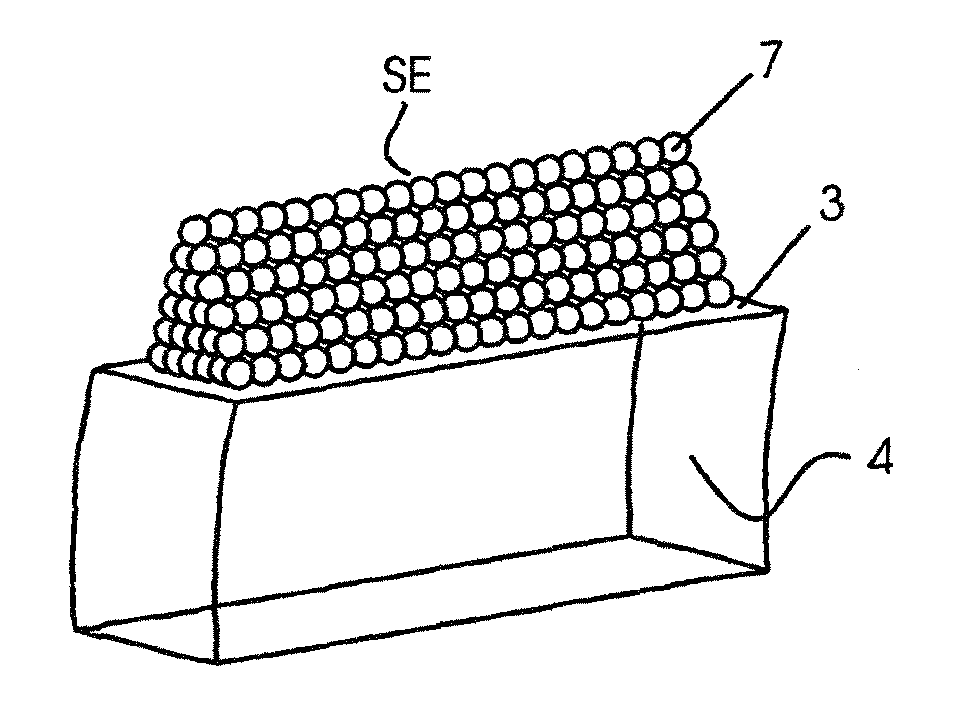

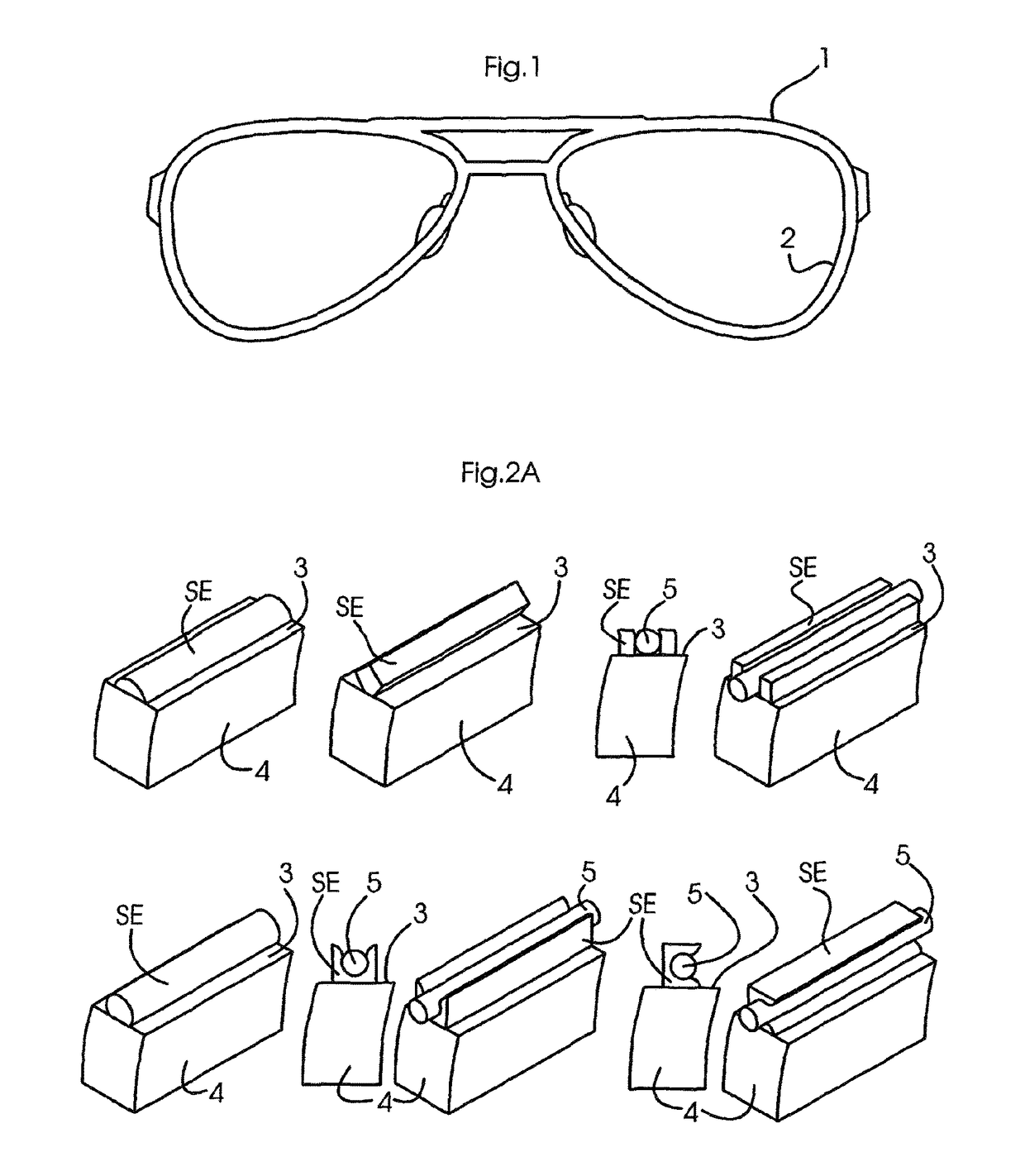

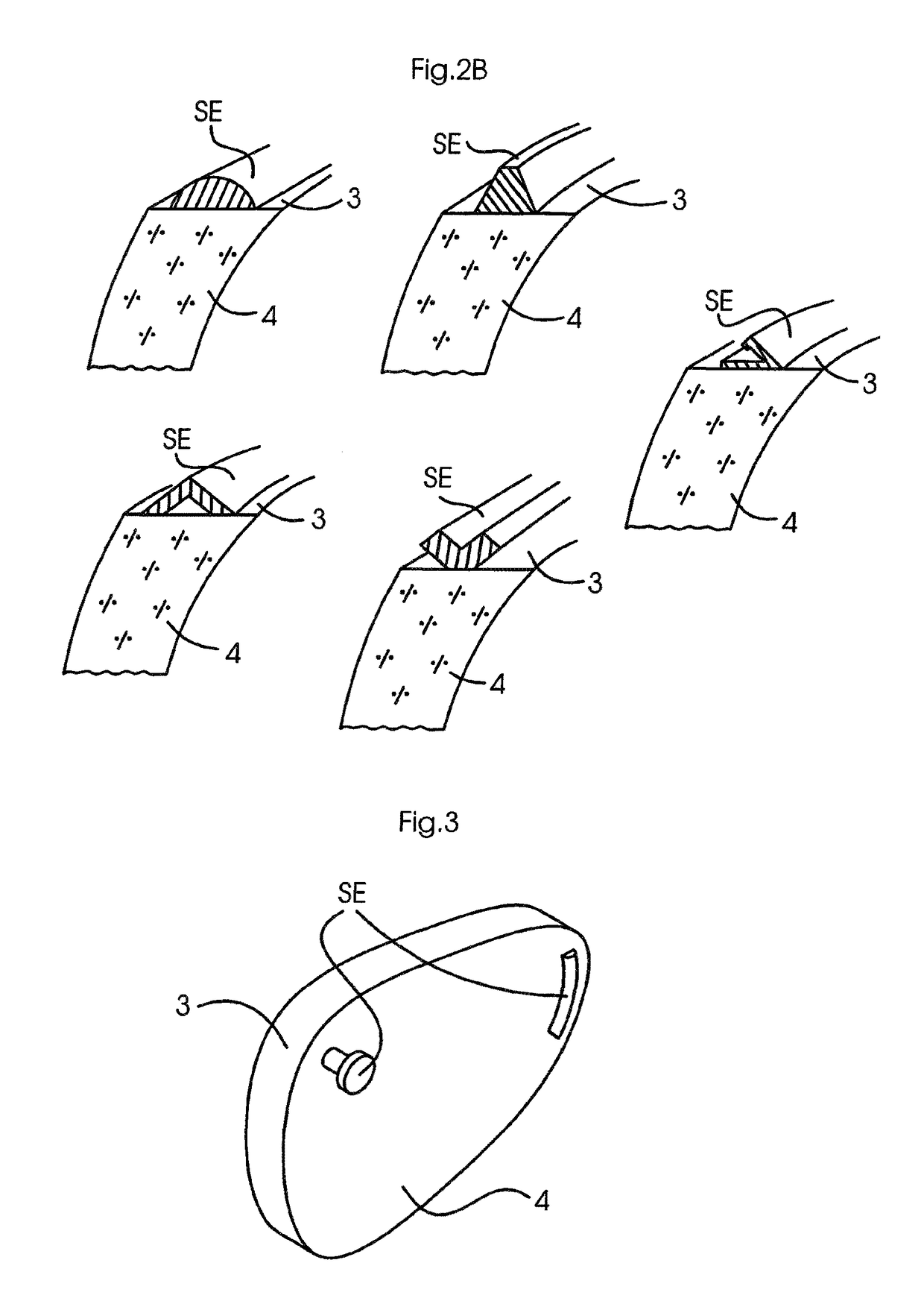

Method of making an eyeglass lens

ActiveUS9851584B2Quick conversionLeast possible manufacturing precisionAdditive manufacturing apparatusOptical articlesEyeglass lensesEngineering

The invention relates to a spectacle lens (3) which comprises at least one structural element (SE) on the outer edge (4) and / or the front or rear surface thereof, wherein the at least one structural element (SE) is formed by a material which is applied in liquid form on the edge (3) and / or the front / rear surface of the spectacle lens (4), is connected in a bonded manner to the lens and is hardened chemically or by radiation. The invention further relates to a method for the production thereof.

Owner:SHAPE ENG GMBH

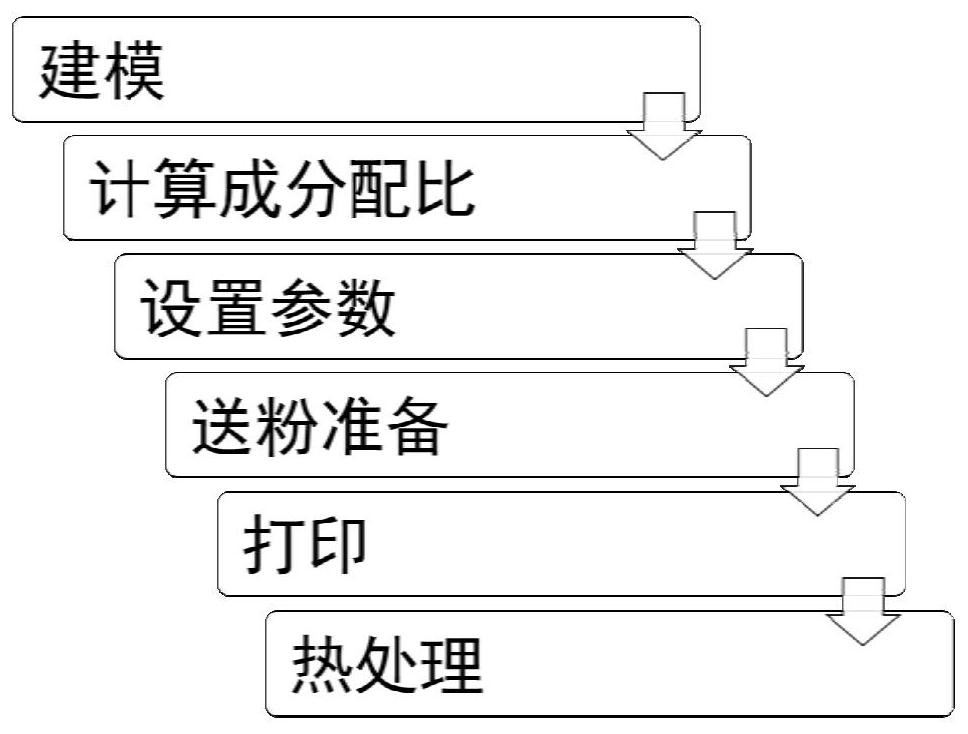

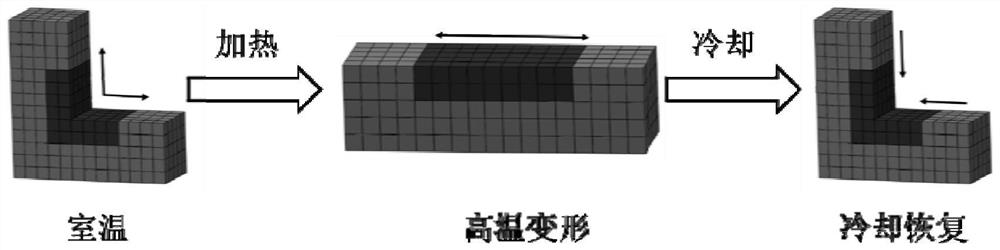

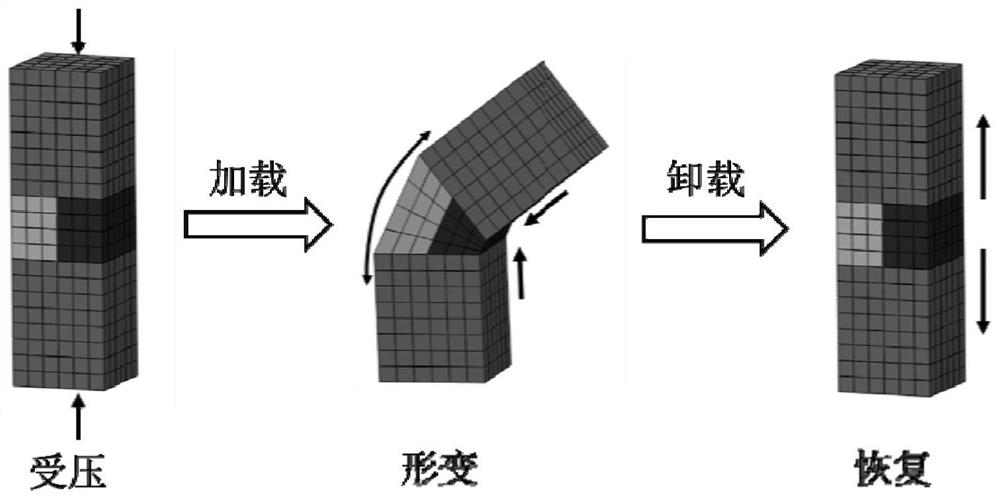

Method and system for preparing part through additive manufacturing, equipment and storage medium

PendingCN113145860AStrong designabilityMeet performance requirementsAdditive manufacturing apparatusPhysical modelProcess engineering

The invention discloses a method and system for preparing a part through additive manufacturing, equipment and a storage medium. A physical model of the material performance of the to-be-prepared part is established, the model is subjected to regional infinitesimal processing, the material composition of each region is determined according to the performance requirement of each region, and any adjacent region is a continuously changing component gradient; a three-dimensional model of the to-be-prepared part is established, the physical model is combined with the three-dimensional model, and hierarchical slicing treatment is performed on the three-dimensional model to obtain material component information of each layer of slice and a slice contour track; and the powder composition proportion is obtained through the slice material composition information, the scanning path of a laser printing system is obtained through the slice contour track, additive manufacturing is performed layer by layer according to the powder composition proportion and the scanning path, and the part is obtained through preparation. The process is simple, and material structures with complex shapes can be manufactured.

Owner:CHANGAN UNIV

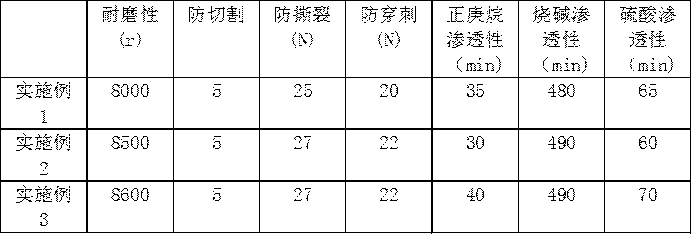

New composite material of polyvinyl chloride and nitrile butadiene rubber

InactiveCN107857906AChanged susceptibility to agingChange low temperature resistanceVulcanizationPolymer science

The invention discloses a new composite material of polyvinyl chloride and nitrile butadiene rubber. Through the modification process of nitrile butadiene rubber and the compounding process of polyvinyl chloride and nitrile butadiene, preparation of the new composite material of polyvinyl chloride and nitrile butadiene rubber is completed. According to the invention, the macromolecular structure of nitrile butadiene rubber is modified to transform into a low molecular reactive flexible plasticizer so as to partially replace the traditional polyvinyl chloride plasticizer DOP and DINP and be well compatible with polyvinyl chloride, thus forming the new composite material. The new composite material changes the softness and resilience of polyvinyl chloride, improves the chemical resistance and oil resistance, also changes the easy aging properties of nitrile butadiene rubber, can avoid vulcanization, shortens the processing time and changes the low temperature resistance of nitrile butadiene rubber.

Owner:江苏瑞斯达安全防护用品有限公司

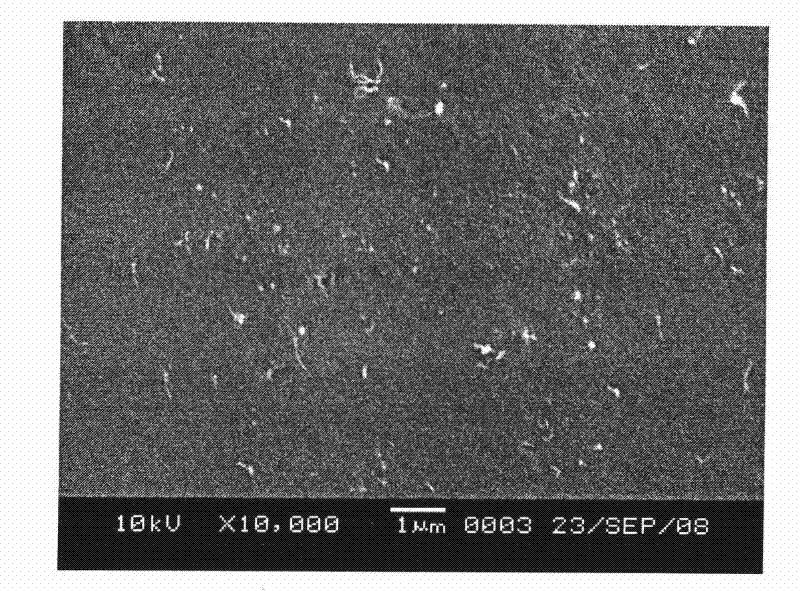

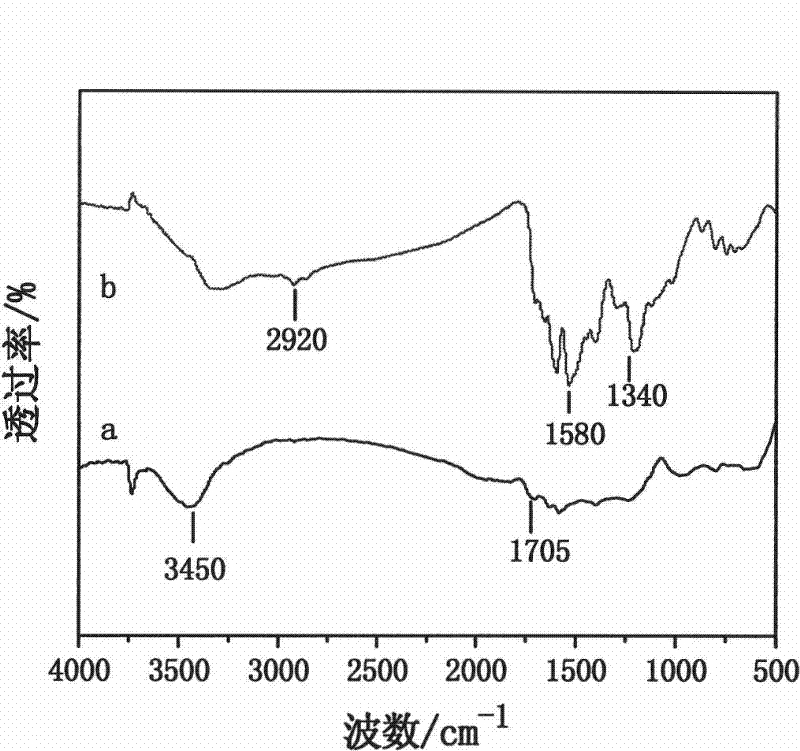

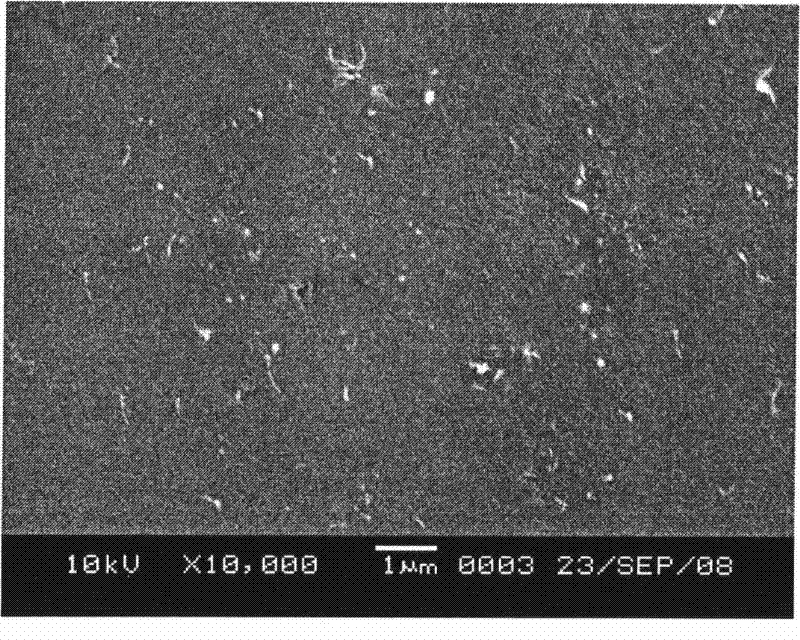

Preparation of functionalized carbon nano-tube modification polyurethane elastomer

The invention relates to a method for preparing a functional carbon nanotube modified polyurethane, which comprises: firstly, preparation of the functional carbon nanotube, namely, dissolving a carbon nanotube into a mixed solution of concentrated sulfuric acid and concentrated nitric acid the volume ratio of which is 3:1, performing ultrasonic vibration for 1 to 2 hours, heating the mixed solution in water bath, refluxing the mixed solution for 3 to 4 hours, taking out the mixed solution, and obtaining CNT-COOH after dilution, centrifugation, filtration and drying of the mixed solution by deionized water; and dispersing the CNT-COOH into an organic solvent, adding isocyanate into the organic solvent, performing heating in water bath, and obtaining the functional carbon nanotube; and secondly, preparation of a functional carbon nanotube / polyurethane composite system, namely, dissolving the functional carbon nanotube into a thermoplastic polyurethane solution by a solution mixing method, and processing the functional carbon nanotube to form the functional carbon nanotube / polyurethane composite system; or directly mixing the functional carbon nanotube and polyurethane by means of fusing and processing, and extruding the functional carbon nanotube to form the functional carbon nanotube / polyurethane composite system. The method is easy, simple and convenient, has simple equipment,and is suitable for mass production and used in the fields of material reinforcement, electrical conductance, heat conduction and so on; and the elasticity, the mechanical property and the thermal stability of the material obtained are changed correspondingly.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com