Patents

Literature

1061results about "Multiple-effect evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

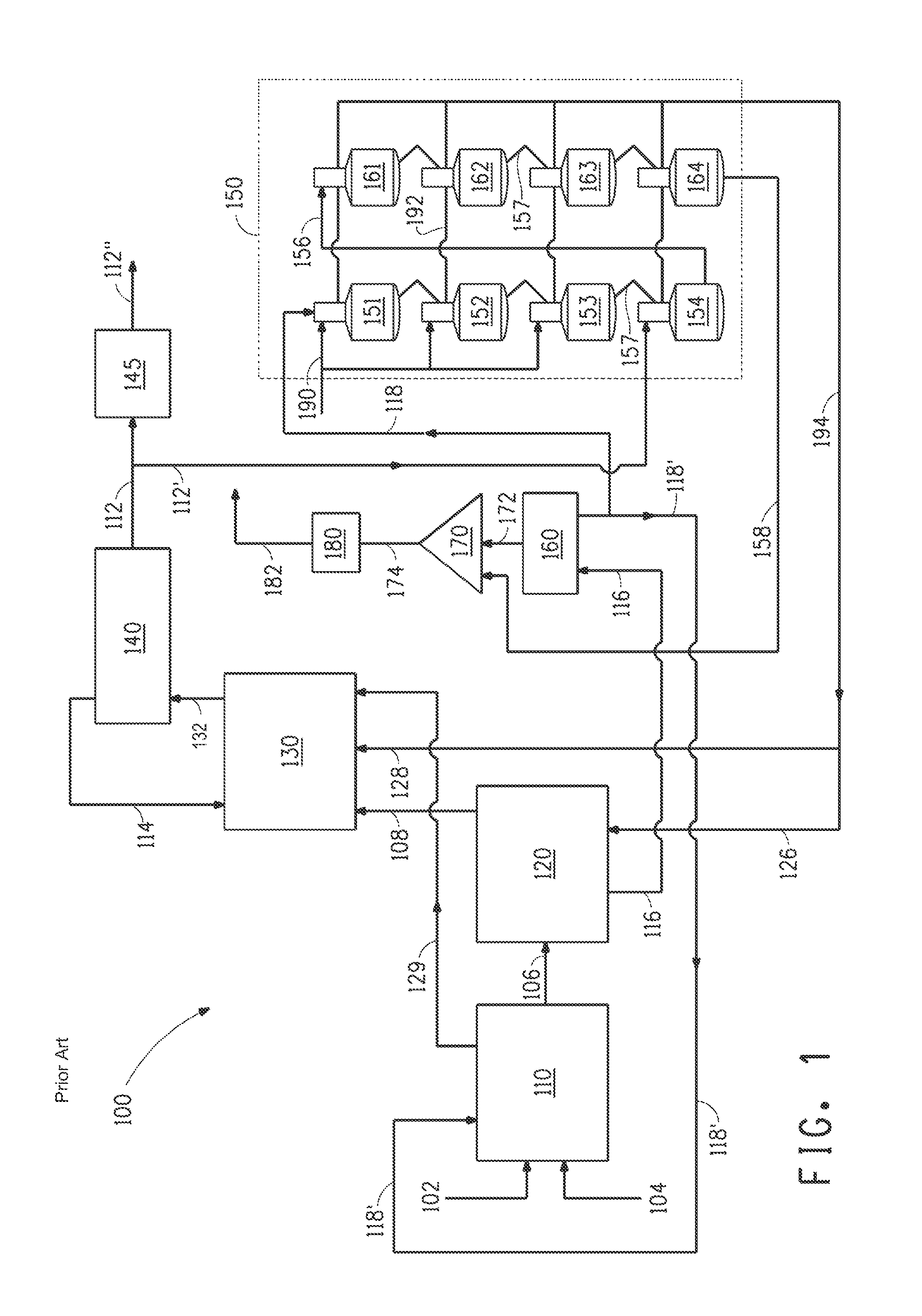

Process for desalination of saline water, especially water, having increased product yield and quality

InactiveUS6508936B1General water supply conservationSeawater treatmentTotal dissolved solidsDistillation

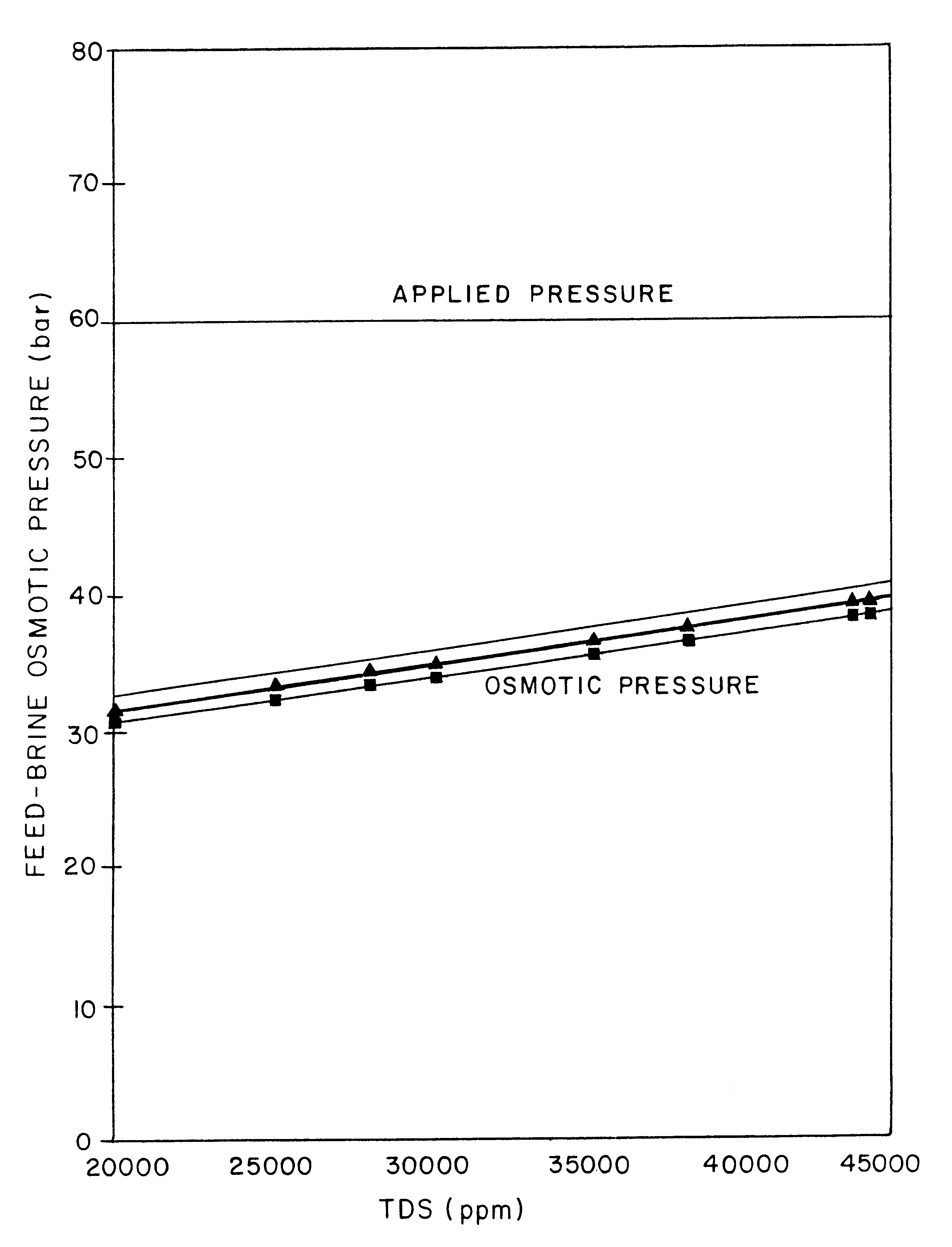

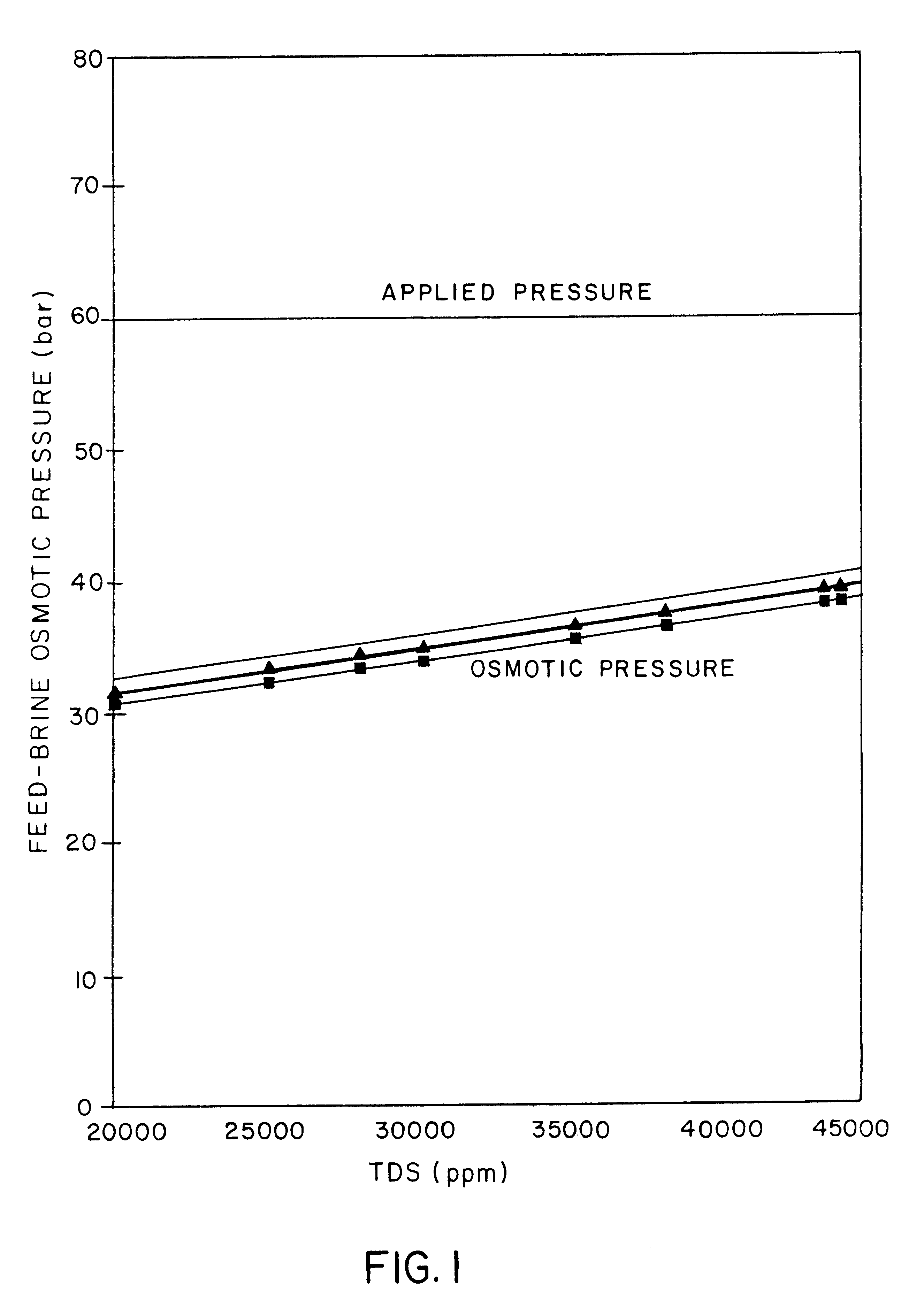

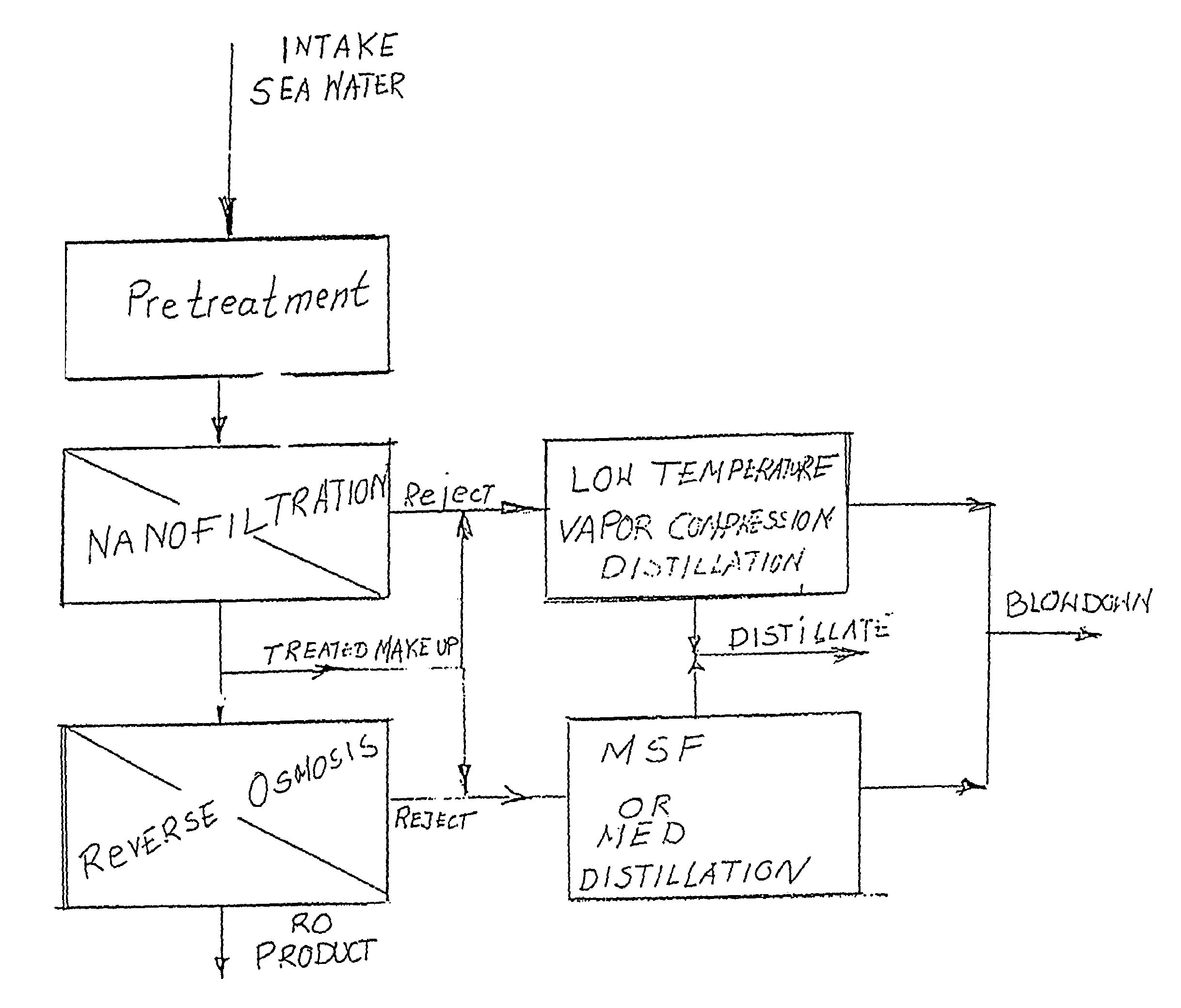

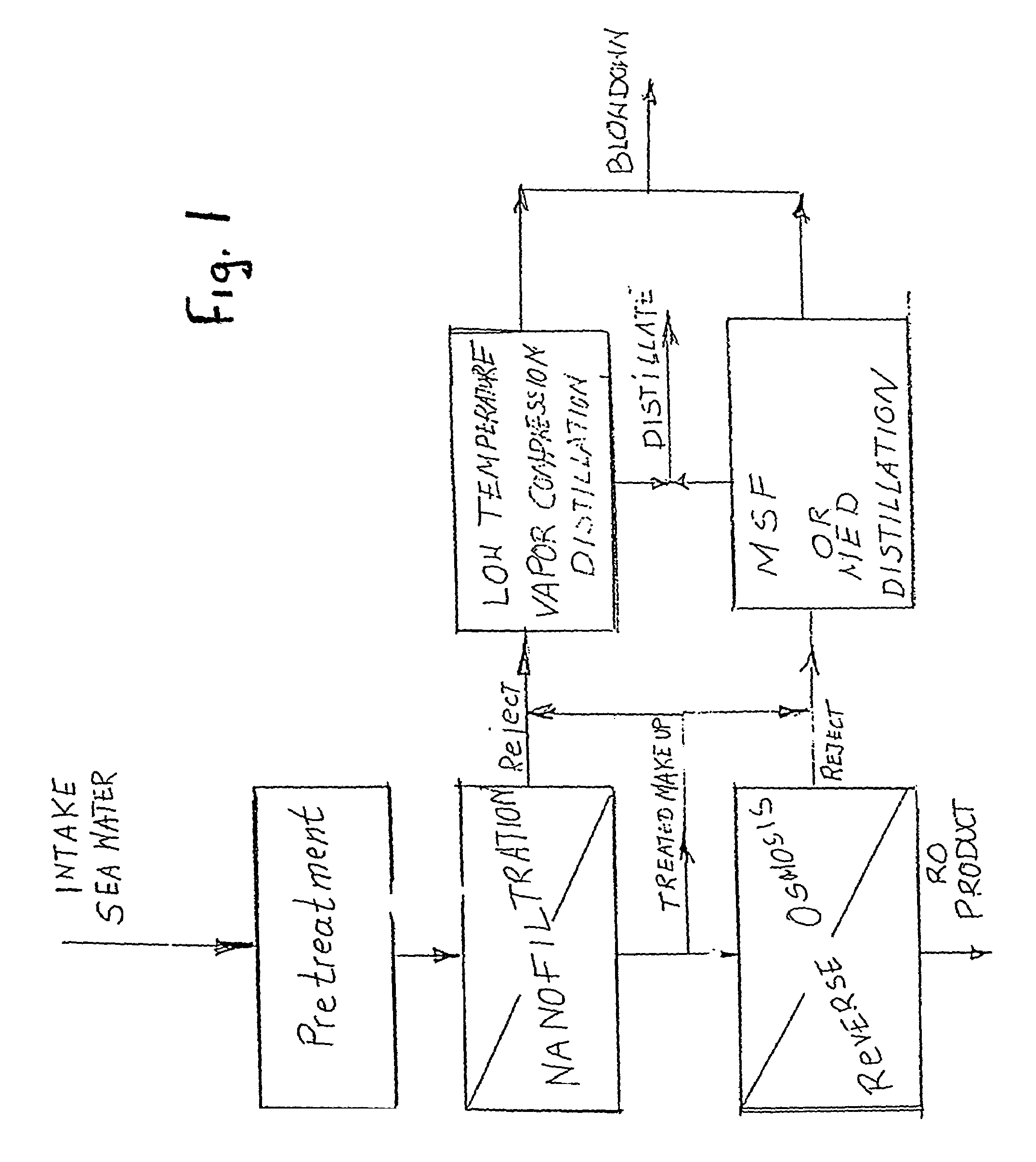

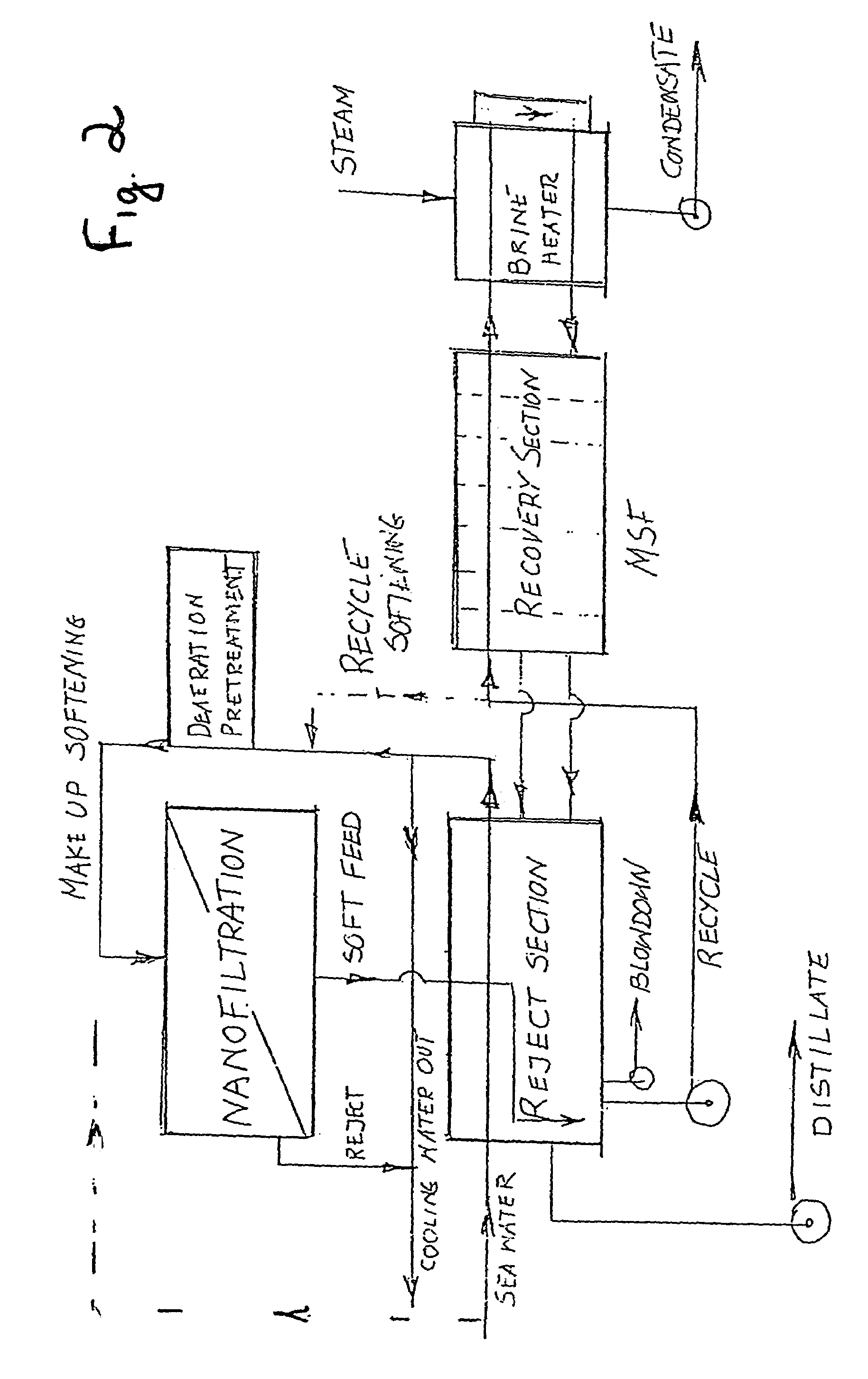

A desalination process is disclosed which combining two or more substantially different water treatment processes in a unique manner to desalinate saline water, especially sea water, to produce a high yield of high quality fresh water, including potable water, at an energy consumption equivalent to or less than much less efficient prior art desalination processes. In this process a nanofiltration step is synergistically combined with at least one of sea water reverse osmosis, multistage flash distillation. multieffect distillation of vapor compression distillation to provide an integrated desalination system by which sea water can be efficiently and economically converted to high quality potable water in yields which are at least 70%-80% greater than the yields available from the prior art processes. Typically a process of this invention using the nanofiltration initial step will produce, with respect to sea water feed properties, calcium, magnesium, sulfate and bicarbonate ion content reductions of 63%-94%, pH decreases of about 0.4-0.5 units and total dissolved solids content reductions of 35%-50%.

Owner:SALINE WATER CONVERSION CORP

Desalination method and desalination apparatus

InactiveUS6833056B1Number of stage increasingIncrease the number ofAuxillariesGeneral water supply conservationDesalinationDistilled water

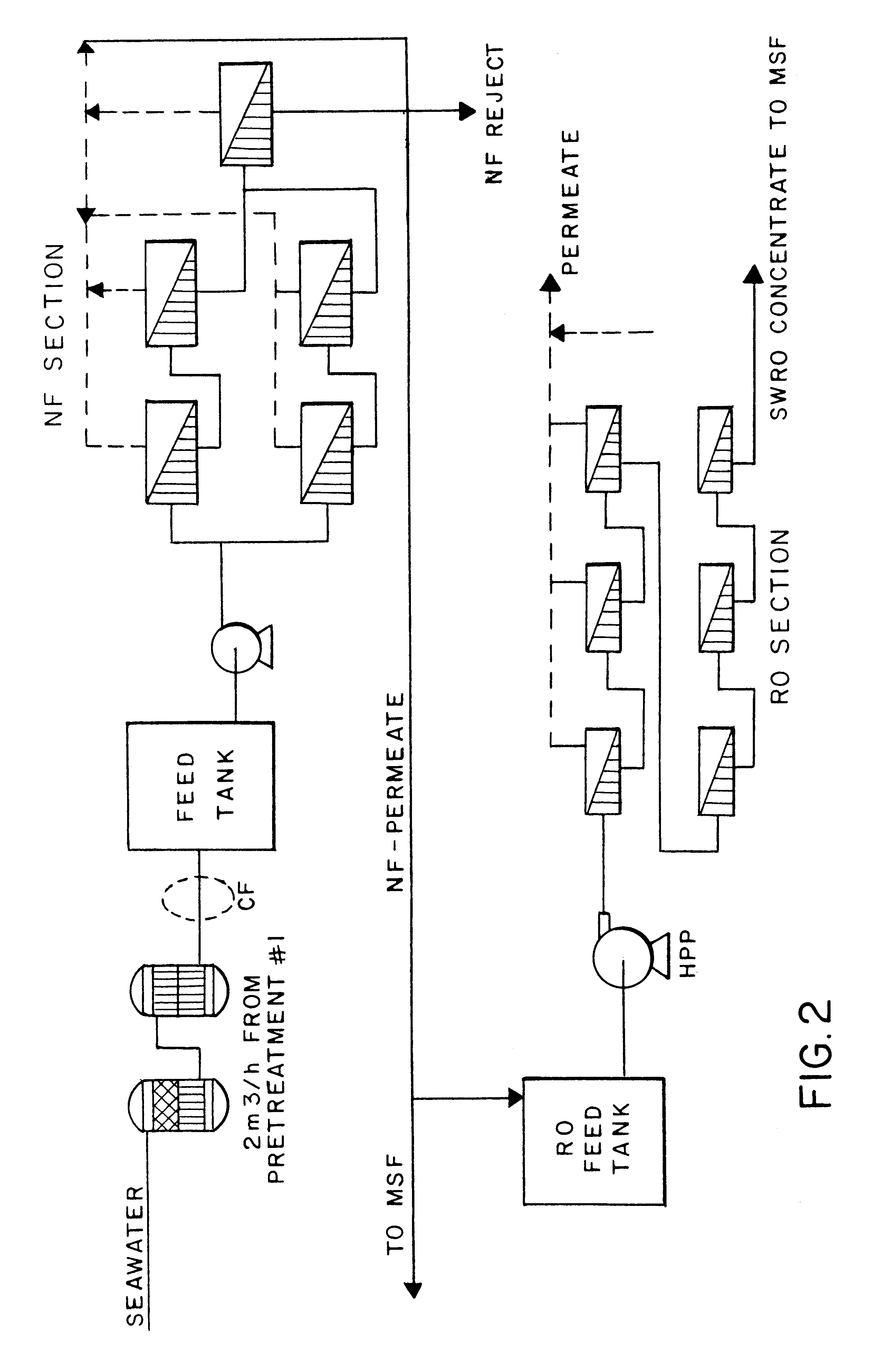

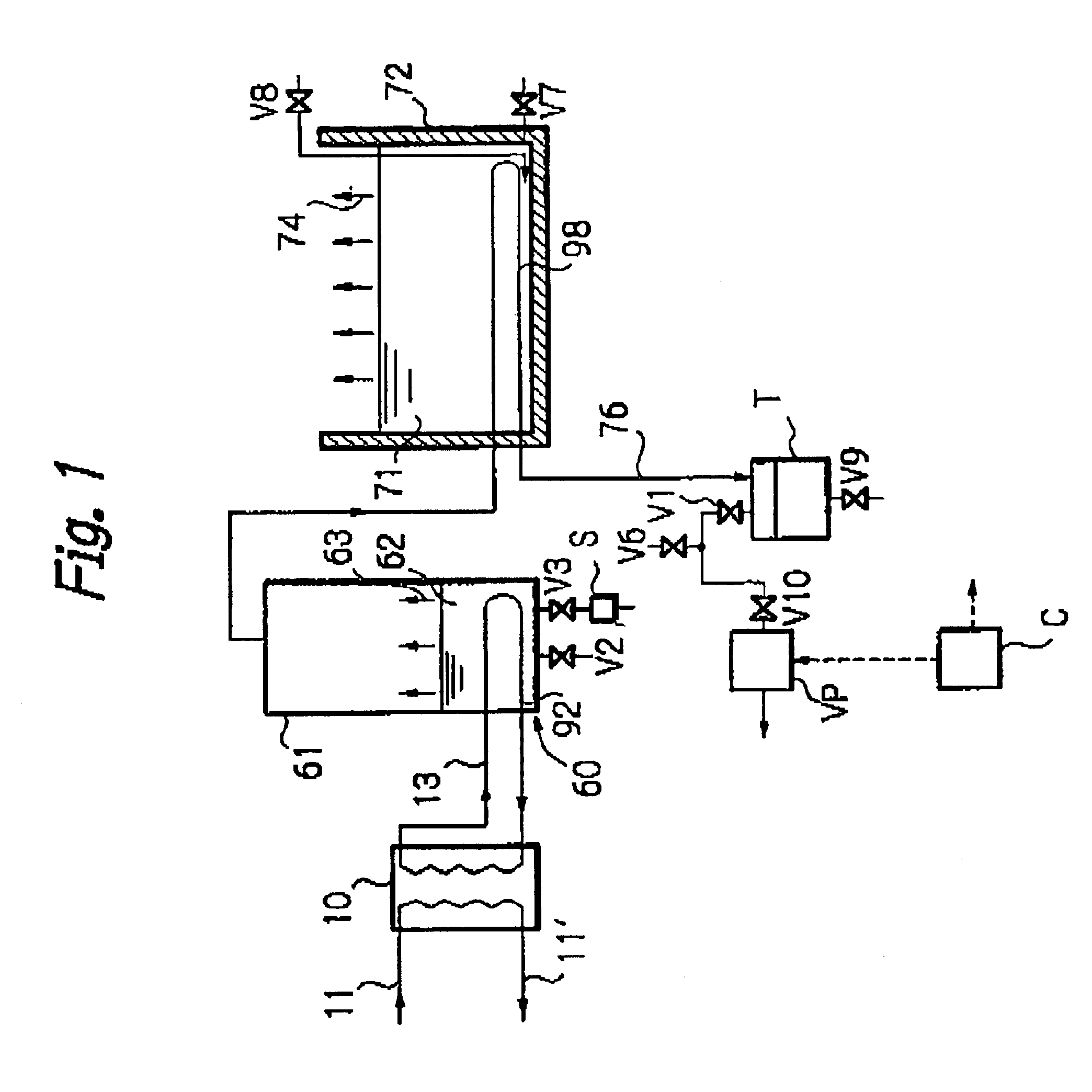

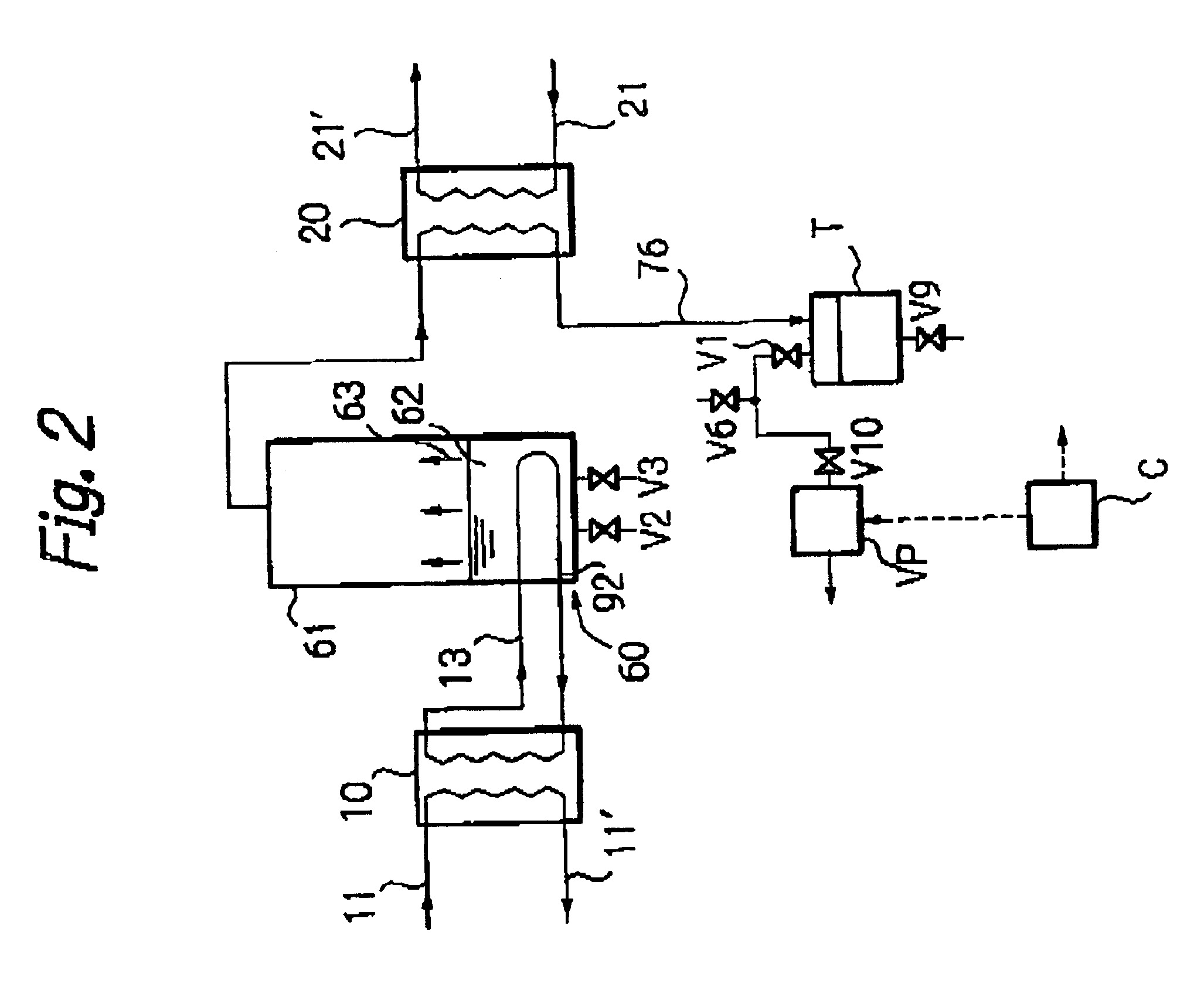

A desalination apparatus capable of obtaining fresh water stably at low cost by utilizing low-temperature waste, wherein the desalination apparatus including a heat exchanger 92 cooperating with an evaporation can 60 so as to subject a low-temperature waste heat 11 and raw water 62 in the evaporation can 60 to heat exchange and generate water vapor 63 in the evaporation can 60; a condenser 98 cooperating with a raw water tank 72 so as to receive the water vapor 63 from the evaporation can 60, cool the water vapor 63 by subjecting the water vapor 63 and raw water 71 in the raw water tank 72 to heat exchange and obtain distilled water 76; a distilled water tank for storing the distilled water 76; vacuum means for evacuating the evaporation can 60 and depressurizing the inside thereof so as to promote generation of water vapor 63 in the evaporation can 60; and raw water supply means for supplying raw water to the evaporation can.

Owner:EBARA CORP

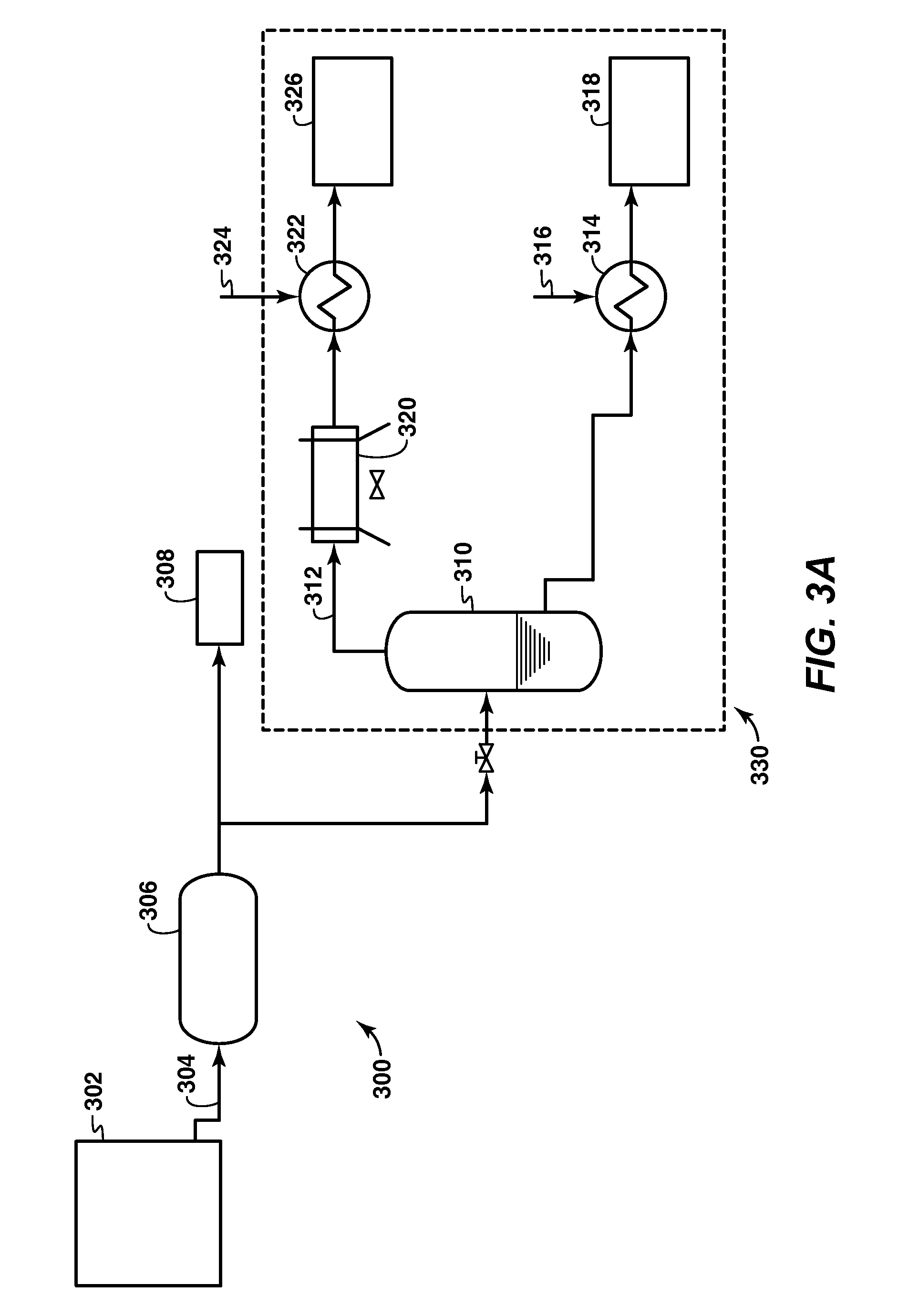

Recovery of high water from produced water arising from a thermal hydrocarbon recovery operation using vaccum technologies

InactiveUS20100282593A1High purityImprove purification effectAuxillariesEvaporation with vapour compressionWater flowVaporization

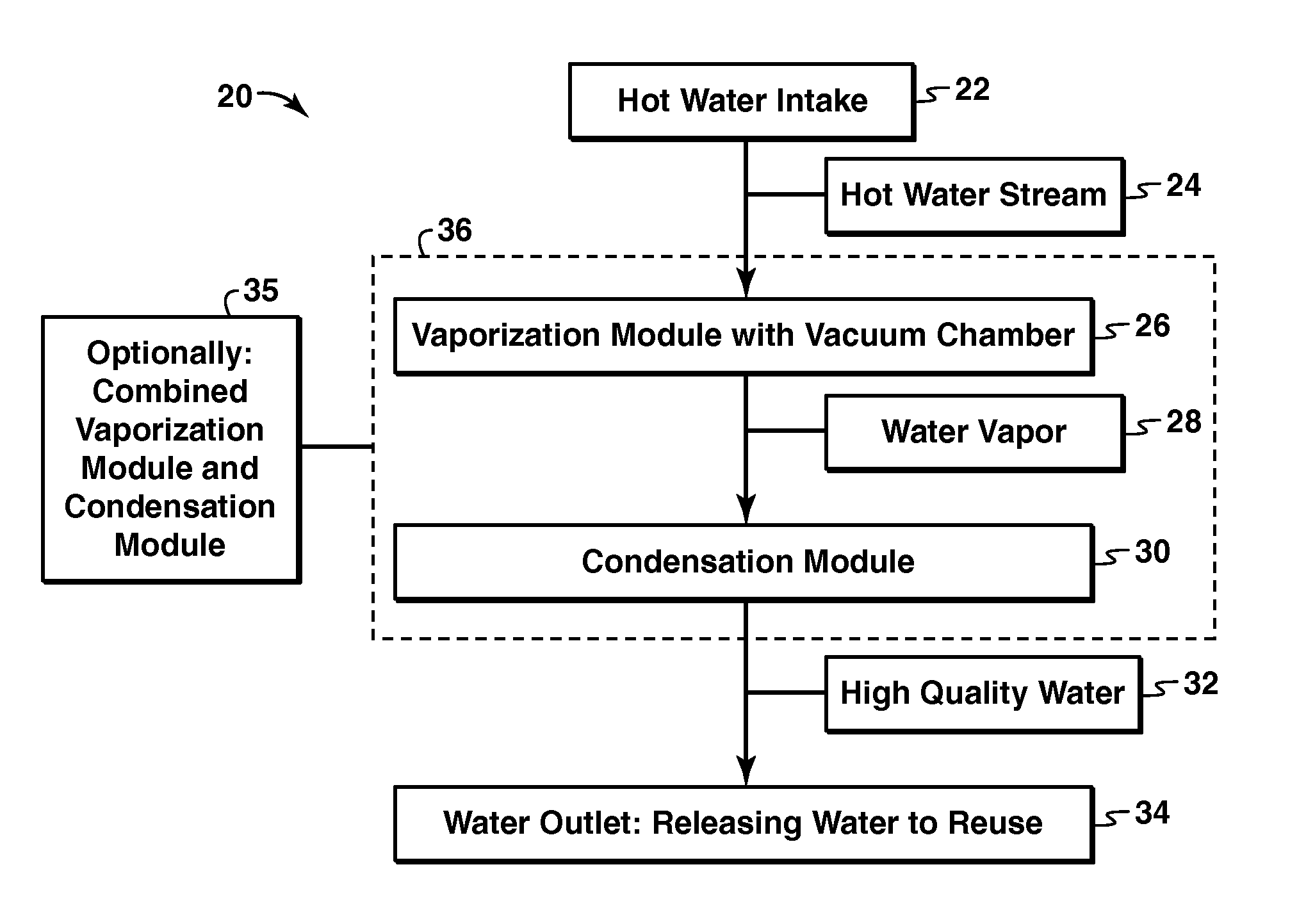

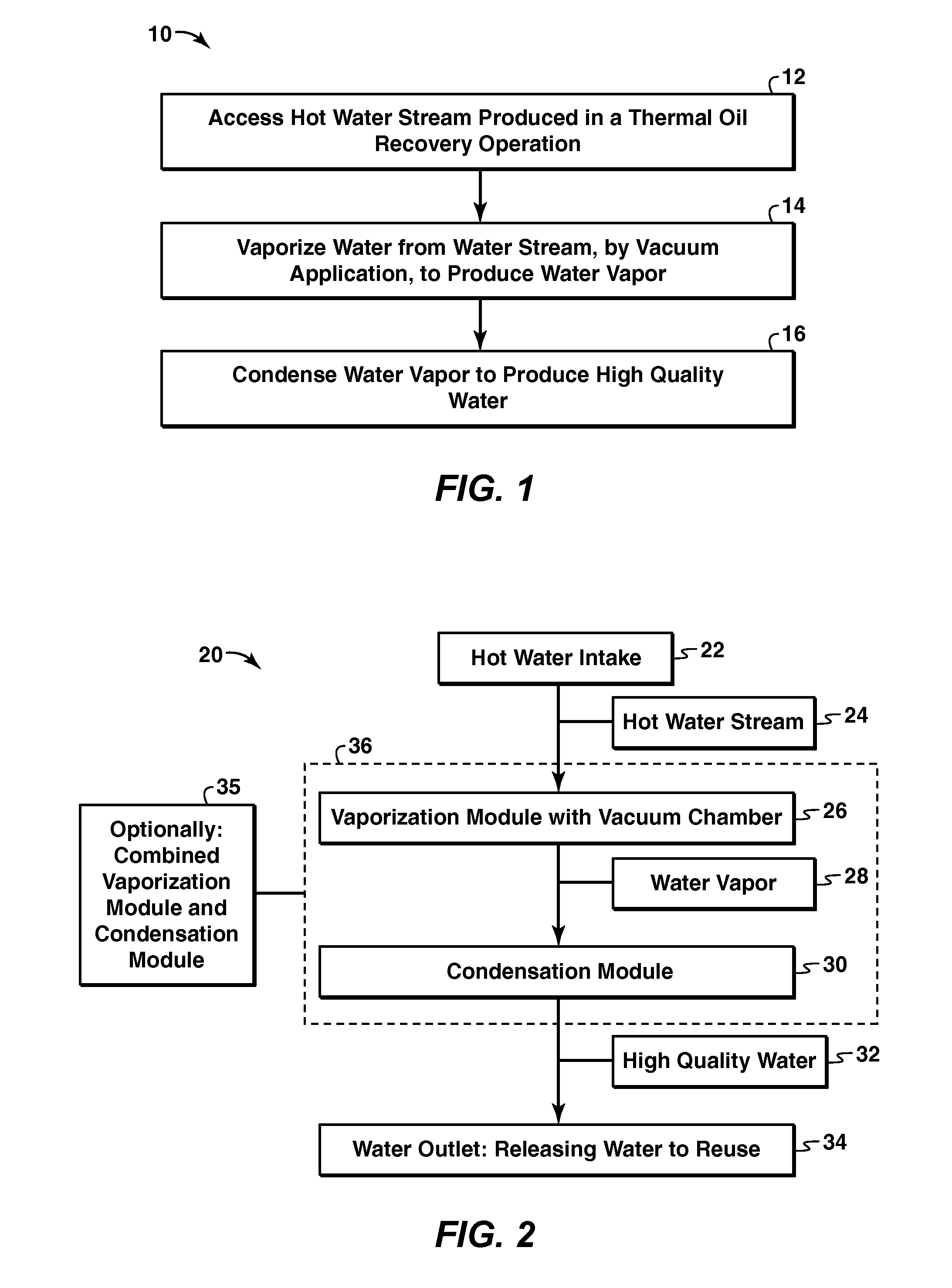

A method for reducing and re-using waste heat and water resulting from thermal hydrocarbon recovery operations involving accessing a hot water stream produced in a thermal hydrocarbon recovery operation; vaporizing water from the water stream by applying a vacuum, thereby producing water vapor; and condensing the water vapor to produce high quality water. A system is described including a hot water intake interfacing with a hot water stream from a thermal hydrocarbon recovery operation; a vaporization module receiving the hot water stream from the hot water intake, comprising a vacuum chamber in which a vacuum is applied to produce water vapor from the hot water stream; a condensation module in which water vapor produced in the vaporization module is condensed to form high quality water; and a water outlet for releasing the high quality water from the condensation module for re-use within the thermal hydrocarbon recovery operation.

Owner:EXXONMOBIL UPSTREAM RES CO

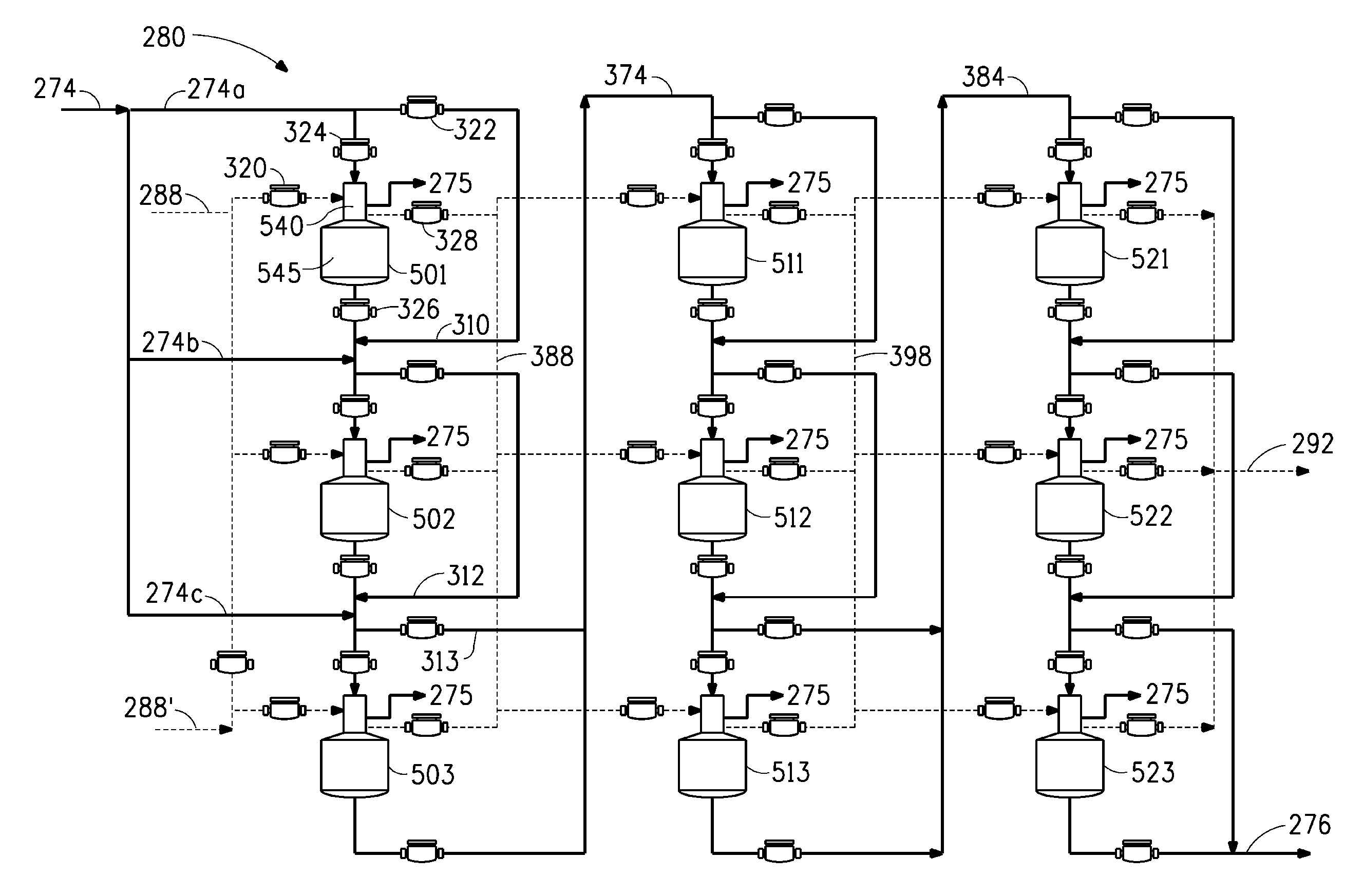

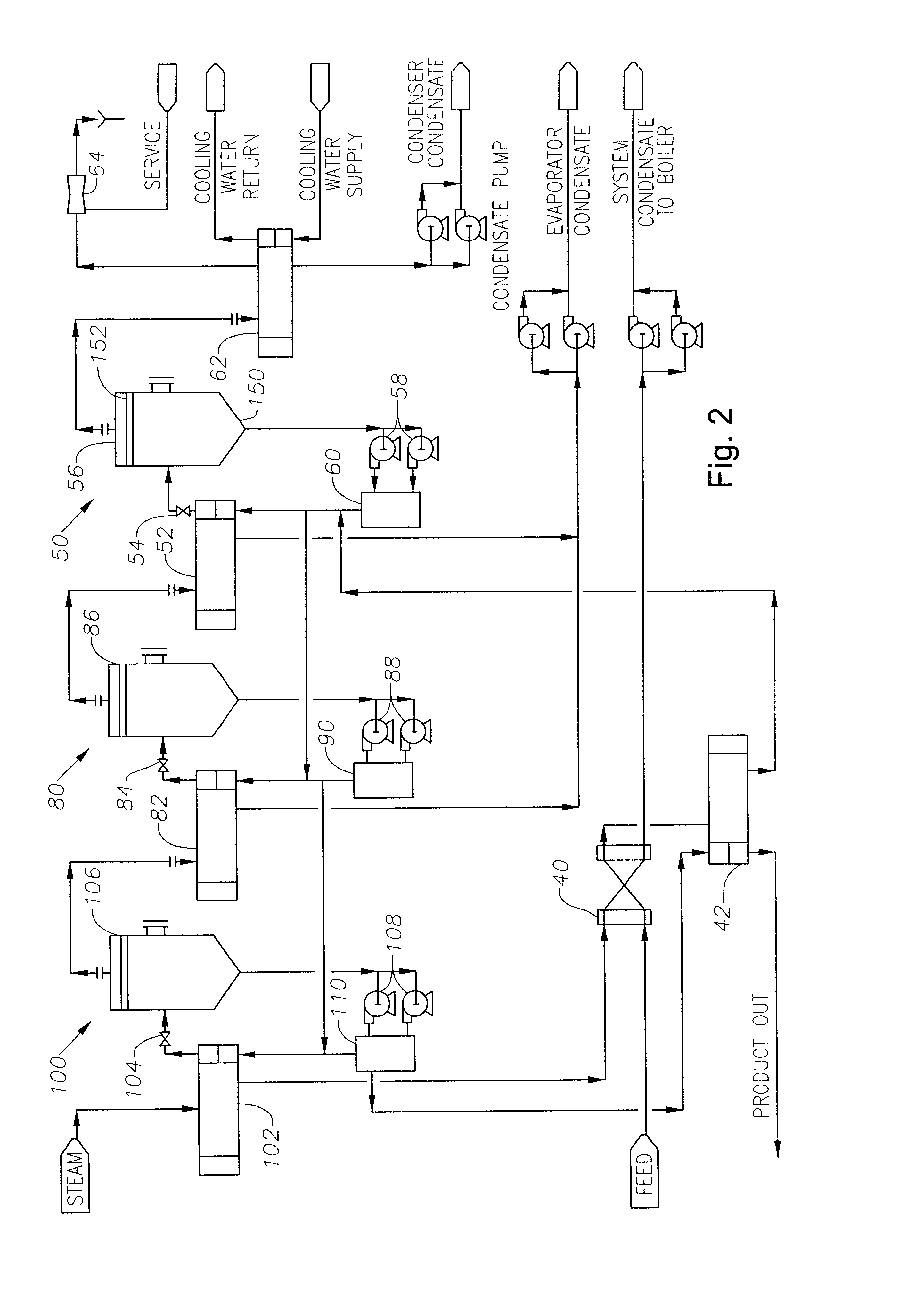

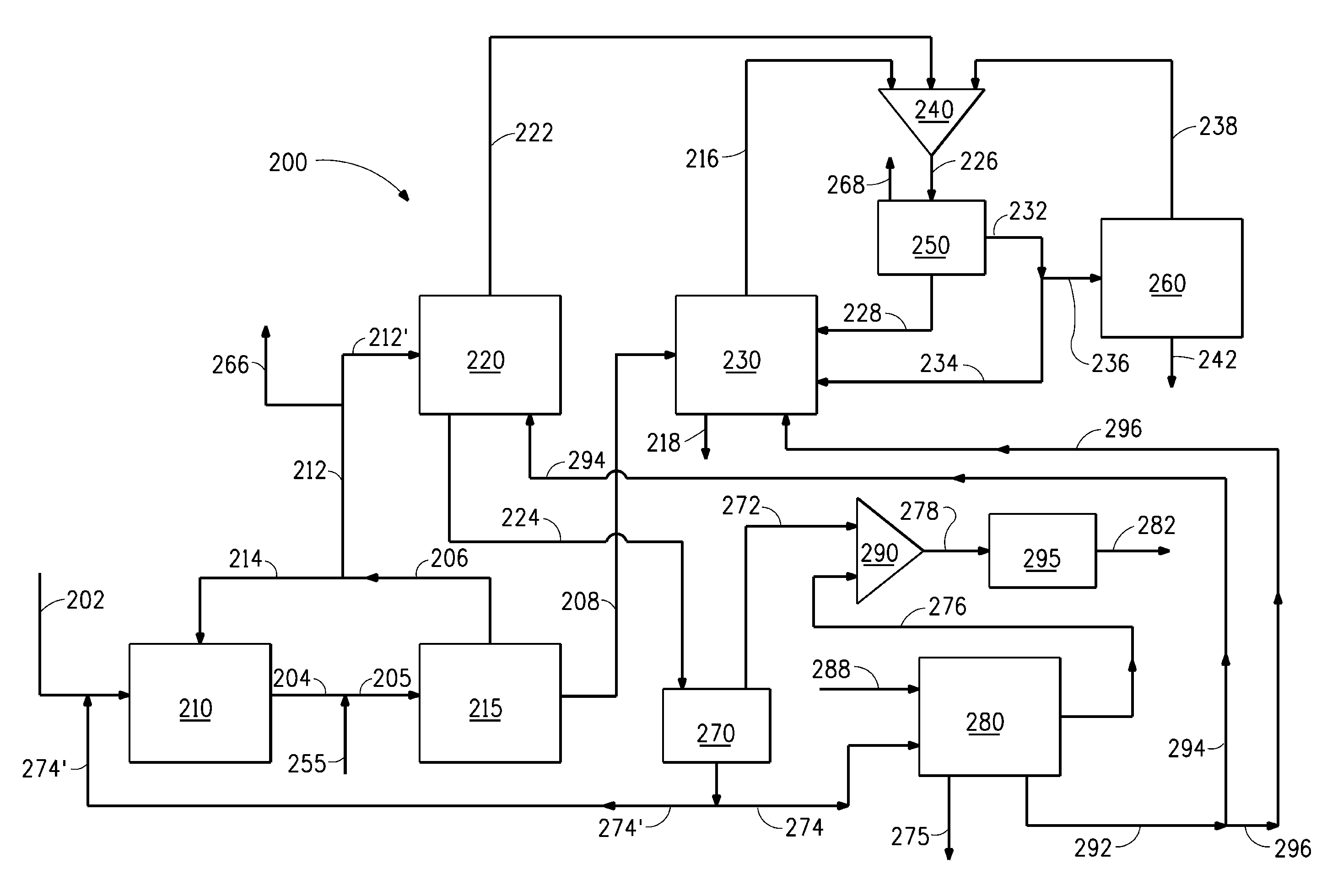

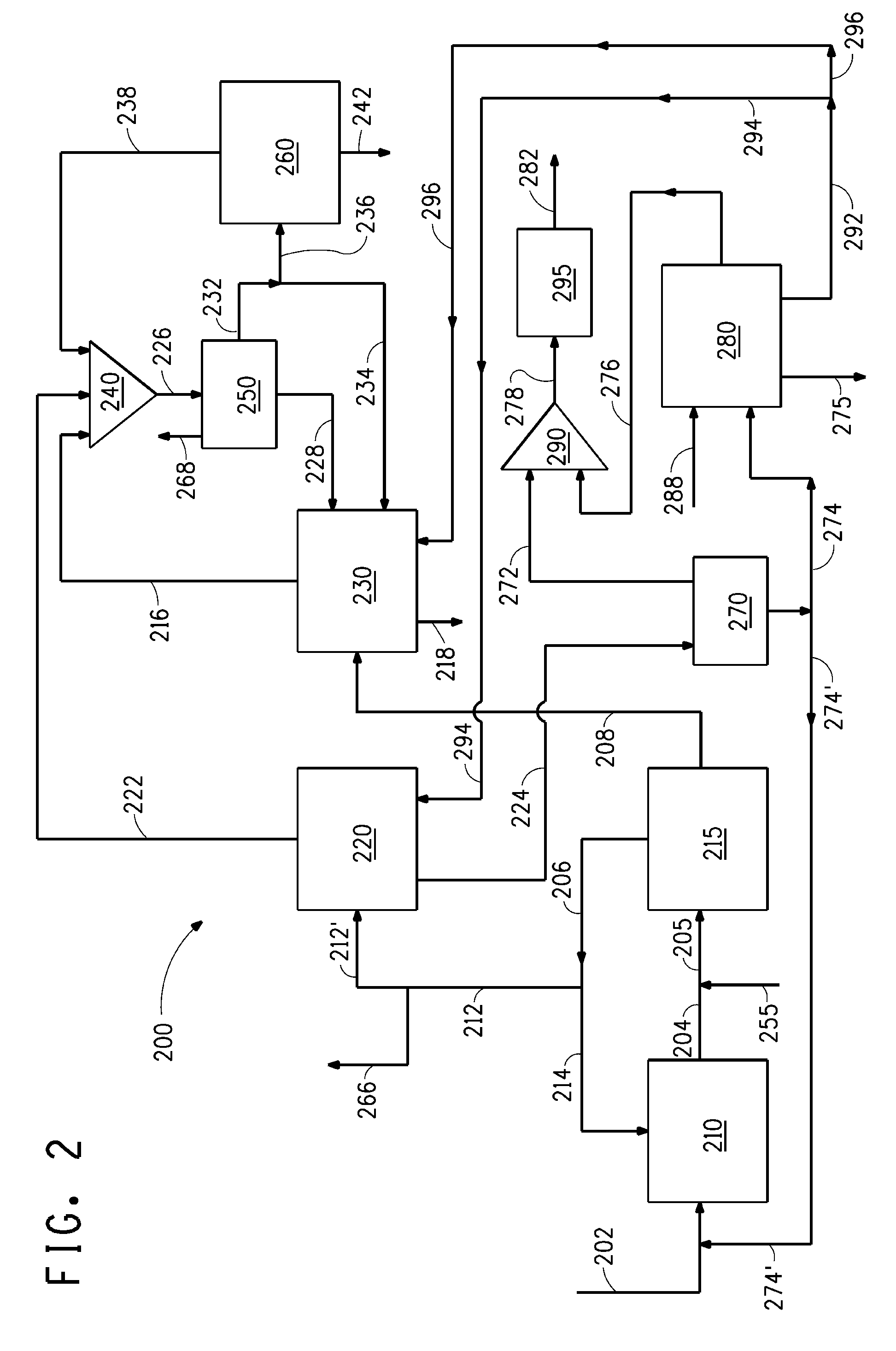

Systems and methods for alcohol recovery and concentration of stillage by-products

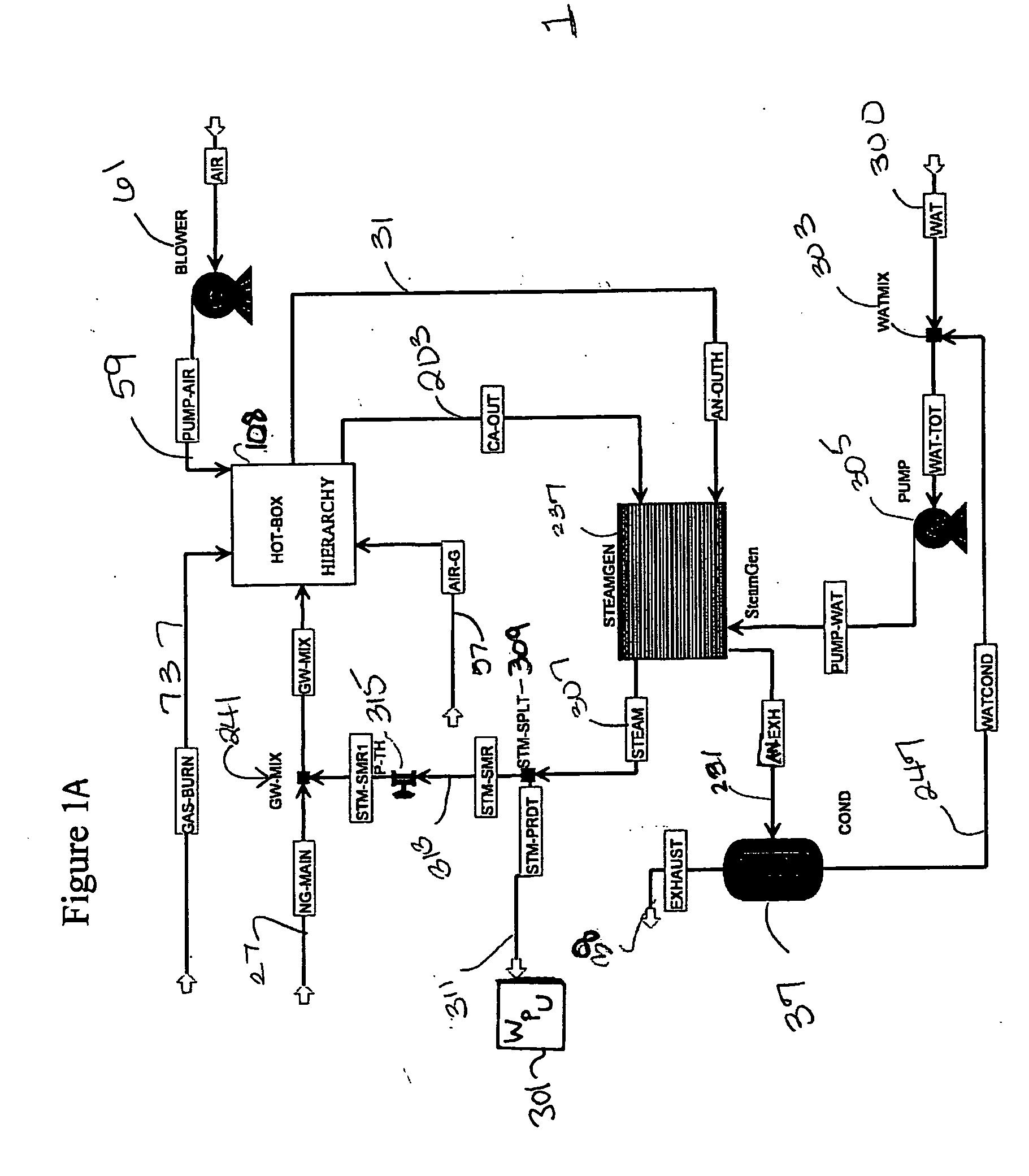

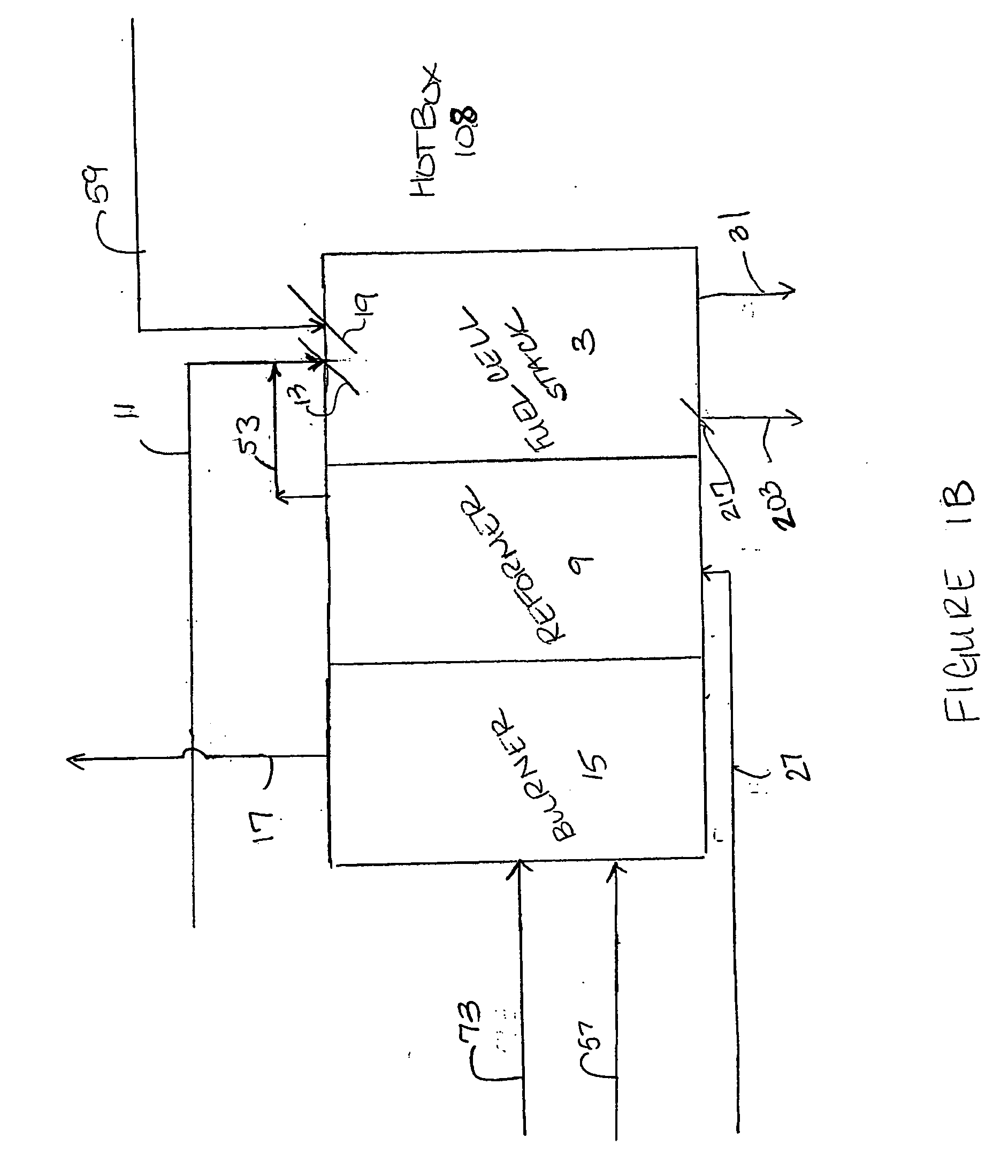

ActiveUS20110315541A1Efficient use ofHydrocarbon purification/separationHydroxy compound preparationAlcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

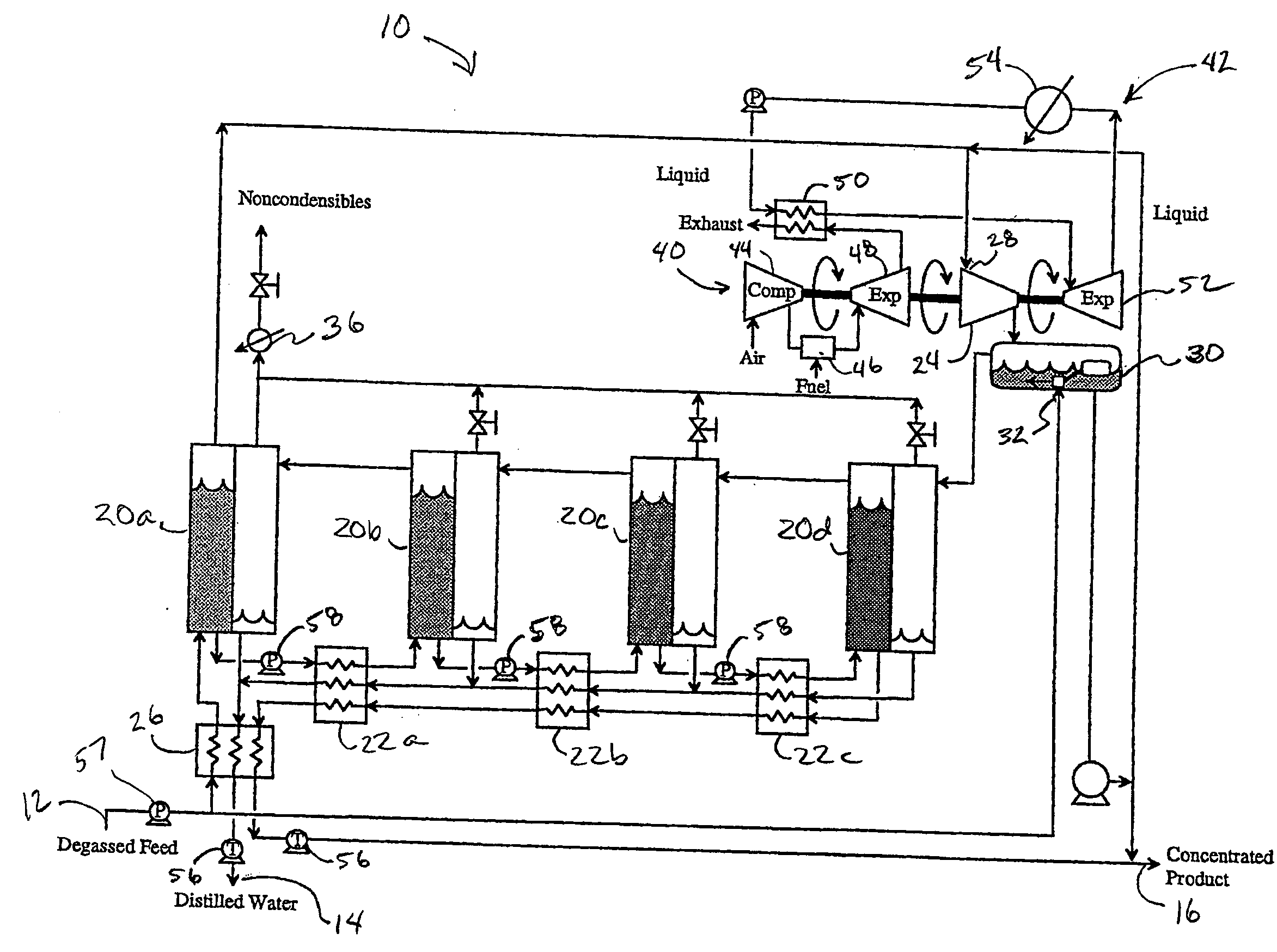

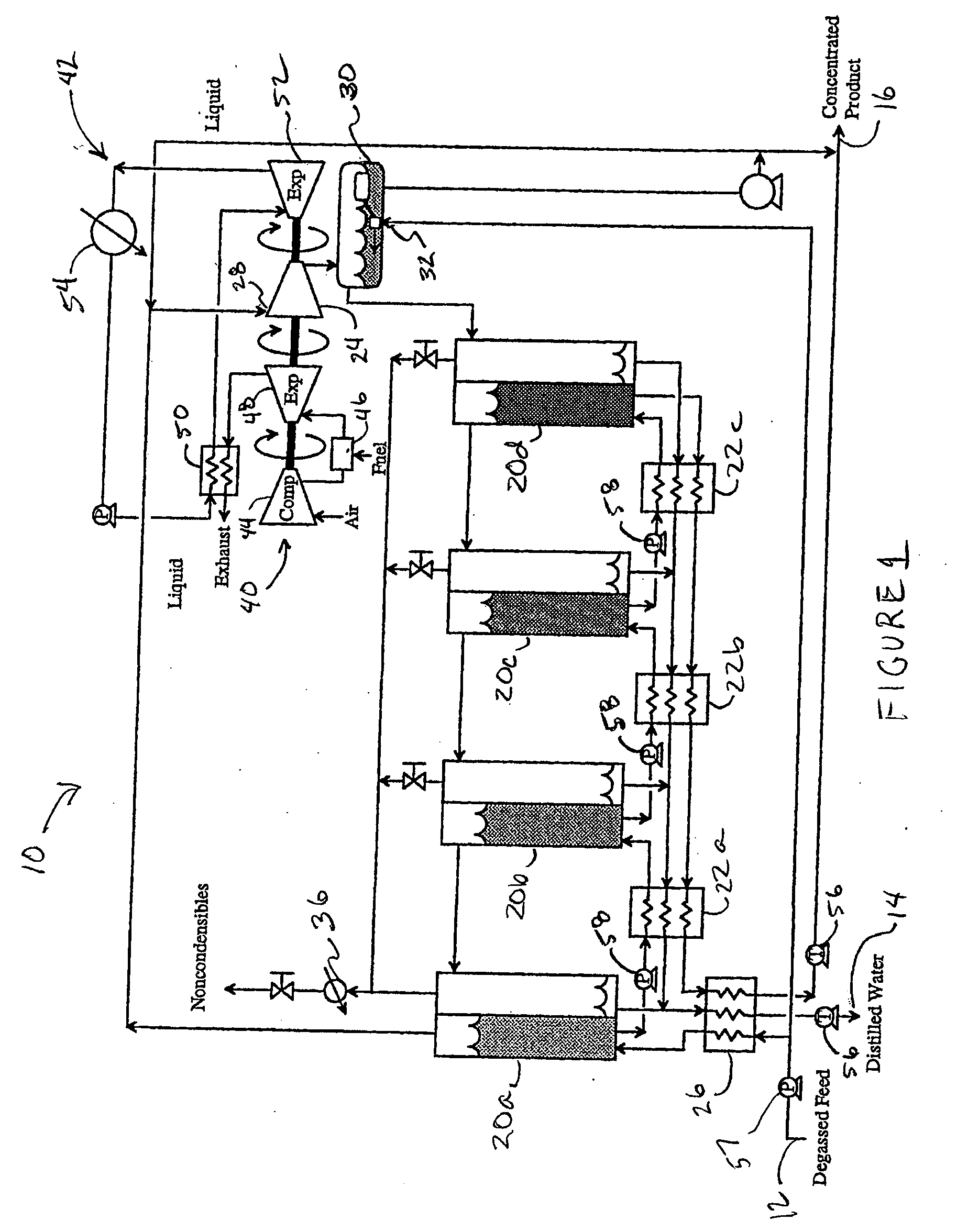

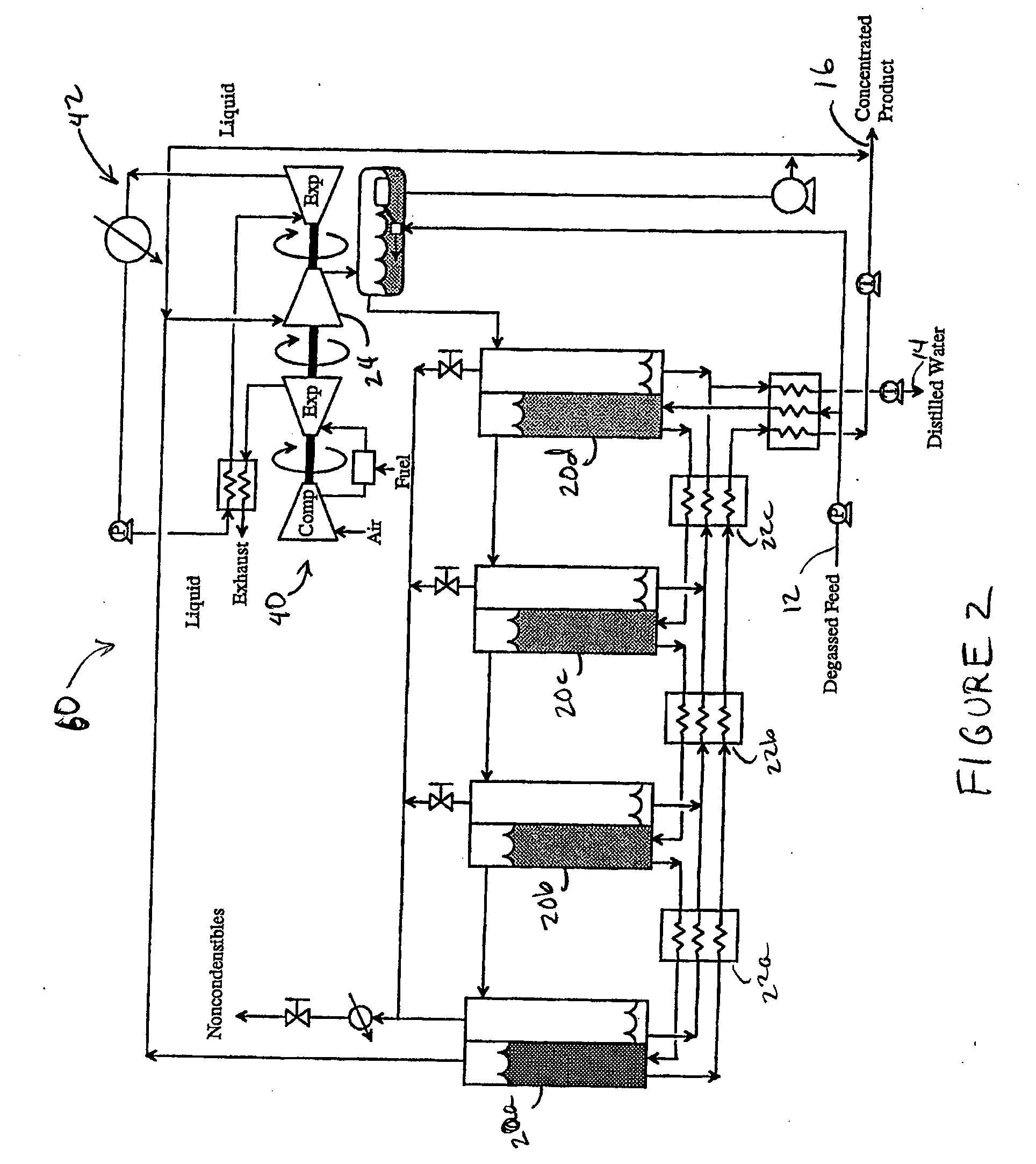

Desalination System

InactiveUS20080083605A1EfficientlyReduce workloadAuxillariesGeneral water supply conservationDesalinationEngineering

In accordance with particular embodiments, a desalination system includes a plurality of evaporators. The plurality of evaporators includes at least a first evaporator and a last evaporator. The plurality of evaporators are arranged in cascading fashion such that a concentration of salt in a brine solution increases as the brine solution passes through the plurality of evaporators from the first evaporator towards the last evaporator. The desalination system also includes a plurality of heat exchangers. An input of each evaporator is coupled to at least one of the plurality of heat exchangers. The system also includes a vapor source coupled to at least one of the plurality of evaporators.

Owner:TERRABON ADVE +1

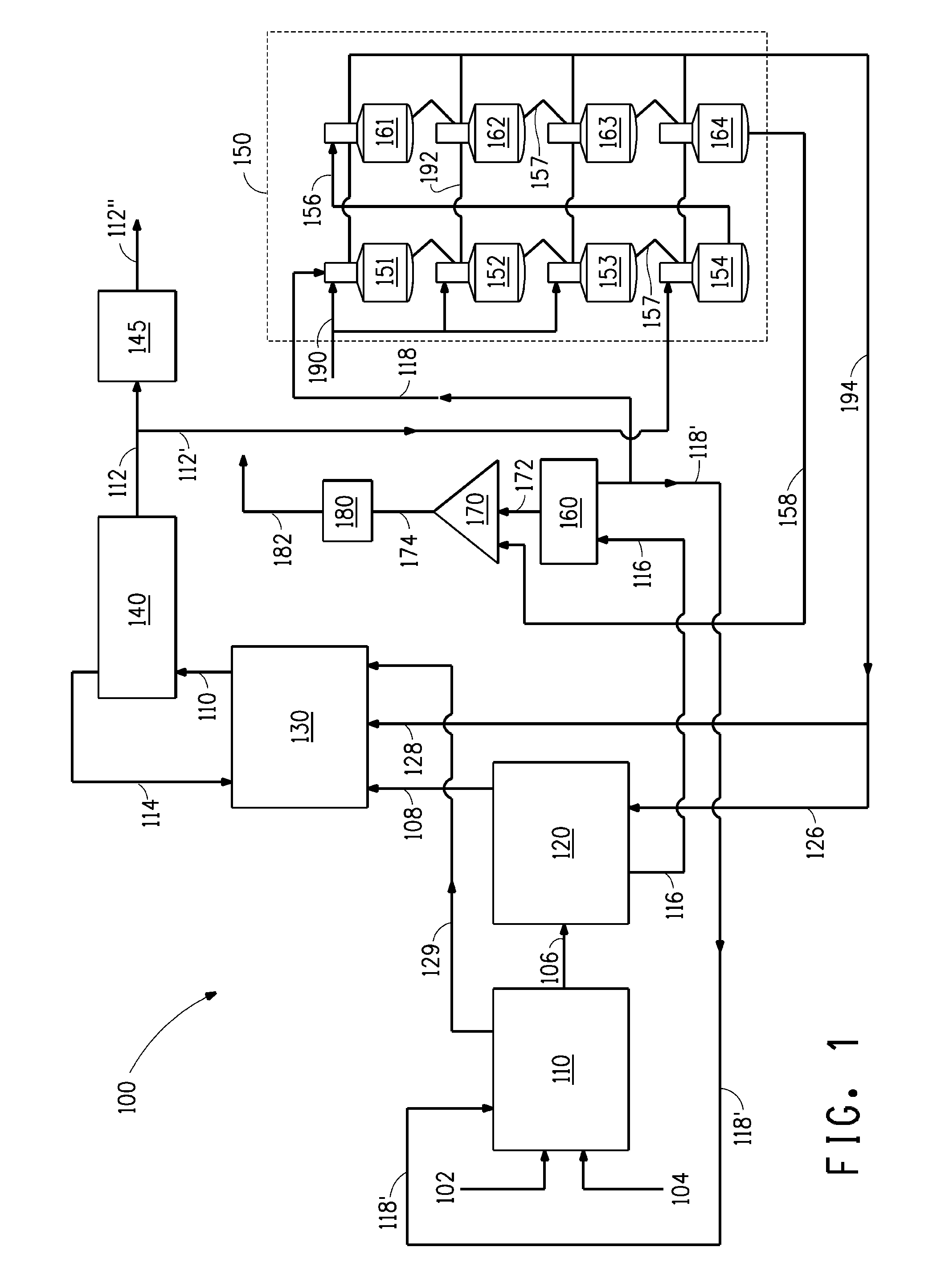

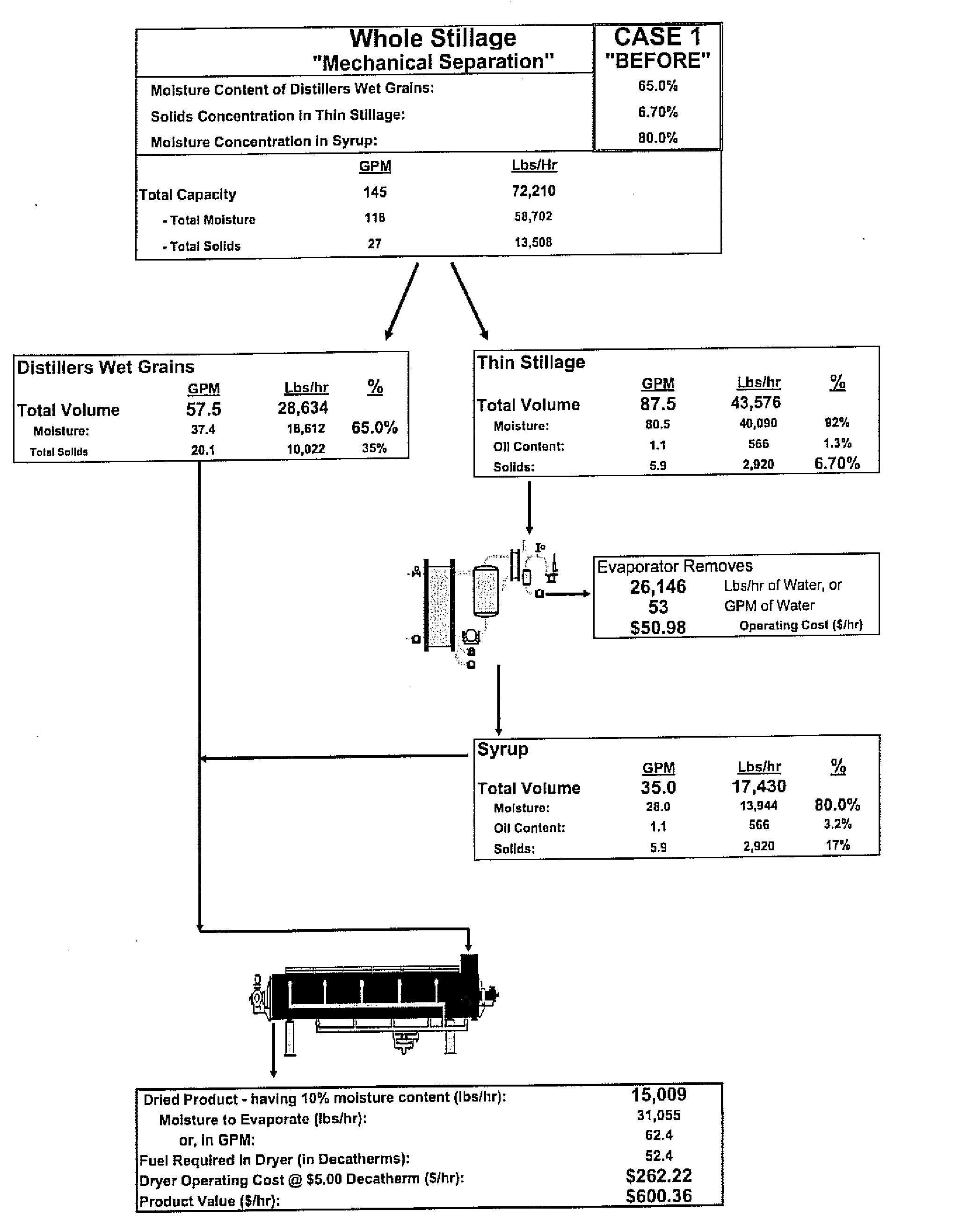

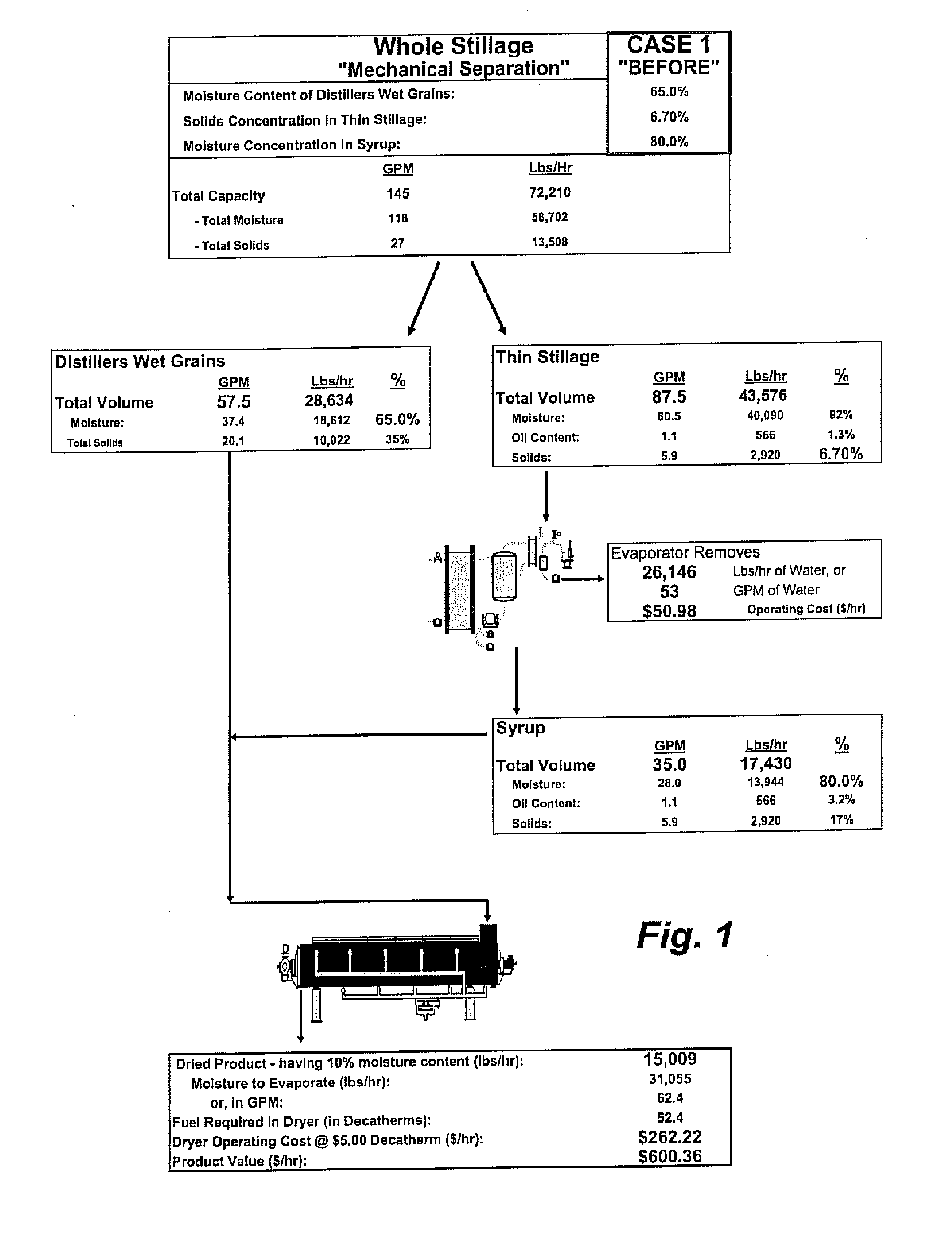

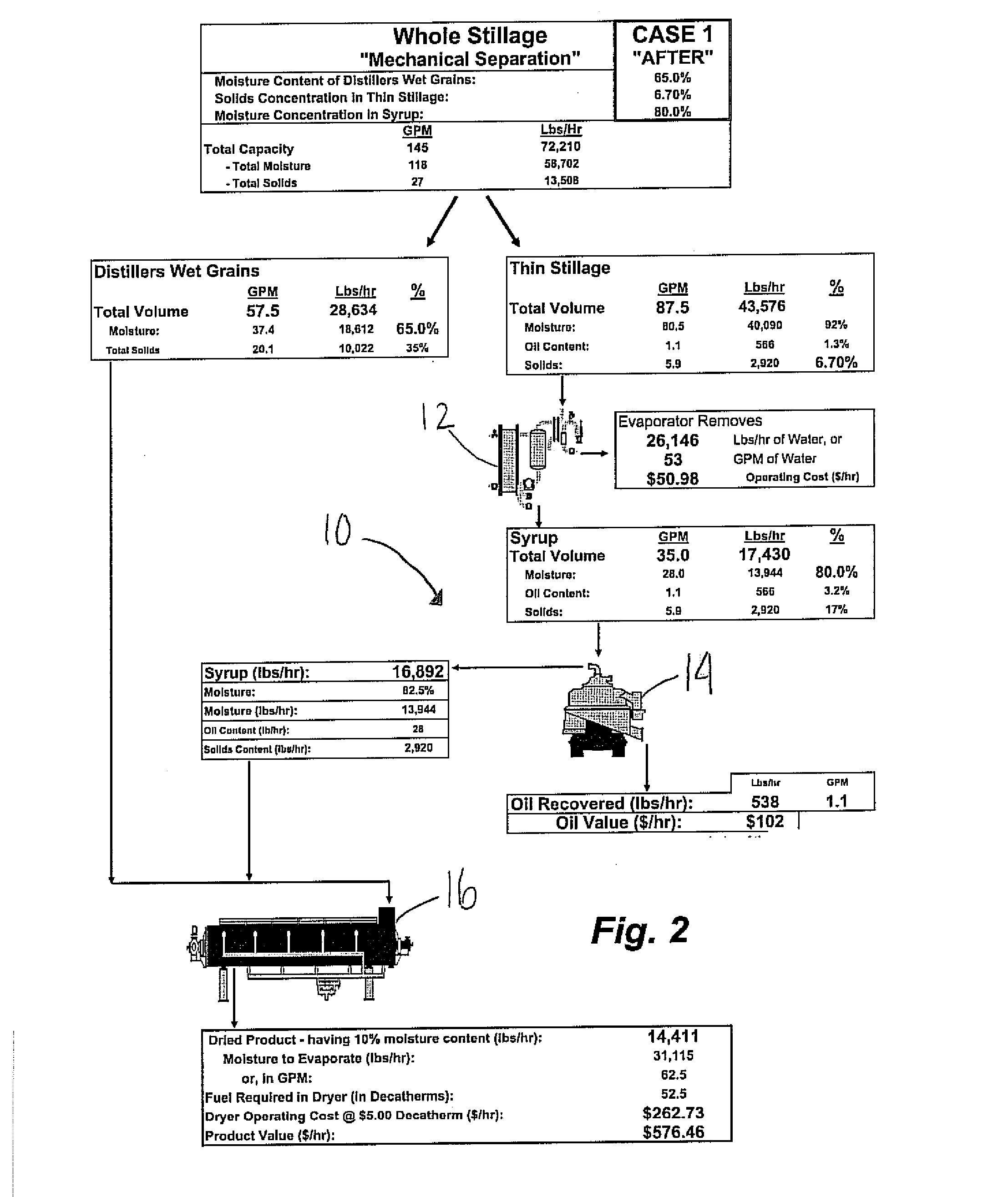

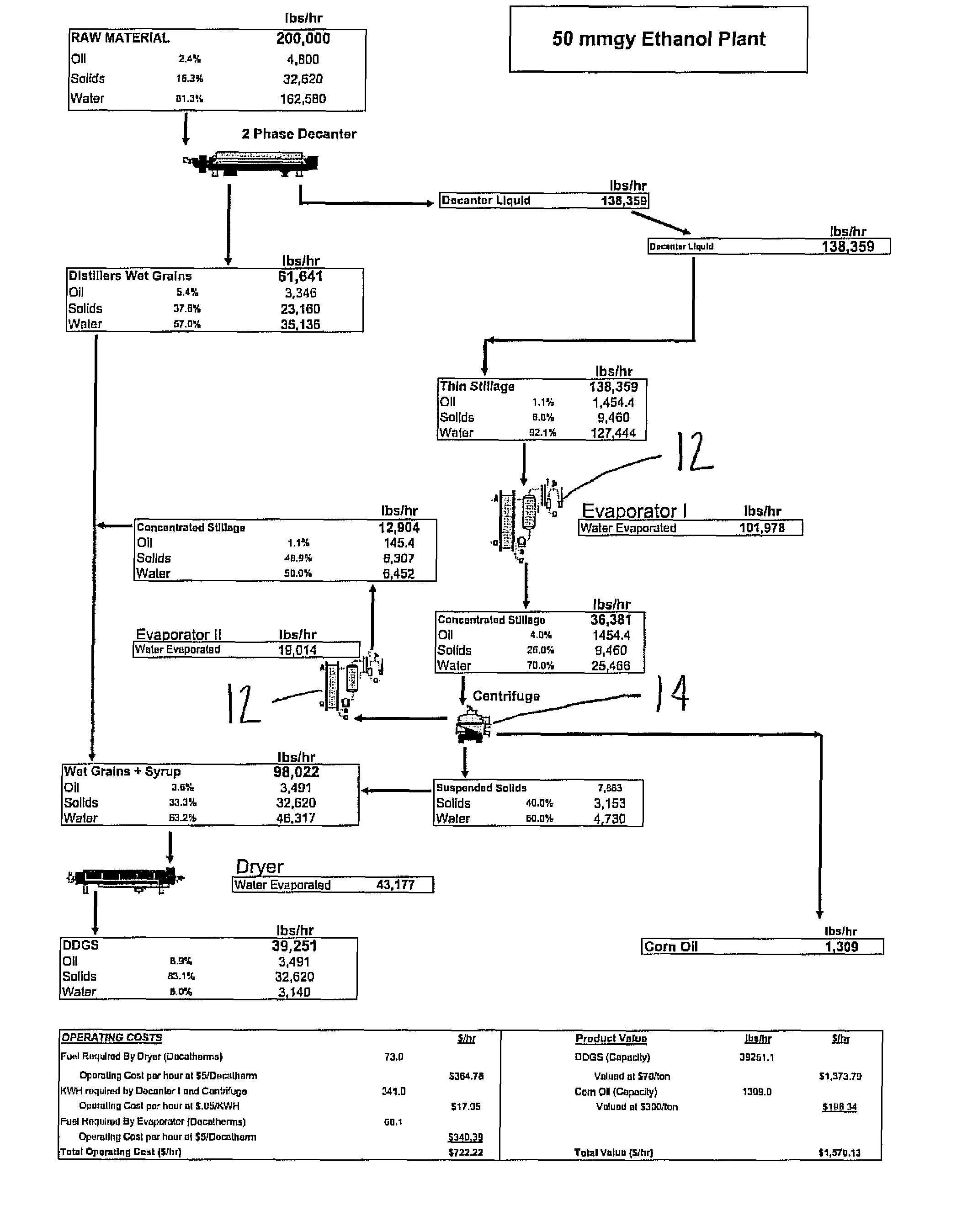

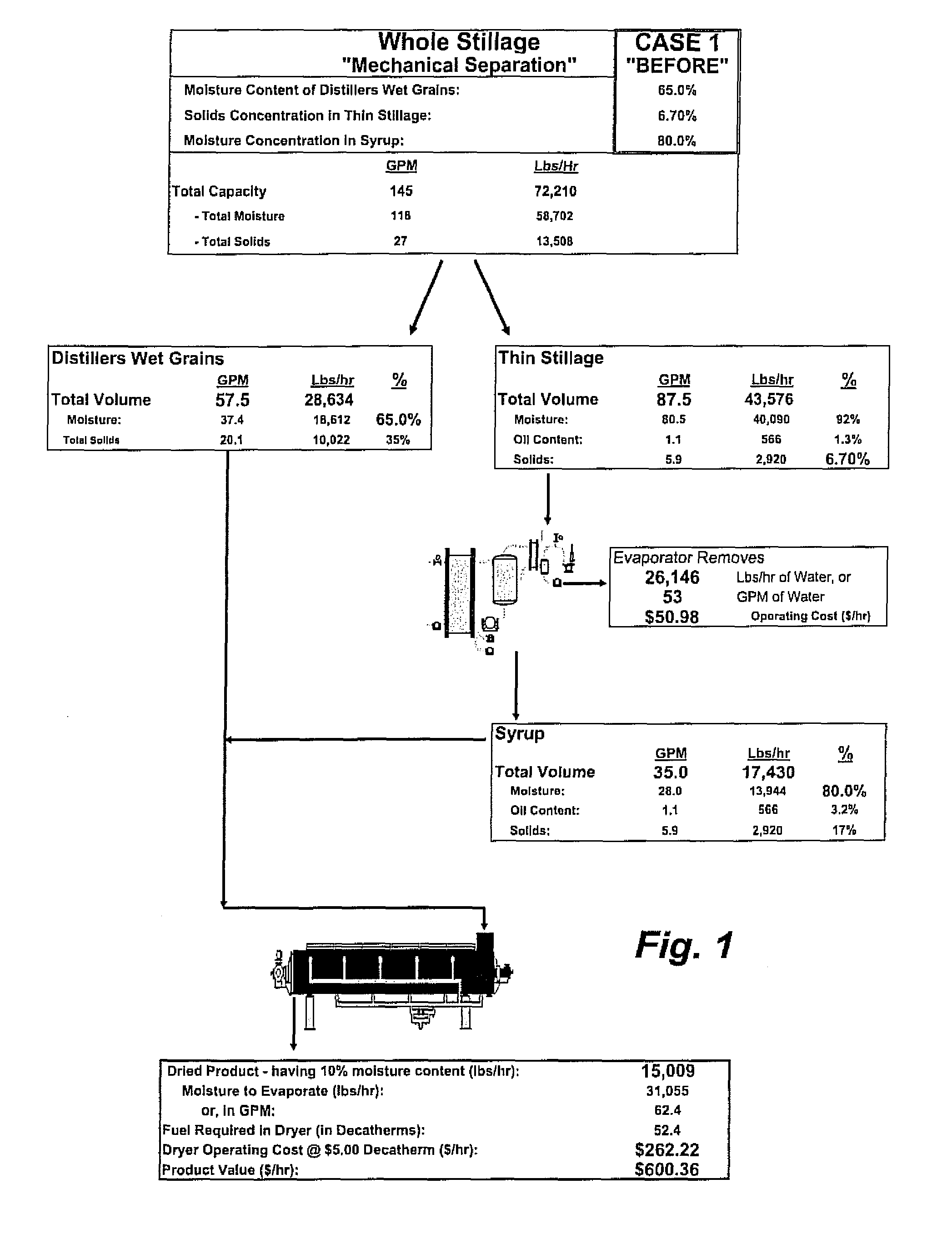

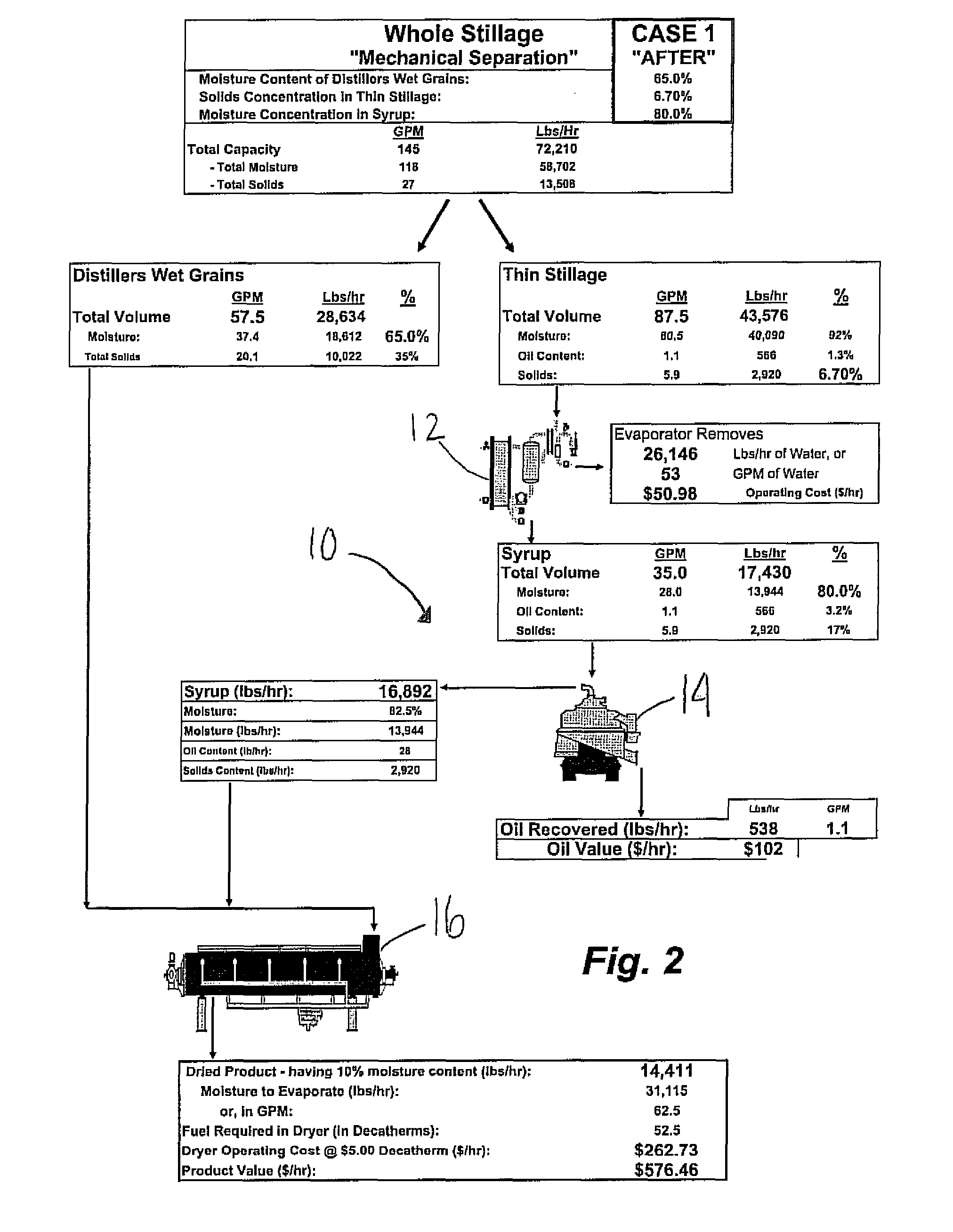

Method and systems for enhancing oil recovery from ethanol production byproducts

ActiveUS20080110577A1Fatty oils/acids recovery from wasteDrying using combination processesEngineeringCentrifuge

Owner:GS CLEANTECH CORP

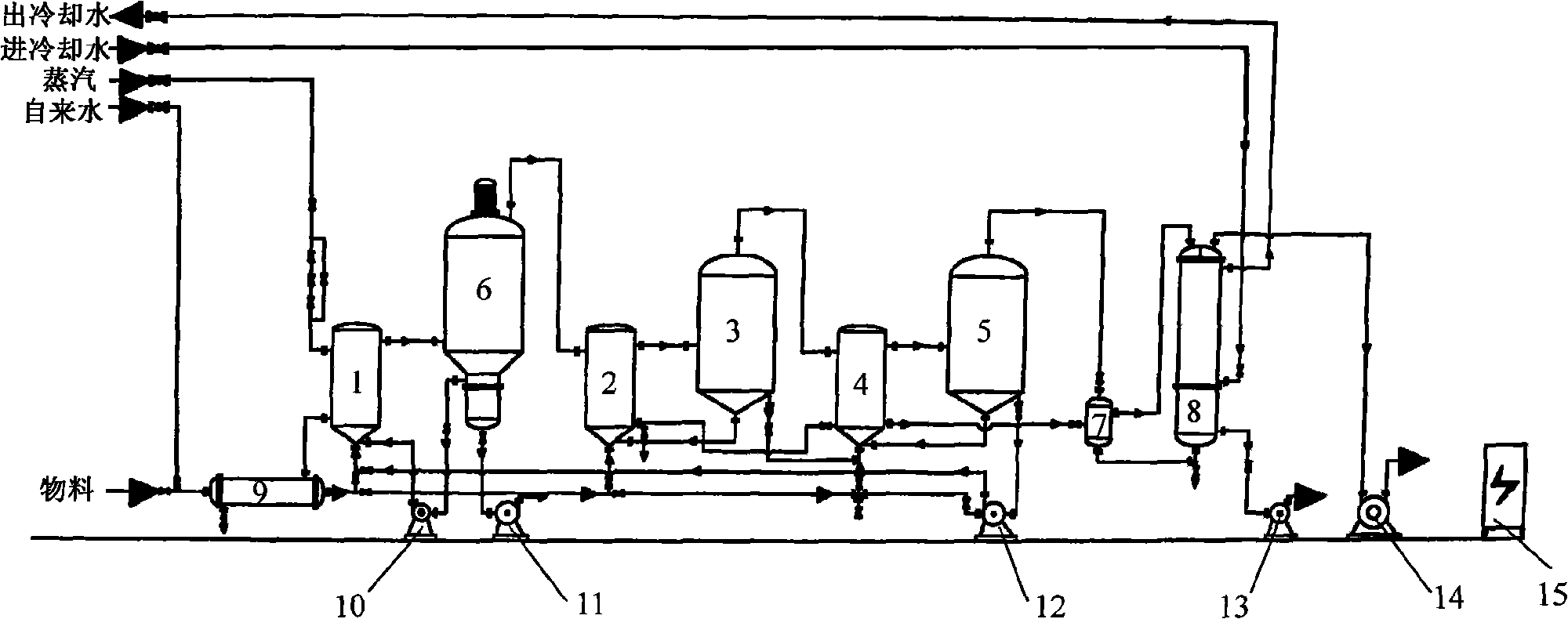

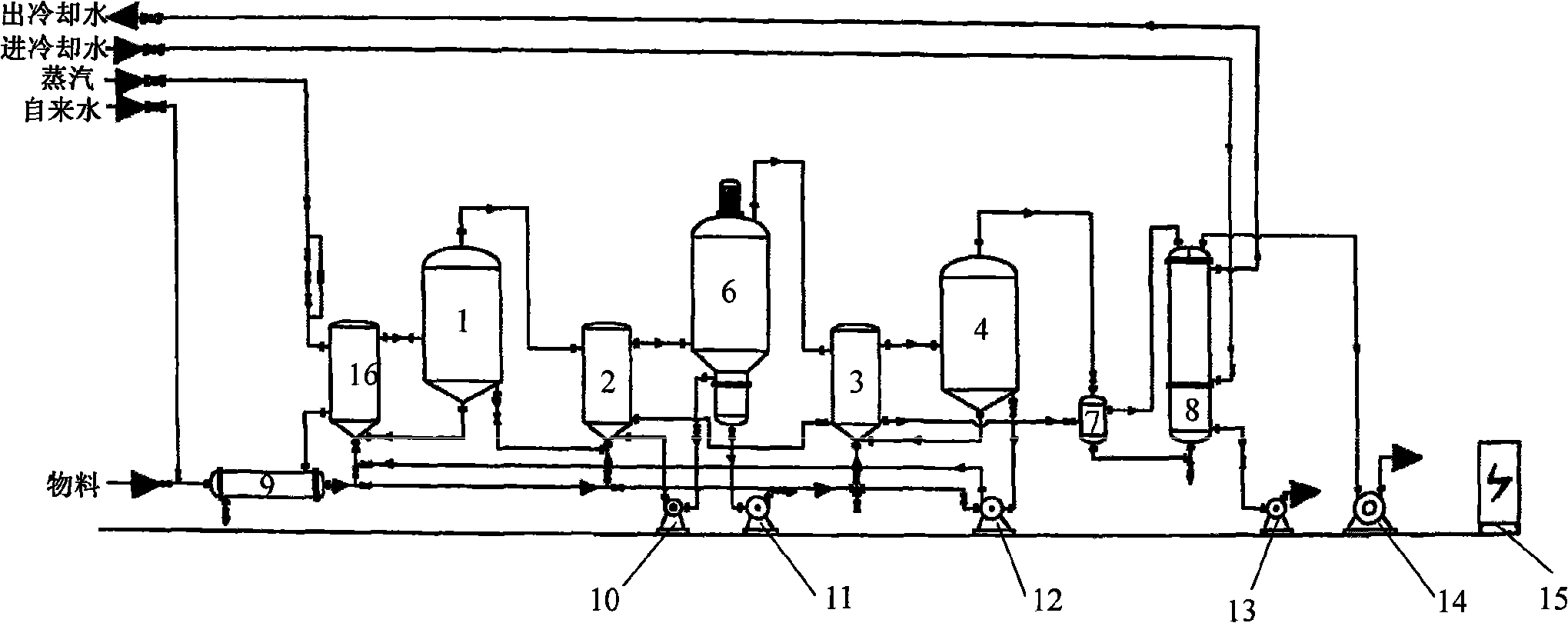

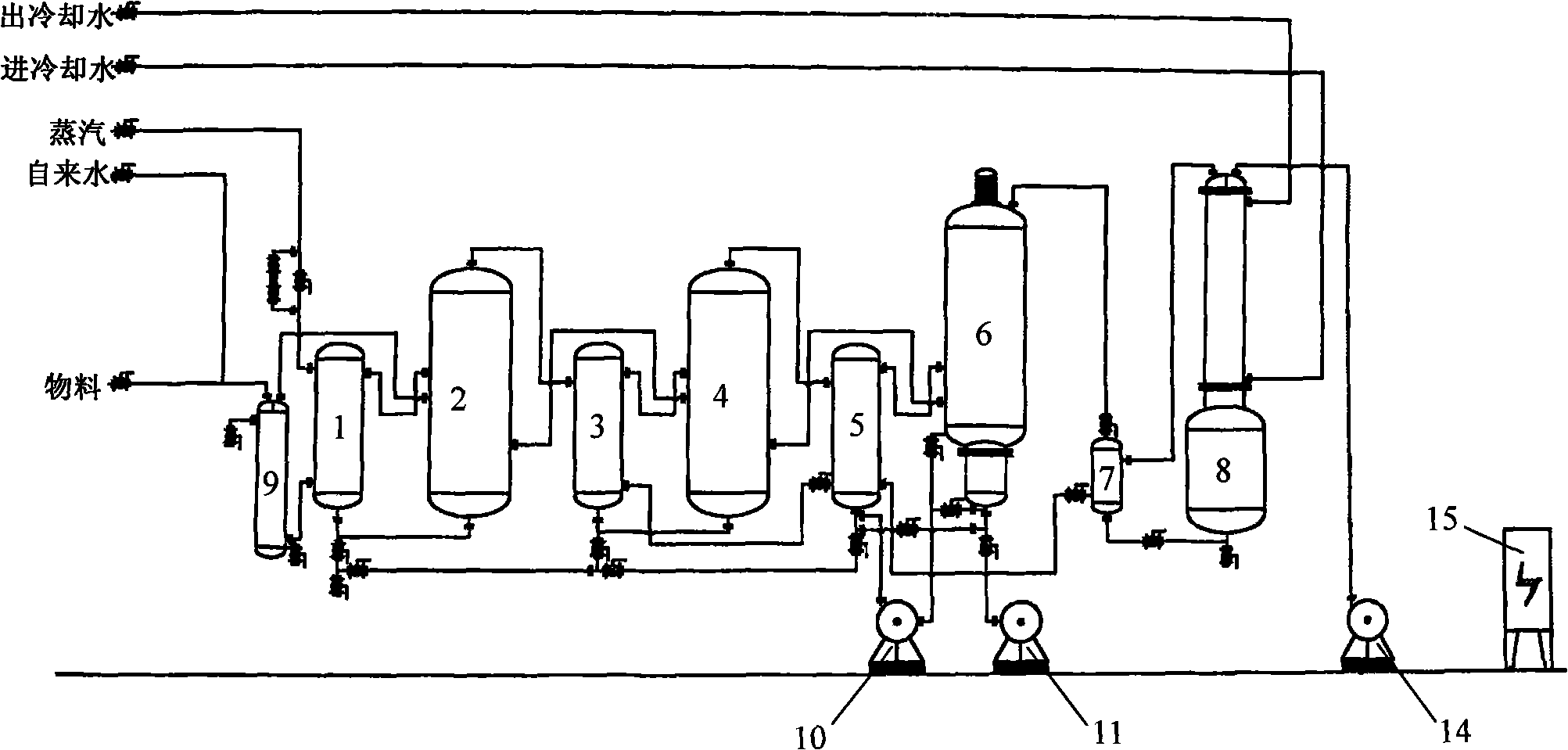

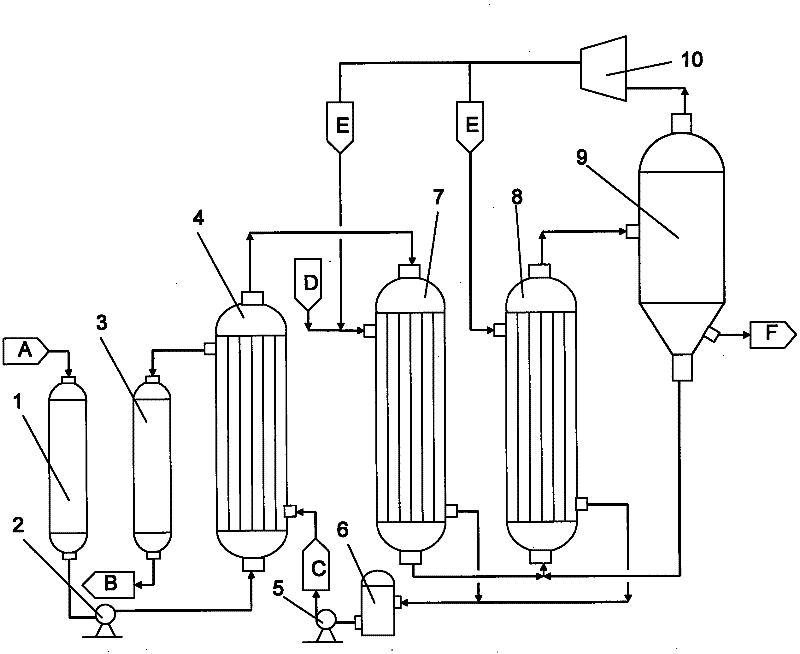

Multifunctional multiple-effect automatic continuous evaporative crystallization technique and crystallization device

InactiveCN101306260AEasy to separateReduce manufacturing costSolution crystallizationMultiple-effect evaporationOrganic solventEconomic benefits

The invention relates to an evaporative crystallization process, in particular to the multifunctional multi-effect automatic continuous evaporative crystallization process and a crystallization device. The process preheats unsaturated water solution or organic solution of materials and carries out the continuous evaporation to the material liquid by a multi-effect evaporator, the temperature of the multi-effect evaporator is gradually reduced and the vacuum degree is gradually increased; when the concentration of the material liquid achieves the saturation, the material liquid enters a crystallizer for the flash evaporation crystallization, and products after the crystallization are subjected to the solid-liquid separation in a centrifuge; the unsaturated solution after the centrifugalization is sent back to the device for the further evaporation crystallization, and the evaporated water or the organic solvent is recycled for use after cooling, thereby realizing the continuous production. The evaporative crystallization process can greatly reduce the labor use and improve the productivity, thereby directly bringing economic benefits to enterprises which use the device and simultaneously reducing the national energy consumption.

Owner:项公浩

Method and systems for enhancing oil recovery from ethanol production byproducts

InactiveUS8168037B2Fatty oils/acids recovery from wasteDrying using combination processesEngineeringCentrifuge

Methods and related systems efficiently and effectively recover a significant amount of valuable, useable oil from byproducts formed during a dry milling process used for producing ethanol. The method may include forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may include evaporating the byproduct using a multi-stage evaporator, as well as recovering the oil before the final stage of the evaporator. Further, the step of recovering oil from the concentrate may include using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil.

Owner:GS CLEANTECH CORP

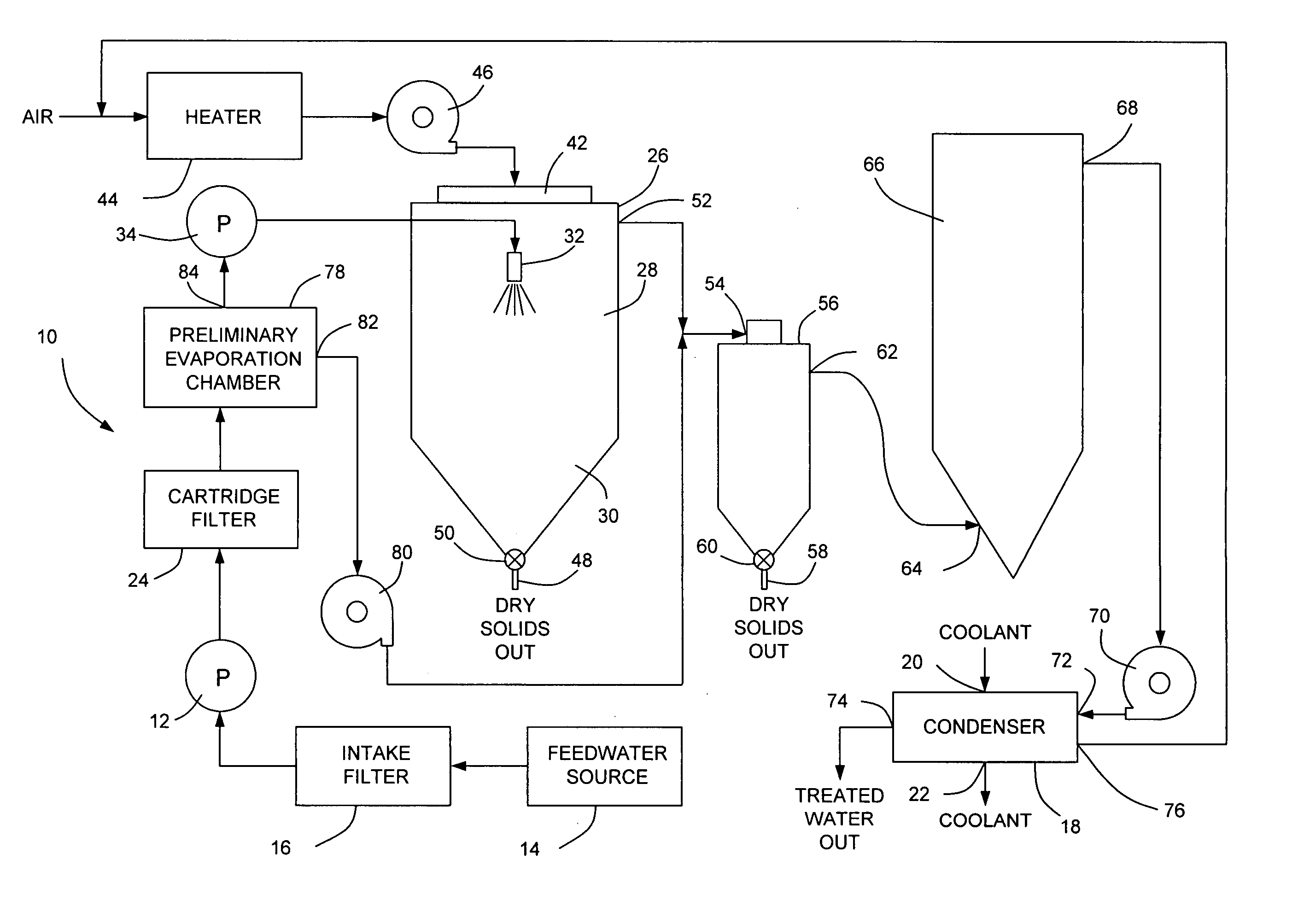

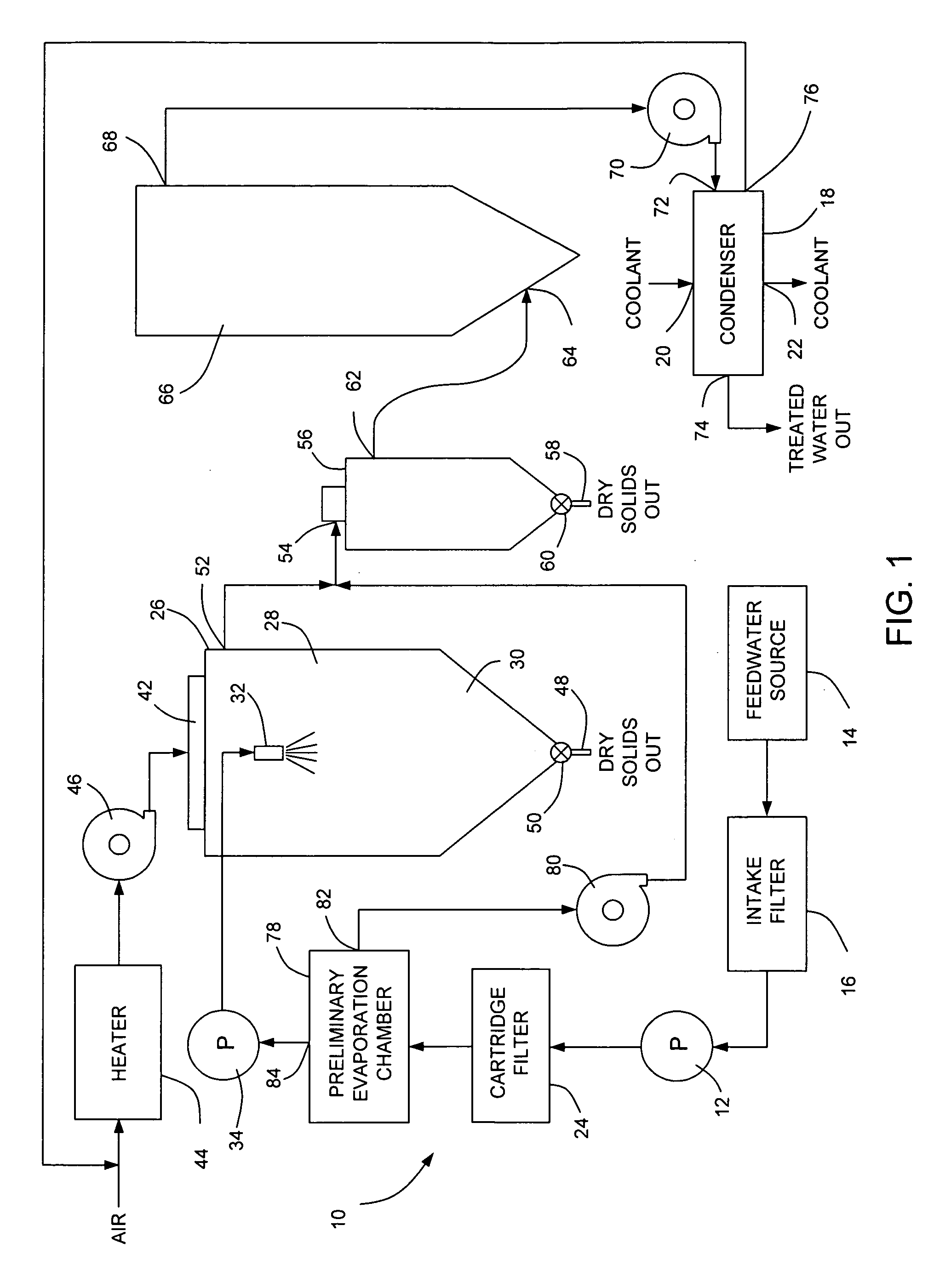

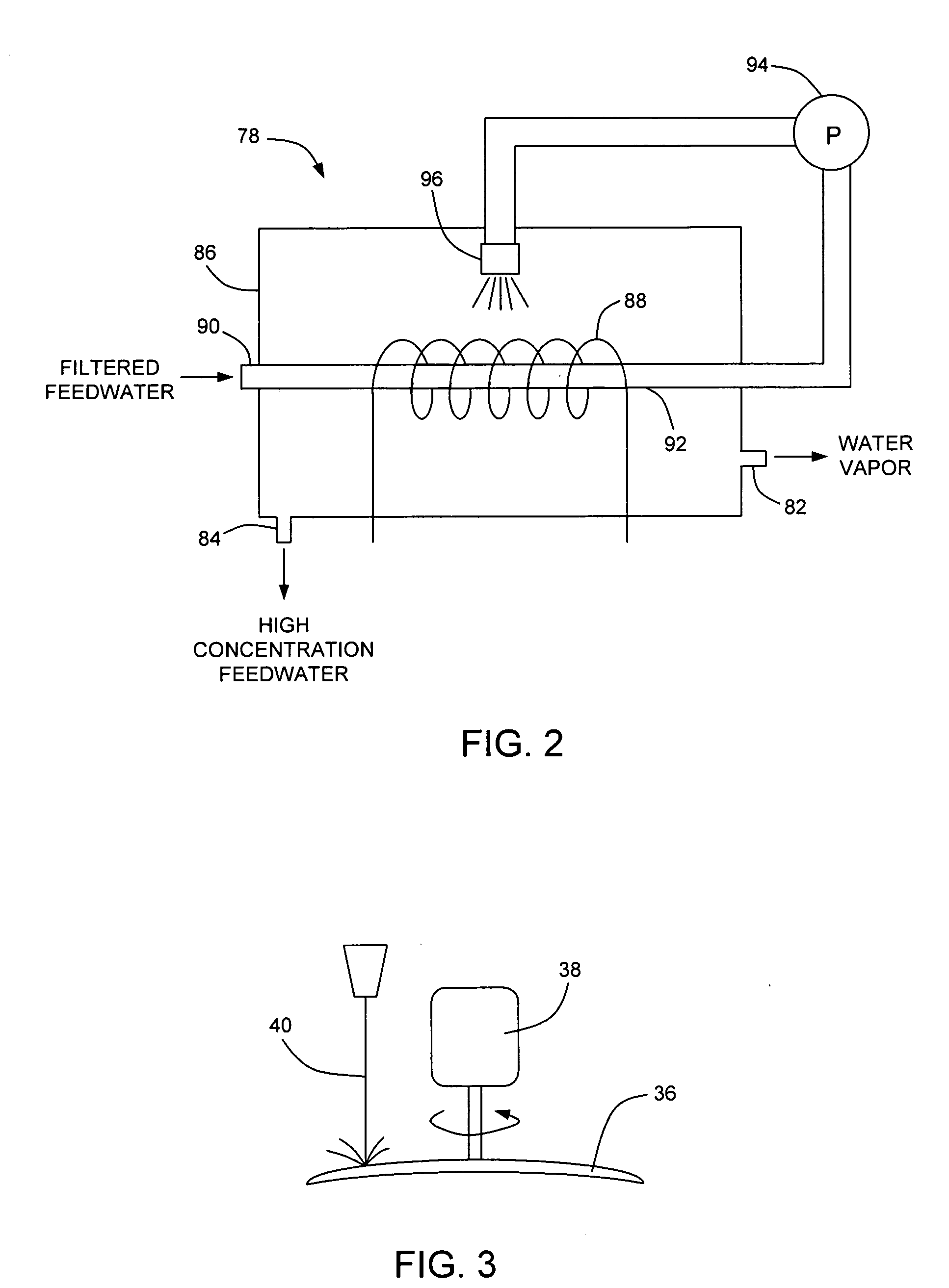

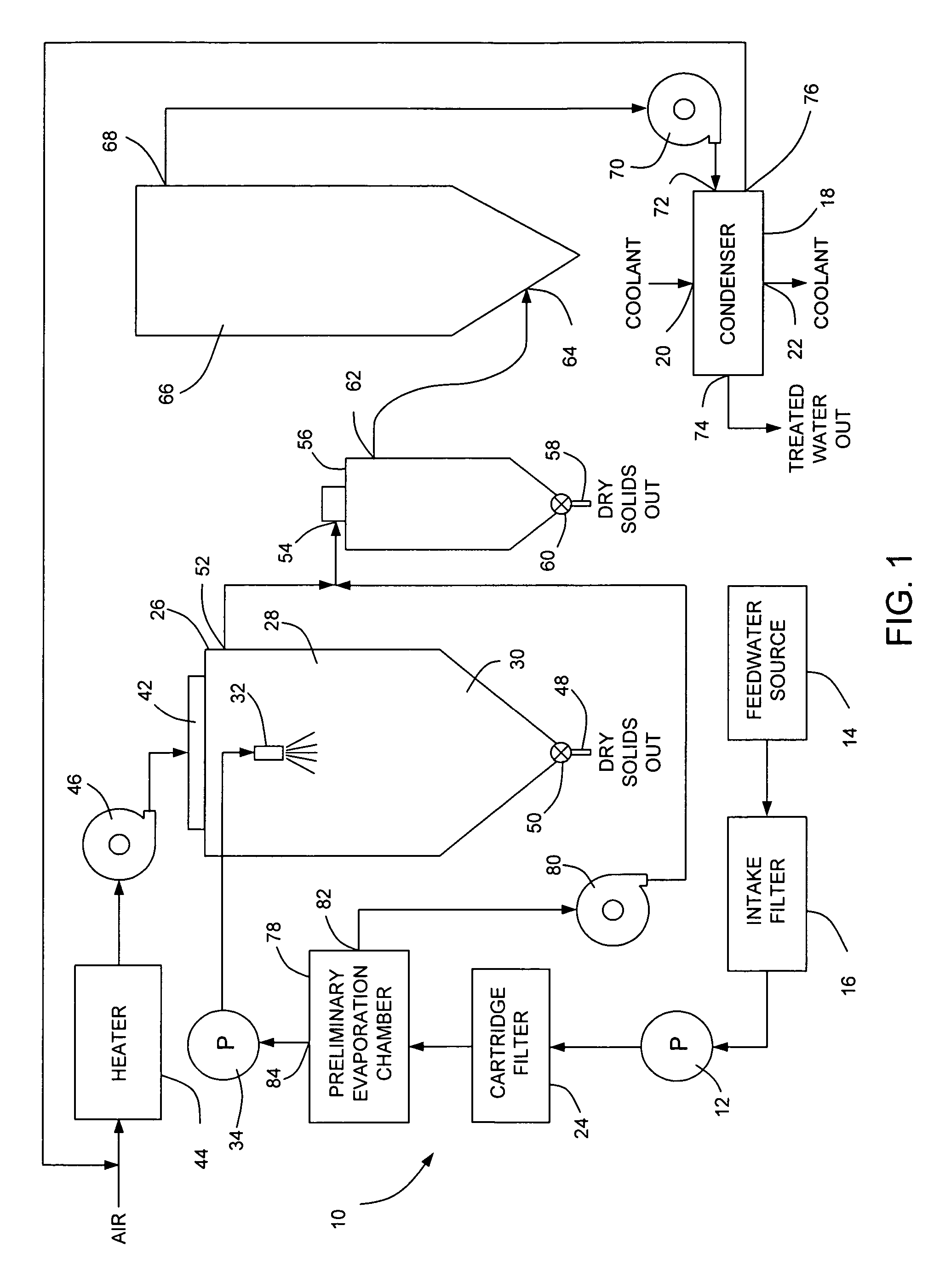

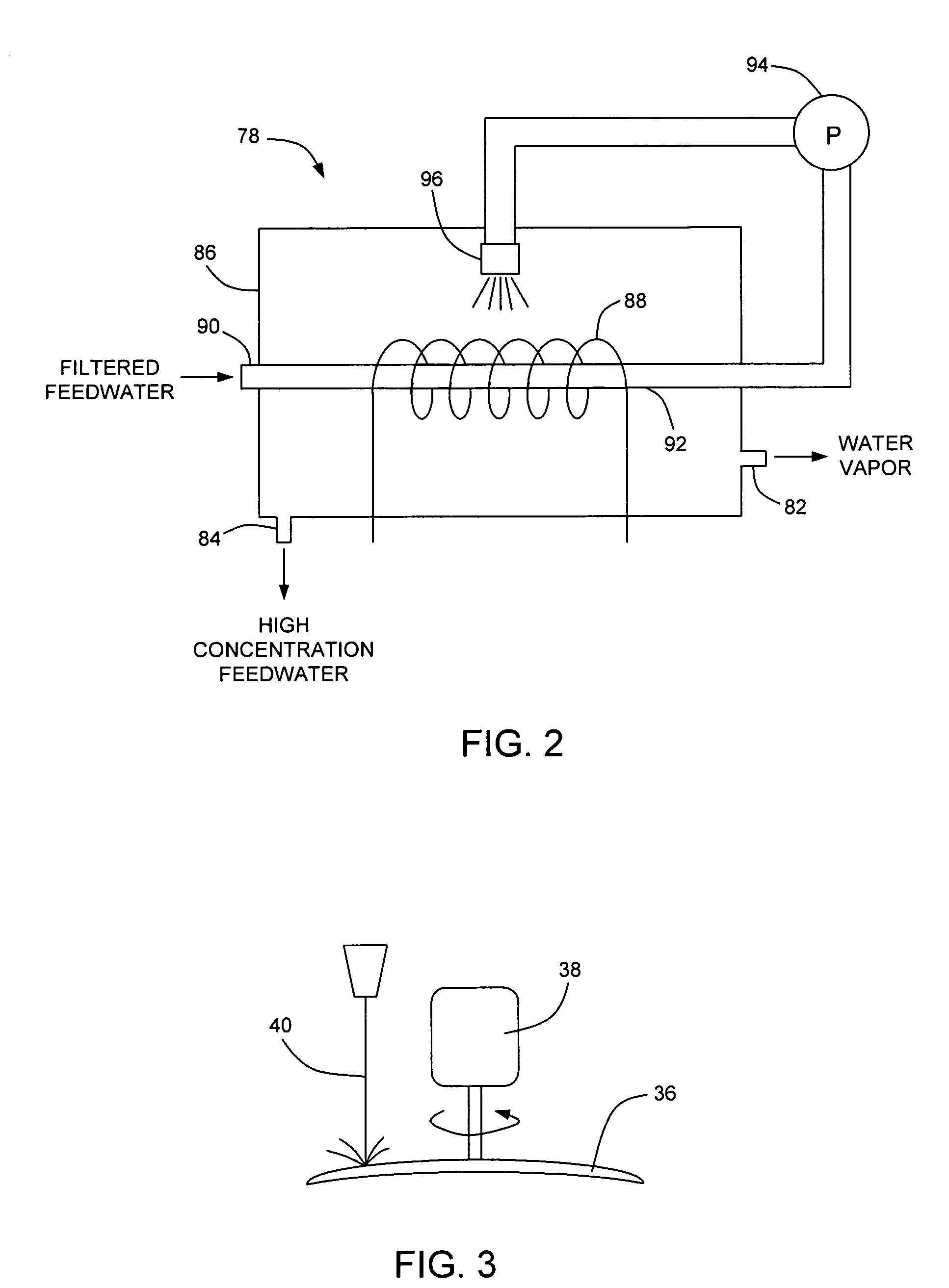

Method and system for separating solids from liquids

A method and system for treating feedwater includes evaporating a portion of the feedwater in a first evaporation chamber so as to separate water vapor from the remaining feedwater. Droplets of the remaining feedwater are dispersed into a stream of hot air produced in a second evaporation chamber. The droplets evaporate and solids in the feedwater precipitate. The precipitated solids are collected in the lower section of the second evaporation chamber. Water vapor discharged from both evaporation chambers can be treated in a cyclone separator to remove residual solids therefrom. The cleansed water vapor output from the cyclone separator can be condensed to recover clean water. Dry solids can be discharged from the second evaporation chamber and the cyclone separator for recovery.

Owner:WATERVAP

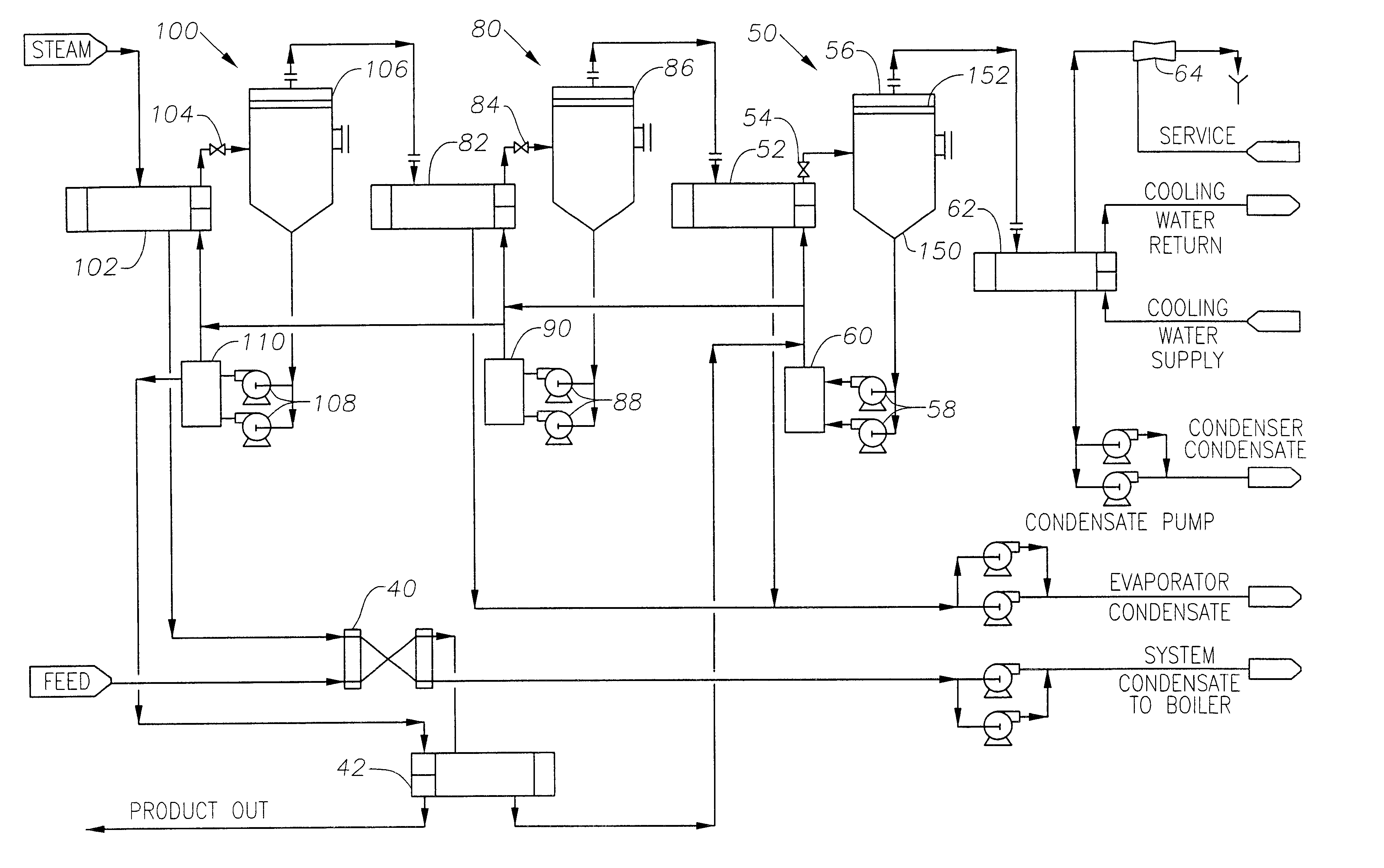

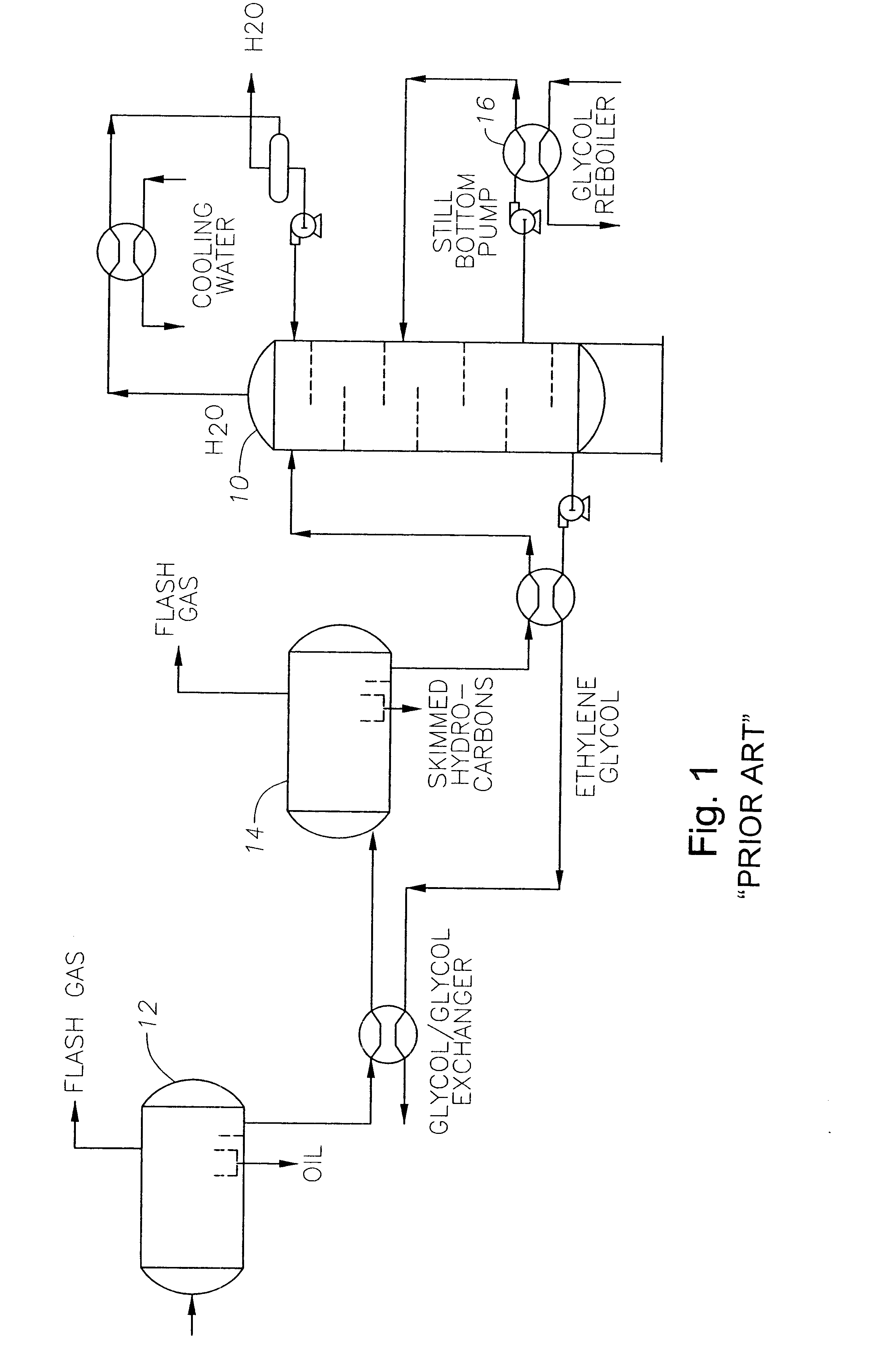

System for recovering glycol from glycol/brine streams

A system for recovering glycol from glycol and brine mixtures produced from oil or natural gas wells that combines energy efficiency with a capability for handling salt and other solids contained in the mixture. The system comprises three effect evaporator systems in series. Each effect evaporator system comprises an evaporator, a separator vessel, product pumps, and a solids removal system.The process utilizes the system to remove salt and other solids as well as excess water leaving a glycol stream that can be reused as a hydrate inhibitor. The process begins by preheating a glycol / brine stream comprising approximately fifty percent (50%) glycol. The stream is then subjected to three evaporation cycles. The first evaporation cycle comprises introducing the preheated stream into a suppressed boiling point evaporator where the stream is heated under a constant pressure. The stream pressure is then dropped to cause a portion of the water contained in the stream to vaporize or flash. The flashing stream is then introduced into a separator vessel where the water vapor is separated from the remaining liquid stream. The water vapor is removed from the separator and condensed. The remaining liquid glycol / brine stream is then pumped from the separator vessel through a solids removal system where precipitated salts and solids are removed. These steps are repeated two additional times. Each time the remaining liquid stream becomes more concentrated with glycol until the finished product is approximately ninety percent (90%) glycol.

Owner:TRANSOCEAN SEDCO FOREX VENTURES LTD

Heat-pipe low-temperature multi-effect sea water desalinating system and process flow

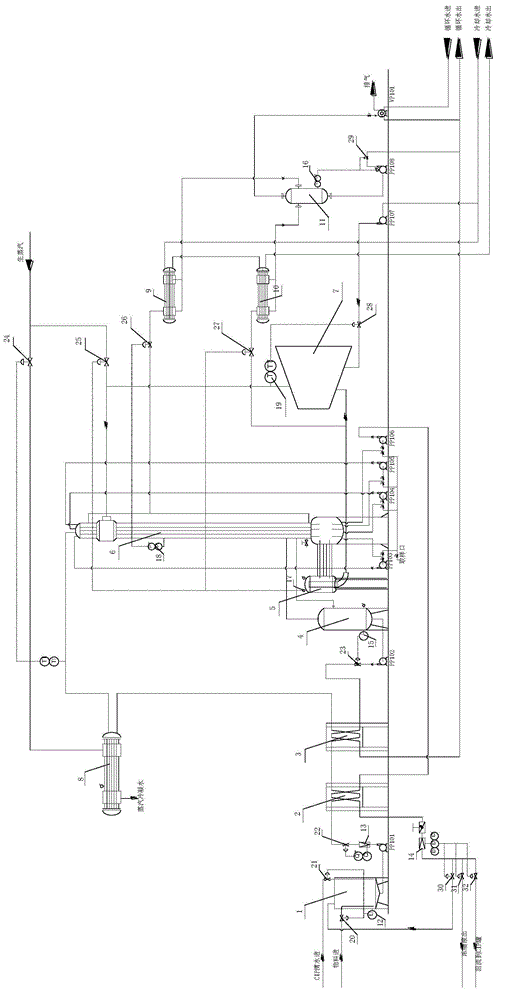

ActiveCN102557168AIncrease profitAchieve fadeGeneral water supply conservationSeawater treatmentEngineeringVacuum pump

The invention discloses a heat-pipe low-temperature multi-effect sea water desalinating system which comprises a plurality of groups of heat-pipe multi-effect evaporators, a steam injector TVC (Thermal Vapor Compressor), a cooler, an air water release device, a steam-water separator, a water ring vacuum pump, a sea water pump, a fresh water pump, a turbine intermediate pressure cylinder and a turbine low pressure cylinder. The invention also discloses a process flow of the heat-pipe low-temperature multi-effect sea water desalinating system, comprising the steps of: extracting steam through the turbine intermediate pressure cylinder, ejecting circulation steam in the cooler and exhaust steam of the turbine low pressure cylinder through the steam injector TVC to ensure that the circulation steam and the exhaust steam of the turbine low pressure cylinder are changed into higher-quality steam to enter the heat-pipe evaporators, condensing and releasing heat of the steam at a heat absorption end through a heat pipe, transferring the heat to heating and atomized sea water at the other end; heating next-stage sea water through taking the heated and vaporized sea water as the heat source of the next multi-effect evaporator while cooling the heated and vaporized sea water to generate fresh water; heating the sea water which cools the last-stage steam entering the cooler and exhausting the generated non-condensable gas through the air water release device; pumping the non-condensable gas of the multi-effect evaporators through the water ring vacuum pump to ensure that the system runs in a negative-pressure state; and discharging concentrated water out of the system through a pipeline and pumping the fresh water to a fresh water tank through a permeated water pump.

Owner:国能朗新明环保科技有限公司

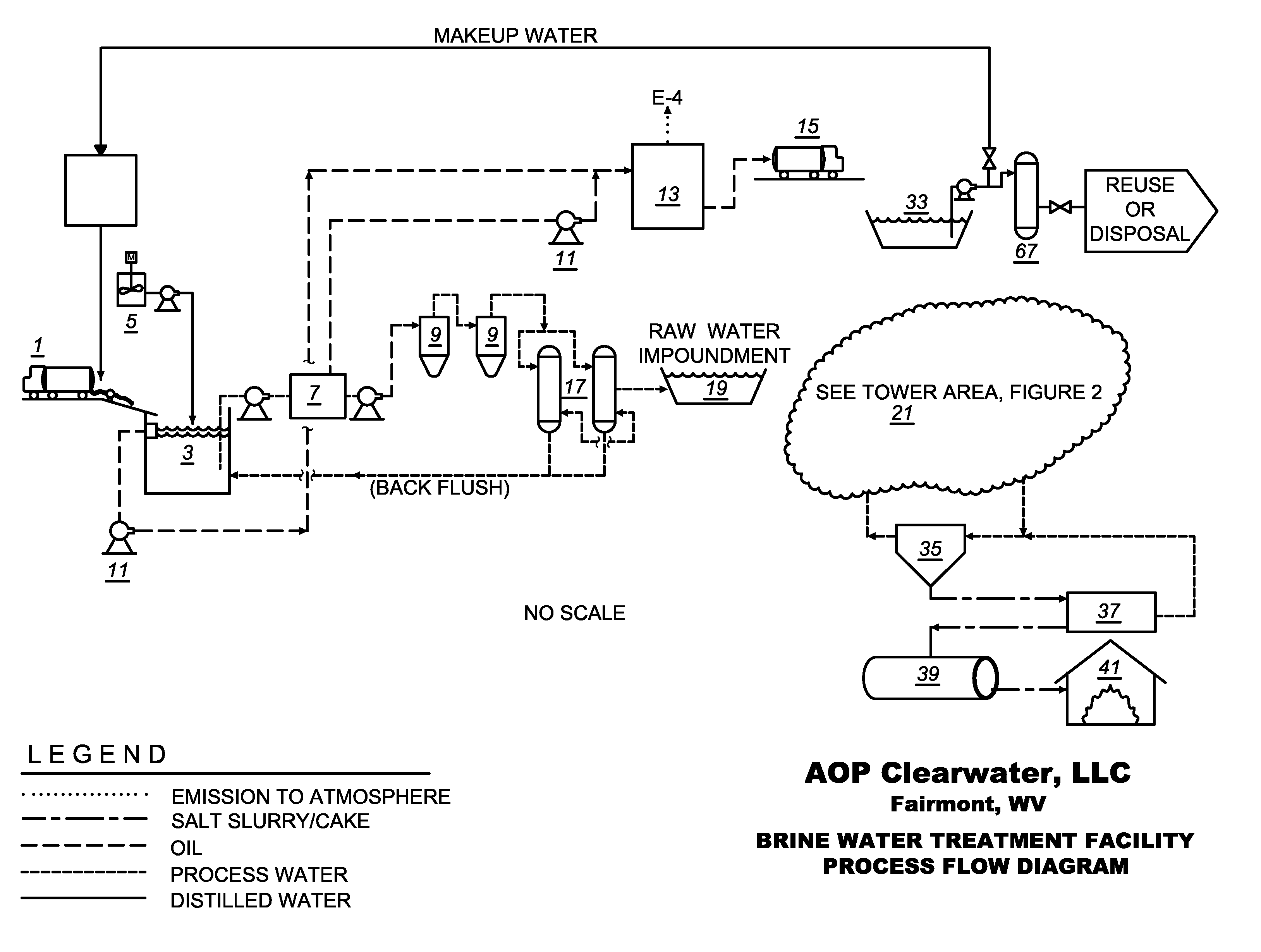

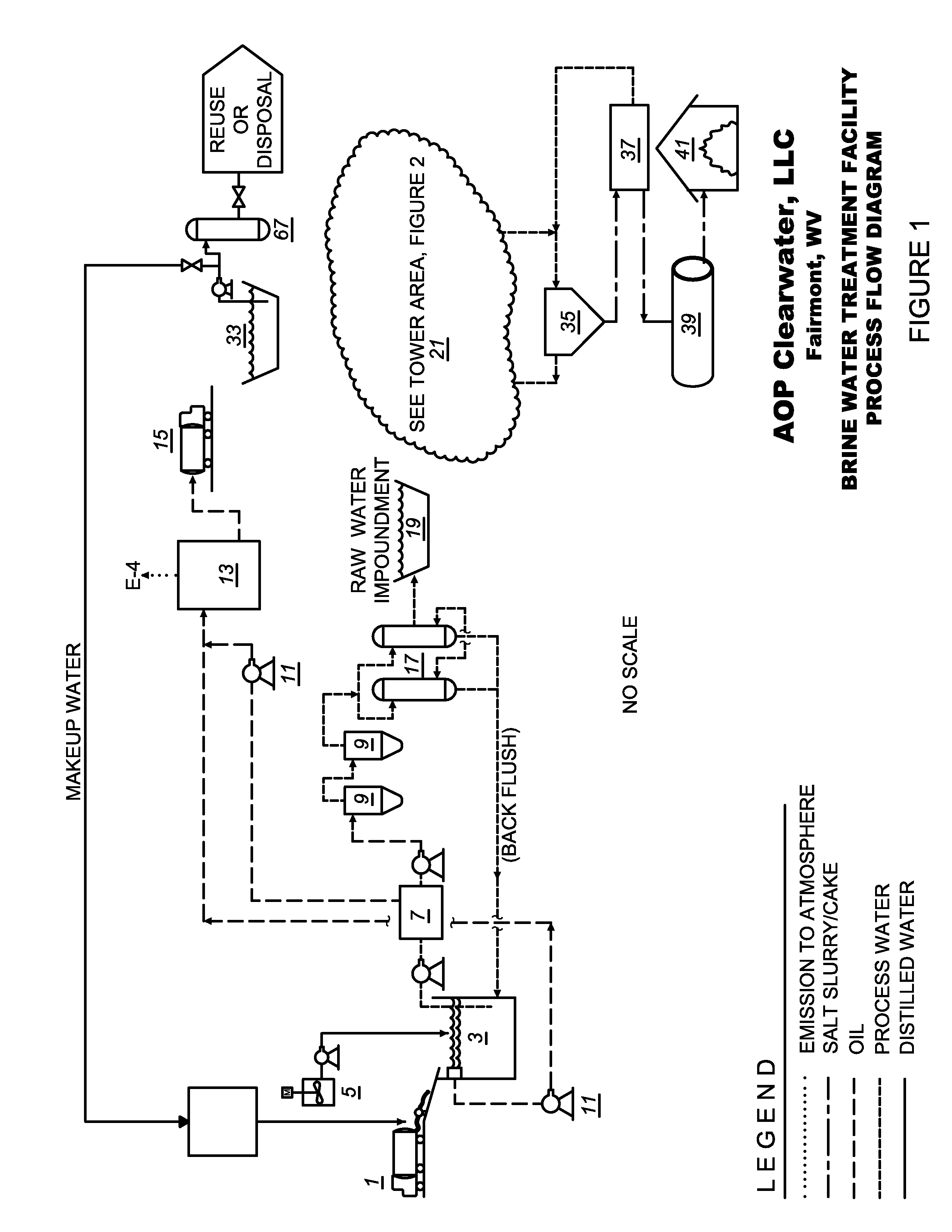

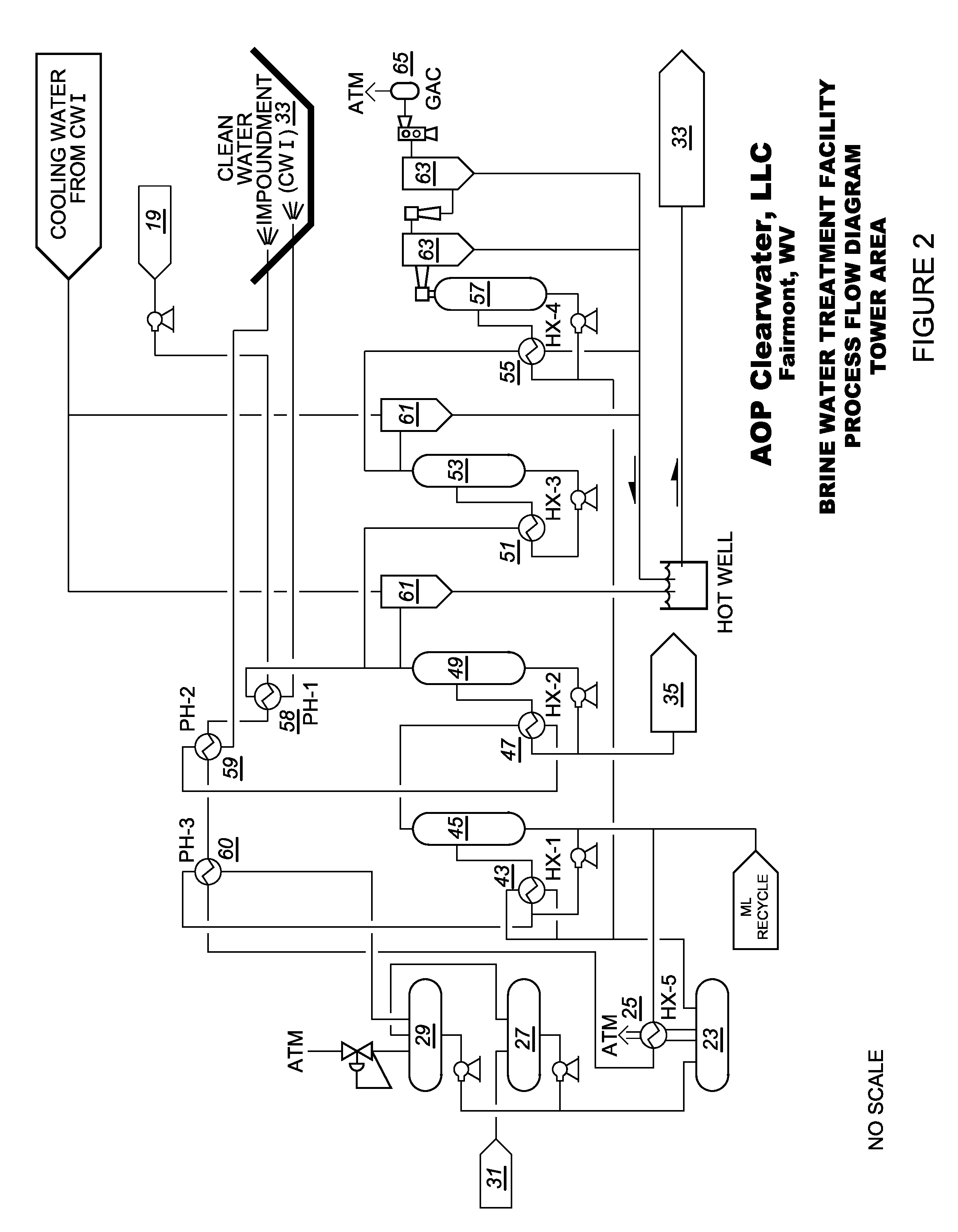

Brine water recycle process

Embodiments provided herein include methods and apparatuses for purification and recycling of hydrofracture water used in natural gas drilling and production. Embodiments include removal of dissolved solids by precipitation with sodium sulfate and by evaporation using, for example, a multiple effect evaporator.

Owner:FAIRMONT BRINE PROCESSING

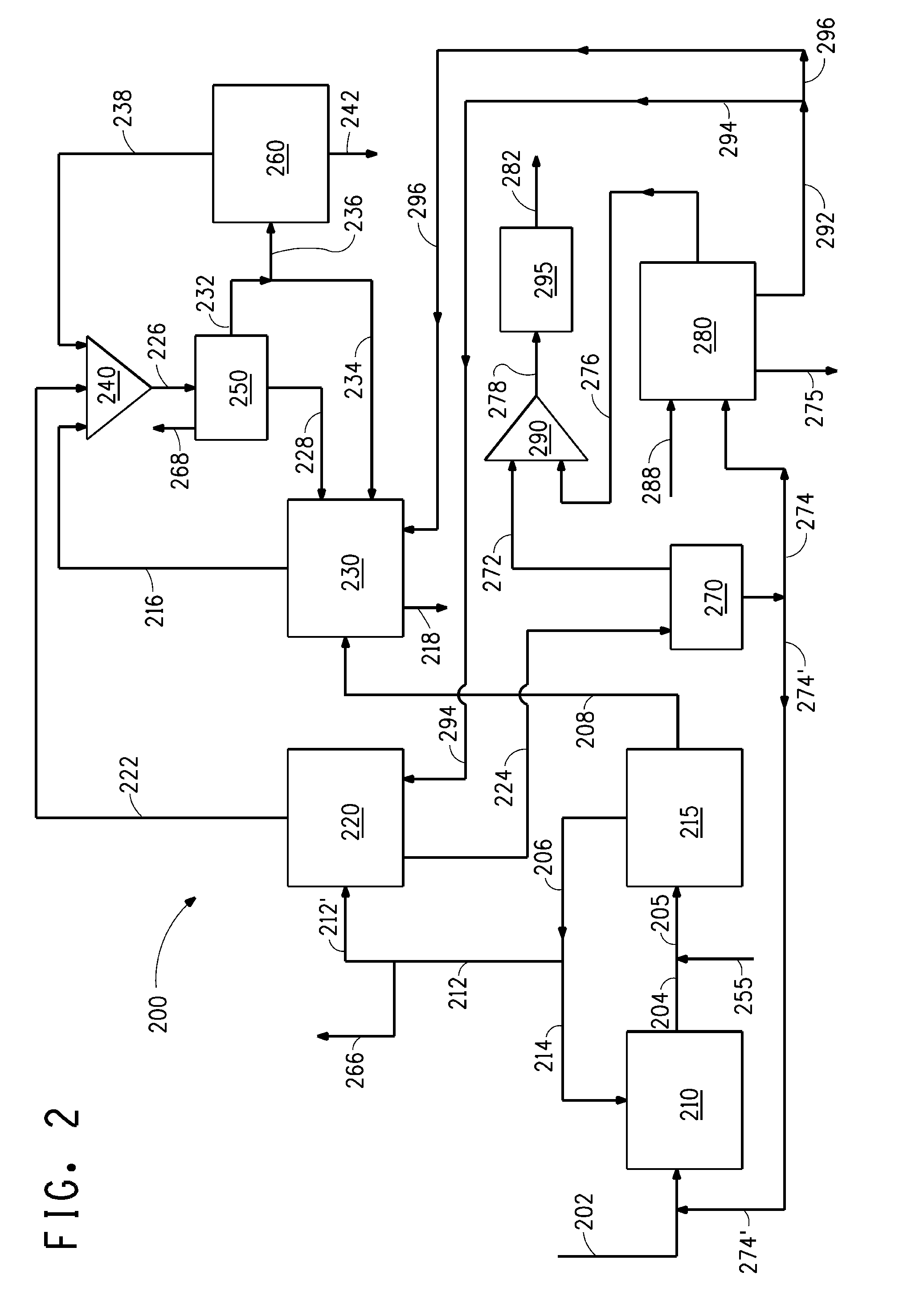

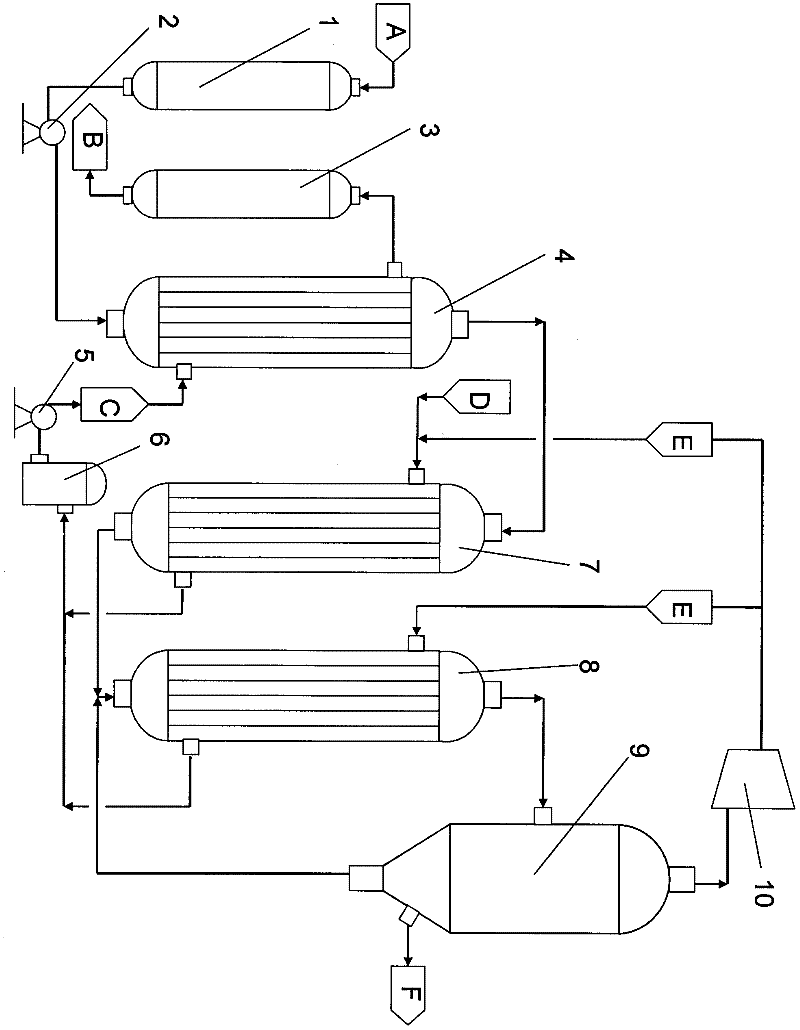

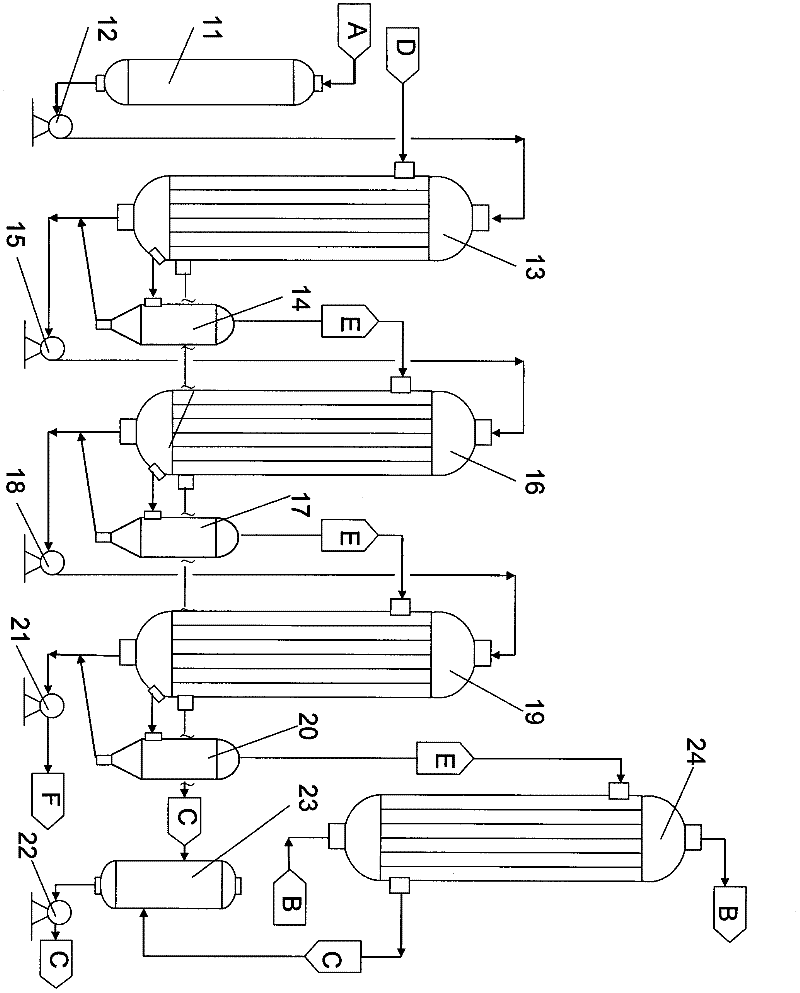

Vapor-compression evaporation system and method

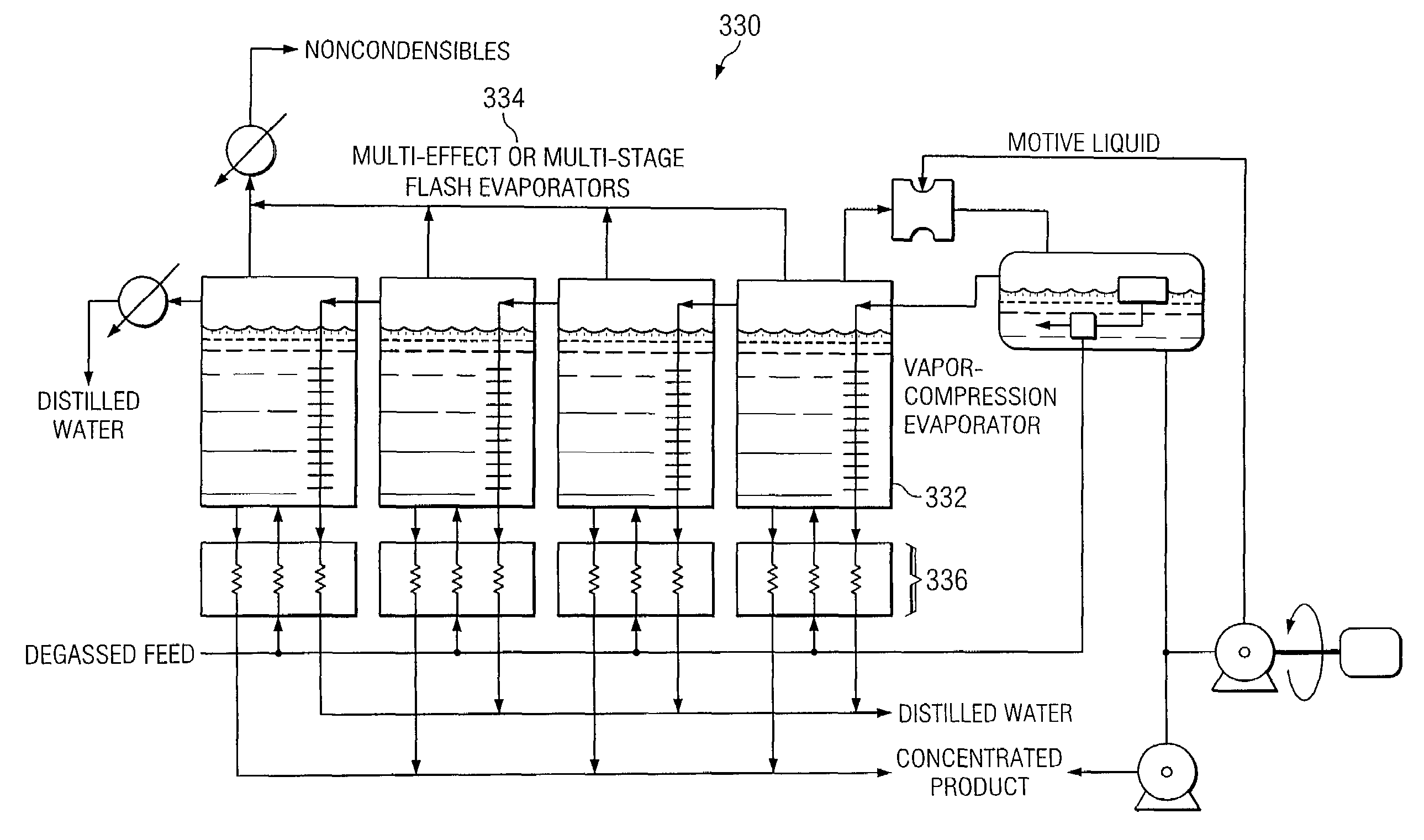

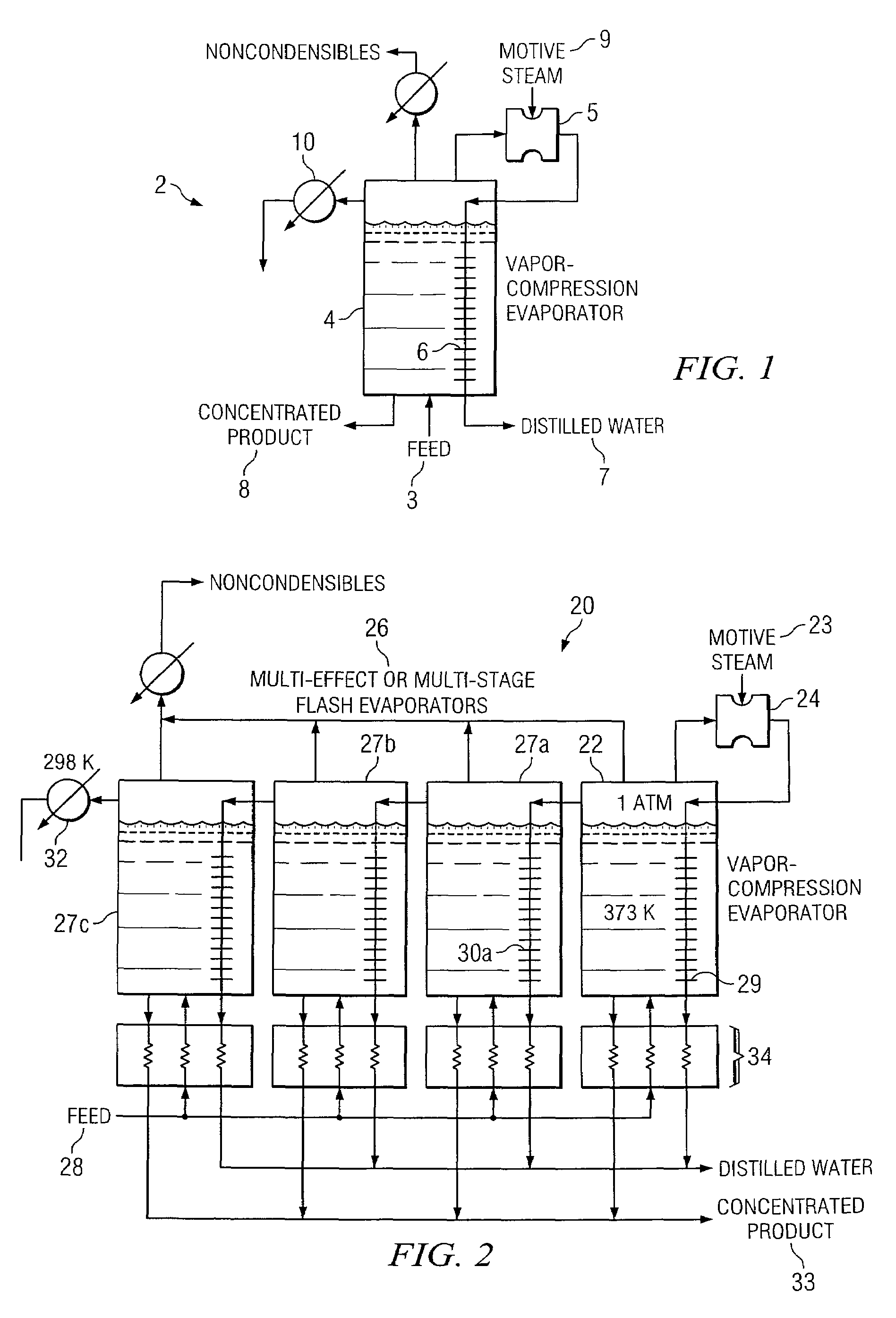

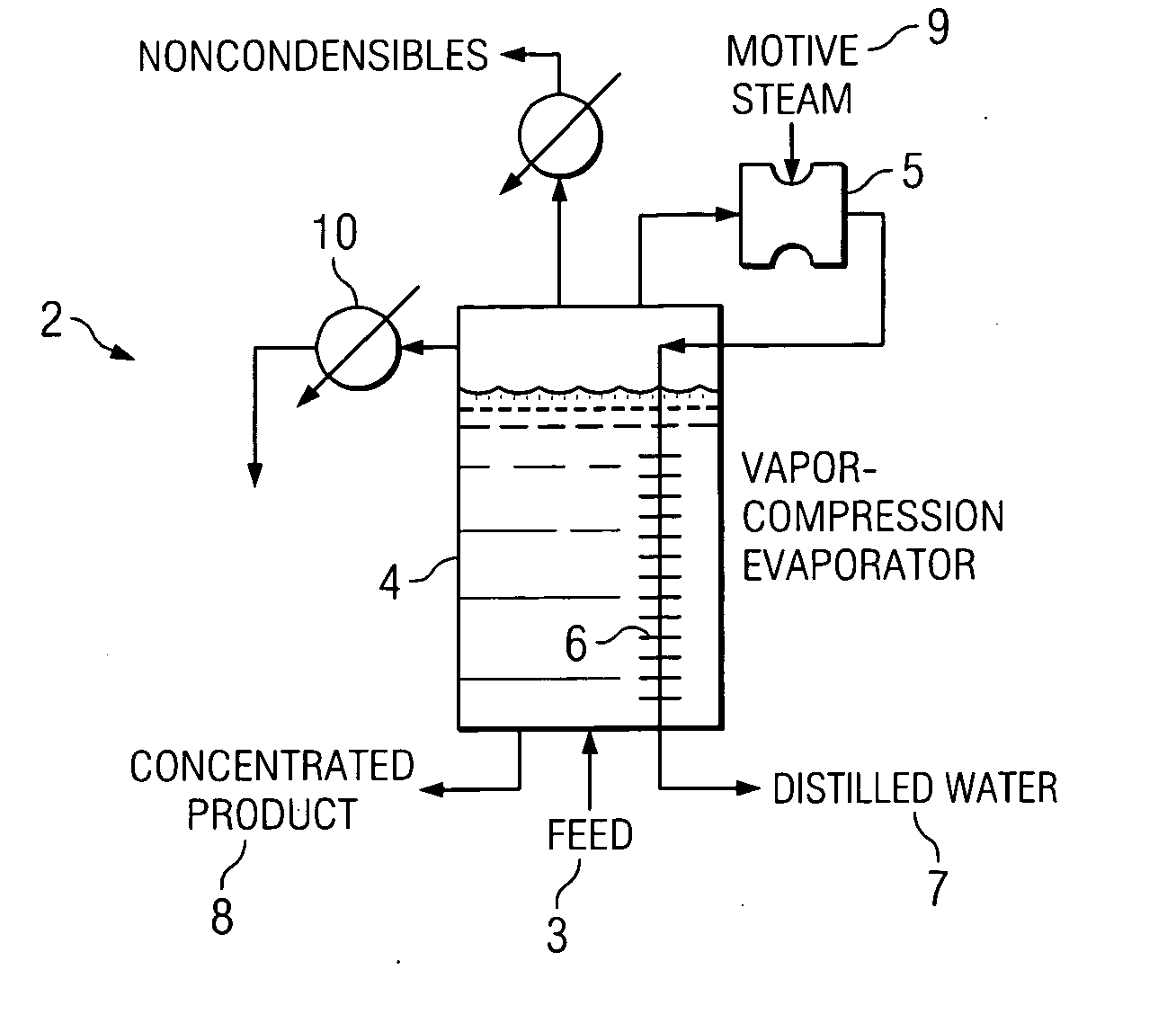

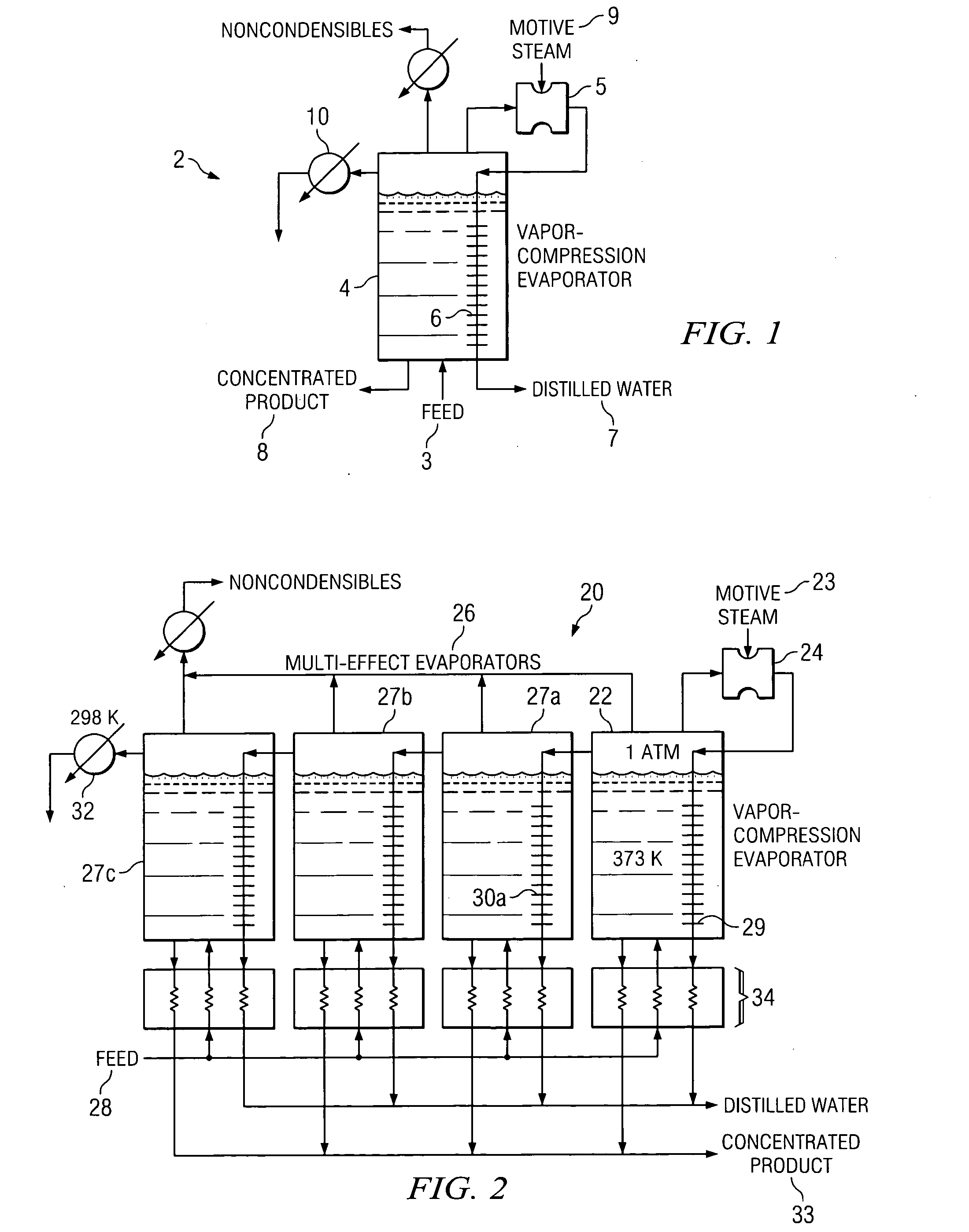

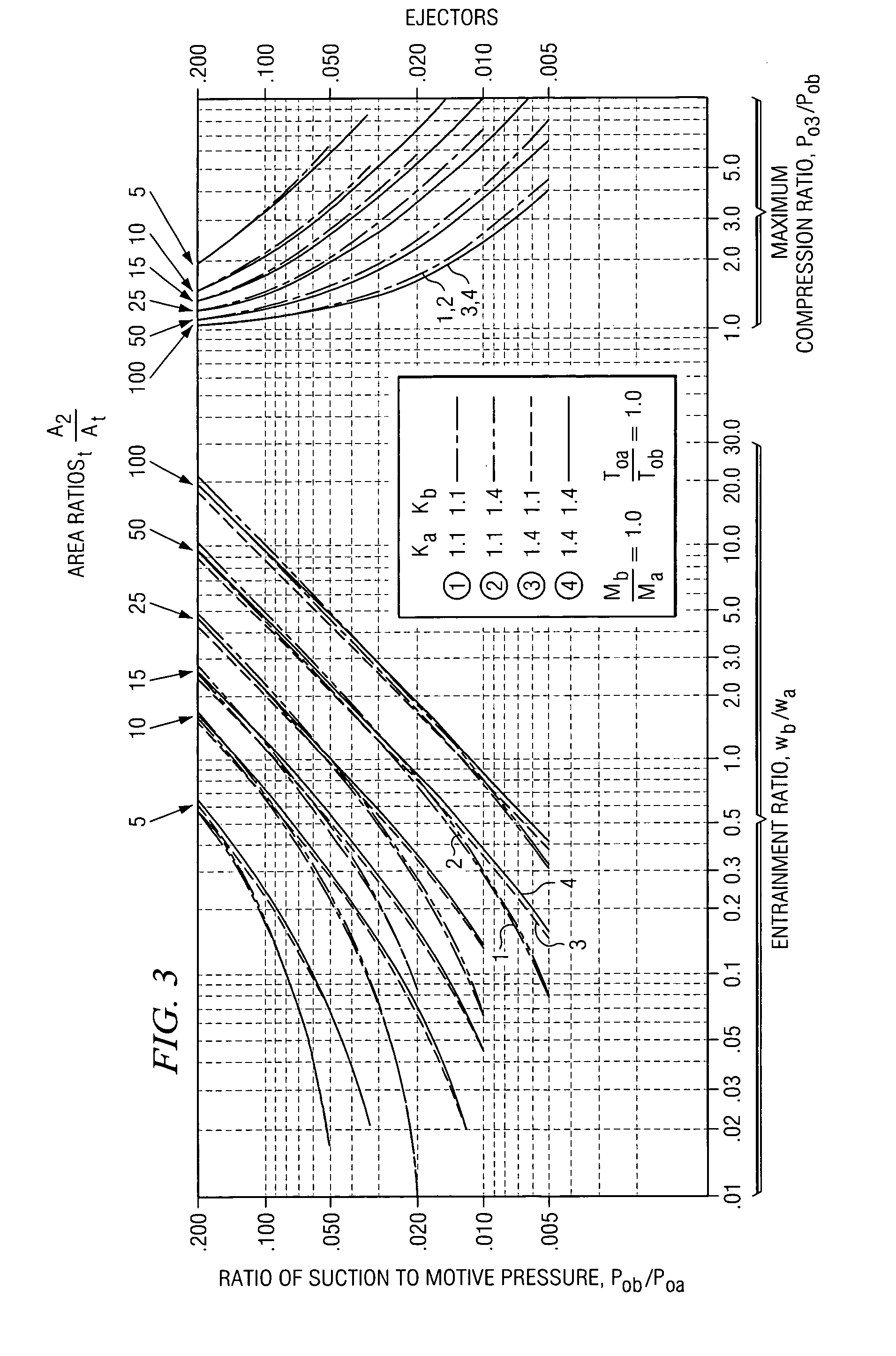

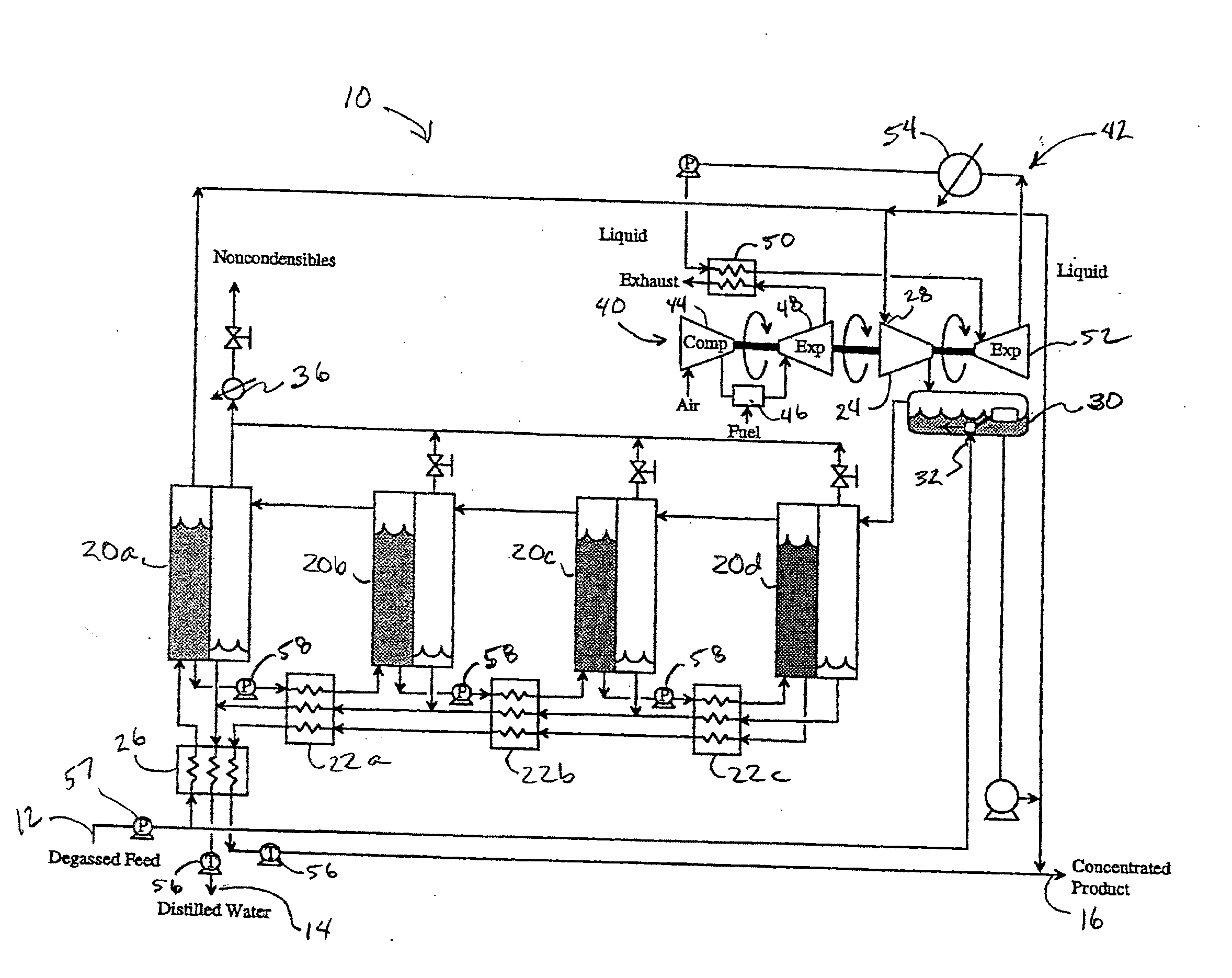

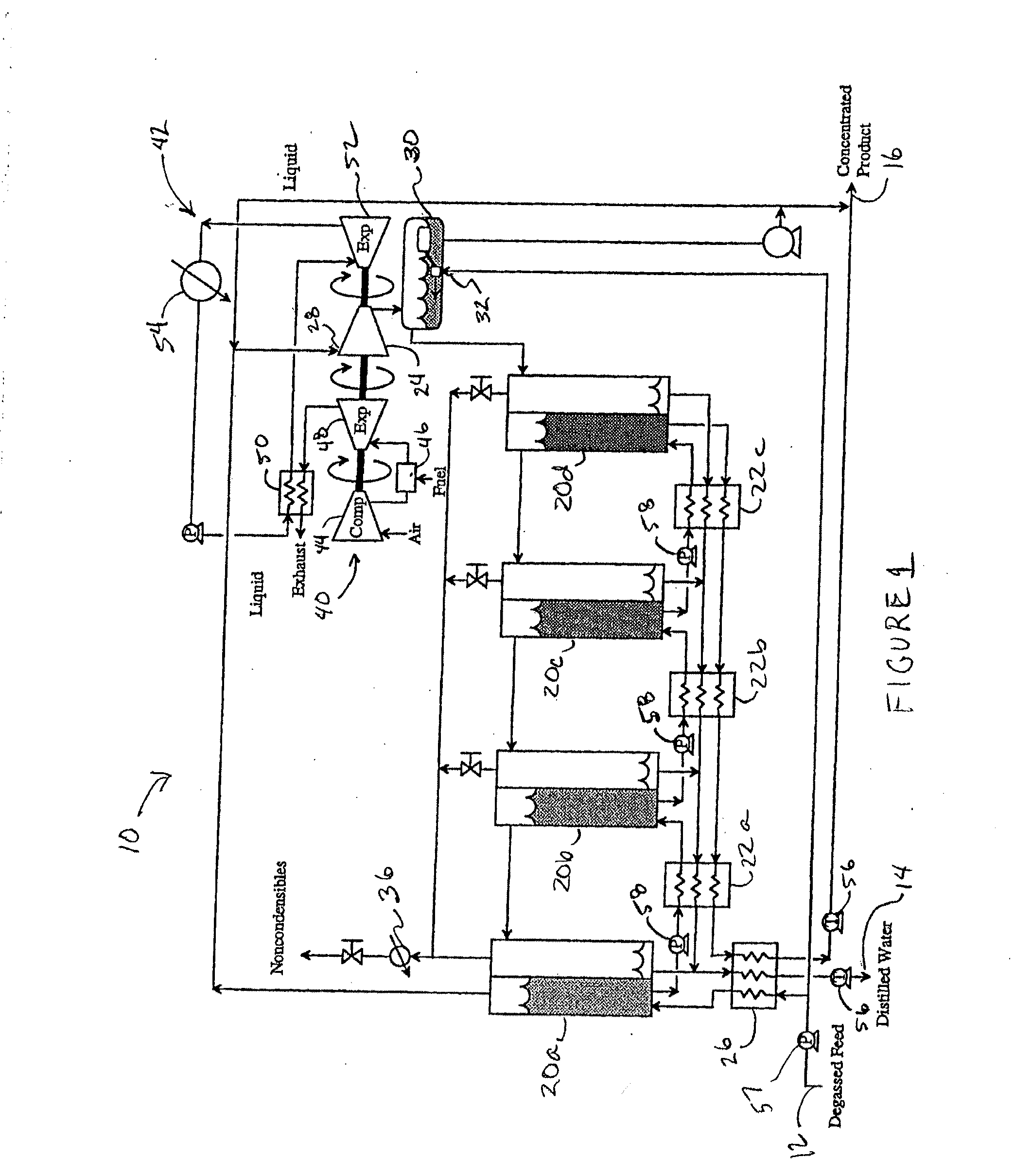

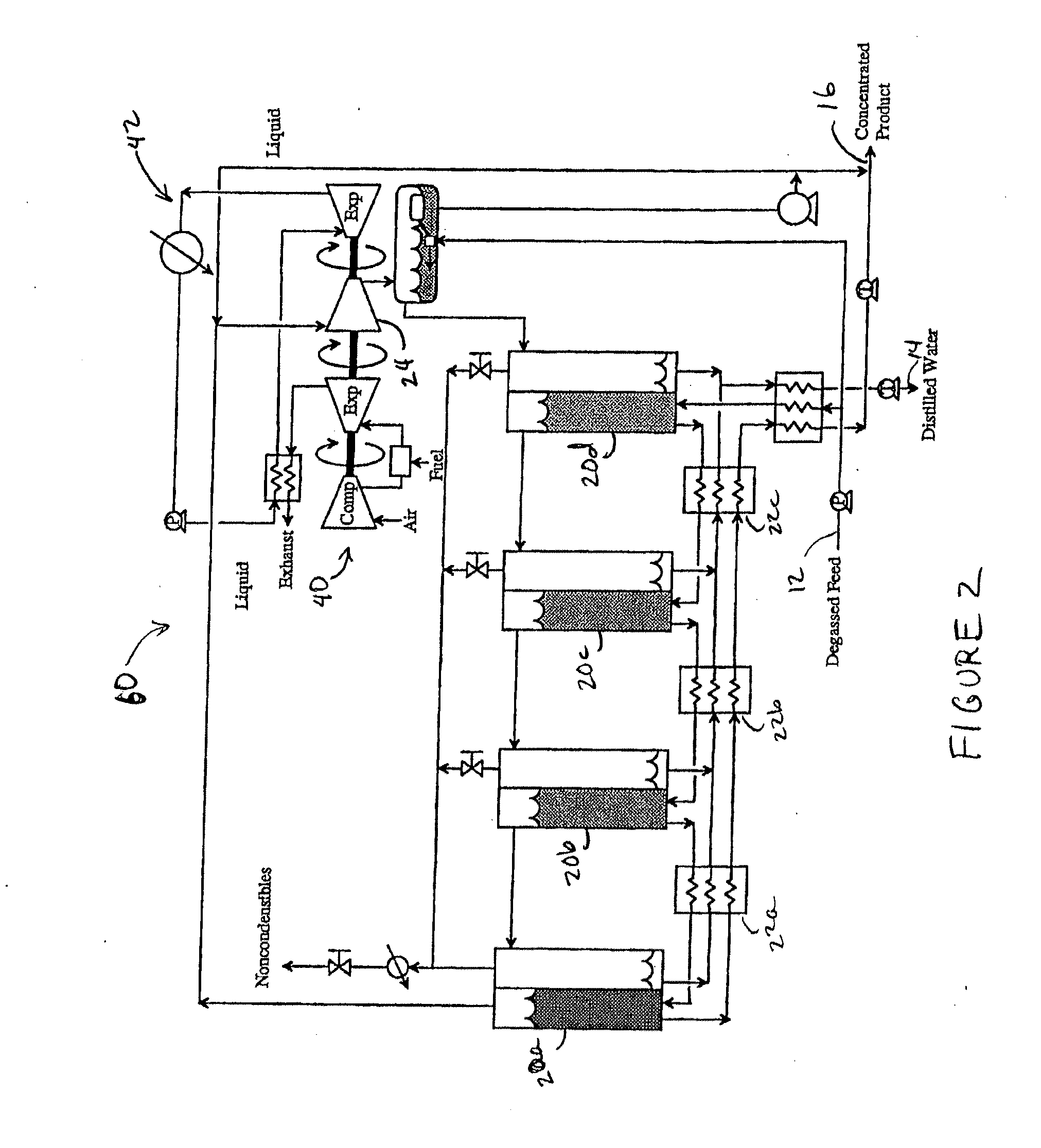

InactiveUS7708865B2Improve efficiencySimple designDrying using combination processesEvaporation with vapour compressionMarine engineeringVapor-compression evaporation

According to one embodiment of the invention, a vapor-compression evaporation system includes a plurality of vessels in series each containing a feed having a nonvolatile component, a mechanical compressor coupled to the last vessel in the series and operable to receive a vapor from the last vessel in the series, a pump operable to deliver a cooling liquid to the mechanical compressor, a tank coupled to the mechanical compressor and operable to separate liquid and vapor received from the mechanical compressor, a plurality of heat exchangers coupled inside respective ones of the vessels, the heat exchanger in the first vessel in the series operable to receive the vapor from the tank, at least some of the vapor condensing therein, whereby the heat of condensation provides the heat of evaporation to the first vessel in the series, and wherein at least some of the vapor inside the first vessel in the series is delivered to the heat exchanger in the next vessel in the series, whereby the condensing, evaporating, and delivering steps continue until the last vessel in the series is reached.

Owner:TEXAS A&M UNIVERSITY +1

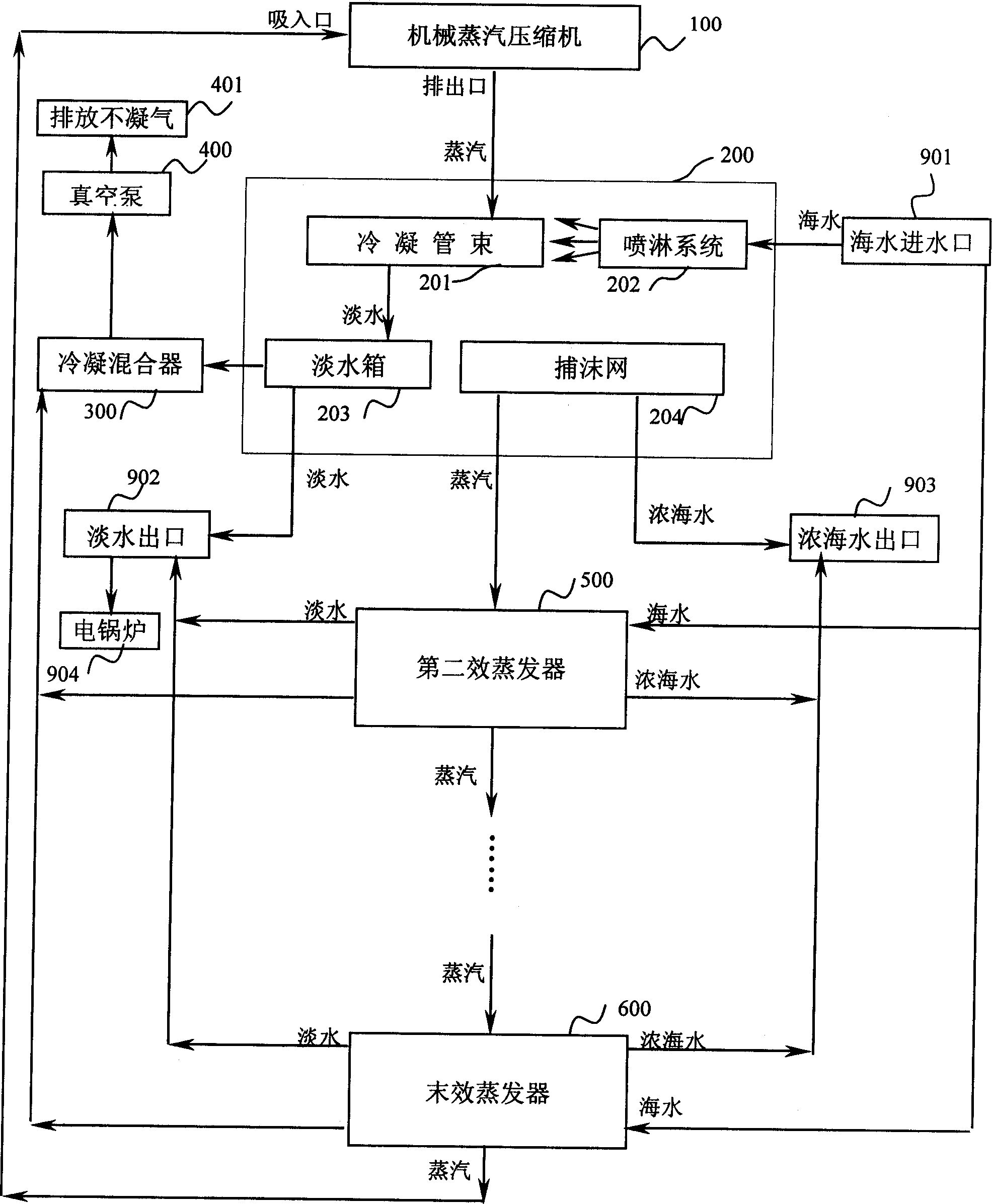

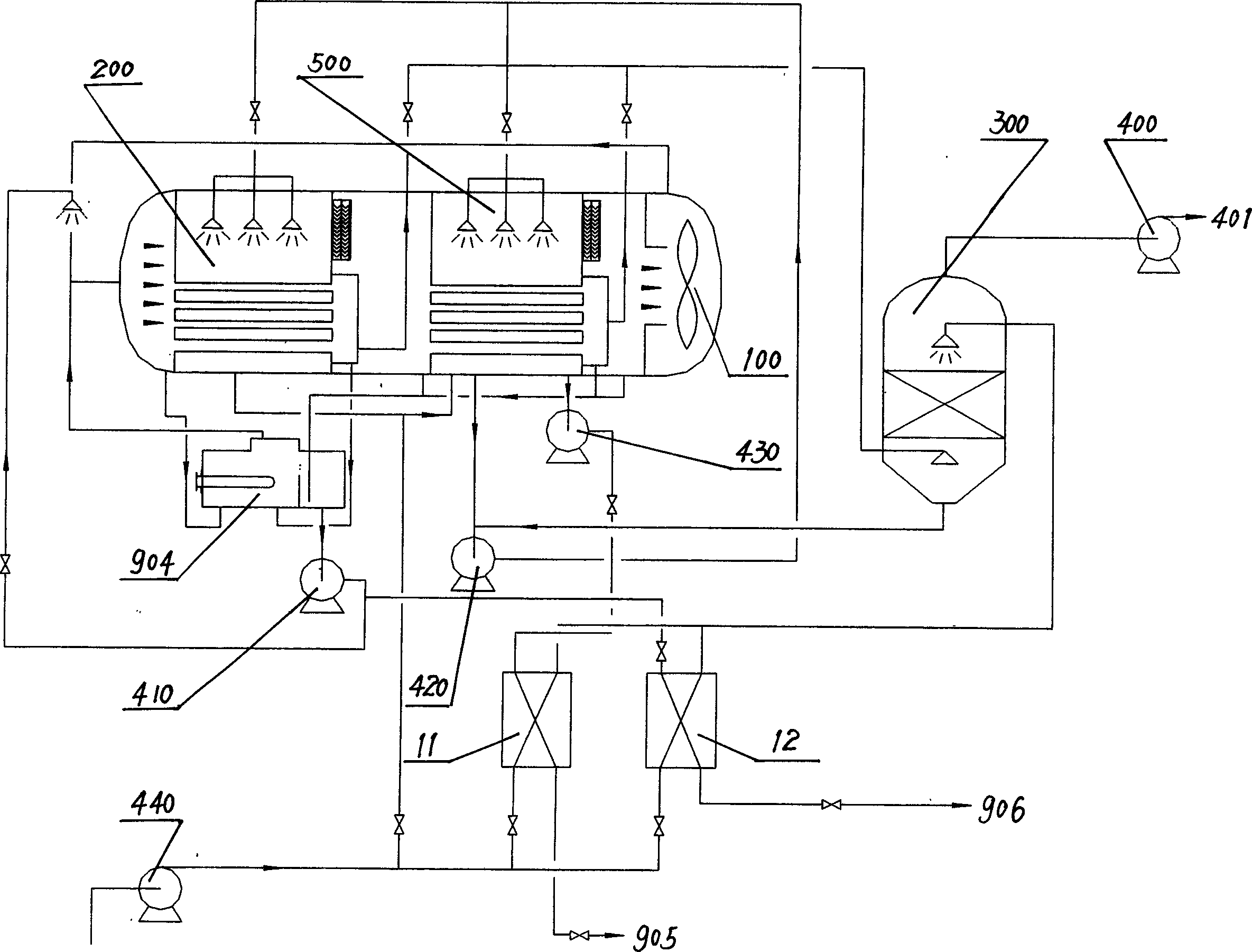

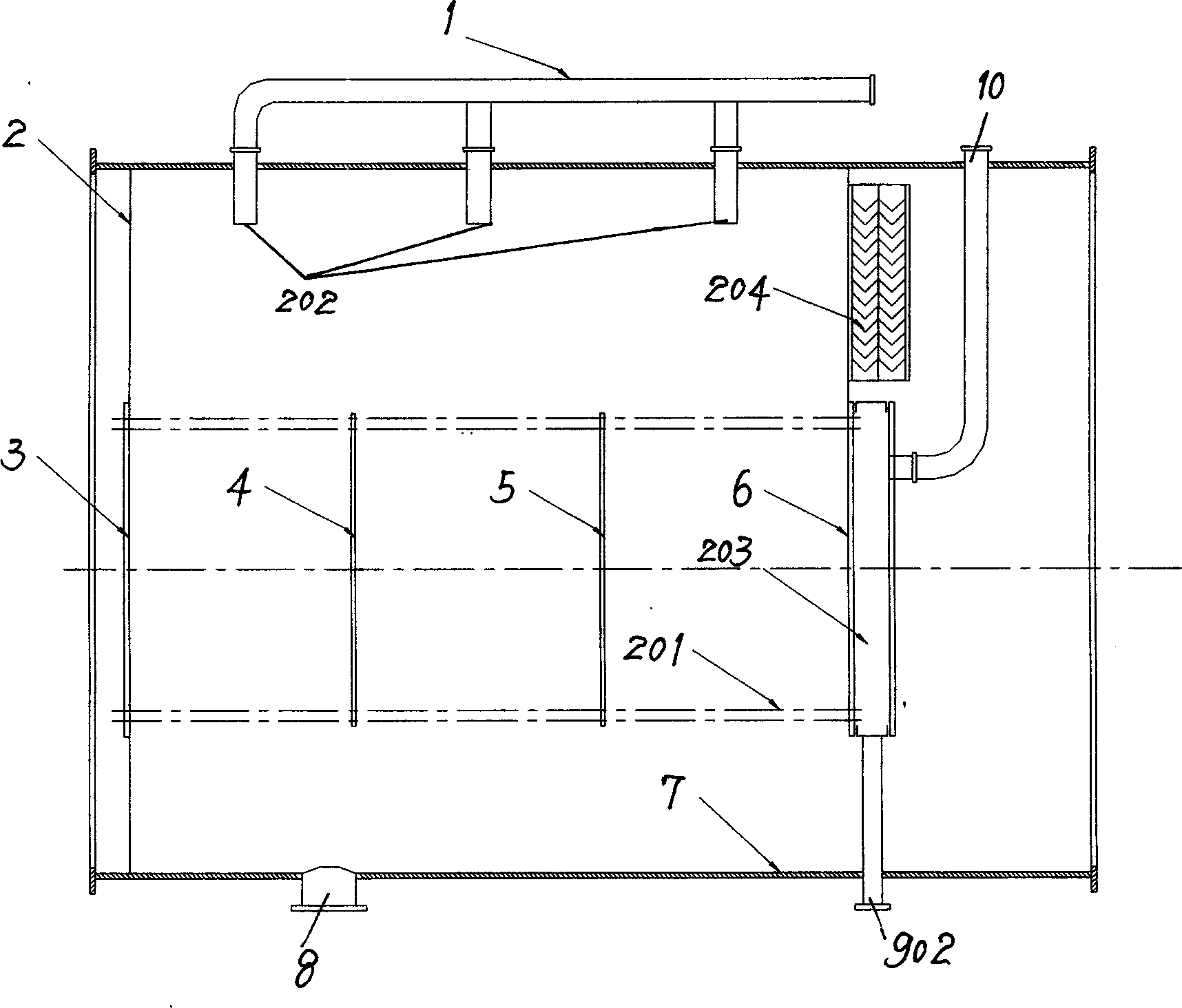

Method and device for desalting sea water using mechanical compression distillation method

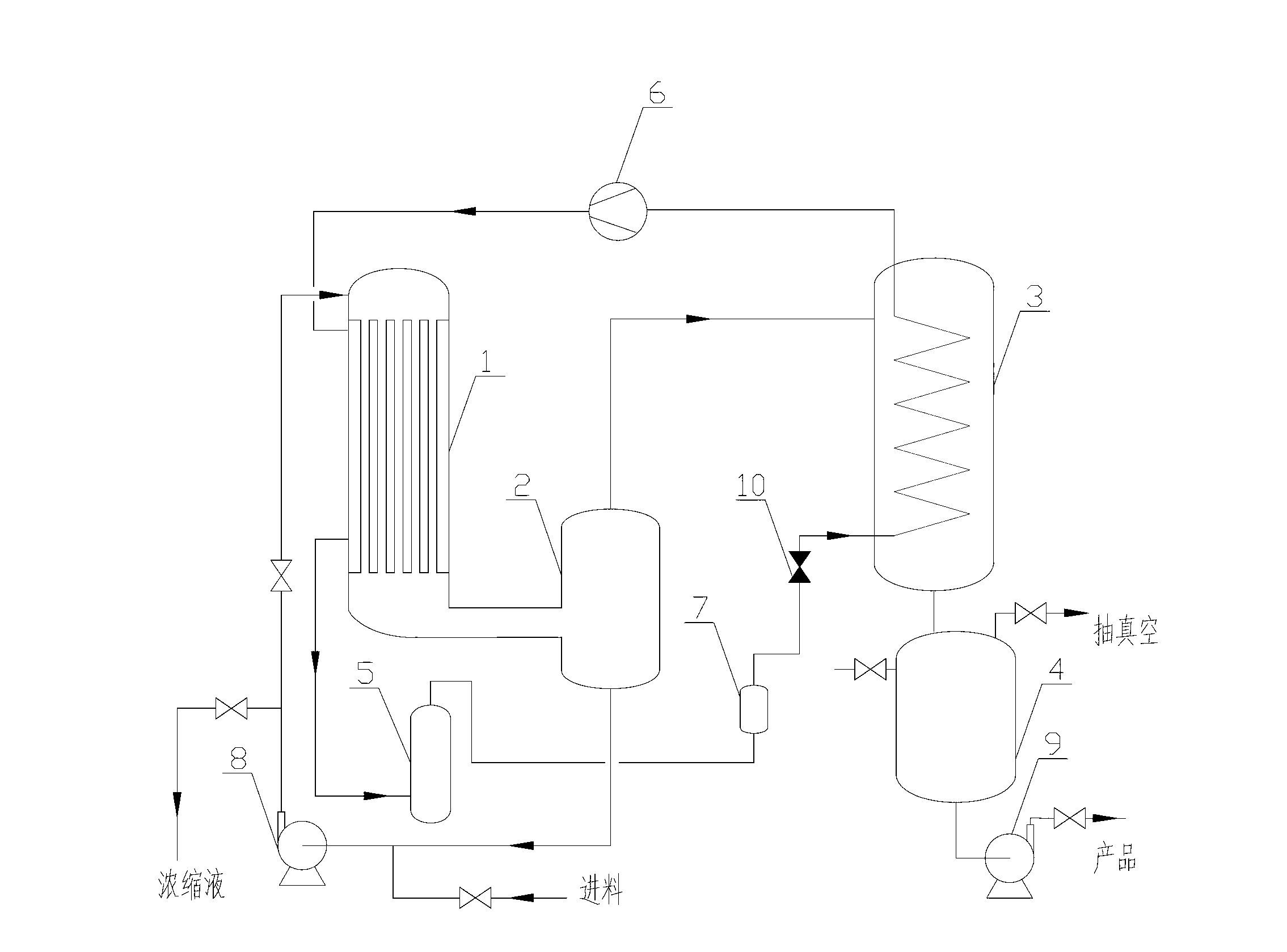

InactiveCN1546386AHigh thermal efficiencyLow costGeneral water supply conservationEvaporation with vapour compressionWater useWater desalination

The invention discloses a sea-water distillation apparatus by mechanical compression distillation method which comprises a steam mechanical compressor, a plurality of evaporators and condensation tubes, spraying systems, fresh water tanks and foam trapping nets arranged in the evaporator, wherein the exit of the steam mechanical compressor is connected with the condensation tube in the first evaporator in the multiple evaporators, the condensation tube in the first evaporator is connected with the fresh water tank, the vapor exit of the first evaporator is connected with the condensation tube in the next evaporator, and so on, until the last evaporator, thus multiple effect step by step evaporation is realized by the various evaporators. The invention also discloses a process for sea water desalination by using the sea-water distillator.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Vapor-compression evaporation system and method

InactiveUS20050072662A1Cost-effectiveLower overall pressure dropDrying using combination processesEvaporation with vapour compressionMarine engineeringVapor-compression evaporation

According to one embodiment of the invention, a vapor-compression evaporation system includes a plurality of vessels in series each containing a feed having a nonvolatile component, a mechanical compressor coupled to the last vessel in the series and operable to receive a vapor from the last vessel in the series, a pump operable to deliver a cooling liquid to the mechanical compressor, a tank coupled to the mechanical compressor and operable to separate liquid and vapor received from the mechanical compressor, a plurality of heat exchangers coupled inside respective ones of the vessels, the heat exchanger in the first vessel in the series operable to receive the vapor from the tank, at least some of the vapor condensing therein, whereby the heat of condensation provides the heat of evaporation to the first vessel in the series, and wherein at least some of the vapor inside the first vessel in the series is delivered to the heat exchanger in the next vessel in the series, whereby the condensing, evaporating, and delivering steps continue until the last vessel in the series is reached.

Owner:TEXAS A&M UNIVERSITY +1

Water desalination process using ion selective membranes

InactiveUS6998053B2OperationReduce energy consumptionMembranesGeneral water supply conservationSaline waterWater desalination

The invention is directed to an improved desalination process to produce potable water. The process represents an improvement of hybrid of membrane and desalination technologies. The improvement of the invention comprises the operation of an ion selective membrane at a variable pressure as a function of the cost of electricity to form a softened salt water that is blended in variable proportions, to increase the top operating temperature of the desalination system and increase recovery of potable water, with untreated salt water.

Owner:L E T LEADING EDGE TECH LTD

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

MVR continuous evaporation system

InactiveCN104667550AStable feed flowThere will be no cut-off stateEvaporator accessoriesMultiple-effect evaporationVapor–liquid separatorSteam condensation

The invention discloses an MVR continuous evaporation system. The system can be applied to the requirements on different evaporation pressures, and automatic control of continuous and stable feeding and continuous discharging can be realized. The system disclosed by the invention comprises a raw material balance tank, a main body evaporator, a gas-liquid separator, a condensate storage tank, a steam compressor, a vacuum system and at least three heat exchange devices which are connected by virtue of pipelines, control valves and related pumps, wherein the bottom of the raw material balance tank is connected with the inlet of a feeding pump and is connected with an interval inlet of the top end of the main body evaporator by virtue of a heat exchange device; multiple evaporation intervals are contained in the main body evaporator; a gas-liquid collection cavity is formed in the bottom end of the main body evaporator and is connected with the next evaporation interval by virtue of a booster pump; the concentrated solution in the final evaporation interval is used for preheating the raw materials by virtue of the heat exchange devices; the shell pass of the main body evaporator is connected with the condensate storage tank; and steam condensate is connected with the heat exchange devices by virtue of the condensate storage tank, and the raw materials can be preheated.

Owner:NANJING UNIV OF TECH

Methods for alcohol recovery and concentration of stillage by-products

ActiveUS8906204B2Efficient use ofHydrocarbon purification/separationAlcoholic beverage preparationAqueous alcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

Desalination methods

InactiveUS20120199534A1EfficientlyReduce workloadGeneral water supply conservationAuxillariesDesalinationEngineering

In accordance with particular embodiments, a desalination system includes a plurality of evaporators. The plurality of evaporators includes at least a first evaporator and a last evaporator. The plurality of evaporators are arranged in cascading fashion such that a concentration of salt in a brine solution increases as the brine solution passes through the plurality of evaporators from the first evaporator towards the last evaporator. The desalination system also includes a plurality of heat exchangers. An input of each evaporator is coupled to at least one of the plurality of heat exchangers. The system also includes a vapor source coupled to at least one of the plurality of evaporators.

Owner:TEXAS A&M UNIVERSITY +1

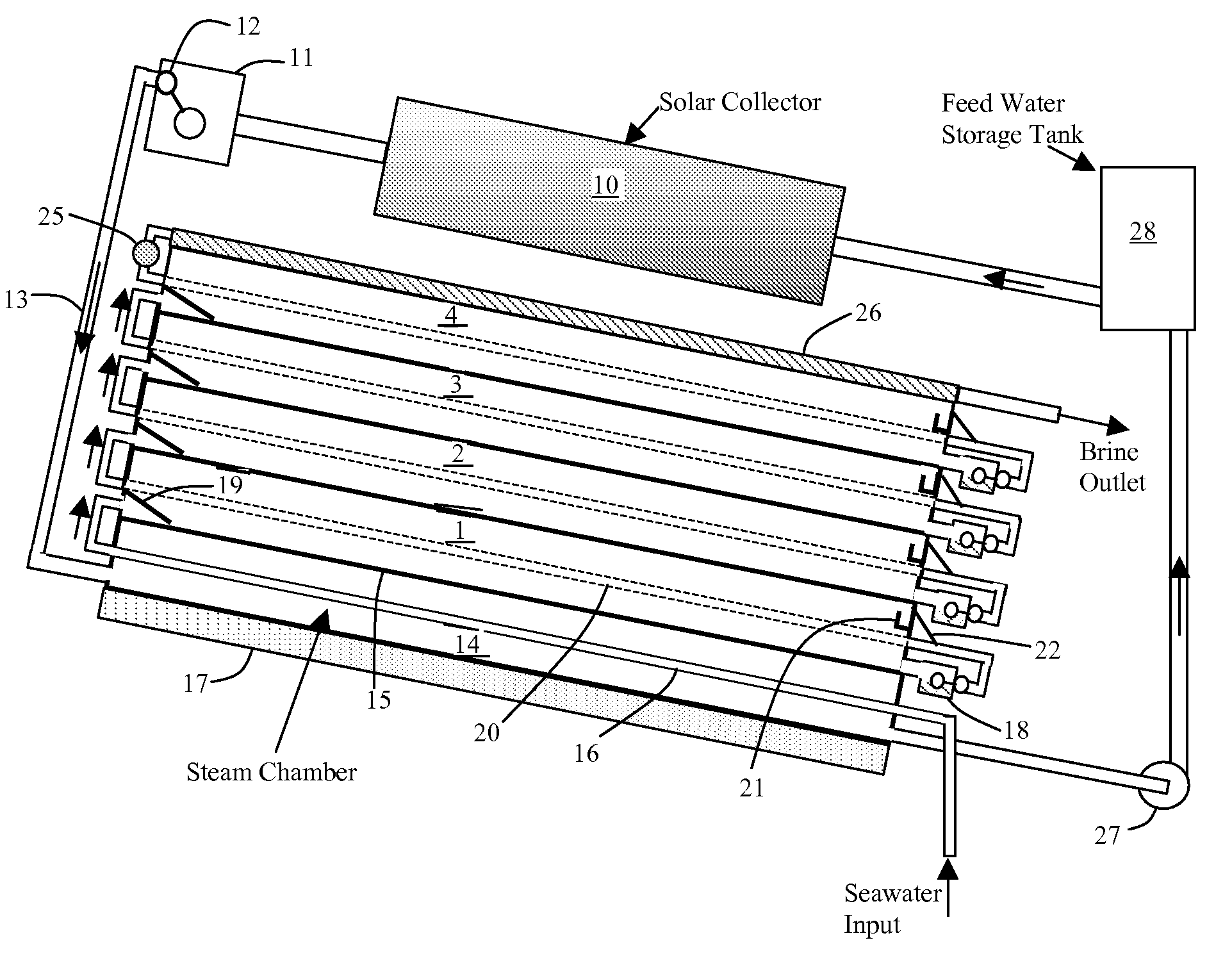

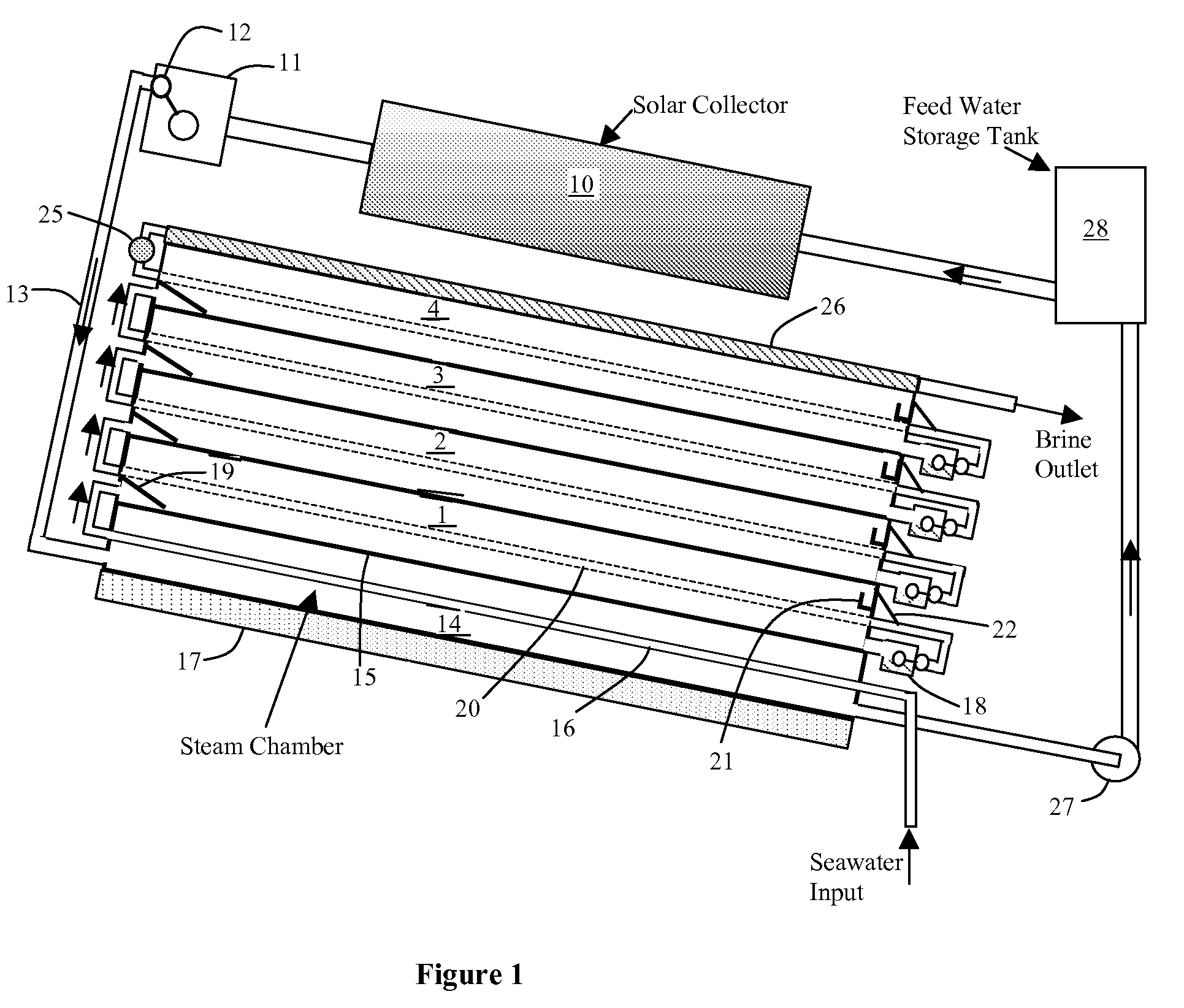

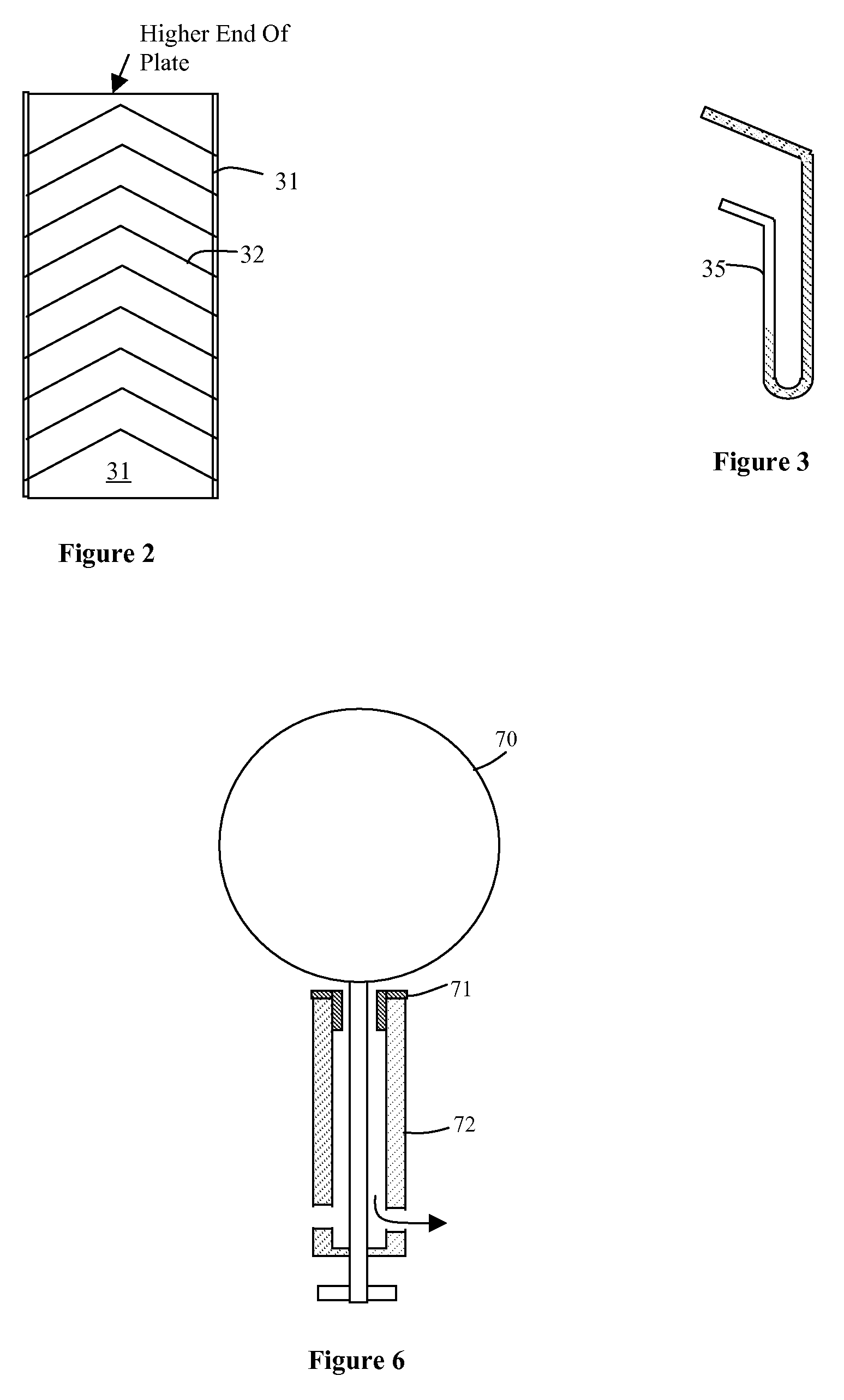

Solar-powered desalination system

InactiveUS20070193870A1Easy to useExcessive numberGeneral water supply conservationMultiple-effect/fractional condensationSaline waterParallel plate

Owner:PRUEITT MELVIN L

Full-automatic descaling multi-effect evaporator

ActiveCN102921179AFast flowAvoid formingEvaporator accessoriesMultiple-effect evaporationMultiple-effect evaporatorEngineering

The invention discloses a full-automatic descaling multi-effect evaporator, which comprises a heater and an evaporation chamber, wherein a granule distributor which can make fluid be distributed to tube nests of the heater uniformly is arranged at the bottom of the heater; and a granule separator is also arranged between the heater and the evaporation chamber. Due to the adoption of the technical scheme, the full-automatic descaling multi-effect evaporator has the advantages that a descaling process can be simplified, heat transfer is enhanced, and a heat transfer coefficient is increased, so that the evaporator can clean and remove scales online to realize continuous production. According to the optimized technical scheme, an intensifier ring is arranged in the granule separator, and a granule separation chamber and a granule storage chamber are also formed in the granule separator, so that liquid forms a vortex which rotates at high speed when passing through the cylindrical granule separation chamber under the action of centrifugal force formed by the intensifier ring to do circular rotary motion, so that granular solids are separated from the liquid quickly.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

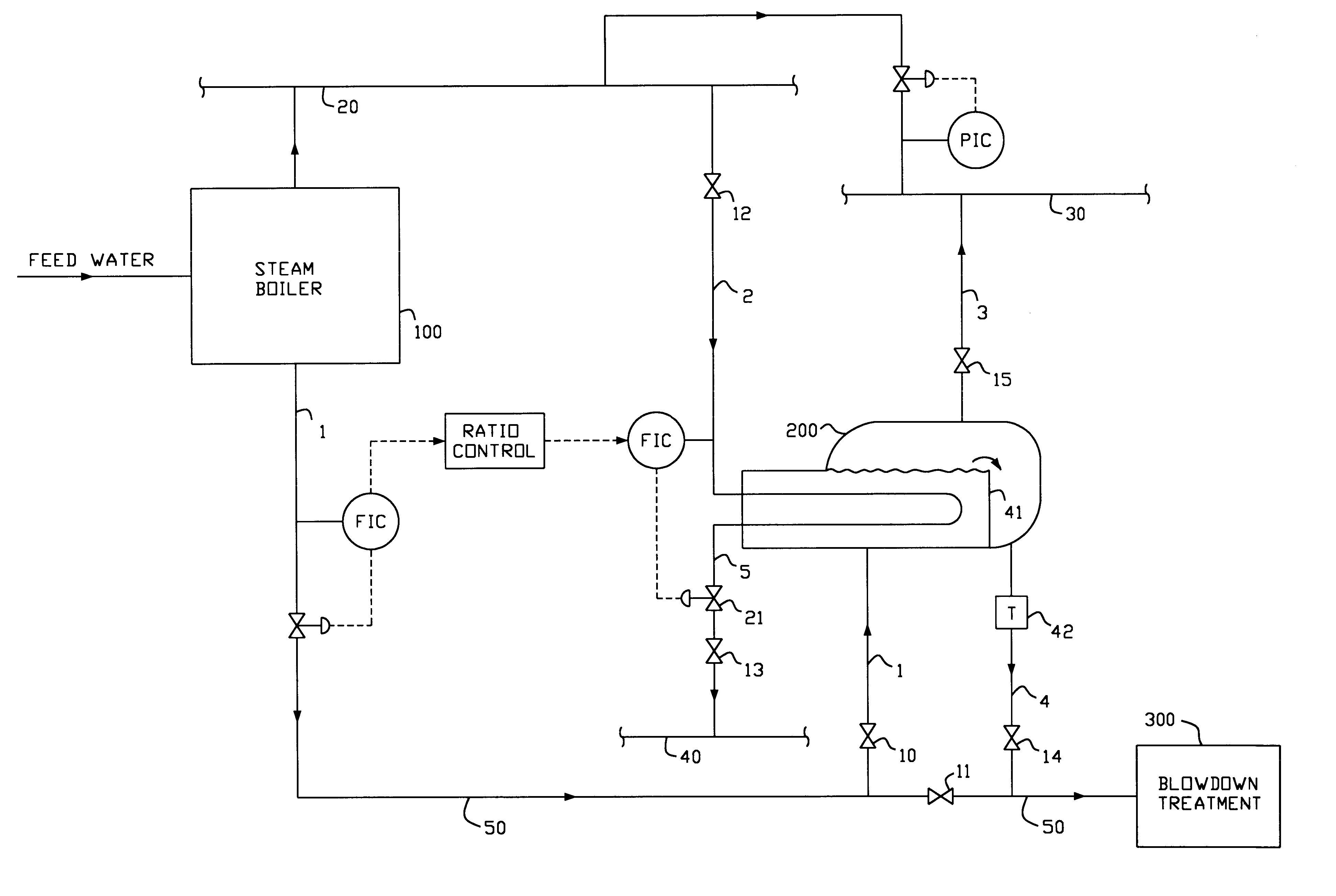

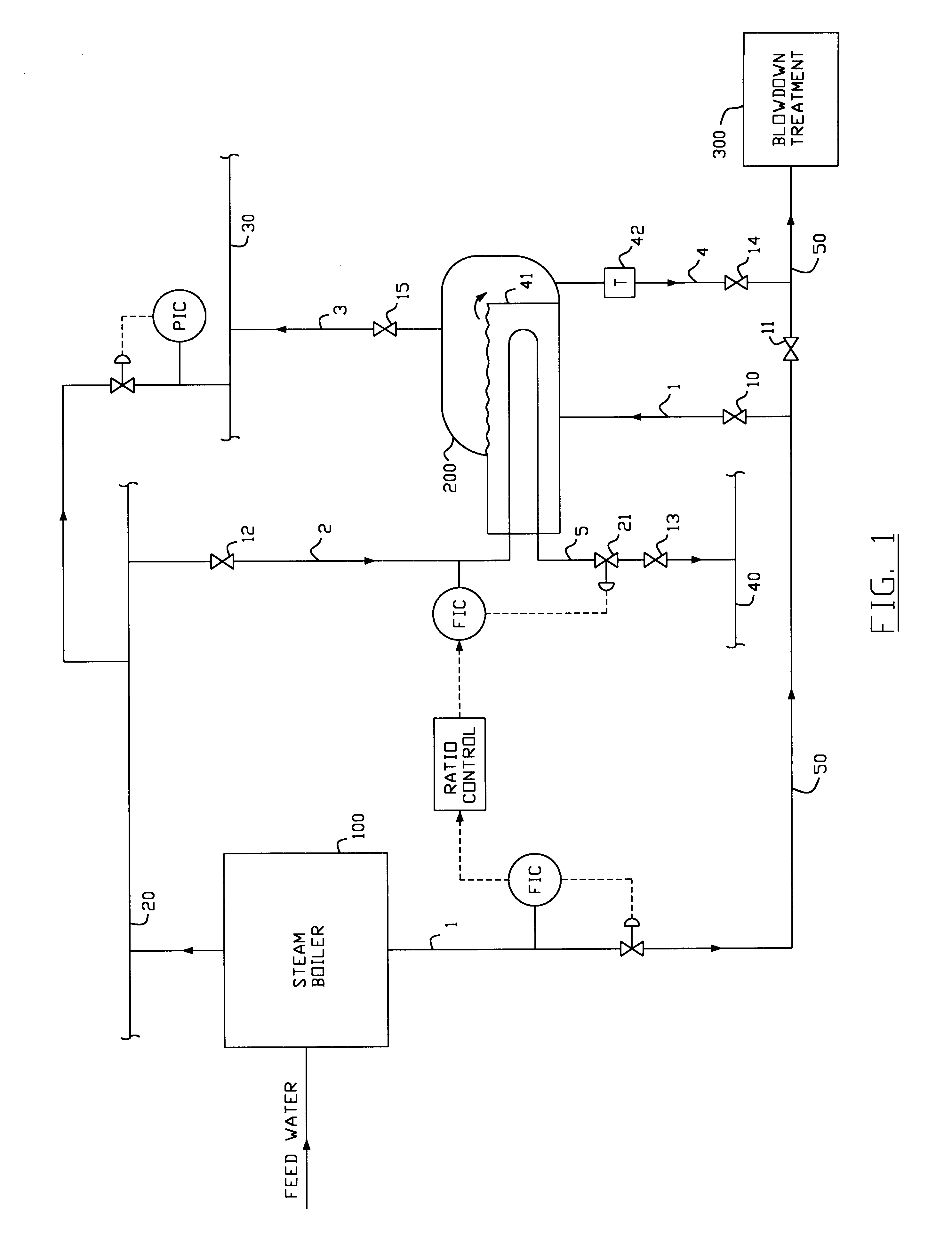

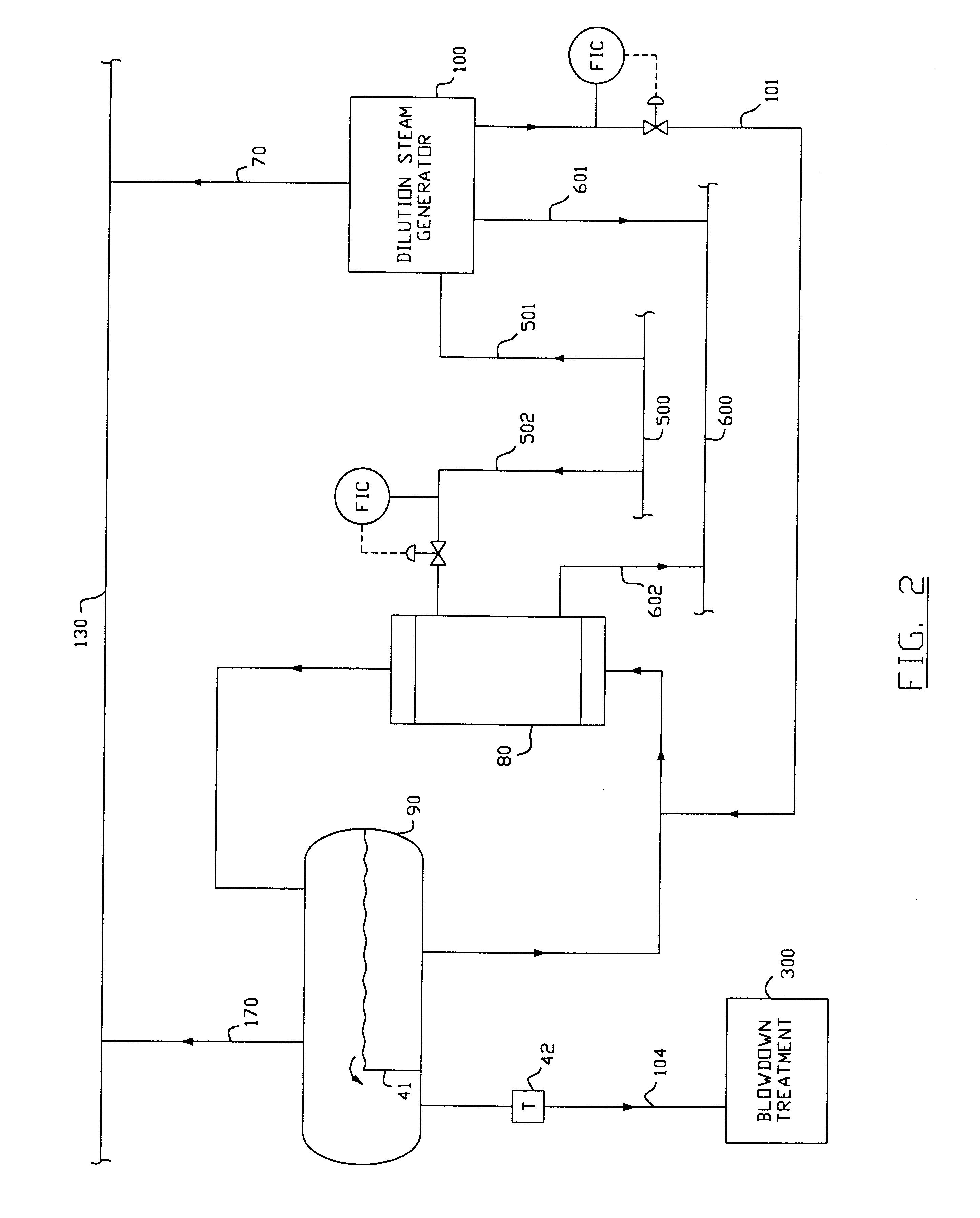

Methods for recycling process wastewater streams

InactiveUS6371058B1High mean blowdown rateChemical treatment costDrying using combination processesSteam separation arrangementsShell and tube heat exchangerWastewater

This invention provides cost-effective alternatives to reduce the cost associated with customary blowdown from steam generating equipment. By selectively recycling process blowdown streams using secondary vaporizers, the net result is a partial replacement of wastewater stream with almost an equivalent quantity of clean steam condensate. The heat transfer is carried out by indirect contact devices, such as shell and tube heat exchanger and the like, without mixing of the two process streams to allow condensate recovery while avoiding cross contamination. This invention carries economic as well as environmental credits. A condensate recovery apparatus can be designed to enable easy connection to existing equipment already in service, as well as easy removal, without causing process disruption.

Owner:TUNG PETER

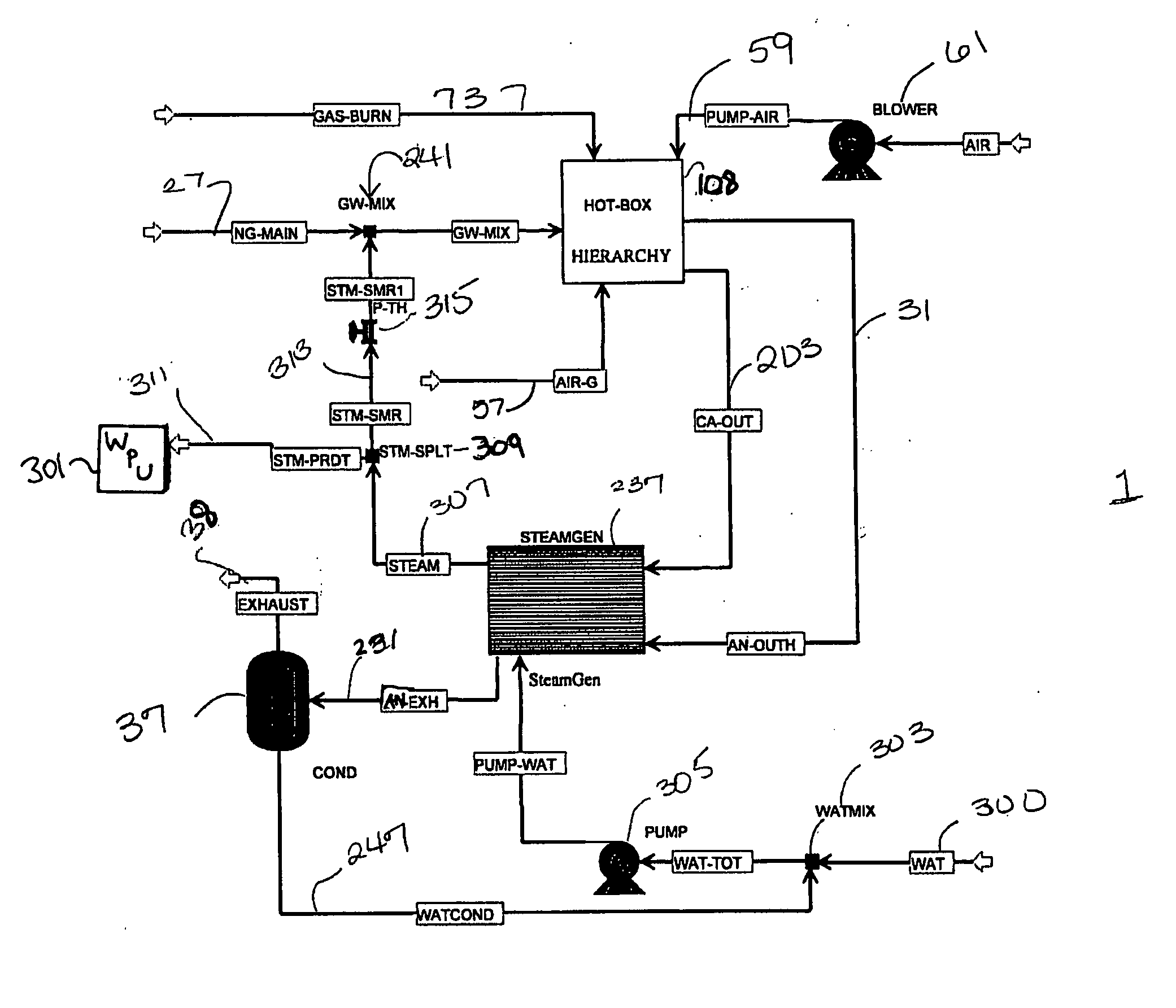

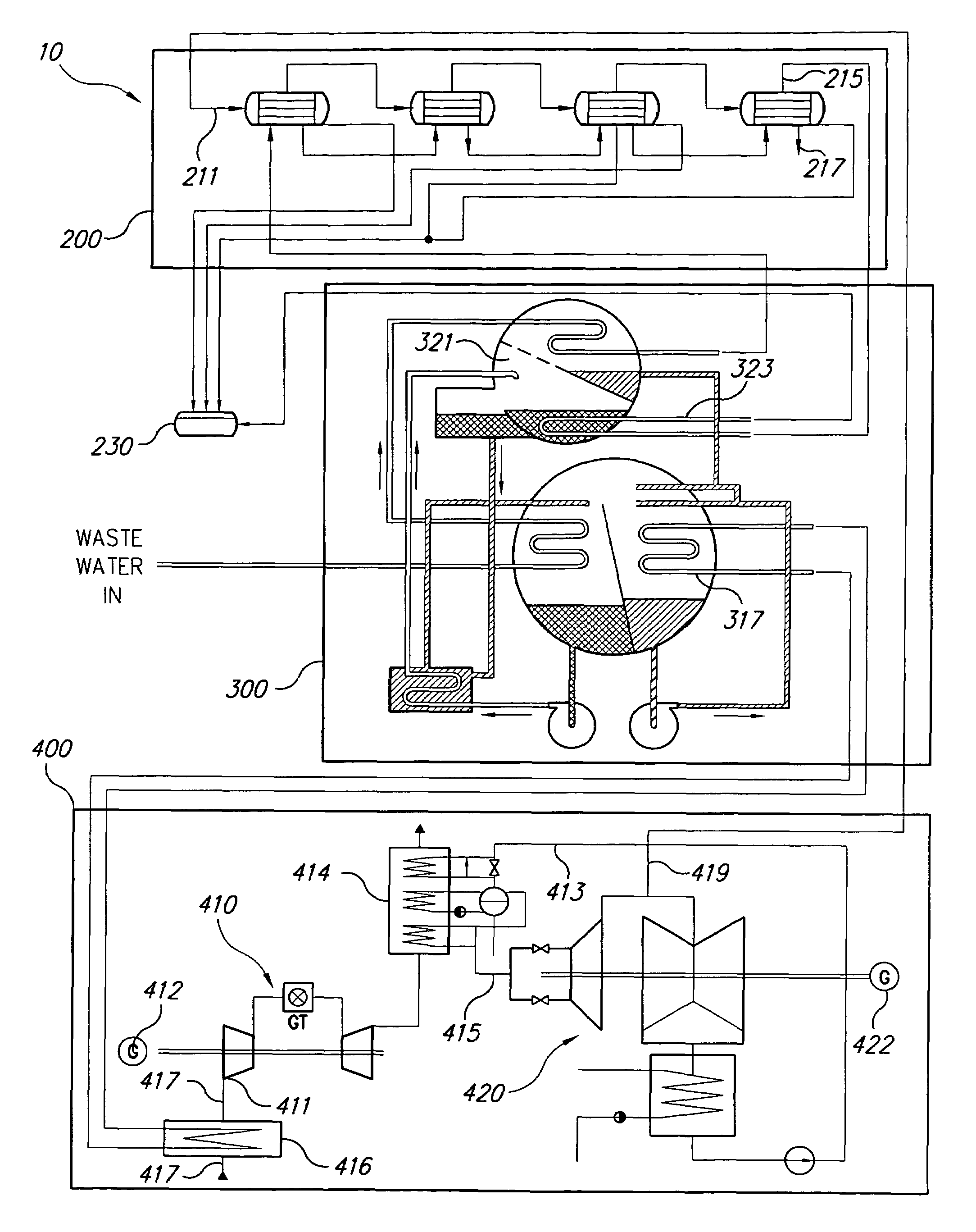

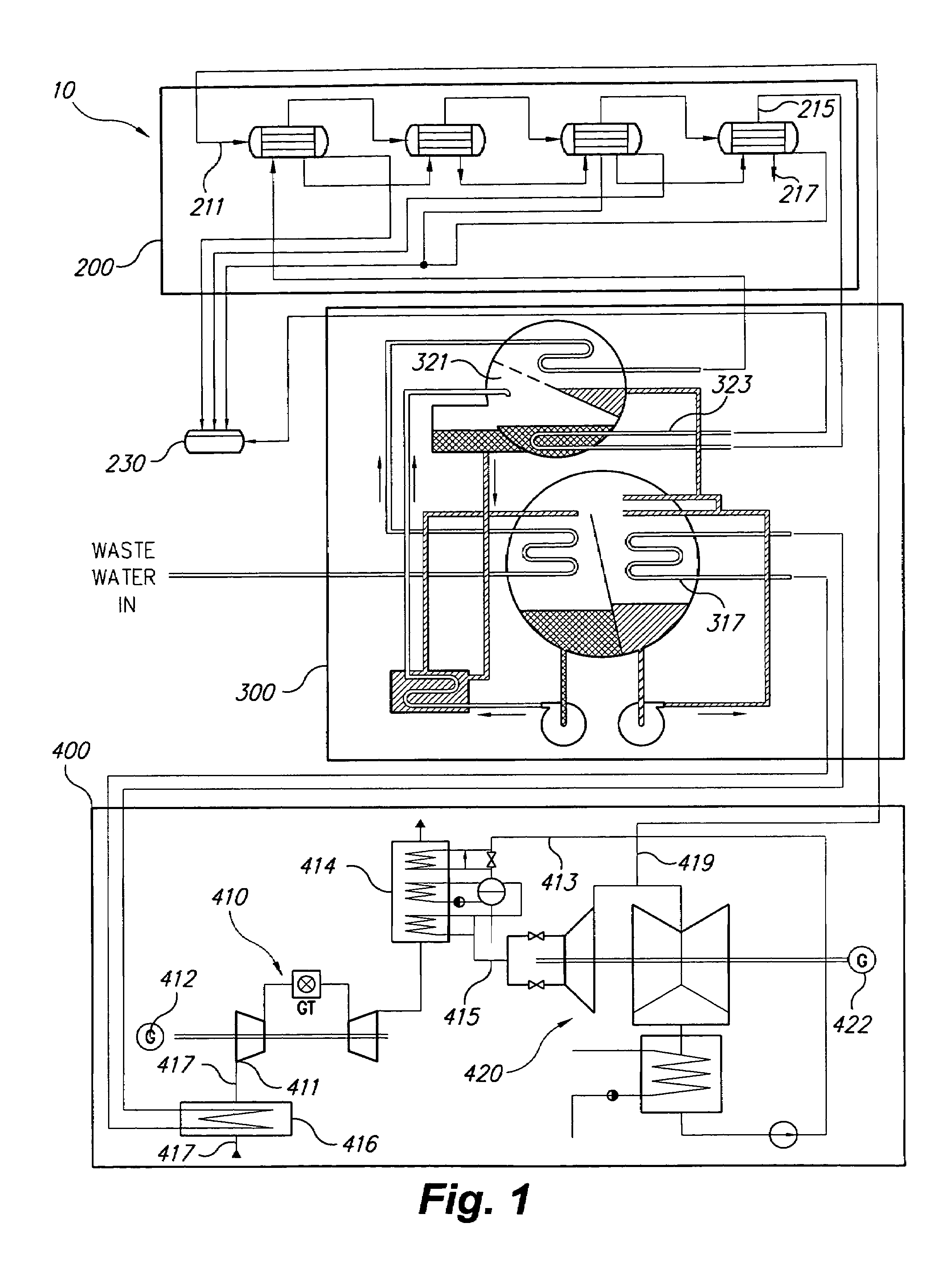

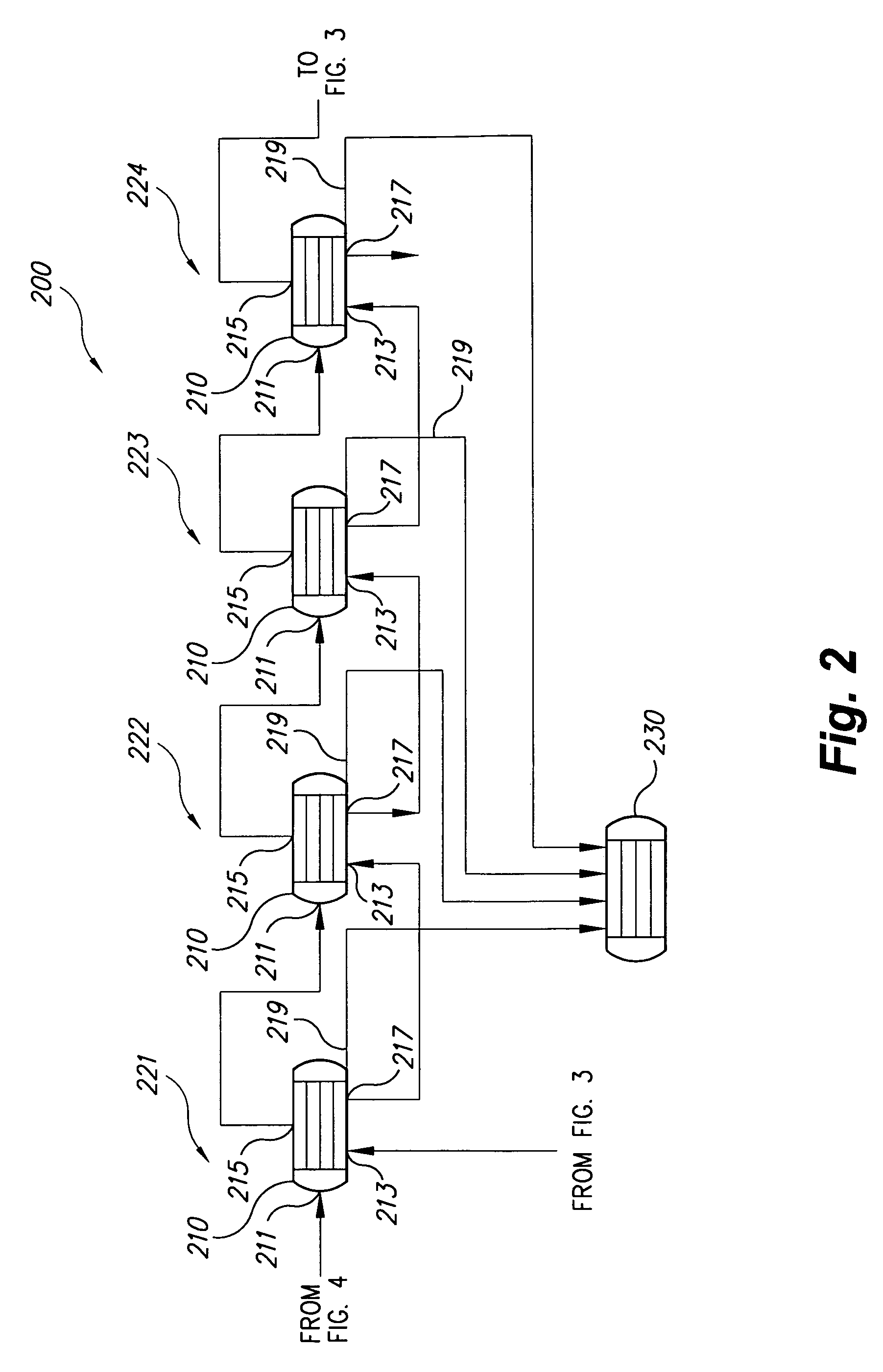

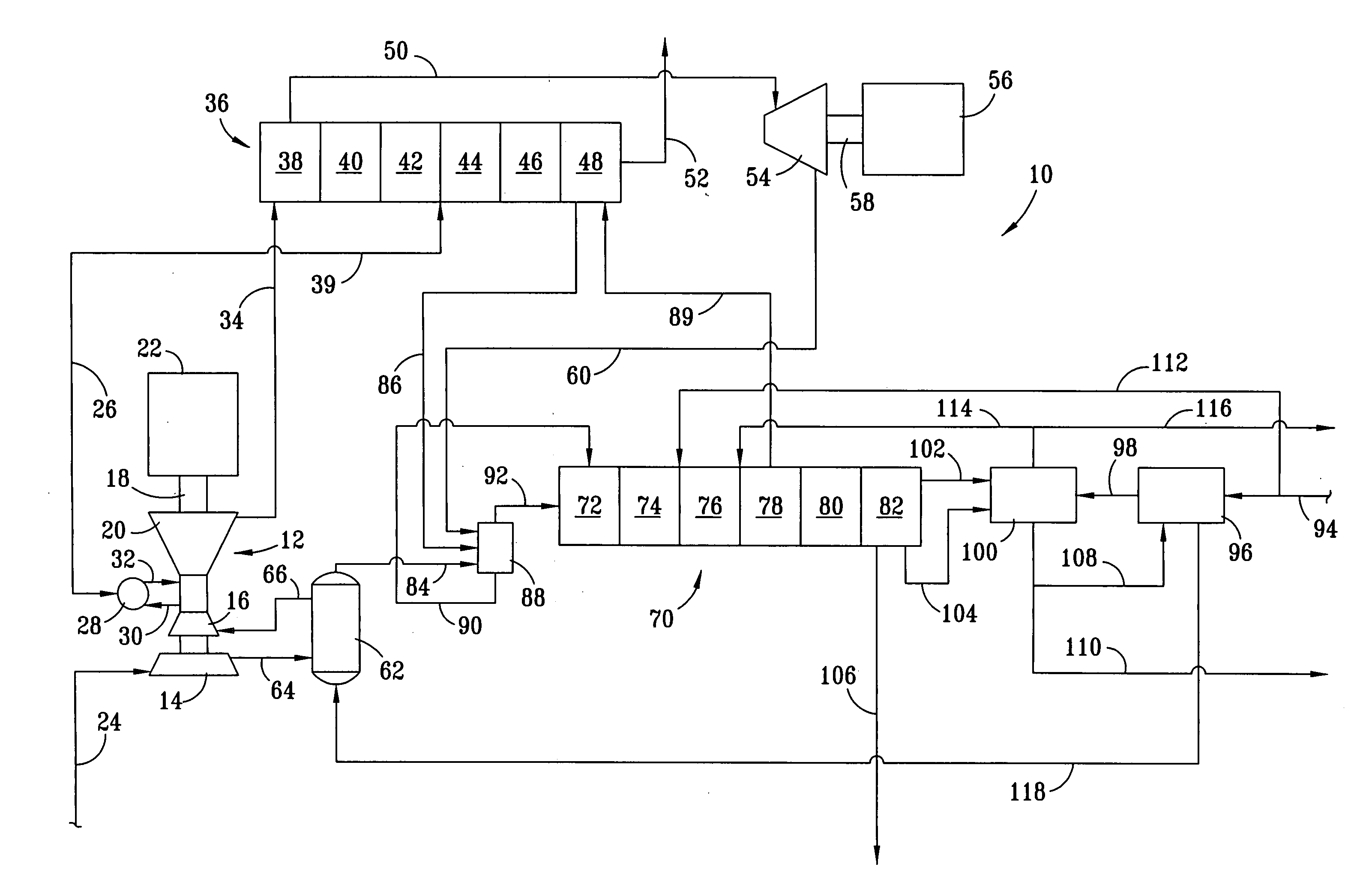

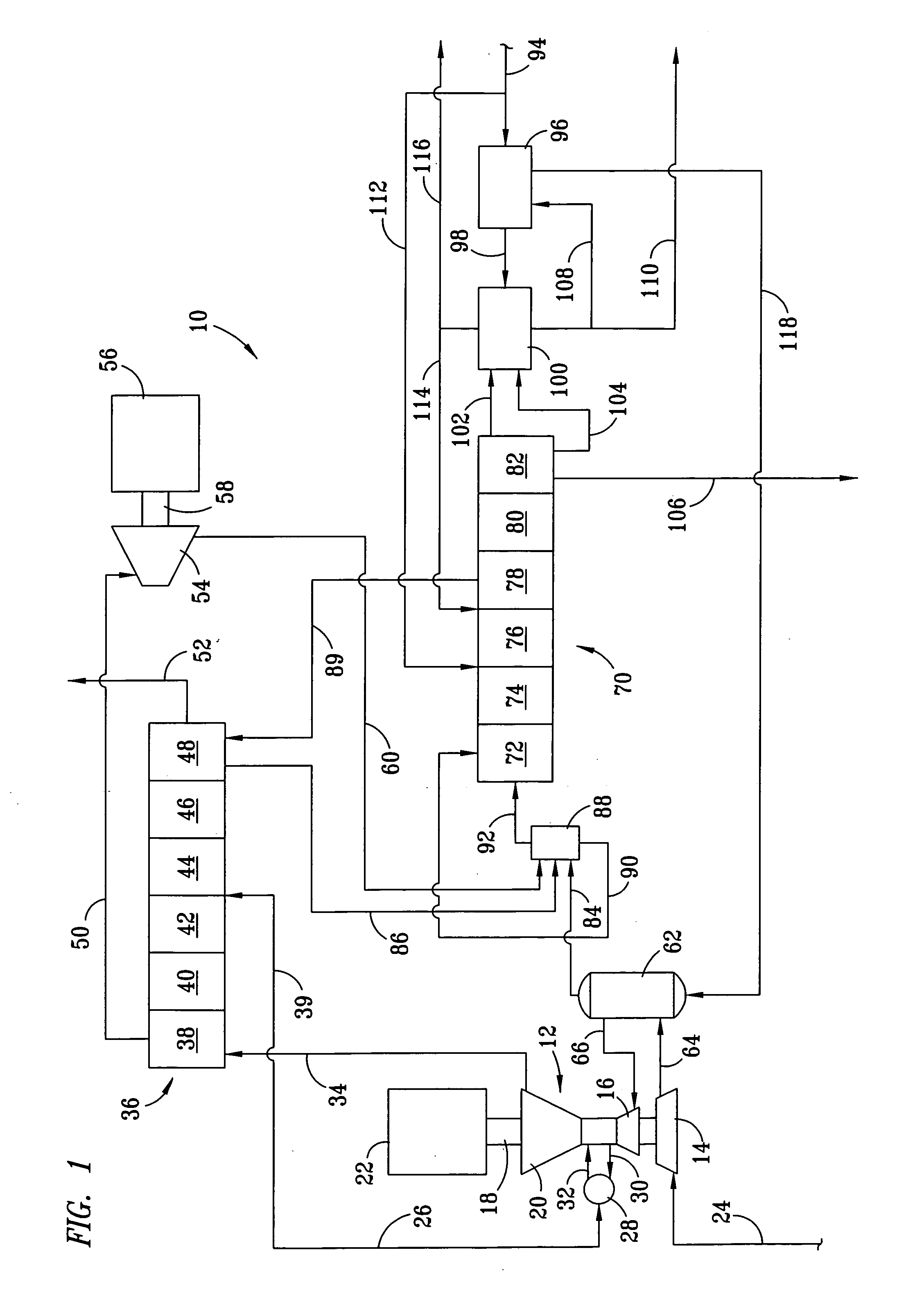

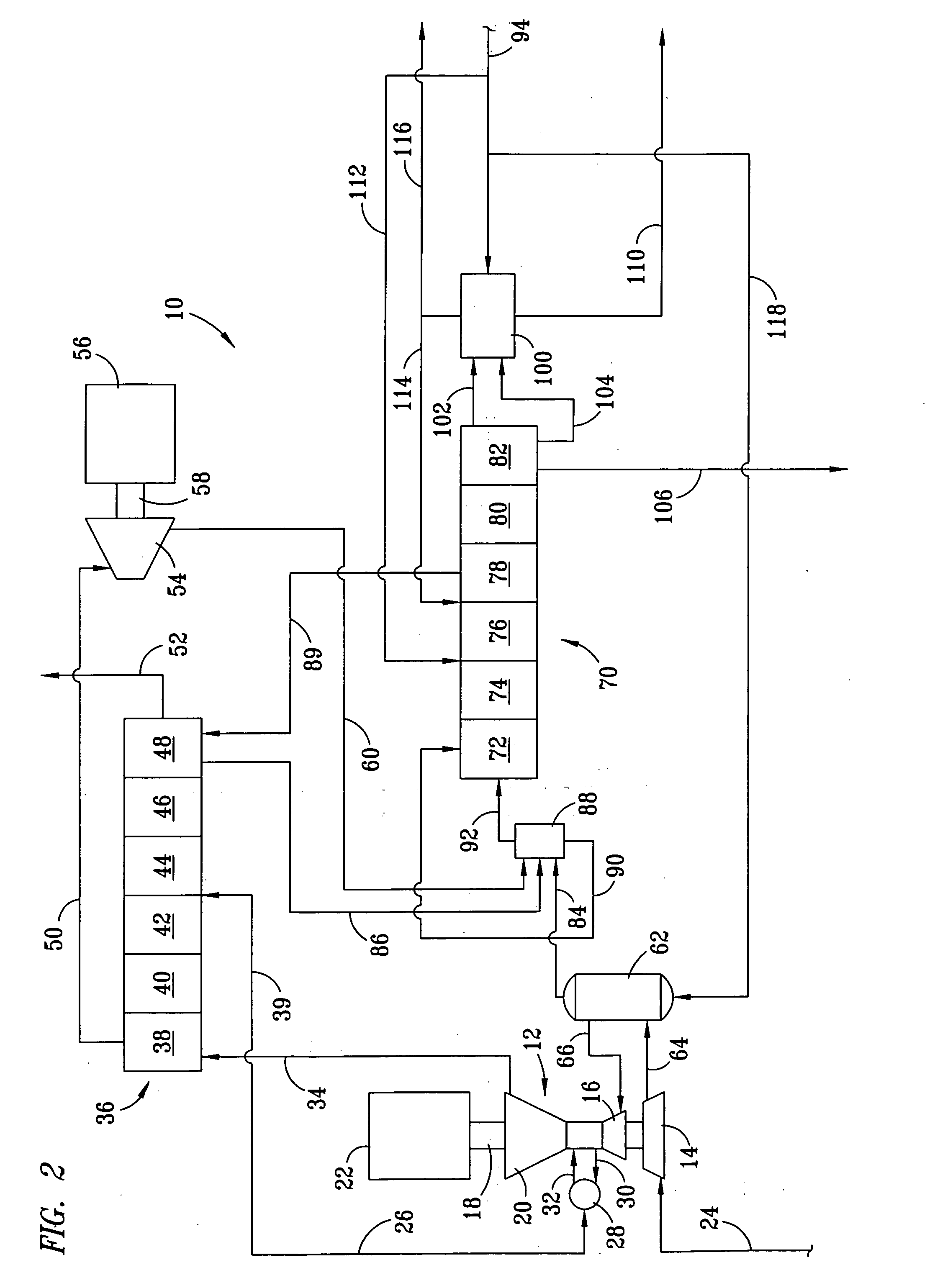

System for augmented electric power generation with distilled water output

InactiveUS7228682B2Minimize consumptionImprove system efficiencyGas turbine plantsWater/sewage treatmentDistillationChilled water

Owner:KASHLER YEFIM

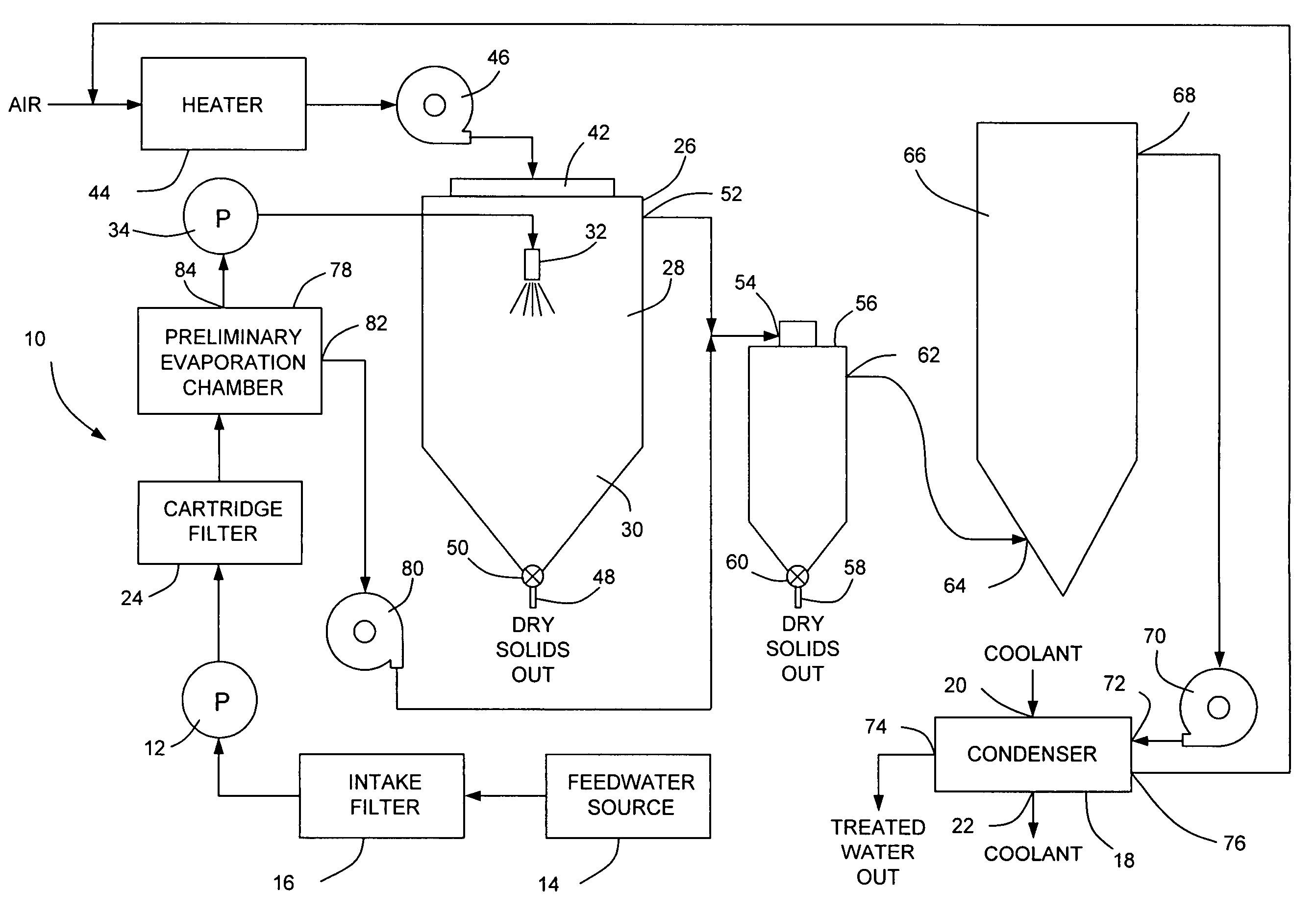

Method and system for separating solids from liquids

A method and system for treating feedwater includes evaporating a portion of the feedwater in a first evaporation chamber so as to separate water vapor from the remaining feedwater. Droplets of the remaining feedwater are dispersed into a stream of hot air produced in a second evaporation chamber. The droplets evaporate and solids in the feedwater precipitate. The precipitated solids are collected in the lower section of the second evaporation chamber. Water vapor discharged from both evaporation chambers can be treated in a cyclone separator to remove residual solids therefrom. The cleansed water vapor output from the cyclone separator can be condensed to recover clean water. Dry solids can be discharged from the second evaporation chamber and the cyclone separator for recovery.

Owner:WATERVAP

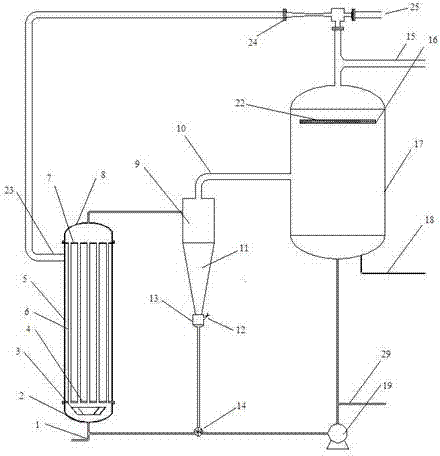

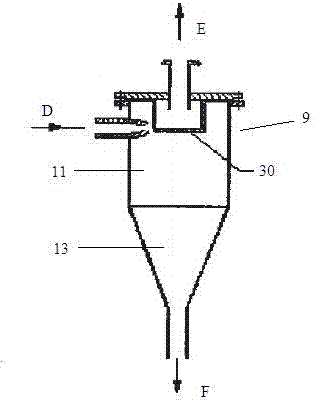

Energy-saving evaporating process and equipment for L-phenylalanine brine solution

ActiveCN102343162ASmall volumeEnergy saving processEvaporator accessoriesMultiple-effect evaporationVapor liquidHeat balance

The invention relates to an energy-saving evaporating process and equipment for a L-phenylalanine brine solution, belonging to the technical field of efficient energy saving and environmental protection. The process comprises the following steps of: preheating a 1 percent concentration of feed solution to 50-60 DEG C with a preheater 4; making the preheated feed solution enter the tube pass and shell pass of a falling film evaporator 7 and a climbing film evaporator 8 for secondary vapor heat exchange at 78-80 DEG C, heating to 70 DEG C, and evaporating in a way of combining a falling film with a climbing film to generate secondary vapor and a concentrated solution; making the secondary vapor and the concentrated solution enter a separator 9 for vapor-liquid separation; making the separated secondary vapor enter a centrifugal compressor 10 for compressing and increasing caloric content, heating to 78-80 DEG C for serving as a heating source of the evaporators 7 and 8, and heating and evaporating the feed solution; discharging the concentrated solution of which the concentration is controlled at 3 percent from the separator 9, and returning the concentrated solution of which the concentration does not reach 3 percent to the climbing film evaporator 8 for continually evaporating and concentrating. The system has the advantages of self-heat balance, small using amount of live vapor, low running cost, high efficiency and saving in energy.

Owner:想莱(常州)节能科技有限公司

Method for producing a distillate stream from a water stream containing at least one dissolved solid

A method and a system to produce a distillate stream from an aqueous stream containing at least one dissolved solid by a distillation process using at least one of a heated aqueous stream from a turbine system intercooler and a stack heater as a heat source.

Owner:BLACK & VEATCH HLDG

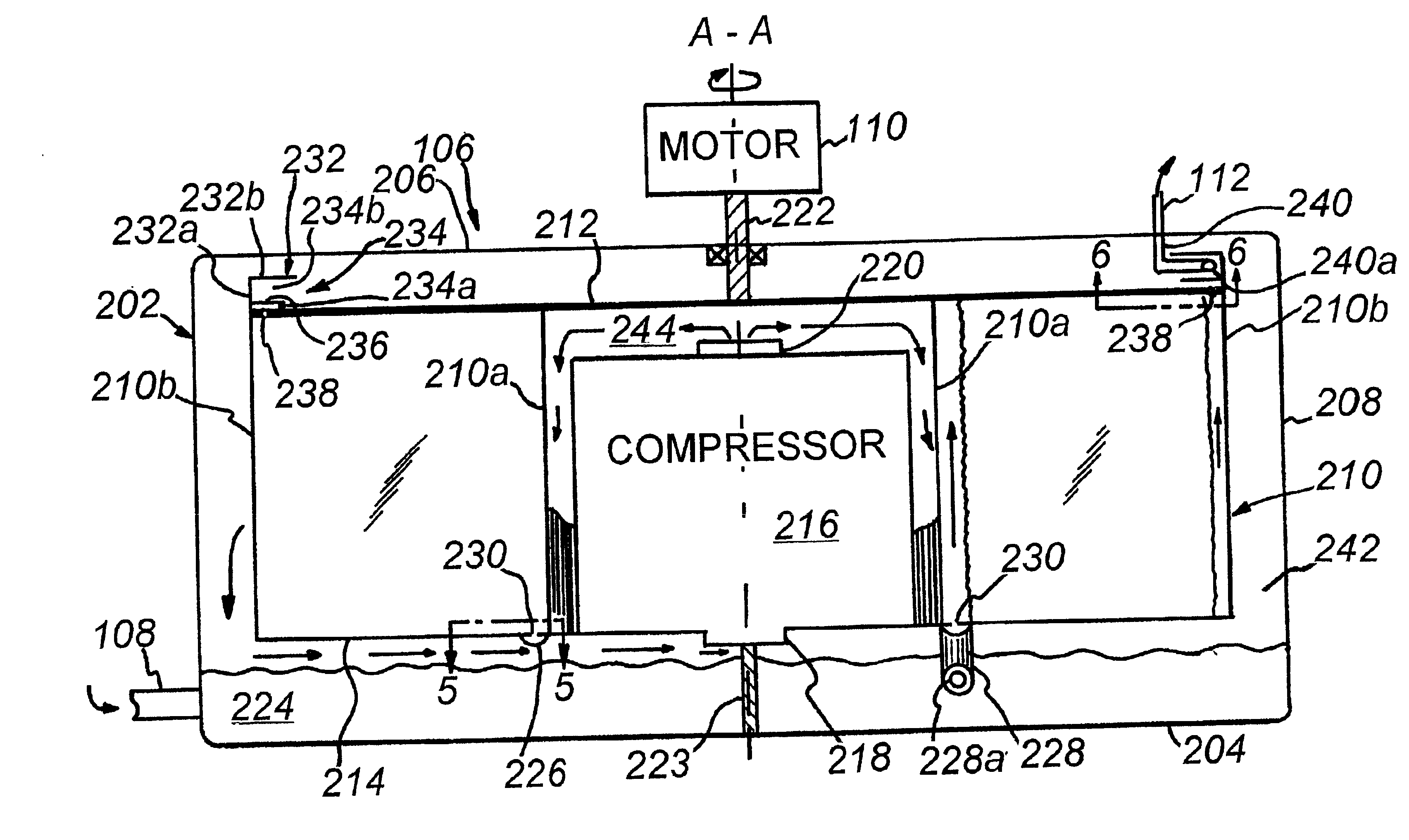

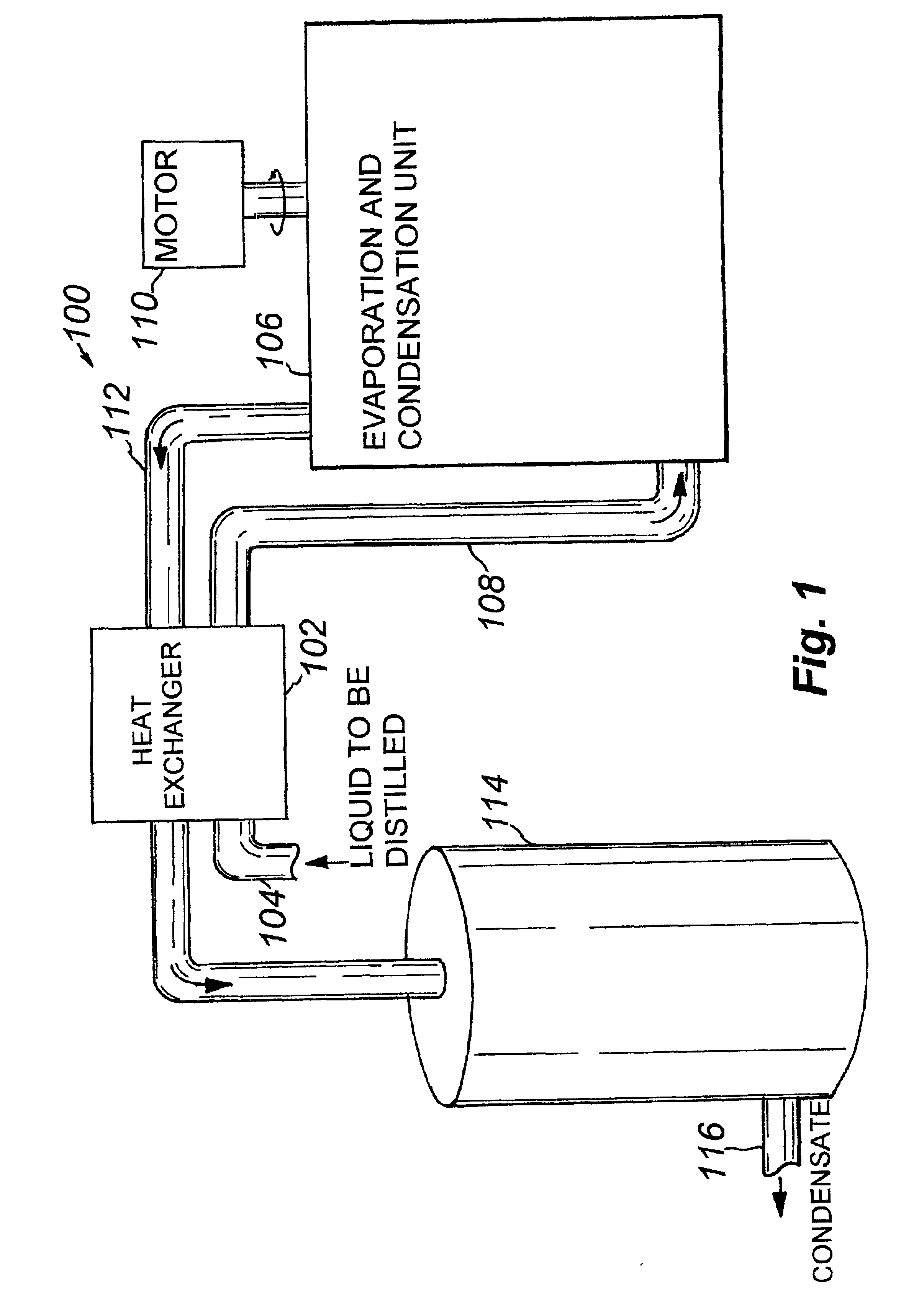

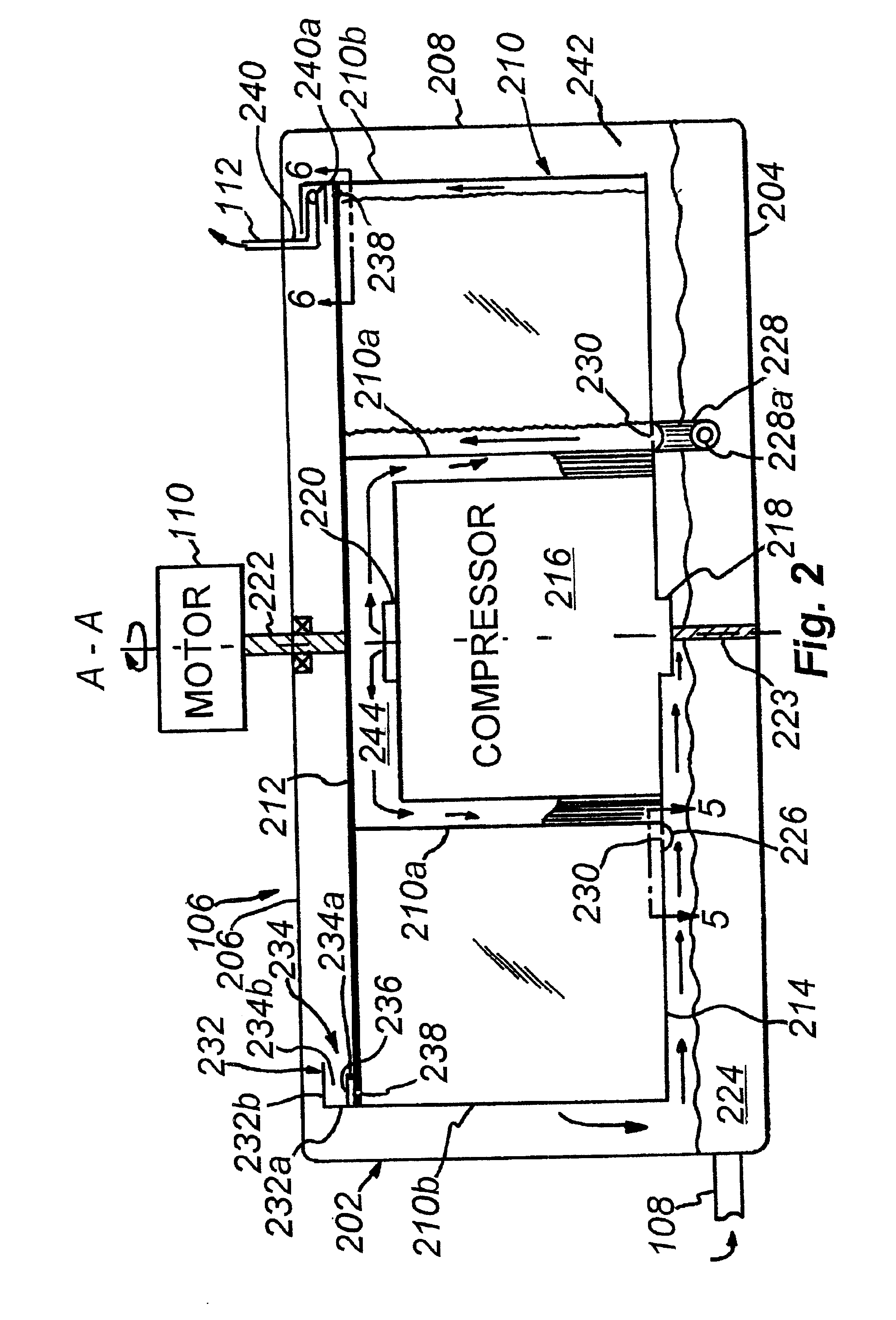

Rotating fluid evaporator and condenser

An evaporator and condenser unit for use in distilling a liquid, such as water, includes a rotary heat exchanger plate having a plurality of accordion-style folds, and having its two ends joined together so as to give the folded plate a generally circular form. The adjacent panels of the folded plate define spaces between their oppositely facing surfaces, and these spaces are alternatingly configured as evaporating and condensing chambers. The evaporating chambers have their inner edges sealed by corresponding folds, while the condensing chambers have their outer edges sealed by corresponding folds. The folded plate is disposed between first and second end plates, and is mounted for rotation about its axis in a housing having a sump containing the liquid to be distilled. Liquid is supplied to the evaporating chambers and compressed vapor is supplied to the condensing chambers. Condensate is removed from the condensing chambers.

Owner:ZANAQUA TECH

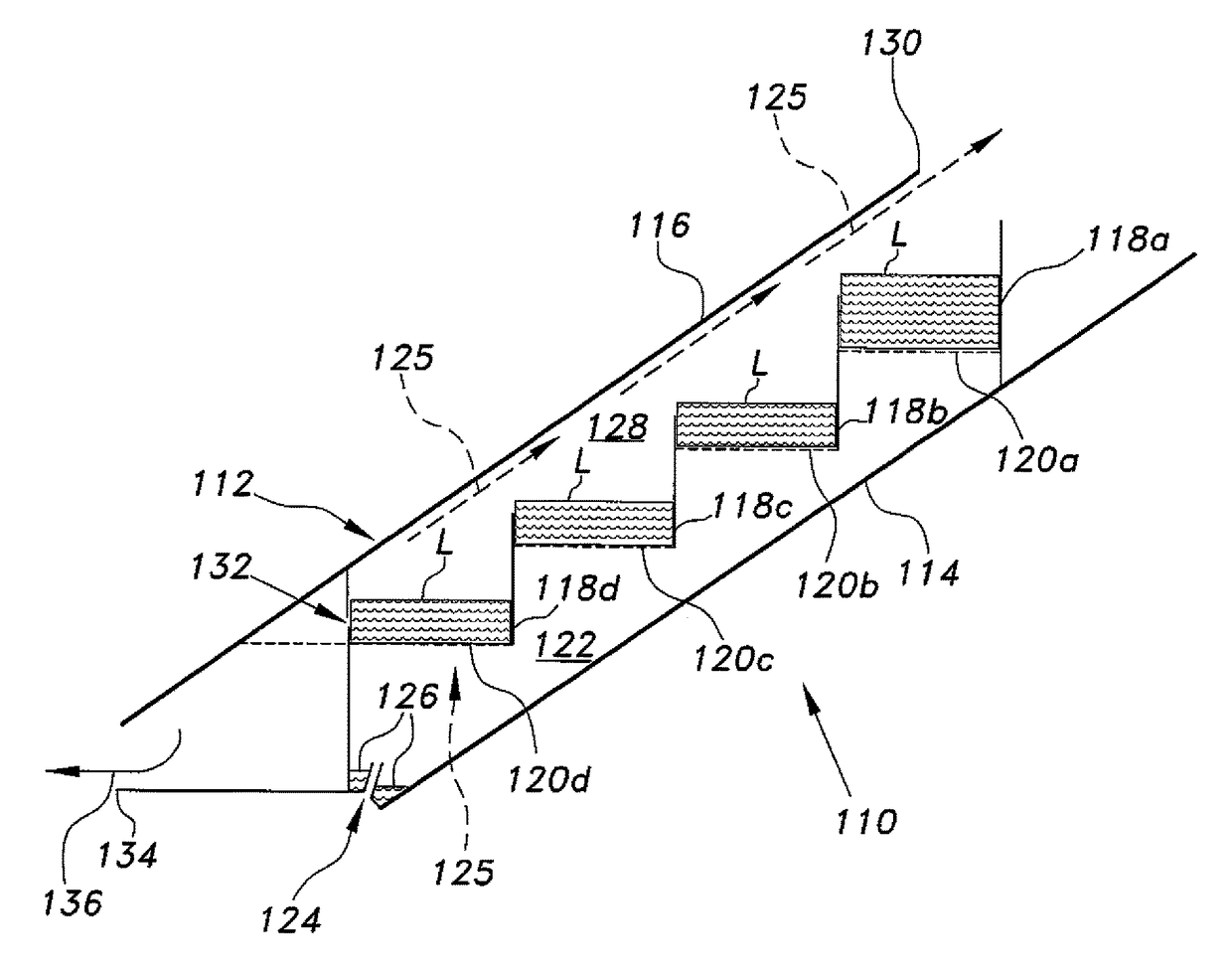

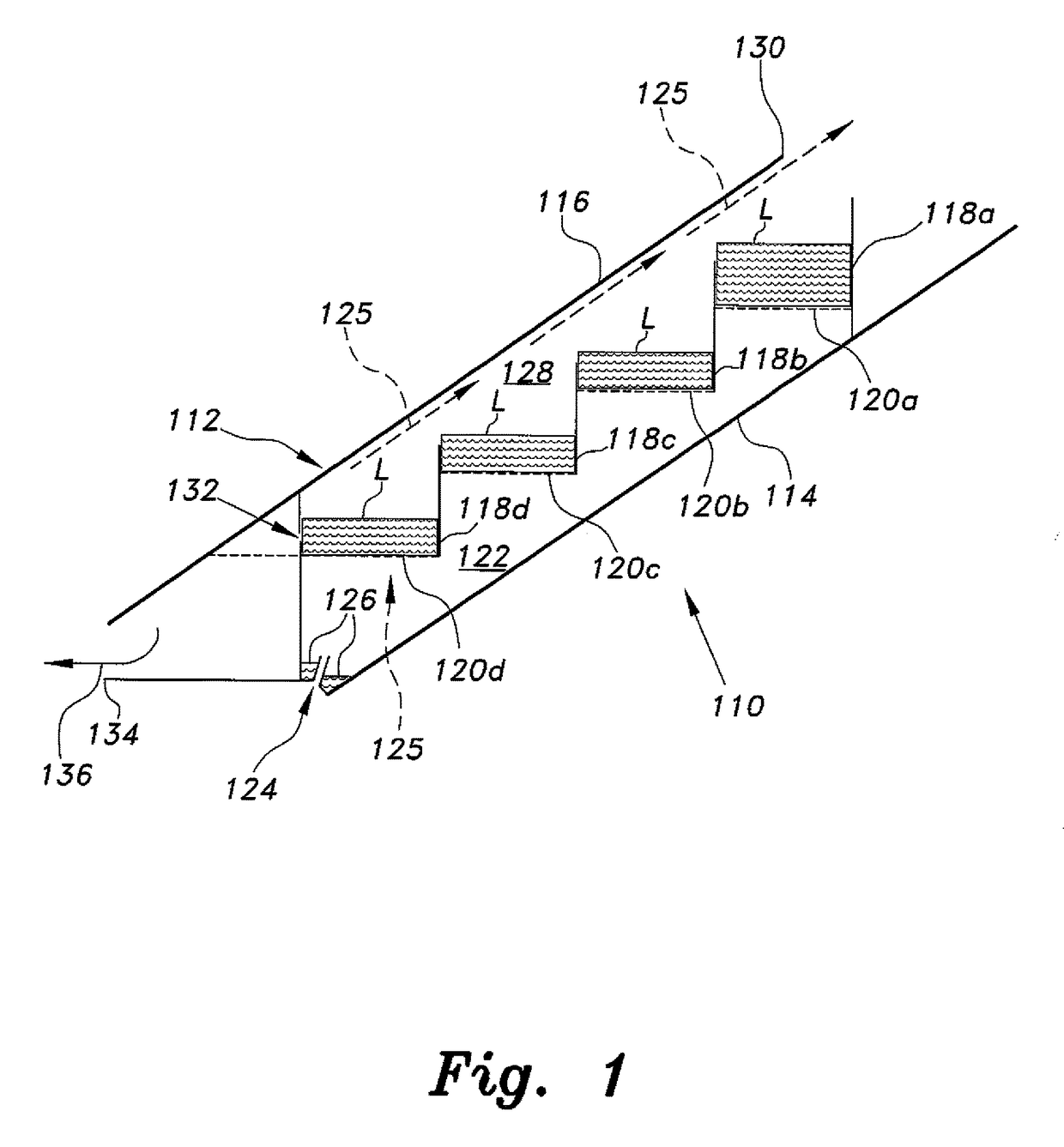

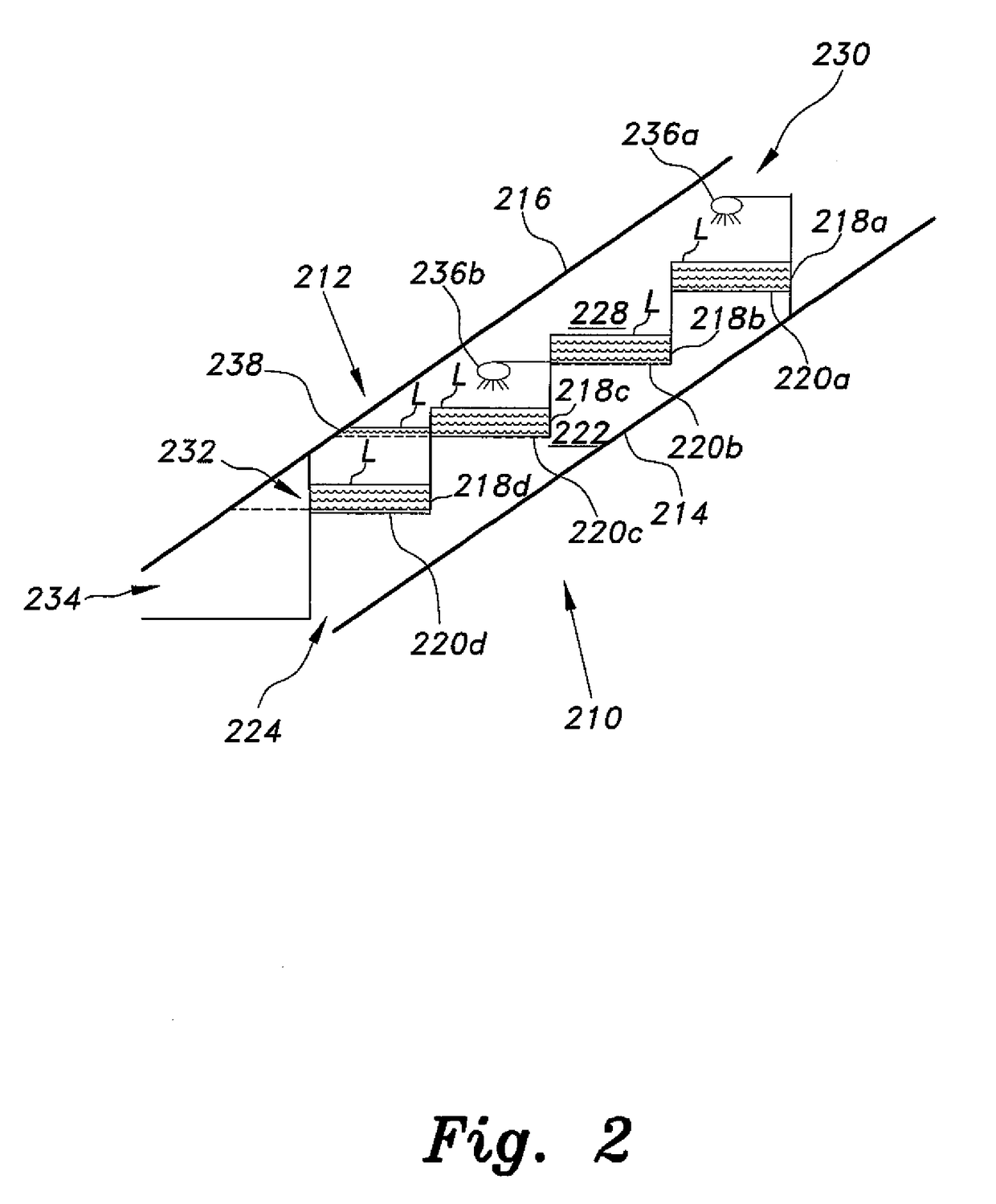

Humidification-dehumidifaction desalination system

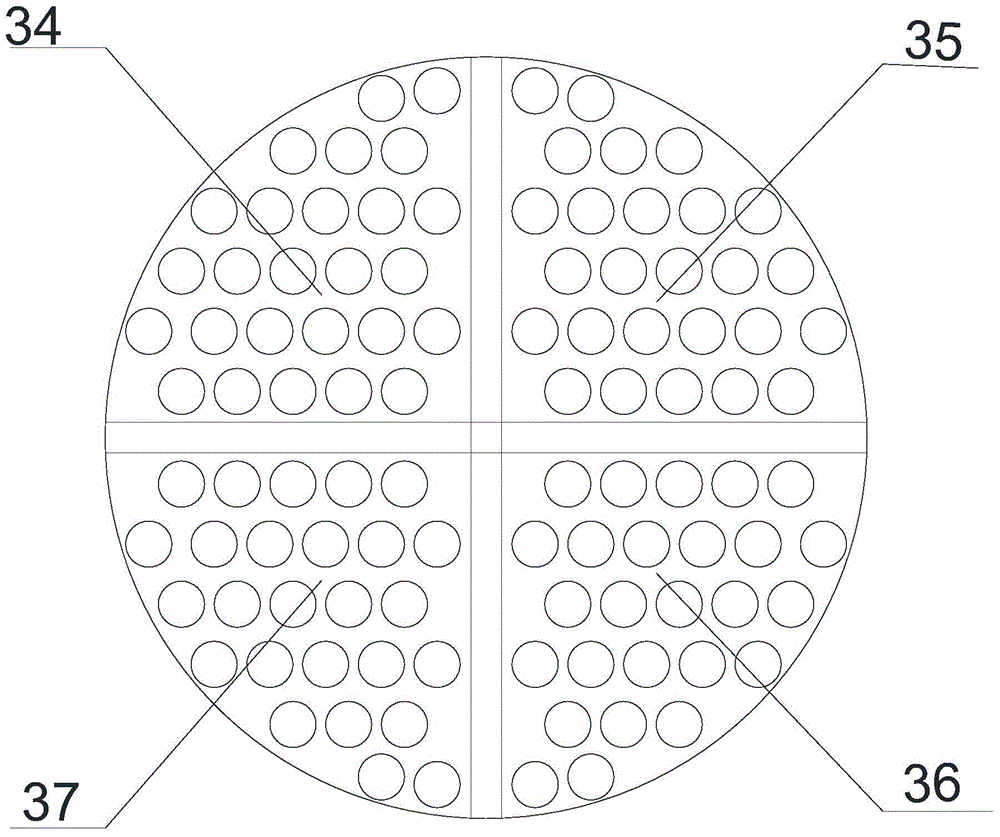

InactiveUS9643102B2Speed up evaporationIncrease profitWaste water treatment from quariesWater treatment parameter controlDesalinationClosed loop

The humidification-dehumidification desalination system includes a humidifier, a dehumidifier, and a carrier gas that is humidified in the humidifier and condensed in the dehumidifier to produce purified water. The humidifier preferably includes multiple stages in a staircase configuration in which at least one stage has a perforated or porous plate and the carrier gas is bubbled through the bottom of the plate into the “liquid to be purified” atop the plate. The dehumidifier may also include multiple stages in a staircase configuration in which at least one stage has a perforated or porous plate and the carrier gas is bubbled through the bottom of the plate into the purified liquid atop the plate. In both the humidifier and the dehumidifier, the liquid travels downward from one stage to the next stage. The system may be operated in a closed loop, so that the carrier gas is recirculated from the dehumidifier to the humidifier.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com