Heat-pipe low-temperature multi-effect sea water desalinating system and process flow

A heat pipe type, low temperature technology, applied in multi-effect evaporation, seawater treatment, heating water/sewage treatment, etc., can solve the problems of high corrosion of heat transfer pipes and equipment body, increase water production cost, and high equipment cost, and achieve energy efficiency. High utilization rate, mitigation of corrosion and scaling, and low chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

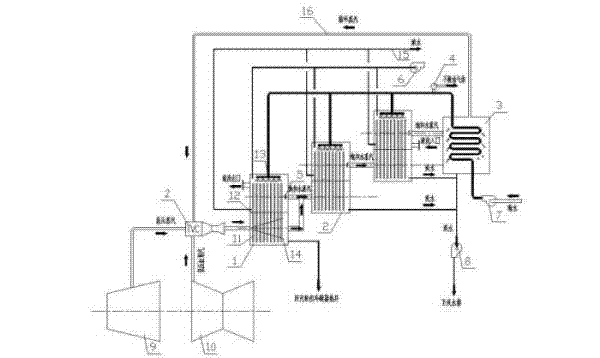

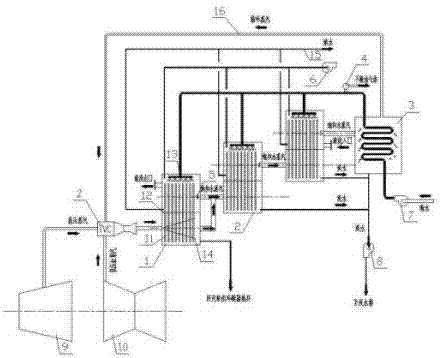

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

[0021] Explanation of the main components and detail reference signs in the drawings of the description:

[0022] 1——Heat pipe multi-effect evaporator 2——TVC steam ejector

[0023] 3—cooler 4—gas release device

[0024] 5——steam water separator 6——water ring vacuum pump

[0025] 7——Sea water pump 8——Permeate pump

[0026] 9——Medium pressure cylinder of steam turbine 10——Low pressure cylinder of steam turbine

[0027] 11——heat pipe 12——baffle

[0028] 13—spray system 14—steam distributor

[0029] 15—concentrated water pipe 16—circulating steam

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0031] A new type of heat pipe low-temperature multi-effect seawater desalination system (see figure 1 ), characterized in that it includes multiple sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com