Environment friendly blast furnace slag treating process and system

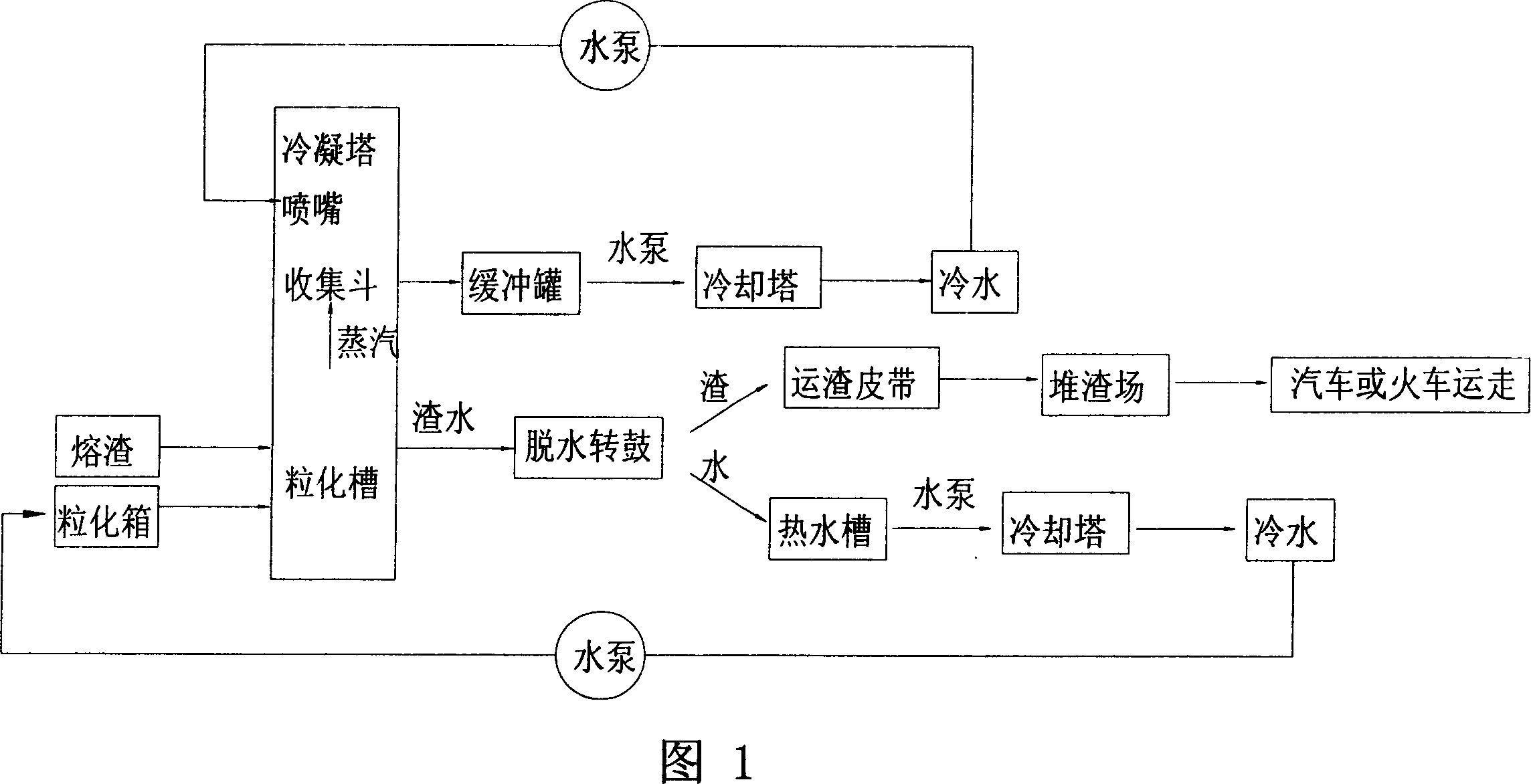

A technology of blast furnace slag and treatment process, which is applied in the field of blast furnace slag treatment process and its system, which can solve the problems of large circulating water volume, complex process and high investment, and achieve the effect of good slag flushing quality, simple system and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

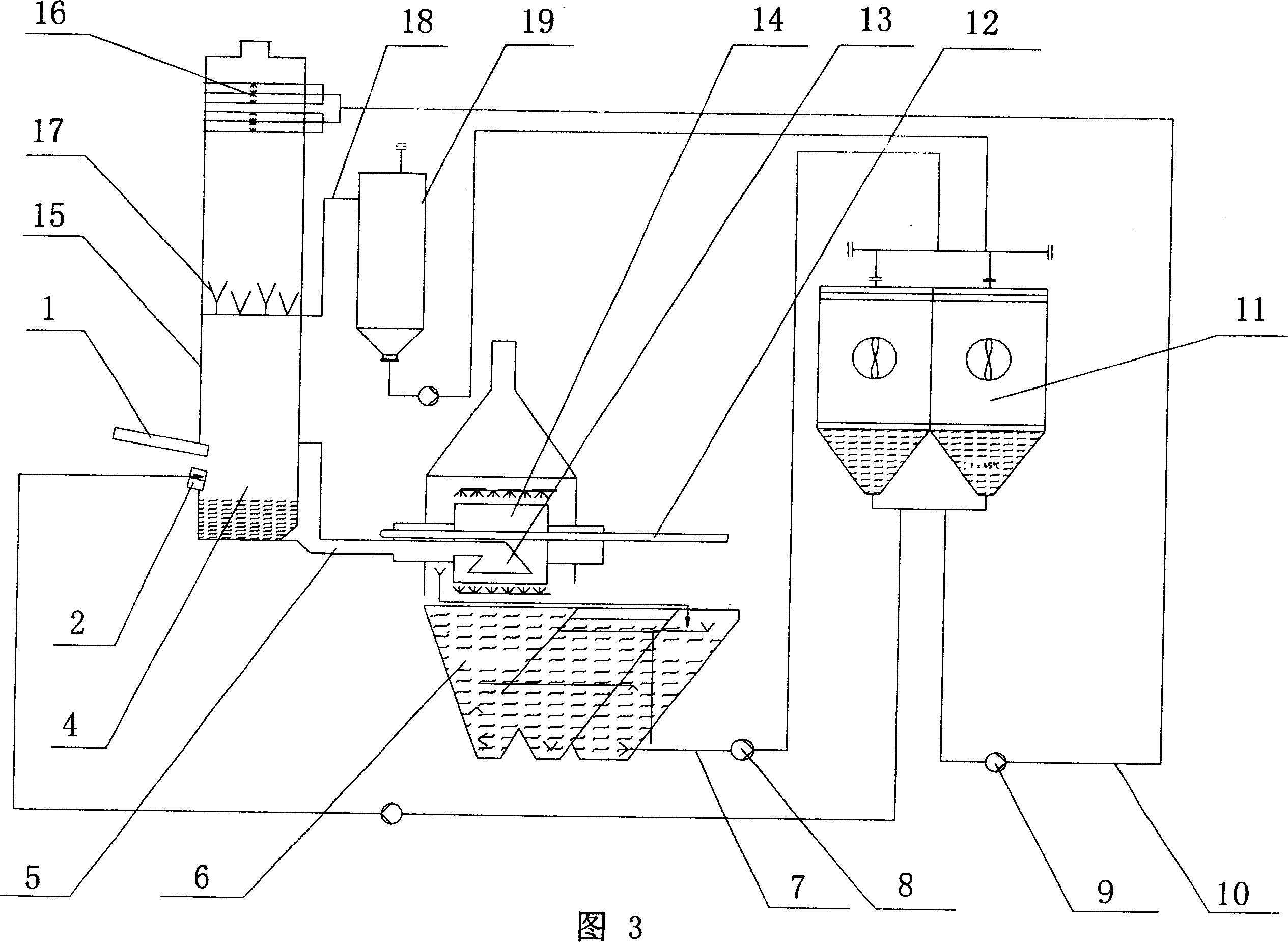

Embodiment Construction

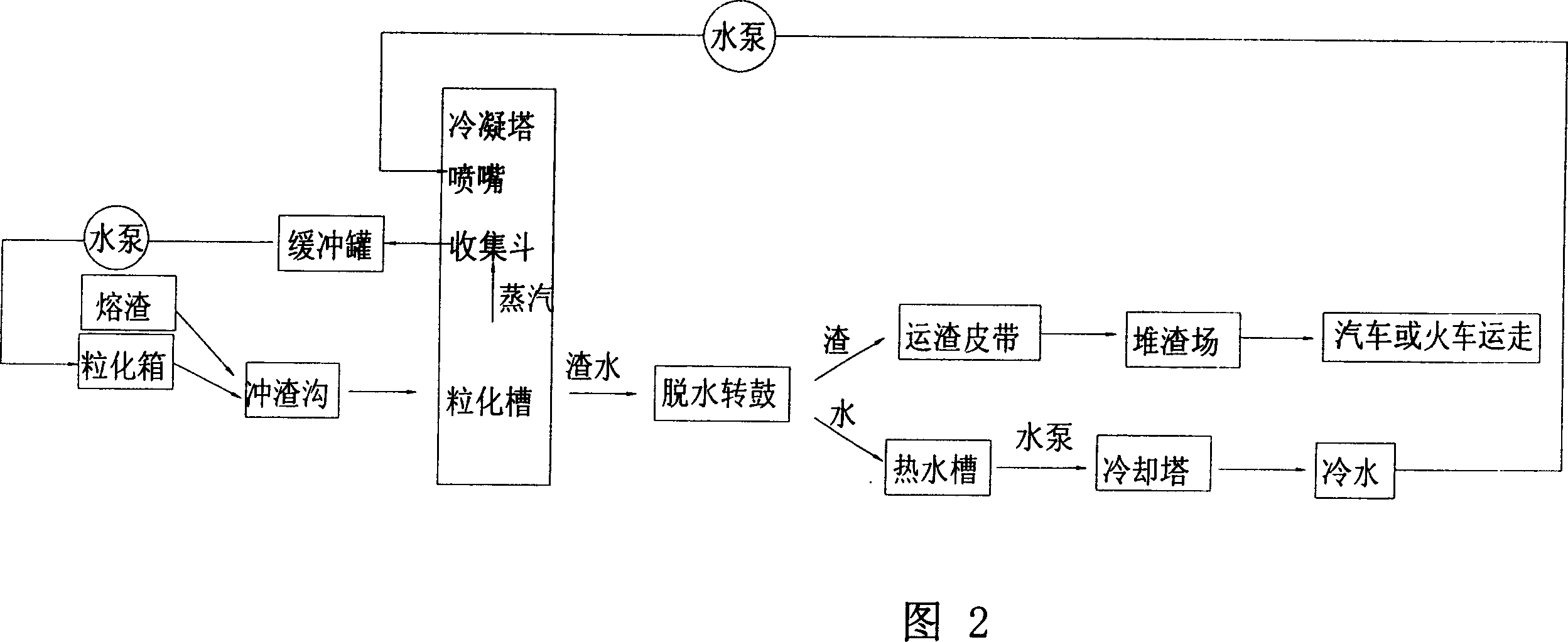

[0024] As shown in Figure 2, the environmental-friendly blast furnace slag treatment process, the red slag produced by the blast furnace is sprayed with cooling water in the granulation box installed under the end of the red slag ditch to quickly cool and water quench, and the slag and water after water quenching first pass through the slag flushing ditch , and then rush into the slag blocking plate in the granulation tank for further crushing, and then enter the collection pipe at the lower part of the granulation tank; then the slag-water mixture in the collection pipe enters the slag water pipe and enters the distributor of the dehydration drum along the slag water pipe. The water in the lower part of the dehydration drum keeps the slag-water mixture cooled, and is rotated and lifted by the dehydrator equipped with a sieve plate to filter. When the dehydration drum turns to a high point, the water slag falls into the belt conveyor in the dehydration drum and is transported ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com