Method of processing p-benzene dicarboxylic acid production wastewater

A technology of terephthalic acid and a treatment method, which is applied in the field of industrial wastewater treatment and reuse, can solve the problems of inability to recover organic matter in wastewater, reuse of effluent, etc., and achieves a wide application range of water quality, simple process flow, and improved use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

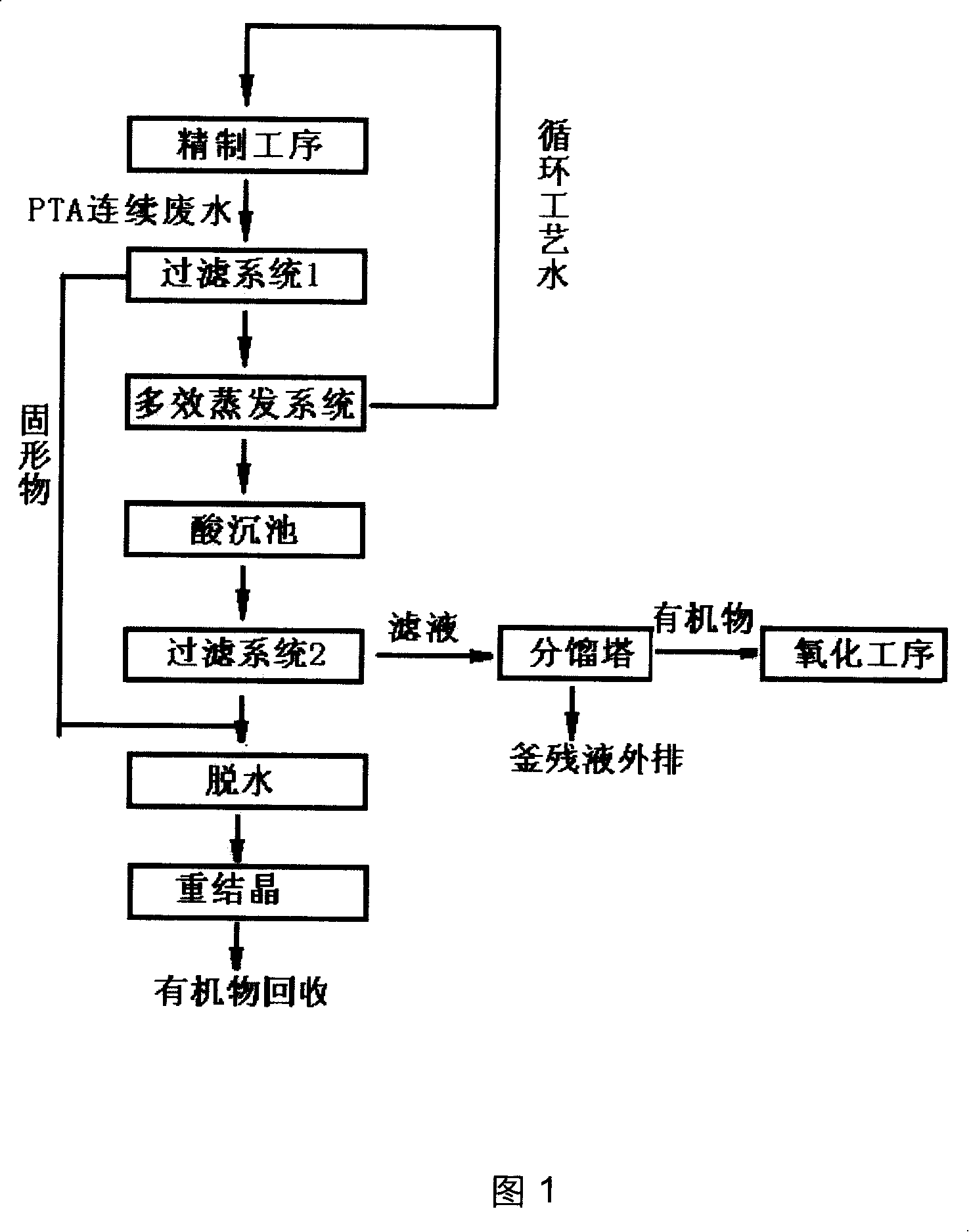

Image

Examples

Embodiment 1

[0036] 1. The raw material wastewater is taken from the continuous wastewater of the refining process of the PTA production unit, and its main composition is as follows:

[0037] Terephthalic acid 0.25%

[0038] p-Toluic acid 0.079%

[0039] Benzoic acid 0.007%

[0040] Acetic acid 0.1%~0.2%

[0041] pH ~2.5

[0042] COD ~2800mg / L

[0043] Raw waste water is firstly filtered through a rotary vacuum filter, and the vacuum degree is selected as (0.4~0.8)×10 5 Pa, filtration rate is 1.5m 3 / min. Obtain solid (2) and filtrate (1)

[0044] 2. The filtrate (1) is directly sent to the 5-effect evaporation system, and the condensed water obtained after the multi-effect evaporation has the following composition, which can be used as process water and reused in the refining process, and the recovery rate of desalinated water is 80%.

[0045] Terephthalic acid ~0

[0046] Conductivity ≤1.0μs / cm

[0047] Copper ≤0.2 mg / L

[0048] Iron ≤0.5 mg / L

[0049] Silicide ≤3.0 mg / L

[00...

Embodiment 2

[0060] 1. Raw waste water, taken from the continuous waste water of the refining process of the PTA production unit, is composed as follows:

[0061] Terephthalic acid 0.47%

[0062] p-Toluic acid 0.1%

[0063] Benzoic acid 0.08%

[0064] Acetic acid 0.1%~0.2%

[0065] pH ~2.8

[0066] COD ~2500mg / L

[0067] Raw waste water is filtered through a vacuum filter with a filtration rate of 1.8m 3 / min. Add sodium hydroxide for neutralization, and adjust the pH value of the wastewater to about 7.

[0068] 2. The neutralized filtrate is sent to the 2-effect evaporation system. The composition of the condensed water obtained after the multi-effect evaporation is as follows, which can be used as process water and reused in the refining process. The recovery rate of desalinated water is 50%.

[0069] Terephthalic acid ~0

[0070] Conductivity ≤1.0μs / cm

[0071] Copper ≤0.2 mg / L

[0072] Iron ≤0.5 mg / L

[0073] Silicide ≤2.0mg / L

[0074] Sulfide (as SO 4 2- Count) ≤ 5.0 mg / ...

Embodiment 3

[0084] 1. Raw waste water, taken from the continuous waste water of the refining process of the PTA production unit, is composed as follows:

[0085] Terephthalic acid 0.86%

[0086] p-Toluic acid 0.15%

[0087] Benzoic acid 0.06%

[0088] Acetic acid 0.1%~0.2%

[0089] pH ~2.8

[0090] COD ~2400mg / L

[0091] Raw wastewater is separated from solids by a pressure centrifuge.

[0092] 2. The filtrate is sent to the 10-effect evaporation system. The composition of the condensed water obtained after multi-effect evaporation is as follows, which can be reused as process water in the refining process, and the recovery rate of desalinated water is 90%.

[0093] Terephthalic acid ~0

[0094] Conductivity ≤1.0μs / cm

[0095] Copper ≤0.2 mg / L

[0096] Iron ≤0.5 mg / L

[0097] Silicide ≤3.0 mg / L

[0098] Sulfide (as SO 4 2- Count) ≤60.0mg / L

[0099] Total solids ≤5.0 mg / L

[0100] Total metals (cobalt, manganese, nickel, chromium, etc.), ≤1.5 mg / L

[0101] The resulting conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com