Continuous single-effect vacuum evaporation crystallization system as well as application and technology

A vacuum evaporation and crystallization system technology, applied in evaporation separation crystallization, evaporation, solution crystallization and other directions, can solve the problems of unstable crystal form of finished sodium glutamate, unstable operating parameters, low degree of automation, etc., to reduce steam consumption. The effect of quantity, uniformity of particles and high quality of crystalline product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

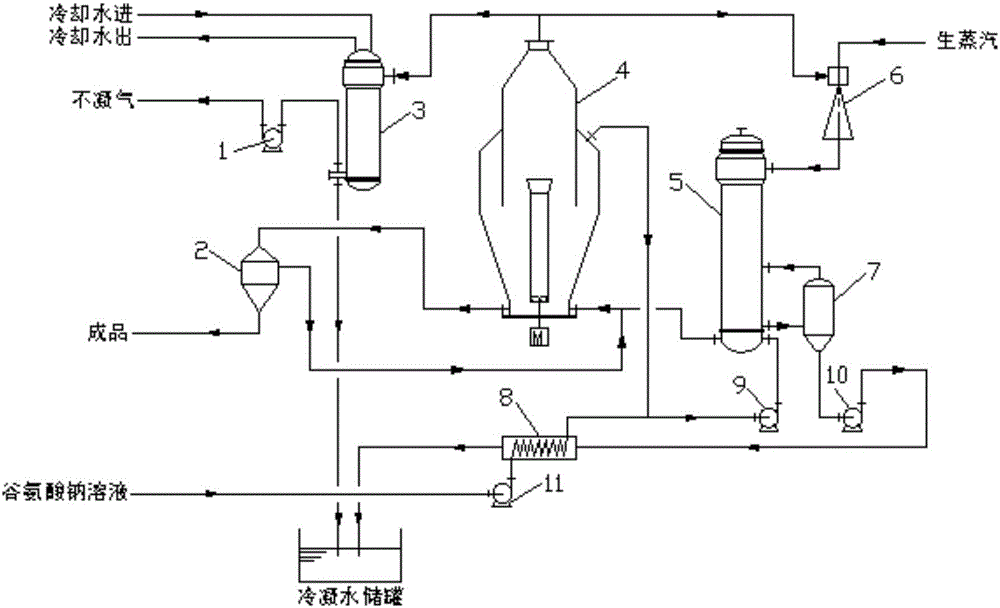

[0038] Such as figure 1 As shown, the continuous single-effect vacuum evaporation crystallization system includes water ring vacuum pump 1, centrifuge 2, surface condenser 3, crystallizer 4, heating chamber 5, steam jet pump 6, liquid storage tank 7, preheater 8, circulation Pump 9, condensate pump 10, raw material pump 11.

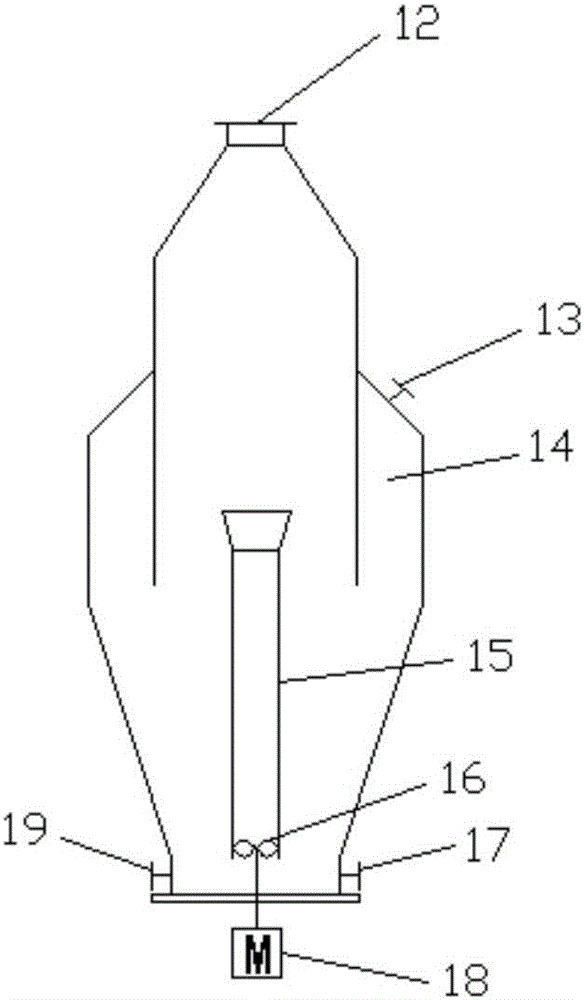

[0039] Such as figure 2 As shown, the DTB crystallizer includes a steam outlet 12, a circulating liquid outlet 13, a clarification zone 14, a draft tube 15, a propeller 16, a solution inlet 17, a mixer 18, and a crystal slurry outlet 19.

[0040] The continuous single-effect vacuum evaporation crystallization system includes a preheater 8 for preheating the solution; a heating chamber 5, the solution inlet of the heating chamber 5 is connected to the preheater 8, and the heating chamber 5 is filled with steam and enters the heating chamber 5 The solution inside is subjected to heat exchange; vacuum crystallizer 4, vacuum crystallizer 4 are separately connect...

Embodiment 2

[0048] A continuous single-effect vacuum evaporation crystallization process for sodium glutamate, the specific steps are as follows:

[0049] 1) The sodium glutamate solution enters the preheater 8 through the raw material pump 11, and the preheated sodium glutamate solution is mixed with the circulating liquid and sent to the heating chamber 5 by the circulating pump 9;

[0050] 2) The sodium glutamate solution exchanges heat with steam in the heating chamber 5. After the heat exchange, the steam becomes condensed water and enters the liquid storage tank 7, and the condensed water passes through the condensate pump 10 to the preheater 8 to perform heat exchange on the sodium glutamate solution. Preheating, the uncondensed steam re-enters the heating chamber 5 to continue heat exchange;

[0051] 3) The heated sodium glutamate solution enters the DTB crystallizer 4 from the solution inlet 17, and continuously crystallizes in the DTB crystallizer 4. The propeller 16 is driven by the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com