Fresh-keeping method for pickle cured meat product

A fresh-keeping method and a technology for curing bacon, which are applied in the field of food preservation, can solve the problems of insufficient compactness and barrier properties of packaging bags, easy contamination of microorganisms, wear and tear of packaging bags, etc., and achieve good sterilization effect, less energy consumption, and change in chewiness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preservation preparation method of Cantonese-style sausage:

[0029] Raw material ratio is: sodium nitrite 20mg / kg, 30% fat meat, 70% lean meat, 20% water, 3.5% salt, 13% sucrose, 4% koji wine. Mince the lean meat and cut the fatty meat into pieces, wash them with hot water at 60°C, mix the meat pieces evenly, add the seasoning prepared by the above formula, and mix well. Soak the casings with clean water, enema, exhaust the needles, tie the ropes in sections, wash them with warm water, hang them on bamboo poles, and bake them in a drying room at a temperature of 50-55°C. When baking, the head needs to be adjusted up and down. After three days of baking, take out the cooling scissors. Sausage, weighing, vacuum packing.

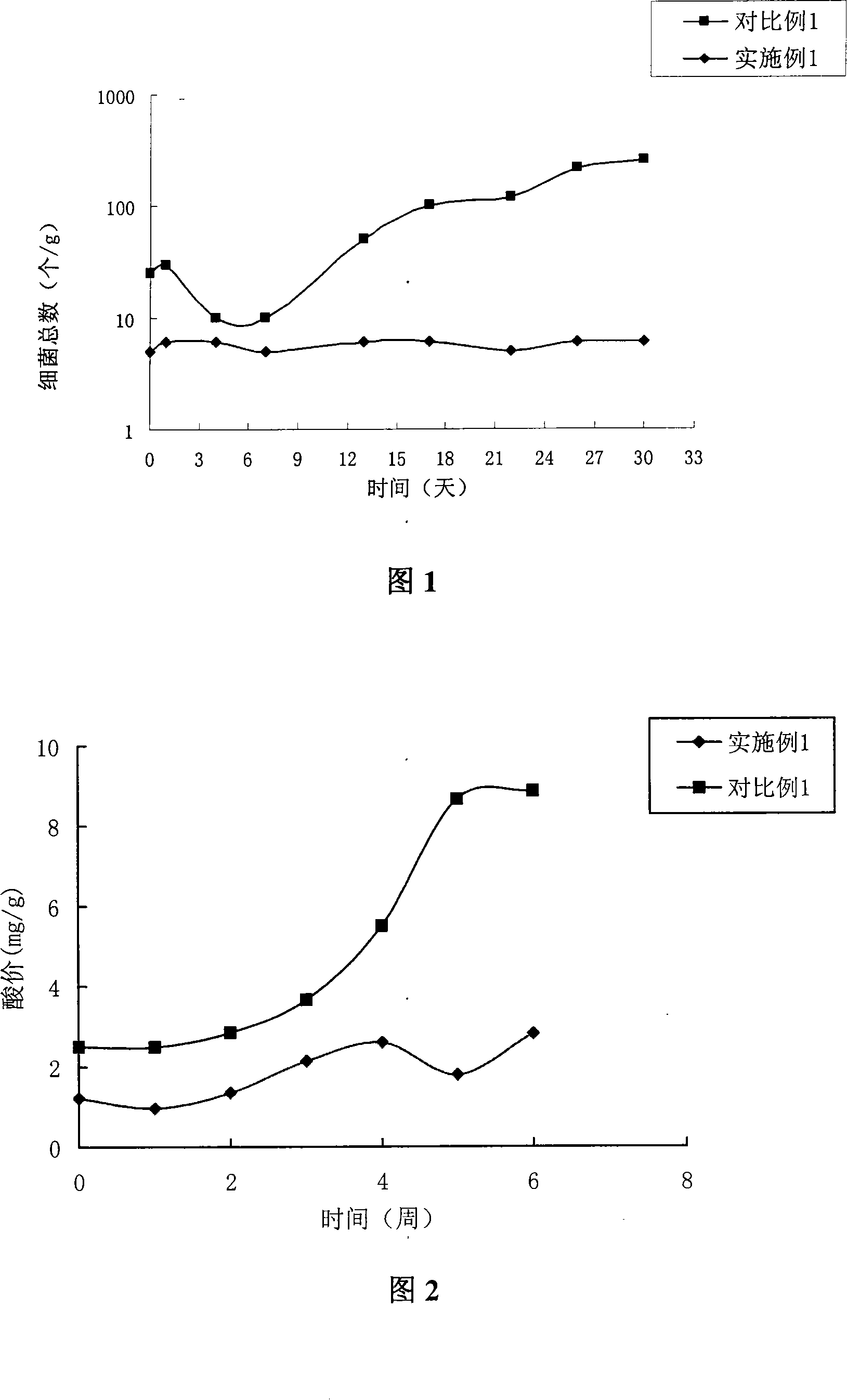

[0030] Put the vacuum-packed sausage into the liquid pressure medium in the ultra-high pressure container; at room temperature, pressurize the sausage to 300 MPa for the first time and keep the pressure for 30 minutes and release the pressure; at room ...

Embodiment 2

[0043] Fresh-keeping preparation method of Cantonese-style bacon:

[0044] Thaw the raw meat ——> season and marinate for 4.5 hours —> pour off the remaining seasoning —> dry the water —> add soy sauce —> string —> bake for 48 hours —> cool —> vacuum Package

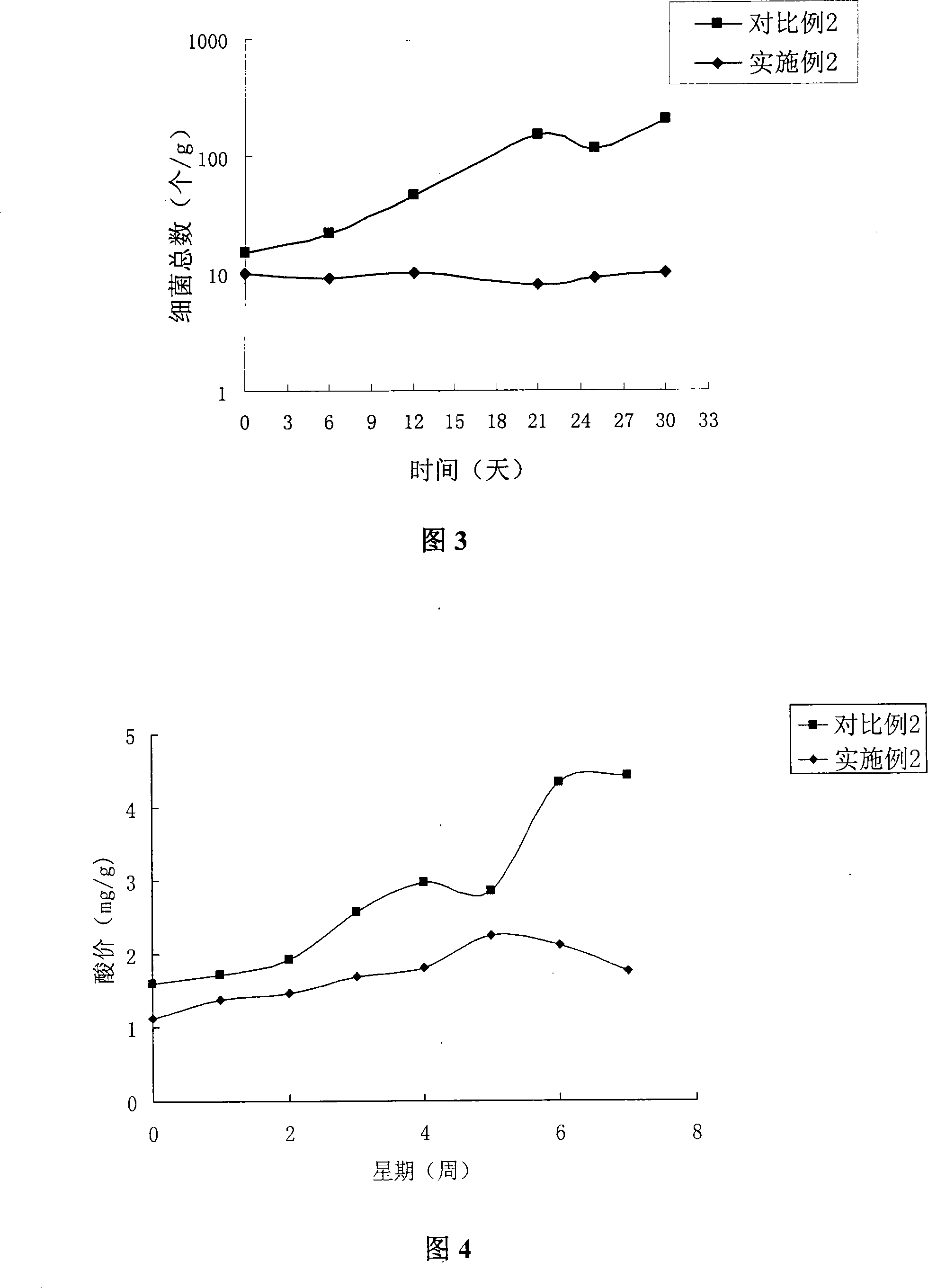

[0045] Put the vacuum-packed bacon into the liquid pressure medium in the ultra-high pressure container; at a temperature of 40°C, pressurize the bacon to 300MPa for the first time and release the pressure after holding the pressure for 30 minutes; at a temperature of 40°C, put the bacon Pressurize to 400MPa for the second time and release the pressure after holding the pressure for 20 minutes; at a temperature of 40°C, pressurize the bacon for the third time to 700MPa and release the pressure after holding the pressure for 15 minutes.

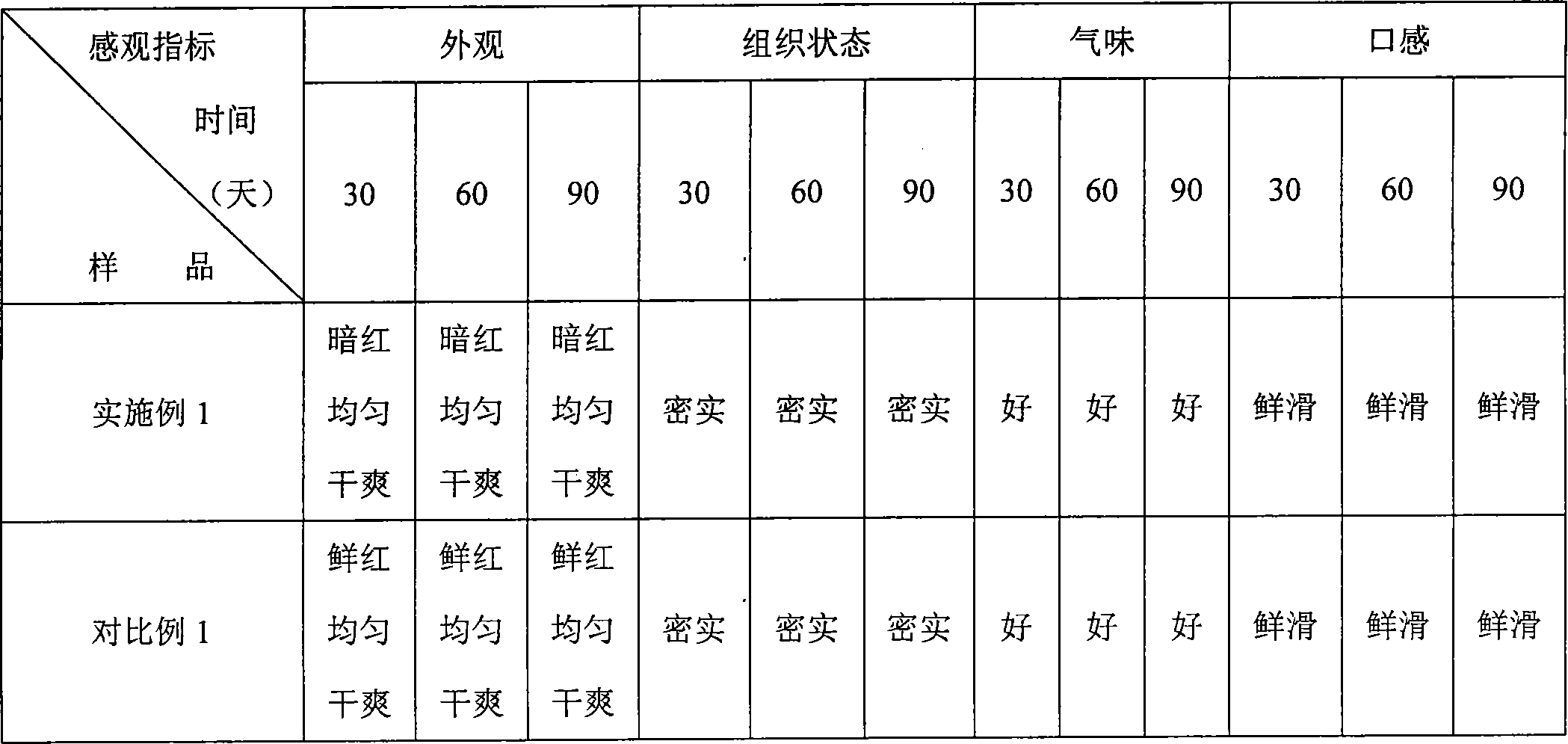

[0046] The appearance, texture, smell and taste of the finished product were evaluated, and the sensory indicators were recorded at room temperature. The results are listed in Table 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com