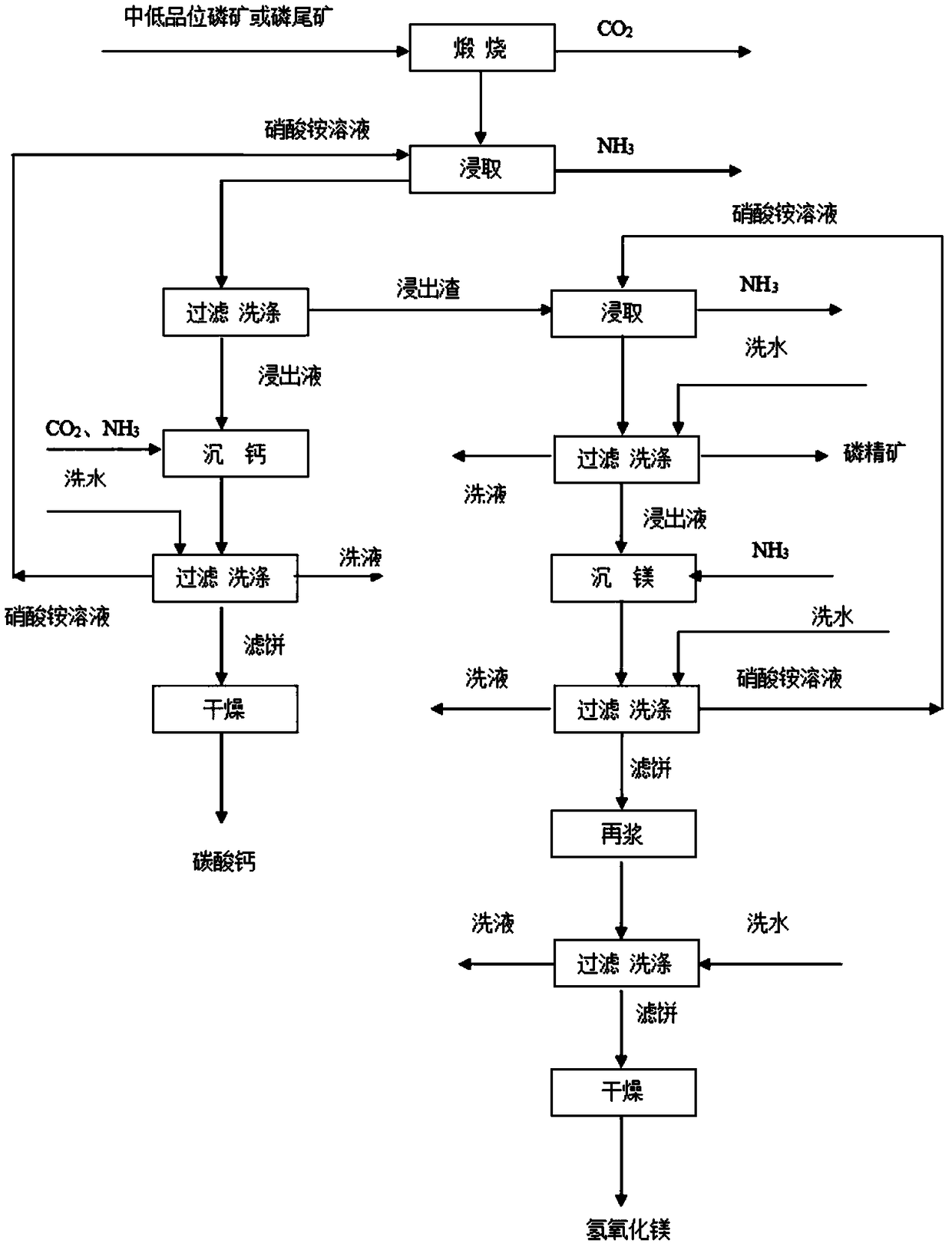

Technology for enriching phosphate concentrate and recycling calcium carbonate and magnesium hydroxide from middle-low grade phosphate rock or phosphate tailing simultaneously

A magnesium hydroxide, low-grade technology, applied in magnesium hydroxide, calcium carbonate/strontium/barium, phosphate material processing and other directions, can solve the problems of difficult separation and control, difficult to elute chloride ions, poor separation effect, etc. , to solve the problem of low phosphorus recovery rate and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

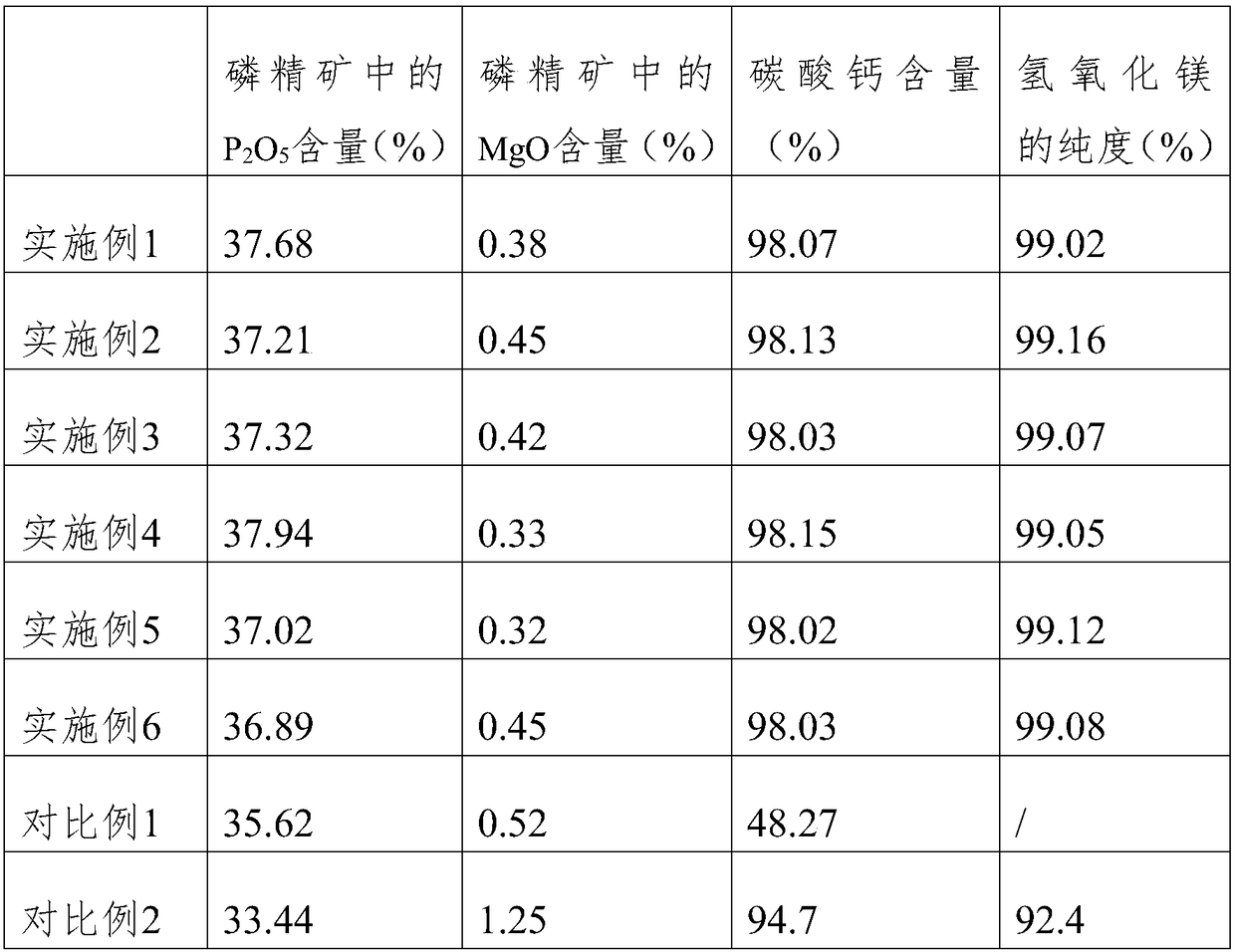

Embodiment 1

[0053] (1) Calcining 100g of medium and low-grade phosphate rock at 700-1200°C for 1.5h to obtain calcined slag and carbon dioxide;

[0054] (2) Calcined slag and 400ml of 20% ammonium nitrate solution are added to the reaction tank, stirred and reacted at a speed of 400r / min, the reaction temperature is 25°C, and the reaction time is 60min to generate ammonia gas, which is separated by filtration to obtain leach solution A and leach residue a;

[0055] (3) Pass sufficient amount of NH produced in steps (1) and (4) into the leach solution A 3 Gas and step (1) produced a concentration of 25% CO 2 , stirring and reacting according to the speed of 200r / min, the reaction temperature is 50°C, the reaction time is 60min, filtering and separating to obtain leaching solution B and leaching residue b, wherein leaching solution B is ammonium nitrate solution; drying the leaching residue b to obtain a calcium carbonate product;

[0056] (4) Add leaching slag a and 400ml of 20% ammonium...

Embodiment 2

[0060] (1) Calcining 100g of medium and low-grade phosphate rock at 700-1200°C for 1 hour to obtain calcined slag and carbon dioxide;

[0061] (2) Calcined slag and 200ml of 50% ammonium nitrate solution are added to the reaction tank, stirred and reacted at a speed of 700r / min, the reaction temperature is 45°C, and the reaction time is 30min to generate ammonia gas, which is separated by filtration to obtain leach solution A and leach residue a;

[0062] (3) In the leaching solution A, a sufficient amount of NH produced in steps (1) and or (4) steps is introduced 3 Gas and step (1) produced a concentration of 30% CO 2 , stirring and reacting according to the speed of 500r / min, the reaction temperature is 80°C, the reaction time is 30min, filtering and separating to obtain leaching solution B and leaching residue b, wherein leaching solution B is ammonium nitrate solution; drying the leaching residue b to obtain a calcium carbonate product;

[0063] (4) Add leaching residue ...

Embodiment 3

[0067] (1) Calcining 100g of medium and low-grade phosphate rock at 700-1200°C for 2 hours to obtain calcined slag and carbon dioxide;

[0068] (2) Calcined slag and 1500ml of 5% ammonium nitrate solution are added in the reaction tank, stirred and reacted according to the speed of 200r / min, the reaction temperature is 10°C, the reaction time is 120min, ammonia gas is generated, and the leaching solution A and leaching solution are obtained through filtration and separation. Slag a;

[0069] (3) Pass sufficient amount of NH produced in steps (1) and (4) into the leach solution A 3 Gas and step (1) produced a concentration of 15% CO 2 , stirring and reacting according to the speed of 50r / min, the reaction temperature is 30°C, and the reaction time is 120min, filtering and separating to obtain leaching solution B and leaching residue b, wherein leaching solution B is ammonium nitrate solution; drying the leaching residue b to obtain a calcium carbonate product;

[0070](4) Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com