Heat pump type low-temperature evaporating device and method

A technology of low-temperature evaporation and heat pump, which is applied in the field of low-temperature evaporation process and equipment, heat pump energy saving, can solve the problems of low boiling point of organic solvents, pollute the environment, inflammable and explosive, etc., achieve light equipment corrosion, low evaporation temperature, and reduce gas emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

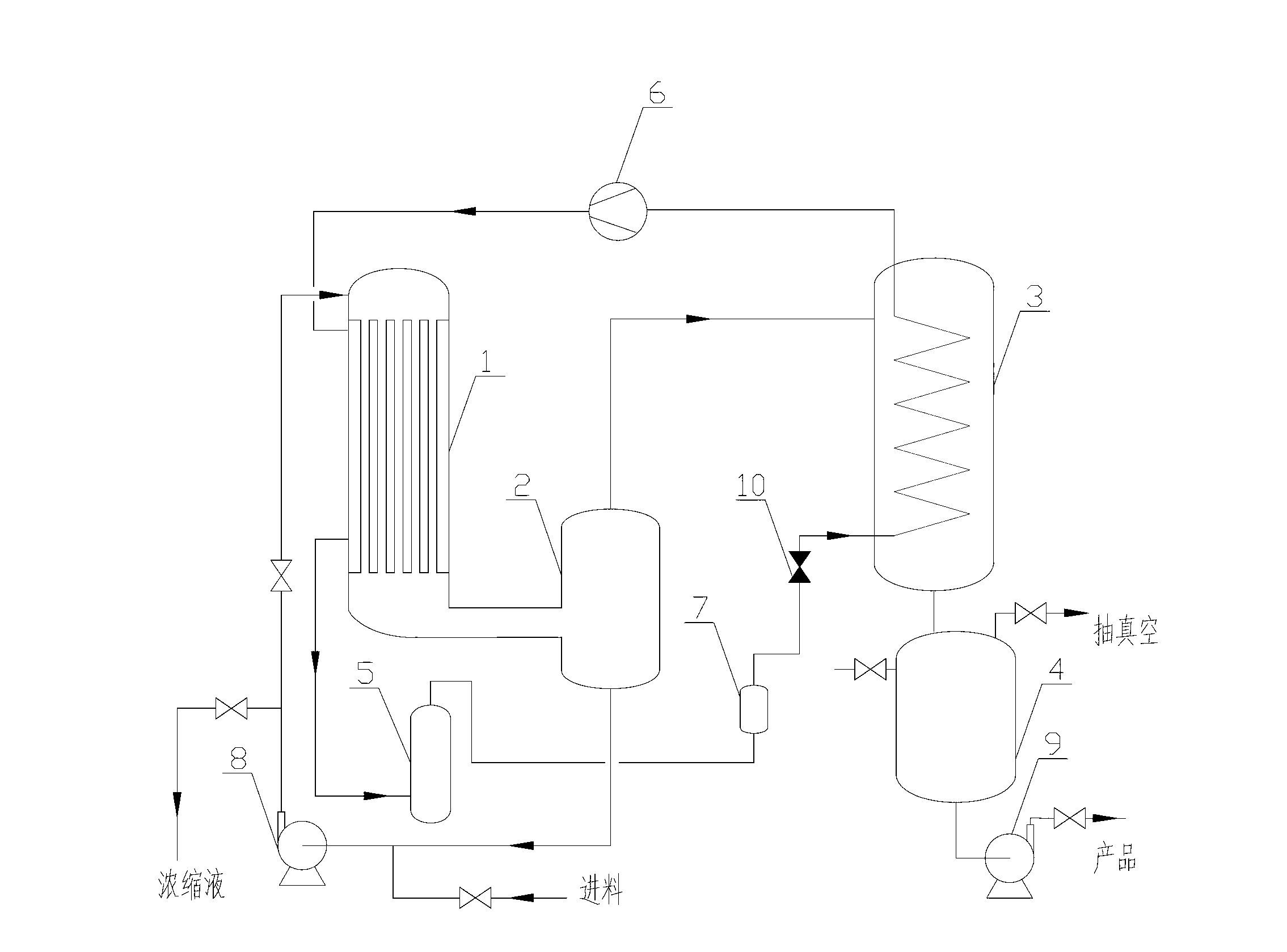

[0019] like picture As shown, the heat transfer area of the feed-liquid evaporator is 0.58m 2 , the steam condenser area is 1.58 m 2 , The compressor uses the Copeland CRNQ-0500-TFO-272 type fully enclosed 5-hp compressor, and the throttling device uses a thermal expansion valve. Using R22 as heat medium, evaporate and concentrate 10.5% glucose solution.

[0020] Material circulation: the non-condensable gas is pumped out by the vacuum pump on the top of the condensate tank to maintain the system pressure between 2.5-5kPa, the thinner liquid is pumped into the evaporator until the liquid level of the separator reaches the specified height, and the spray volume of the pumped liquid is 300L / h The film distributor on the top of the evaporator is evenly distributed to the heat transfer tubes of the evaporator and flows down in the form of a film. The liquid film absorbs the heat of the heat medium steam outside the tube and evaporates at the evaporation temperature between 28°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com