Method for crushing and separating section steel concrete structural components

A technology of concrete structure and separation method, which is applied in building construction, building maintenance, construction, etc., can solve the problem of inability to effectively break apart steel-concrete structural components, and achieve the effect of less dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

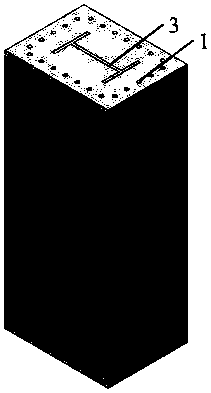

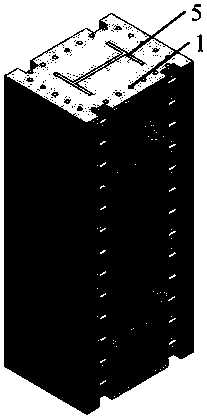

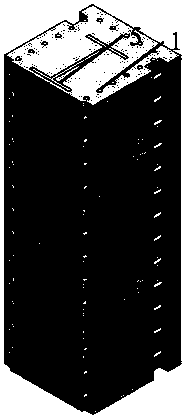

[0033] Specific implementation mode one: the method for crushing and separating the steel concrete structural members of this implementation mode is specifically carried out according to the following steps:

[0034] 1. Determine the type and conditions of use of the static breaking agent according to the reinforcement of the steel concrete structural members to be removed and the position of the steel, and determine the static crushing hole diameter, hole spacing and hole depth in combination with the reinforcement of the component to ensure that the hole spacing and the stirrup There is a multiple relationship between the spacing to ensure that the steel bars are avoided when drilling;

[0035] 2. Determine the location of the static crushing and demolition drilling hole and perform oblique drilling on the outside of the steel flange to form the first tunnel; the first tunnel is parallel to the steel flange and tangent to the outer edge of the adjacent steel flange, and the w...

specific Embodiment approach 2

[0044] Specific embodiment two: the difference between this embodiment and specific embodiment one is that: the inclination angle of the inclined borehole described in step two is 5° to 15°; the inclination angle of the inclined borehole described in step five is 5° to 15° . Others are the same as the first embodiment.

specific Embodiment approach 3

[0045] Specific Embodiment 3: This embodiment differs from Specific Embodiment 1 or 2 in that: the drill holes are drilled. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com