Method for concentrating thin urine using falling film type evaporation heater

A heater and falling film technology, applied in the field of concentration, can solve problems such as unfavorable energy saving, and achieve the effects of independent working conditions, significant promotion significance, and significant energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

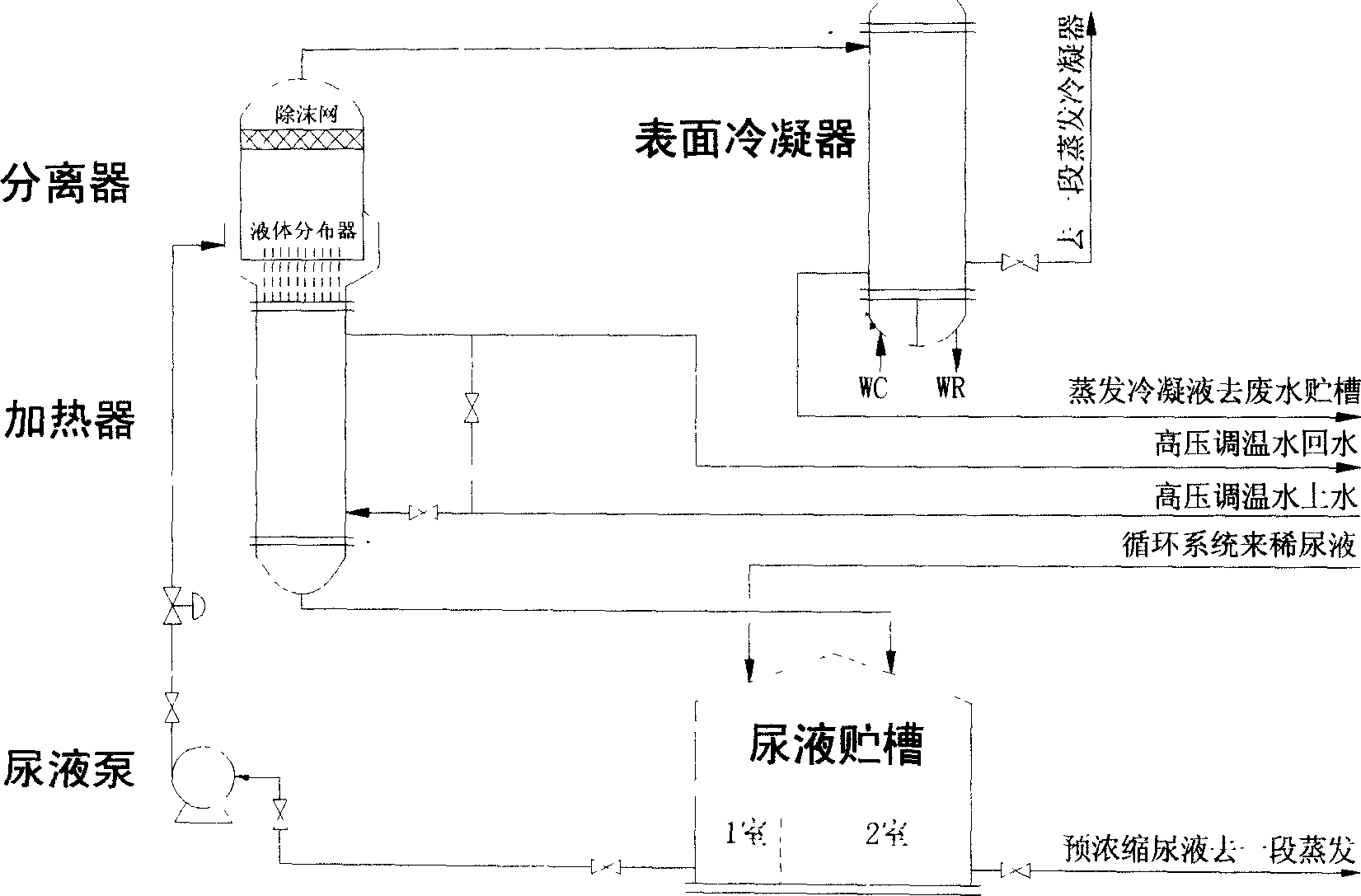

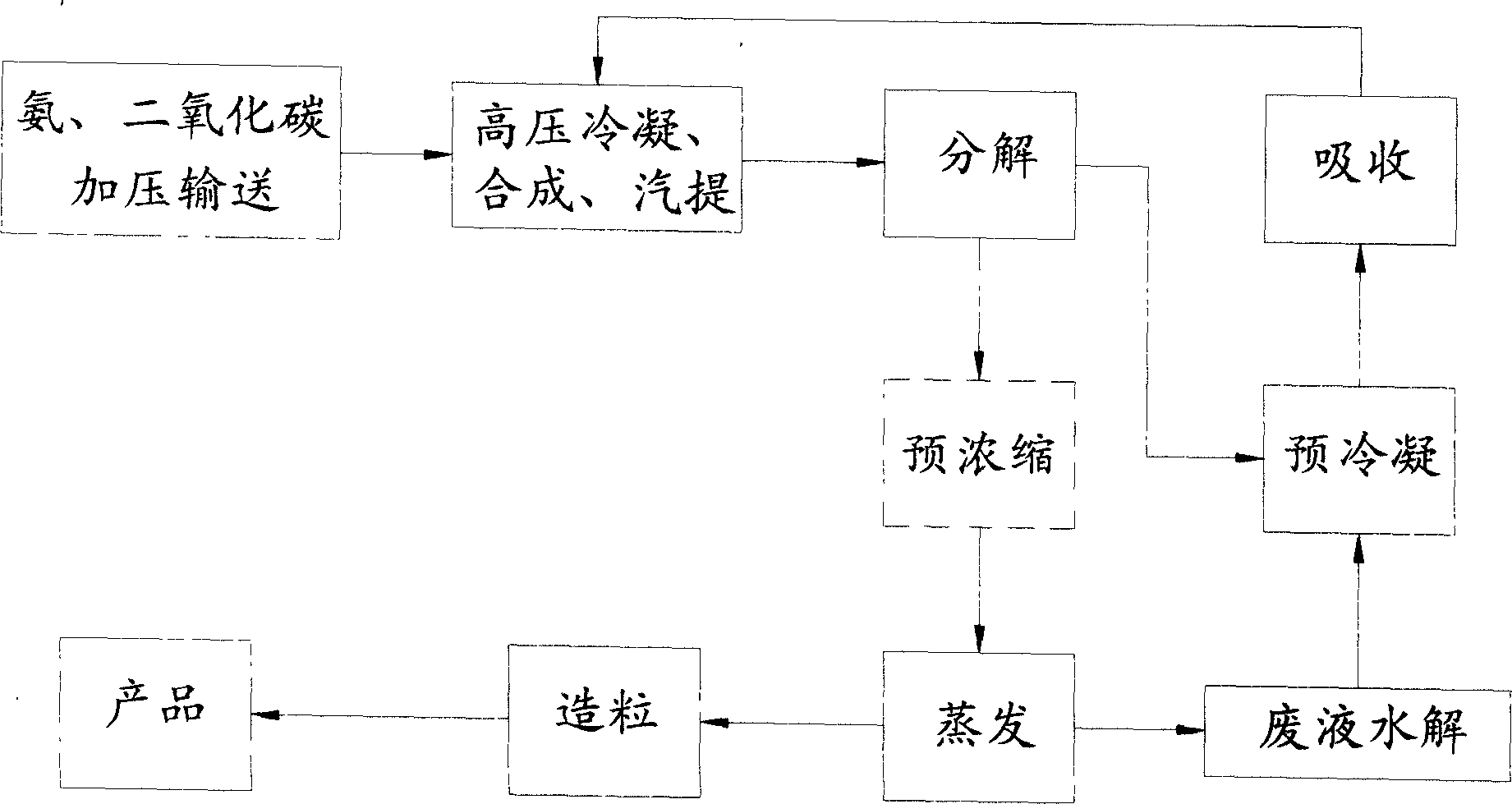

[0030] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, this embodiment is applied to a daily production of 1620 tons of CO 2 The process flow of the stripping urea plant, from the circulation system, the urine with a concentration of about 72% and a temperature of 95°C enters the first chamber of the urine storage tank, and is transported to the annular liquid inlet chamber at the lower part of the separator through a urine pump. Urine flow control is achieved by a manual regulator set on the outlet line. The urine, which is pre-divided by the bidirectional symmetrical liquid inlet method, descends to the upper tube plate of the heater along the periphery of the separator wall. At this position, an intercalated distributor is installed on the top of each tube. The four tangential holes distribute the urine to each tube of the evaporation heater, and form a liquid film on the inner wall of the tube, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com