Patents

Literature

71 results about "Surface condenser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of glycolaldehyde by hydrous thermolysis of sugars

ActiveUS7094932B2Increase productionMinimize formationOrganic compound preparationConfectioneryGlucose polymersD-Glucose

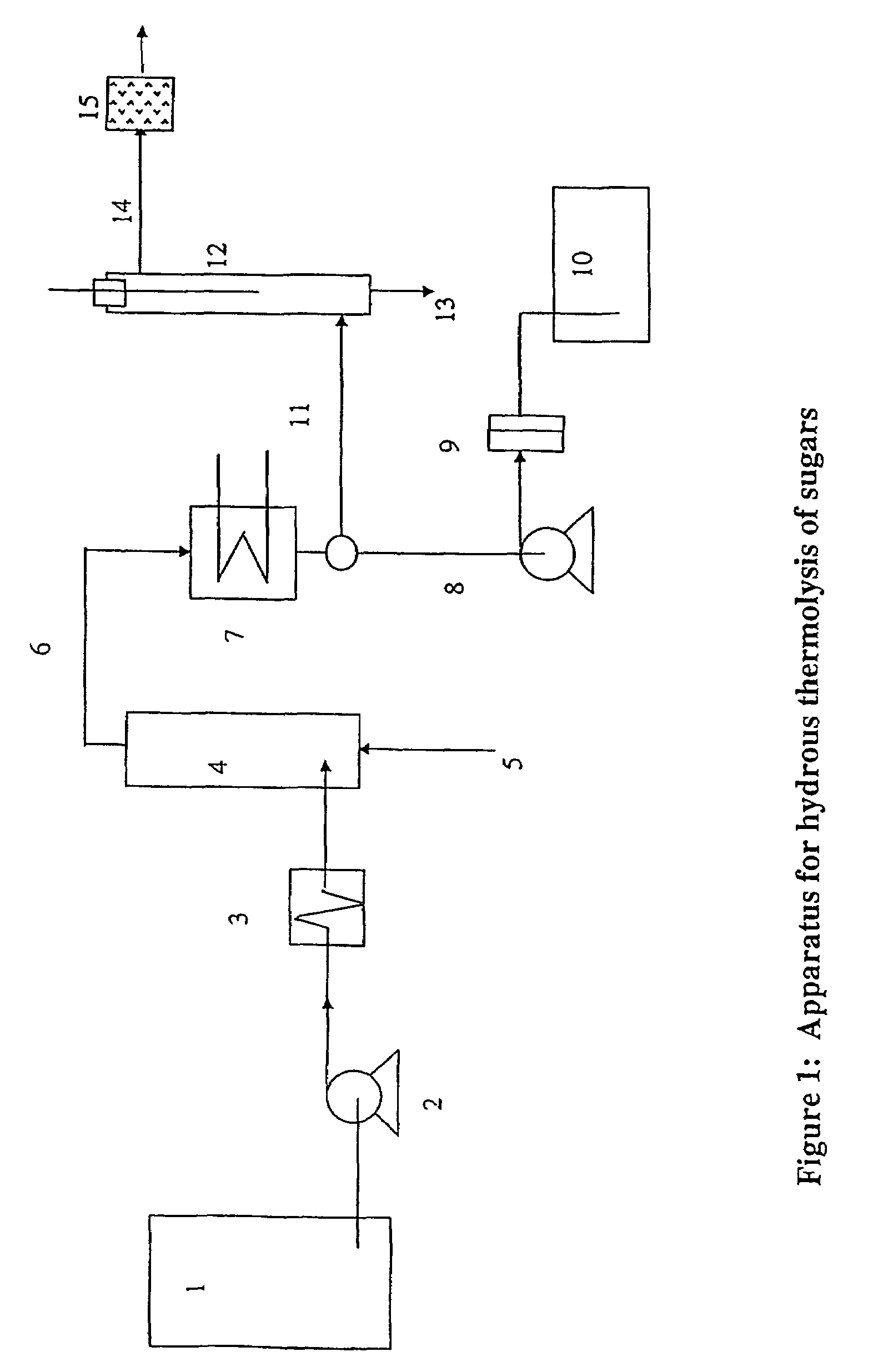

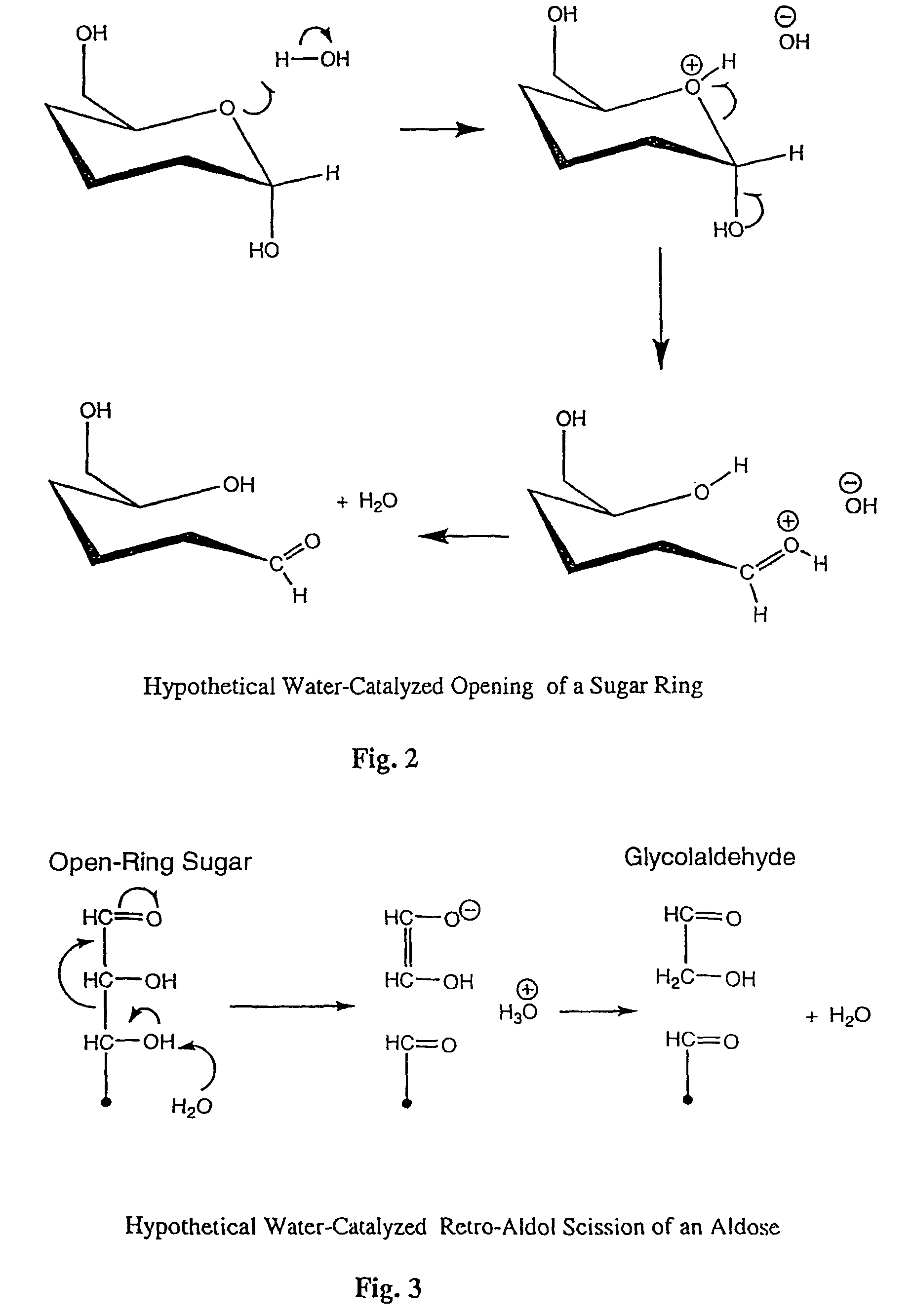

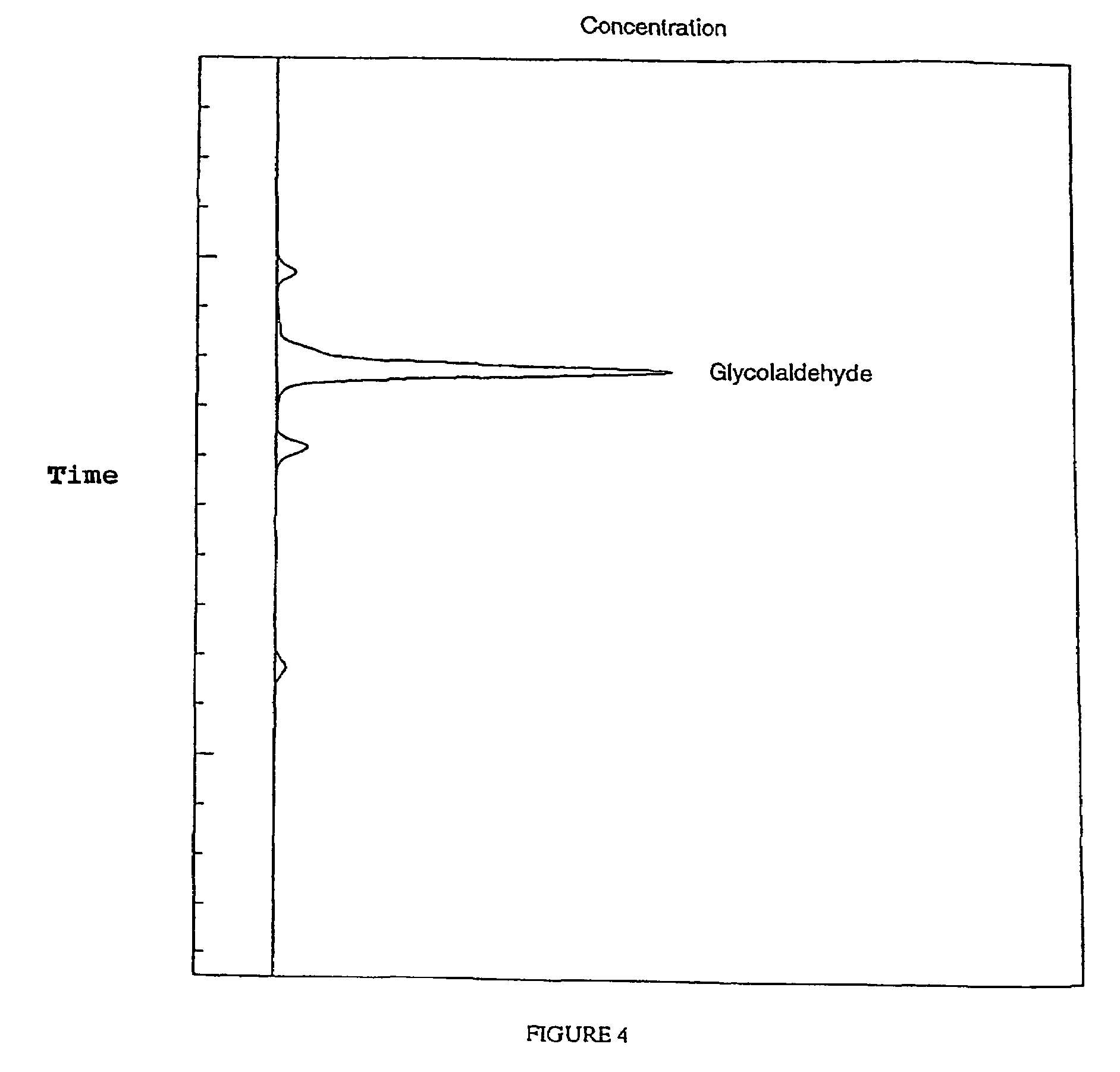

The present invention provides a method for the production of glycolaldehyde with high specificity. The hydrous thermolysis consists of the spraying of aqueous sugar solutions containing from 25 to 80% of water but preferably 30 to 60% water, as a fine mist into a reactor held at the between 500 and 600° C., but preferably between 520 and 560° C. and the condensation of the resulting vaporous product in a surface condenser with optional heat recovery. The residence time of the vaporous product in the reactor should be in the range 0.1–5 seconds, but preferably in the range 0.5 to 2 seconds. Aldose monomeric sugars, preferably glucose (also known as dextrose), are preferred for use in the aqueous solution. The yield of glycolaldehyde in the condensed liquid is minimum 50% by weight of the sugar fed for glucose solutions.

Owner:KERRY GRP SERVICES INT

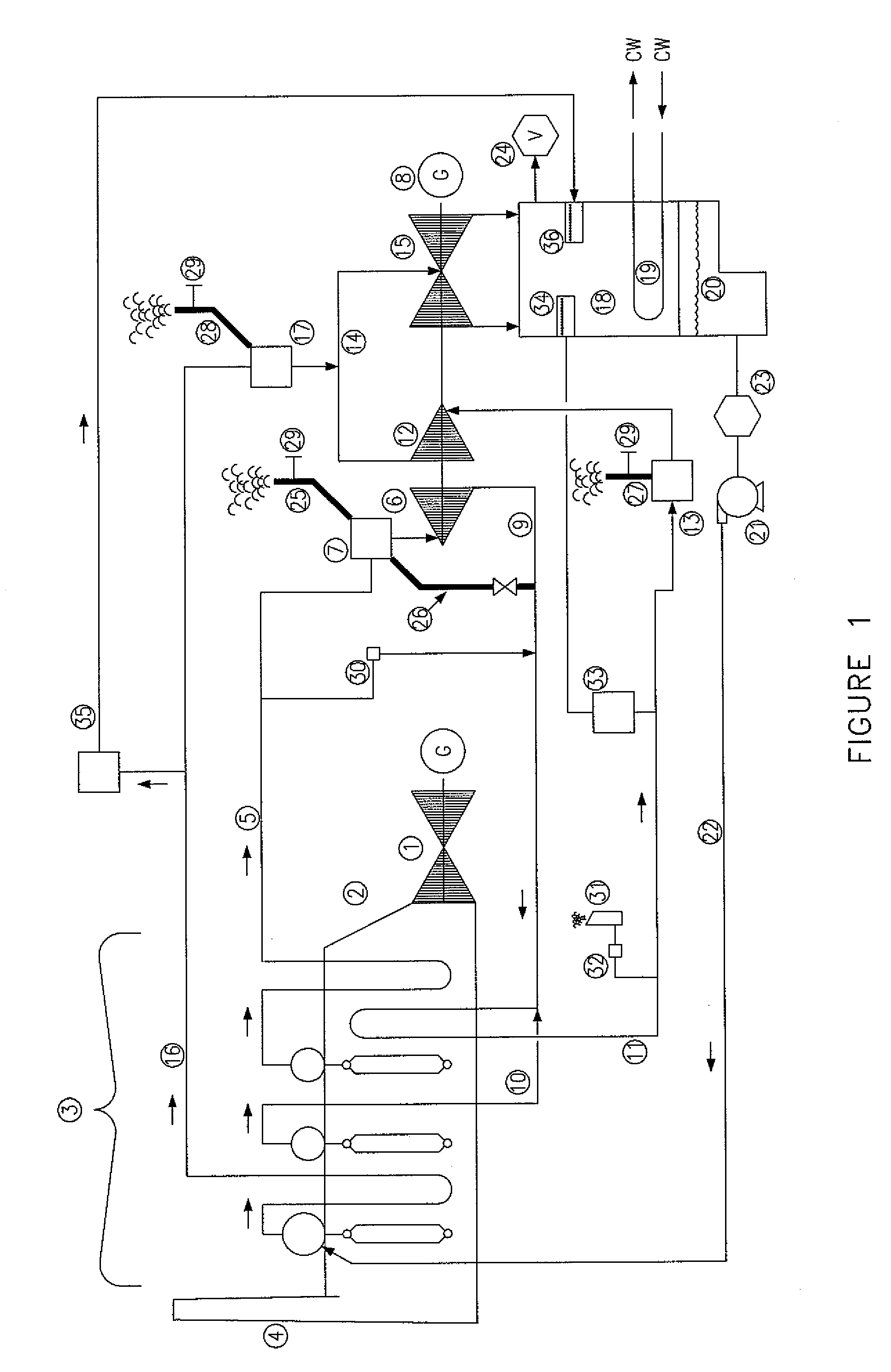

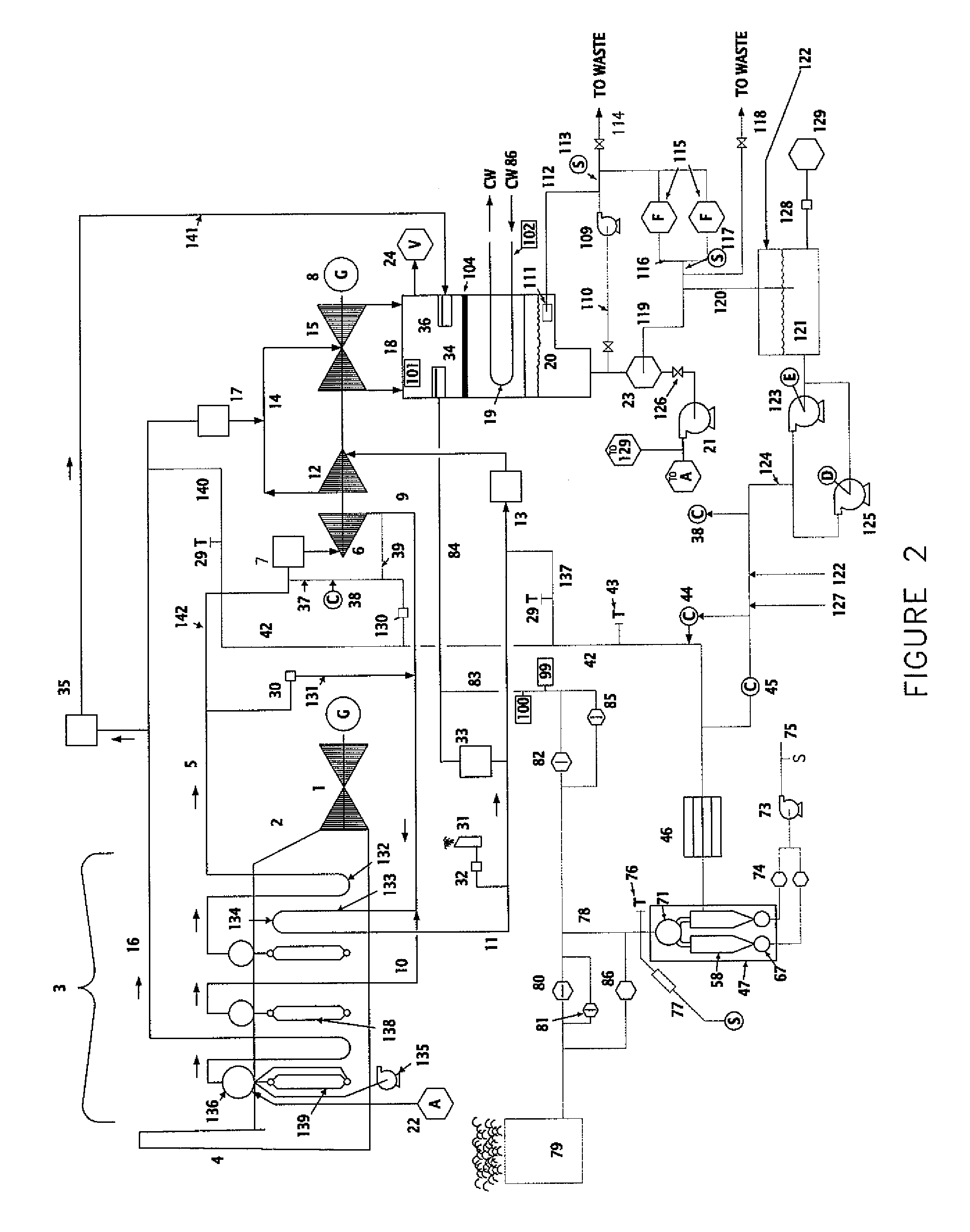

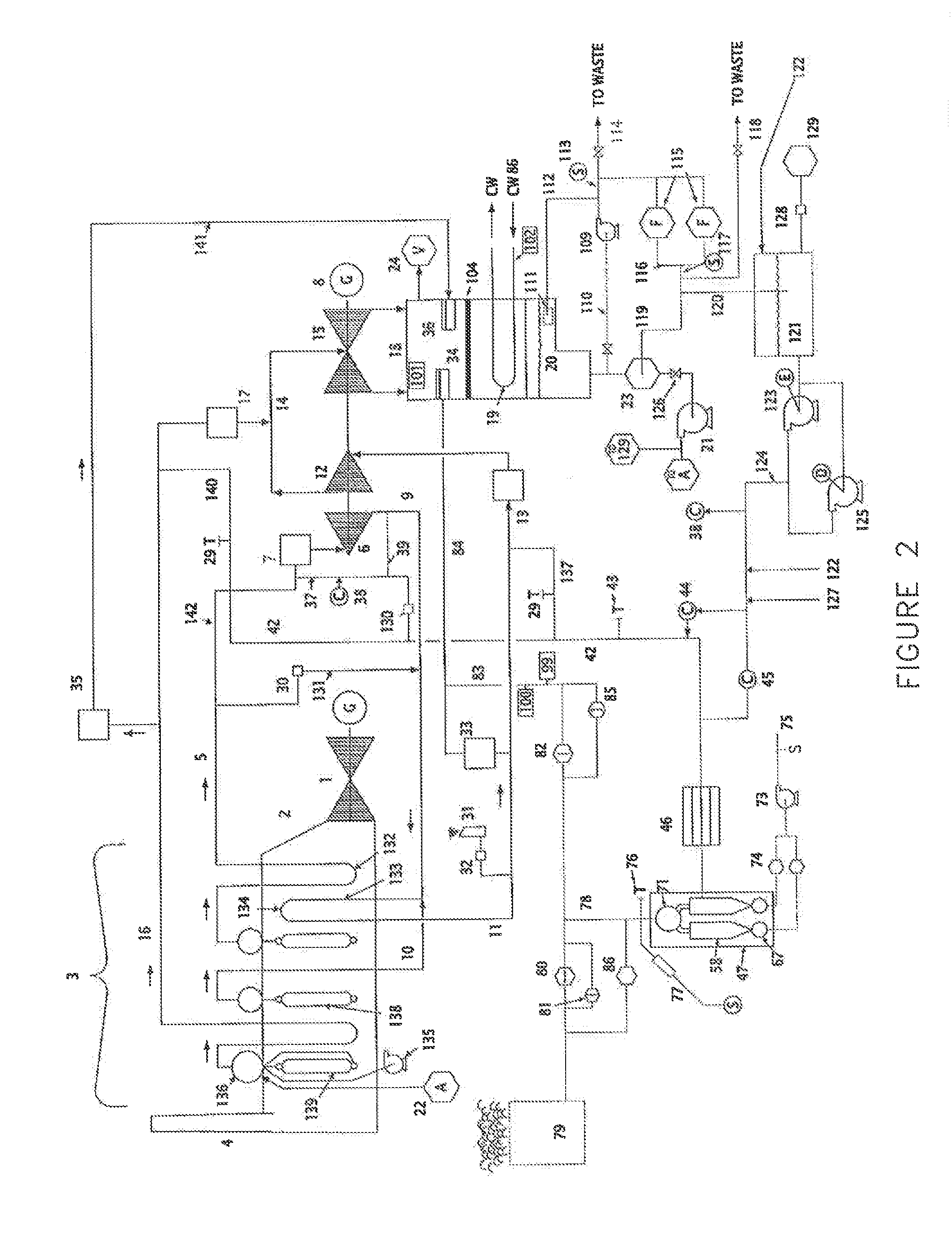

Method and apparatus for commissioning power plants

ActiveUS20080236616A1Reduce fuel consumptionReduce water consumptionLiquid degasificationDrying solid materials without heatPower stationEngineering

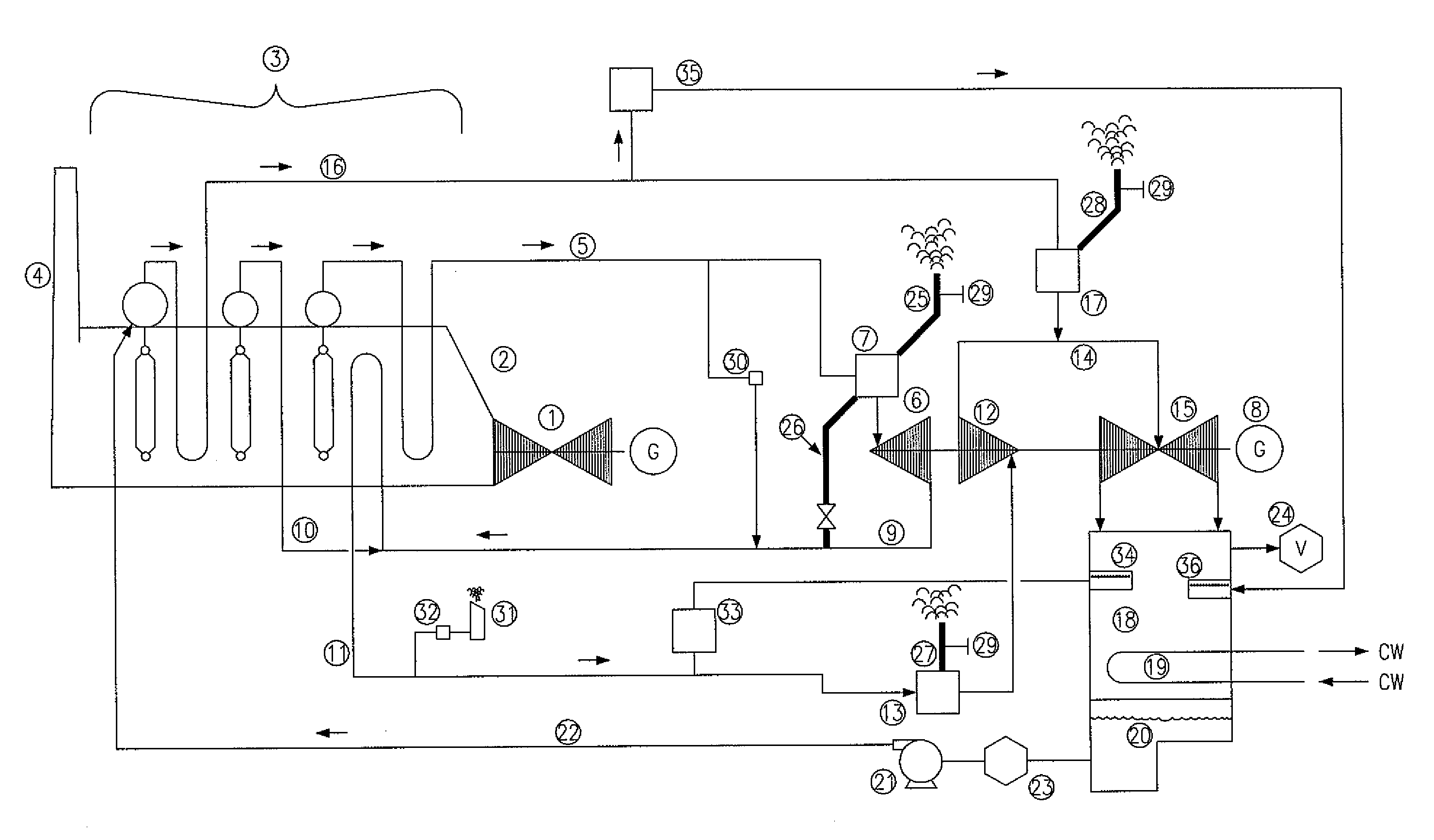

An apparatus and method for commissioning steam turbine generator power plants to advance the cleanliness of the complete steam cycle by the conditioned discharge of steam to the plant surface condenser.

Owner:BEST ENERGY SERVICES INC

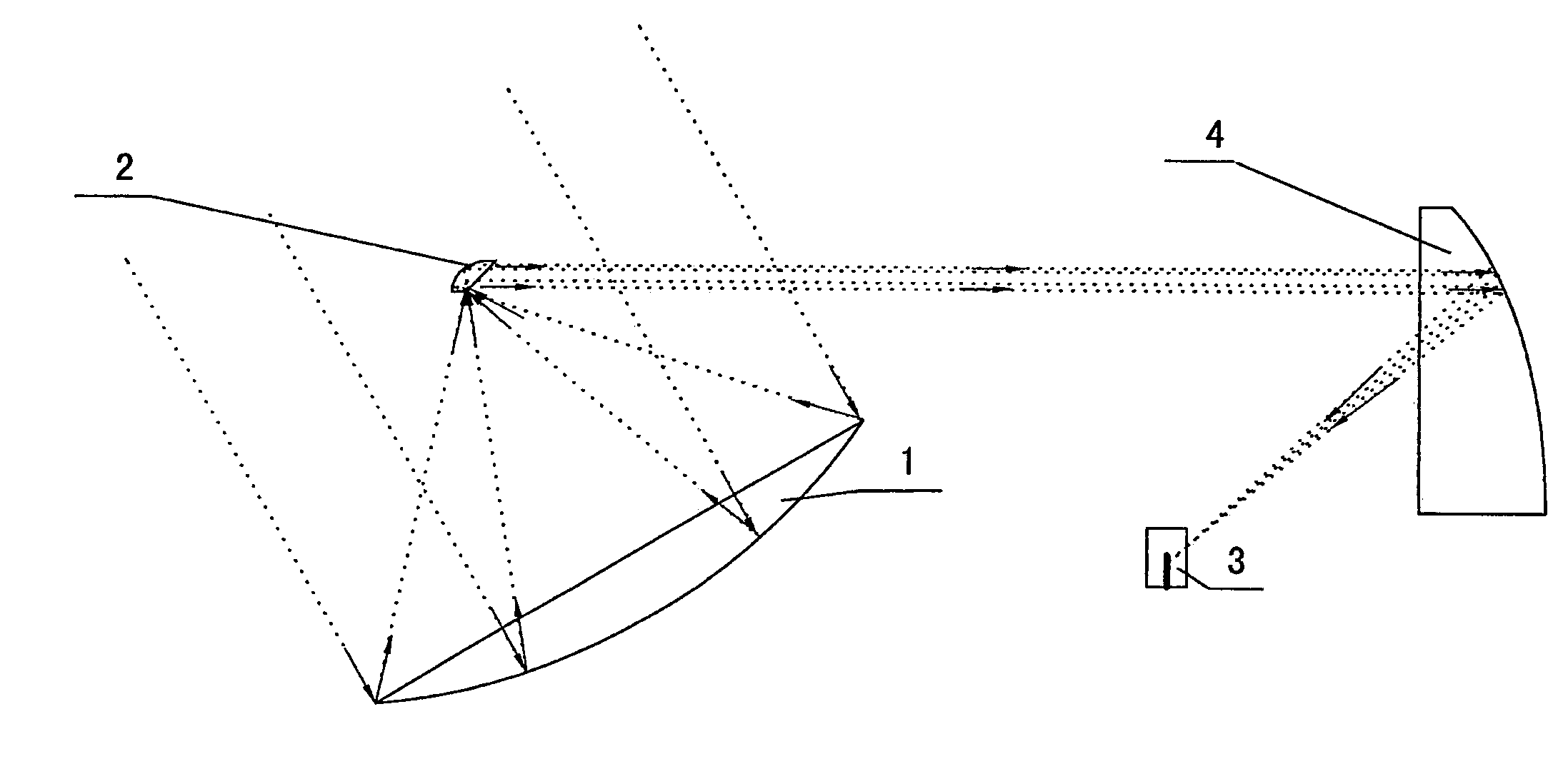

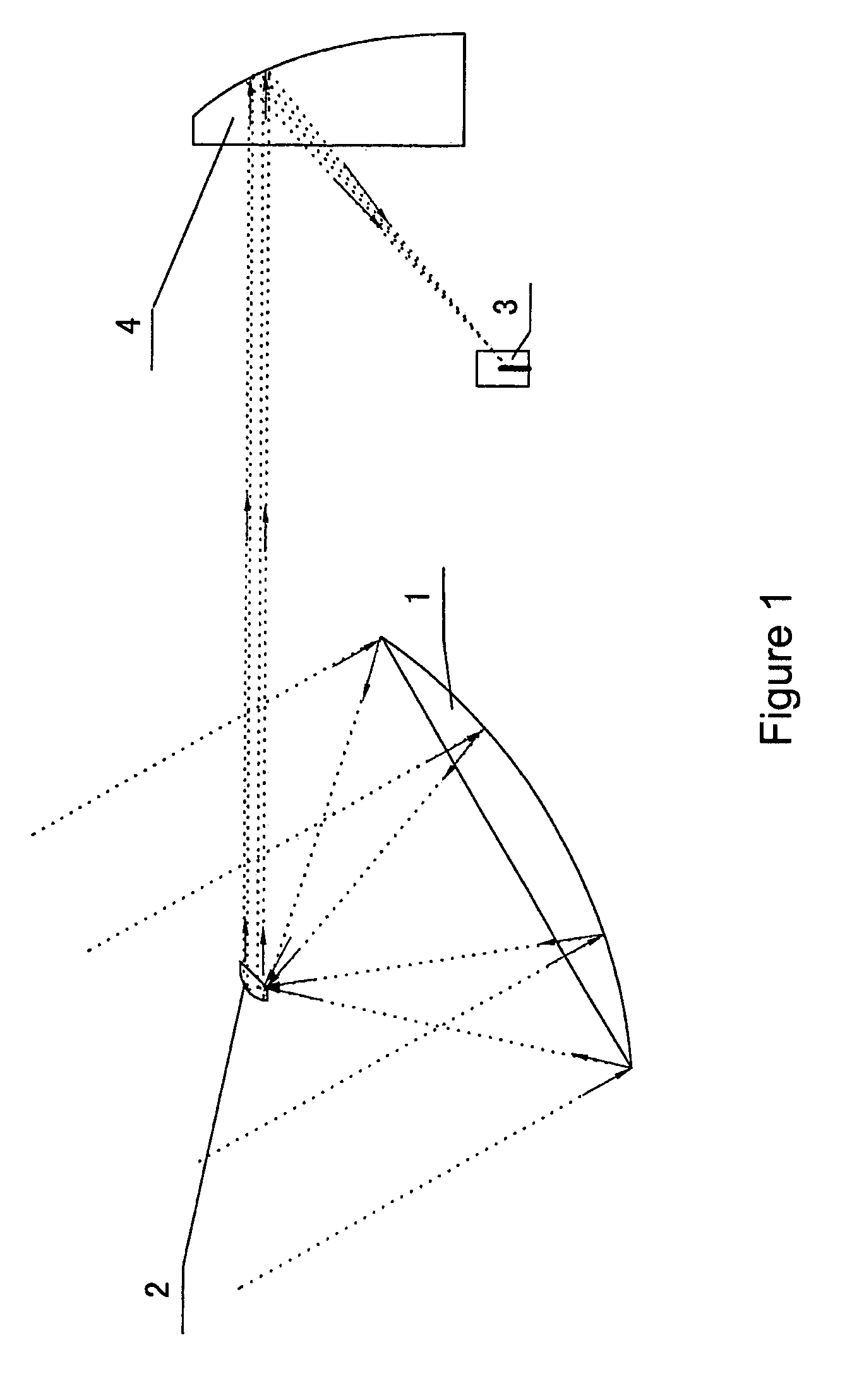

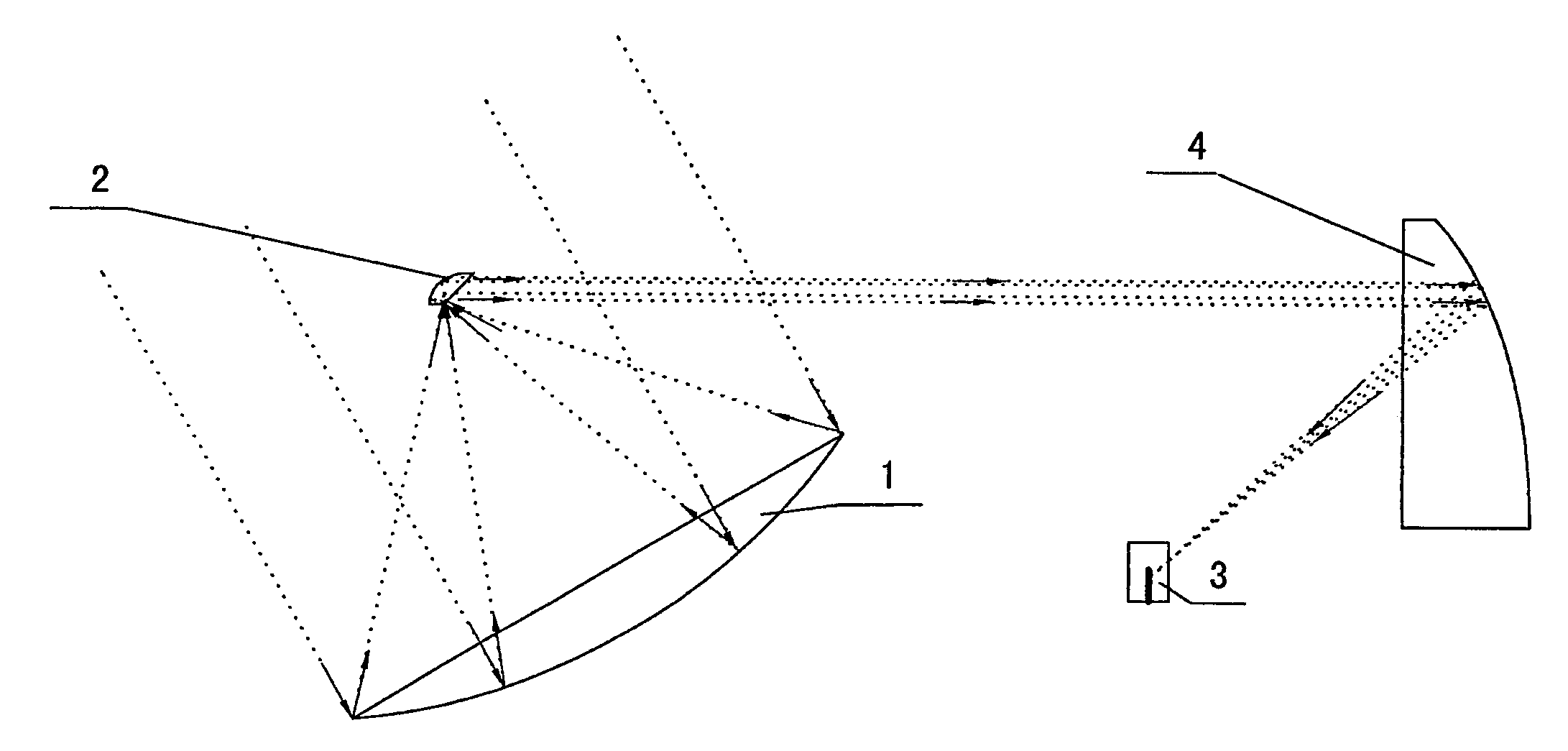

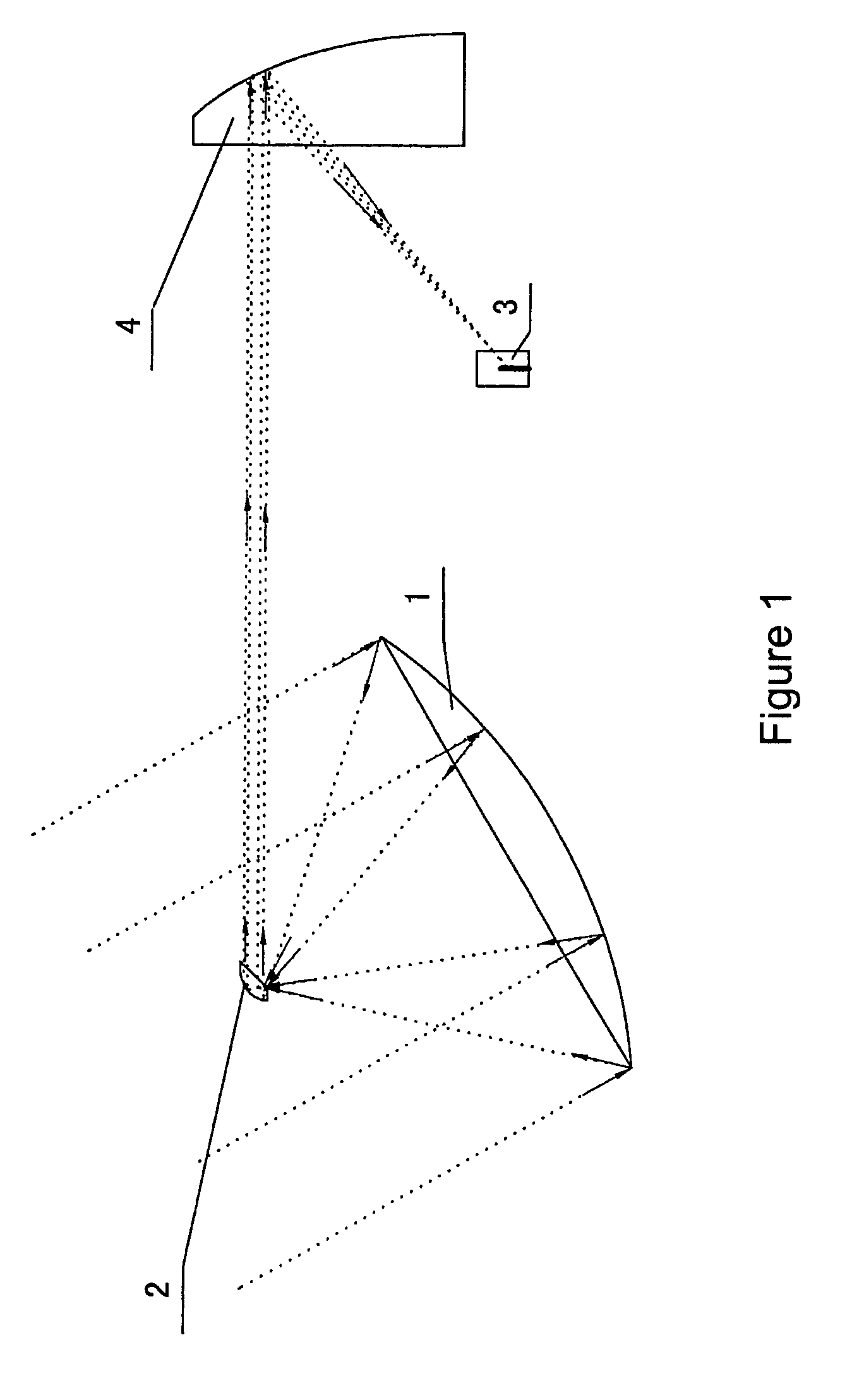

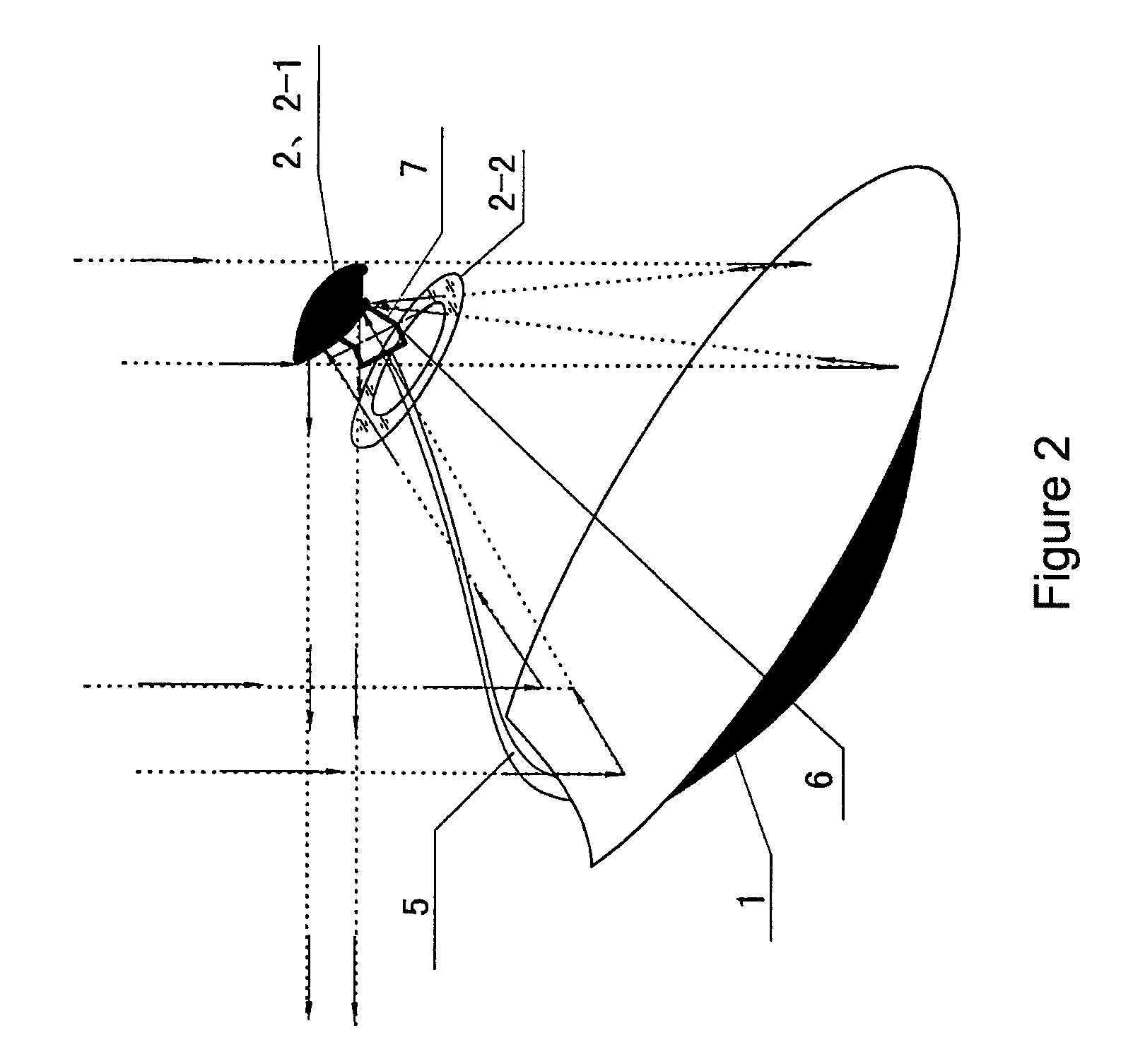

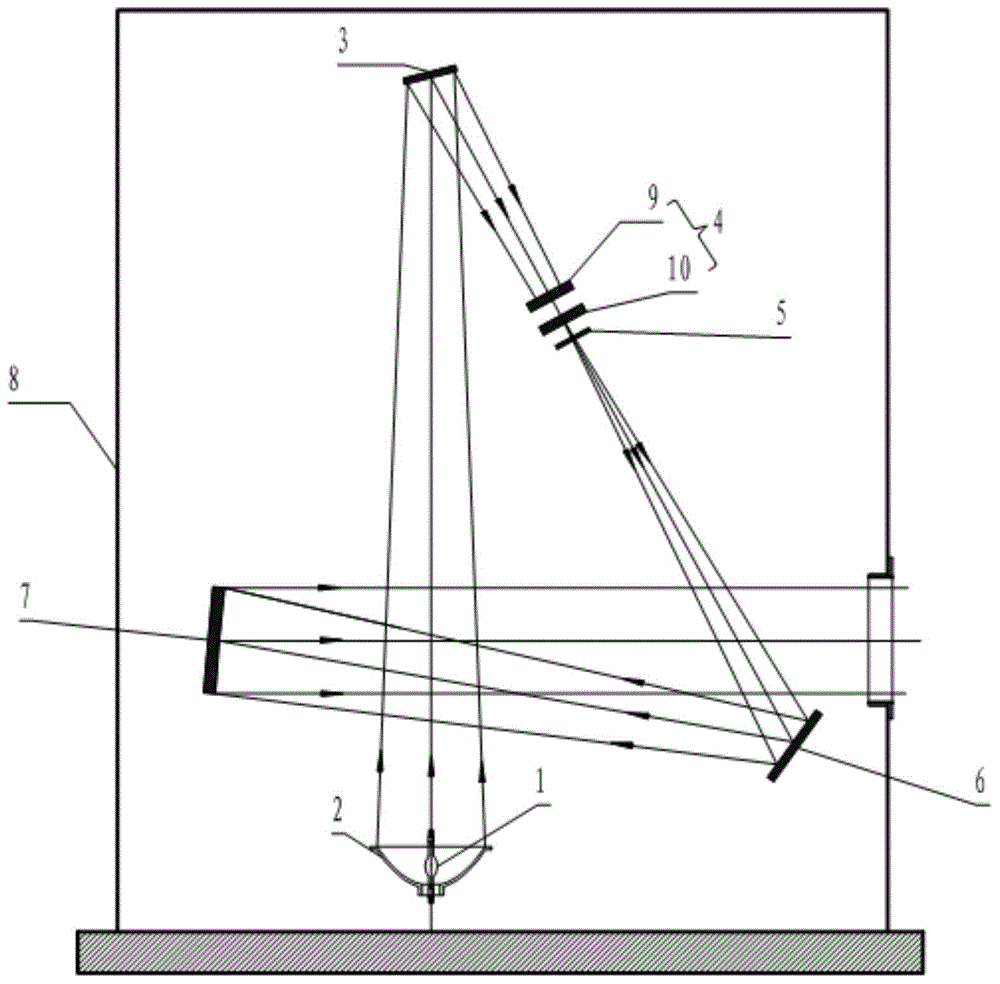

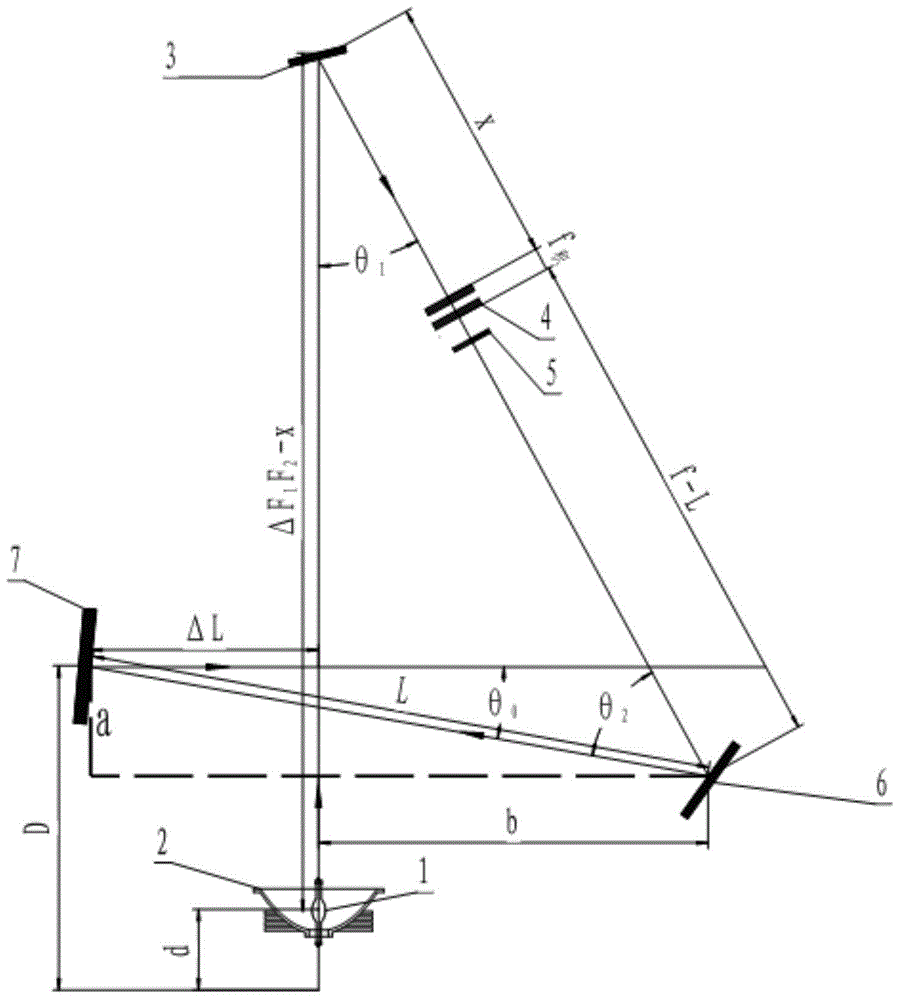

Solar collecting and utilizing device

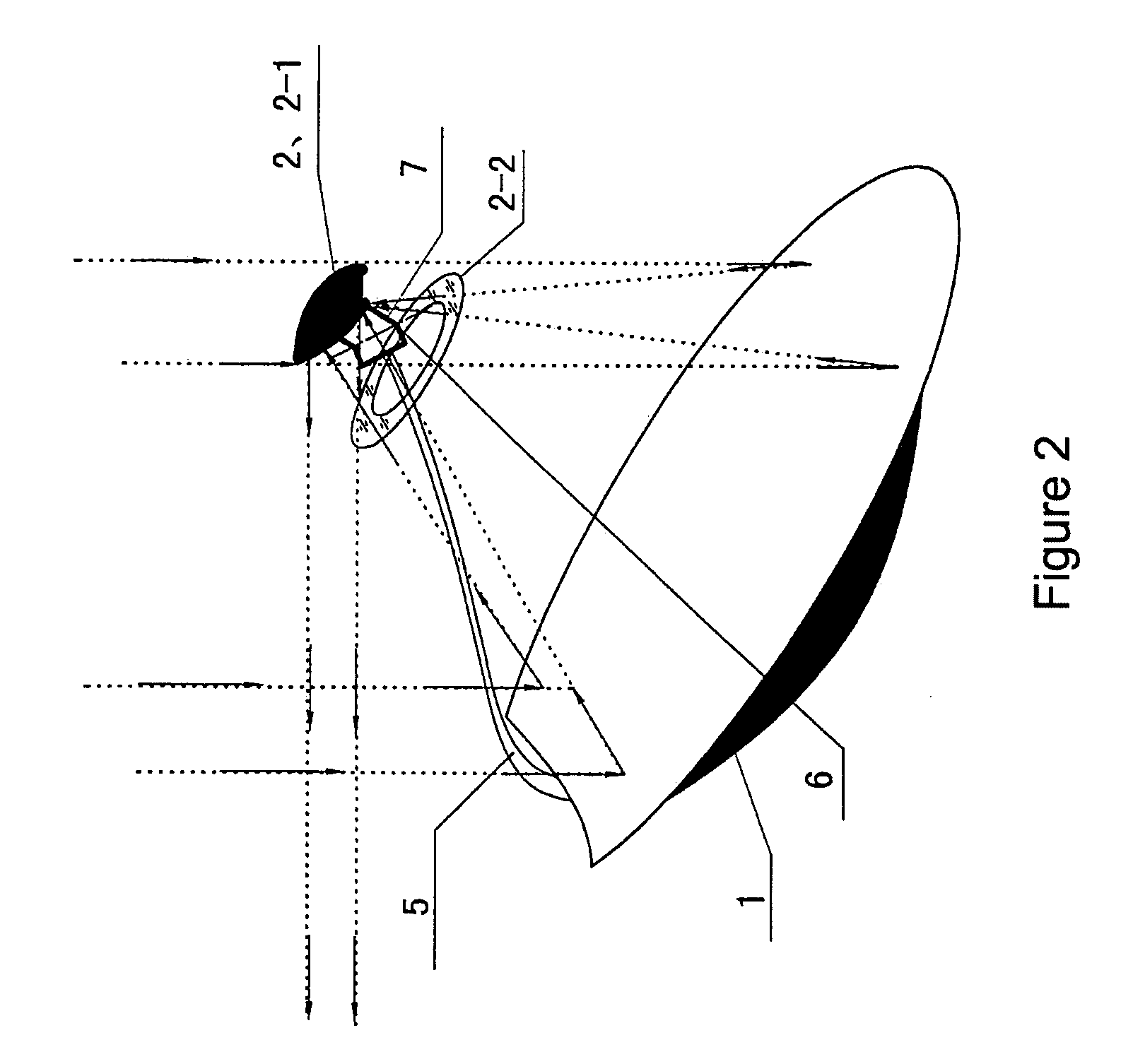

InactiveUS20080087276A1Raise the ratioQuality improvementSolar heating energySolar heat collector controllersMechanical reliabilityLight beam

The present invention relates to a solar collecting and utilizing device comprising: a paraboloidal mirror for collecting the sunlight and converging it as a facula, a sunlight collector, a solar storage and conversion device, and a solar tracking equipment, wherein, said solar tracking equipment comprises implementing mechanical parts and photoelectrical control parts; said sunlight collector includes a light guider which converts the facula into substantially parallel light beams and reflects them in a desired direction, and a curved surface condenser mirror which receives the substantially parallel light beams reflected from the sunlight guider and converges them into solar storage and conversion device; said light guider includes a light guider mirror for point focusing the light beams. The present invention provides a device which can enhance highly the solar collection density, centralize the energy conversion / utilizing points, simplify the sunlight tracking mechanism, improve the mechanical reliability of the whole system, and lower the investment and the cost of operation.

Owner:ZHAO XIAOFENG

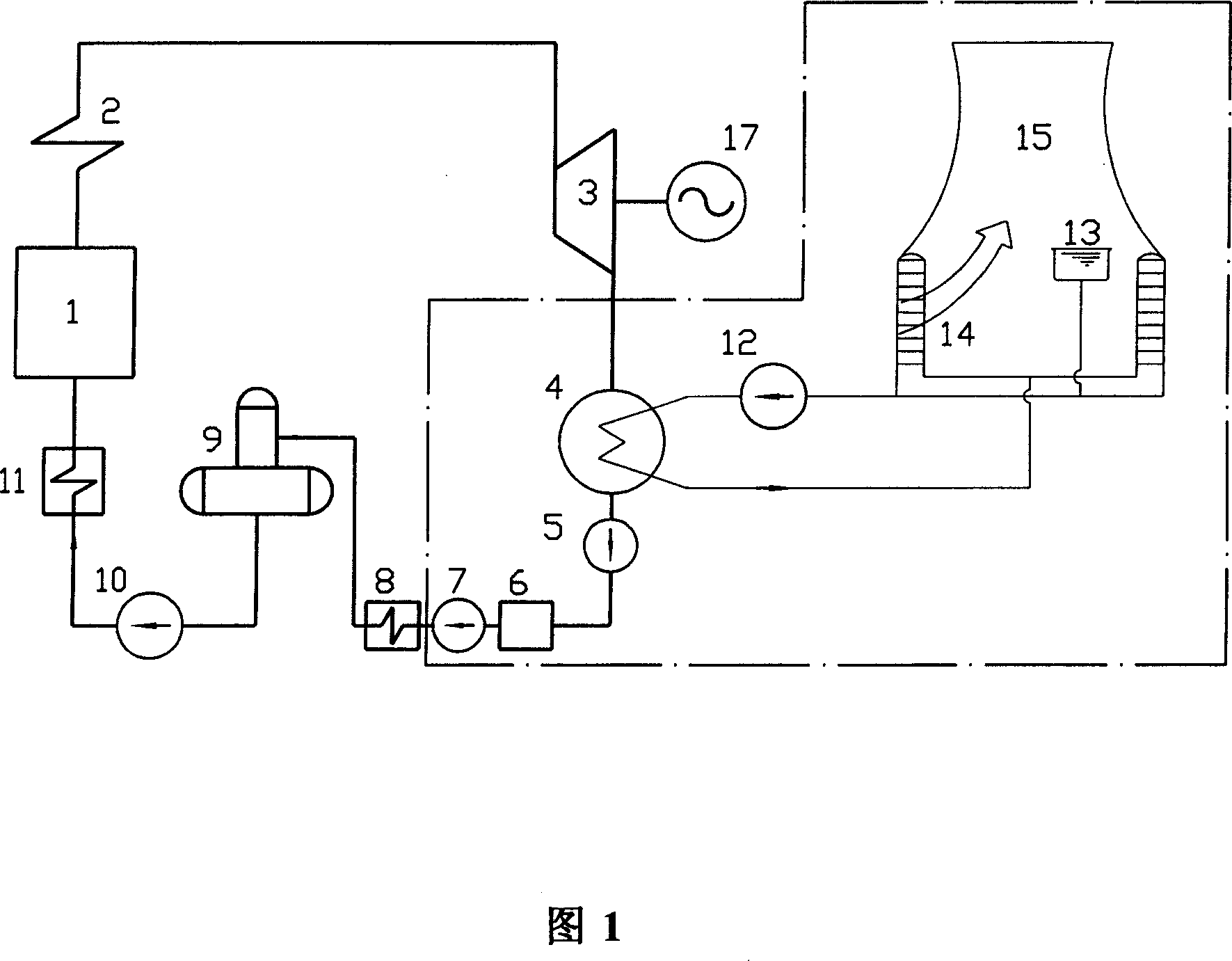

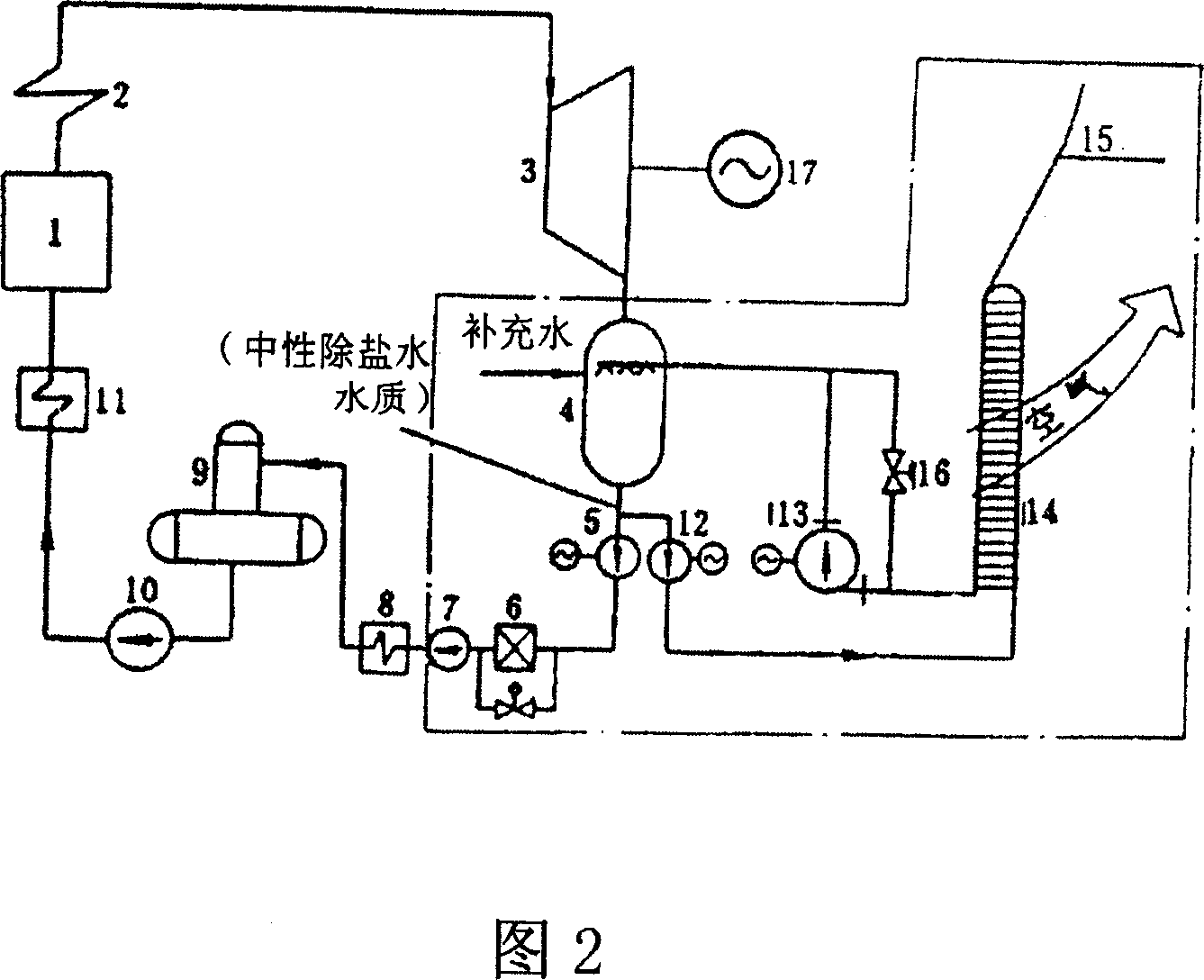

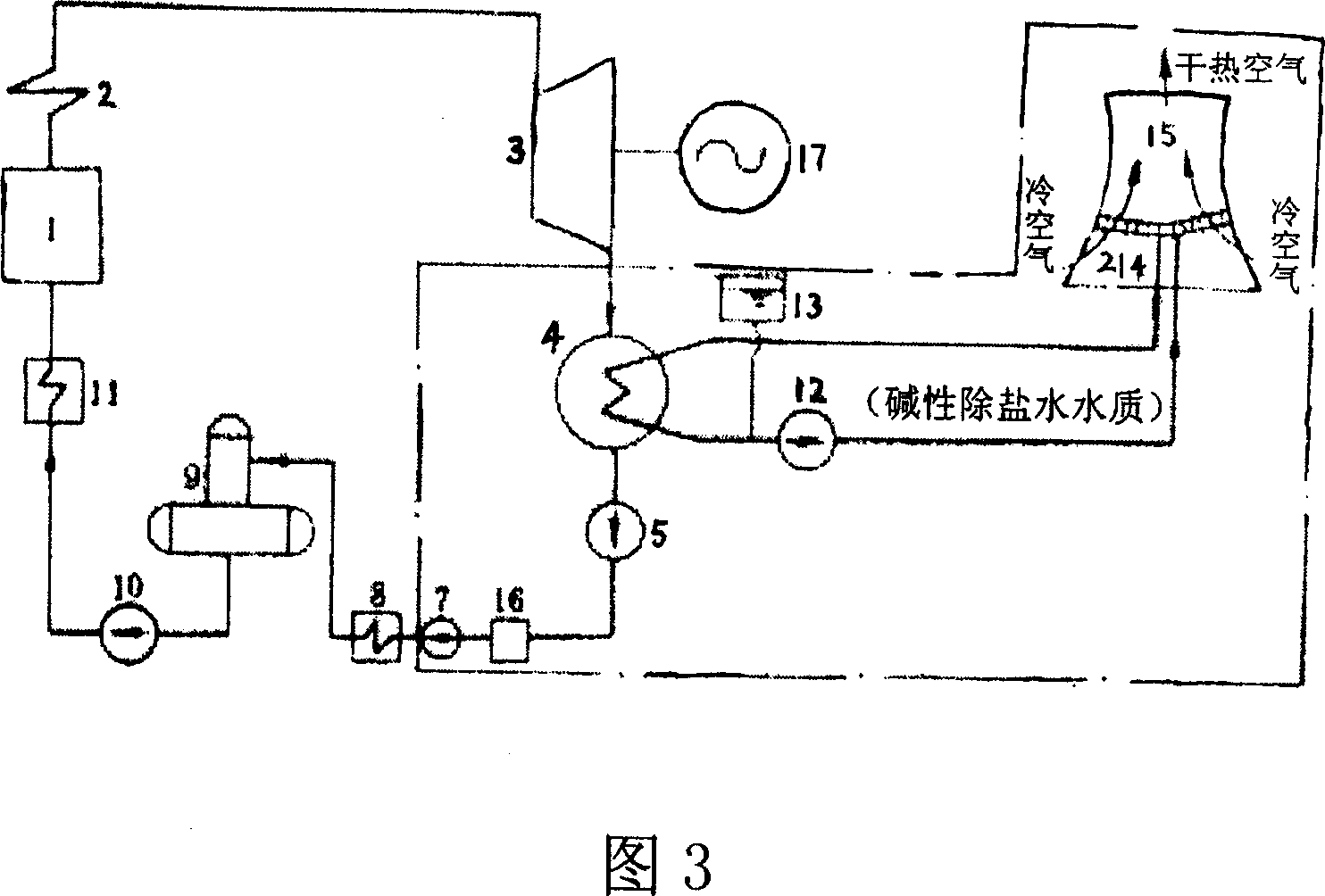

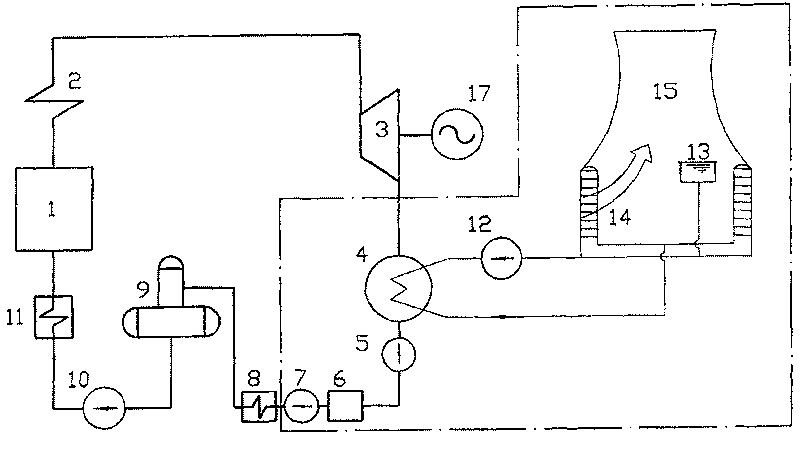

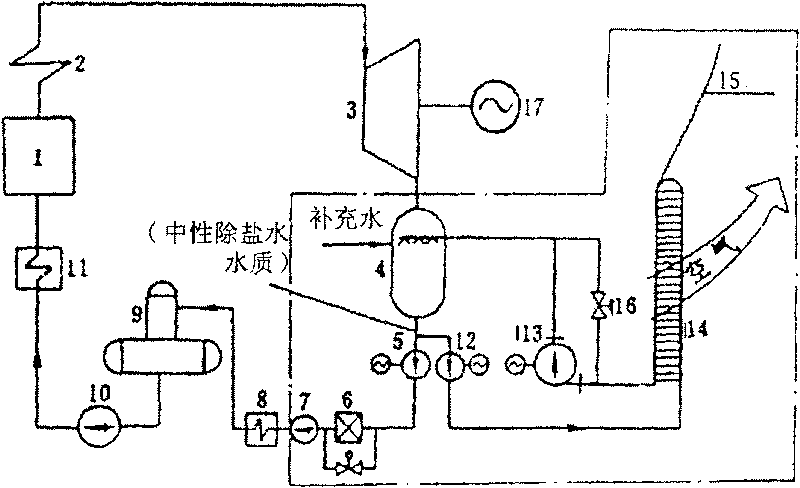

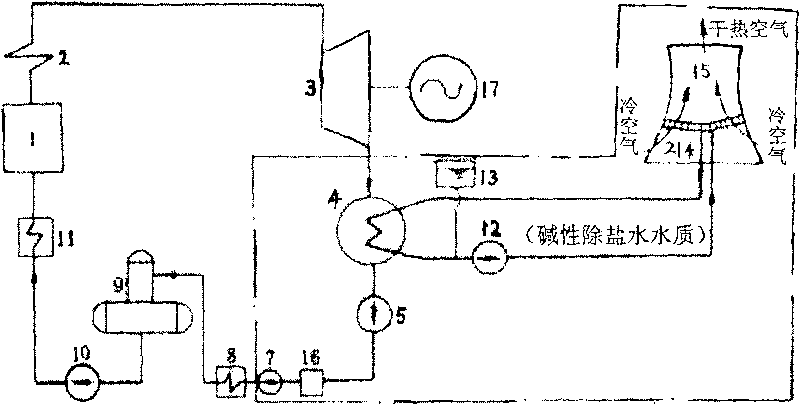

SCAL indirect air cooling system

ActiveCN101063595AReduce sizeSmall footprintSteam/vapor condensersStationary conduit assembliesCooling towerWater quality

The invention relates to a SCAL indirect air-cooling system, mainly comprising a surface condenser, a recycling water system, a fog type aluminum pipe and aluminum flake radiator and an air-cooling tower, wherein in the surface condenser, after the wasted steam discharged from the steam turbine performs the first heat exchange with the cooling water, the wasted steam transmits the heat to the cooling water and condensed to condensed water, then flow back to the air-cooling system heat system, the cooling water flows to the fog type aluminum pipe and aluminum flake radiator via the recycling water pump after it is heated up, and the cooling water secondarily exchange heat with the environmental air, the cooling water transmits the heat to the air and makes the water temperature decrease, and then return to the cooling steam turbine of the surface condenser, the system recycles like this. The invention has the advantages that the Haman type indirect air-cooling system is separated from the steam water system, the water quality controlling and disposing is easy, the Hailer system air-cooling tower has a small body, The invention takes up small area and the capital cost of reactor plant is low.

Owner:NORTH CHINA POWER ENG +1

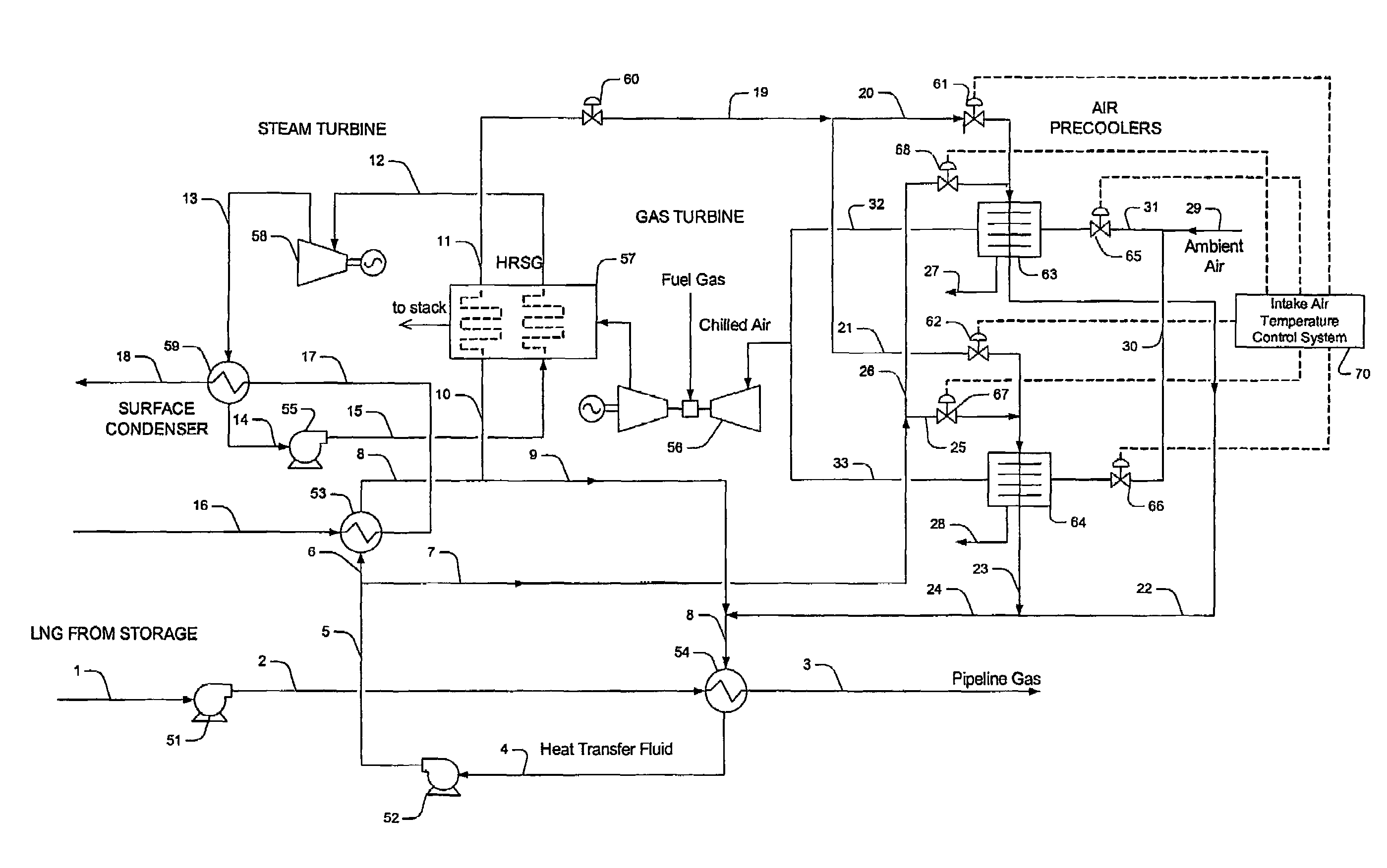

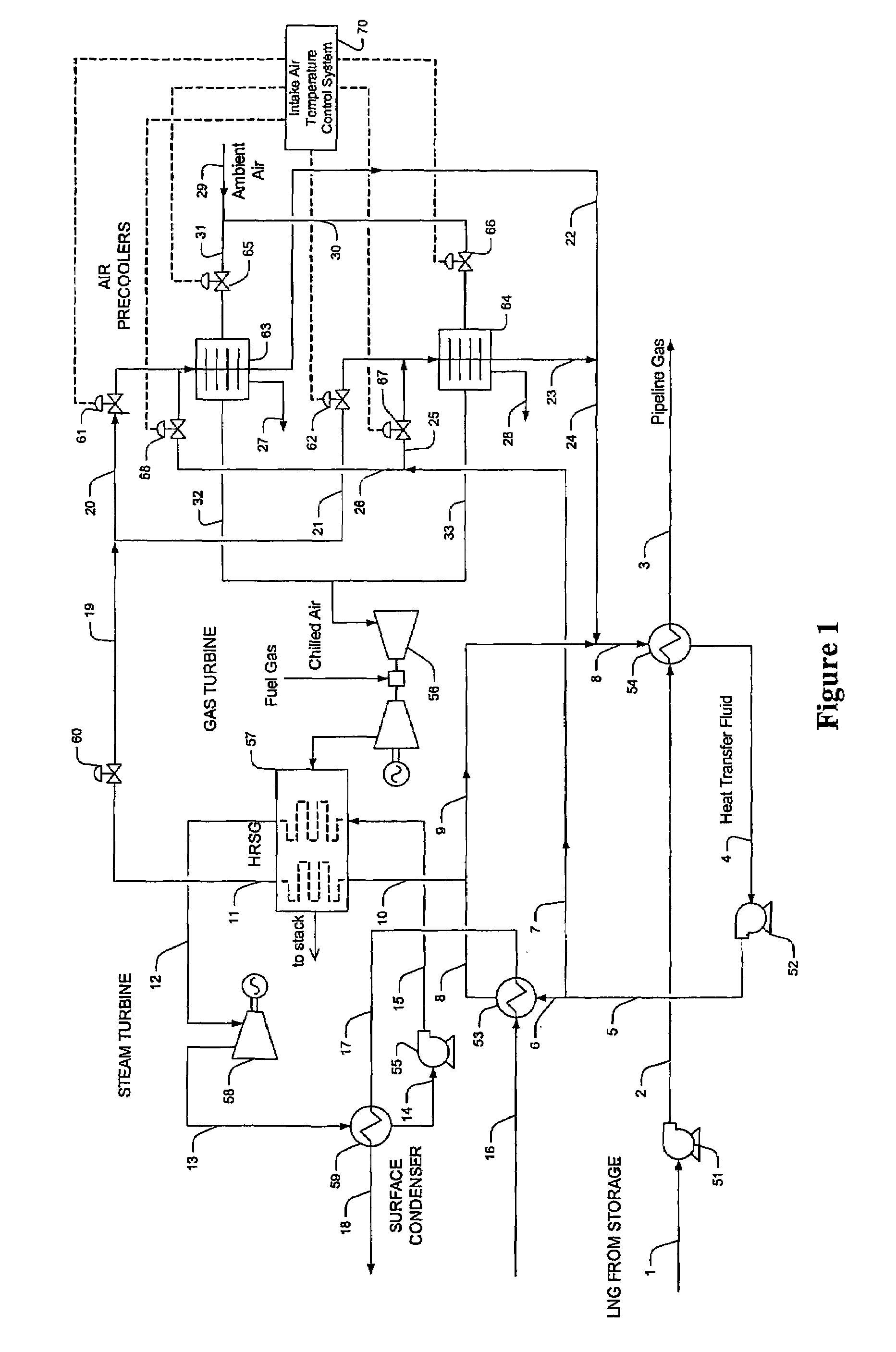

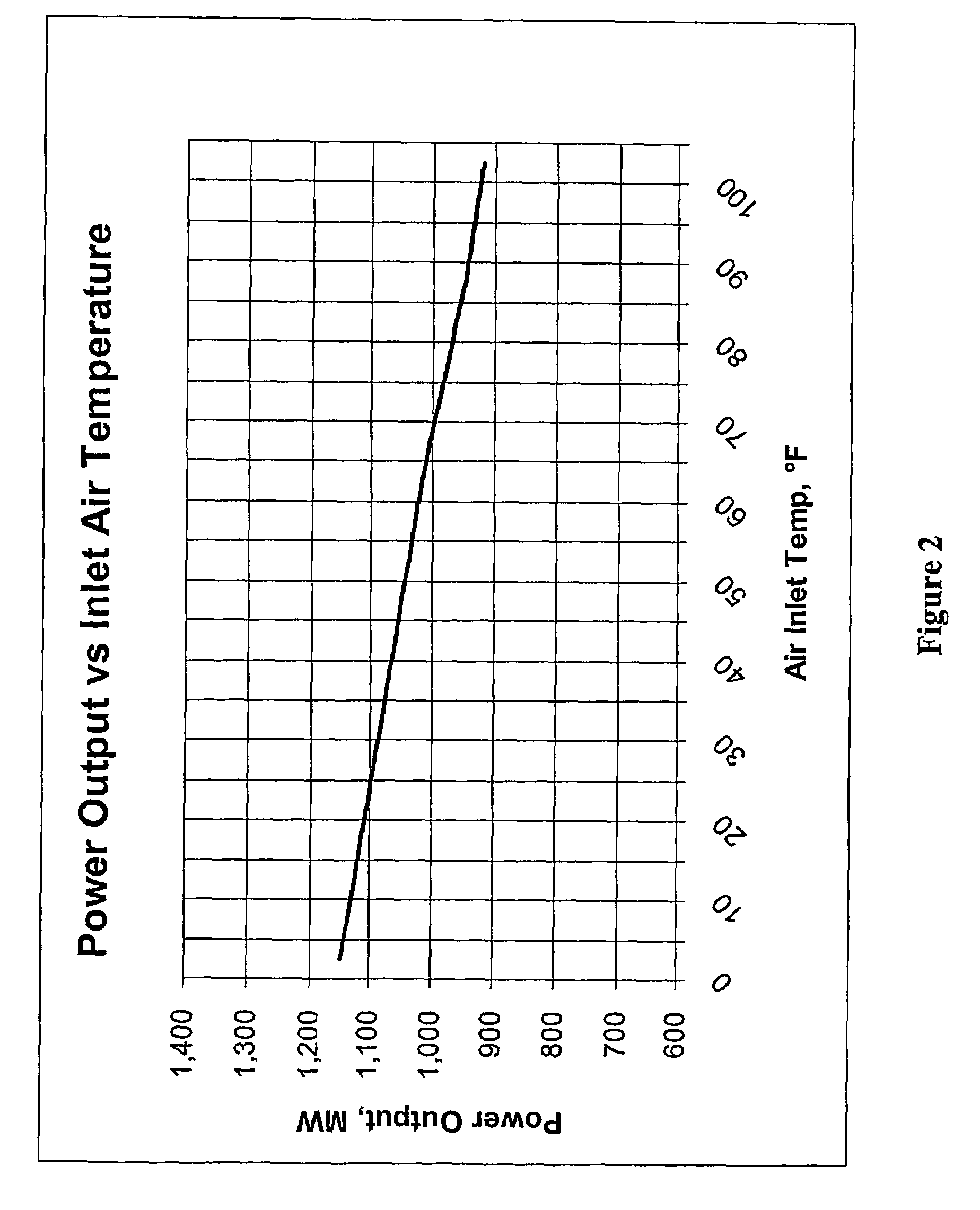

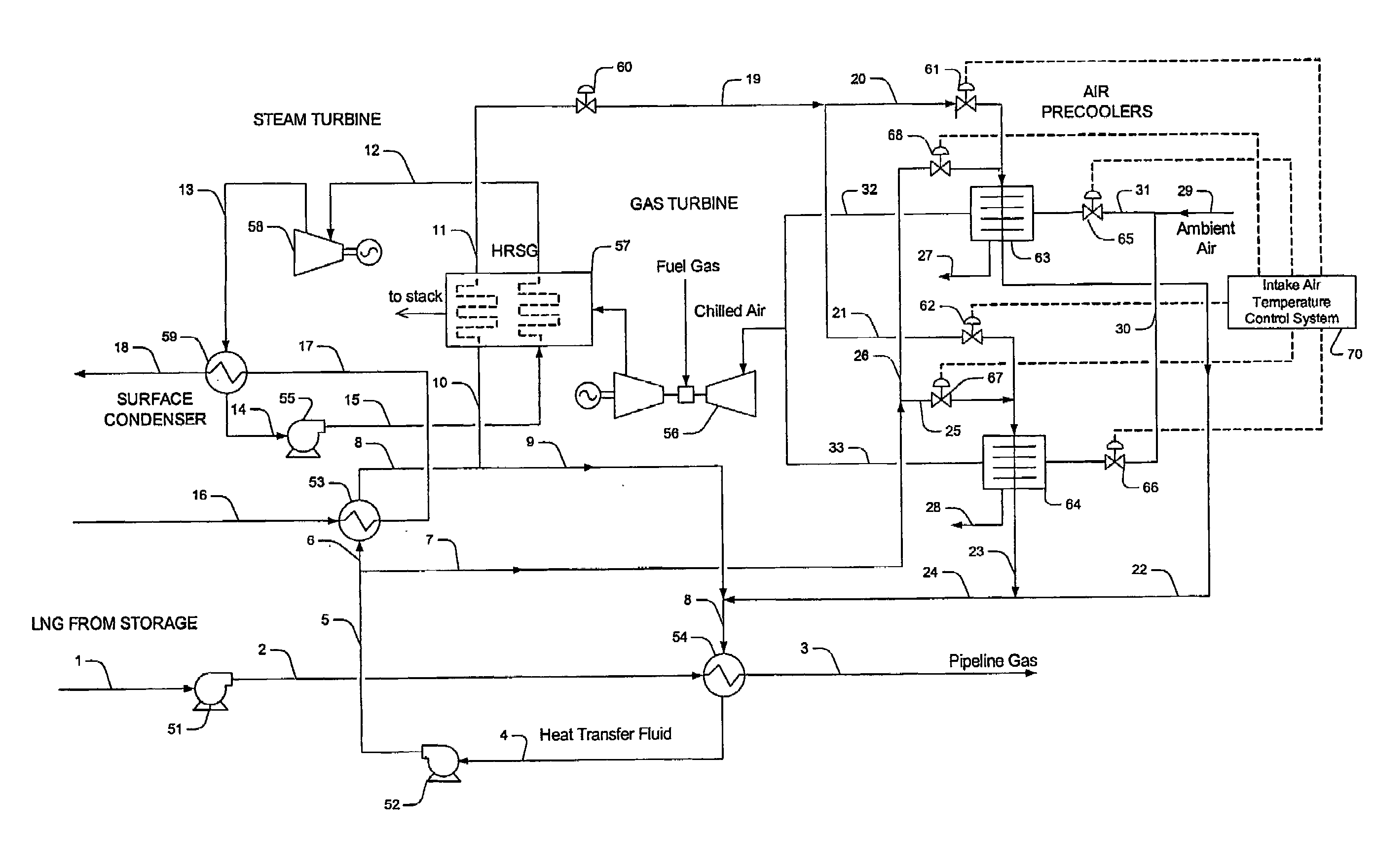

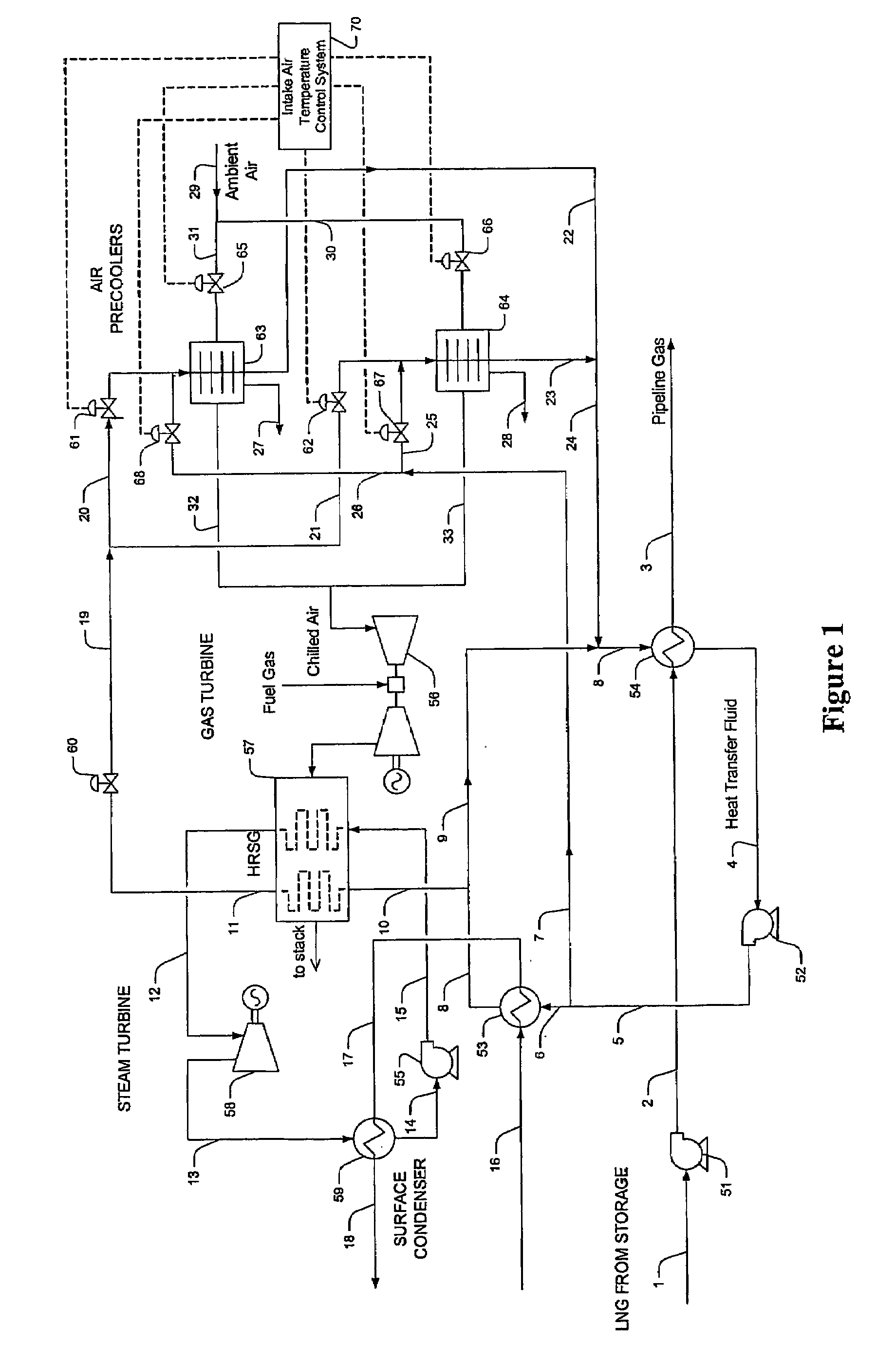

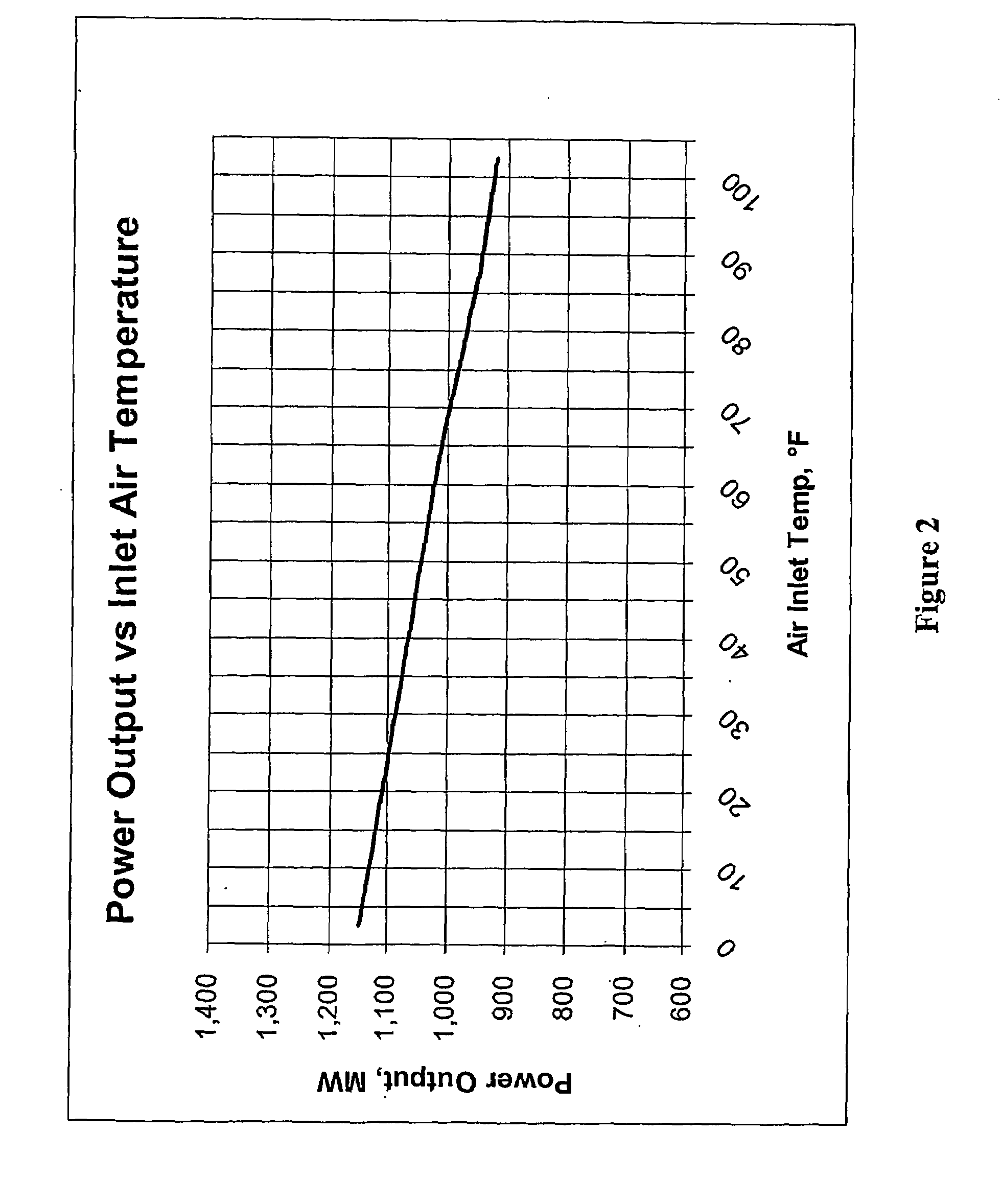

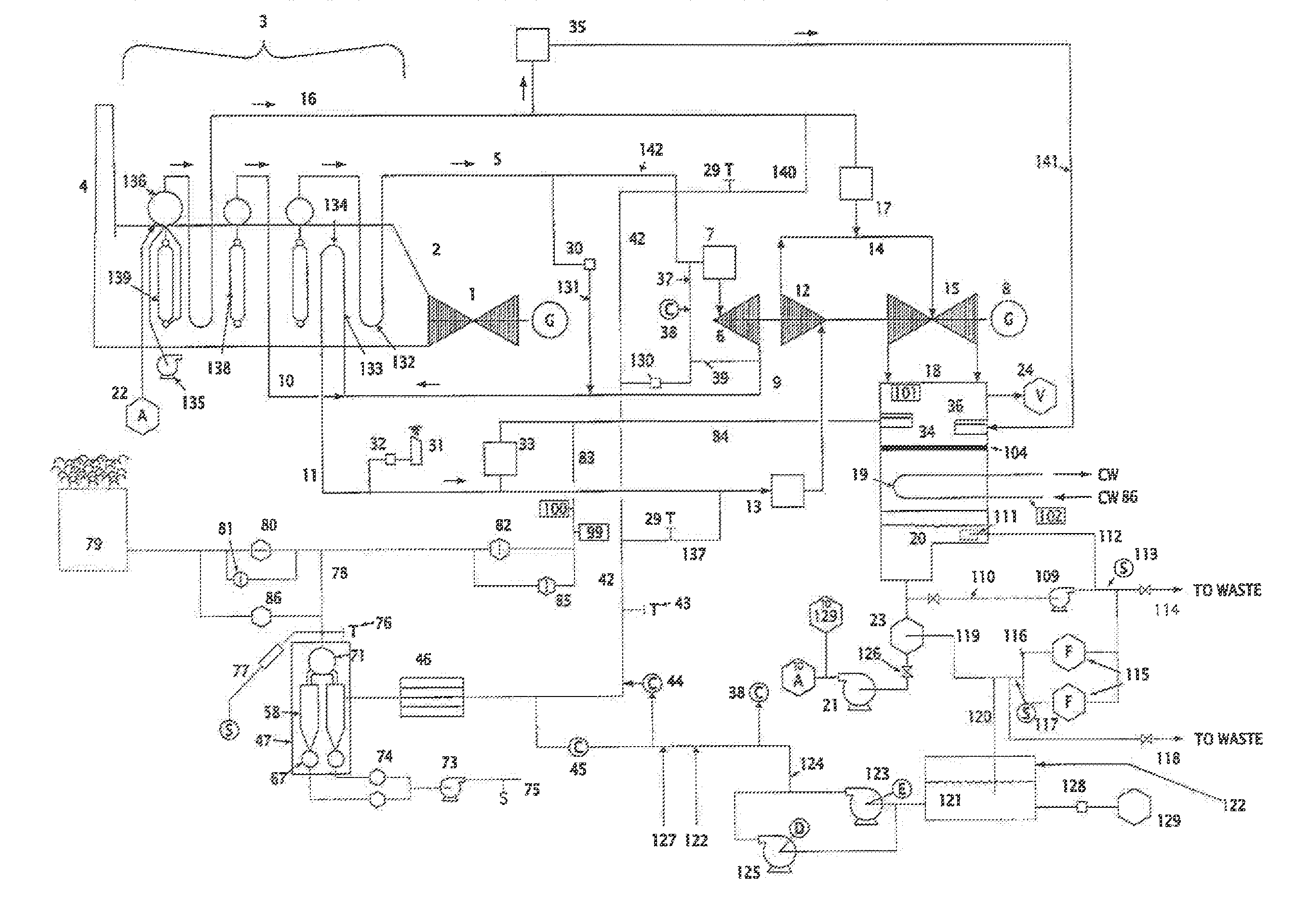

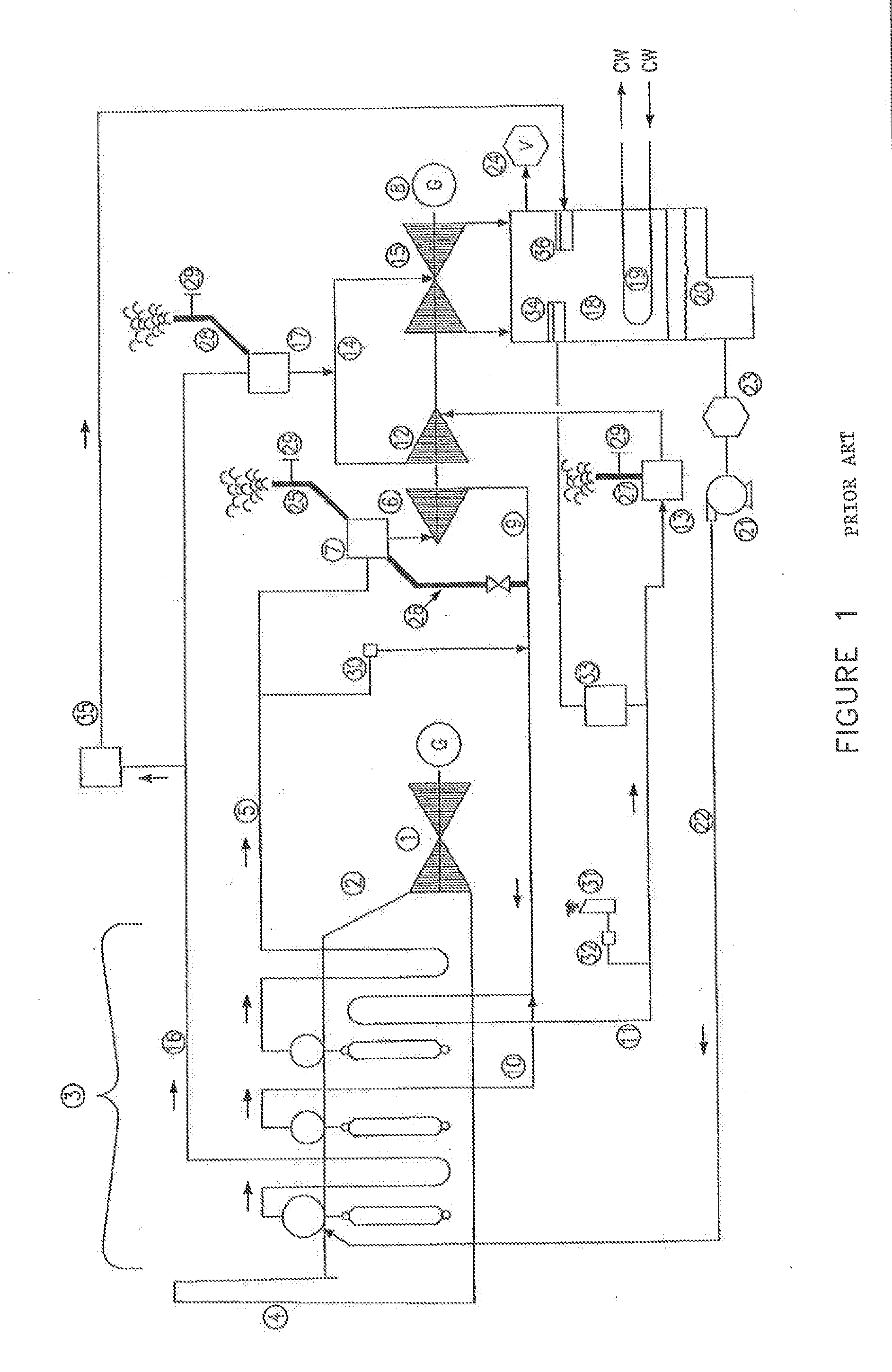

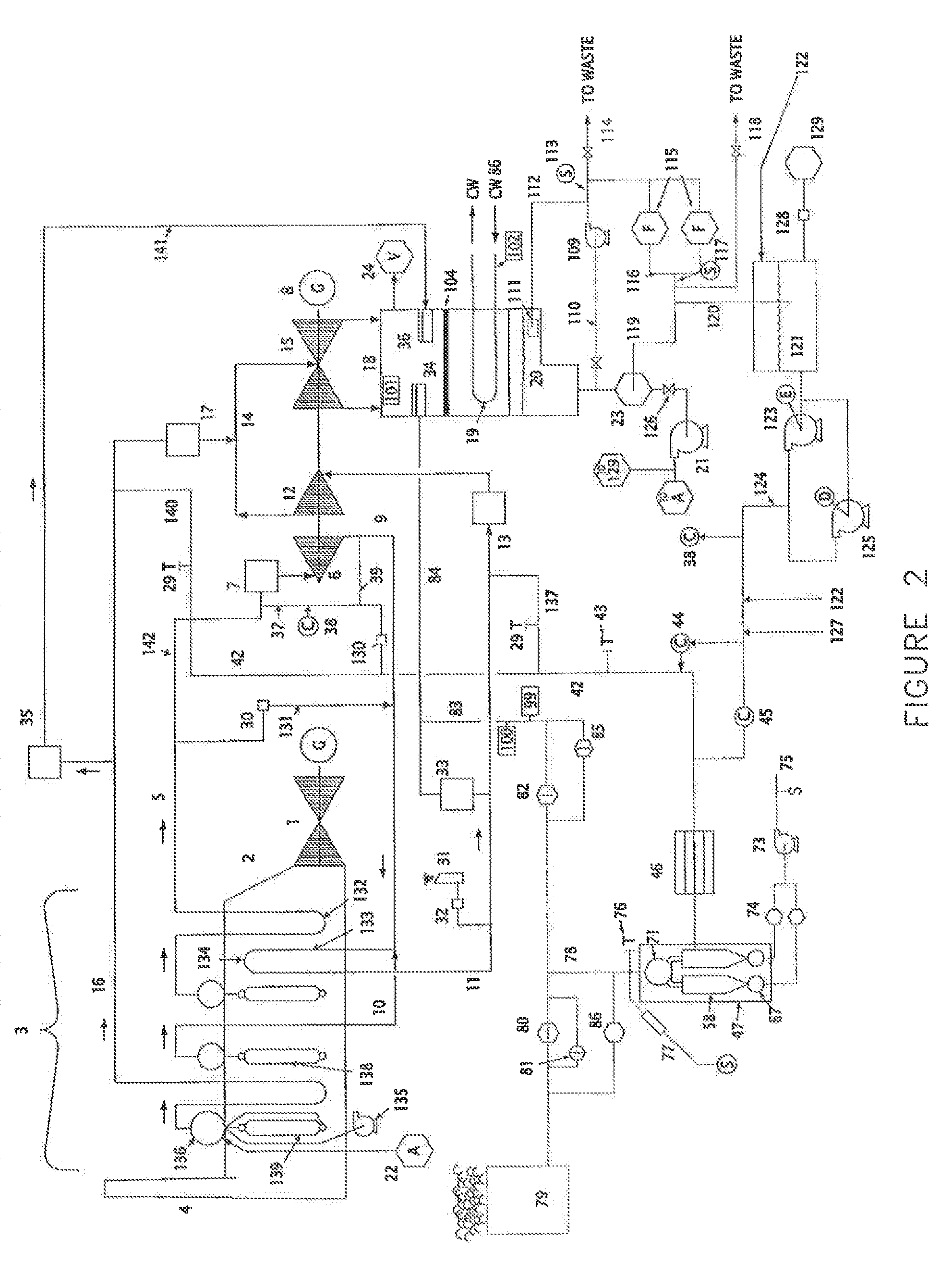

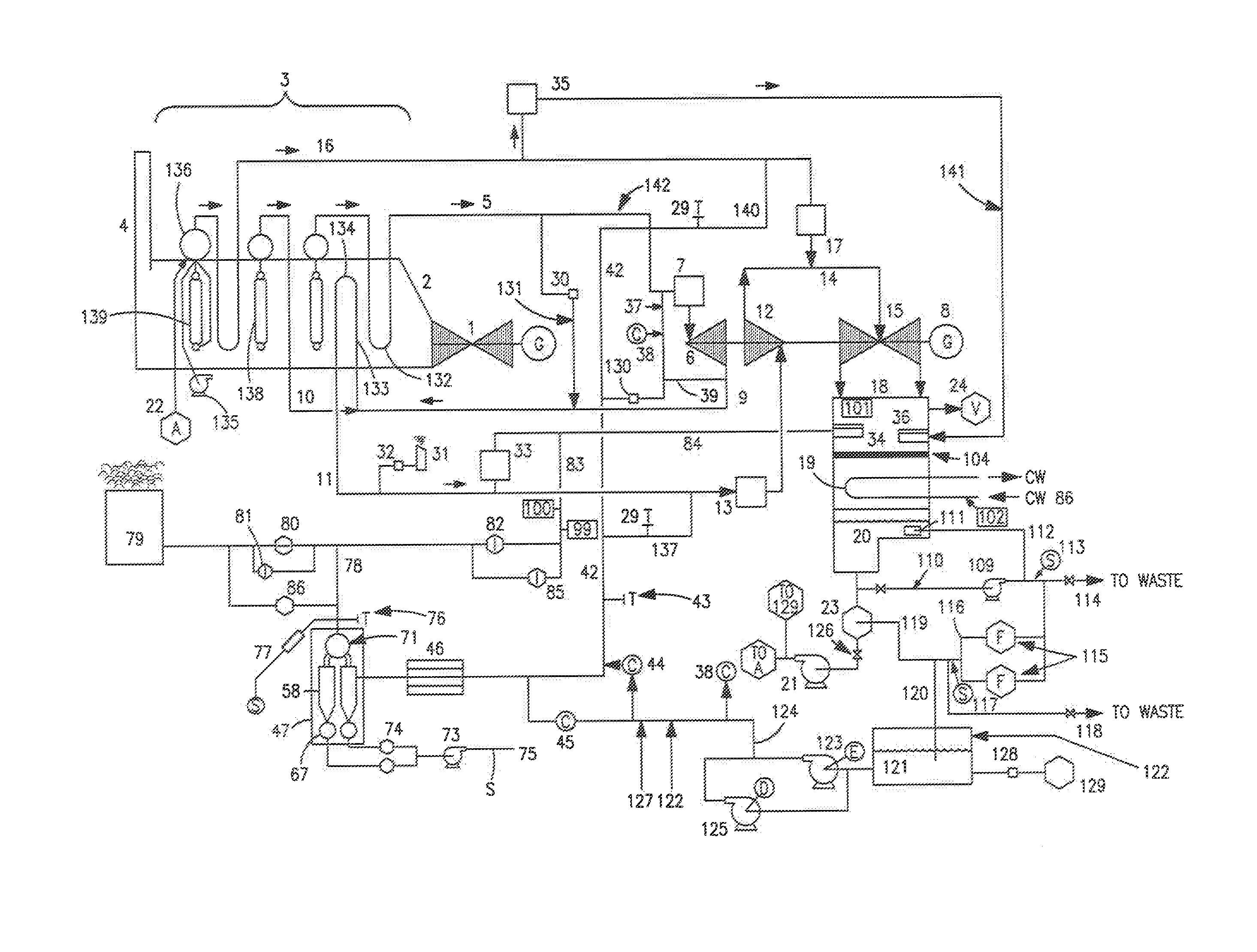

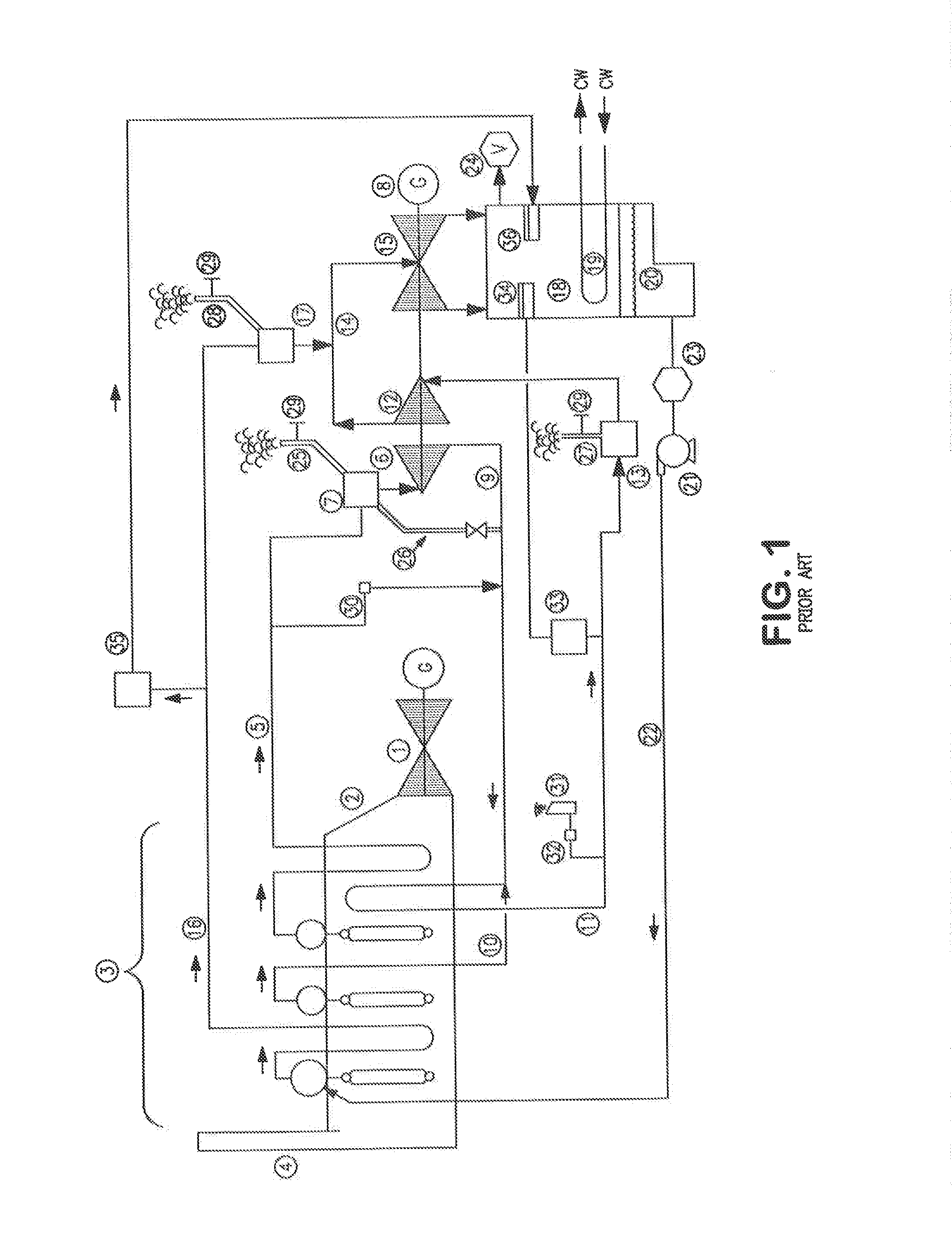

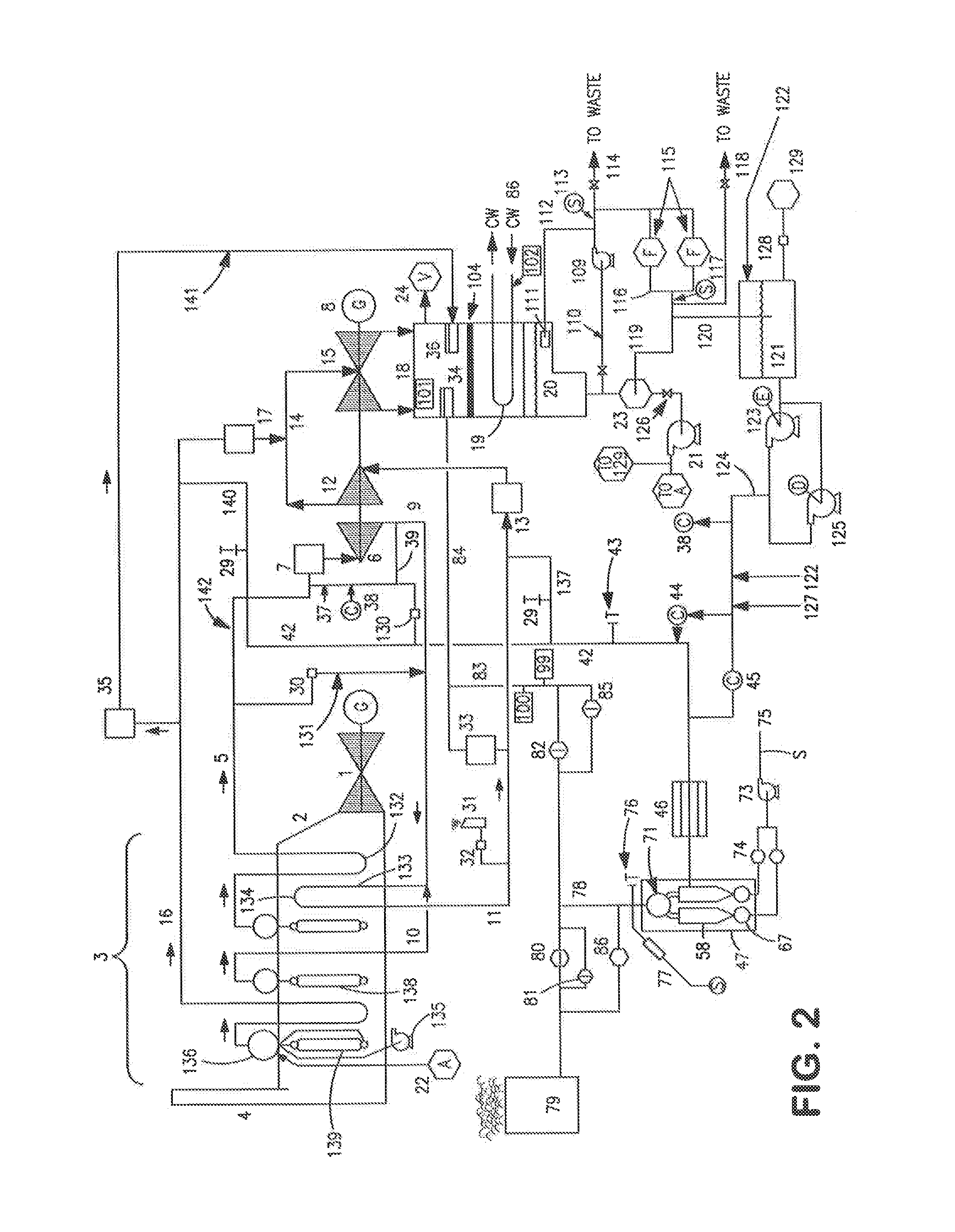

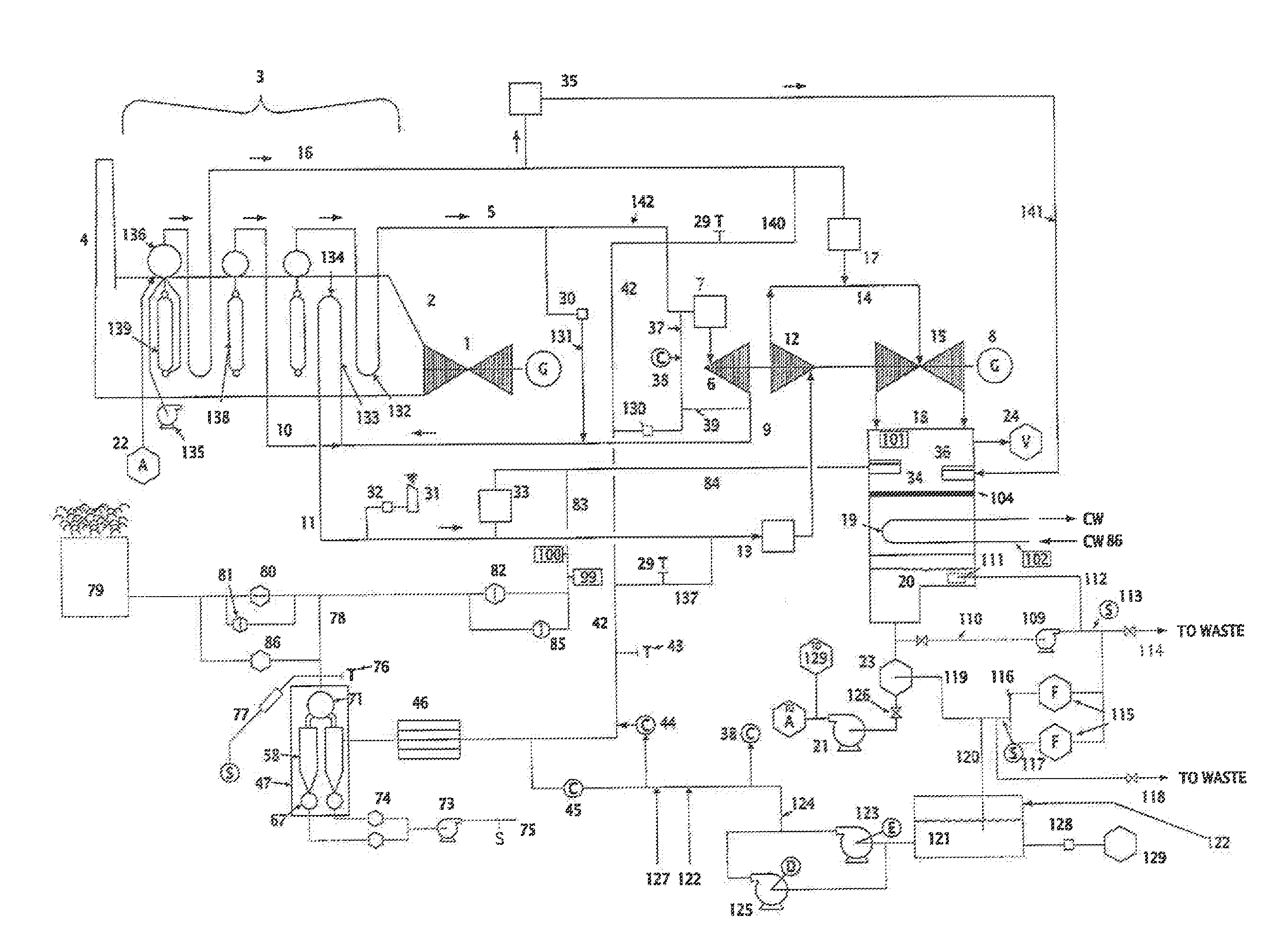

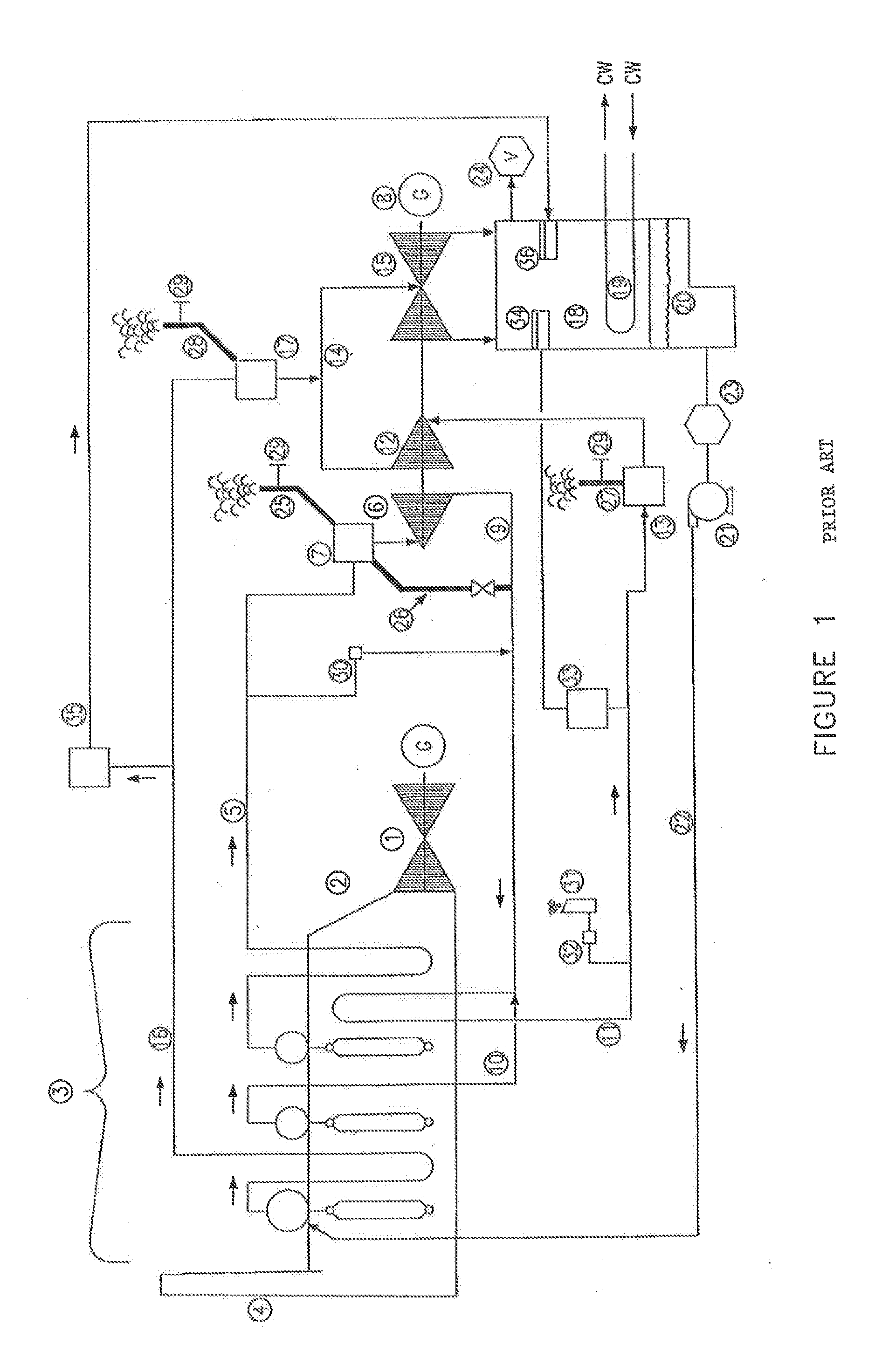

Configurations and methods for LNG fueled power plants

InactiveUS7980081B2High power outputReduce condensationTurbine/propulsion engine coolingGas handling/storage effectsCombustionPower cycle

Owner:FLUOR TECH CORP

Solar collecting and utilizing device

InactiveUS7975685B2Raise the ratioQuality improvementSolar heating energySolar heat collector controllersMechanical reliabilityLight beam

The present invention relates to a solar collecting and utilizing device, comprising: one or more paraboloidal light collecting mirrors for collecting / converging the sunlight; a light guider including a light guider mirror for receiving the sunlight converged by said paraboloidal light collecting mirrors and converting it into parallel light beams in a desired direction; one or more curved surface condenser mirrors for receiving / converging substantially parallel light beams from said light guider; a solar storage and conversion device for storing / converting the energy converged by said curved surface condenser mirrors; a solar tracking equipment for tracking automatically the sunlight so as to always keep the opening surface of said paraboloidal light collecting mirrors substantially vertical to the sunlight. The focus of said light collecting mirror always superposes the focus of the corresponding light guider mirror. Such device can enhance highly the solar collecting density, centralize the energy conversion / utilization points, simplify the sunlight tracking mechanism, improve the mechanical reliability of the whole system, and lower the investment and the cost of operation.

Owner:ZHAO XIAOFENG

Configurations And Methods For LNG Fueled Power Plants

InactiveUS20090282836A1High power outputReduce condensationTurbine/propulsion engine coolingGas turbine plantsCombustionPower cycle

Contemplated configurations and methods use first and second precoolers, preferably in alternating operation, to provide a combustion turbine with air at a temperature of 50° F., and more typically less than 32° F. and most typically less than 0° F. In such configurations and methods it is generally preferred that a heat transfer fluid circuit provides both, heated and cooled heat transfer fluid to thereby allow cooling and deicing of the precoolers. Most preferably, refrigeration is provided from an LNG regasification unit to form the cooled heat transfer fluid while heat from a power cycle (e.g., from surface condenser) is used to form the heated heat transfer fluid.

Owner:FLUOR TECH CORP

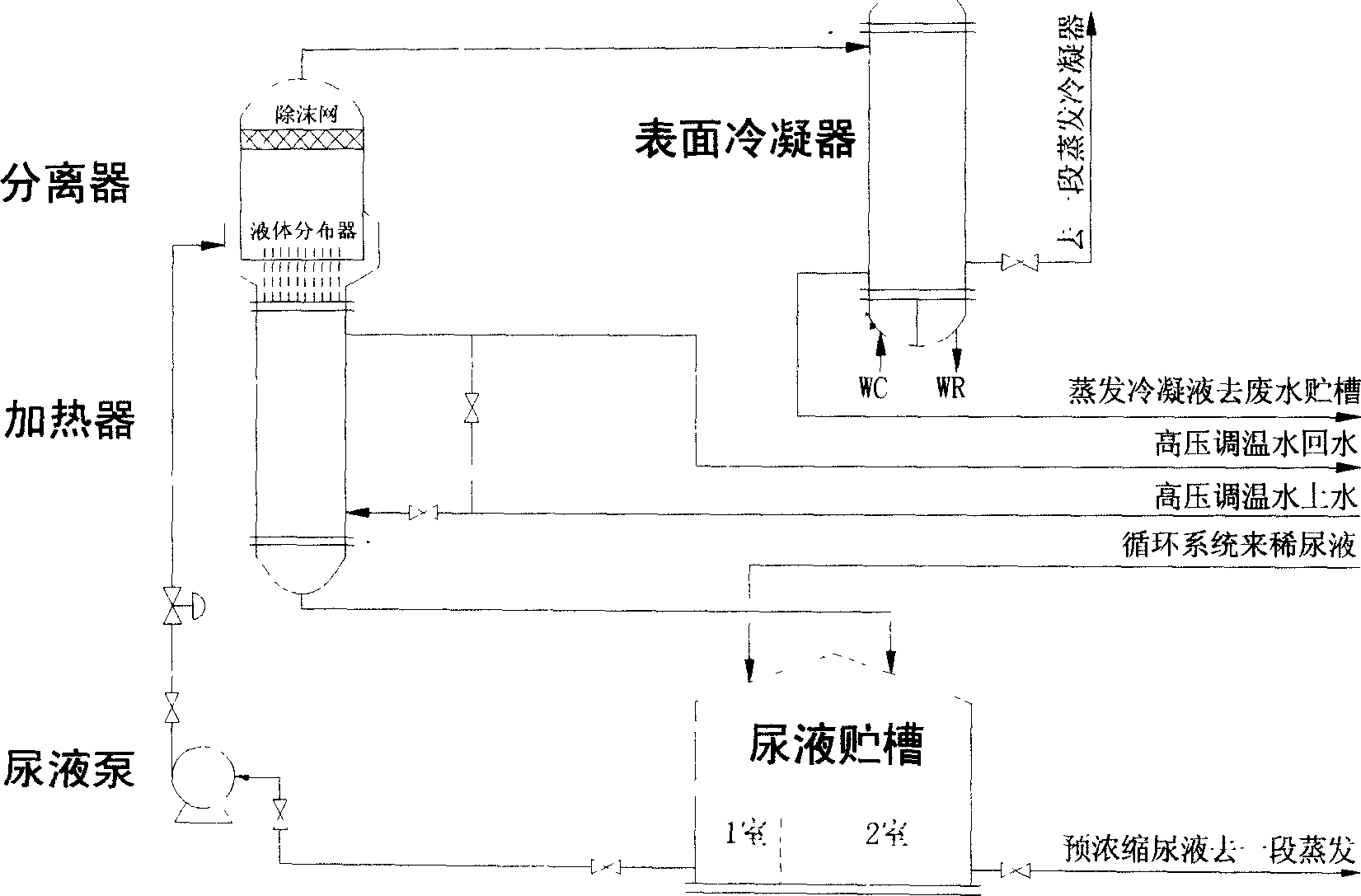

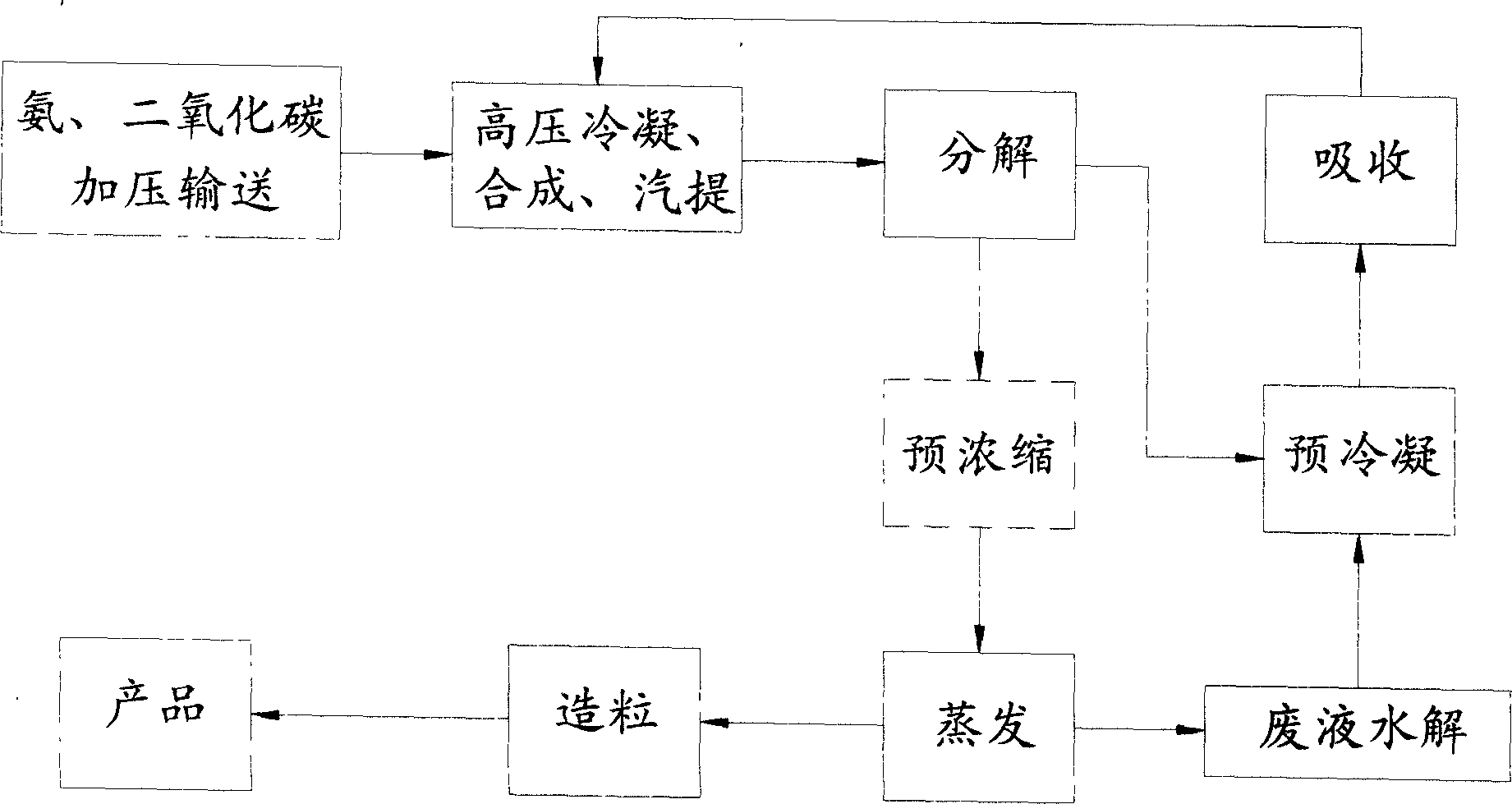

Method for concentrating thin urine using falling film type evaporation heater

ActiveCN1749242ACondition independentStable working conditionUrea derivatives preparationOrganic compound preparationEvaporationBottle neck

The present invention discloses method of concentrating thin urea liquid with falling film type evaporation heater. In the urea producing apparatus on CO2 vaporizing extract process, the falling film type evaporation heater is set behind circulation section and before the evaporation section, and urea liquid through the liquid distributor flows along the inner walls of the tube array from up to down to evaporate partial water and raise concentration, with the vacuum condition of the pre-concentration system being maintained with the surface condenser and the first section evaporation jetting pump. The present invention has the advantages of eliminating bottle neck in the evaporation system, independent and stable evaporation condition, and utilization of afterheat of the high pressure washer to save energy.

Owner:SICHUAN LUTIANHUA

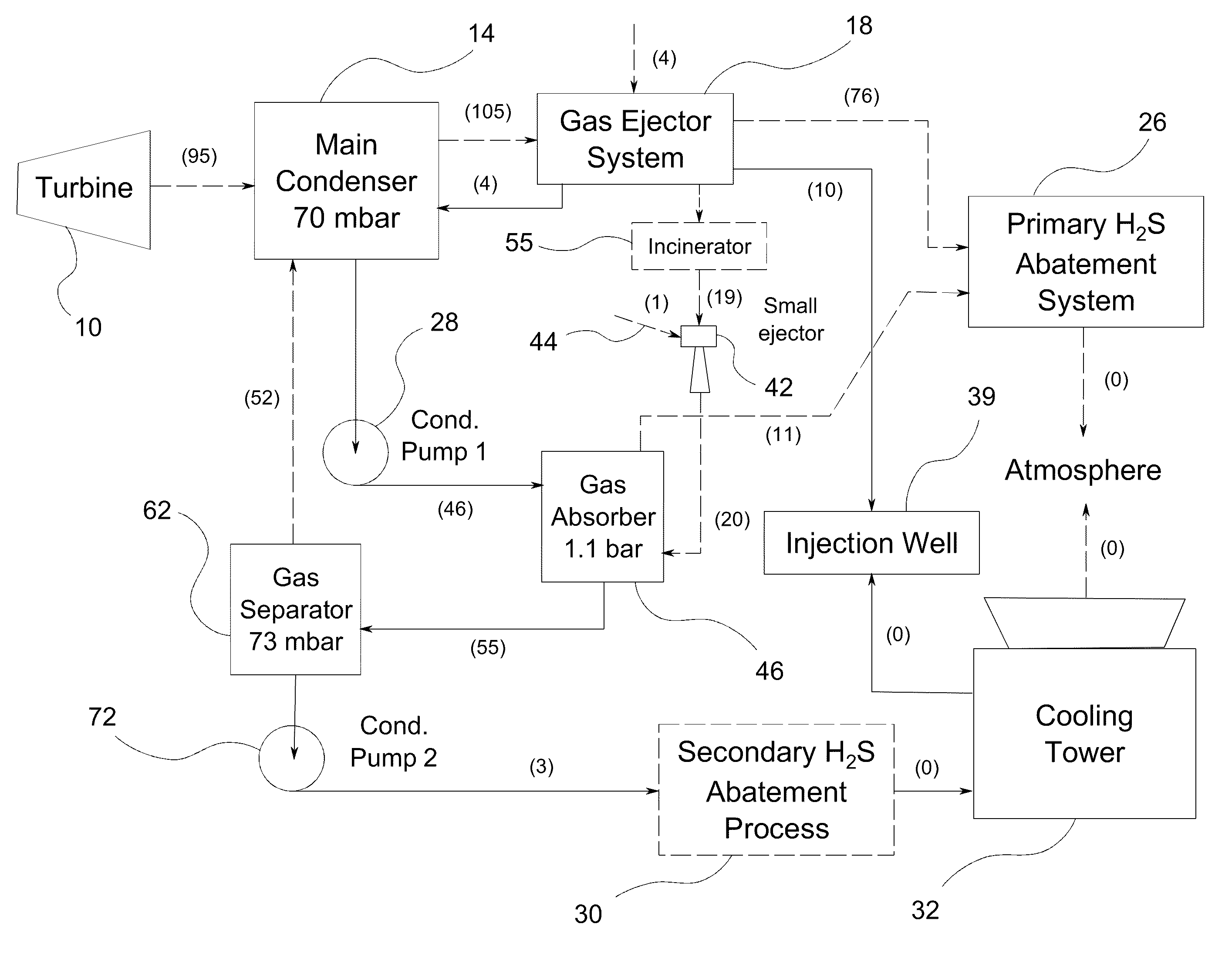

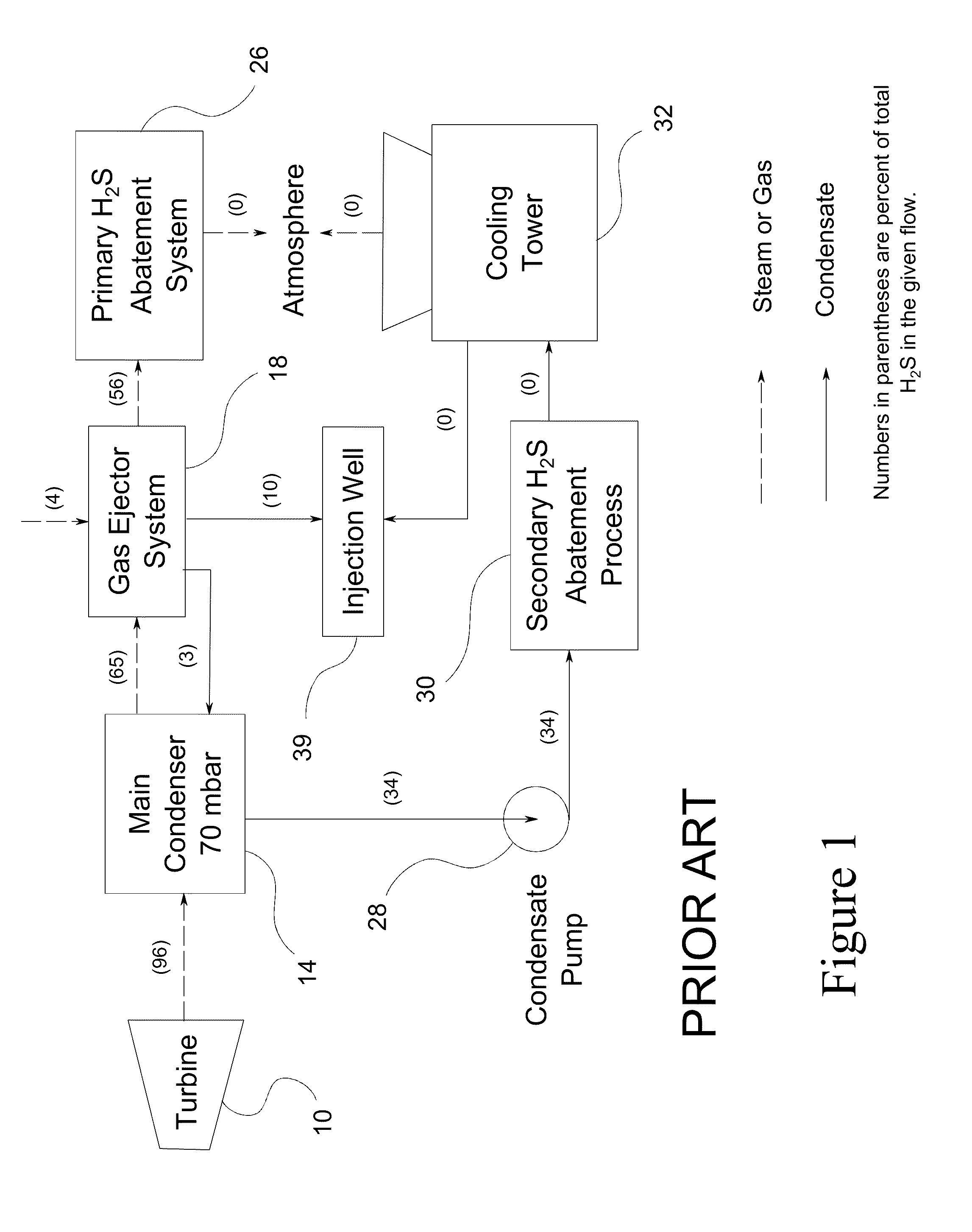

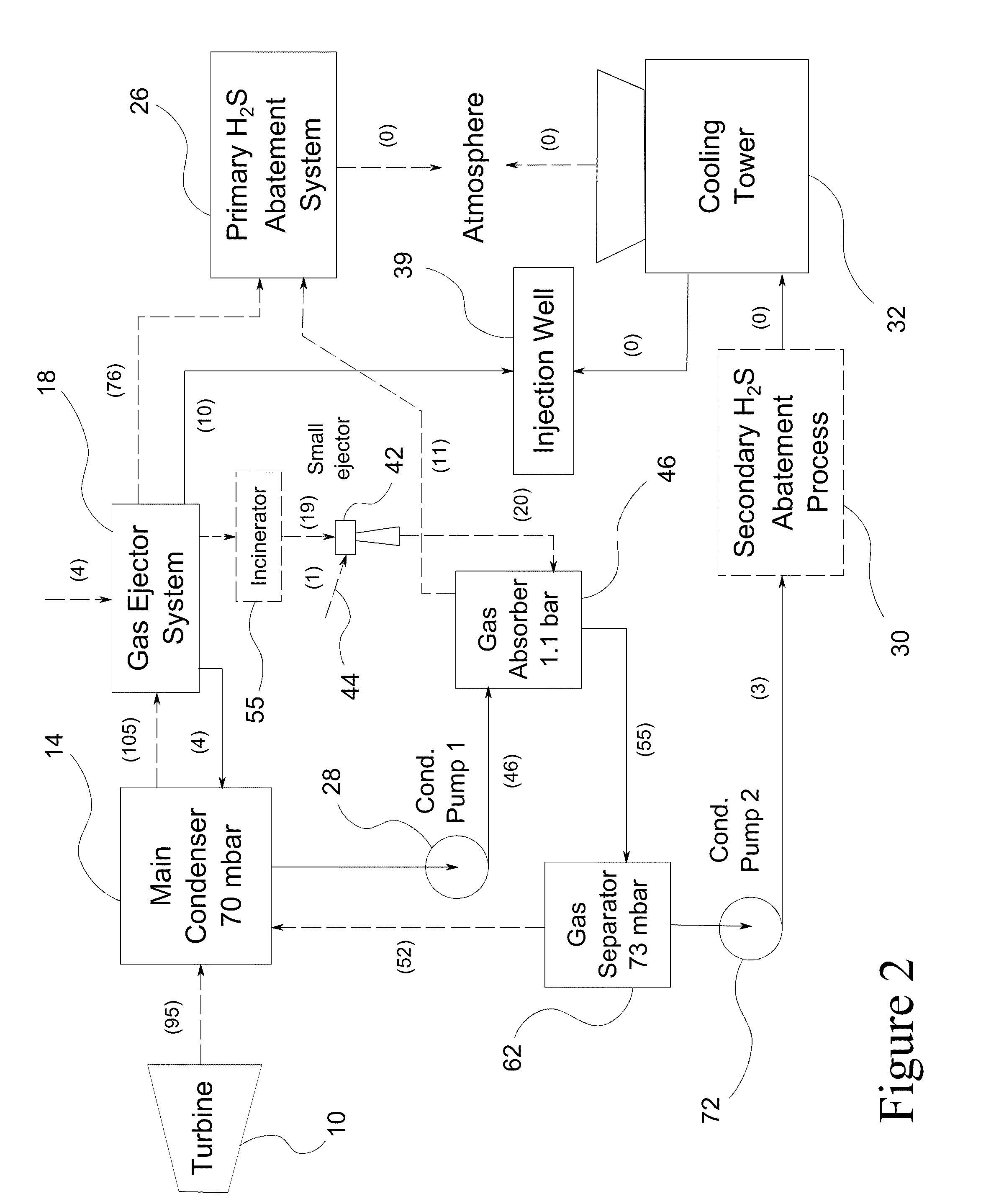

Method and Device to Remove Hydrogen Sulfide from Steam Condensate in a Geothermal Power Generating Unit

InactiveUS20110225971A1Improve condensation effectIncrease the volume ratioUsing liquid separation agentGeothermal energy generationChemical treatmentSolubility

Ammonia sometimes present in geothermal steam increases the solubility of hydrogen sulfide in the steam condensate produced by the surface condenser in a steam cycle geothermal power generating unit by reacting with the hydrogen sulfide to produce nonvolatile ammonium bisulfide. The condenser vent gas also produced contains carbon dioxide. Contacting the steam condensate with the condenser vent gas at a pressure slightly greater than atmospheric causes carbon dioxide to dissolve in the condensate, decreasing pH and converting bisulfide ion back to hydrogen sulfide. Subsequently exposing the acidified condensate to condenser vacuum strips the hydrogen sulfide from the condensate, eliminating the need for further chemical treatment of the condensate to prevent air pollution. Hydrogen sulfide partitioning performance is further improved by converting the hydrogen sulfide in the vent gas to sulfur dioxide before contacting it with the condensate.

Owner:CHEMTREAT

Solar simulator optical system

InactiveCN104914571AReduce axial sizeCompact structureLighting device detailsOptical elementsIntegratorBeam collimation

The invention discloses a solar simulator optical system. The solar simulator optical system includes a xenon lamp, an ellipsoid surface condenser, a first plane reflecting mirror, an optical integrator, an optical filter, a second plane reflecting mirror, an off-axis parabolic reflecting mirror and a shell; the xenon lamp is located at the first focus of the ellipsoid surface condenser; the optical integrator is of a symmetric structure and is composed of two sets of element lens arrays, wherein the front set of lenses is an integrator field lens which is located at the second focus of the ellipsoid surface condenser, and the back set of lenses is an integrator projection lens which is located at the front focal plane of a collimating mirror; and the off-axis parabolic mirror is the system collimating mirror. According to the solar simulator optical system, two plane reflecting mirrors are adopted, so that an optical path can be effectively folded, and the size of the optical path can be compressed; the system is an off-axis reflecting collimating system, and therefore, the collimating angle of a light beam is larger, and radiation uniformity is high, and central obscuration of an outputted light beam can be avoided; and a framework built by the system is a 4-shaped mirror image, and with such as an optical path structure realized, the center height of an outgoing light beam can be flexibly adjusted according to design requirements.

Owner:NANJING UNIV OF SCI & TECH

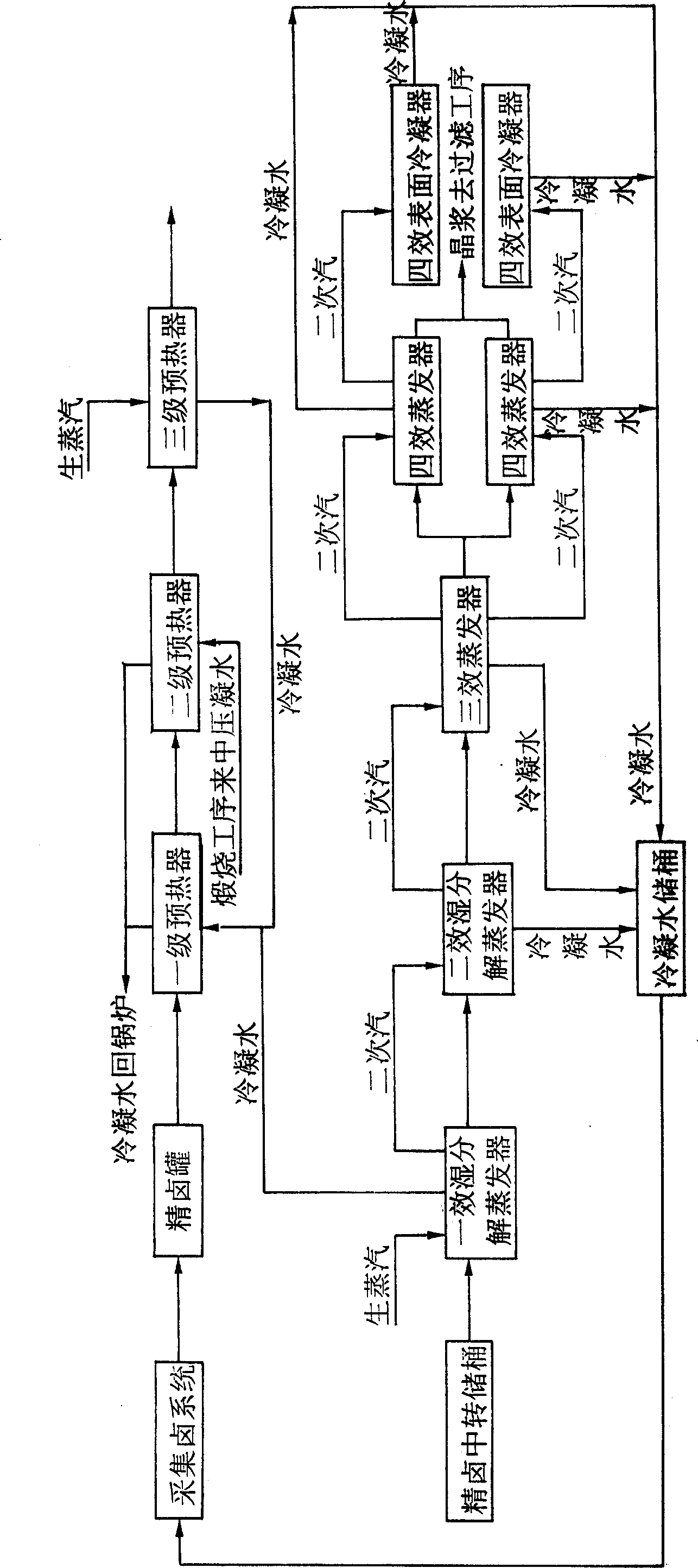

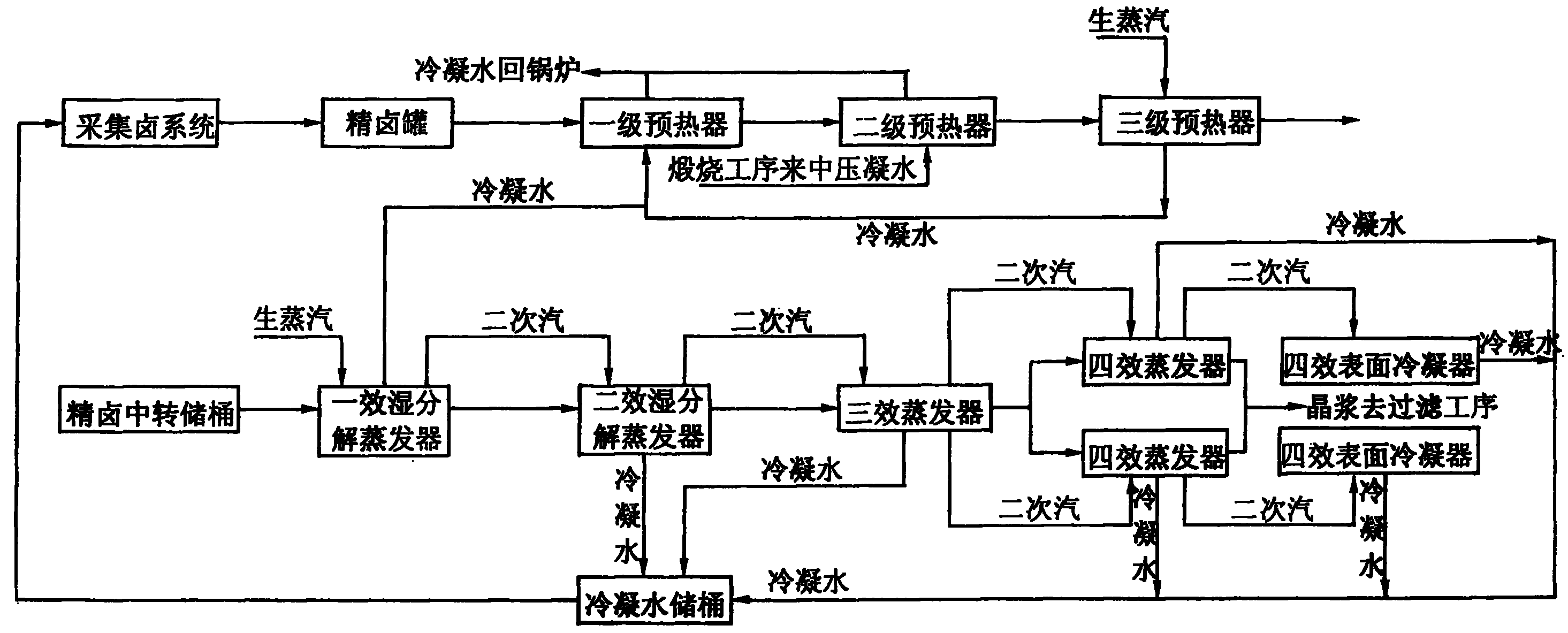

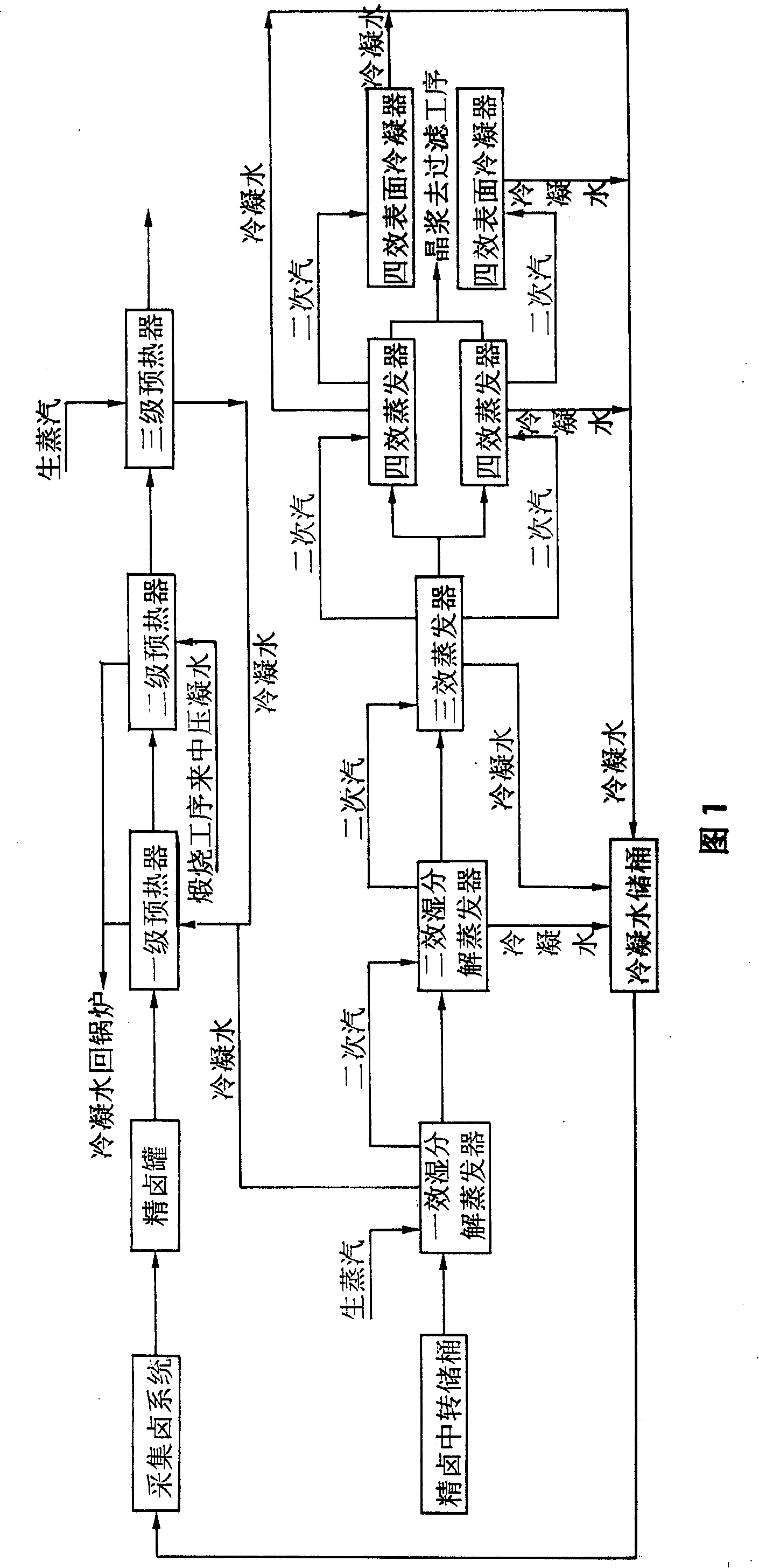

Wet decomposition evaporation alkali production technique for NaHCO3 alkali halide

ActiveCN101503204AShort processSolve the pollution of the environmentCarbonate preparationDecompositionEvaporation

The invention discloses an alkali preparing process for wetly decomposing and evaporating alkali halide containing NaHCO3, which comprises the following steps: adding purified brine in the refining process into a clear liquid storage tank; successively adding the brine into a first effective wet decomposition evaporator, a second effective wet decomposition evaporator, a third effective evaporator and a fourth effective crystallizer after the brine is sent to a primary preheater, a secondary preheater and a tertiary preheater in sequence by using a purified brine pump; and obtaining a crystal in the fourth effective crystallizer; and then sending the crystal to the filtering process. Primary steam used by the first effective wet decomposition evaporator adopts back pressure steam of 0.45 MPa (absolute pressure); condensed water generated after being preheated by a primary clear liquid preheater is returned to a boiler; secondary steam generated by each effective evaporator is used as a next effective heat source; and secondary steam generated during the fourth effective evaporation process is emptied after passing through a surface condenser. By adopting the production technology of the wet decomposition and evaporation process, the process flow of natural alkali preparing pure alkali is shortened, the production cost is reduced, the problem of environmental pollution in the traditional art is solved, and the production of the pollution-free natural alkali preparing pure alkali is achieved.

Owner:HENAN ZHONGYUAN CHEM

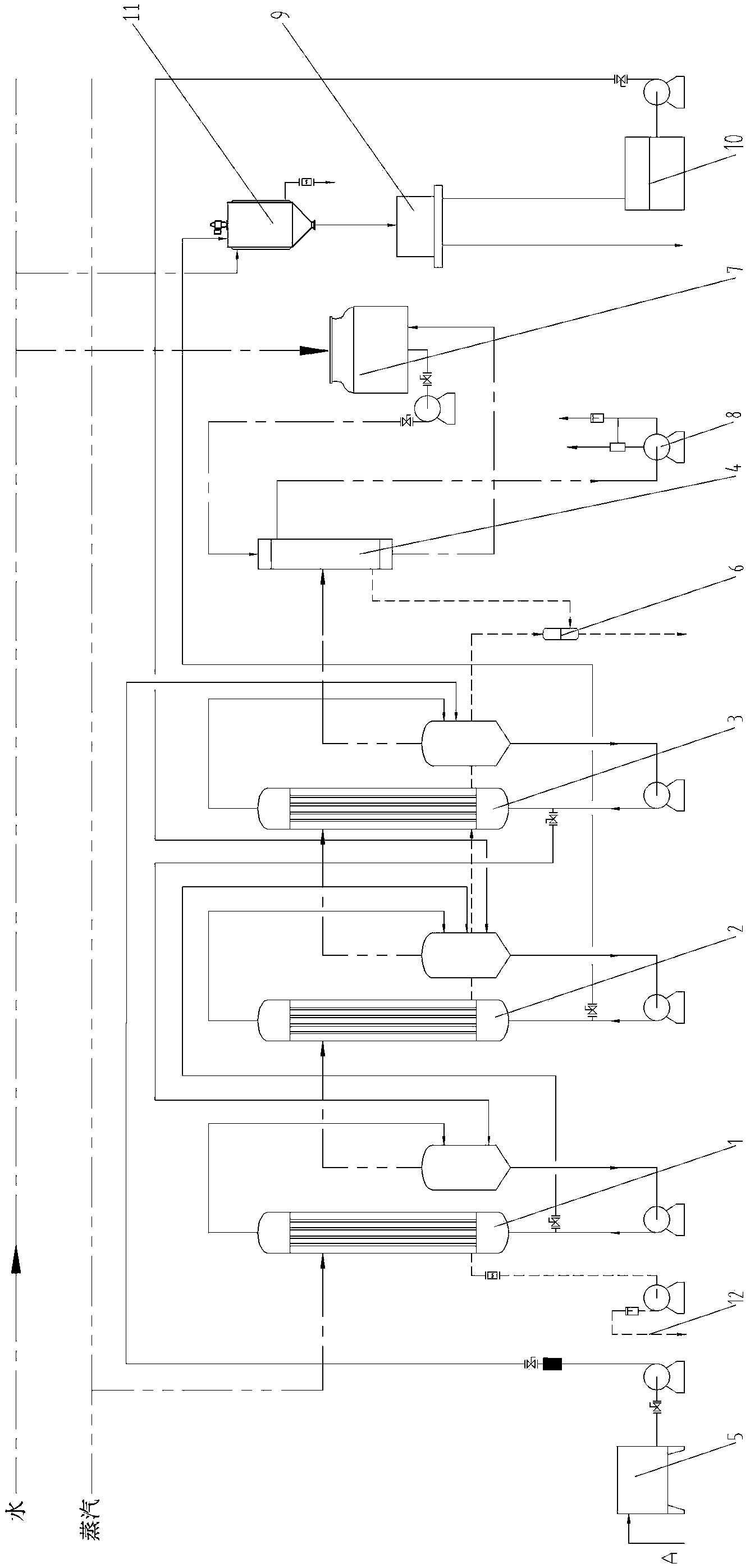

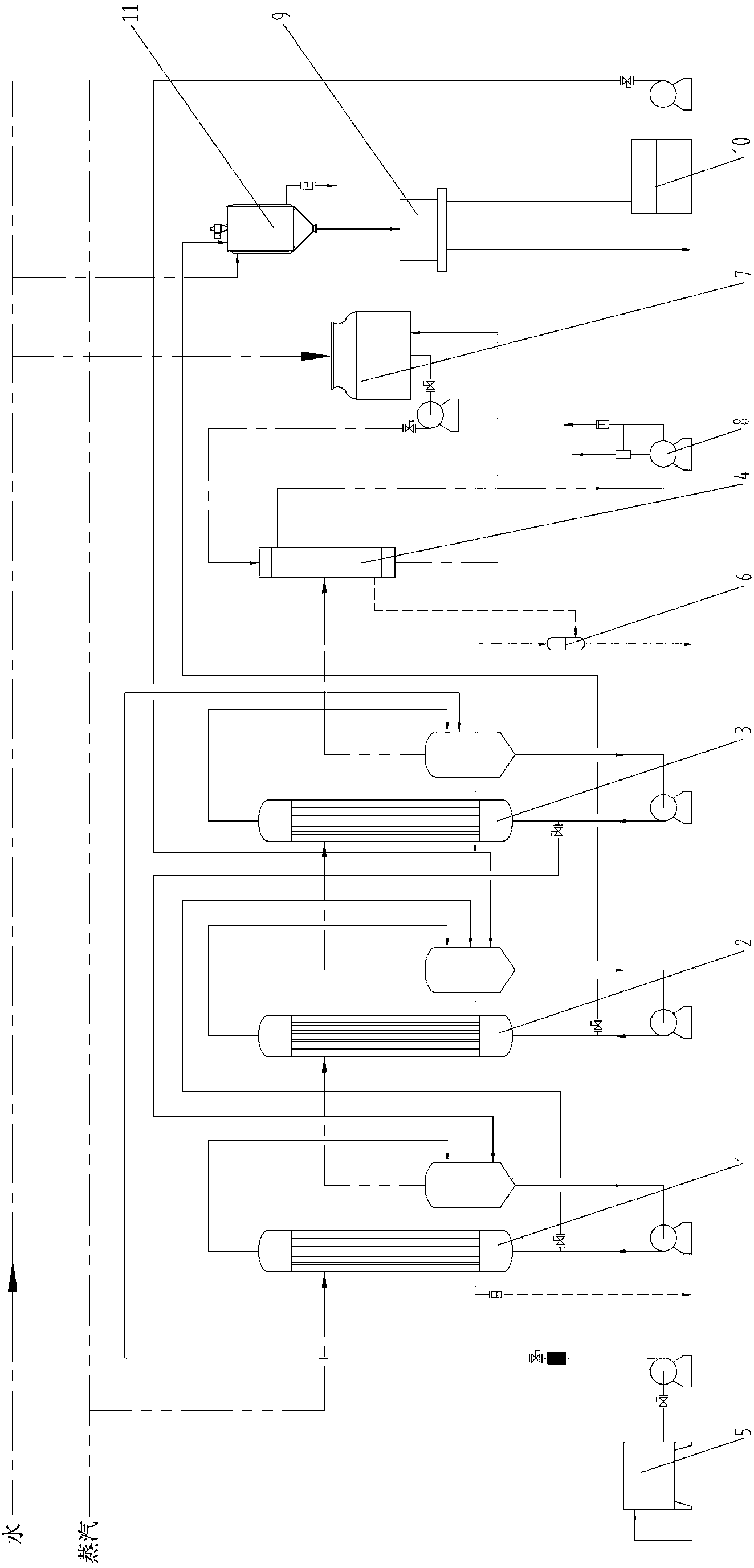

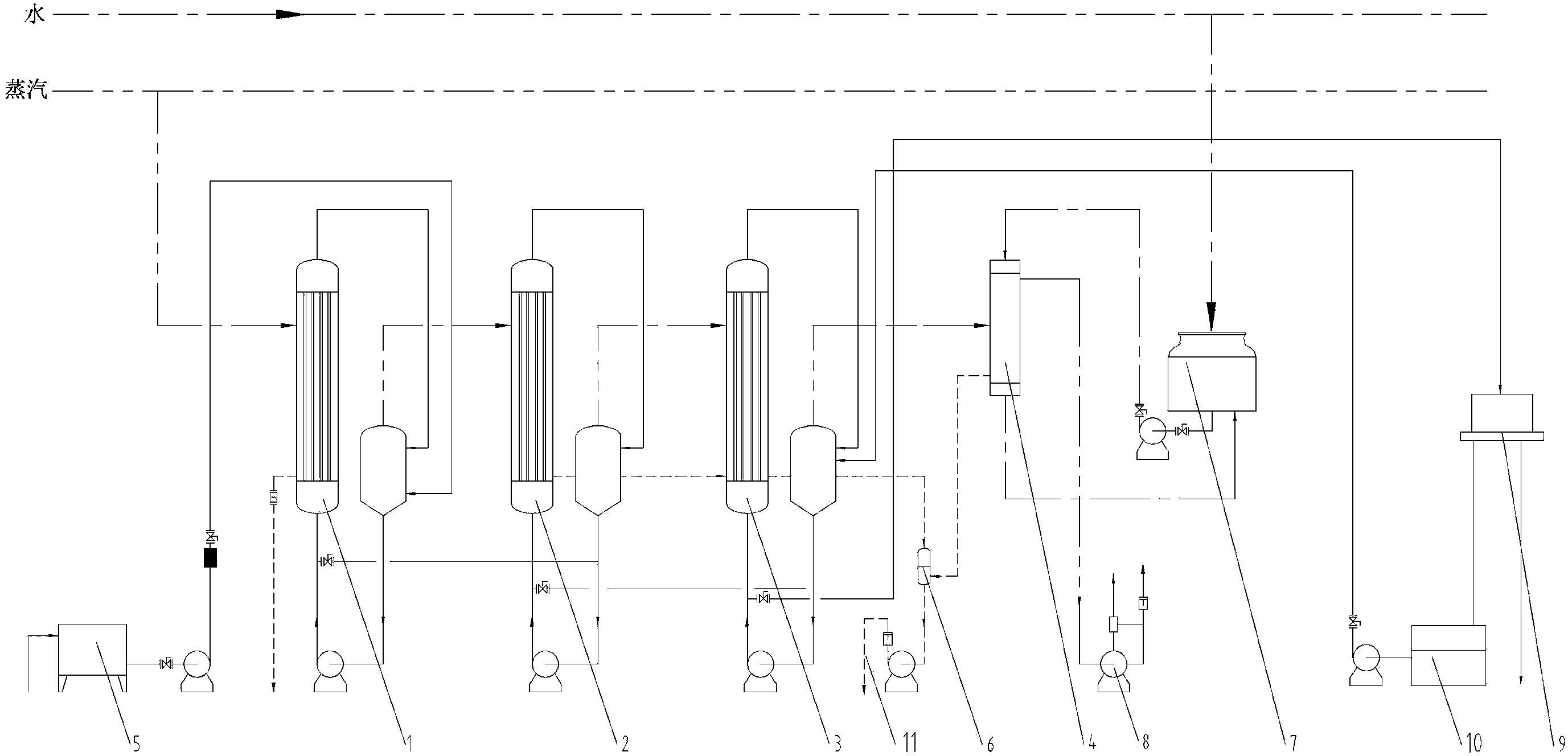

Multiple-effect evaporation system steam condensation water heat energy reutilizationoun device

InactiveCN104014143AIncrease temperatureSave heatEvaporator accessoriesMultiple-effect evaporationCooling towerSteam condensation

The invention discloses a multiple-effect evaporation system steam condensation water heat energy reutilizationoun device which comprises a first effect evaporation unit, a second effect evaporation unit and a third effect evaporation unit which are connected in sequence, the first effect evaporation unit is connected with a steam input pipe, the third effect evaporation unit is connected with a feeding groove, a gas phase tube of the third effect evaporation unit is connected to a surface condenser, a vacuum pump is arranged on the surface condenser, and the surface condenser and a cooling tower form a cooling loop; a steam condensation water pipe of the first effect evaporation unit is connected to a boiler room or a preheater, evaporation condensate tubes of the second effect evaporation unit, the third effect evaporation unit and the surface condenser are connected to a condensate collection groove, and a crystal slurry pipe of the second effect evaporation unit is connected to a cooler crystallizer. The multiple-effect evaporation system steam condensation water heat energy reutilizationoun device has the advantages of high crystallization efficiency and low heat energy consumption.

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

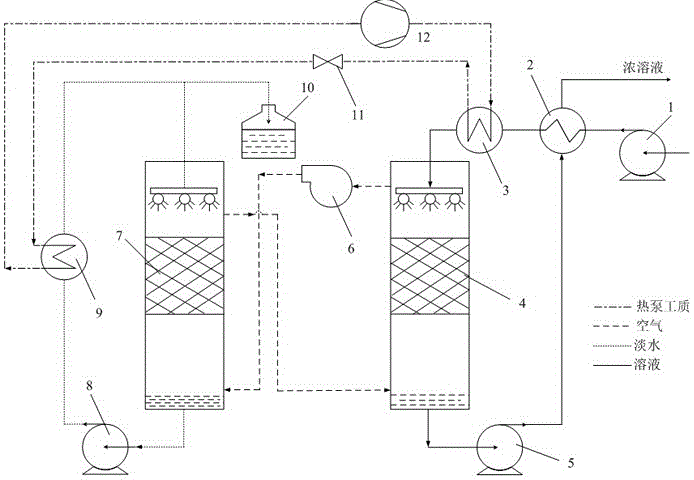

Heat pump dual-heat-mass coupled humidification and dehumidification evaporation system and method

ActiveCN106839494AEliminate dependenciesFully recover sensible heatCompression machines with reversible cycleSorption machinesEvaporationPower engineering

A heat pump dual-heat-mass coupled humidification and dehumidification evaporation system and a method belong to the fields of energy and power engineering and evaporation. A condenser of a heat pump system is utilized to drive the evaporation system according to the energy transfer and conversion mechanism in a compression heat pump and an air-water system, and the energy utilization efficiency of the evaporation system is improved through humidification, dehumidification and the in-system heat recovery process. The advantage that the heat pump system is high in performance coefficient is fully utilized, restrictions of heat source conditions on the evaporation system are broken through, and meanwhile, mass transfer and heat transfer processes are introduced into the dehumidification process, so that the cost due to application of corrosion-resistant noble metals to a conventional surface condenser is greatly reduced; and sensible heat of in-system fresh water and concentrated solutions is fully utilized, so that the energy utilization efficiency of the evaporation system is improved, the energy-saving effect is obvious, and the heat pump dual-heat-mass coupled humidification and dehumidification evaporation system conforms to the national standards of energy conservation and emission reduction and the sustainable development strategy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

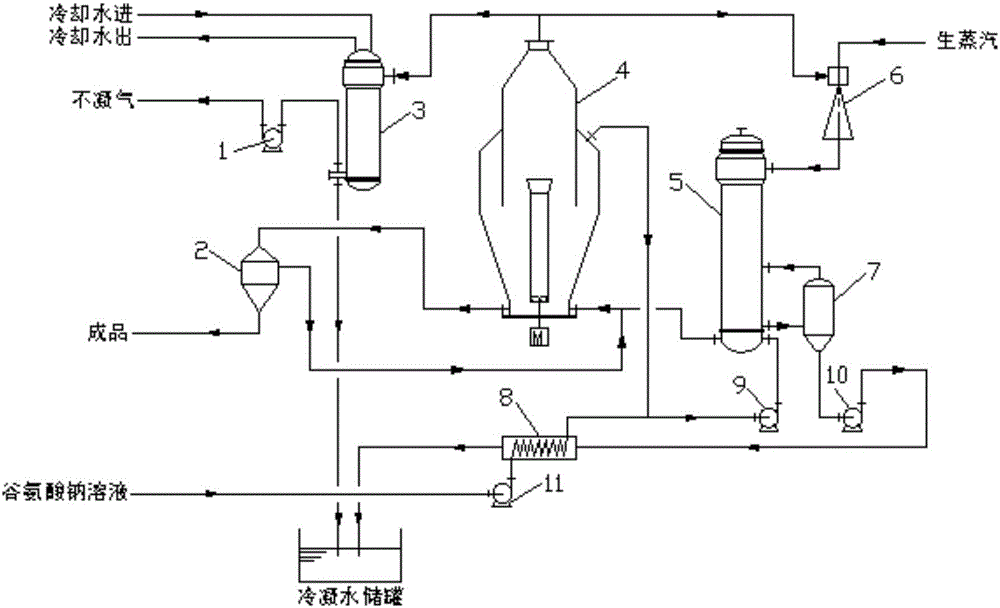

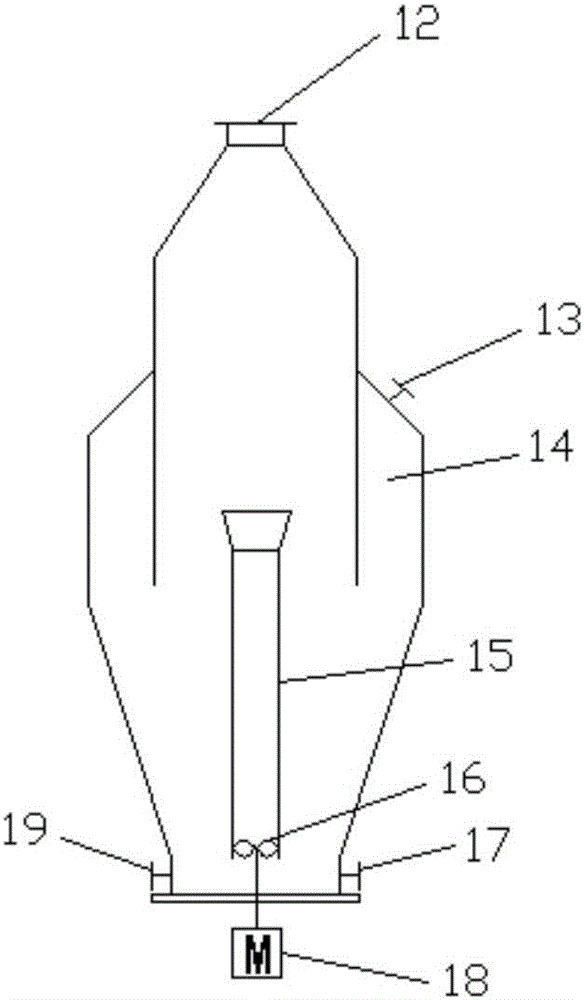

Continuous single-effect vacuum evaporation crystallization system as well as application and technology

InactiveCN106310704AReduce consumptionRealize continuous productionEvaporator accessoriesSolution crystallizationSlurryEngineering

The invention discloses a continuous single-effect vacuum evaporation crystallization system as well as application and technology. The system comprises a preheater, a heating chamber and a vacuum crystallizer, wherein the preheater is used for preheating a solution; a solution inlet of the heating chamber is communicated with the preheater; steam is introduced into the heating chamber and performs heat exchange with the solution in the heating chamber; the vacuum crystallizer is connected with the heating chamber, a centrifuge and a surface condenser respectively; the solution heated by the heating chamber is crystallized in the crystallizer; the crystallized crystal slurry enters the centrifuge and is separated to obtain a finished product of crystal; one part of the secondary steam generated by the vacuum crystallizer enters the surface condenser to be condensed, and the other part of the secondary steam enters the heating chamber for cyclic utilization; through the arrangement of the heating chamber, the solution is heated for the second time, and the heating chamber can make use of live steam as well as secondary steam generated by an evaporator; and the whole system realizes continuous circular generation of sodium glutamate particles, and the crystal product has the advantages of high quality, large crystalline particle size, uniform particles and smooth surface.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Method and apparatus for commissioning power plants

ActiveUS20140174559A1Reduce consumptionShorten the timePlug valvesDrying solid materials without heatPower stationEngineering

An apparatus and method for commissioning steam turbine generator power plants to advance the cleanliness of the complete steam cycle by the conditioned discharge of steam to the plant surface condenser.

Owner:BEST ENERGY SERVICES INC

Method and apparatus for commissioning power plants

ActiveUS20140230862A1Reduce consumptionShorten the timeDrying solid materials without heatBoiler cleaning apparatusPower stationEngineering

An apparatus and method for commissioning steam turbine generator power plants to advance the cleanliness of the complete steam cycle by the conditioned discharge of steam to the plant surface condenser.

Owner:BEST ENERGY SERVICES INC

Sodium sulfate evaporation crystallization device

InactiveCN104016383ALess quantityIncrease temperatureAlkali metal sulfite/sulfate purificationCooling towerGas phase

The invention discloses a sodium sulfate evaporation crystallization device which comprises a first effect evaporation unit, a second effect evaporation unit and a third effect evaporation unit which are connected in sequence, the first effect evaporation unit is connected with a steam input pipe, the third effect evaporation unit is connected with a feeding groove, a gas phase tube of the third effect evaporation unit is connected to a surface condenser, a vacuum pump is arranged on the surface condenser, and the surface condenser and a cooling tower form a cooling loop; evaporation condensate tubes of the second effect evaporation unit, the third effect evaporation unit and the surface condenser are connected to a condensate collection groove, a crystal slurry pipe of the second effect evaporation unit is connected to a cooler crystallizer, a spiral conveyer is arranged at the position of the inlet of the crystal slurry pipe, the output end of the cooling crystallizer is connected to a centrifuge, the centrifuge is provided with a solid salt output end and a mother liquor tube, and the mother liquor tube is connected to a mother liquor tank. The sodium sulfate evaporation crystallization device has the advantages of high crystallization efficiency and low heat energy consumption.

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

Sodium chloride evaporation crystallization device

InactiveCN104014156AReduce high vacuum suction effectAvoid cloggingSolution crystallizationAlkali metal chloridesCooling towerGas phase

The invention discloses a sodium chloride evaporation crystallization device which comprises a first effect evaporation unit, a second effect evaporation unit and a third effect evaporation unit which are connected in sequence, the first effect evaporation unit is connected with a steam input pipe and a feeding groove, a gas phase tube of the third effect evaporation unit is connected to a surface condenser, a crystal slurry pipe of the third effect evaporation unit is connected to a centrifuge, the centrifuge is provided with a solid salt output end and a mother liquor tube, and the mother liquor tube is connected to a mother liquor tank; a throttling gear is arranged on a connecting pipe of a separator and heating column tubes in the first effect evaporation unit, the second effect evaporation unit and the third effect evaporation unit; a vacuum pump is arranged on the surface condenser, and the surface condenser and a cooling tower form a cooling loop; evaporation condensate tubes of the second effect evaporation unit, the third effect evaporation unit and the surface condenser are connected to a condensate collection groove. The sodium chloride evaporation crystallization device has the advantages of high operation concentration and less reflux mother liquor.

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

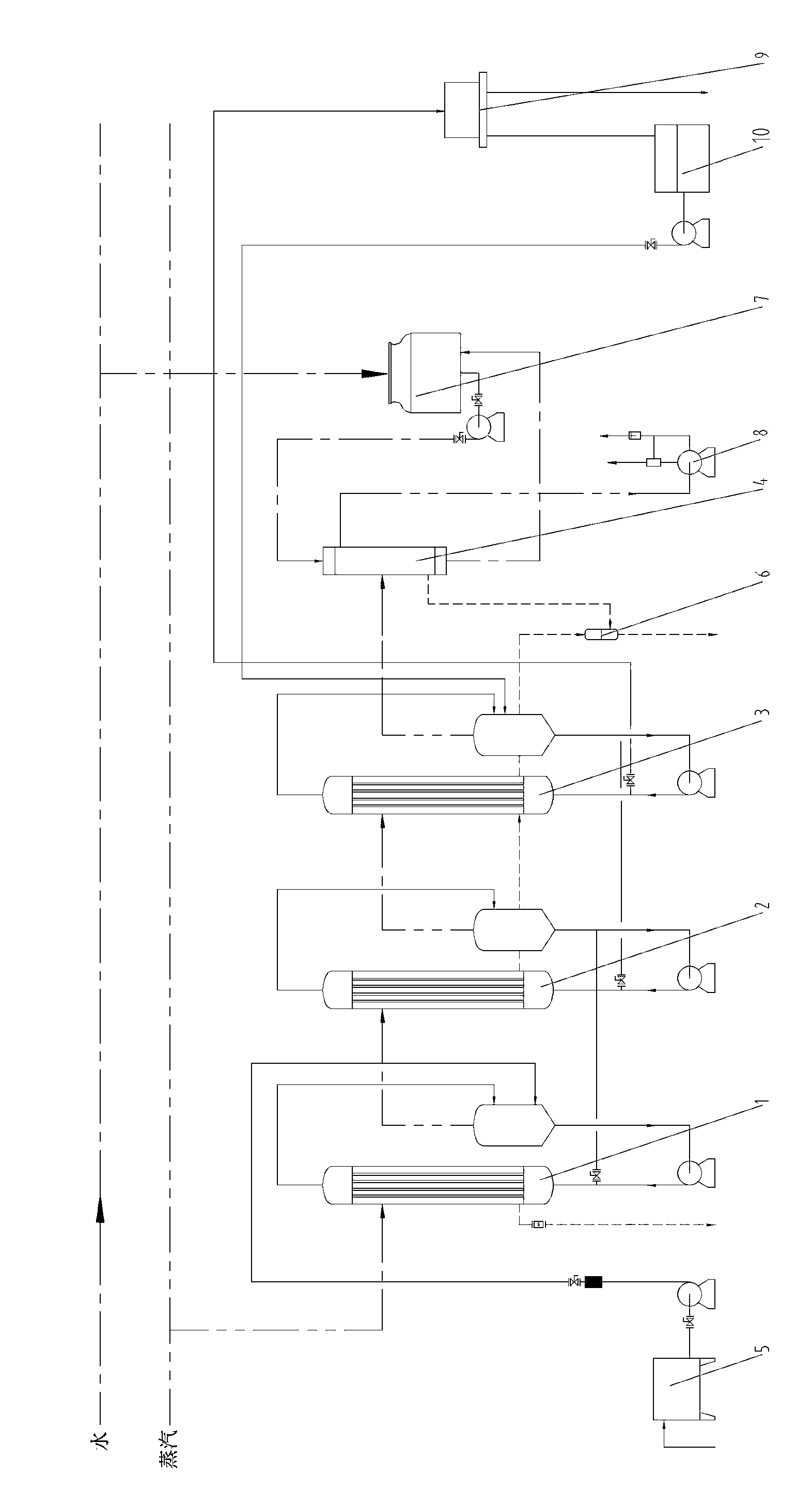

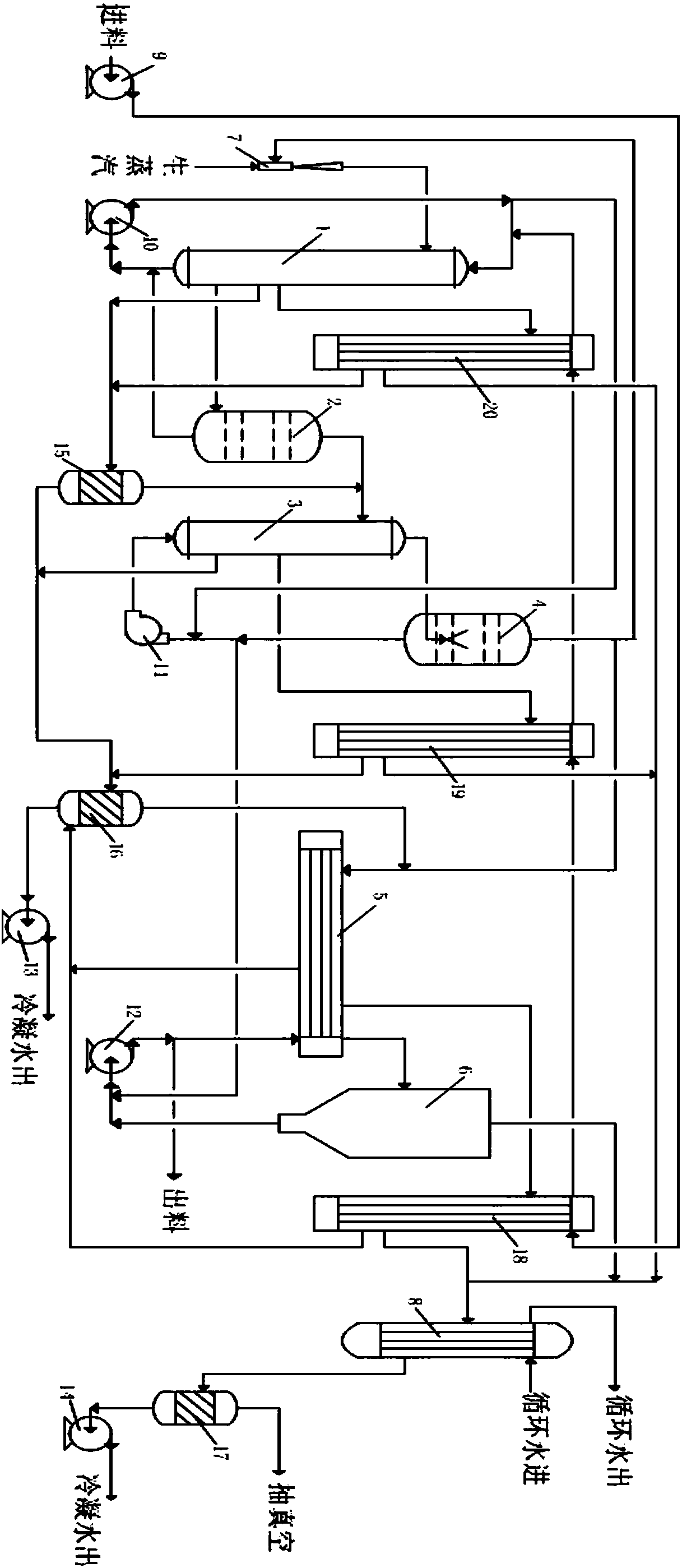

Energy-saving environment-friendly DDGS (Distillers Dried Grains with Solubles) waste heat vaporization system

PendingCN109432808AAchieve primary recyclingSolve problems such as pollutionEvaporator accessoriesVapor condensationEvaporationVaporization

The invention relates to an energy-saving environment-friendly DDGS (Distillers Dried Grains with Solubles) waste heat vaporization system which comprises a condensate water flash tank, a high-temperature condensate pump, a waste gas washing tower, a washing water pump, a first effective heater, a first effective separator, a second effective heat exchanger, a second effective separator, evaporators, a surface condenser, a condensate water collecting tank and a condensate pump, wherein the quantity of the evaporators is three, namely, a third effective evaporator, a fourth effective evaporatorand a fifth effective evaporator. According to the invention, secondary steam generated by a tube bundle dryer is washed by the washing tower and then is fed into a multi-level vaporization system; the condensate water generated by the tube bundle dryer is treated by the flash tank to generate steam and then the generated steam is fed into the multi-level vaporization system; the secondary steamafter washing and the steam generated by the flash tank are utilized to perform evaporation concentration on a filtrate formed after solid-liquid separation of distiller liquor; the secondary steam generated by the tube bundle dryer and heat in the condensate water are fully recovered; the recovery ratio of waste heat is high; dust pollutants in the secondary steam are absorbed; and the purpose ofsaving energy and reducing emission is achieved.

Owner:郑州博大浓缩干燥设备有限公司

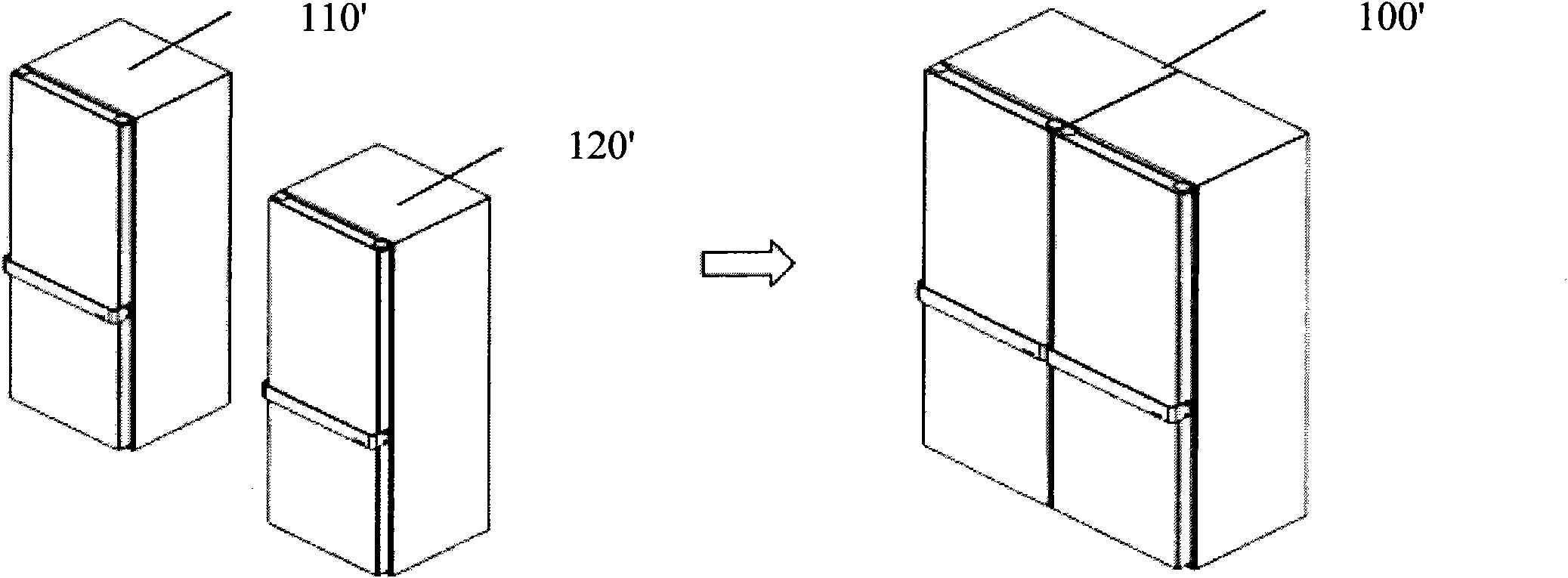

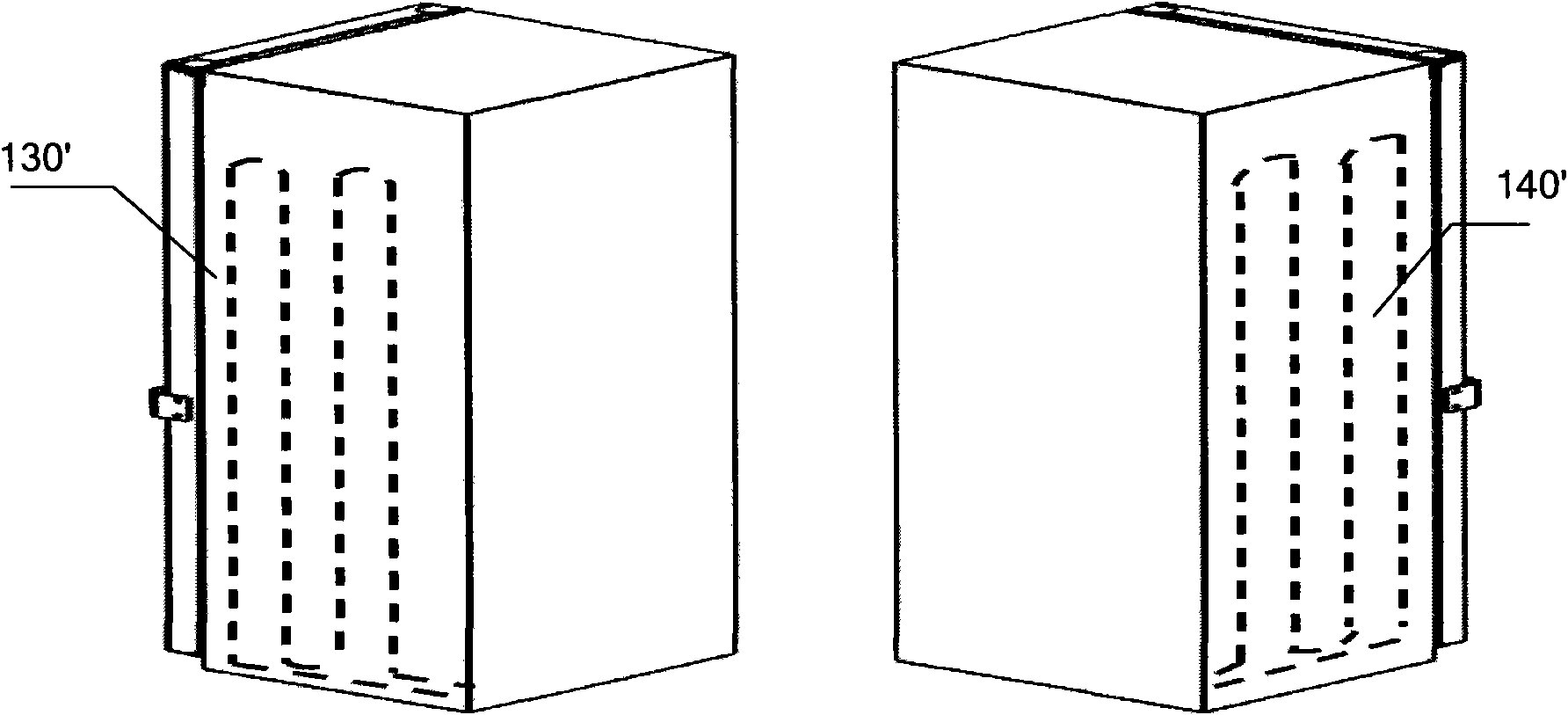

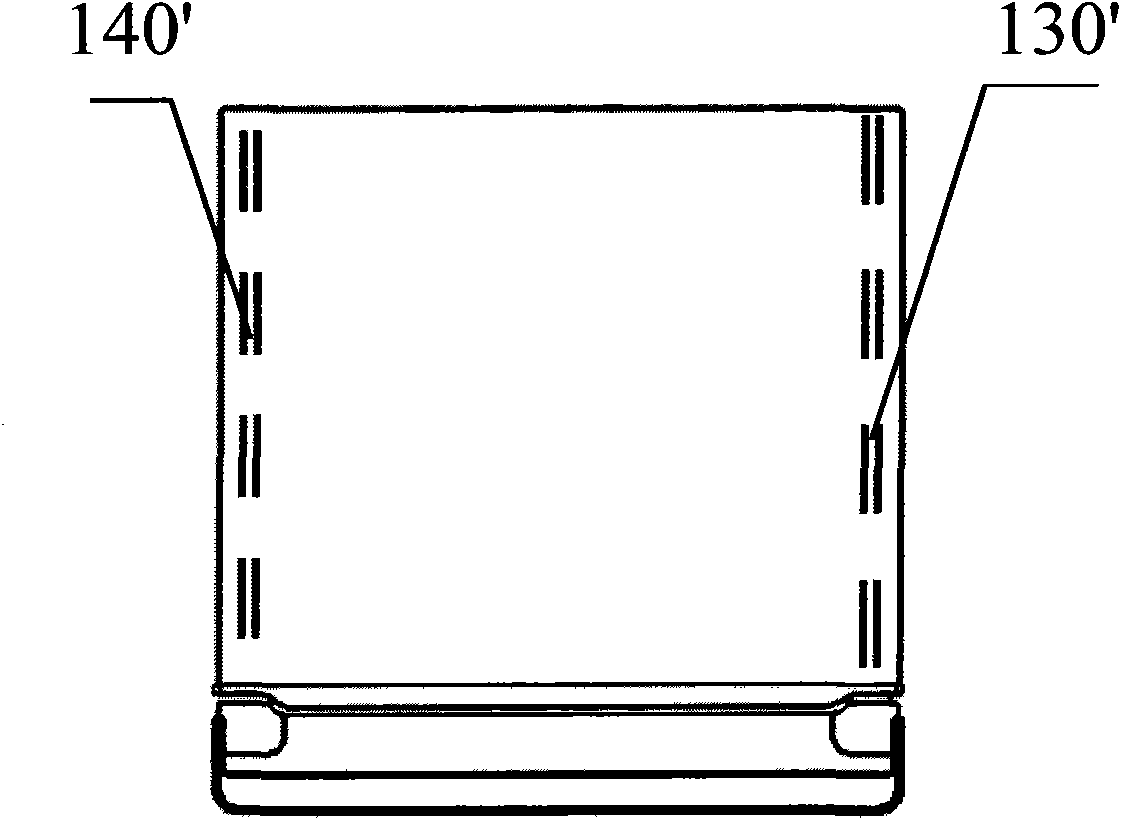

Combined refrigeration equipment

InactiveCN102183115ASolve the cooling problemPerformance is not affectedLighting and heating apparatusRefrigeration devicesEngineeringRefrigeration

The invention provides combined refrigeration equipment. The combined refrigeration equipment comprises first refrigeration equipment, second refrigeration equipment and a connection component, wherein the back surface of the first refrigeration equipment is provided with a first back surface condenser; a left condenser is arranged on the left side of the first refrigeration equipment; the back surface of a box body of the second refrigeration equipment is provided with a second back surface condenser; a right condenser is arranged on the right side of the box body of the second refrigeration equipment; and one end of the connection component is detachably connected with the box body of the first refrigeration equipment, and the other end of the connection component is detachably connected with the box body of the second refrigeration equipment, so that the right side of the first refrigeration equipment is adjacent to the left side of the second refrigeration equipment during combination. In the embodiment of the invention, the built-in condensers, which are conventionally arranged on two sides, are arranged on the side face and the back surface, so that the problem of heat dissipation of the refrigeration equipment with the built-in condensers in a combined state is solved, and furthermore, the performance of the refrigeration equipment is not influenced no matter whether single equipment is used or a plurality of sets of equipment are combined for use.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Method and apparatus for commissioning power plants

InactiveUS20140174477A1Reduce consumptionShorten the timeDrying solid materials without heatHollow article cleaningPower stationEngineering

An apparatus and method for commissioning steam turbine generator power plants to advance the cleanliness of the complete steam cycle by the conditioned discharge of steam to the plant surface condenser.

Owner:BEST ENERGY SERVICES INC

Wet decomposition evaporation alkali production technique for NaHCO3 alkali halide

ActiveCN101503204BSolve the pollution of the environmentReduce the impact of thermal efficiencyCarbonate preparationDecompositionEvaporation

The invention discloses an alkali preparing process for wetly decomposing and evaporating alkali halide containing NaHCO3, which comprises the following steps: adding purified brine in the refining process into a clear liquid storage tank; successively adding the brine into a first effective wet decomposition evaporator, a second effective wet decomposition evaporator, a third effective evaporator and a fourth effective crystallizer after the brine is sent to a primary preheater, a secondary preheater and a tertiary preheater in sequence by using a purified brine pump; and obtaining a crystal in the fourth effective crystallizer; and then sending the crystal to the filtering process. Primary steam used by the first effective wet decomposition evaporator adopts back pressure steam of 0.45MPa (absolute pressure); condensed water generated after being preheated by a primary clear liquid preheater is returned to a boiler; secondary steam generated by each effective evaporator is used asa next effective heat source; and secondary steam generated during the fourth effective evaporation process is emptied after passing through a surface condenser. By adopting the production technologyof the wet decomposition and evaporation process, the process flow of natural alkali preparing pure alkali is shortened, the production cost is reduced, the problem of environmental pollution in the traditional art is solved, and the production of the pollution-free natural alkali preparing pure alkali is achieved.

Owner:HENAN ZHONGYUAN CHEM

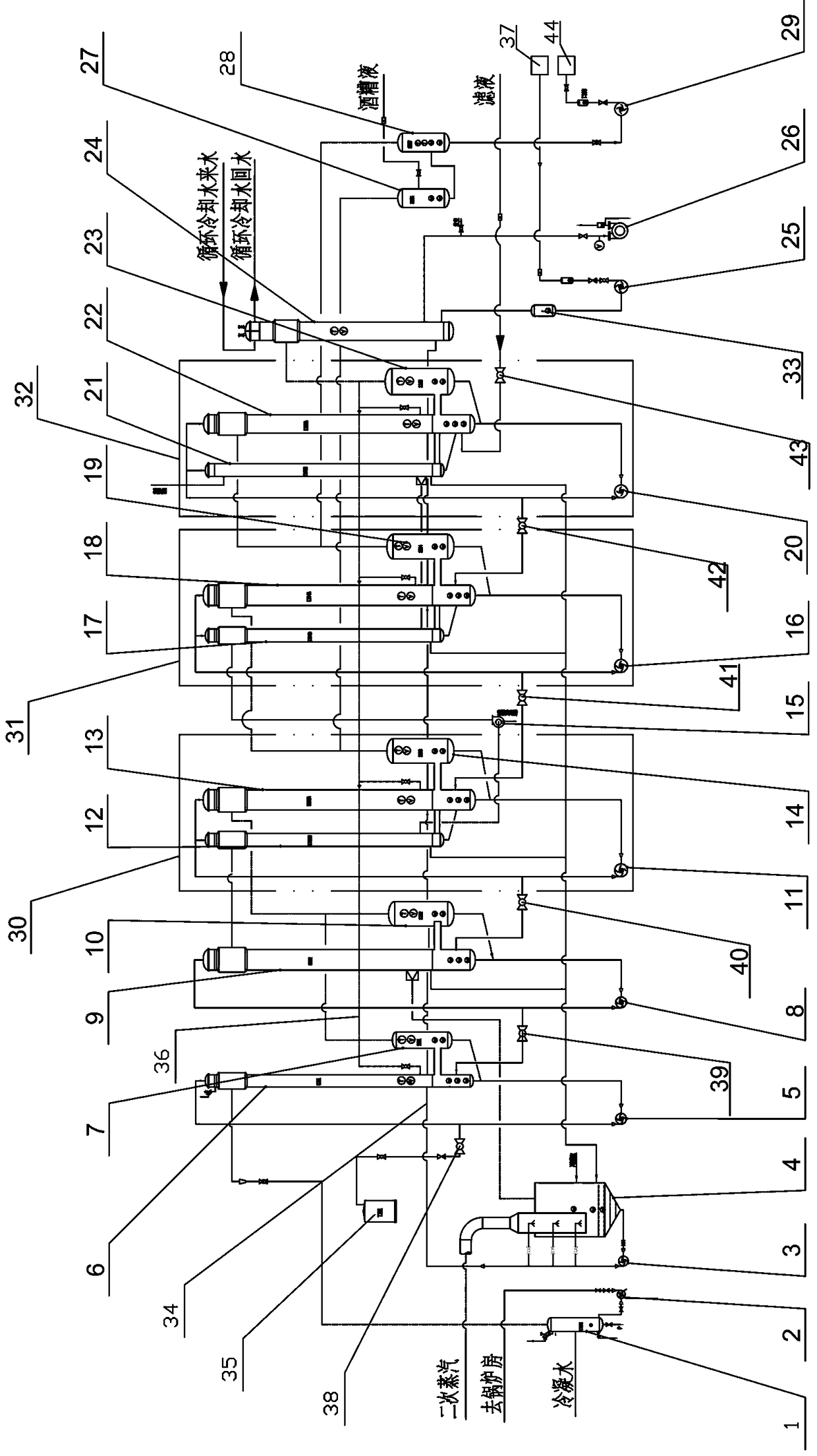

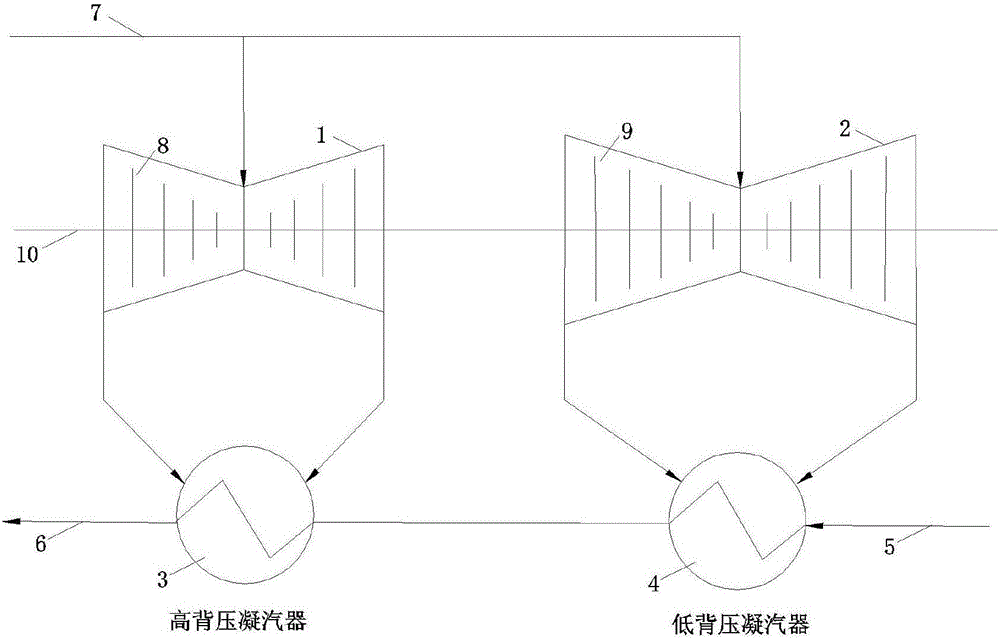

Low-pressure cylinder module system of double-back-pressure asymmetric turbine and operation method of low-pressure cylinder module system

InactiveCN106014503AImprove operating economyImprove operational safetyEngine manufactureBlade accessoriesEngineeringTurbine

The invention relates to a dual-backpressure asymmetric steam turbine low-pressure cylinder module system and its operating method. The system includes a low-pressure cylinder installed on the steam turbine platform, a high-backpressure surface condenser connected to the low-pressure cylinder, and a high-backpressure surface condenser installed on the low-pressure cylinder. The internal short final stage blade set is installed on the low-pressure cylinder of the steam turbine platform, the low back pressure surface condenser connected to the low-pressure cylinder, the long final-stage blade set installed inside the low-pressure cylinder, and the medium-low The cylinder pressure connecting pipe, the circulating water pipe installed at the circulating water inlet of the low back pressure condenser, the circulating water pipe installed at the circulating water outlet pipe of the high back pressure condenser; the exhaust steam of the medium pressure cylinder of the steam turbine passes through the medium and low pressure connecting pipe Enter the first low-pressure cylinder and the second low-pressure cylinder respectively, and after doing work in the first low-pressure cylinder and the second low-pressure cylinder, the steam is respectively discharged into the high back pressure surface condenser and the low back pressure surface condenser for surface heat exchange .

Owner:中国大唐集团科学技术研究总院有限公司

SCAL indirect air cooling system used for building 600MW air cooling set

ActiveCN101063595BReduce sizeSmall footprintSteam/vapor condensersStationary conduit assembliesCooling towerWater quality

The invention relates to a SCAL indirect air-cooling system, mainly comprising a surface condenser, a recycling water system, a fog type aluminum pipe and aluminum flake radiator and an air-cooling tower, wherein in the surface condenser, after the wasted steam discharged from the steam turbine performs the first heat exchange with the cooling water, the wasted steam transmits the heat to the cooling water and condensed to condensed water, then flow back to the air-cooling system heat system, the cooling water flows to the fog type aluminum pipe and aluminum flake radiator via the recycling water pump after it is heated up, and the cooling water secondarily exchange heat with the environmental air, the cooling water transmits the heat to the air and makes the water temperature decrease, and then return to the cooling steam turbine of the surface condenser, the system recycles like this. The invention has the advantages that the Haman type indirect air-cooling system is separated from the steam water system, the water quality controlling and disposing is easy, the Hailer system air-cooling tower has a small body, The invention takes up small area and the capital cost of reactor plant is low.

Owner:NORTH CHINA POWER ENG +1

Multiple-effect evaporation system evaporation condensation water heat energy reutilizationoun device

InactiveCN104014144AIncrease heatIncrease temperatureEvaporator accessoriesMultiple-effect evaporationGas phaseEngineering

The invention discloses a multiple-effect evaporation system evaporation condensation water heat energy reutilizationoun device which comprises a first effect evaporation unit, a second effect evaporation unit and a third effect evaporation unit which are connected in sequence, the first effect evaporation unit is connected with a steam input pipe, the first effect evaporation unit is connected with a feeding groove, a gas phase tube of the third effect evaporation unit is connected to a surface condenser, a crystal slurry tube of the third effect evaporation unit is connected to a centrifuge, evaporation condensate tubes of the second effect evaporation unit, the third effect evaporation unit and the surface condenser are connected to a condensate collection groove, the output end of the condensate collection groove is connected to a preheater, the preheater is connected in series between the first effect evaporation unit and the feeding groove. The multiple-effect evaporation system evaporation condensation water heat energy reutilizationoun device can make full use of waste heat of condensation water, and saves live steam consumption amount of an evaporation crystallization device.

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

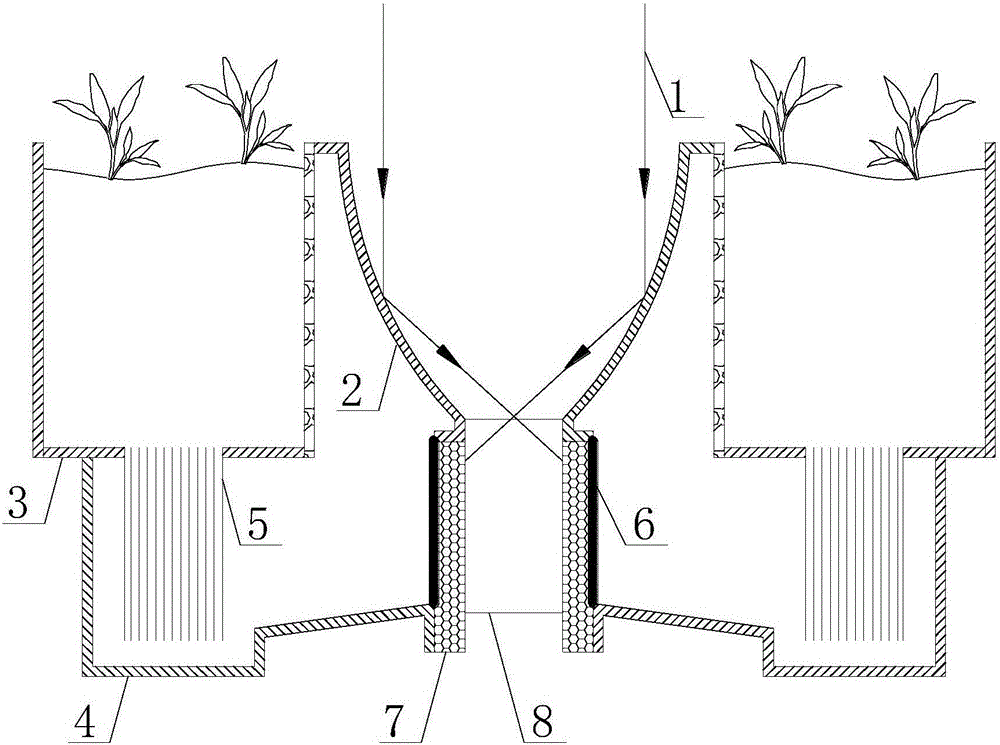

Solar energy focus and membrane distillation process based sea agriculture ecological membrane

InactiveCN106034797AReasonable useEfficient separationGeneral water supply conservationSeawater treatmentDistillationMembrane distillation

The invention discloses a solar energy focus and membrane distillation process based sea agriculture ecological membrane, and belongs to the field of solar energy focus heat collection and ecological agriculture. The sea agriculture ecological membrane includes curved surface condensers, solar-heat converters, ecological agriculture planting grooves, fresh water collection grooves, sea distillation membranes, porous material water absorption devices, and ecological agriculture water controllers, which are connected; the solar energy focus and membrane distillation process based sea agriculture ecological membrane can be used in a single manner and in a combined manner; sun light comes to surfaces of the curved surface condensers, and then reaches the solar-heat converters via multiple reflections to be converted into heat energy; sides surfaces of the solar-heat converters are fixedly provided with the porous material water absorption devices, wherein the absorbed sea water is heated and evaporated by the solar-heat converters, the evaporated sea water enters over the fresh water collection grooves to be condensed via the sea water distillation membranes near the porous material water absorption devices, and the condensed water is utilized by crops through water absorption materials on the side surfaces of the ecological agriculture planting grooves or is collected in the fresh water collection grooves; and the collected water is utilized by plants in the ecological agriculture planting grooves through the ecological agriculture water controllers.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Sunlight illumination optical system of south exit of tunnel

A sunlight illumination optical system of a south exit of a tunnel comprises a parabolic cylinder curved surface light adjusting lens, a parabolic cylinder curved surface condenser lens, an emitting groove, a secondary light guide lens, a plane mirror set and a primary light guide lens, a condenser is formed by the parabolic cylinder curved surface condenser lens facing the sun and the parabolic cylinder curved surface light adjusting lens having the same focal point with the parabolic cylinder curved surface condenser lens, parallel sunlight is condensed by the parabolic cylinder curved surface condenser lens and then becomes parallel light after light paths are adjusted by the parabolic cylinder curved surface light adjusting lens, the parallel light is output out of the emitting groove of the parabolic cylinder curved surface condenser lens to the primary light guide lens and reflected into the secondary light guide lens by the primary light guide lens, reflected light of the secondary light guide lens has the same direction with the tunnel, the secondary light guide lens is arranged outside the south exit of the tunnel, and the inclined plane mirror set is arranged at the positions, located in the light paths of the secondary light guide lens, of the top of the tunnel and used for transmitting the sunlight onto all road surfaces in the area of the south exist of the tunnel. The sunlight illumination optical system of the south exit of the tunnel is simple in structure and therefore has broad application prospects.

Owner:XIAN DAYU PHOTOELECTRIC TECH

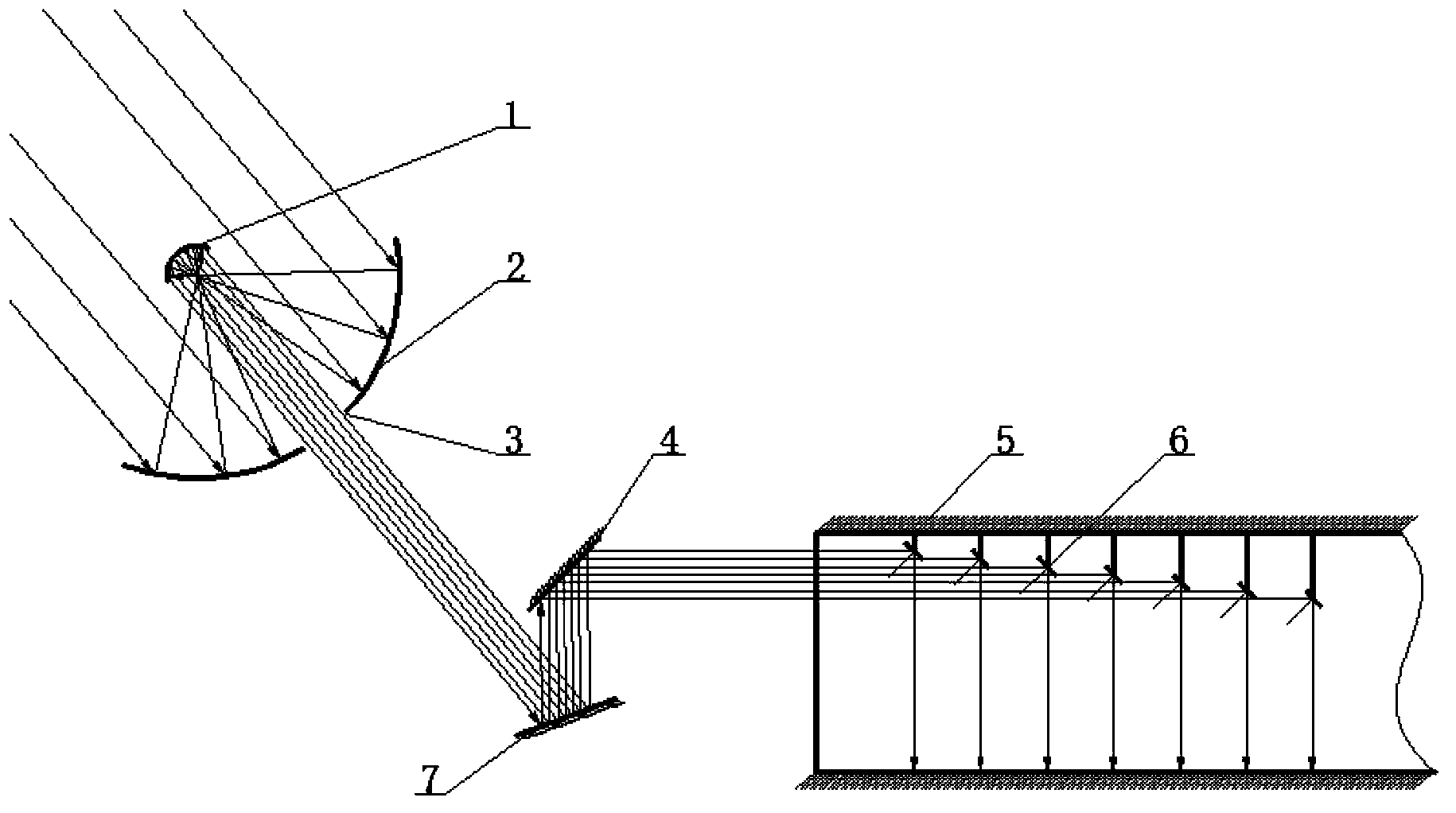

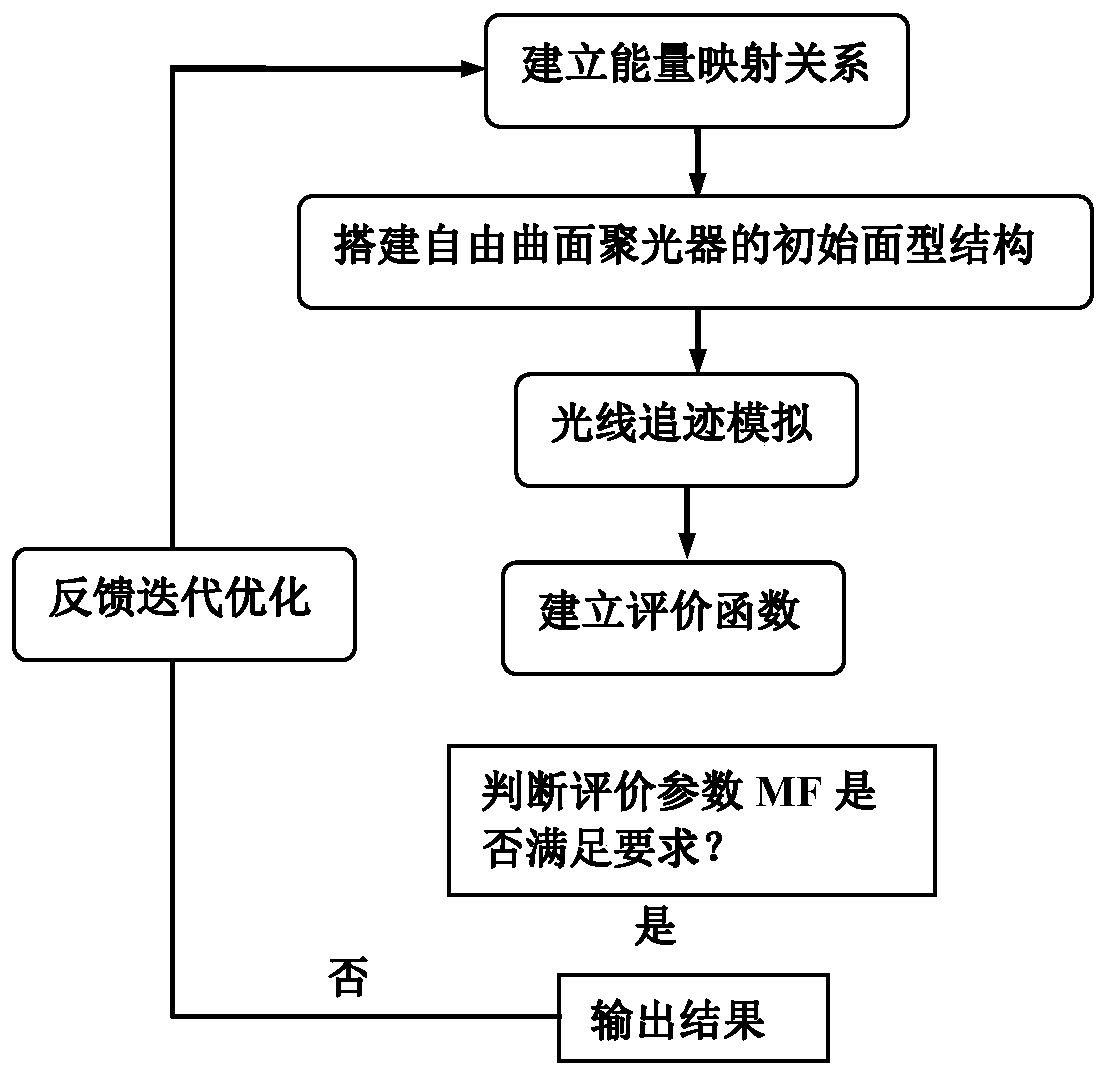

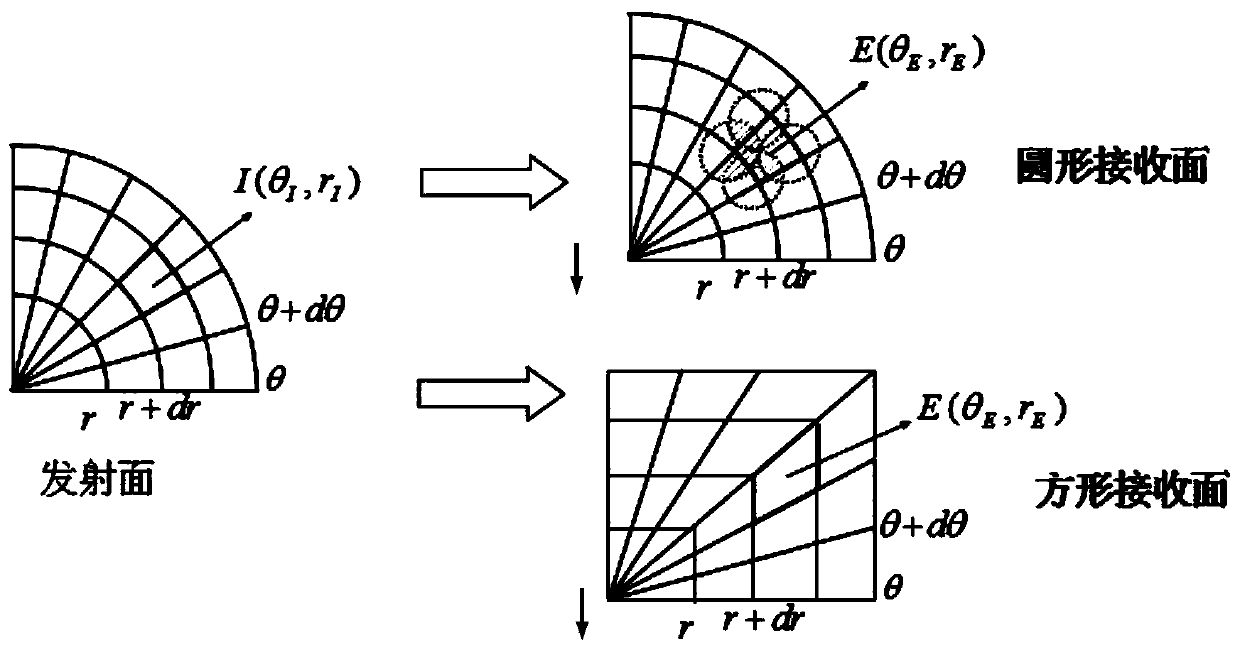

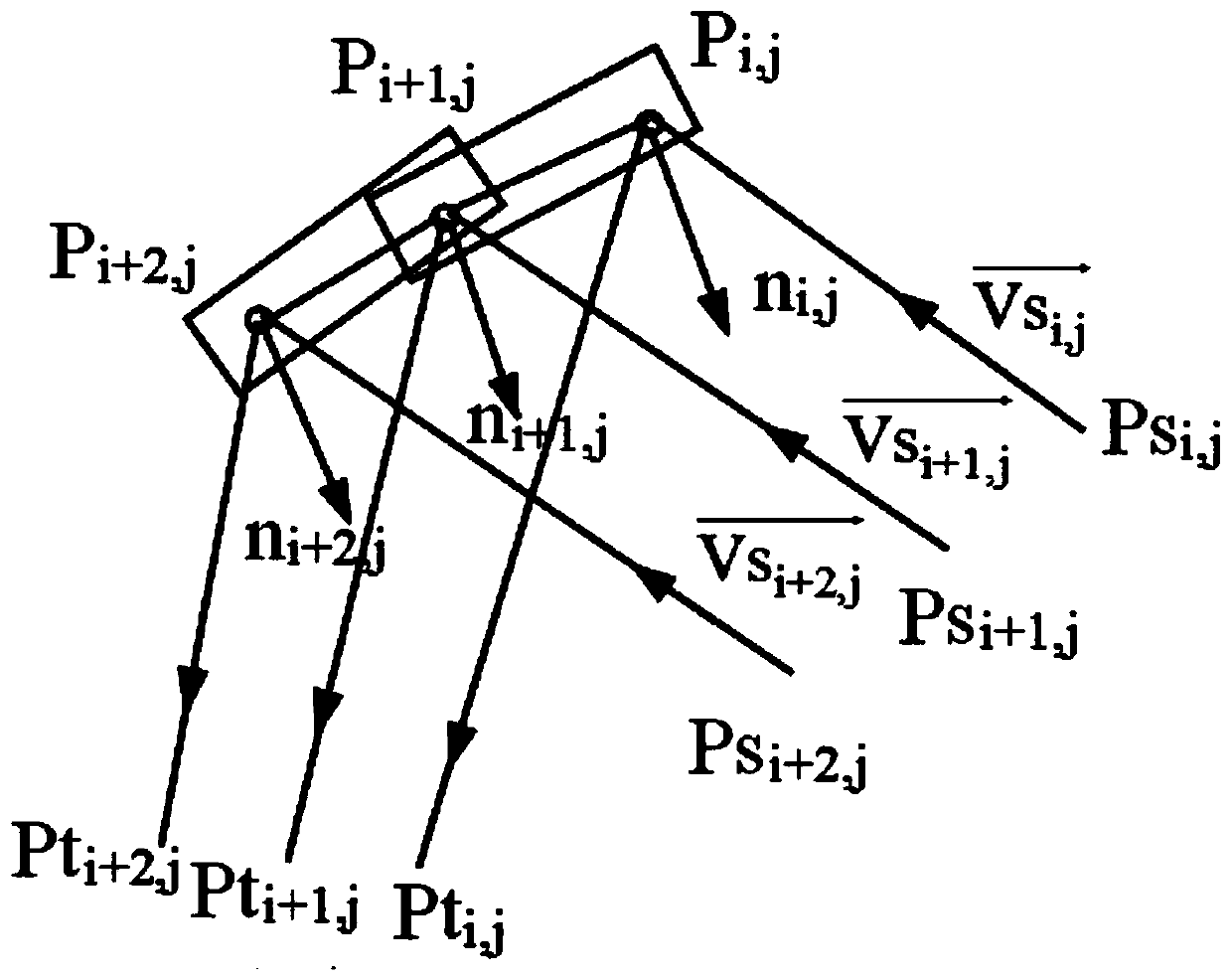

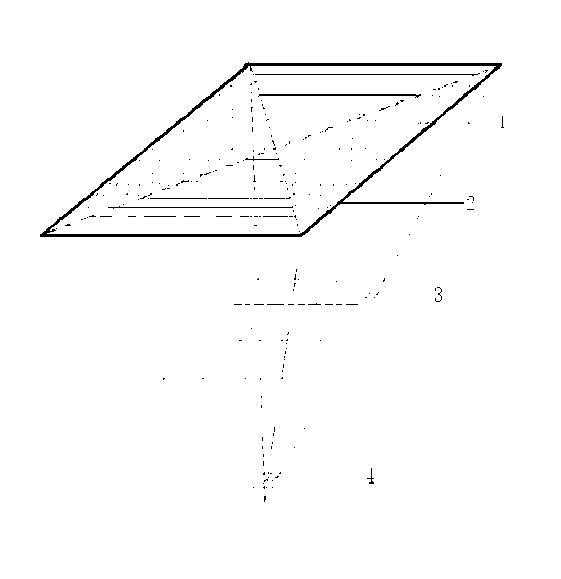

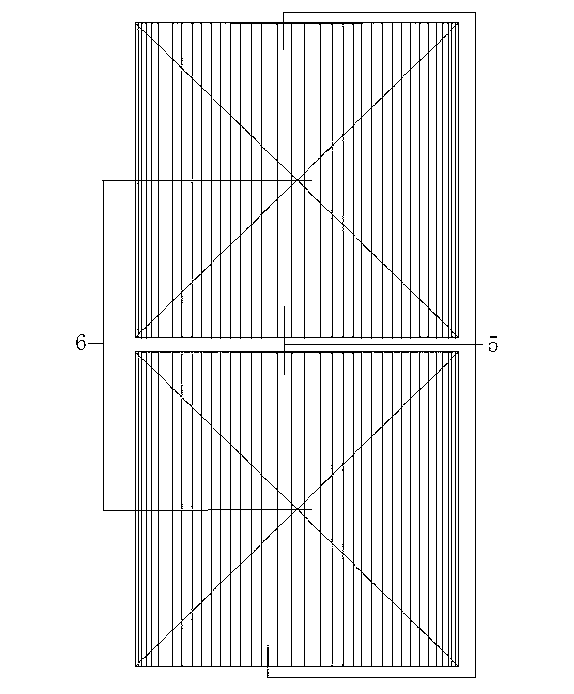

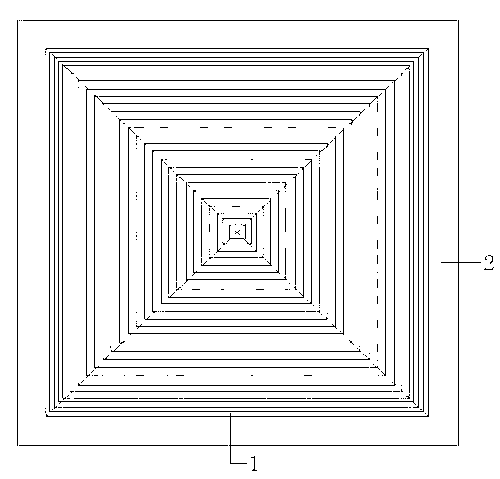

Reverse design method of three-dimensional condenser taking energy flow distribution of receiving surface as target

ActiveCN110348159AImprove design flexibilityFlexible Design FreedomDesign optimisation/simulationSpecial data processing applicationsFree formClosed loop

The invention relates to a reverse design method of a three-dimensional condenser taking energy flow distribution of a receiving surface as a target, belongs to the technical field of solar energy utilization and optical engineering, solves the problem that the design of the three-dimensional asymmetric free-form surface optical path system has many limitations by adopting a generalized solution.The method specifically comprises the following steps: S1, establishing an energy mapping relationship to obtain discrete point data of a transmitting source / receiving surface; s2, constructing an initial surface structure of the free-form surface condenser by using the discrete point data; s3, acquiring the actual receiving surface energy flow density by adopting a ray tracing simulation method;s4, establishing an evaluation function; s5, judging whether the evaluation parameter MF meets the requirement or not, and if MF is smaller than or equal to 0.001, ending the design and outputting anoptimal solution of the surface structure; otherwise, establishing a feedback iterative relational expression, solving the new target energy flow density, and substituting the new target energy flow density into the S1 for continuous execution. The method is high in design flexibility, automatic in closed-loop solving, free of complex operation, high in design accuracy and high in solving speed.

Owner:西北工业大学太仓长三角研究院

Condensing cell assembly

InactiveCN102800733ASimple structureWith light-gathering propertiesPhotovoltaic energy generationSemiconductor devicesElectrical batteryLight Cell

The invention relates to a condensing cell assembly, belonging to the field of solar photoelectricity. The condensing cell assembly comprises three parts of a glass condenser, a cell assembly and an outer frame, wherein the glass condenser adopts the inverted pyramid collapse type condenser lens design principle, a linear Fresnel condenser lens is produced by using the glass melting roll-in calendaring molding process, a rectangular-ambulatory-plane-shaped surface condenser lens is formed after segmentation and combination, the condensing power is adjustable, the condensing surface is matched with the battery assembly in dimension, and incident sunlight is condensed on the fixed solar cell assembly by matching accurate tracking. A low-power condensing silicon cell is used for generating electricity or a high-power condensing gallium arsenide cell is used for generating electricity according to needs, intermediate and high temperature water vapor is obtained by using the water-cooling radiating way, and the low-price high-efficiency utilization of solar energy is realized.

Owner:王英

Tryptophan TVR (Thermal Vapour Recompressor) evaporation, concentration and crystallization system, and method for concentrating and crystallizing by using system

ActiveCN108159721AStable temperatureEfficient use ofEvaporator accessoriesChemical industryThermal energyEvaporation

The invention relates to a tryptophan TVR (Thermal Vapor Recompressor) evaporation, concentration and crystallization system, and a method for concentrating and crystallizing by using the system, which belong to the field of biotechnology manufacturing. A first effect evaporator and a first effect circulating pump form a circulation path through a pipeline; the first effect evaporator and a firsteffect separator are communicated through a pipeline; the first effect separator and a second effect evaporator are communicated; the second effect evaporator and a second effect separator are communicated; the second effect separator is connected with a second effect circulating pump through a pipeline; the second effect circulating pump is communicated with the second effect evaporator through apipeline; an evaporation and crystallization device and a circulation discharge pump form a circulation path through a pipeline; the evaporation and crystallization device is also communicated with asurface condenser; the surface condenser is connected with a vacuum condensation water tank through a pipeline; the vacuum condensation water tank is connected with a vacuum condensation water pump.According to the tryptophan TVR evaporation, concentration and crystallization system, and the method for concentrating and crystallizing by using the system provided by the invention, through ingenious and effective combination of an evaporation and concentration technology, a TVR technology, a multiple-effect evaporation technology, and an evaporation and crystallization technology, heat energyin various parts in the system are fully utilized, so that vapor and materials fully exchange heat to achieve heat balance, so that the whole system is stable in temperature, steady, and easy to control.

Owner:江苏澳创生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com