Patents

Literature

180 results about "Pre concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-concentration is the procedure used to obtain a high local protein concentration at the sensor chip surface. Pre-concentration makes the immobilization of the protein to the sensor chip surface more efficient. Pre-concentration is done with the dextran-carboxyl group based sensor chips.

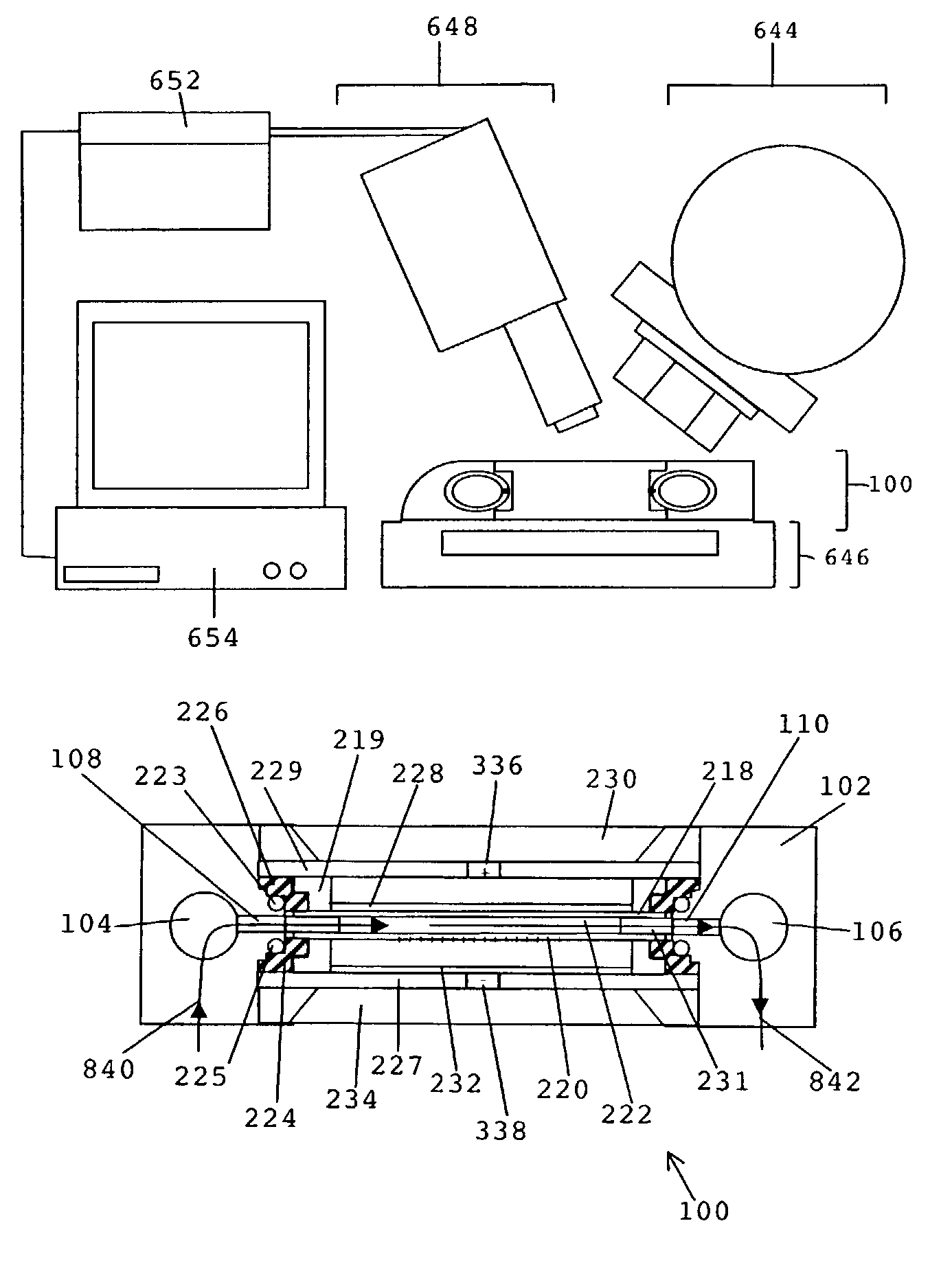

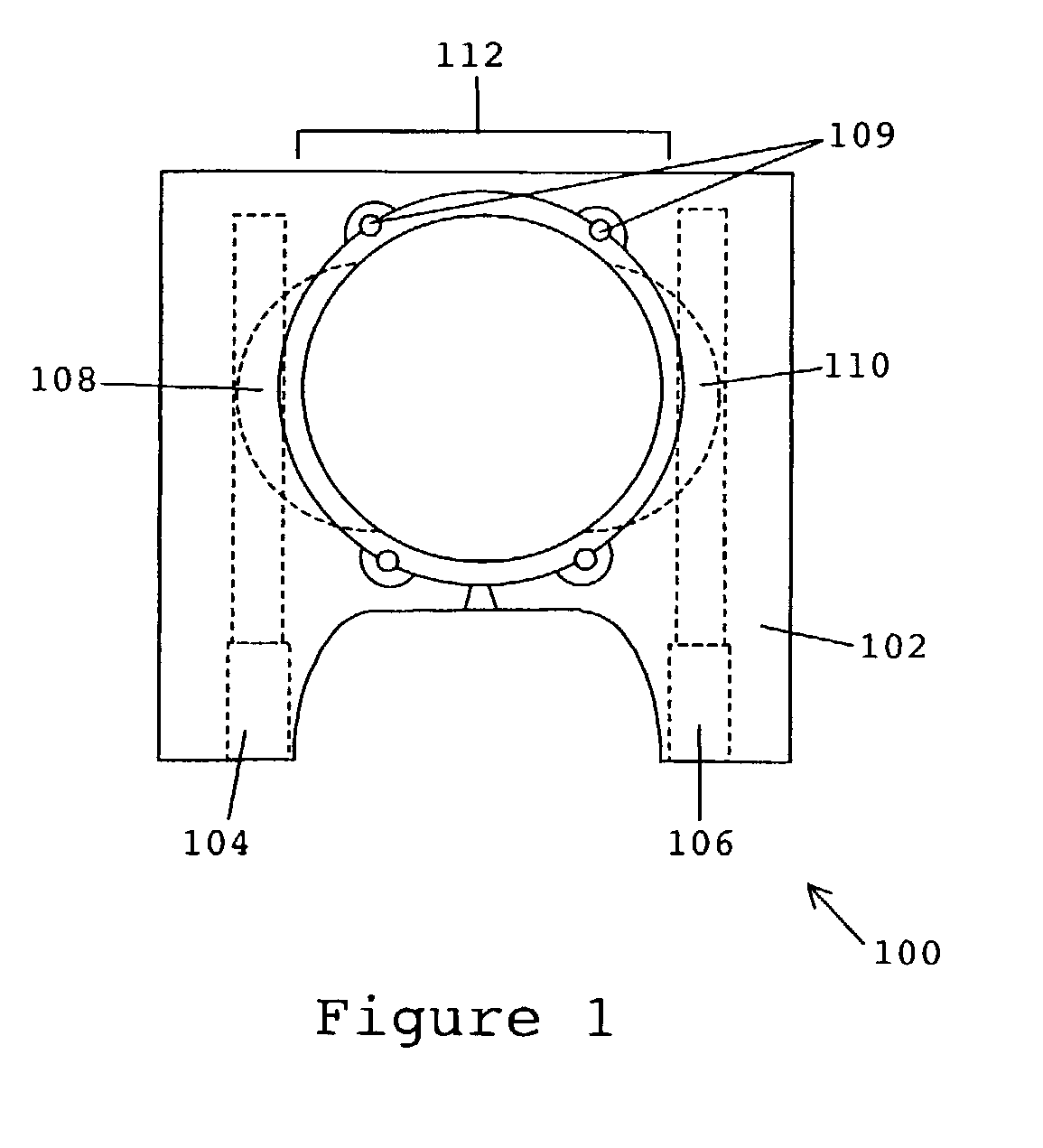

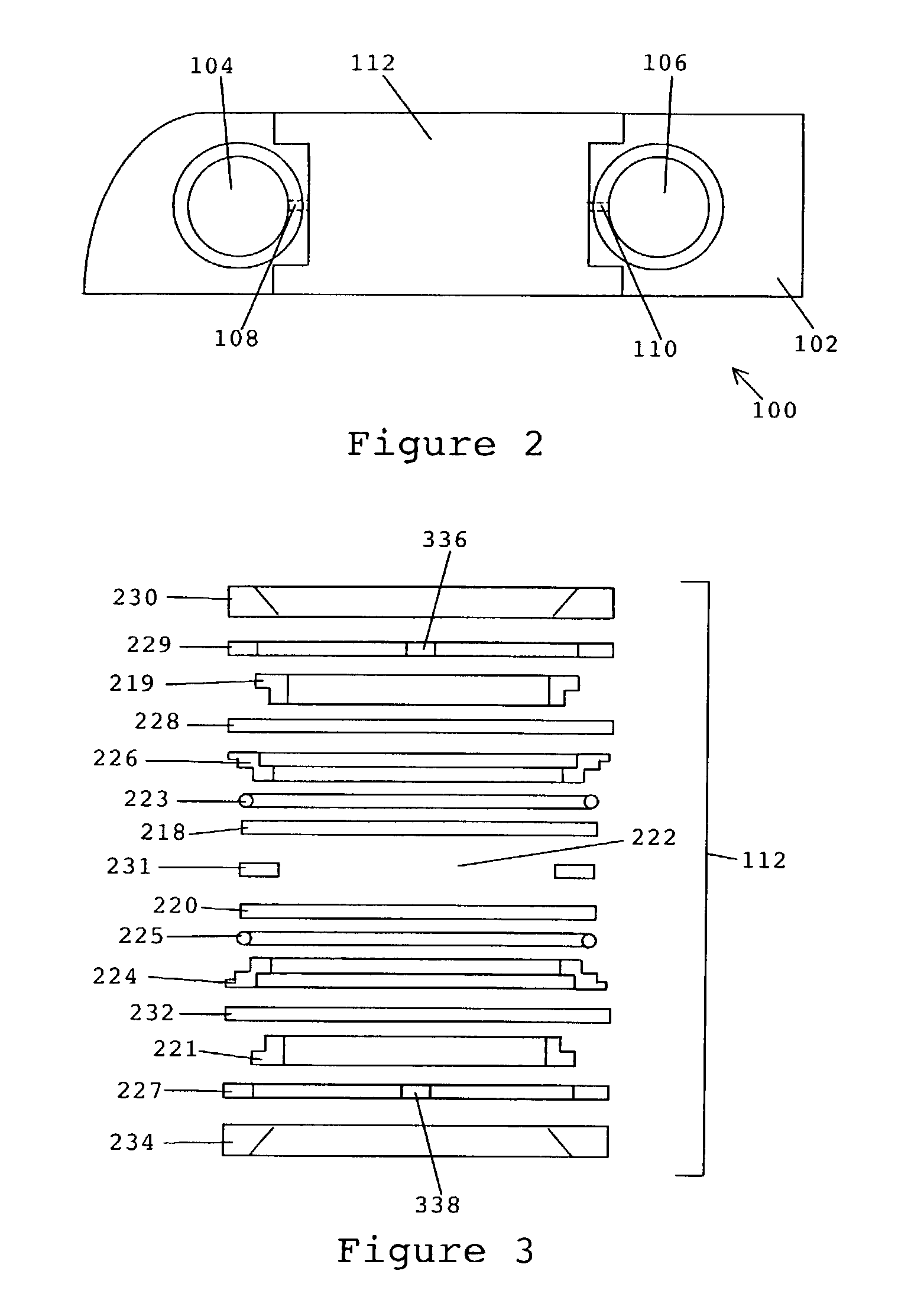

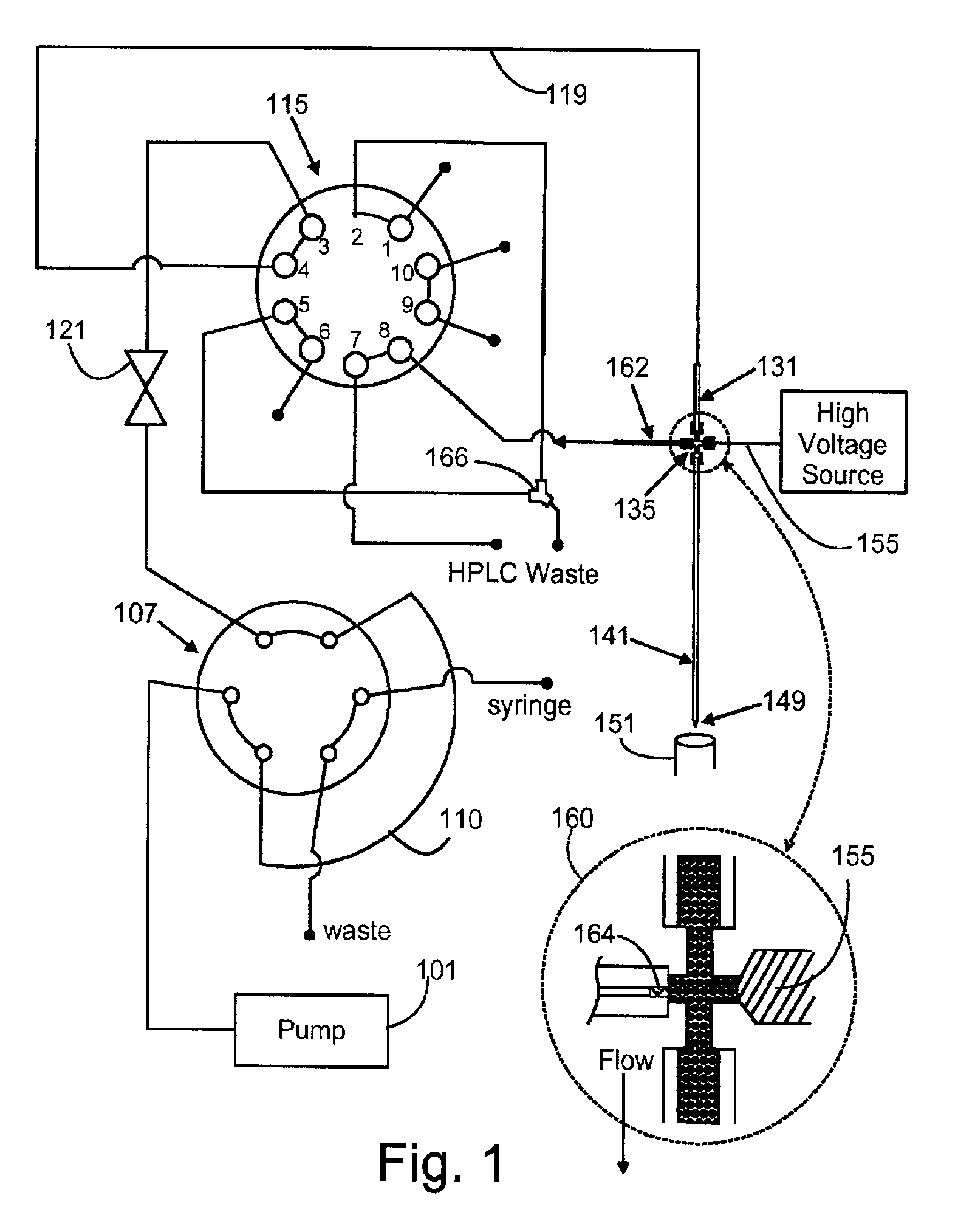

Ionic pre-concentration XRF identification and analysis device, system and method

InactiveUS7016462B1High sensitivityHinder full rangeMaterial analysis using wave/particle radiationX-ray spectral distribution measurementCapacitanceX-ray

A device, system and method for detecting and measuring concentrations of elements in fluids comprises: flowing a fluid through a central flow interelectrode gap of an ionic preconcentration cell separating an upper high specific surface area electrode from a lower high specific surface area electrode of the ionic preconcentration cell by a predetermined interelectrode gap width; and applying a voltage differential between the upper high surface area electrode and the lower high surface area electrode while the fluid is flowing through the central flow interelectrode gap. As such, this cell that utilizes its inherent capacitance for double layer formation to extract ultra-trace levels of ionic contaminants from fluids in order to enhance detection by x-ray fluorescence analysis.

Owner:INTERSCI +1

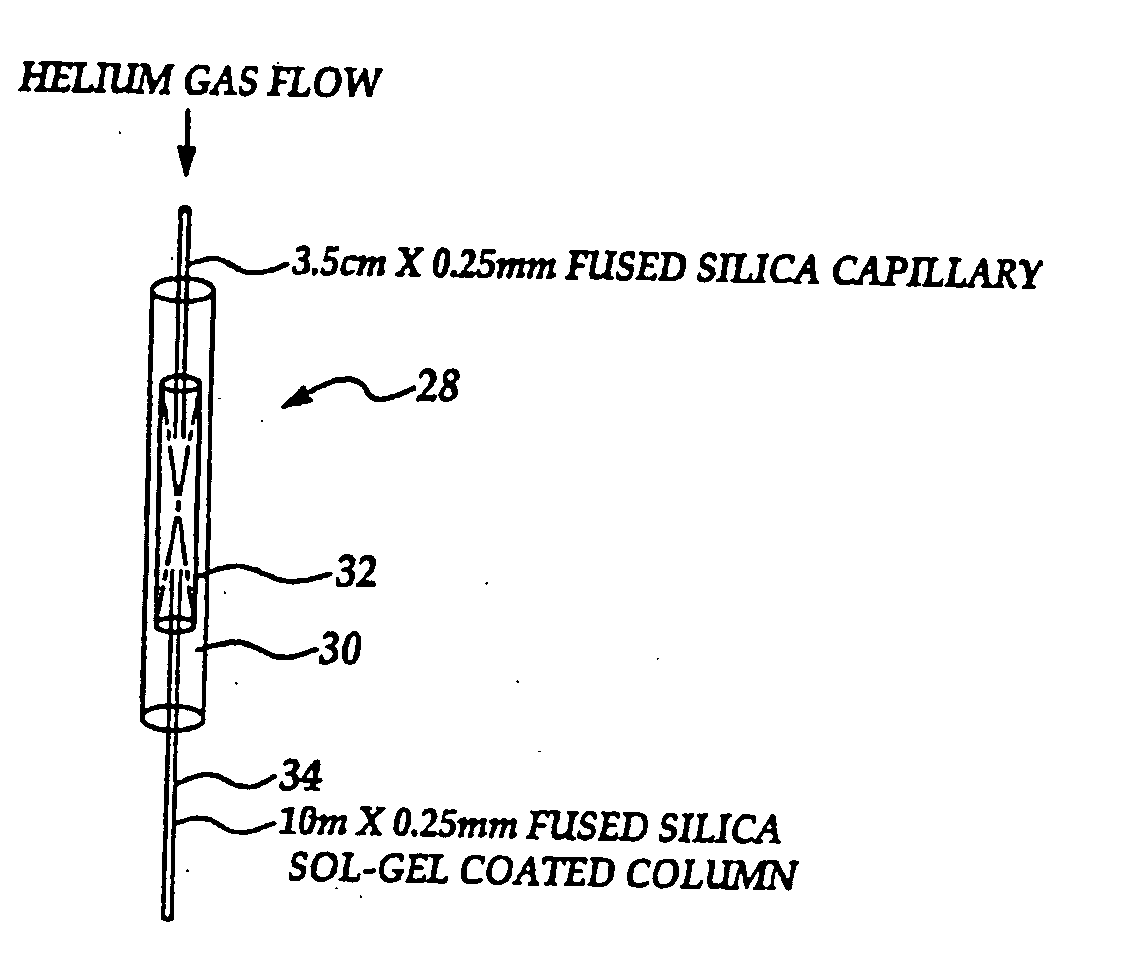

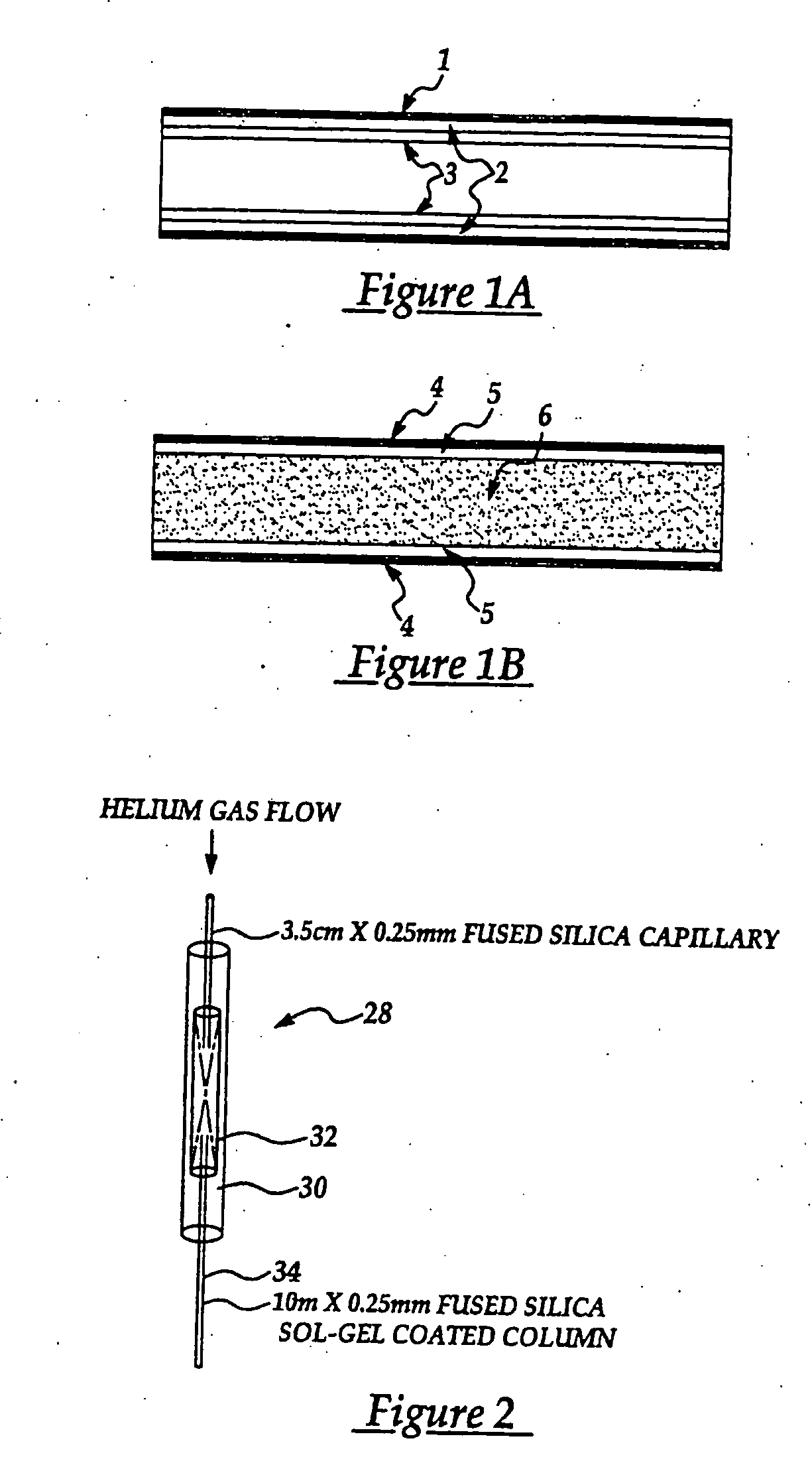

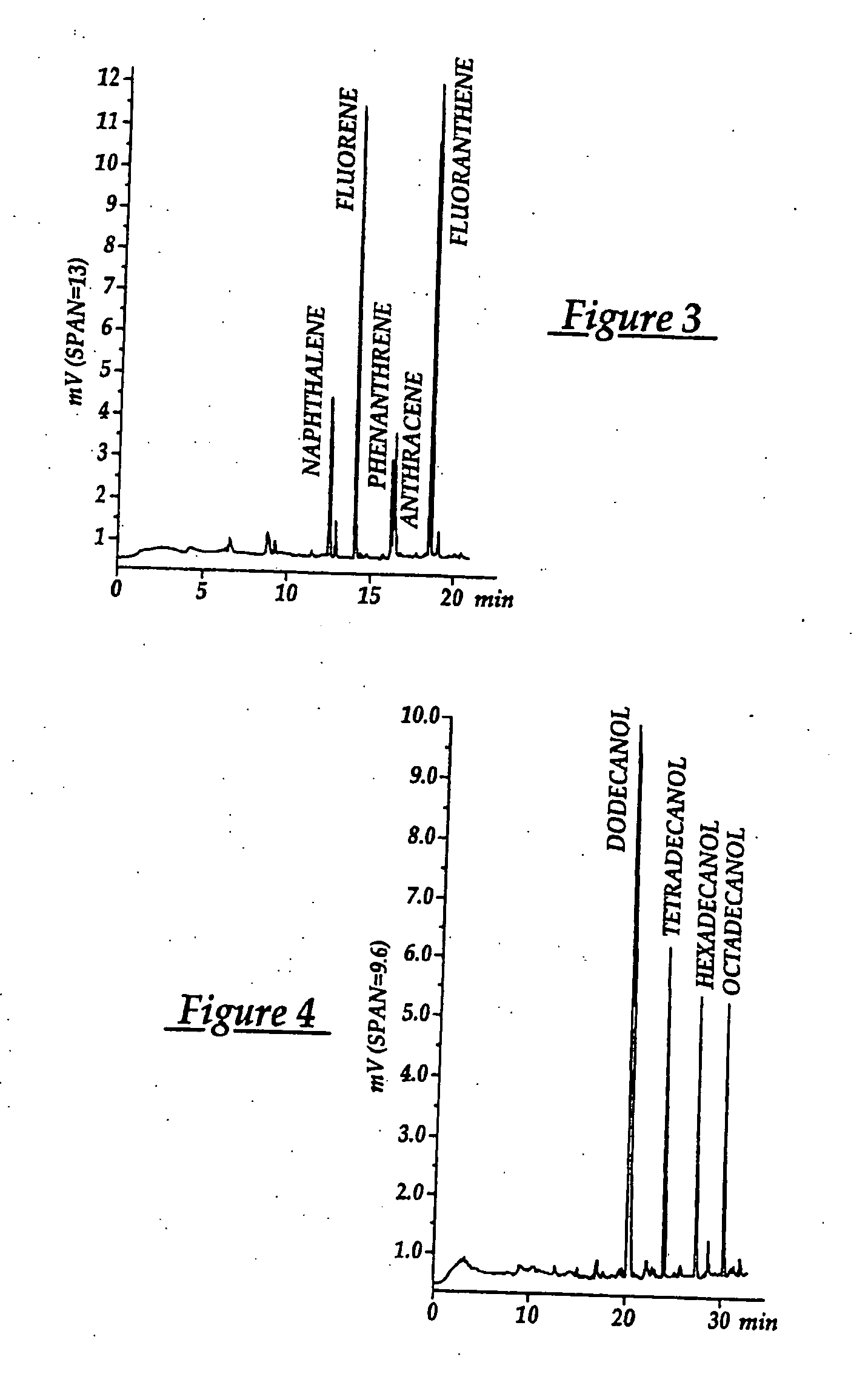

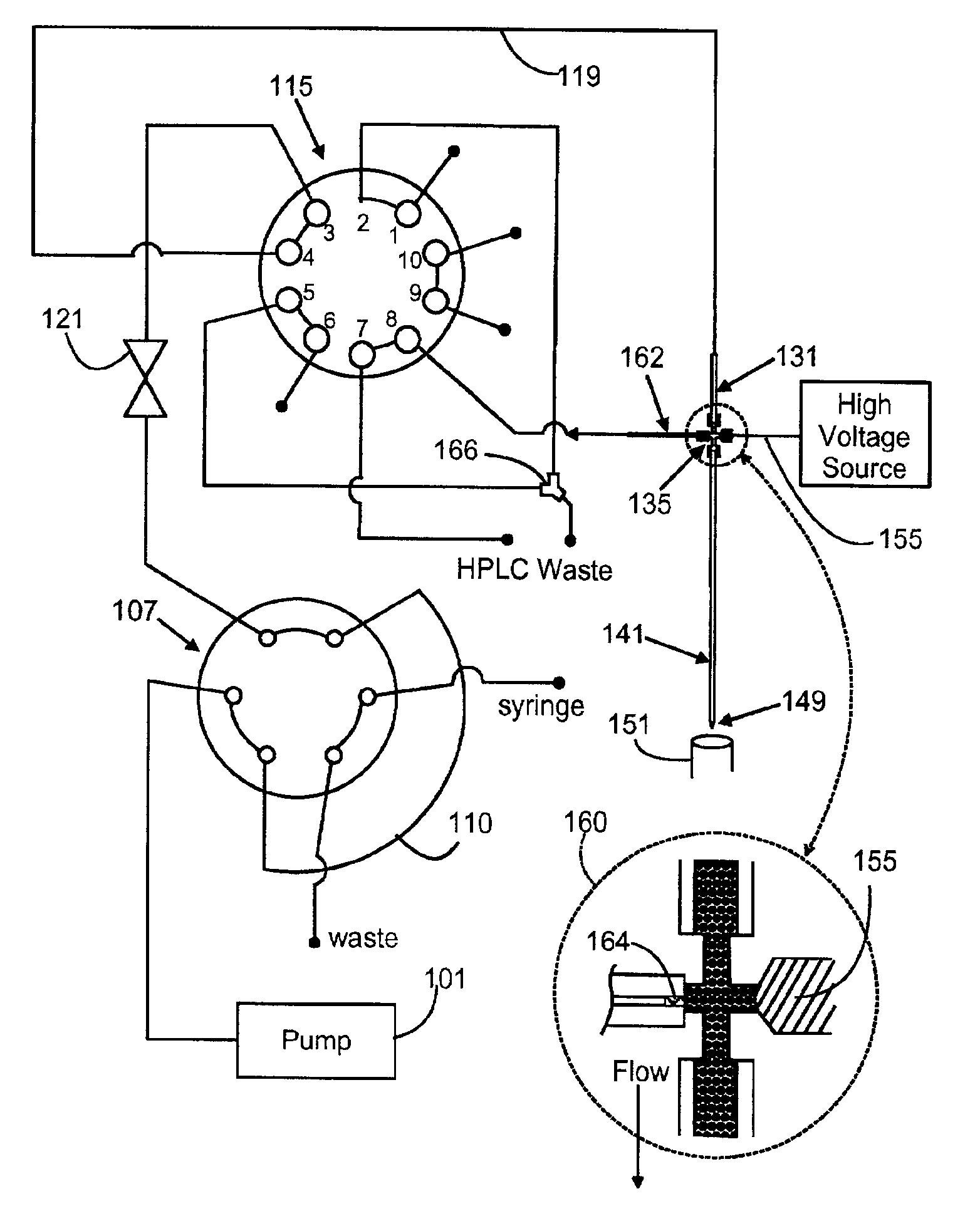

Sample pre-concentration tubes with sol-gel surface coatings and/or sol-gel monolithic beds

Owner:UNIV OF SOUTH FLORIDA

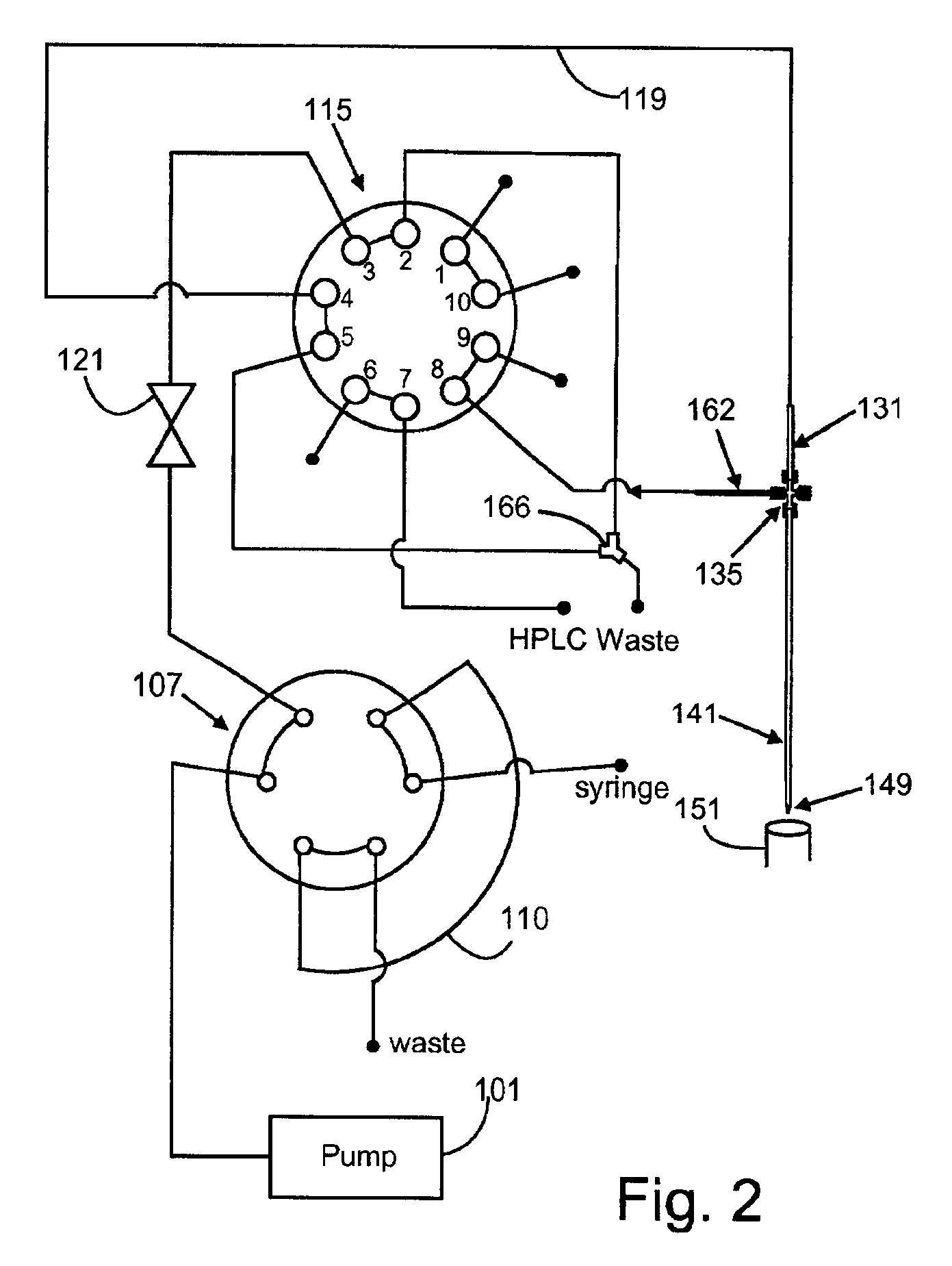

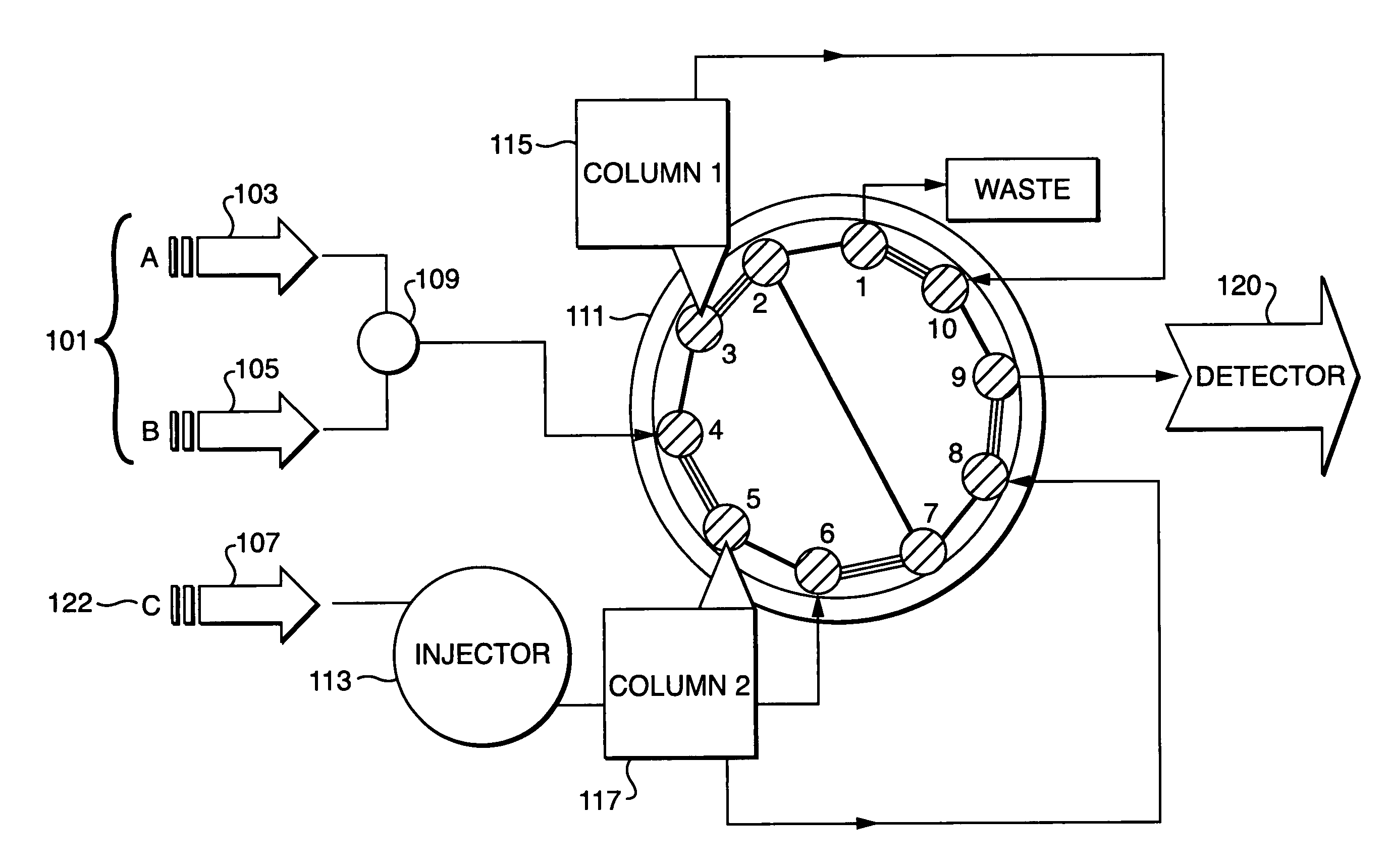

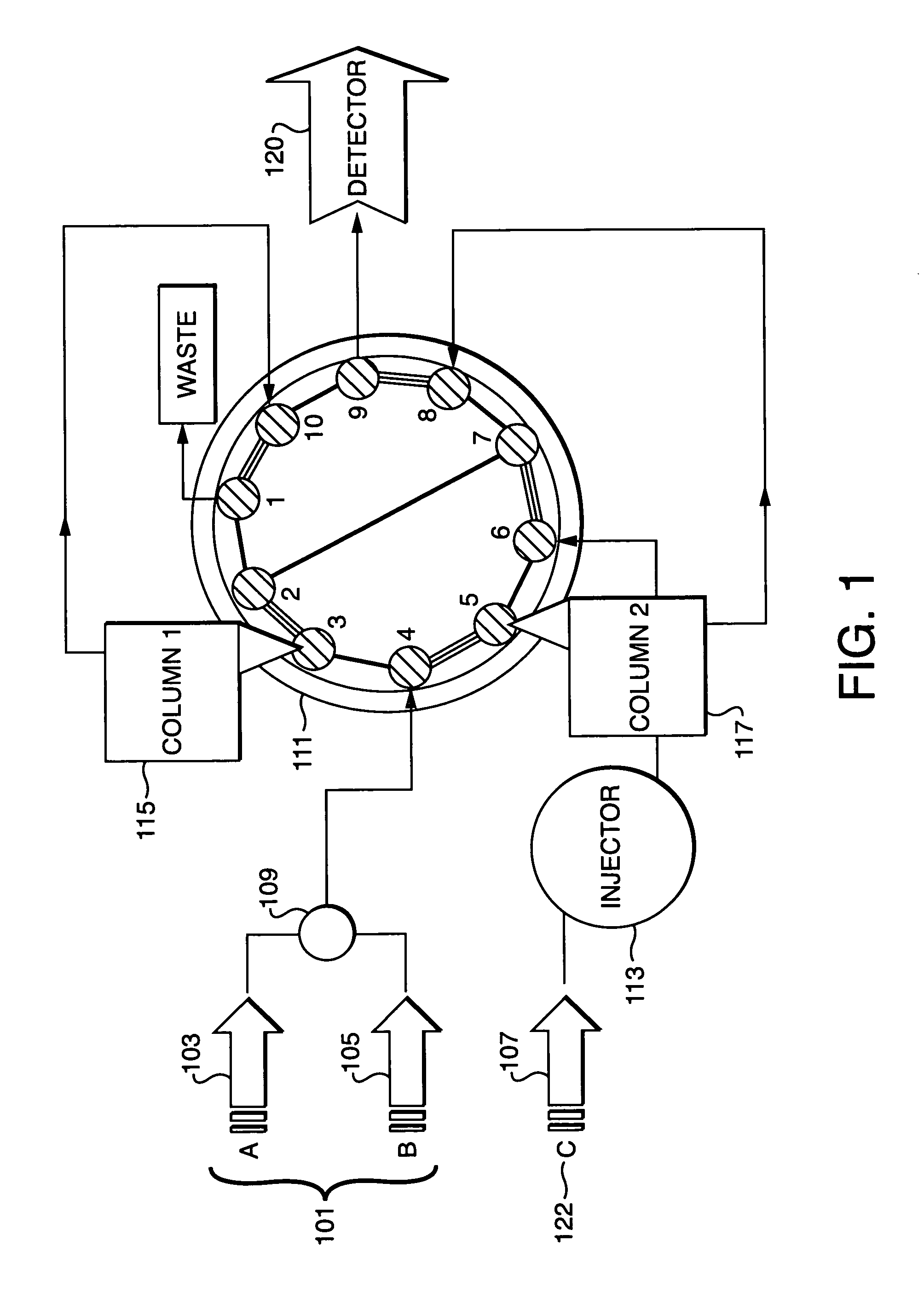

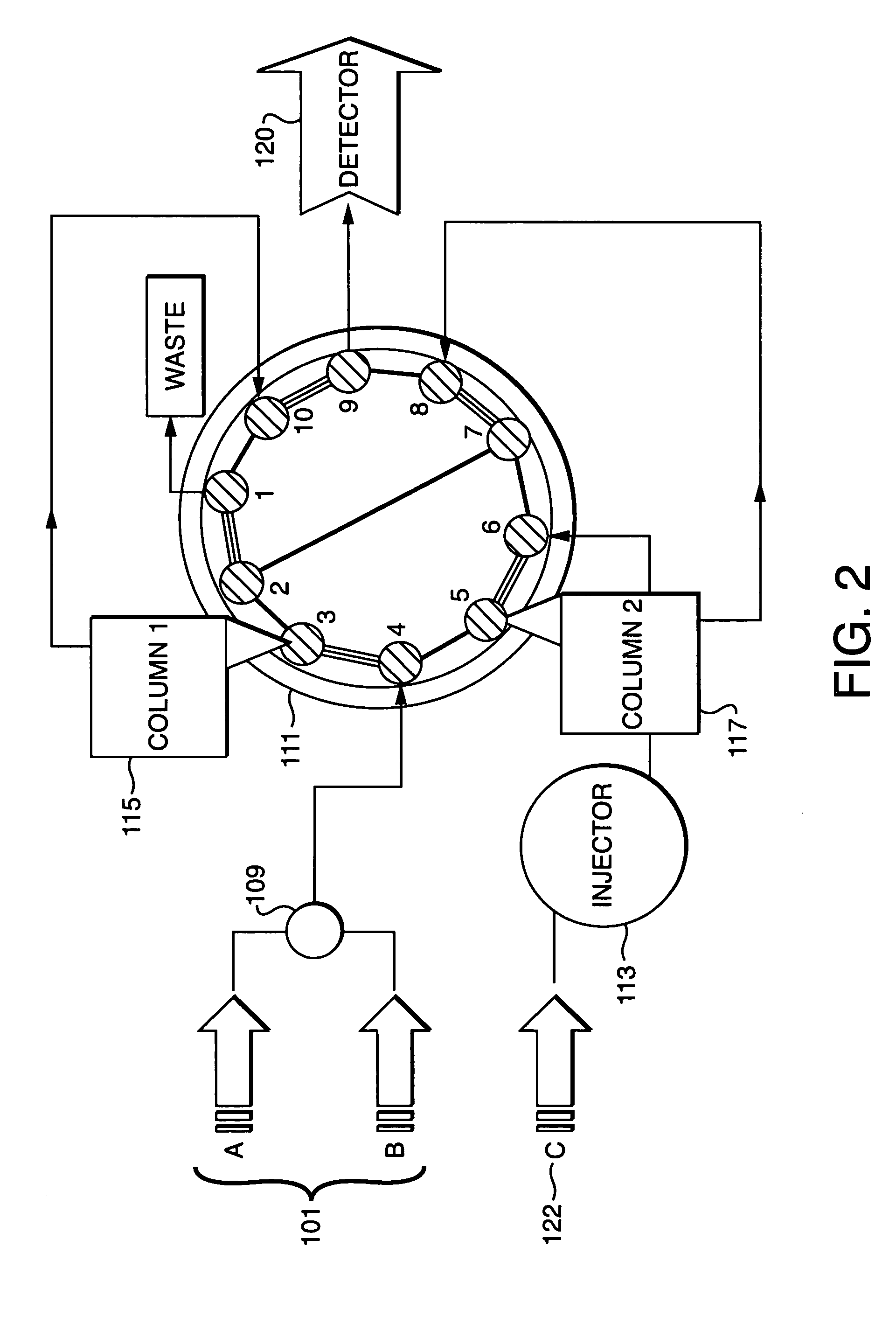

Automated capillary liquid chromatography small volume analysis system

InactiveUS6989129B2Reduce flow rateImprove performanceSamplingComponent separationChromatographic separationAutosampler

A system for automatically performing liquid chromatography analysis of low volume liquid chemical samples at nanosecond flow rates using an analysis column that integrates a pre-concentration trapping column and a chromatography separation column terminating at an electrospray nozzle of an online mass spectrometer. The analysis column consists of a capillary having an inside diameter of between 75 and 125 microns packed throughout with a porous bed of micron particles. A branch outlet positioned 10 to 16 centimeters upstream from the nozzle divides the analysis column into an upstream pre-concentration trap and a downstream separation column. An autosampler delivers low volume liquid samples to the upstream inlet via a two-position valve. Feed connections couple the autosampler to upstream inlet when the valve is open to inject a liquid sample into the pre-concentration trap at a maximum loading flow rate in the range from 0.5 to 50 microliters / minute. Thereafter, when the valve closes, it terminates the further injection the sample, and a concentrated portion of the sample then passes though the chromatography separation column at a much slower flow rate between 10 and 1,000 nanoliters per minute. Throughput can be doubled by coupling two such analysis columns to a single autosampler using a ten-port, two position valve. A single column can be supplied through a six port two-position valve.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

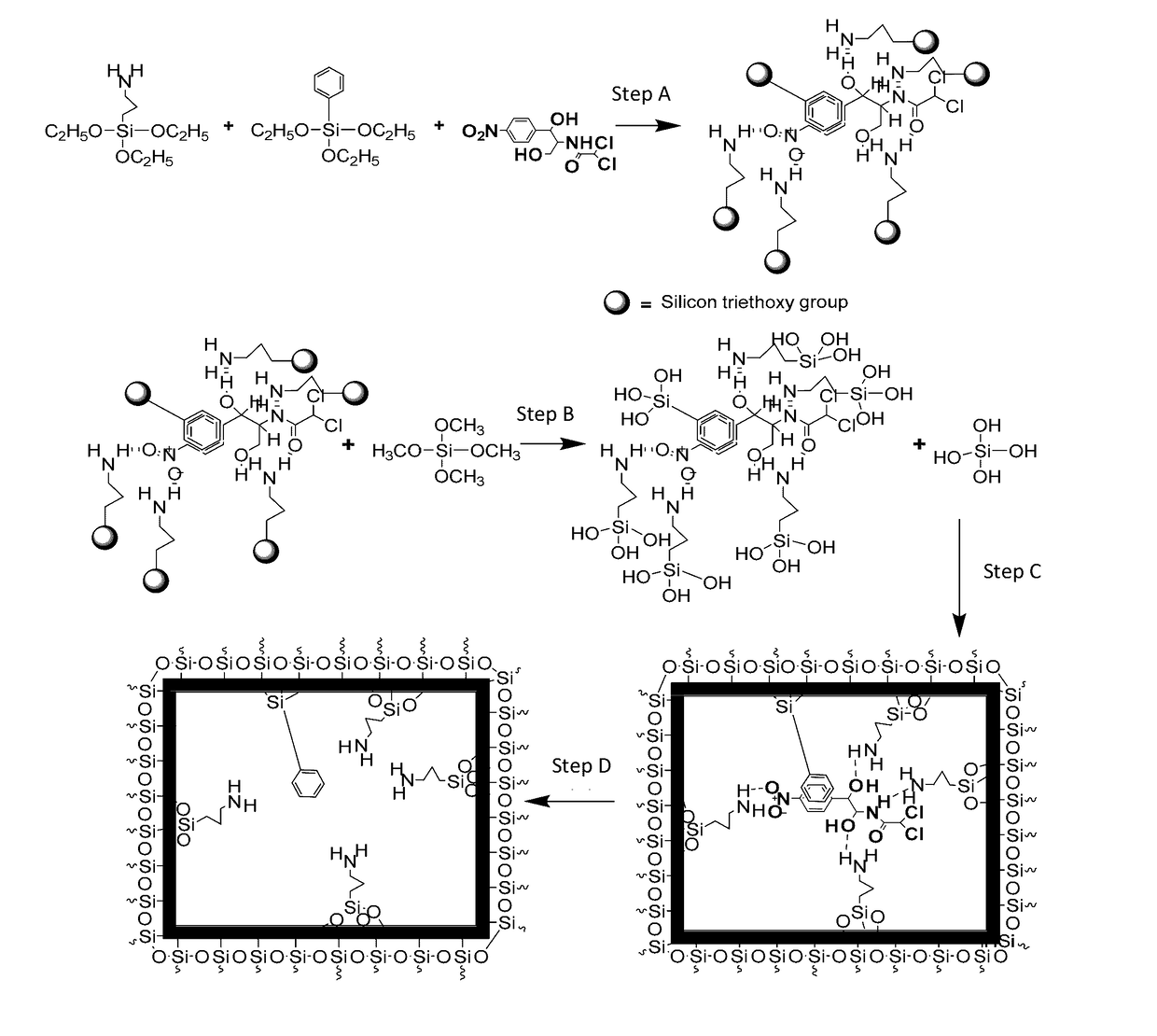

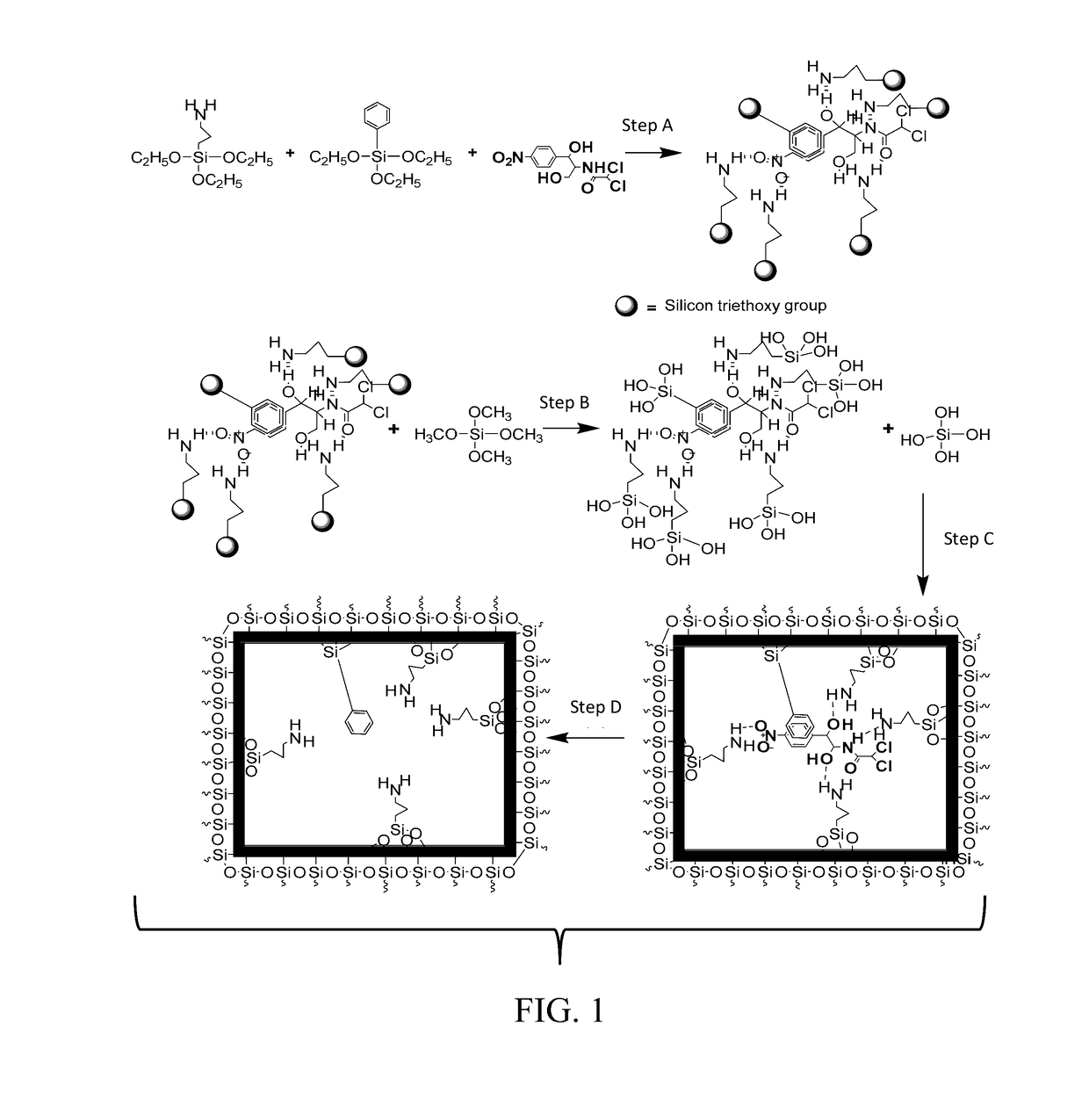

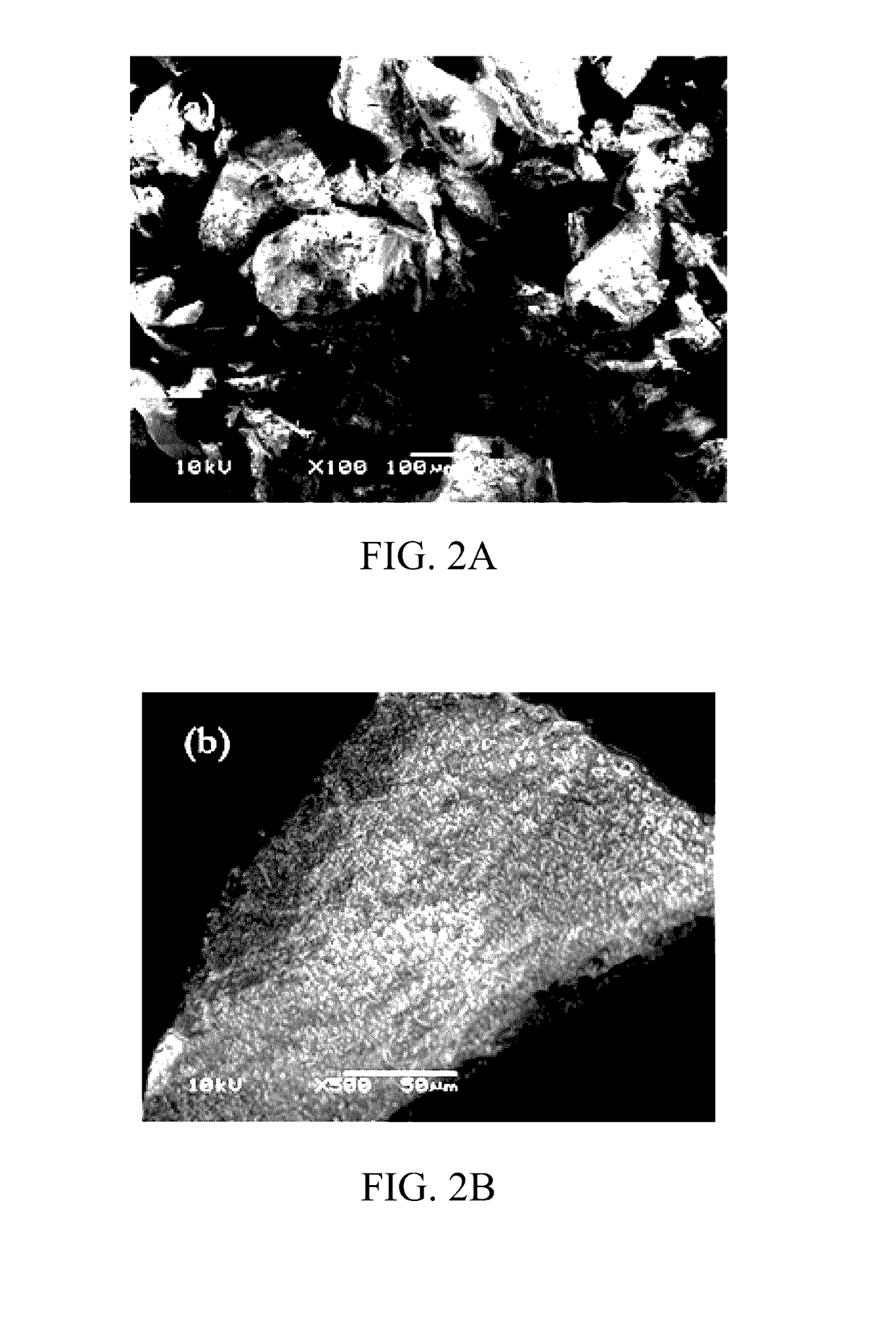

Materials and methods for the detection of trace amounts of substances in biological and environmental samples

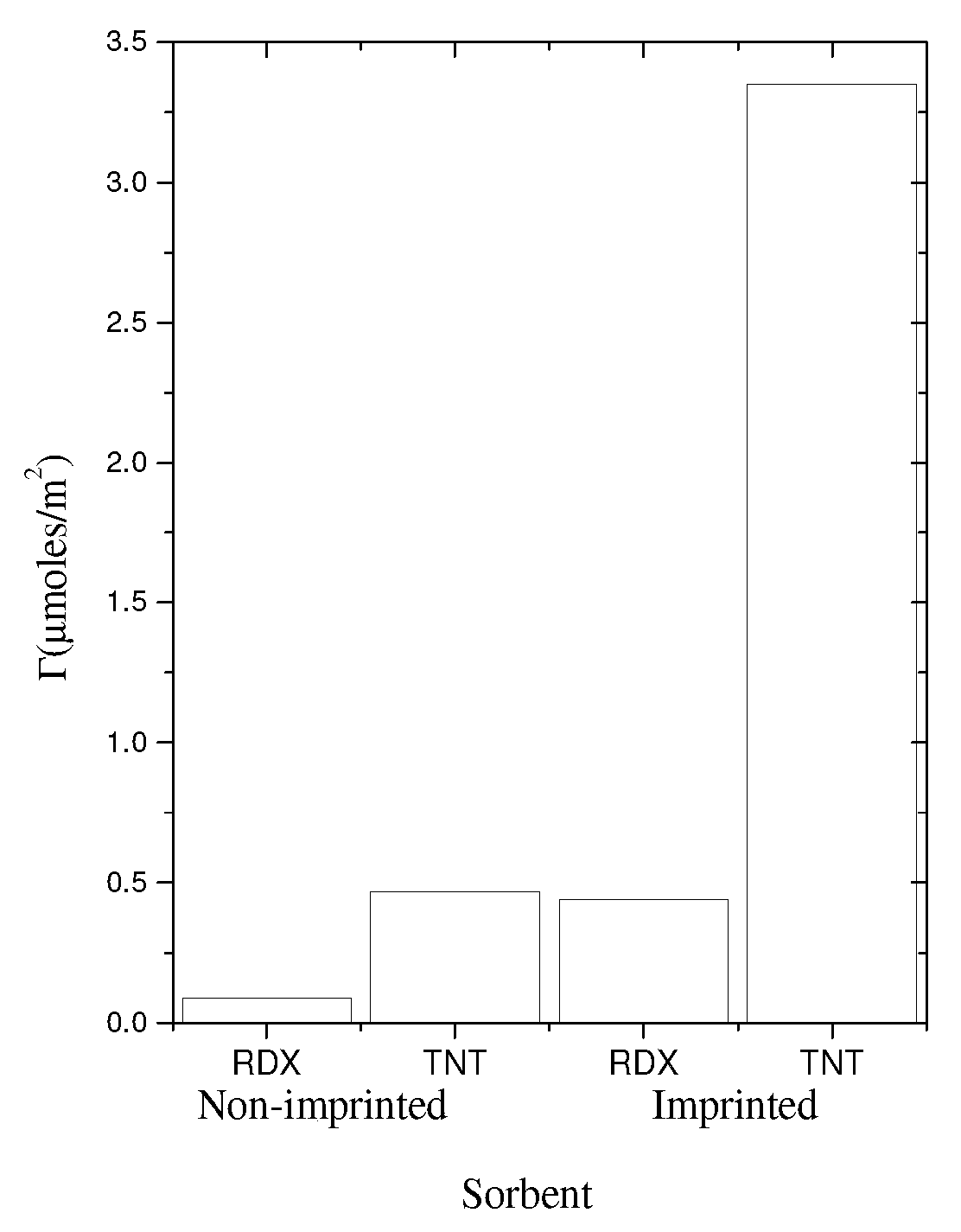

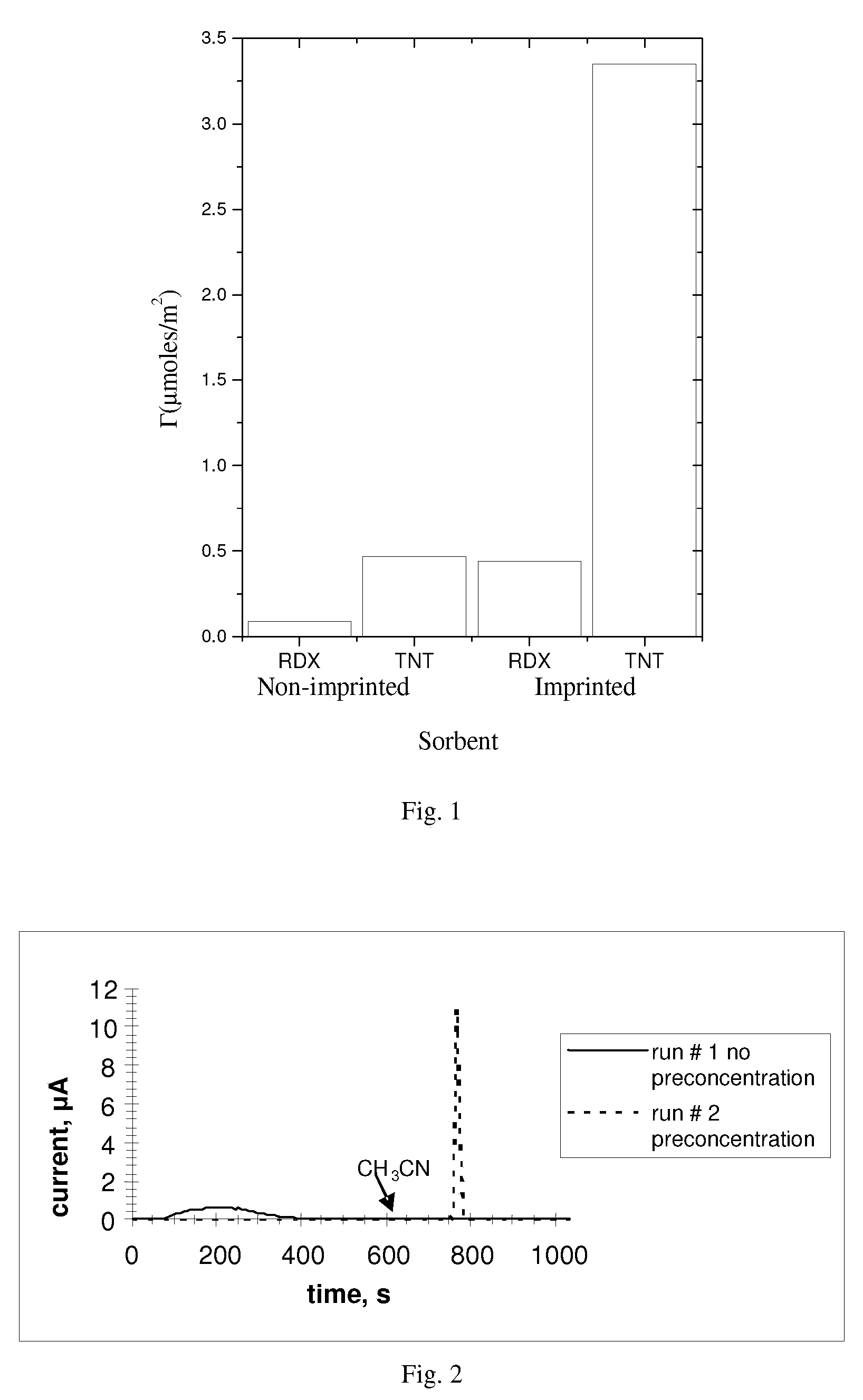

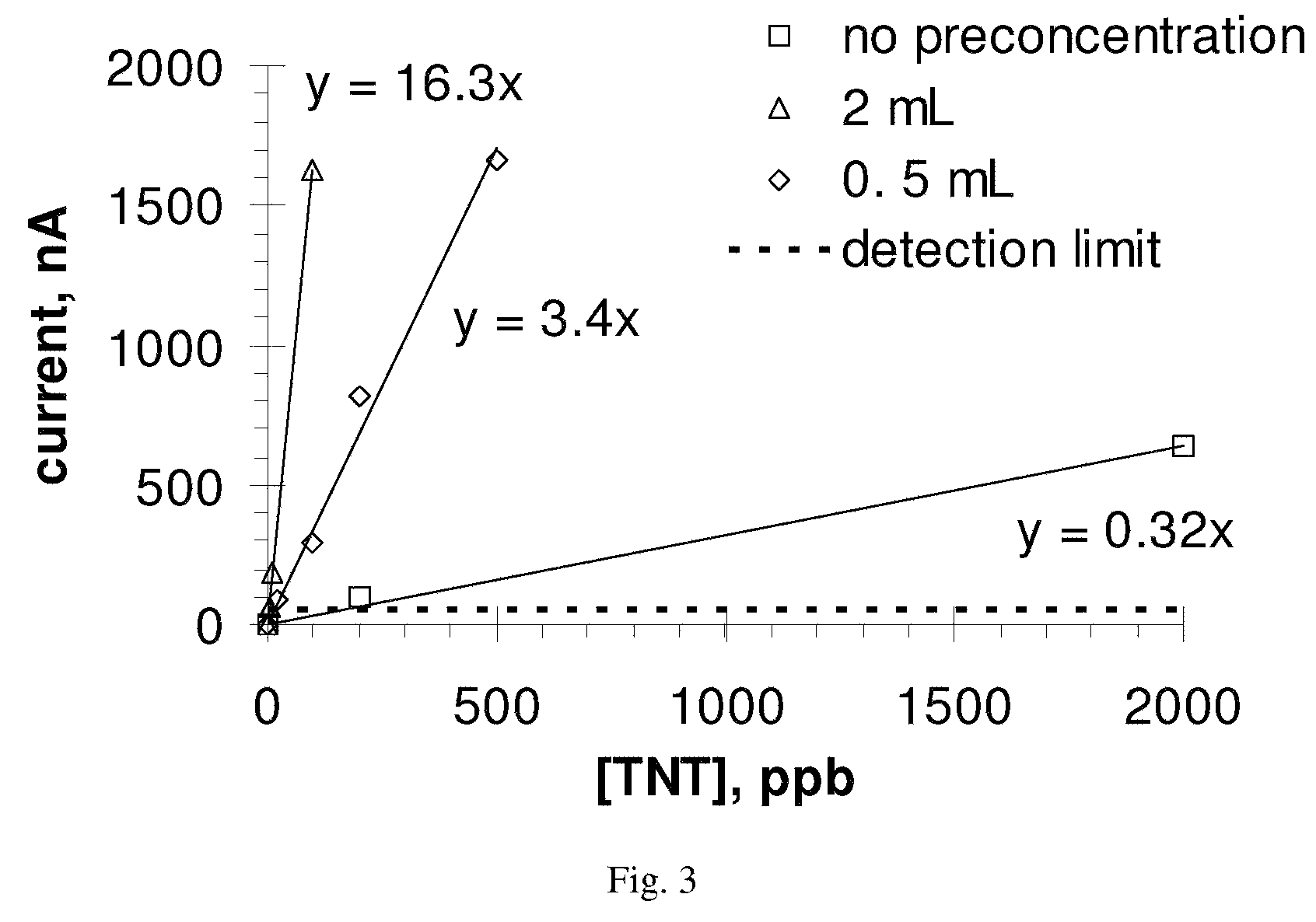

ActiveUS20170108520A1Speed up recoveryPerformance deteriorationOther chemical processesBiological material analysisSorbentSolid phase extraction

The subject invention provides chemical compositions and synthesis strategies to create molecularly imprinted polymers (MIPs) via sol-gel processes. In a specific embodiment, the subject invention utilizes a(n) organic, inorganic, or metallic template analyte to create a hybrid organic-inorganic or inorganic three-dimensional network possessing cavities complementary to the shape, size, and functional orientation of the template molecule or ions. The subject invention further pertains to the use of the novel MIPs as selective solid phase extraction (SPE) sorbents for pre-concentration and clean-up of trace substances in biological and environmental samples. Synthesis of other molecularly imprinted polymers with environmental, pharmaceutical, chemical, clinical, toxicological, and national security implications can be conducted in accordance with the teachings of the subject invention.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Method for comprehensive using tail gas of rotary kiln and dilute sulfuric acid in procedure of producing white titanium pigment through sulfuric acid method

This invention discloses a method for utilizing rotary kiln tail gas and diluted H2SO4 produced during TiO2 powder production by H2SO4 method. The method comprises: contacting rotary kiln tail gas and diluted H2SO4 for heat exchange, settling the obtain pre-concentrated H2SO4, performing medium-temperature concentration by using its own heat, cooling for crystallization in vacuum, and mixing with 98% concentrated H2SO4 to obtain H2SO4 with the concentration needed for TiO2 powder and calcium superphosphate production. This invention effectively utilizes the heat of rotary kiln tail gas for pre-concentration and medium-temperature concentration of diluted H2SO4, and does not need extra heat source. FeSO4 is further precipitated from concentrated H2SO4, thus can realize effective separation of FeSO4 and H2SO4.

Owner:ANHUI ANNADA TITANIUM IND CO LTD

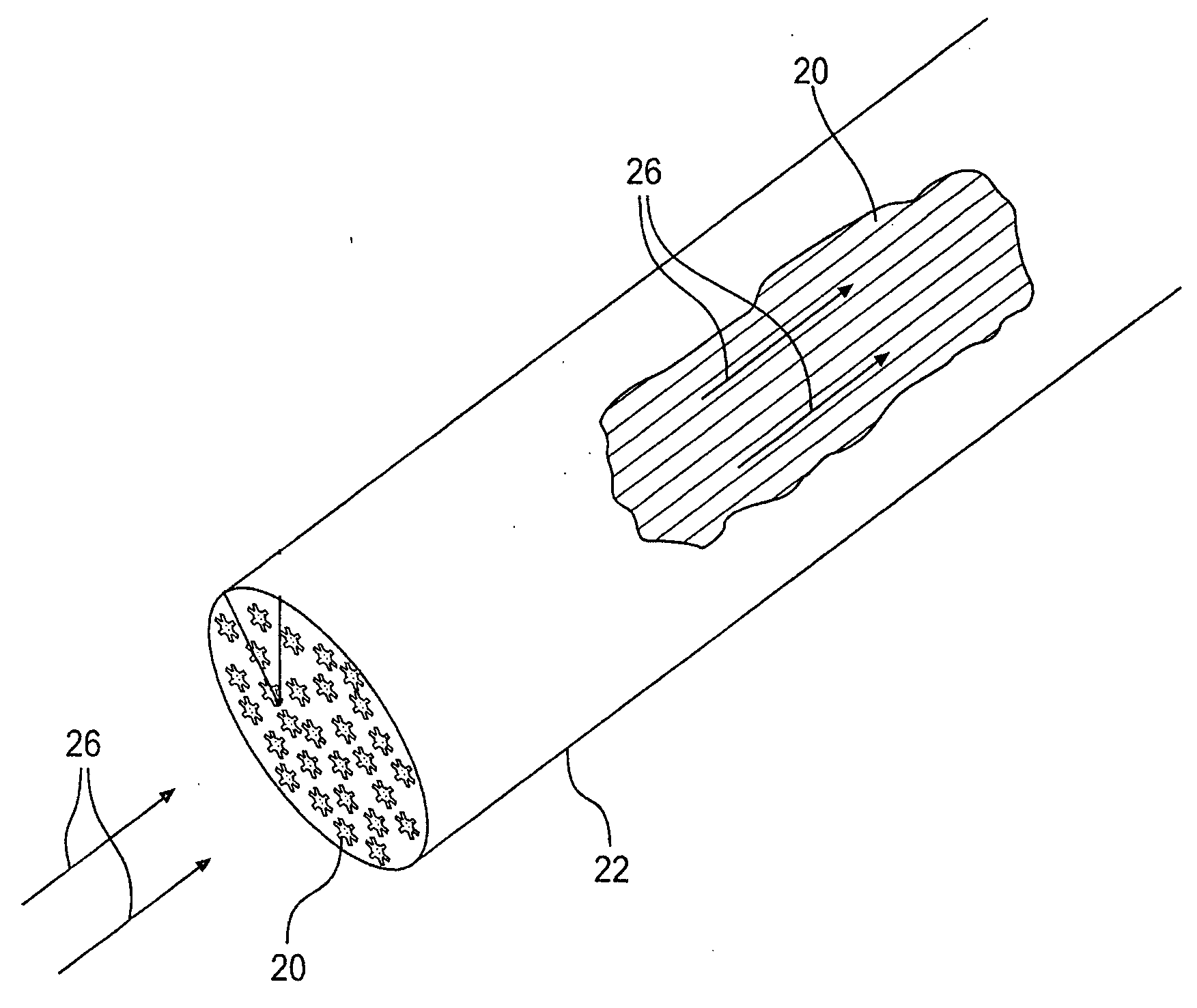

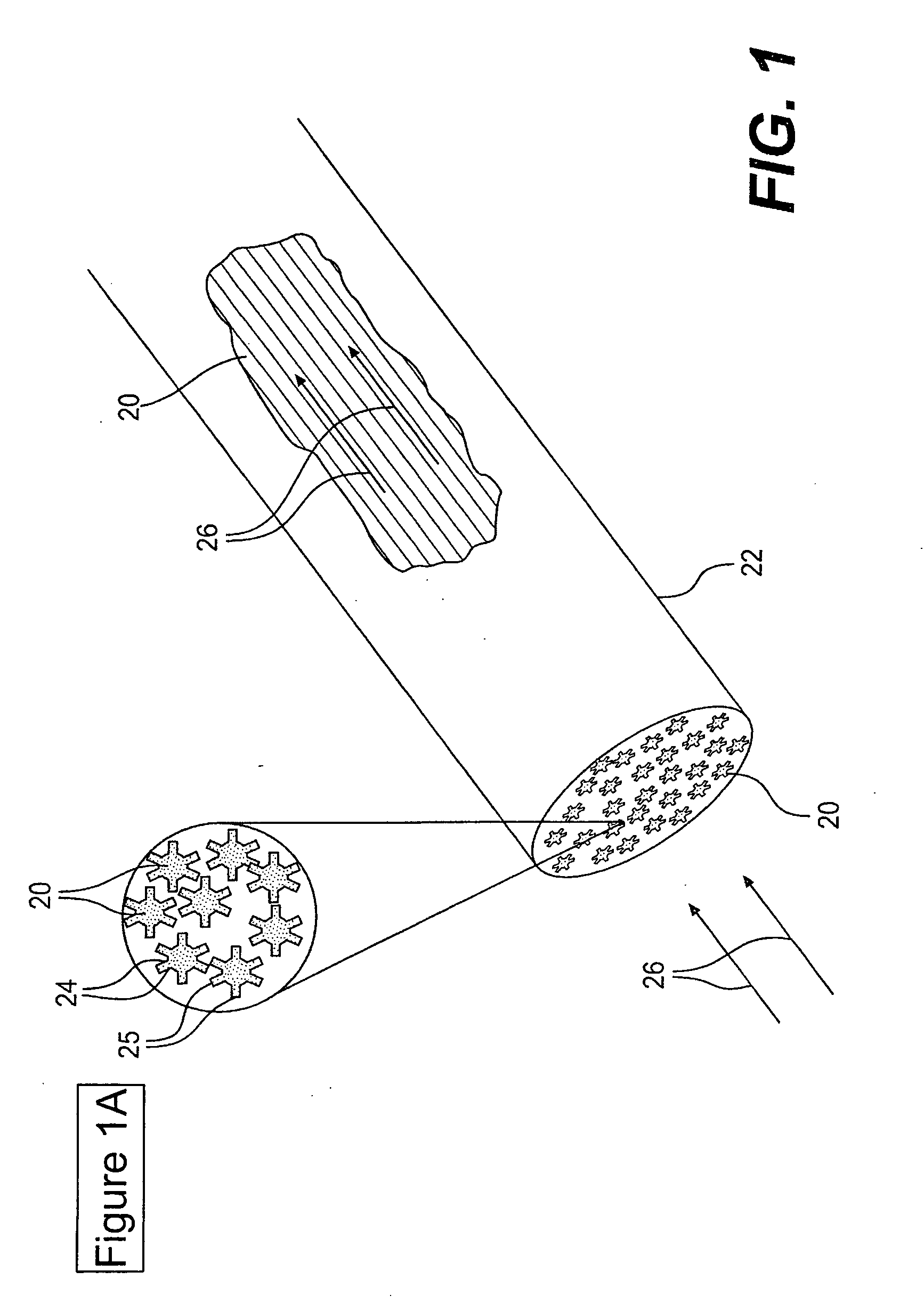

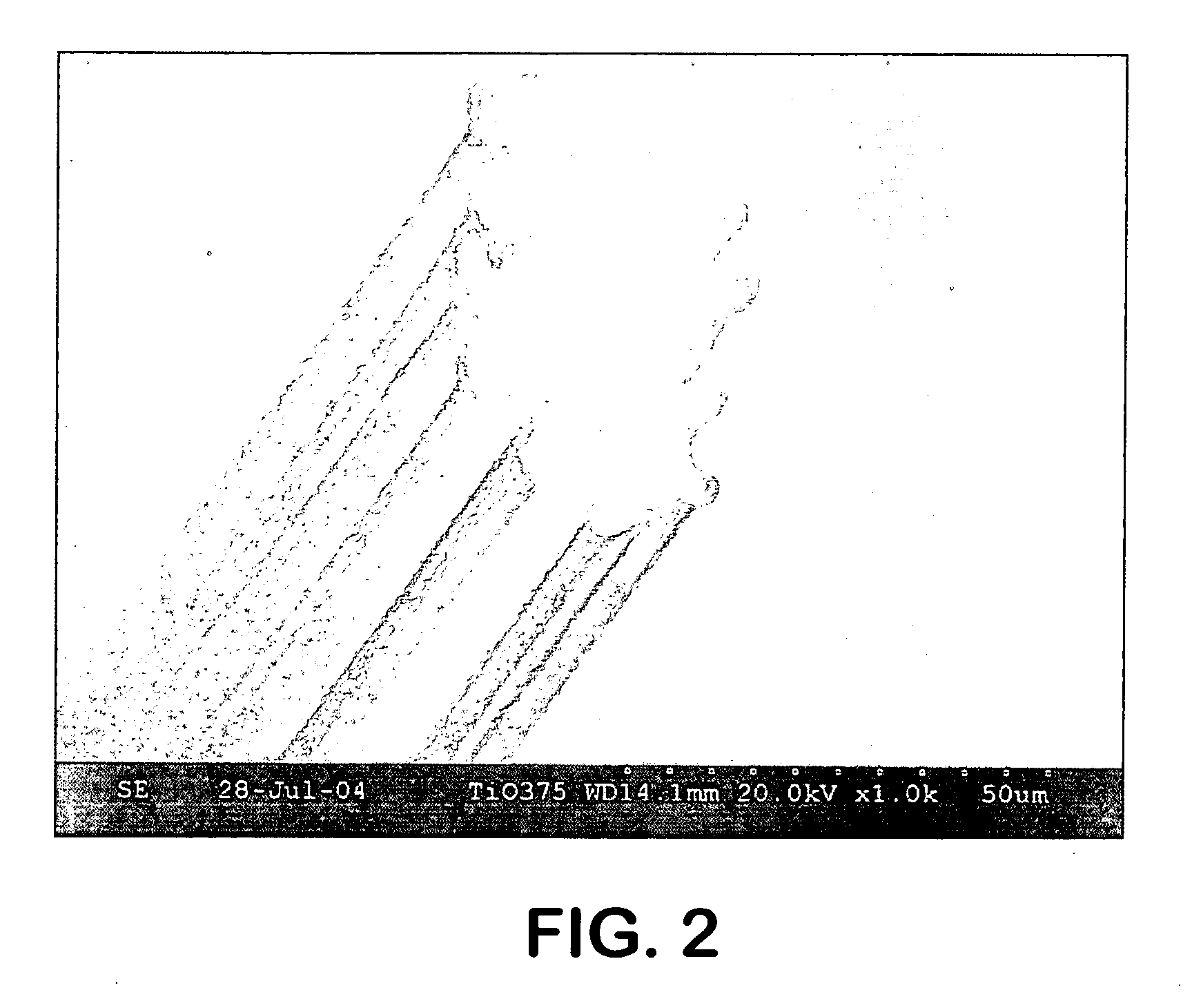

Capillary-channeled polymeric fiber as solid phase extraction media

ActiveUS20060201881A1Improve flow characteristicsIncrease surface areaComponent separationSolvent extractionFiberCapillary channel

Solid phase extraction devices including a plurality of packed nominally aligned capillary-channeled polymeric fibers for use as stationary phase materials are disclosed. A plurality of fibers are packed together in a casing so as to provide good flow characteristics through the fibers and high surface area contact between a sample and the fibers. Different polymer compositions of the fibers permit the “chemical tuning” of the extraction process. The fibers can be physically or chemically derivatized to target specific analytes for separation from a test sample. Use of the fibers allows a wide range of liquid flow rates with very low backpressures. The fibers are easily packed into a micropipette tip or a conduit for use with a fluid flow device such as an aspirator or a pump. The devices can be used for isolation and pre-concentration of analytes from samples, for instance for proteins from buffer solutions or extraction of pollutants from remote locations.

Owner:CLEMSON UNIV RES FOUND

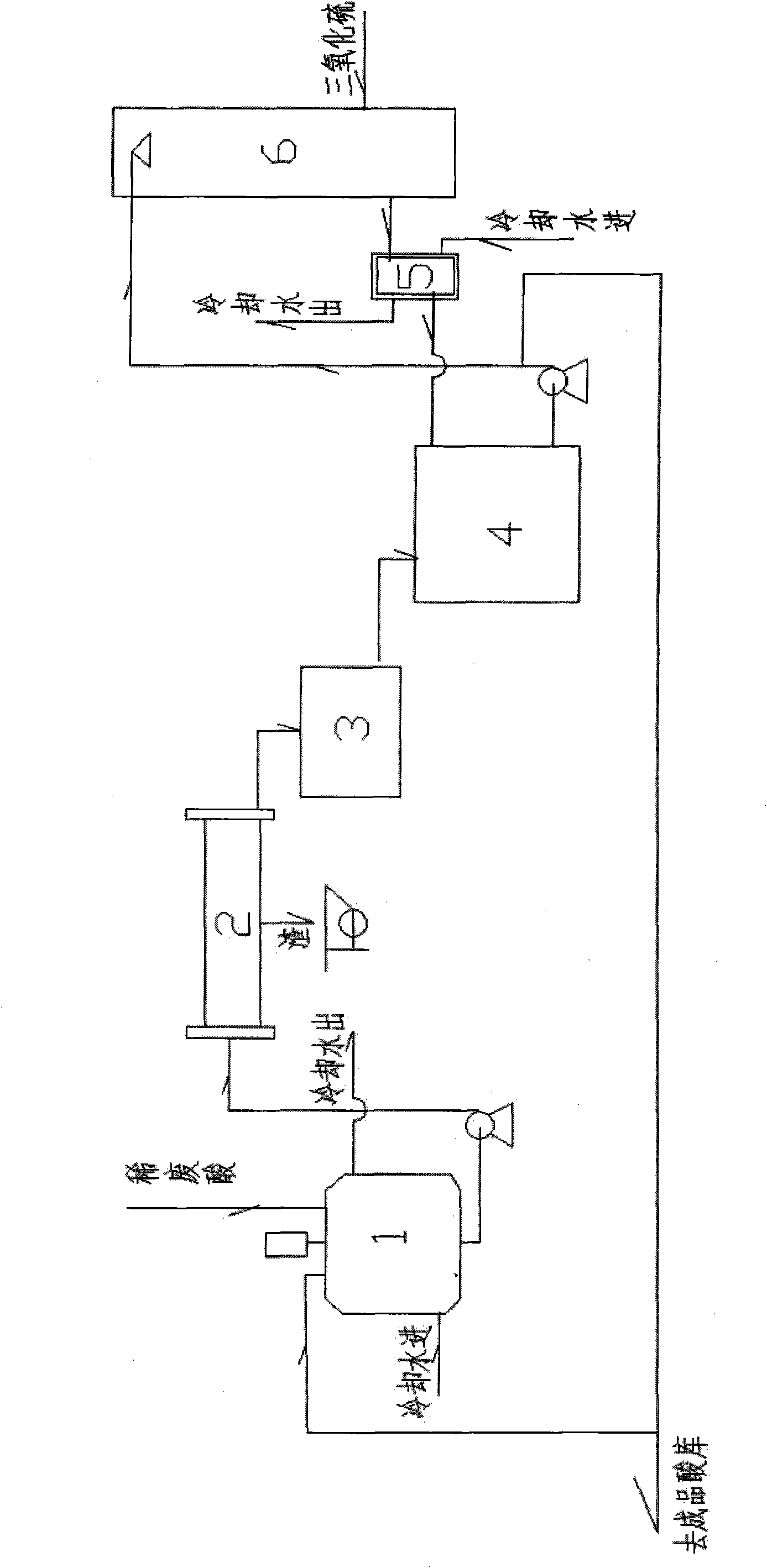

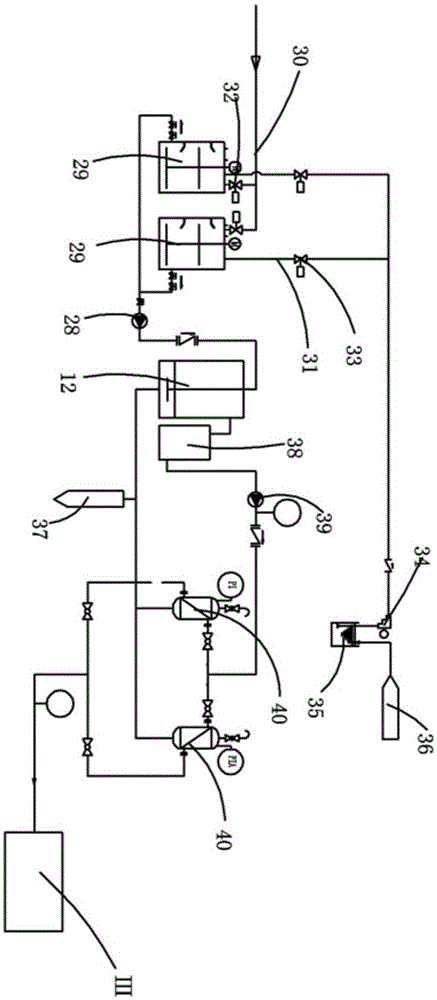

Method and device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production

ActiveCN101538021ASolving production challenges of reuseIncrease productionSulfur-trioxide/sulfuric-acidSulfurSulfate

The recycling of diluted waste acid produced in the production process of sulfate process titanium dioxide is a bottleneck limiting the development of the sulfate process titanium dioxide. In addition, manufacturers of sulfate process titanium dioxide usually have sulfate acid production devices due to the need of a large amount sulfate acid. The invention relates to a method and a device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production. The method comprises the following steps: firstly, performing the pre-concentration of the diluted sulfate acid; secondly, removing most impurities carried by the diluted sulfate acid through settlement; and finally, using the sulfate acid subjected to pre-concentration and impurity removal to replace make up water of a sulfate production system, adding the sulfate acid into a sulfate circulating tank of a sulfate acid absorption tower to produce concentrated sulfate acid after sulfate acid absorption tower absorbs sulfur trioxides, and thus recycling the diluted sulfate acid. The method has the advantages of making a plurality of achievements at one time, namely changing pre-concentrated diluted sulfate acid into concentrated sulfate acid without extra energy consumption and equipment addition while reducing the cooling load of sulfate acid flowing out from the tower at the same time.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

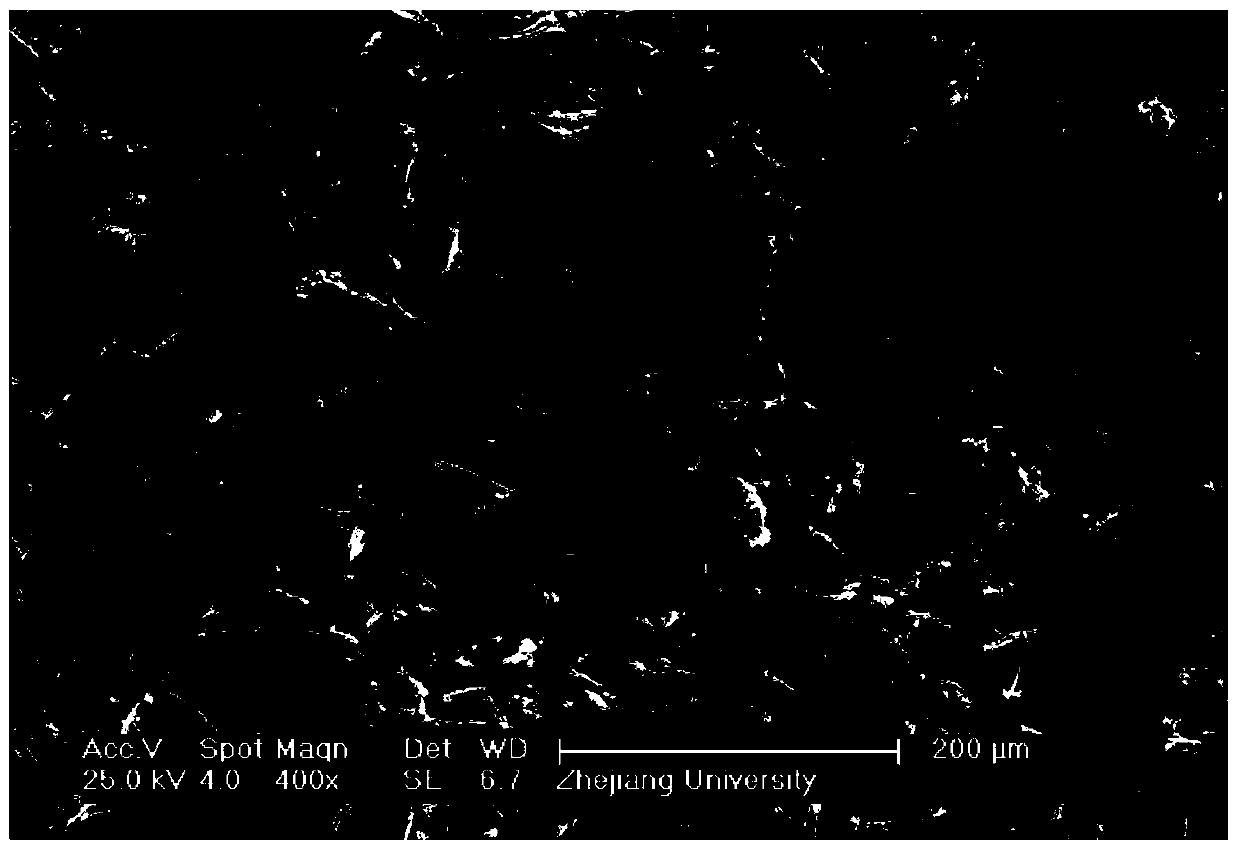

Green and environment-friendly method for preparing silk fibroin powder

ActiveCN103739691ADoes not damage the internal structureNo pollution in the processPeptide preparation methodsAnimals/human peptidesFiberHigh pressure

The invention relates to a method for preparing and dissolving silk fibroin powder, which comprises the steps of degumming, pre-alkali washing, high-temperature high-pressure treatment, purification, pre-concentration, drying, and ultrafine grinding. The method of the invention adopts a high-temperature high-pressure method combined with ultralow-concentration alkali liquor to dissolve fibroin fibers, can completely dissolve fibroin fibers, and breaks the precedent that a high-temperature high-pressure method cannot dissolve silk fibroin; when compared with other technology in the prior art, the method adopts alkali liquor with an ultralow concentration, does not destroy the internal structure of natural silk fibroin, is simple and high-efficient in process, has significantly decreased cost, is short in production period, high in biological safety, simple and convenient, does not generate other wastes, and causes no environment pollution.

Owner:ZHEJIANG UNIV

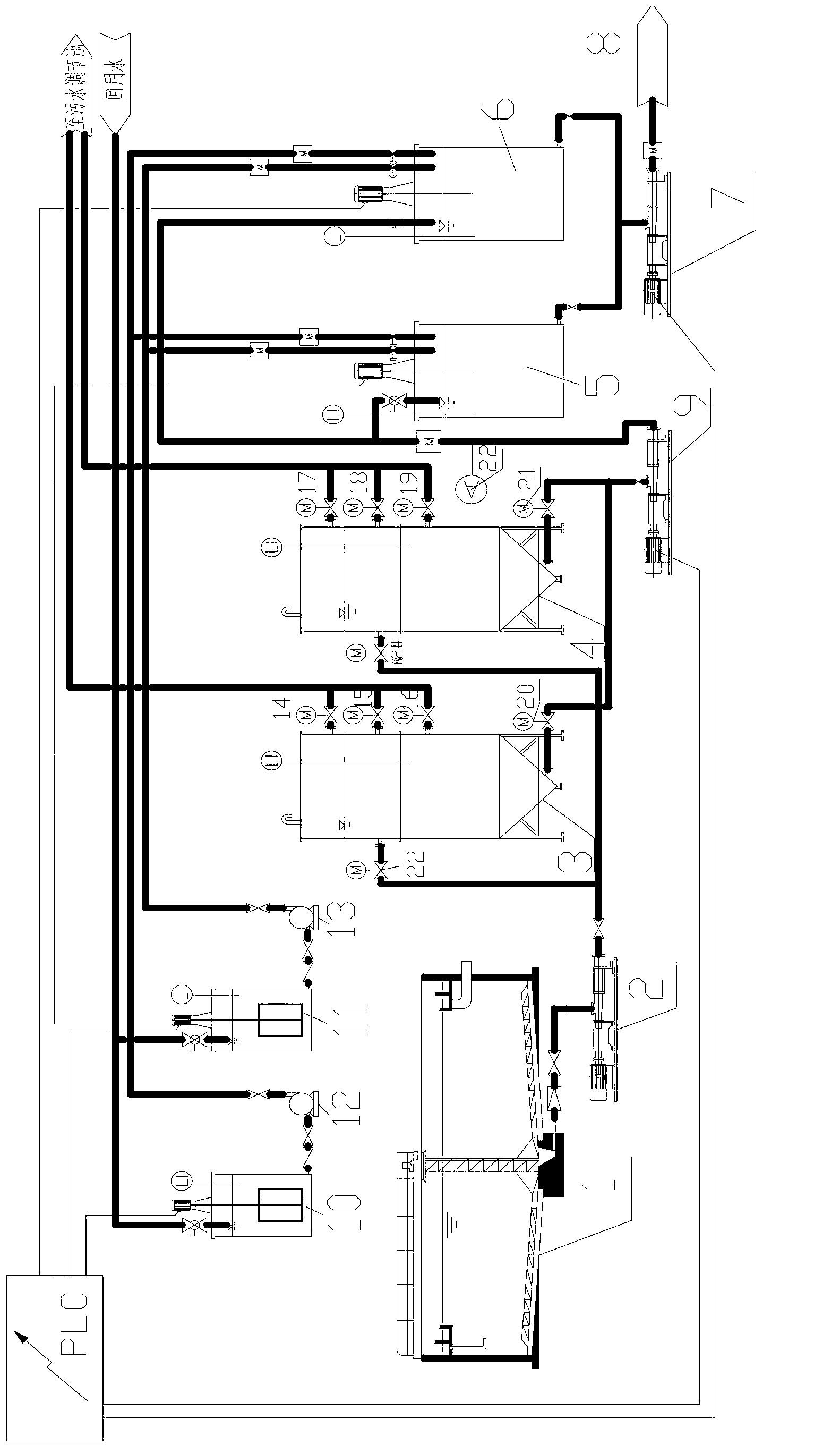

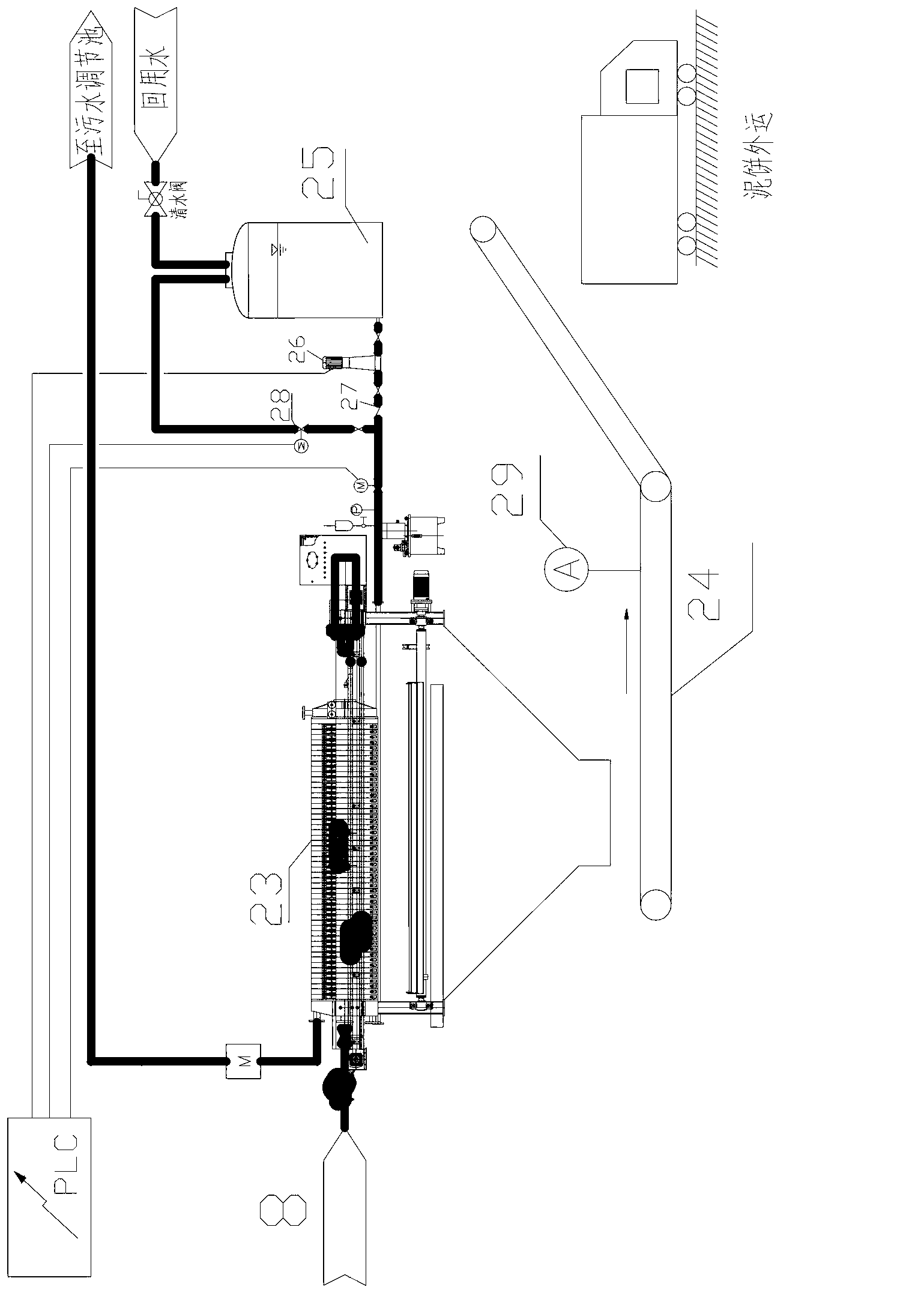

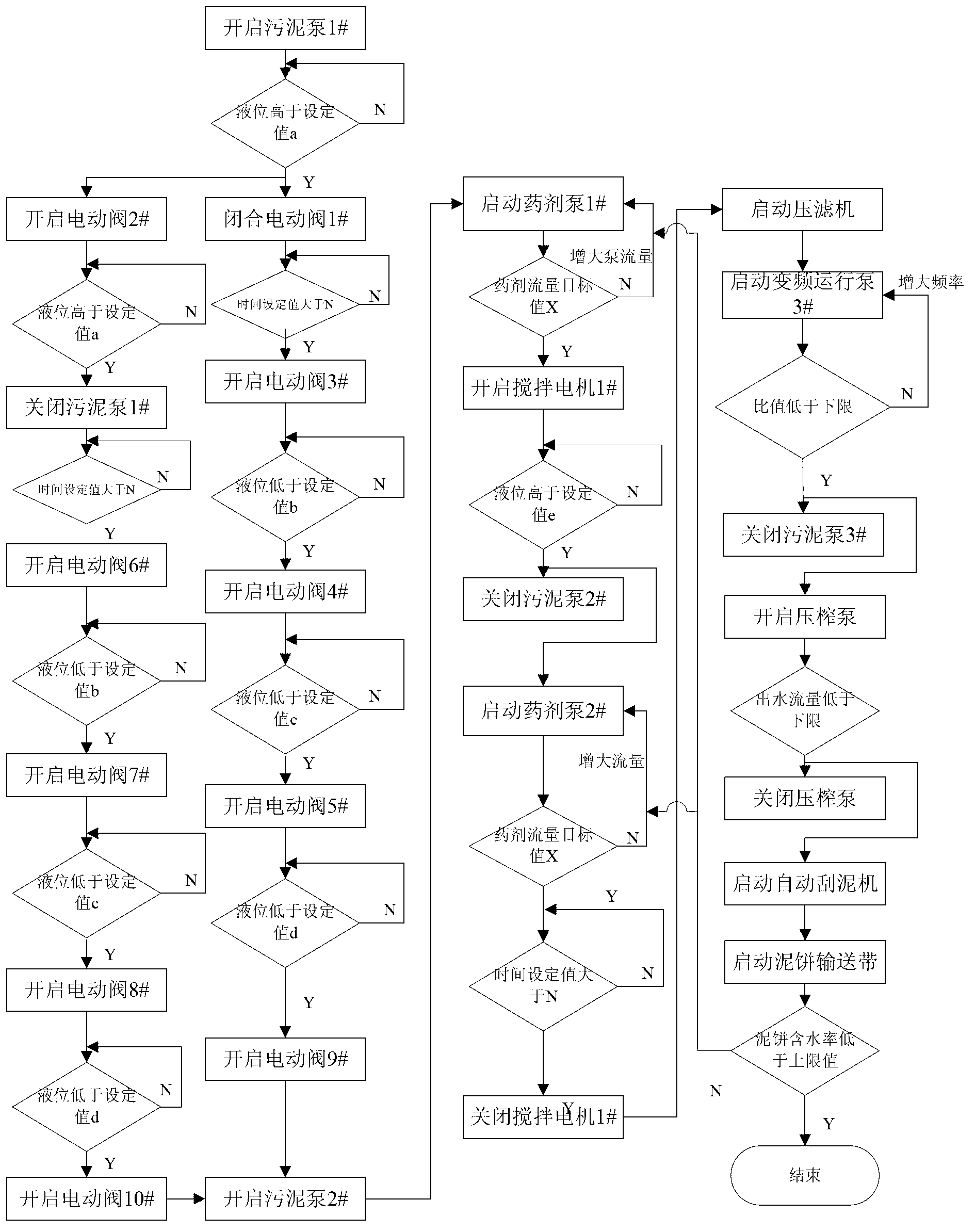

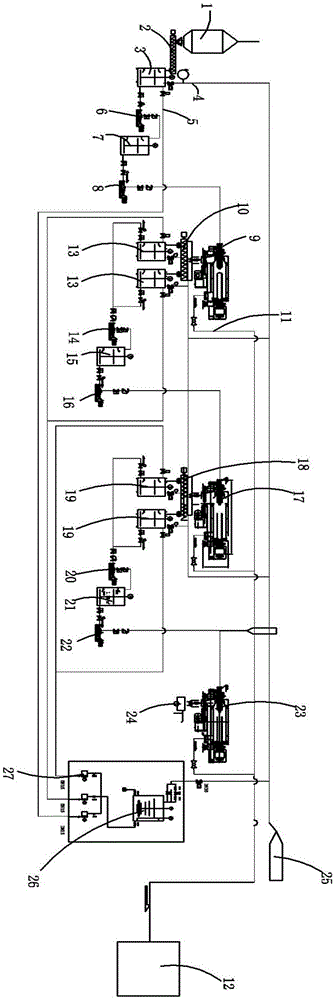

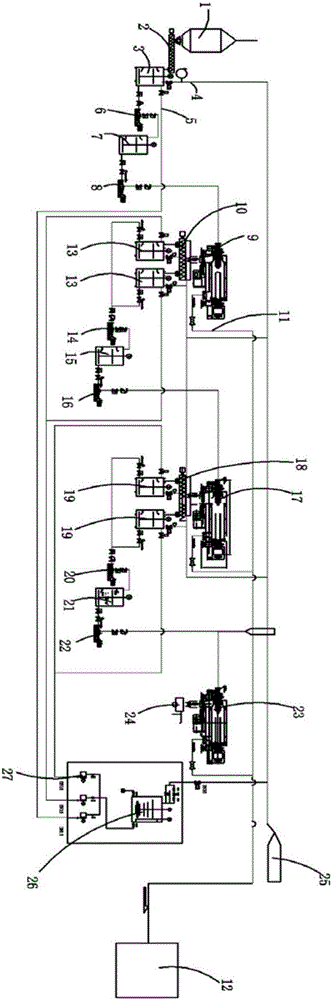

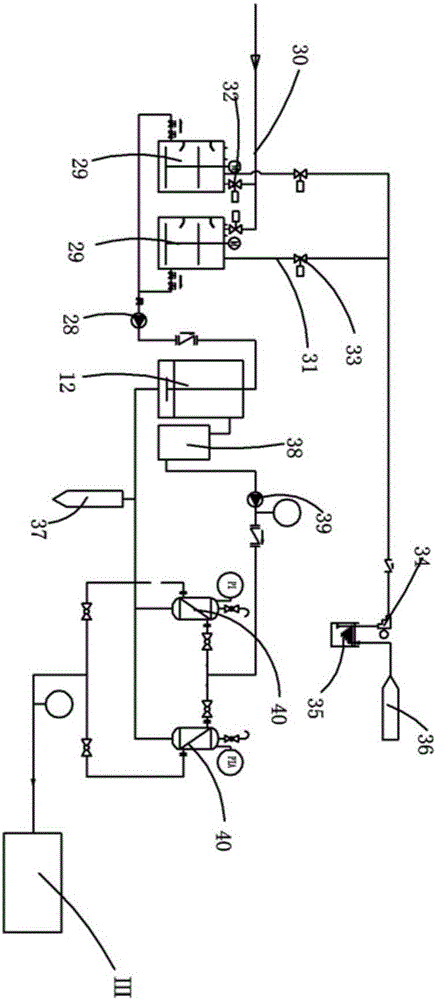

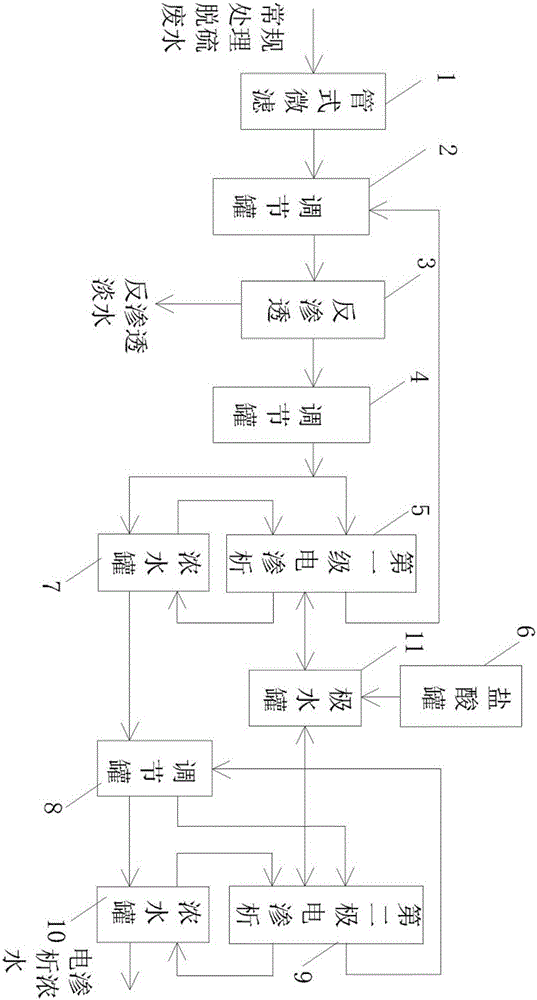

Automatic control system of sludge deep dewatering overall process and treatment method

ActiveCN102936089ALow running costReduce doseSludge treatment by de-watering/drying/thickeningTotal factory controlAutomatic controlControl system

The invention discloses an automatic control system of a sludge deep dewatering overall process and a treatment method. The automatic control system comprises a sludge pre-concentration control system, a sludge tempering control system, a sludge deep dewatering control system and a mud cake transmitting control part. According to the invention, the whole sludge deep dewatering process is controlled on the basis of an optimization algorithm. The design concept of the automatic control system is as follows: the operation cost in a boundary range set by a user is always lowest and the total property is maintained optimal. The automatic control system has the advantages of providing the real-time monitoring for a sludge conditioning and deep dewatering integrated process, ensuring the lowest dose quantity and the maximum treating capacity in a set target range, enabling a mud cake to accord with the set requirement, and guaranteeing the stable and continuous optimal operation.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI

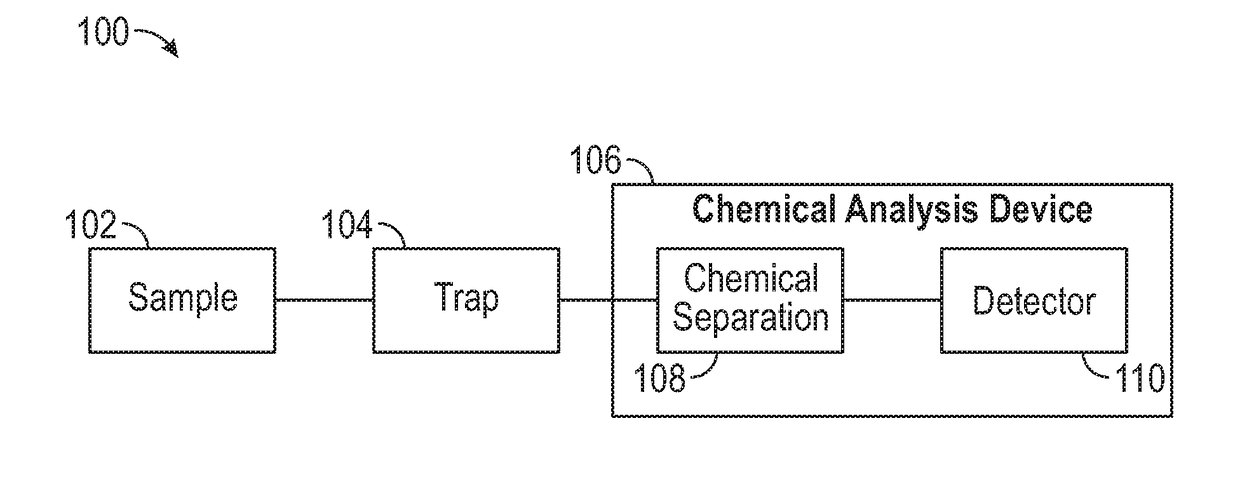

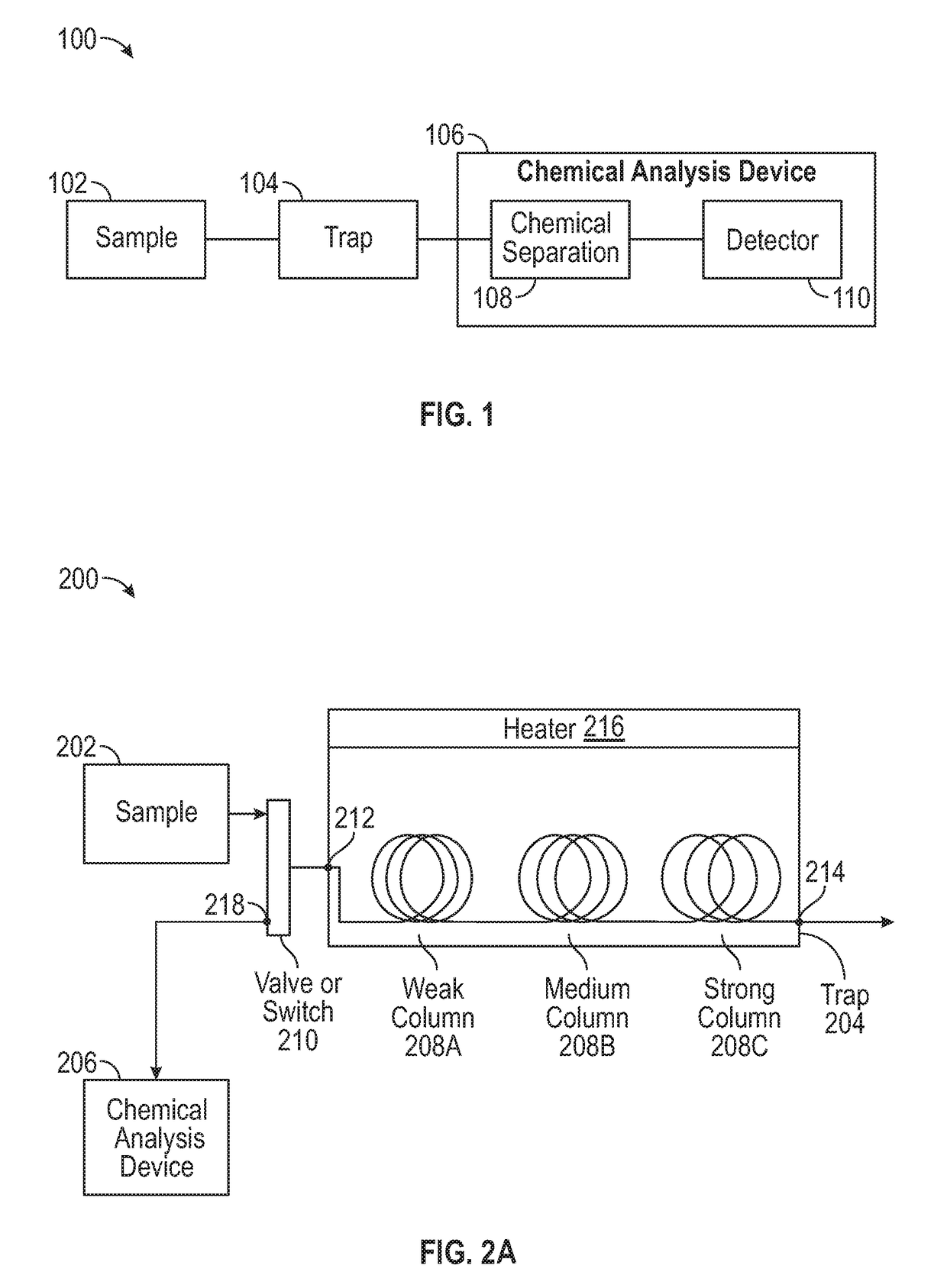

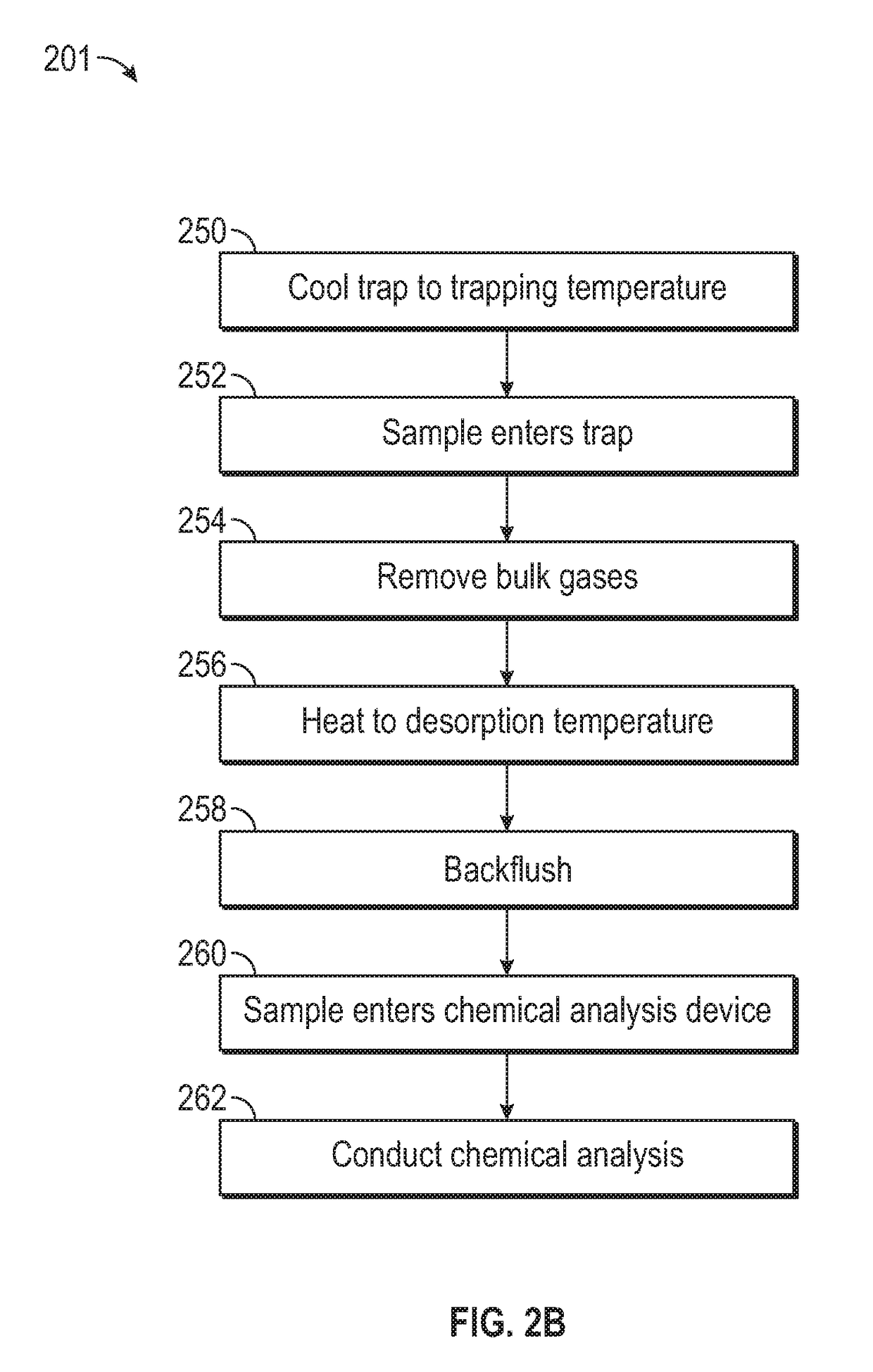

Multi-Capillary Column Pre-Concentration System for Enhanced Sensitivity in Gas Chromatography (GC) and Gas Chromatography-Mass Spectrometry (GCMS)

ActiveUS20170284978A1High strengthHigh affinityComponent separationPreparing sample for investigationGas chromatography–mass spectrometryMass chromatography

A multi-capillary column pre-concentration trap for use in various chromatography techniques (e.g., gas chromatography (GC) or gas chromatography-mass spectrometry (GCMS)) is disclosed. In some examples, the trap can include a plurality of capillary columns connected in series in order of increasing strength (i.e., increasing chemical affinity for one or more sample compounds). A sample can enter the trap, flowing from a sample vial to a relatively weak column to the relatively strongest column of the trap by way of any additional columns included in the trap, for example. In some examples, the trap can be heated and backflushed so that the sample exits the trap through the head of the relatively weak column. Next, the sample can be injected into a chemical analysis device for performing the chromatography technique (e.g., GC or GCMS) or it can be injected into a secondary multi-capillary column trap for further concentration.

Owner:ENTECH INSTR INC

Nanoporous organosilicas as pre-concentration materials for sensors

A molecularly imprinted material made from polymerizing a monomer having the structural formula (OR)3Si—B-A-B—Si(OR)3. A is a divalent organic group, B is a saturated or unsaturated divalent hydrocarbon group or a covalent bond, and R is an independently selected saturated or unsaturated monovalent hydrocarbon group. A preconcentrator having: a container comprising in inlet and an outlet and the above material within the container. The inlet is capable of allowing a fluid to enter the container. The outlet is capable of being coupled to a sensor and of allowing the fluid to exit the container.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Cement kiln co-processing system for waste incineration fly ash

ActiveCN105107820ANo secondary pollutionAvoid pollutionSolid waste disposalCement productionFiltrationReverse osmosis

The invention relates to a cement kiln co-processing system for waste incineration fly ash. Washing water generated by a waste incineration fly ash three-stage washing desalination system enters a coagulating sedimentation heavy-metal removal system through a pipeline; a solution with the salt content of 1-2 percent, obtained by the coagulating sedimentation heavy-metal removal system, enters a sodium filtration and reverse osmosis pre-concentration system; and the sodium filtration and reverse osmosis pre-concentration system removes calcium and magnesium ions in washing water and concentrates the solution with the salt content of 1-2 percent into a concentrated liquor with the salt content of 6-8 percent, which is conveyed into a slight trace carnallite removal system for carnallite removal, and finally, a nearly saturated liquid enters an MVR (Mechanical Vapor Recompression) evaporative crystallization system for evaporative crystallization. The cement kiln co-processing system for waste incineration fly ash is a device for cement kiln co-processing of waste incineration fly ash, can dispose a great amount of fly ash, is high in cement output, realizes innocent treatment, and obtains industrial salt through evaporative crystallization, which is used in paper making process, snow-melting agents and the chlor-alkali industry.

Owner:湖州京兰环保科技有限公司

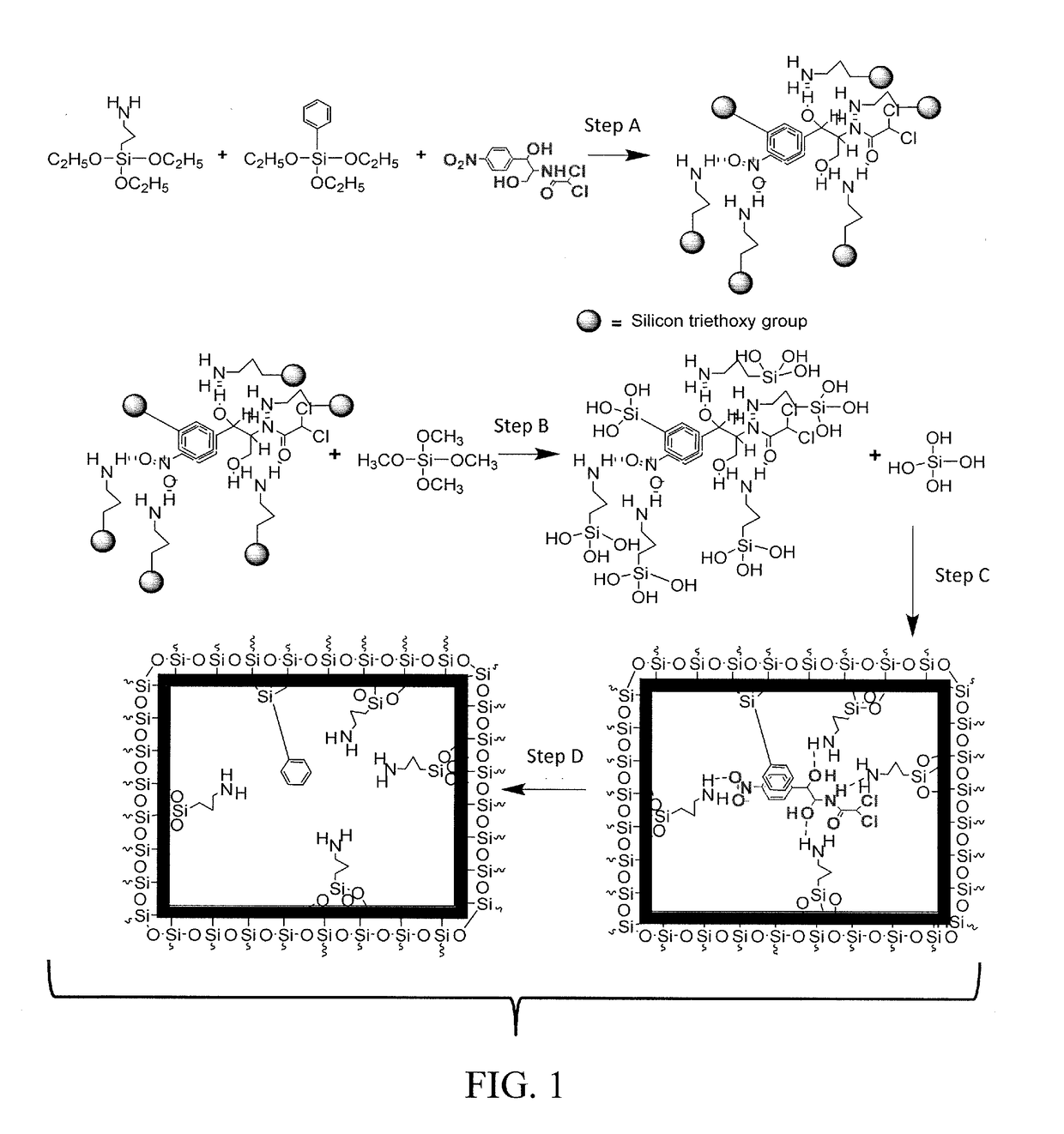

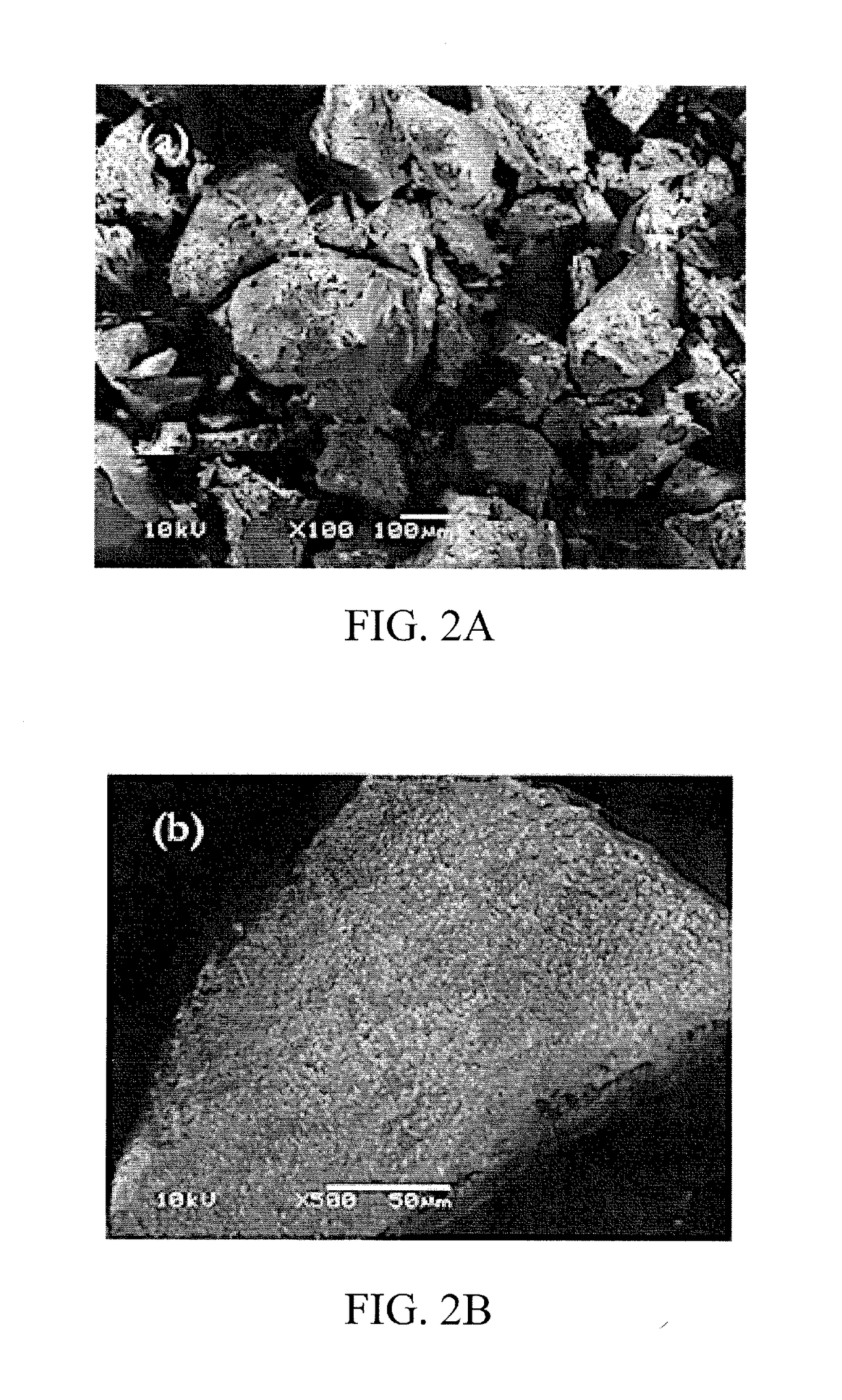

Materials and methods for the detection of trace amounts of substances in biological and environmental samples

ActiveUS20180059082A1Speed up recoveryPerformance deteriorationOther chemical processesBiological material analysisSorbentSolid phase extraction

The subject invention provides chemical compositions and synthesis strategies to create molecularly imprinted polymers (MIPs) via sol-gel processes. In a specific embodiment, the subject invention utilizes a(n) organic, inorganic, or metallic template analyte to create a hybrid organic-inorganic or inorganic three-dimensional network possessing cavities complementary to the shape, size, and functional orientation of the template molecule or ions. The subject invention further pertains to the use of the novel MIPs as selective solid phase extraction (SPE) sorbents for pre-concentration and clean-up of trace substances in biological and environmental samples. Synthesis of other molecularly imprinted polymers with environmental, pharmaceutical, chemical, clinical, toxicological, and national security implications can be conducted in accordance with the teachings of the subject invention.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

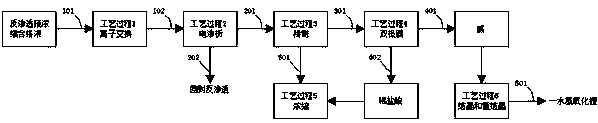

Method for producing xylose by using eucalyptus pulp pre-hydrolyzing liquid

InactiveCN102605108ARealize rational utilizationSolve processing problemsSaccharides productionPulp industryIon exchange

The invention discloses a method for producing xylose by using eucalyptus pulp pre-hydrolyzing liquid and belongs to the technical field of the production of functional sugars. The eucalyptus pulp pre-hydrolyzing liquid serves as a raw material and is prepared into the xylose through the procedures of pre-concentration, hydrolyzation, neutralization, decoloring, ion exchange, concentration, crystallization and drying processes. The reasonable utilization of eucalyptus pulp pre-hydrolyzing liquid is realized, the problem about treatment on the pre-hydrolyzing liquid in the eucalyptus pulp industry is solved, waste is changed into useful things, xylose products with multiple physiological functions are extracted from the pre-hydrolyzing liquid, the vacancy of producing the xylose by using the eucalyptus pulp pre-hydrolyzing liquid in China is filled, and a new raw material way for xylose production is made.

Owner:FUTASTE PHARM CO LTD

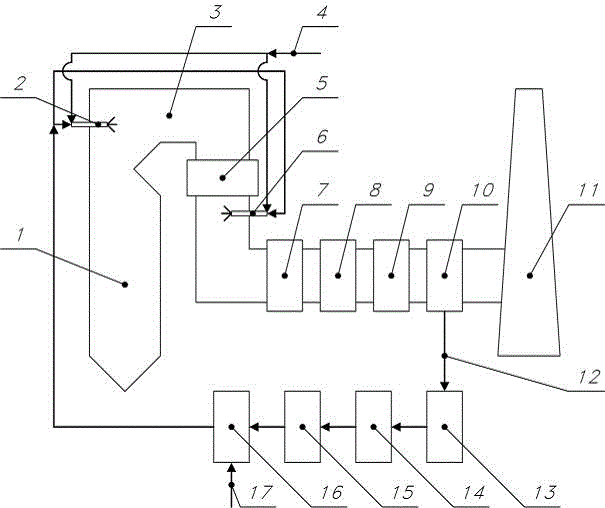

Synergistic gas-liquid-solid pollutant treatment system based on power plant wastewater zero-discharge technology

InactiveCN105967420AImprove economyImprove operational efficiencyElectrostatic separationDispersed particle separationDevice failureEconomizer

The invention provides a synergistic gas-liquid-solid pollutant treatment system based on a power plant wastewater zero-discharge technology and belongs to the technical field of coal-fired boiler pollutant control. The synergistic gas-liquid-solid pollutant treatment system includes a desulfurized wastewater zero-discharge treatment system, an SNCR + SCR united denitration system and a high-temperature electric dust removal system, wherein the desulfurized wastewater zero-discharge treatment system performs desulfurized wastewater pretreatment and pre-concentration, the SNCR + SCR united denitration system absorbs dissolved ammonia or urea of the treated desulfurized wastewater, uses the dissolved ammonia or urea as a reducing agent to be sprayed into an outlet of a boiler and a flue behind a coal economizer to complete denitration reaction, and the high-temperature electric dust removal system is arranged behind the coal economizer to collect and remove evaporated crystal substances of the wastewater. The synergistic gas-liquid-solid pollutant treatment system has excellent properties, is stable in process operation, achieves zero discharge of wastewater while achieving synergistic and coupled gas-liquid-solid pollutant treatment, reduces equipment investment by 10%-50% and the operation costs by 75%-90%, greatly reduces the equipment failure rate and maintains the working amount.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

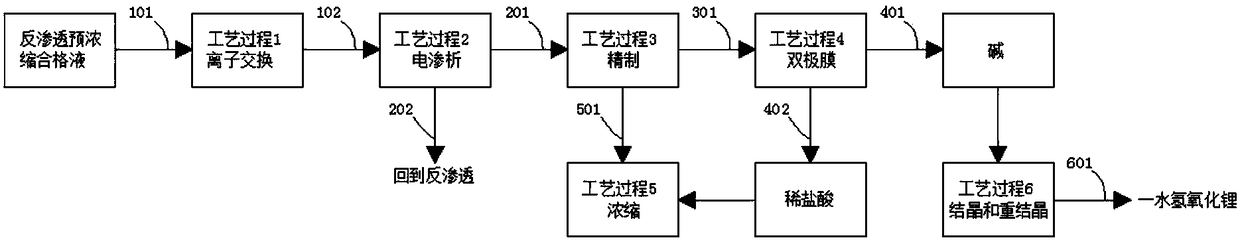

Novel process for producing high-purity lithium hydroxide by salt lake brine

InactiveCN108385128AOptimize acid and alkali consumptioOptimize product lossElectrolysis componentsProcess efficiency improvementLithium chlorideElectrolysis

The invention discloses a novel process for producing high-purity lithium hydroxide by salt lake brine. The process comprises the following steps that A, and the process comprises the following operation mode that the process adopts continuous operation, wherein the scale of each device is optimized through the data calculated by the process, the operation mode is optimized, so that continuous operation is achieved; and B, the salt lake brine is subjected to lithium extraction (by an adsorption method or an electrodialysis method), lithium-magnesium separation, purification and reverse osmosispre-concentration to obtain a lithium chloride qualified solution, and the reverse osmosis pre-concentration qualified solution comprise the following raw materials of, 35-50 g / L of lithium chloride,lower than 10 mg / L of calcium-magnesium ions, and lower than 200 mg / L of boron ions. According to the method, (an adsorption method or a membrane method) ), the magnesium chloride solution subjectedto lithium extracting by brine, magnesium removal and reverse osmosis pre-concentration is taken as the raw material, the electrodialysis technology, a reverse osmosis technology, a resin adsorption technology, an ion membrane electrolysis technology, an evaporative crystallization technology and the like are adopted, so that the high-purity lithium hydroxide product is produced, and therefore cyclic utilization of salt lake lithium resources is guaranteed.

Owner:何朋飞

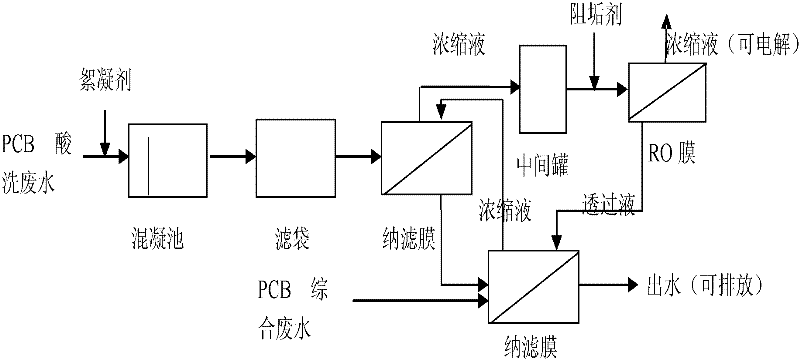

Membrane treatment process for heavy metal waste water generated during PCB production process

InactiveCN102358644AAvoid diversionImprove processing efficiencyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectrolysisFiltration membrane

The present invention discloses a membrane treatment process for heavy metal waste water generated during a printed circuit board (PCB) production process. According to the present invention, firstly large granular suspended matters are removed from acidic heavy metal waste water containing copper, lead, chromium, cadmium, nickel and the like by a filtration bag, wherein the acidic heavy metal waste water containing the copper, the lead, the chromium, the cadmium, the nickel and the like is generated during the PCB production process; then a nano-filtration system is adopted to realize pre-concentration; finally a reverse osmosis system is adopted to deep concentrate and recover the heavy metal ions in the waste water, wherein the resulting concentrated solution can be adopted for electrolysis, the resulting dialysis solution and the comprehensive waste water pass through the nano-filtration membrane, such that the processed dialysis solution can meet the discharge standard. The process of the present invention has advantages of low resource consumption, less environmental pollution, good economic benefits and the like.

Owner:CENT SOUTH UNIV

Selective Salt Recovery from

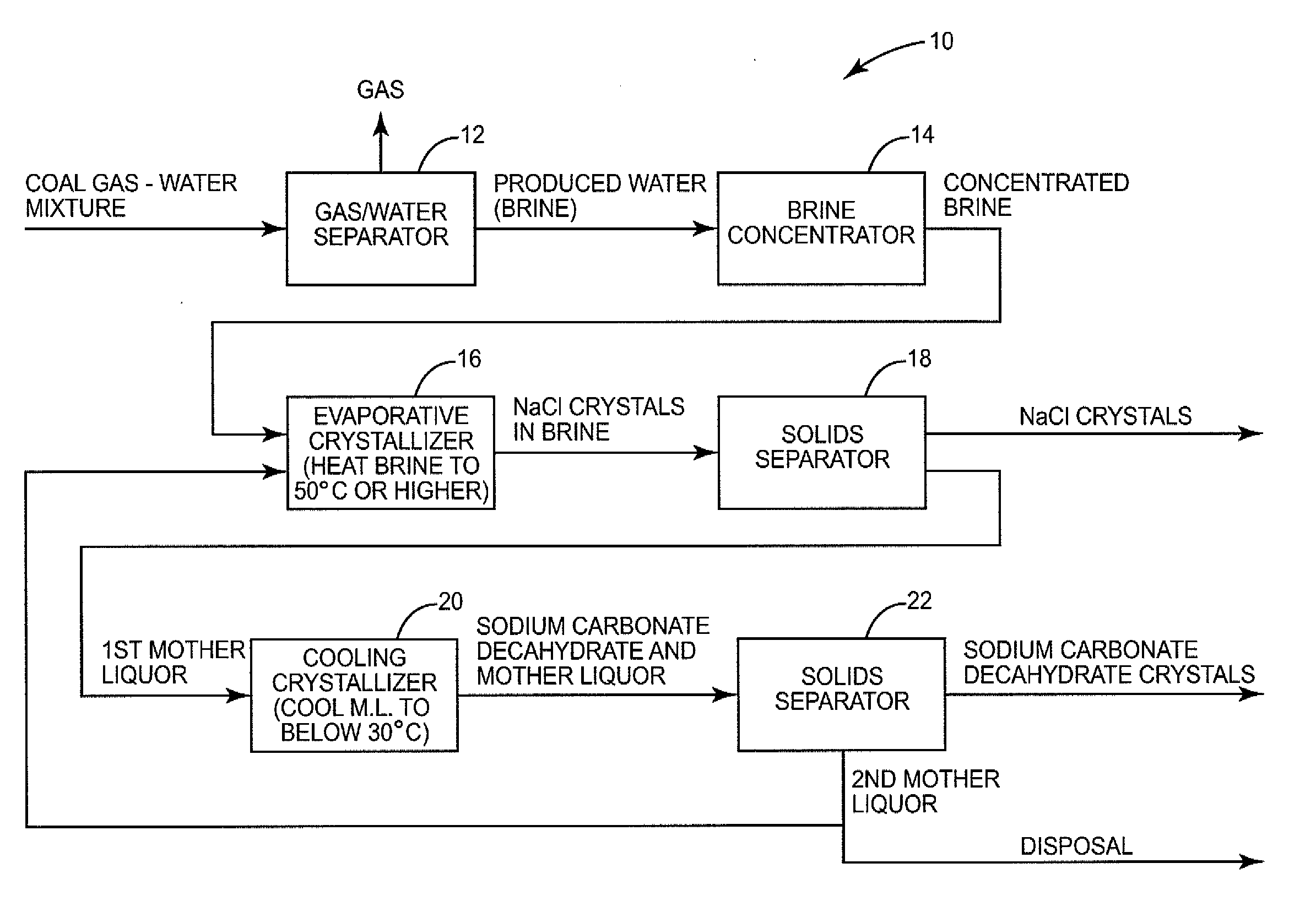

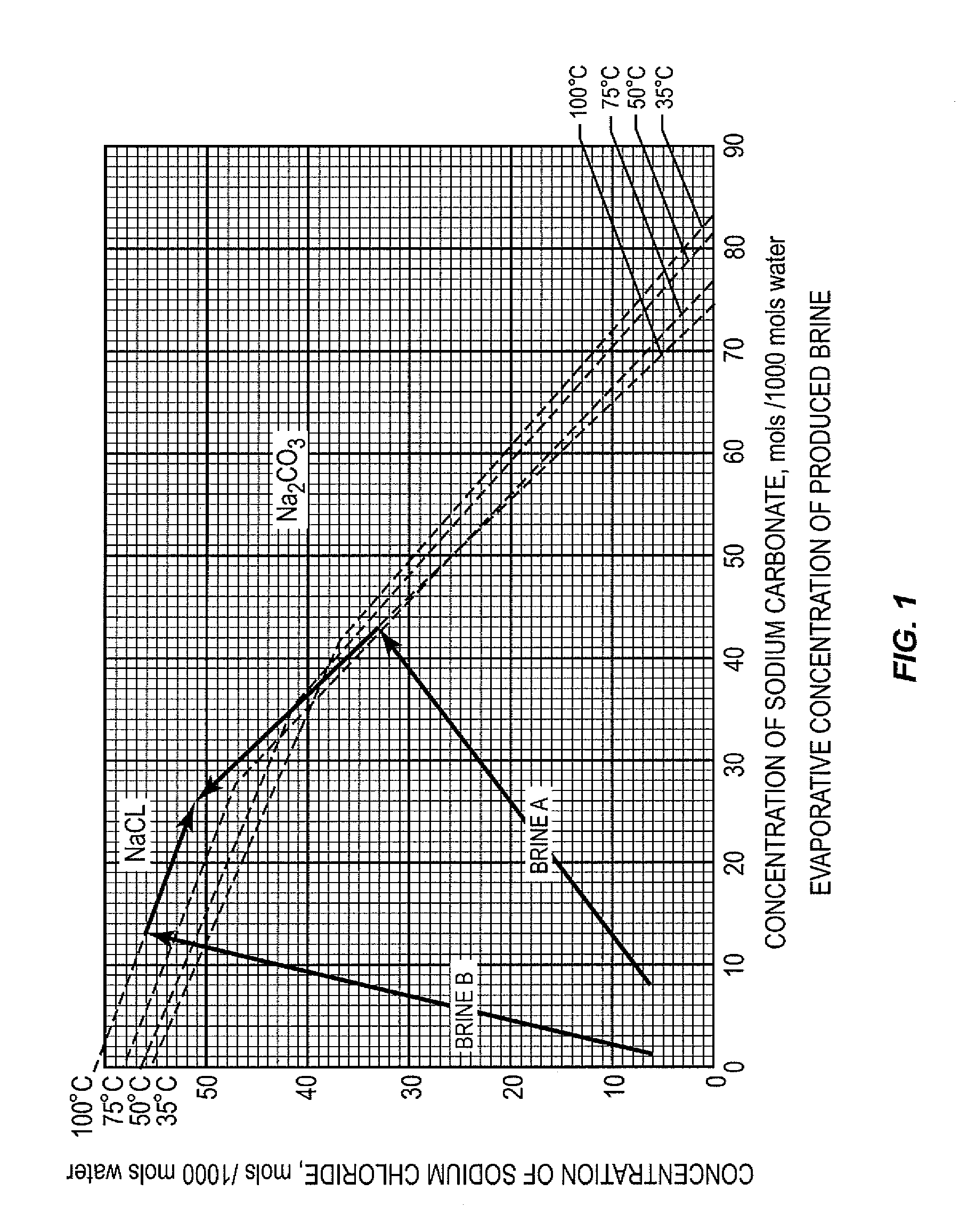

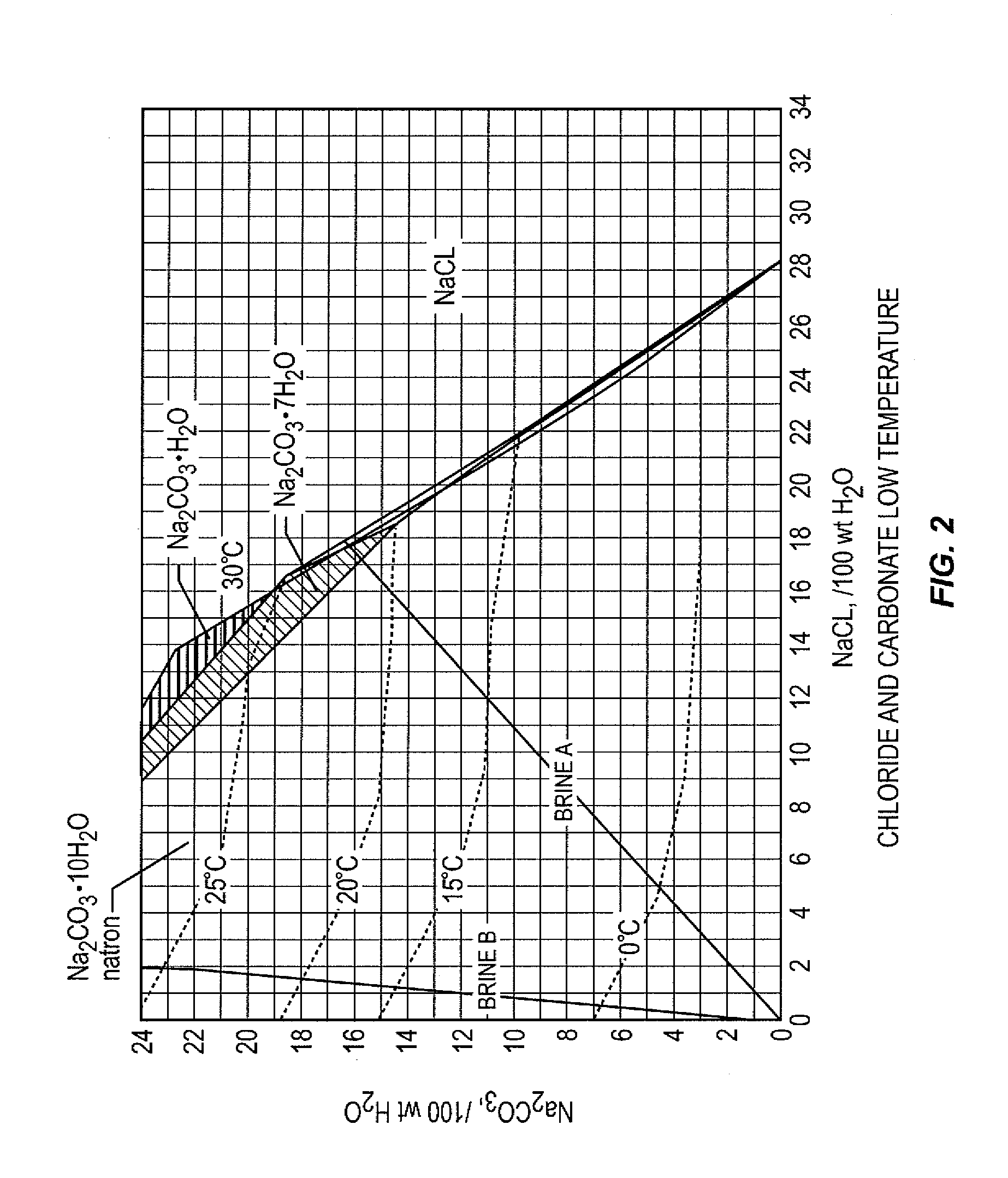

InactiveUS20120213689A1Rubidium/caesium/francium compoundsAlkali metal chloridesSodium bicarbonateSalt water

A process is provided for recovering sodium chloride crystals and sodium carbonate decahydrate crystals from a concentrated brine that results from a gas mining operation where gas and produced water is recovered and the produced water constitutes a brine. An initial pre-concentration process is carried out where the brine is concentrated and in the process carbon dioxide is removed from the brine and at least some sodium bicarbonate is converted to sodium carbonate. In one process, the concentrated brine is directed to a sodium chloride crystallizer where the brine is heated and further concentrated to form sodium chloride crystals which are separated from the brine to yield a product and wherein the resulting brine is termed a first mother liquor. The first mother liquor is then directed to a sodium carbonate decahydrate crystallizer where the first mother liquor is cooled and concentrated resulting in the formation of sodium carbonate decahydrate crystals and a second mother liquor. The second mother liquor is split into two streams where one stream is directed back to the sodium chloride crystallizer while the other stream is wasted or further treated.

Owner:VEOLIA WATER TECH INC

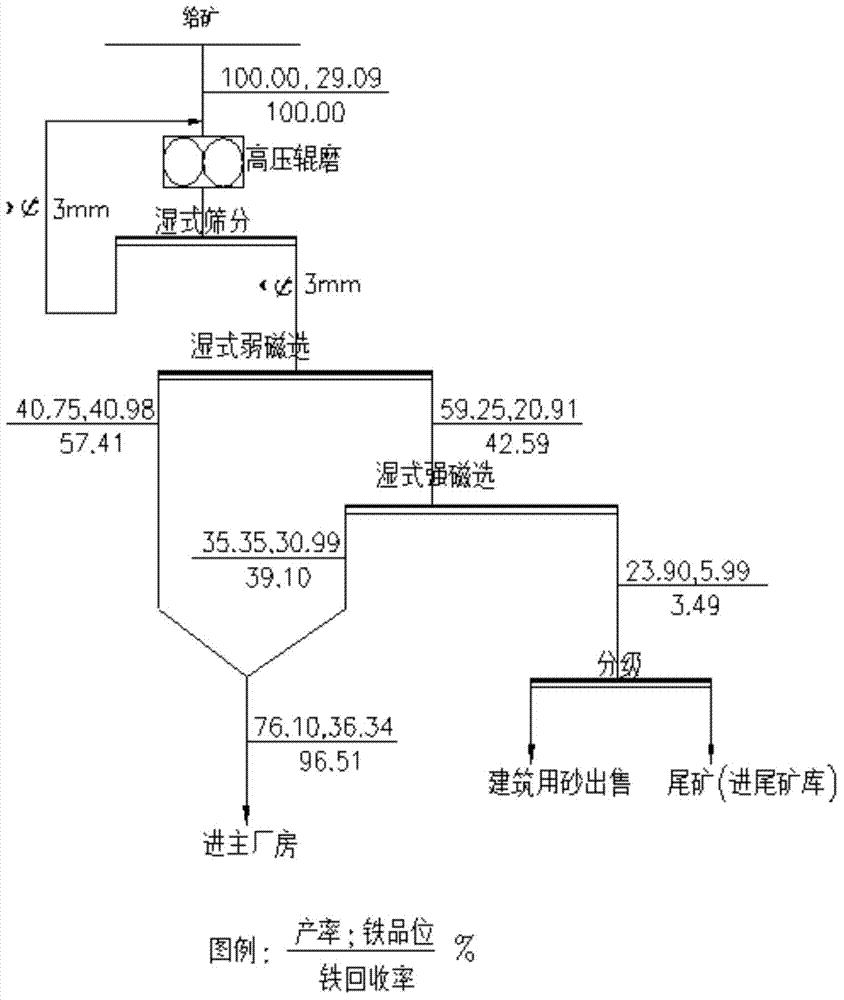

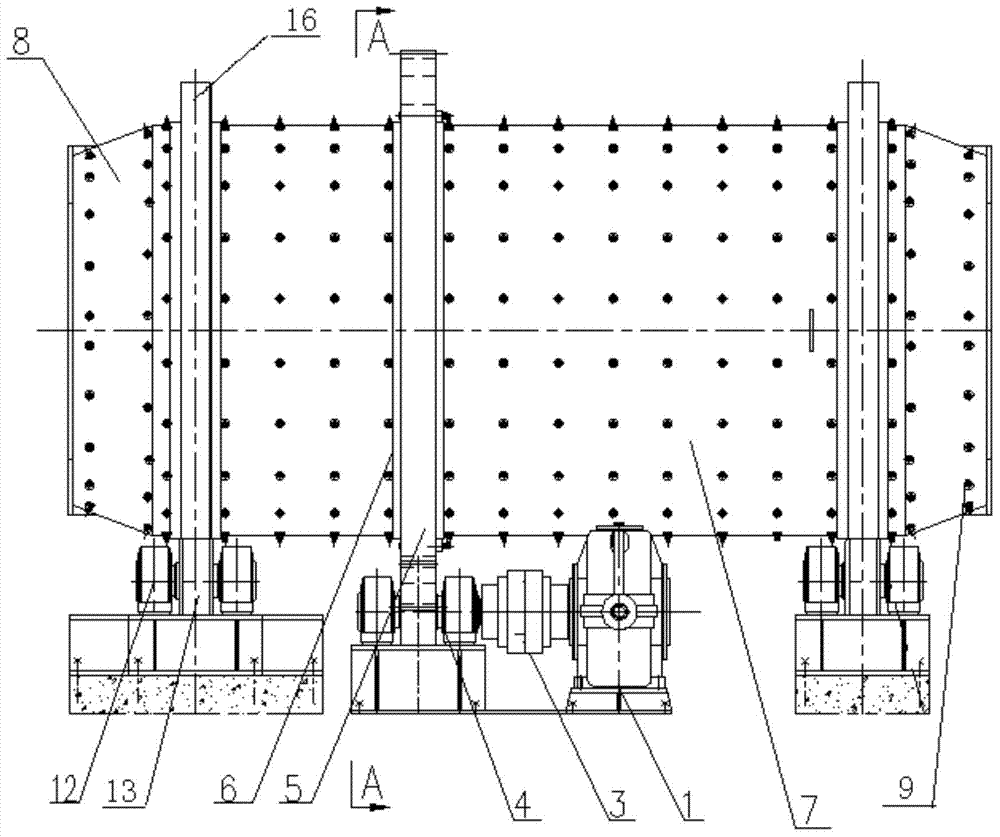

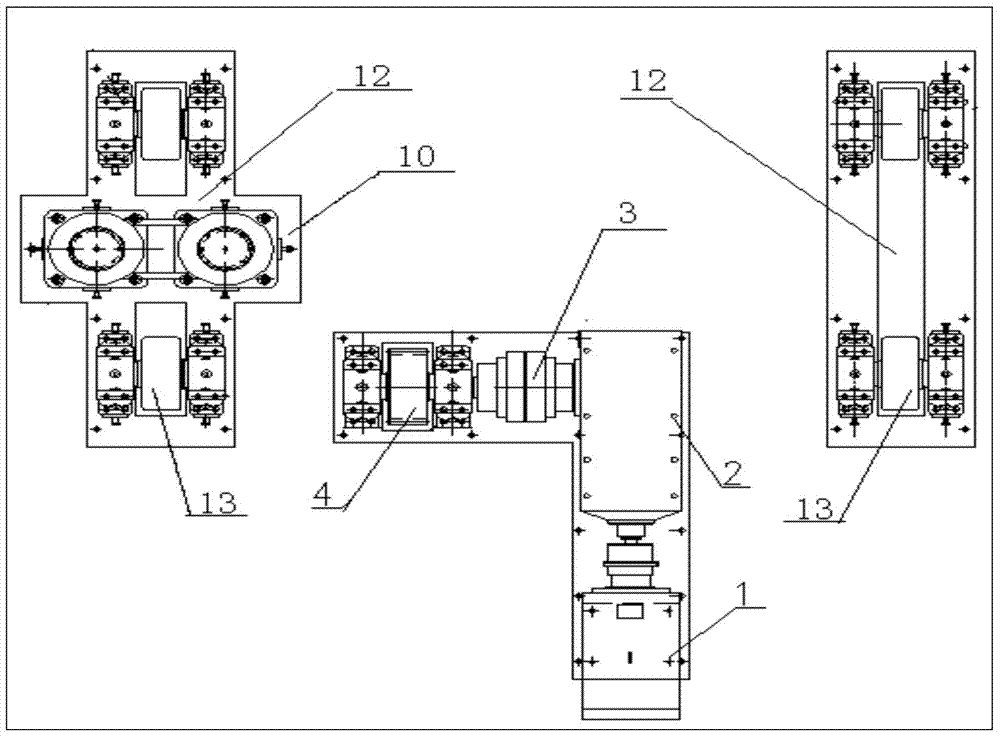

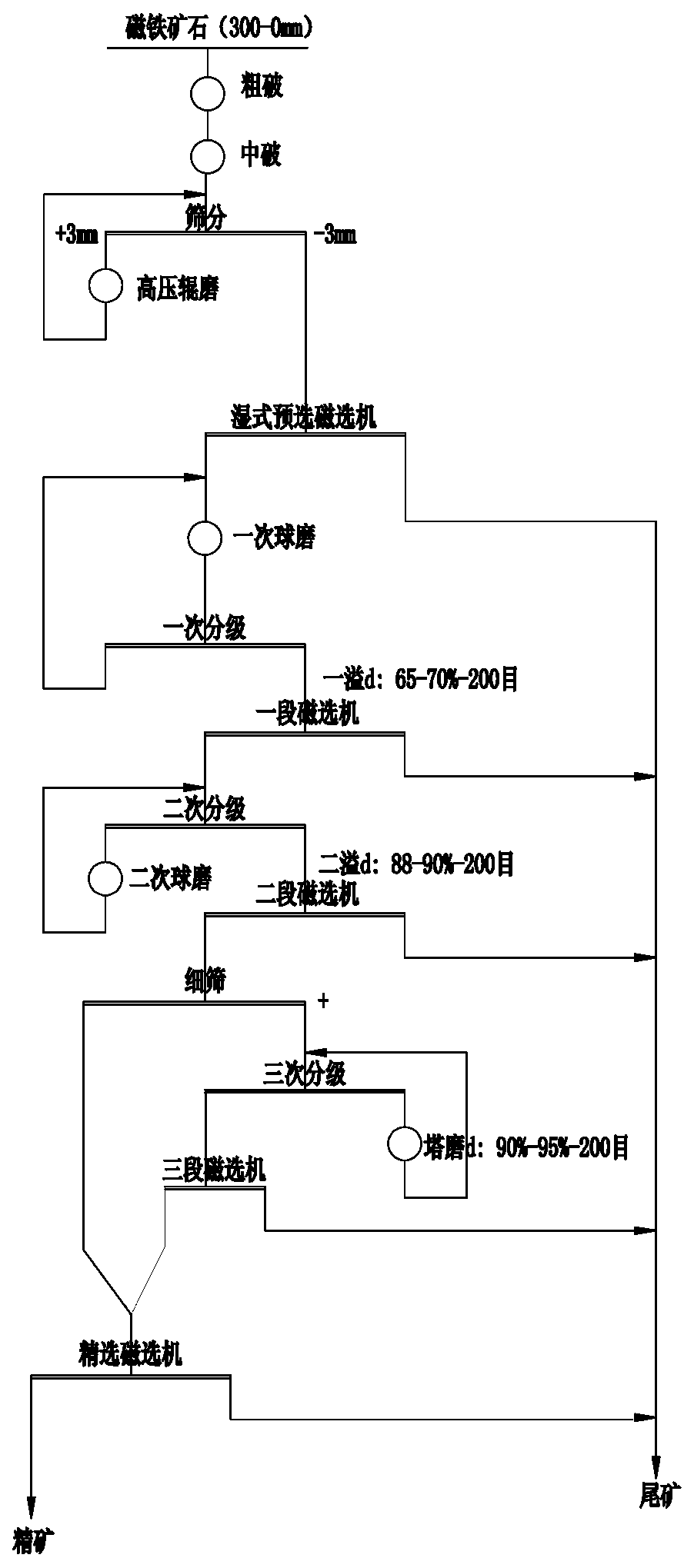

Novel composite lean iron ore pre-concentration technology and production system thereof

ActiveCN104722394AReduce power consumptionReduce consumptionSievingScreeningAssembly lineHigh intensity

The invention discloses a novel composite lean iron ore pre-concentration technology and a production system thereof, and belongs to the technical field of ore concentration. The novel composite lean iron ore pre-concentration technology includes the steps that composite lean iron ore is crushed; the crushed products are smashed to be phi 3 mm through a high-pressure roller milling screen fully-closed superfine crushing technology; a wet low-intensity magnetic separation and wet high-intensity magnetic separation combined technology is carried out; concentrate of a low-intensity magnetic separation machine and concentration of a high-intensity magnetic separation machine are mixed and then later ball milling grading starts; tailings of the high-intensity magnetic separation machine enters a linear vibration screen II for dehydration. The production system of the novel composite lean iron ore pre-concentration technology comprises a high-pressure roller grinding machine, a wet efficient beating machine, a linear vibration screen I, the low-intensity magnetic separation machine, the high-intensity magnetic separation machine and the linear vibration screen II which are sequentially distributed on a production assembly line according to the process sequence. By means of the technology and the system, a large amount of qualified tailings can be abandoned before the composite lean iron ore is ground, the grinding amount is lowered, and the aims that more tailing is crushed, little tailing is ground and the tailing is abandoned earlier are achieved.

Owner:ANHUI MASTEEL ENG & TECH GRP

Co-processing and water reclamation method for garbage fly ash through cement kiln

ActiveCN105107821ANo secondary pollutionAvoid pollutionGeneral water supply conservationSolid waste disposalReverse osmosisMembrane distillation

The invention relates to a co-processing and water reclamation method for garbage fly ash through a cement kiln. The co-processing and water reclamation method for the garbage fly ash through the cement kiln includes a three-stage water washing desalination and microorganism dioxin removal process, a micellar-enhanced heavy metal removal process, a nanofiltration process, a reverse osmosis pre-concentration process, a membrane distillation concentration process, a trace carnallite removal process and a mechanical vapor recompression (MVR) evaporative crystallization process. Heavy metal and chloride ions in the fly ash can be removed through the three-stage water washing desalination and microorganism dioxin removal process, and the fly ash with the dioxin eroded by microorganisms can serve as building materials. Heavy metal, calcium and magnesium in the fly ash can be removed through the micellar-enhanced heavy metal removal process, and sediment is pre-desiccated and then enters the cement kiln to be combusted. Residual calcium and magnesium in washing water are removed through the nanofiltration process. The washing water can be concentrated to 6-8% through the reverse osmosis pre-concentration process, and produced water is reused. Chloride ions in a solution can be removed through the membrane distillation concentration process, and produced distilled water can be reused. Trace carnallite is removed through the trace carnallite removal process. Concentrated liquor is evaporated and separated through the MVR evaporative crystallization process, so that industrial salt is obtained.

Owner:湖州京兰环保科技有限公司

Production method of complete biodegradable aliphatic polyester

The invention discloses a production method of complete biodegradable aliphatic polyester. The production method comprises the following three steps: (1) an esterification phase that: aliphatic dibasic acid monomer and aliphatic dibasic alcohol monomer are added to a reactor according to certain proportions, an esterification catalyst is added, and a normal-pressure esterification reaction is carried out under the protection of an inert gas; (2) a pre-concentration phase that: when the esterification reaction is completely finished, a main catalyst is added, and the mixture is subject to a reaction for 1 to 2 hours; (3) a concentration phase: an auxiliary catalyst is added, and the mixture is subject to a reaction for 4 to 9 hours, such that aliphatic ???? with a weight average molecular weight greater than 150 thousands is obtained. The polyester product provided by the present invention has good heat stability, stretching ductility, environment friendly performance and a good color, and can be biodegraded.

Owner:ZHEJIANG BILI PACKAGING

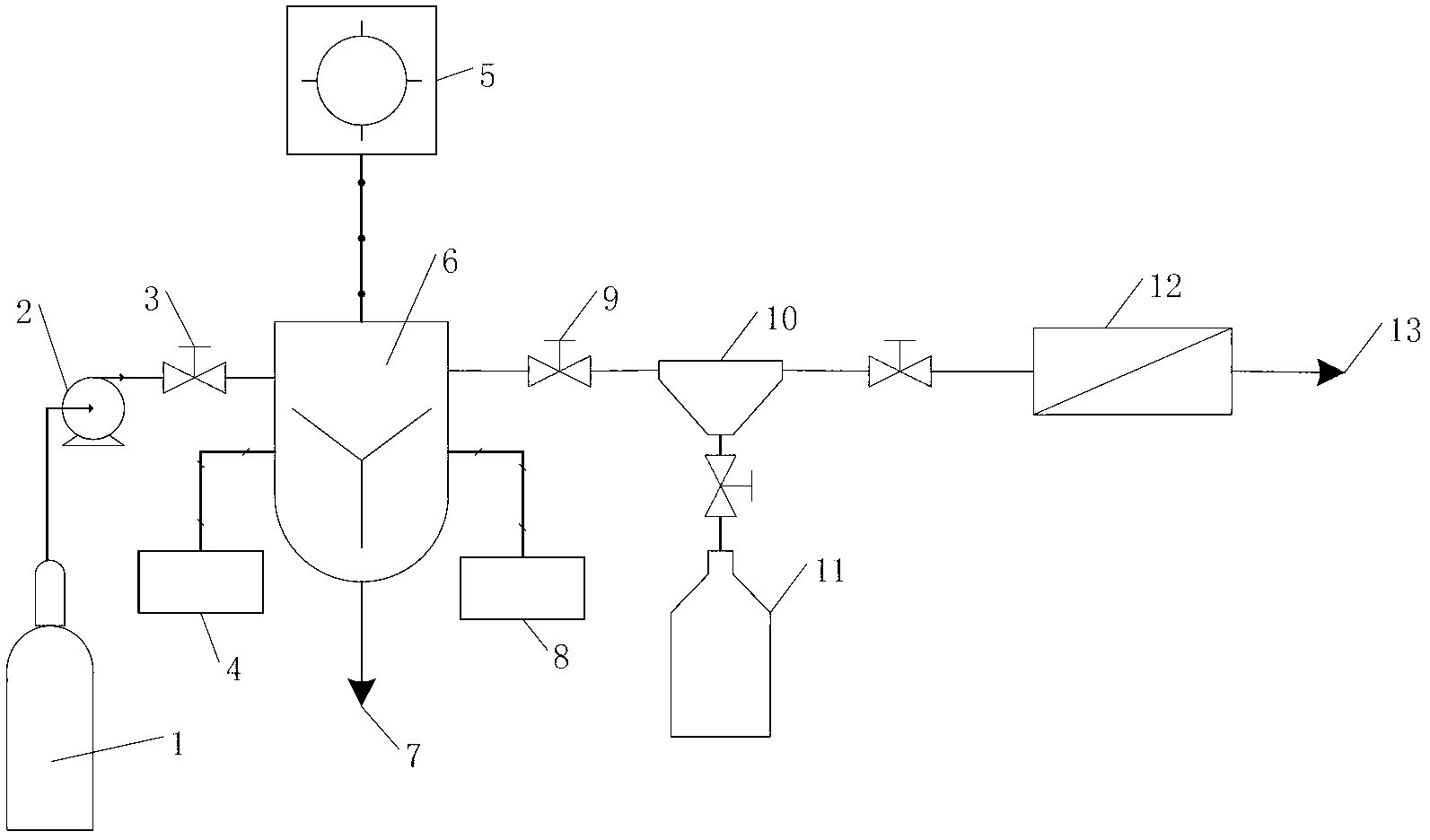

A device for remediation of organic contaminated soil by using supercritical CO2 fluid and a remediation method

InactiveCN103230932AReduce dosageNo pollution in the processContaminated soil reclamationCo2 storageInlet valve

The invention belongs to the technical field of environmental protection and pollution control, and in particular relates to a device for remediation of organic contaminated soil by using supercritical CO2 fluid and a remediation method. The device of the invention is composed of a CO2 storage tank, a pressure pump, an inlet valve, a pressure monitoring device, a soil pretreatment device, a stirring extraction vessel, a temperature control device, a pressure reducing valve, a gas-liquid separator, an organic pollutants storage tank and an organic pollutants filtering device. The method of the invention has the characteristics such as short extraction time, less solvent consumption, easy operation, high extraction efficiency, no pollution, and highly selective extraction realized through changing extraction conditions. Compared with traditional extraction techniques such as Soxhlet extraction, ultrasonic extraction, and accelerated solvent extraction, the method of the invention has the advantages such as short extraction time, no need of pre-concentration and purification, and no secondary pollution generated.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

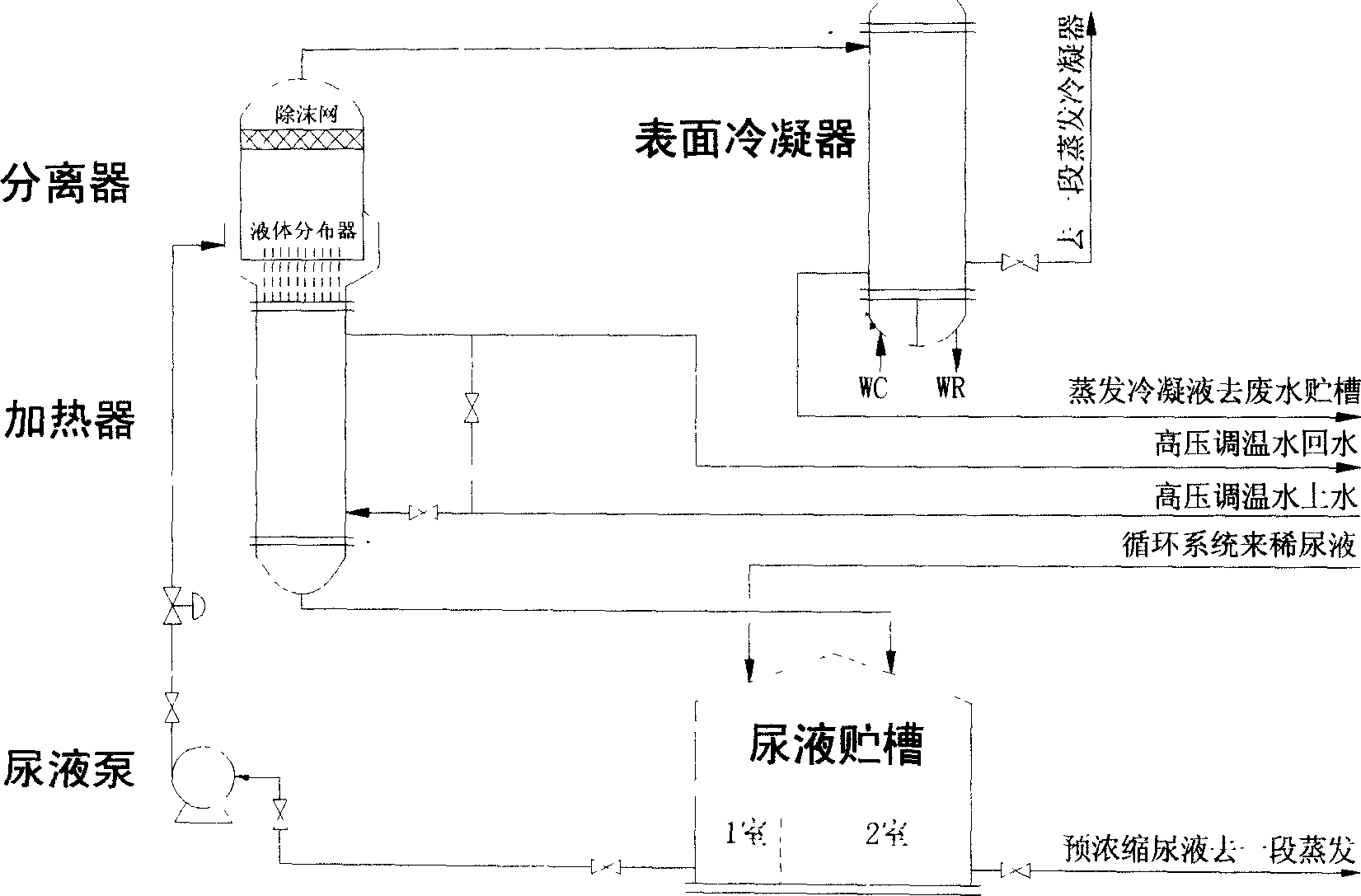

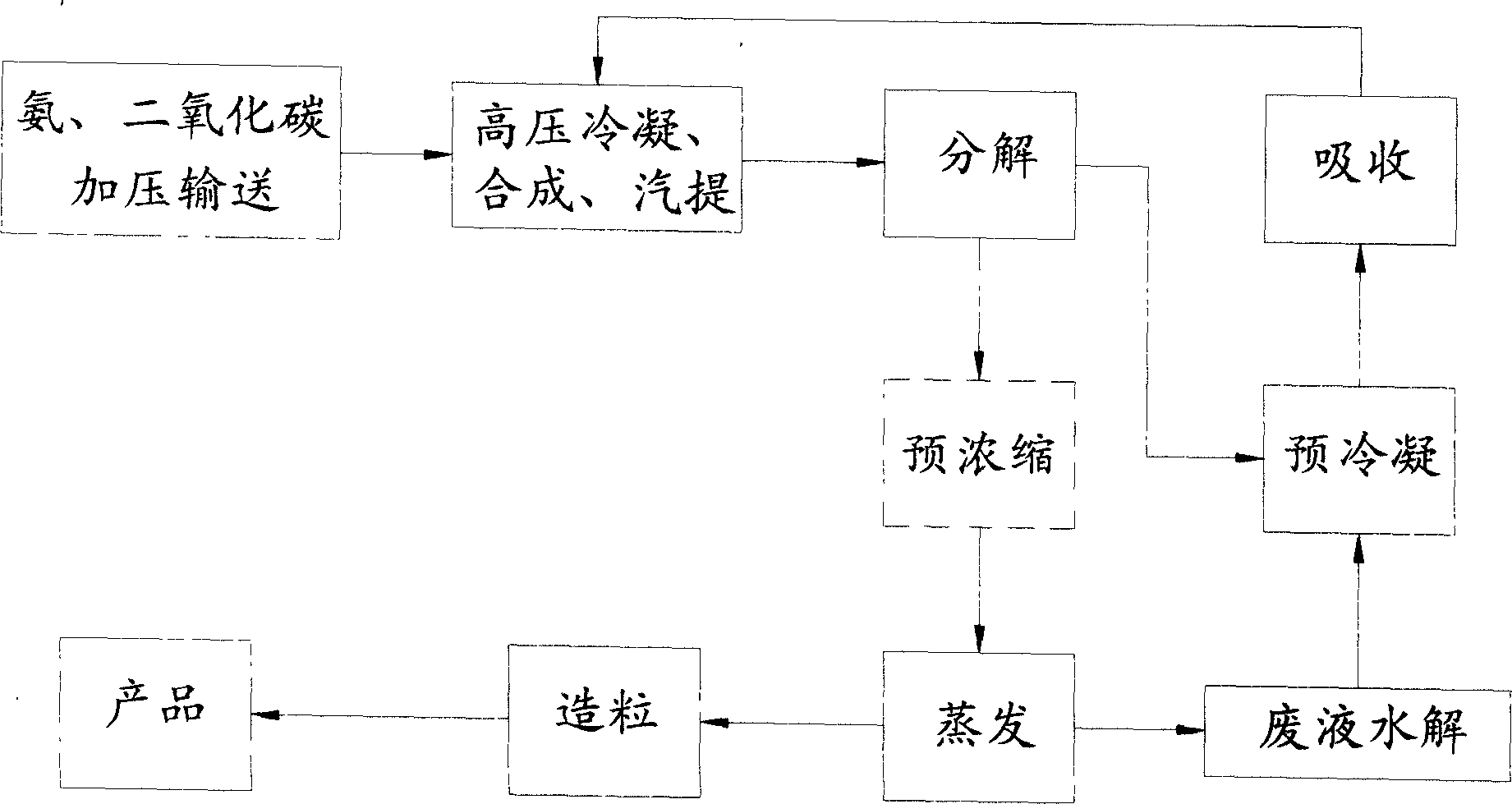

Method for concentrating thin urine using falling film type evaporation heater

ActiveCN1749242ACondition independentStable working conditionUrea derivatives preparationOrganic compound preparationEvaporationBottle neck

The present invention discloses method of concentrating thin urea liquid with falling film type evaporation heater. In the urea producing apparatus on CO2 vaporizing extract process, the falling film type evaporation heater is set behind circulation section and before the evaporation section, and urea liquid through the liquid distributor flows along the inner walls of the tube array from up to down to evaporate partial water and raise concentration, with the vacuum condition of the pre-concentration system being maintained with the surface condenser and the first section evaporation jetting pump. The present invention has the advantages of eliminating bottle neck in the evaporation system, independent and stable evaporation condition, and utilization of afterheat of the high pressure washer to save energy.

Owner:SICHUAN LUTIANHUA

Gravity separation and floatation combined separating technology for antimony oxide ores

The invention discloses a gravity separation and floatation combined separating technology for antimony oxide ores. A selective crushing technology is adopted for a quartz-calcite antimony oxide ore containing 0.50%-7.50% of Sb; over-crushing and argillation of the antimony oxide are reduced; the pre-concentration for the antimony oxide is realized by adopting a gravity separation method; the pH of the pulp of a rough concentrate obtained from the gravity separation is adjusted to 9-11; primary amine cation collecting agents are added and the reverse flotation is performed for removing carbonate gangue ores; the pH of the pulp of the product in a tank obtained from the reverse flotation is adjusted to 6-8; metal ions are added as antimony oxide flotation activating agents; an organic inhibitor is added for inhibiting quartz gangue ores; and alkyl sulfate anion collecting agents are added for performing floatation on the antimony oxide ores, so that the floatation separation of the antimony oxide and quartz gangue ores is realized. The gravity separation and floatation combined separating technology for the antimony oxide ores provided by the invention is suitable for the treatment of middle / low-grade antimony oxide ores. Compared with the grade and the recovery rate of the antimony oxide concentrate obtained according to a single gravity separation technology, the grade and the recovery rate of the antimony oxide concentrate obtained according to the gravity separation and floatation combined separating technology are both obviously increased.

Owner:CENT SOUTH UNIV

Parallel concentration, desalting and deposition onto MALDI targets

InactiveUS7015465B2Improve throughputHigh sensitivityComponent separationSamples introduction/extractionAnalyteGradient elution

A method and apparatus for the continuous deposition of RP HPLC eluent, from isocratic or gradient elutions, on to a MALDI target using a parallel sample desalting method, allows increased sensitivity of the MALDI sample by pre-concentration of the analyte, separation of interfering contaminants from the analyte and increased dynamic range of peptide abundance that can be analyzed. The parallel processing of sample material allows greater throughput than that of manual methods.

Owner:WATERS TECH CORP

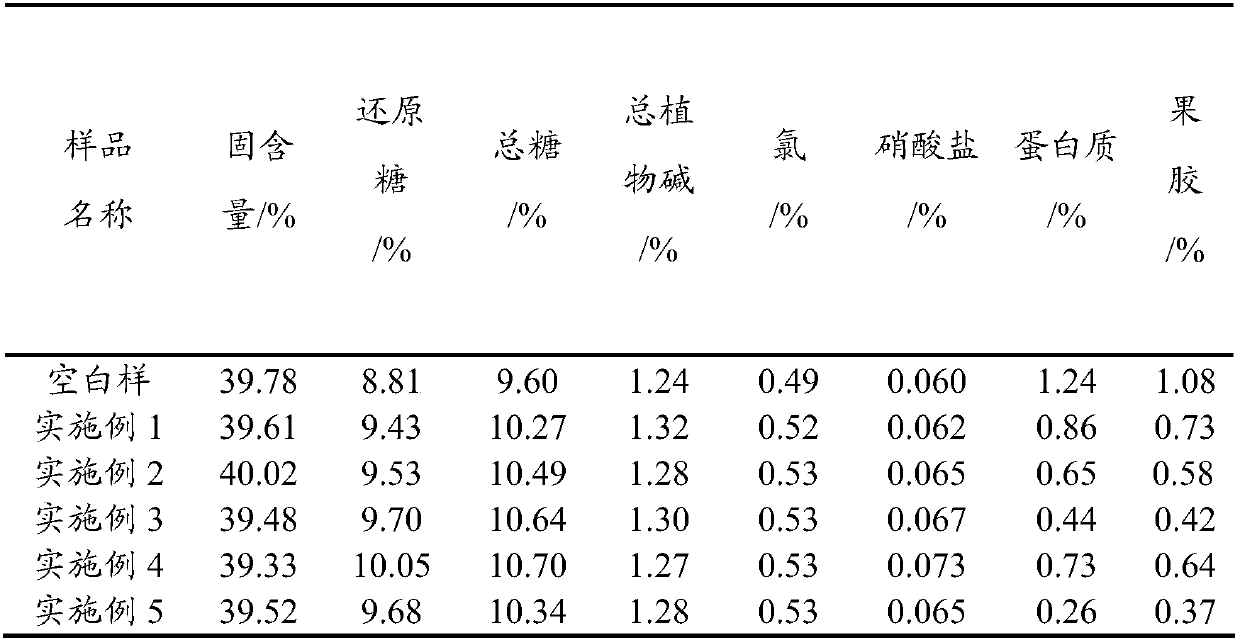

Method for improving sensory quality of reconstituted tobacco

The invention provides a method for improving the sensory quality of reconstituted tobacco. Tobacco raw materials are extracted and separated to obtain extraction solution solid and an extraction solution, the extraction solution solid and added wood pulp are pulped and then mixed, and papermaking and forming are conducted to obtain a reconstituted tobacco substrate; the extraction solution is concentrated to obtain a tobacco concentrated solution, then materials are added to prepare coating liquid, the reconstituted tobacco substrate is coated with the coating liquid, and the papermaking method reconstituted tobacco can be obtained through drying and slitting procedures. The method is characterized in that after the extraction solution is extracted and before concentration, the extraction solution is subjected to flocculation purification through chitosan liquid, and then alcohol precipitation purification treatment is conducted after pre-concentration. The chitosan flocculation and alcohol precipitation treatment technology are comprehensively used, the reconstituted tobacco extraction solution is purified, protein, pectin and other large molecules are selectively removed, and the sensory quality of the papermaking method reconstituted tobacco is improved.

Owner:HUBEI CHINA TOBACCO IND

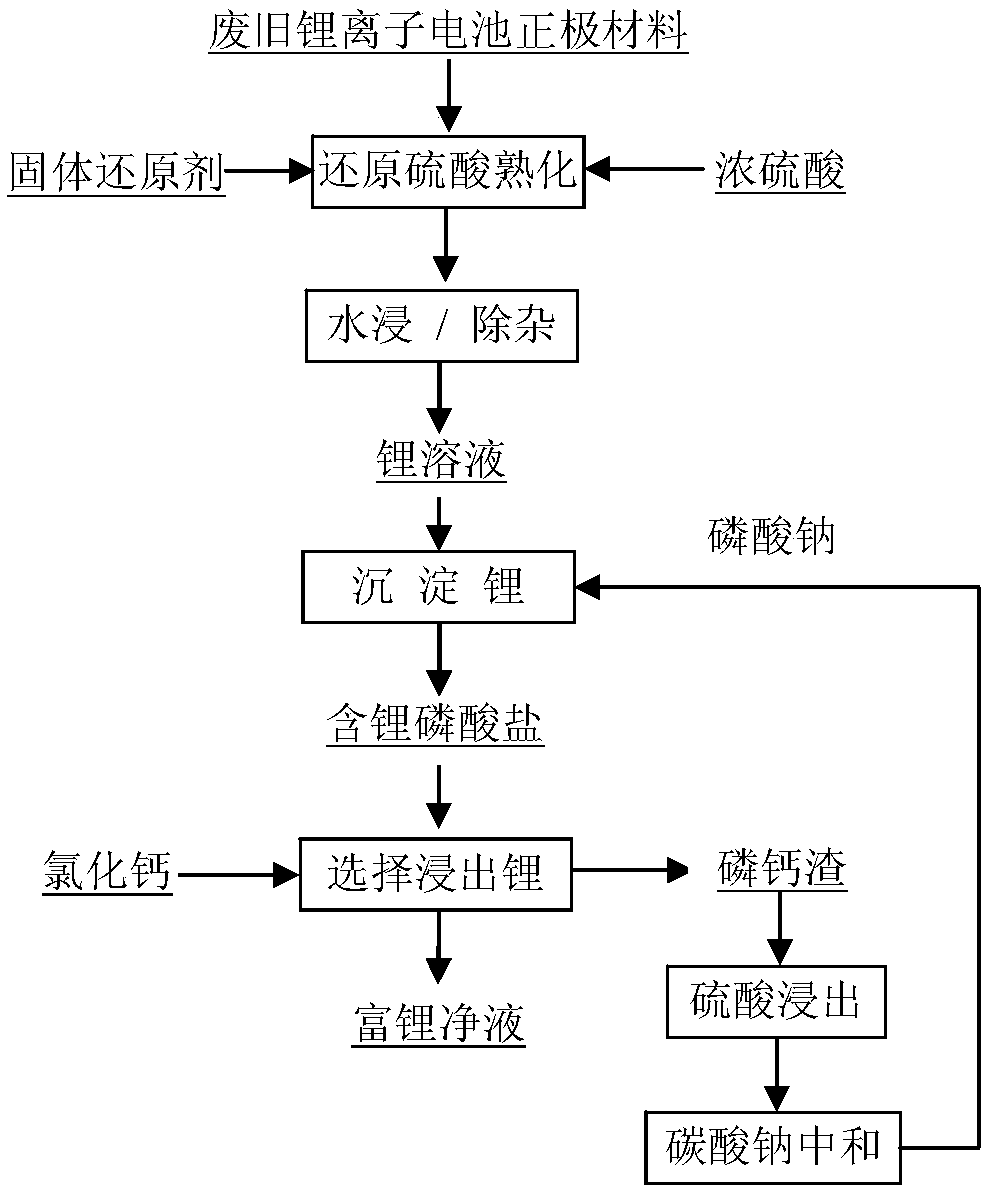

Method for producing lithium-rich pure solution from waste lithium ion battery positive electrode active material

ActiveCN108767353AHigh recovery rateAvoid pre-concentrationWaste accumulators reclaimingBattery recyclingHigh sodiumLithium chloride

The invention discloses a method for producing a lithium-rich pure solution from a waste lithium ion battery positive electrode active material, belongs to the technical field of waste lithium ion battery material recycling, and particularly provides a method for producing a lithium-rich pure solution from a reduced sulfuric acid leaching solution of a positive electrode active material. A high-sodium and low-lithium lithium sulfate solution obtained after the positive electrode active material is subjected to reduction leaching and leaching solution purification is subjected to lithium deposition with phosphoric acid or phosphate to obtain lithium-containing phosphate enrichment; lithium is selectively leached out from the lithium-containing phosphate enrichment by using less than a theoretically required amount of a calcium chloride solution to obtain the lithium-rich pure solution and lithium-containing phosphorus-calcium residues; and the lithium-containing pure solution is used for producing a product such as battery-grade lithium carbonate or lithium chloride through a conventional method such as deposition or crystallization, and a solution obtained after the lithium-containing phosphorus-calcium residues are subjected to sulfuric acid leaching and neutralization returns to the lithium deposition step for cyclic use. According to the method, the lithium-rich pure solution can be directly produced from the high-sodium and low-lithium solution without pre-concentration, the energy consumption and the cost are low, and the lithium recycling rate is high.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

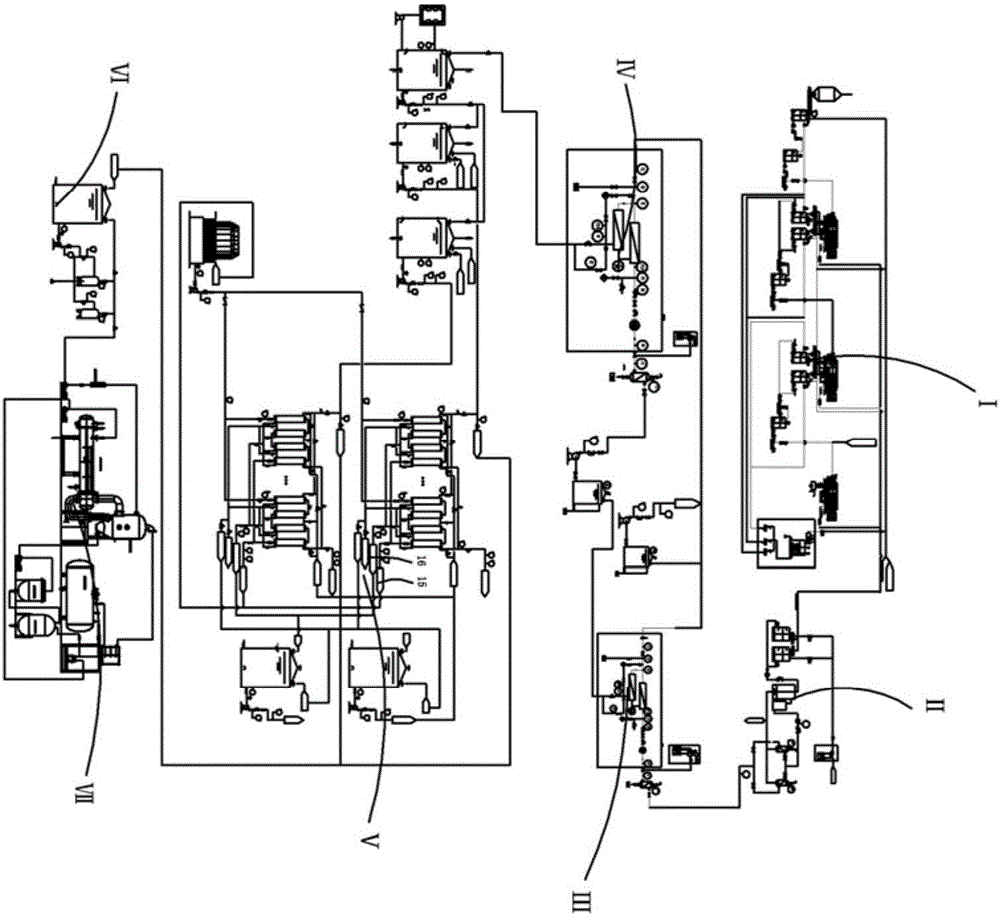

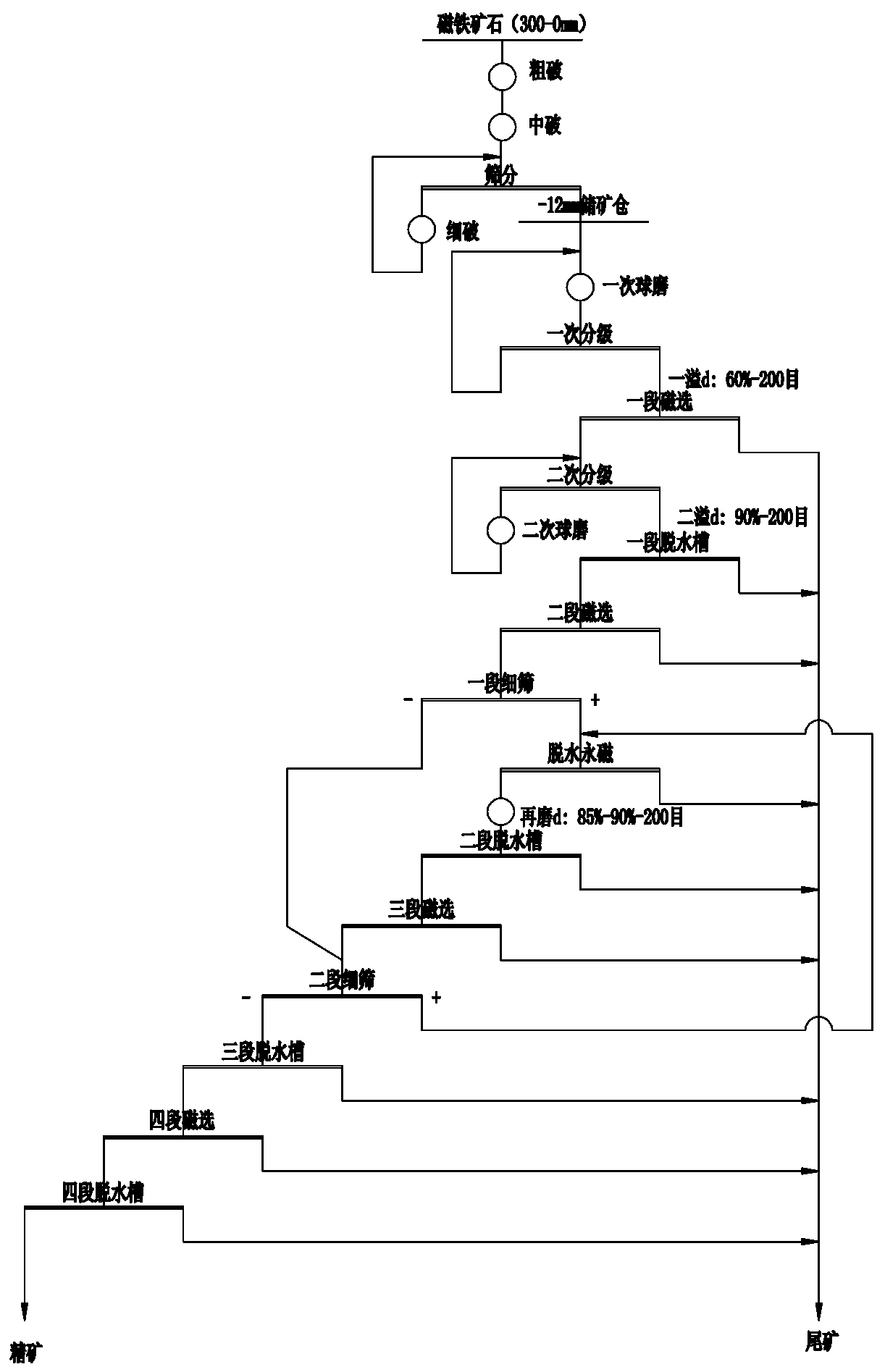

Magnetite high compression rolling wet pre-concentration-stage grinding-fine screen tower rolling magnetic separation process

The invention relates to a magnetite high compression rolling wet pre-concentration-stage grinding-fine screen tower rolling magnetic separation process. The process comprises coarse breaking and mildbreaking, and is characterized by further comprising the following steps that ores with the grade being 30%-32% and the granularity being -25mm are subjected to closed circuit high compression rolling; rolling products are subjected to beforehand magnetic separation; premagnetization concentrates are subjected to first-stage closed-circuit grinding; primary overflow is subjected to first-stage magnetic separation; first-stage magnetic separation concentrates are subjected to second-stage closed-circuit grinding; secondary overflow is subjected to second-stage magnetic separation and fine screening; screen residues are subjected to third-stage closed-circuit tower milling and grinding; third-time graded overflow products are graded by a third-stage magnetic separator; concentrates of the third-stage magnetic separator and screen underflow products are subjected to fine magnetic separation to obtain 67%-67.5% final concentrates; and tailings of all stages of magnetic separation work arecombined to be combined tailings. The magnetite high compression rolling wet pre-concentration-stage grinding-fine screen tower rolling magnetic separation process has the advantages that (1) high compression rolling pre-concentration is conducted, so that the particle size of grinding feed is reduced, and the grade of crude ores and grinding fineness are improved; (2) a cyclone and a tower millare combined, so that one stage of fine screening and multiple stages of magnetic separation operation are omitted; (3) the flow is simplified, and the ore mineral separation cost is lowered.

Owner:ANSTEEL GRP MINING CO LTD

Homogeneous ion-exchange membrane electrodialysis reduction treatment process for desulfurization waste water of coal-fired power plant

ActiveCN106242133AReduce energy consumptionImprove efficiencyWater/sewage treatmentWaste water treatment from gaseous effluentsReduction treatmentReverse osmosis

The invention belongs to the field of water treatment and particularly relates to a homogeneous ion-exchange membrane electrodialysis reduction treatment process for desulfurization waste water of a coal-fired power plant. The process comprises the following steps of: (1) filtering the desulfurization waste water by virtue of a tube-type microfiltration device; (2) performing pre-concentration on the clarified desulfurization waste water obtained in the step (1) by virtue of a reverse osmosis apparatus; (3) returning reverse osmosis fresh water obtained in the step (2) to a desulfurizing tower; (4) performing primary concentration on the pre-concentrated desulfuration waste water obtained in the step (2) by virtue of a primary electrodialysis device, thereby obtaining primarily concentrated desulfuration waste water; (5) returning primary electrodialysis fresh water obtained in the step (4) to a first regulating tank; and (6) sucking the primarily concentrated desulfuration waste water obtained in the step (4) from a first water concentration tank into a third regulating tank, then performing deep concentration by use of a secondary electrodialysis device so as to obtain deep concentrated desulfuration waste water, and enabling the deep concentrated desulfuration waste water to flow into a second water concentration tank, thereby realizing desulfuration waste water reduction treatment.

Owner:XIAMEN KENING WOTE WATER TREATMENT TECH

Novel process for producing high-purity lithium hydroxide from salt lake brine

ActiveCN108660476AOptimize acid and alkali consumptioOptimize product lossElectrolysis componentsLithium halidesElectrolysisLithium chloride

The invention discloses a novel process for producing high-purity lithium hydroxide from salt lake brine. The process comprises the following steps of A, an operating mode; and B, raw materials; in the step A, continuous operation is adopted by the process, the scale of each device is optimized through the data calculated by the process, the operating mode is optimized, and continuous operation isachieved; and in the step B, after salt lake brine is subject to lithium extraction (adsorption method or electrodialysis method), lithium-magnesium separation, purification and reverse osmosis pre-concentration, lithium chloride qualified solution and reverse osmosis pre-concentration qualified solution raw materials comprise 35-50 g / L of lithium chloride, 10 mg / L of calcium-magnesium ions and 200 mg / L of boron ion. According to the method, lithium chloride solution after the brine is subject to lithium extraction (the adsorption method or a membrane method), magnesium removal and reverse osmosis pre-concentration is taken as raw materials, and electrodialysis technology, reverse osmosis technology, resin adsorption technology, ion membrane electrolysis technology, evaporative crystallization technology and the like are adopted, so that high-purity lithium hydroxide products are produced, and a guarantee is provided for cyclic utilization of salt lake lithium resources.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com