A zero-discharge fracturing flowback fluid treatment system and its adjustment method

A technology of fracturing flowback fluid and treatment system, which is applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. Problems such as the inability of the liquid to be recycled and reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. In the description of the present invention, the connection between devices refers to the connection by pipes.

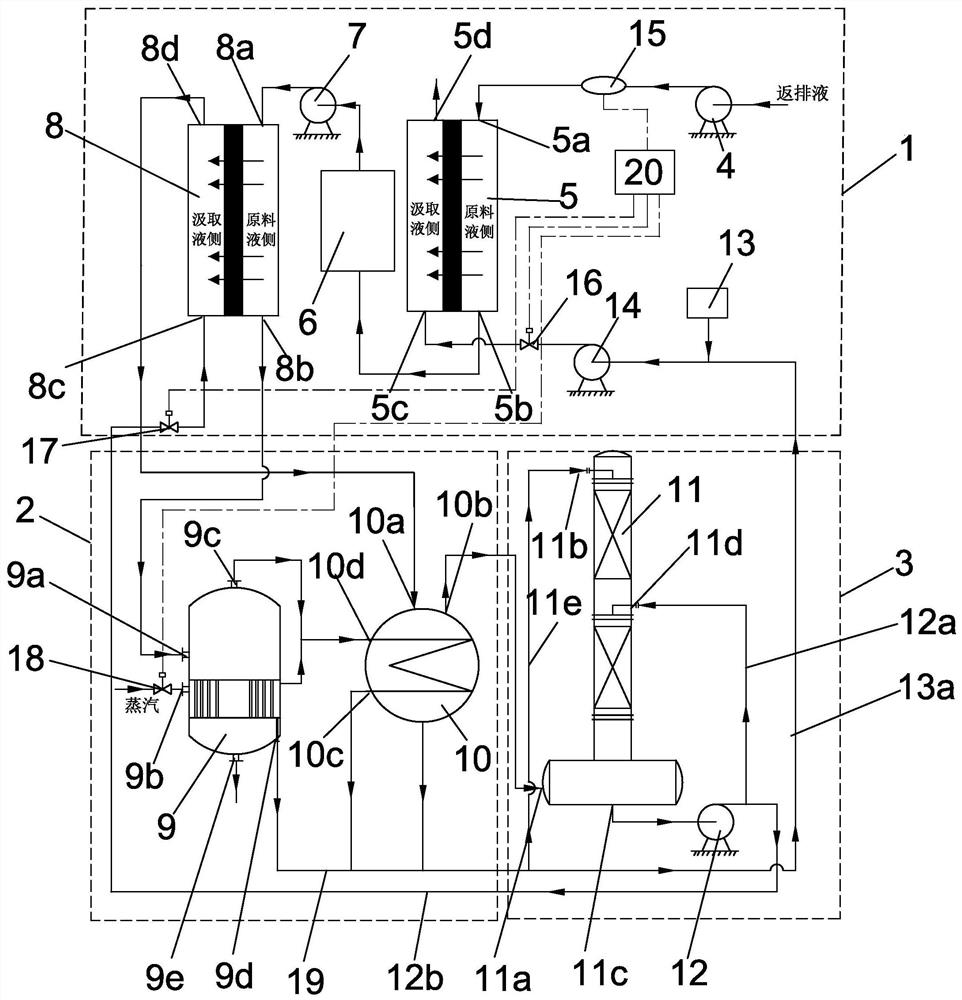

[0018] figure 1 A system diagram for zero discharge frac flowback fluid treatment is shown. The system in the figure includes a forward osmosis water treatment unit 1 , an evaporation crystallization unit 2 , a draw liquid reuse unit 3 and an adjustment control unit 20 . The fracturing flowback liquid enters the raw material liquid side of the front forward osmosis membrane module 5 from the flowback liquid inlet 5a through the self-priming pump 4, and the NaCl draw solution of the front forward osmosis membrane module 5 enters the front positive osmosis membrane module 5 through the draw liquid self-priming pump 14. On the draw liquid side of the osmotic membrane module 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com