High-differential-pressure cold extraction concentration unit

A concentrating unit and high pressure difference technology, which is applied in solid solvent extraction, pressure vessels and membranes used in chemical processes, etc., can solve the problems of low solution clarity and poor material purity, and achieve high extraction efficiency and energy saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

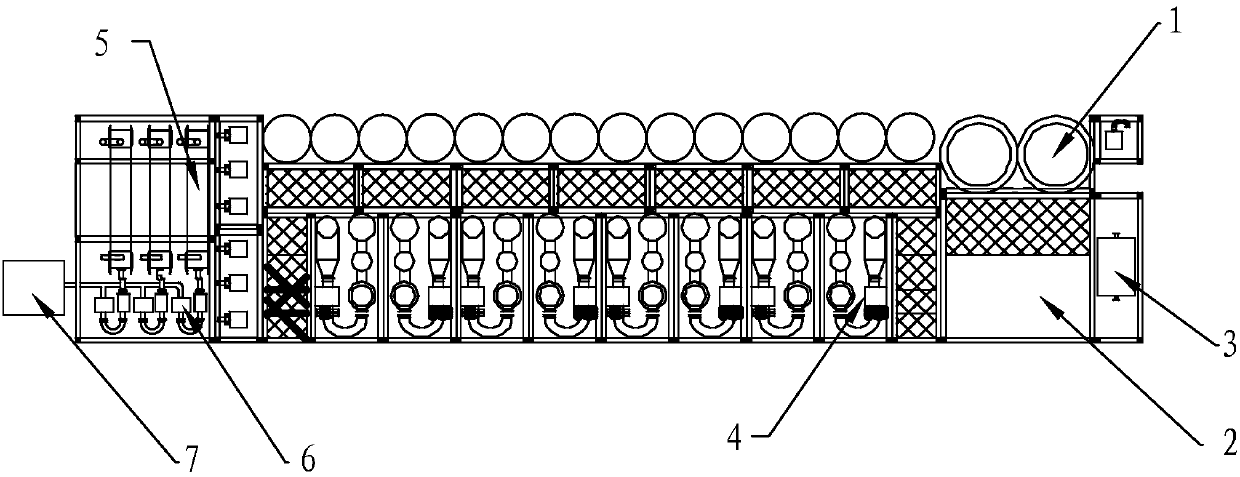

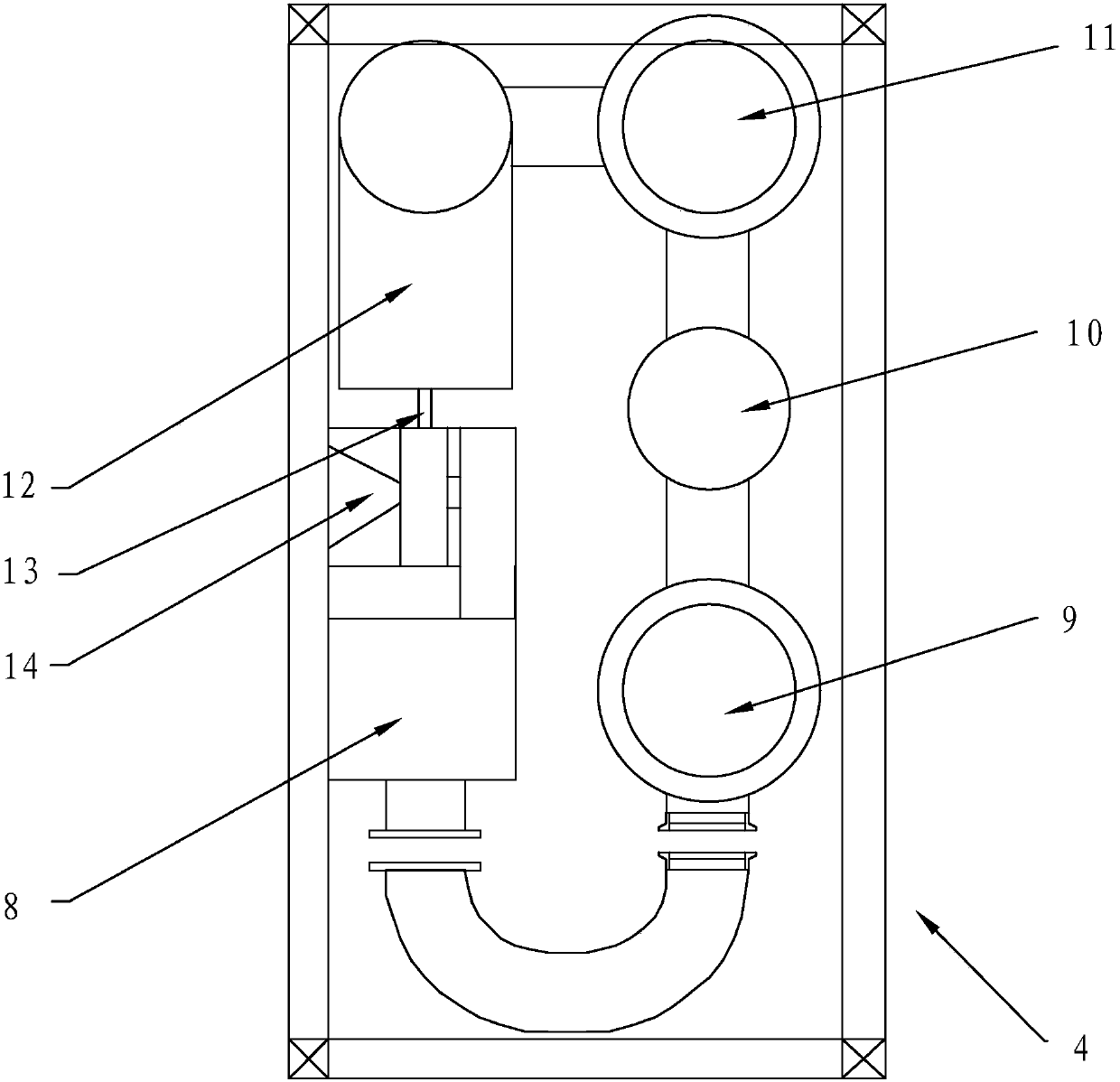

[0031] A high-pressure differential cold extraction and concentration unit, referring to figure 1 , including soaking device 1, differential pressure extraction device 2, solid-liquid separation device 3, separation and clarification device 4, pre-concentration device 5, re-concentration device 6 and drying device 7, which are connected in sequence, and are equipped with display pressure, temperature, flow rate, etc. The digital display of the information, the raw material first enters the soaking device 1 and soaks it with the soaking liquid, stretches and soaks the raw material fully, and then sends it to the differential pressure extraction device 2, first maintains high pressure to inject the soaking pressure into the cells, and then releases it instantaneously using the soaking liquid Release, make the cells burst, release the internal functional components, send them to the solid-liquid separation device 3, separate and discharge most of the waste residues, add fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com