Energy-saving environment-friendly DDGS (Distillers Dried Grains with Solubles) waste heat vaporization system

A DDGS, energy-saving and environmentally friendly technology, applied in forced circulation evaporators, evaporation, multi-effect evaporation, etc., can solve the problems of low heat recovery rate of secondary steam, failure to meet the requirements of energy saving and emission reduction, and failure to meet the requirements of energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

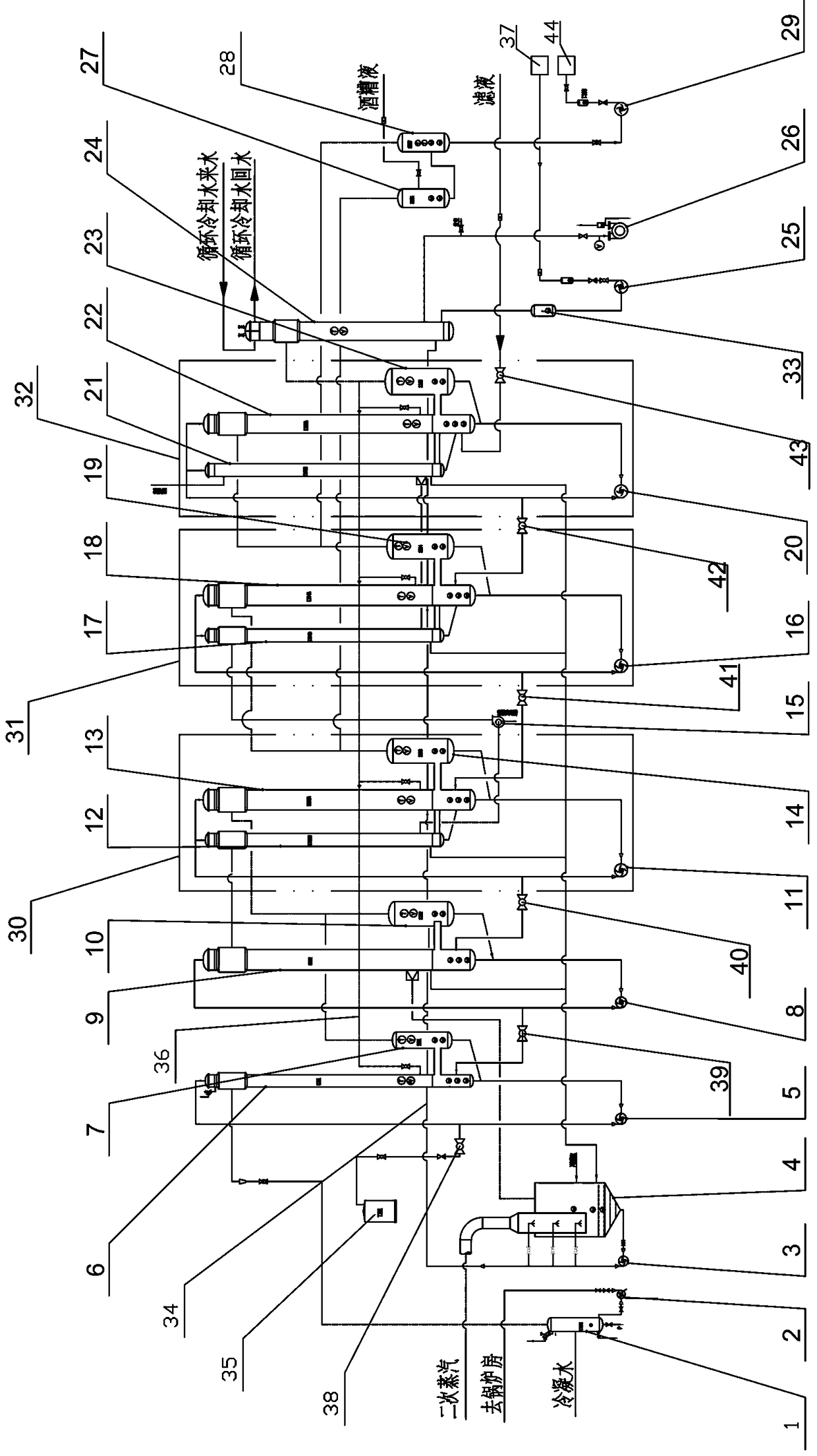

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1As shown, an energy-saving and environmentally friendly DDGS waste heat evaporation system includes a condensate flash tank 1, a high-temperature condensate pump 2, an exhaust gas scrubber 4, a scrubbing pump 3, a first-effect heater 6, a first-effect separator 7, and a second-effect replacement Heater 9, two-effect separator 10, evaporator, surface condenser 24, condensed water collecting tank 33 and condensed water pump 25, the first-effect heater 6 and the second-effect heat exchanger 9 are all tube heat exchangers , the heat exchange tube of the first-effect heater 6 communicates with the air inlet of the first-effect separator 7, the outlet of the first-effect separator 7 communicates with the outlet of the first-effect heater 6, and the outlet of the second-effect heat exchanger 9 The heat exchange tube is communicated with the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com