Patents

Literature

71results about How to "Reduce circulating water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

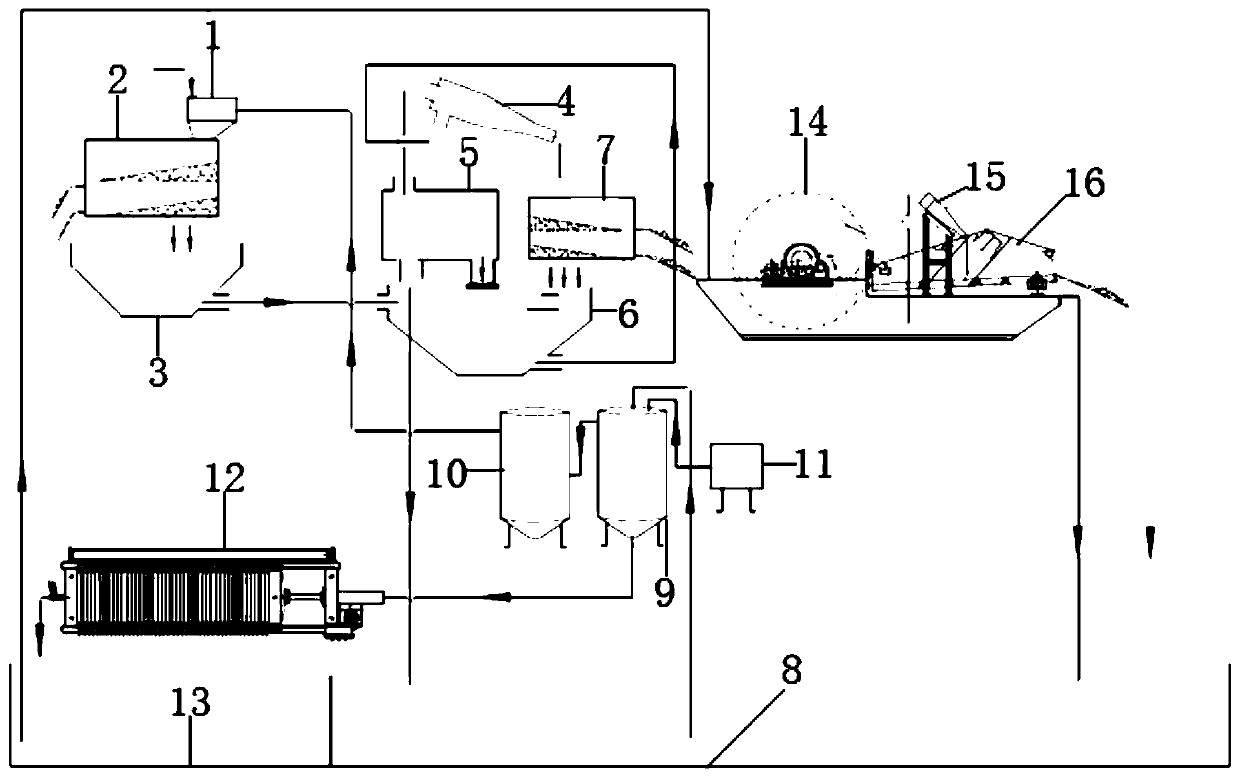

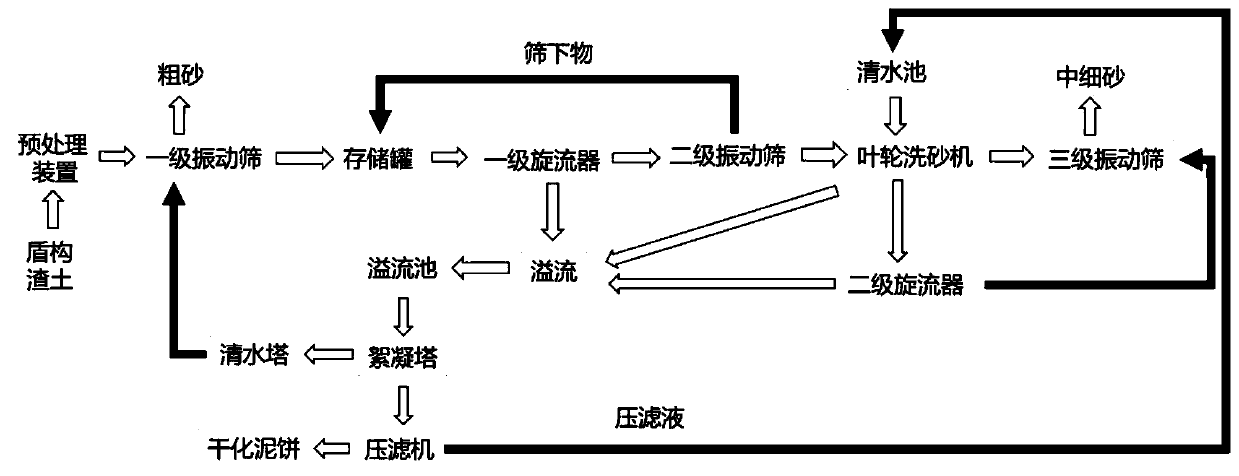

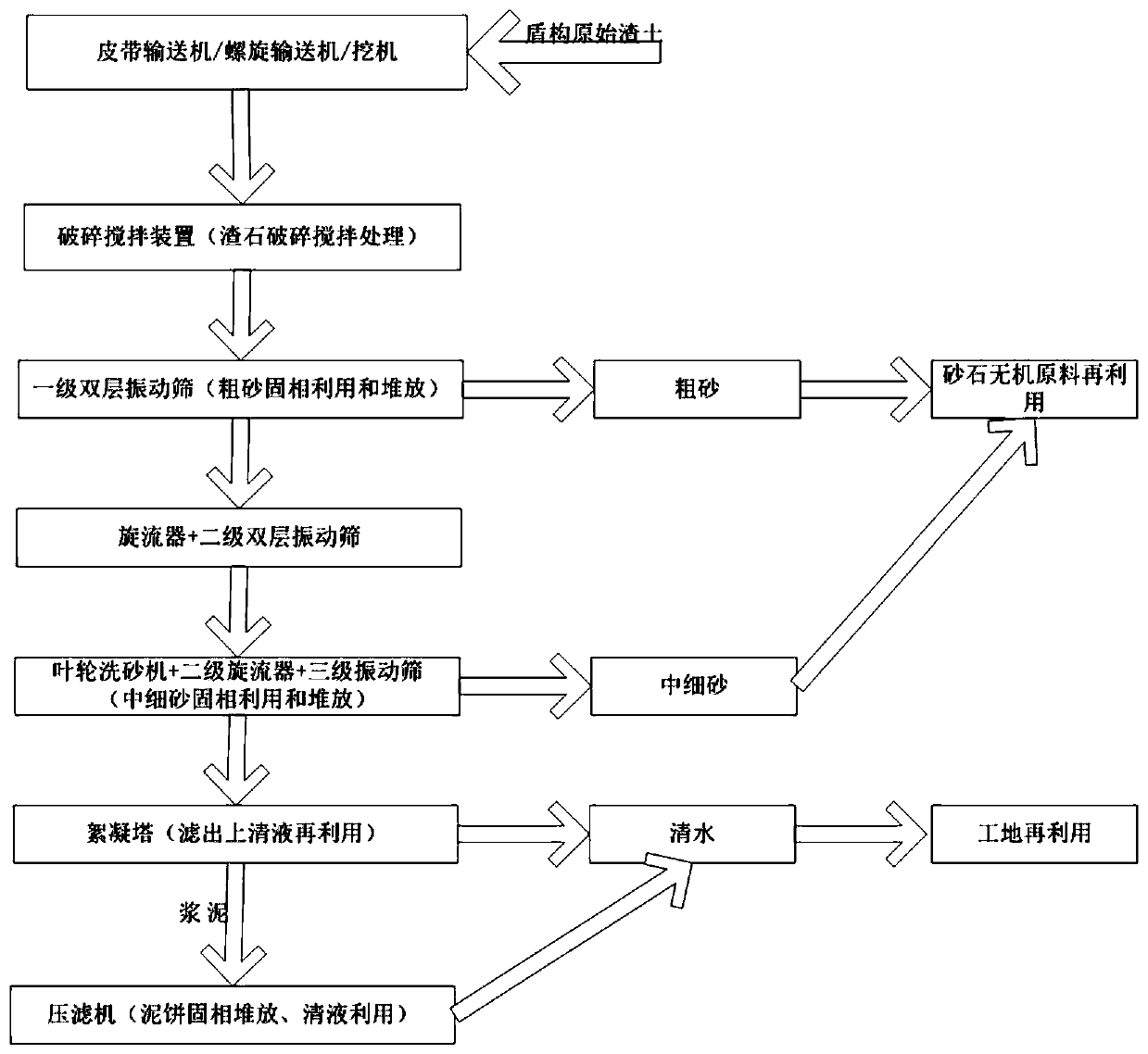

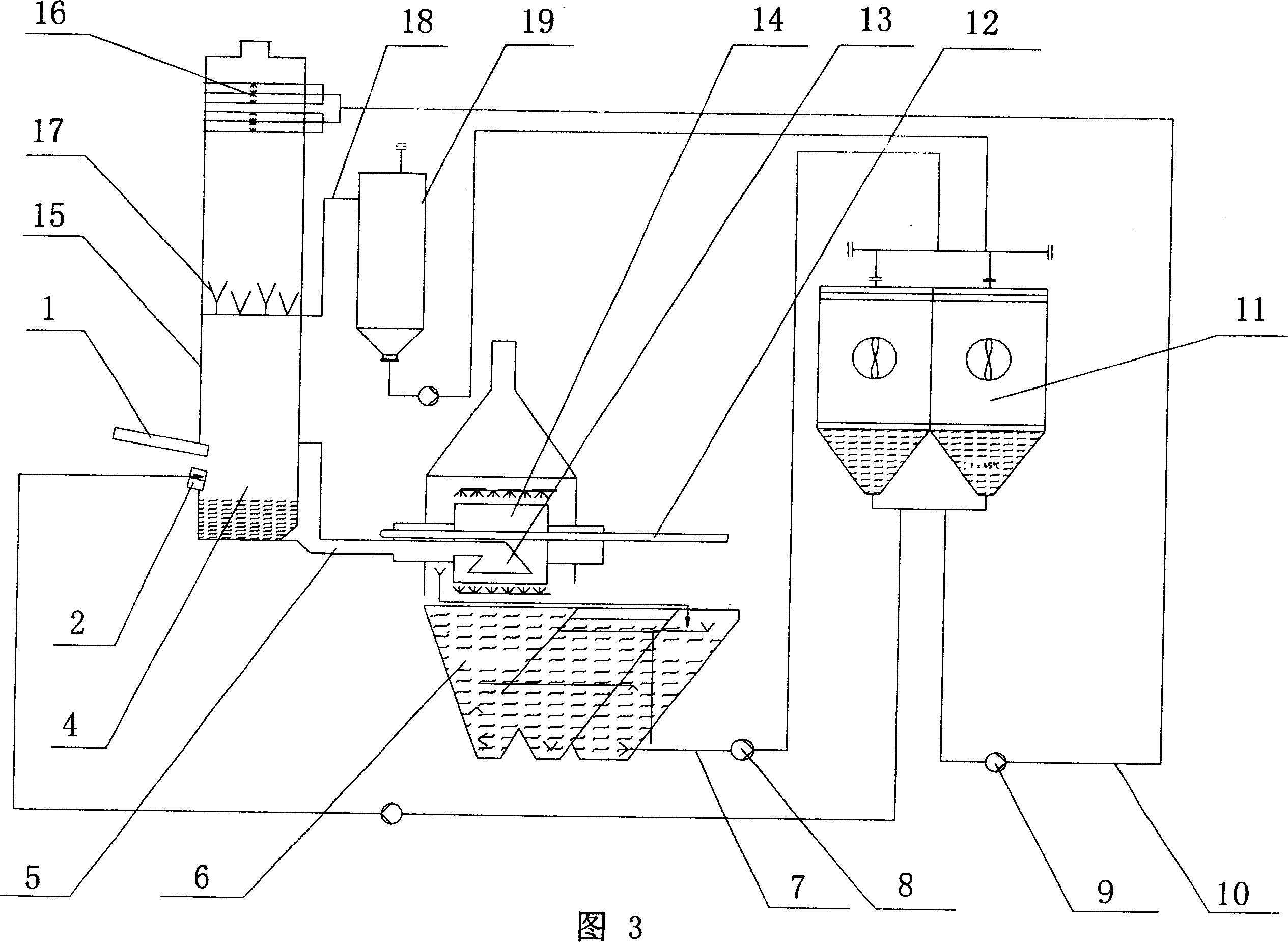

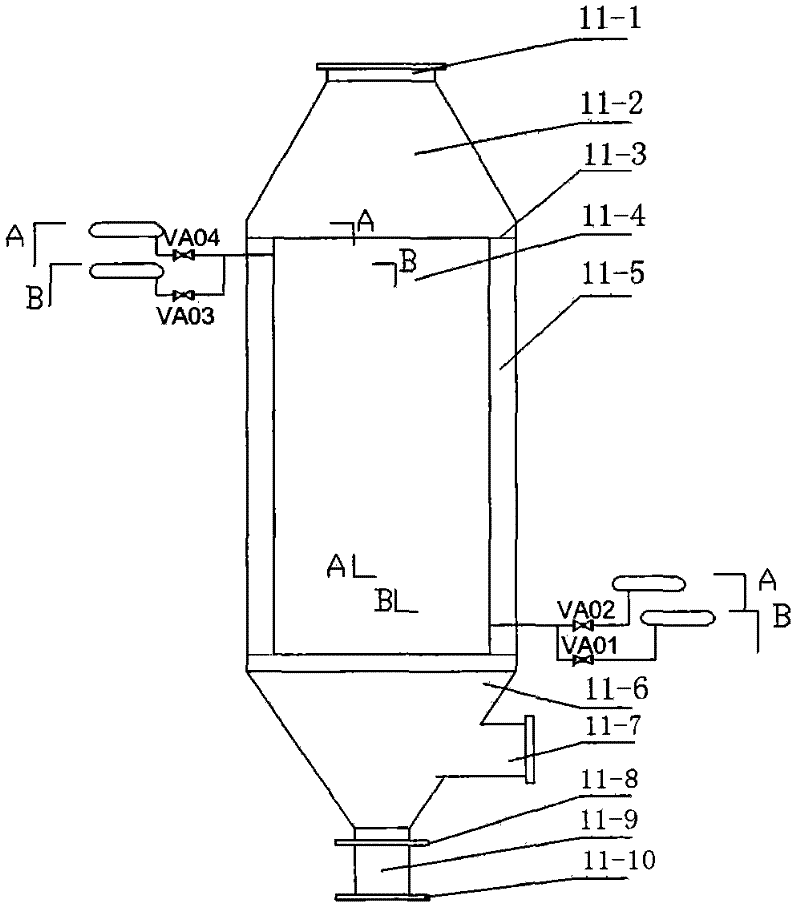

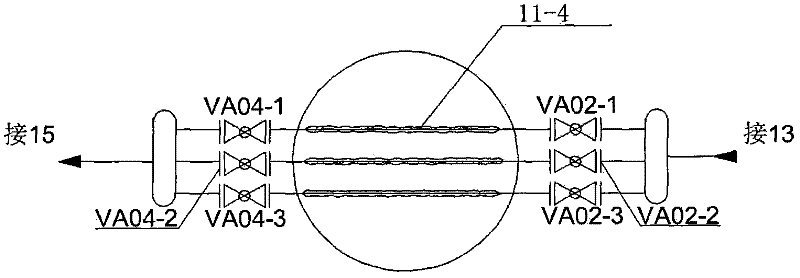

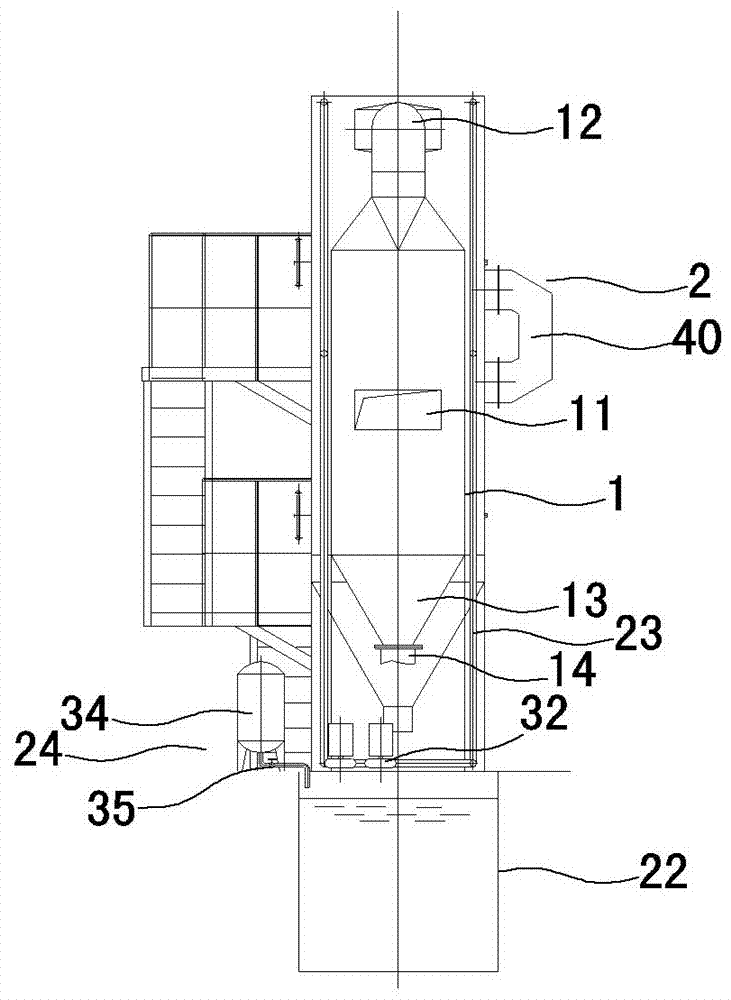

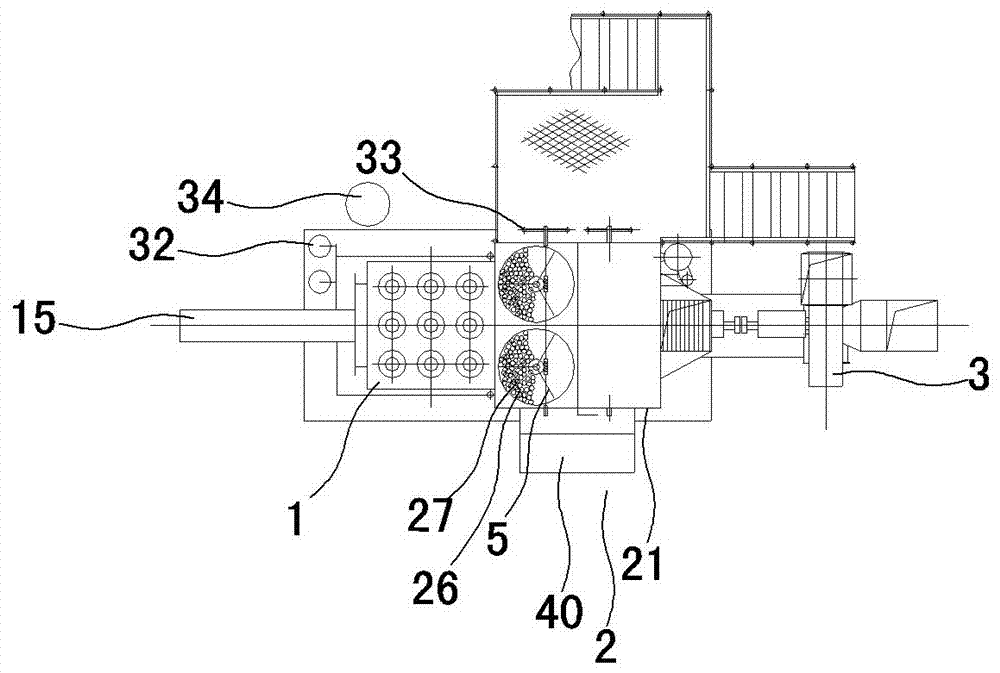

Shield construction muck treatment system and method

ActiveCN110303033AAchieve graded solid-liquid separationReduce transport volumeSievingConstruction waste recoveryEngineeringSlurry

The invention relates to the technical field of shield construction muck treatment, in particular to a shield construction muck treatment system and method. The muck generated by shield construction is crushed and stirred by a crushing and stirring device and then enters a primary-stage double-layer vibrating screen, oversize products are discharged out of the system, undersize products enter a sieve cone tank, the sieve cone tank is connected with a swirler through a pump, an intermediate tank is connected to an overflow port of the swirler, a discharge port of the intermediate tank is connected to an overflow tank through a pipeline, the slurry in the overflow tank is pumped to a flocculation tower through a pump, the flocculation tower is connected with an automatic dosing device, a flocculation medicament is pumped into the flocculation tower, the slurry in the flocculation tower is pumped to a filter press through a pump, drying mud cake treatment is carried out through the filterpress, the treated clear water flows into a clear water tank for reutilization, the dried mud cake is discharged out of the system, so that classified solid-liquid separation of different particle size components and water in the shield muck is realized, reutilization of inorganic raw materials and water resources of the shield muck is formed, and huge economic benefits are generated while the social resources are saved.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

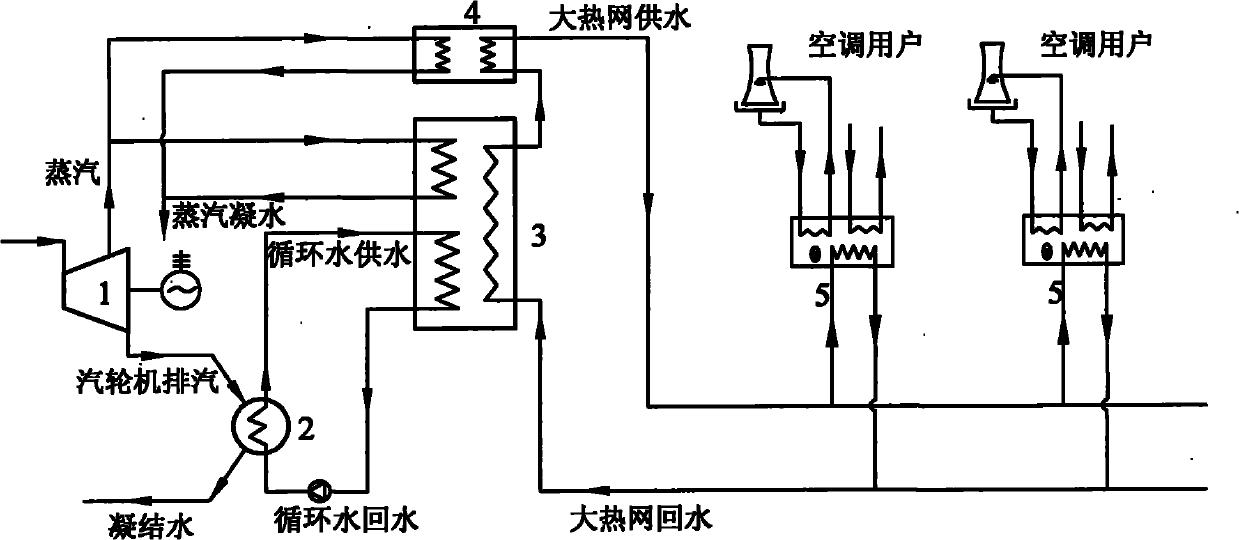

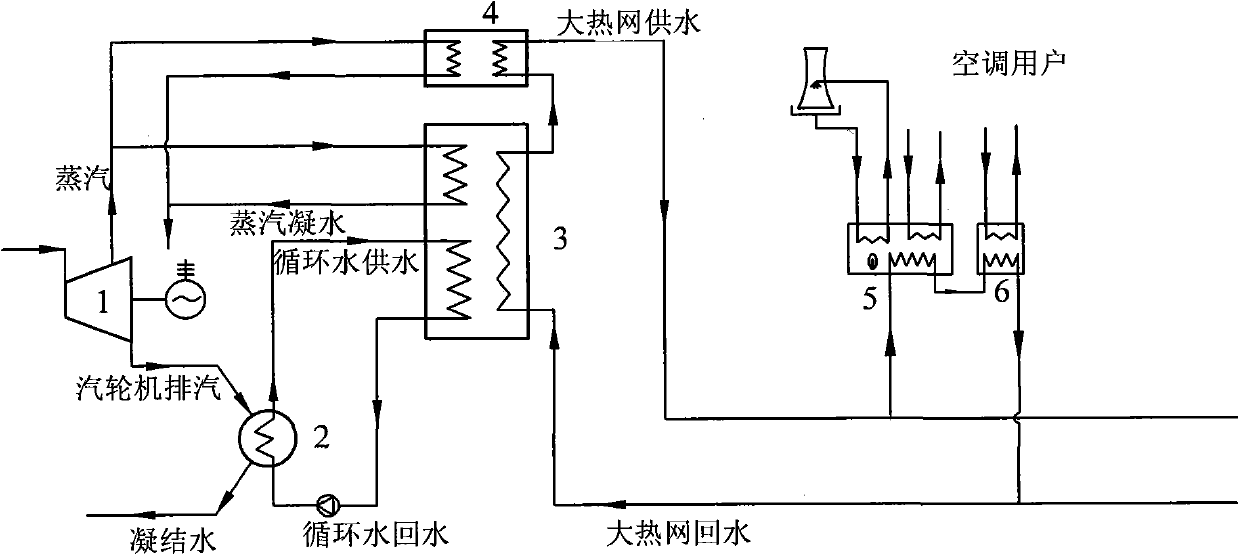

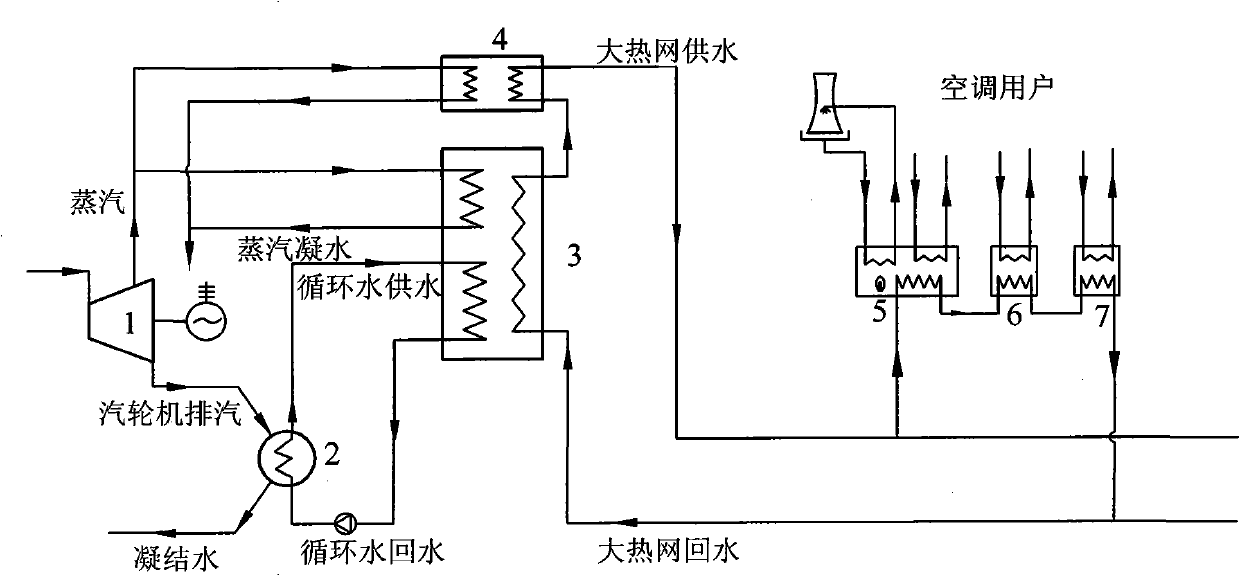

Cooling mode driven by utilizing urban heat supply network

InactiveCN101949612AIncrease heat loadCut power peaksClimate change adaptationSteam useNuclear engineeringWater supply

The invention discloses a cooling mode driven by utilizing an urban heat supply network, which belongs to the technical field of cooling modes. In the mode, hot water of the heat supply network is utilized to drive an absorption refrigerator and a solution dehumidifier to cool and dehumidify the place of a user; meanwhile, the water of the heat supply network after driving the cooling and the dehumidification can be used for preheating domestic hot water and further recharging the heat to the underground through a buried pipe so as to gradually reduce the backwater temperature of the heat supply network, and the heat recharged to the underground can be extracted for heat supply in winter. In a power plant, a mode of the combination heating of a condenser, a steam absorption heat pump and a steam-water heat exchanger is adopted to realize the gradual heating of the backwater of the heat supply network. Compared with the conventional distributed cooling mode and centralized cold water supply mode, the mode can utilize spare urban heat supply network resource in a refrigeration season, increase the heat load of a thermal power plant, recycle the waste heat of the circulating water of the power plant, and facilitate cutting down a power peak due to air conditioning load and even saving power.

Owner:TSINGHUA UNIV +1

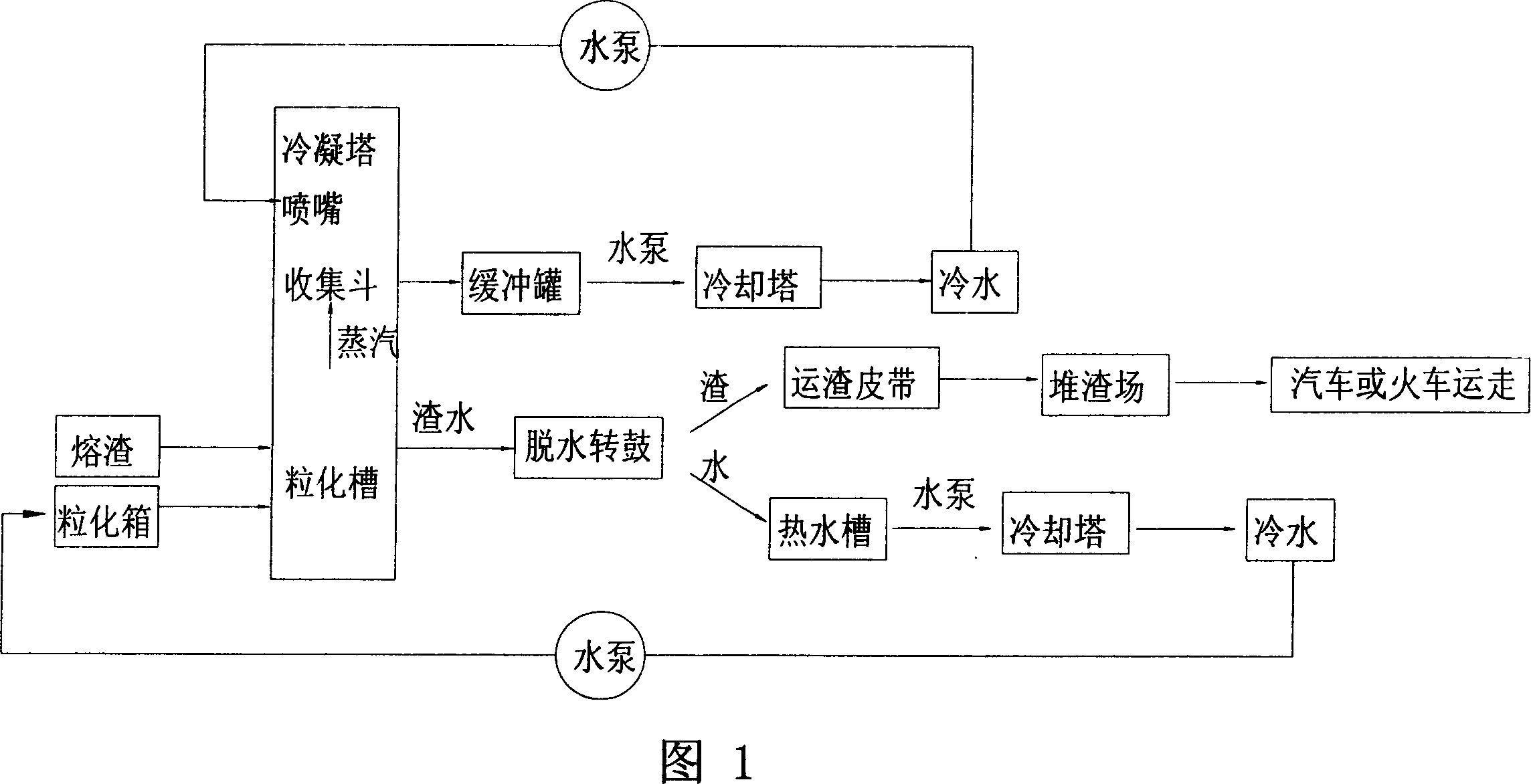

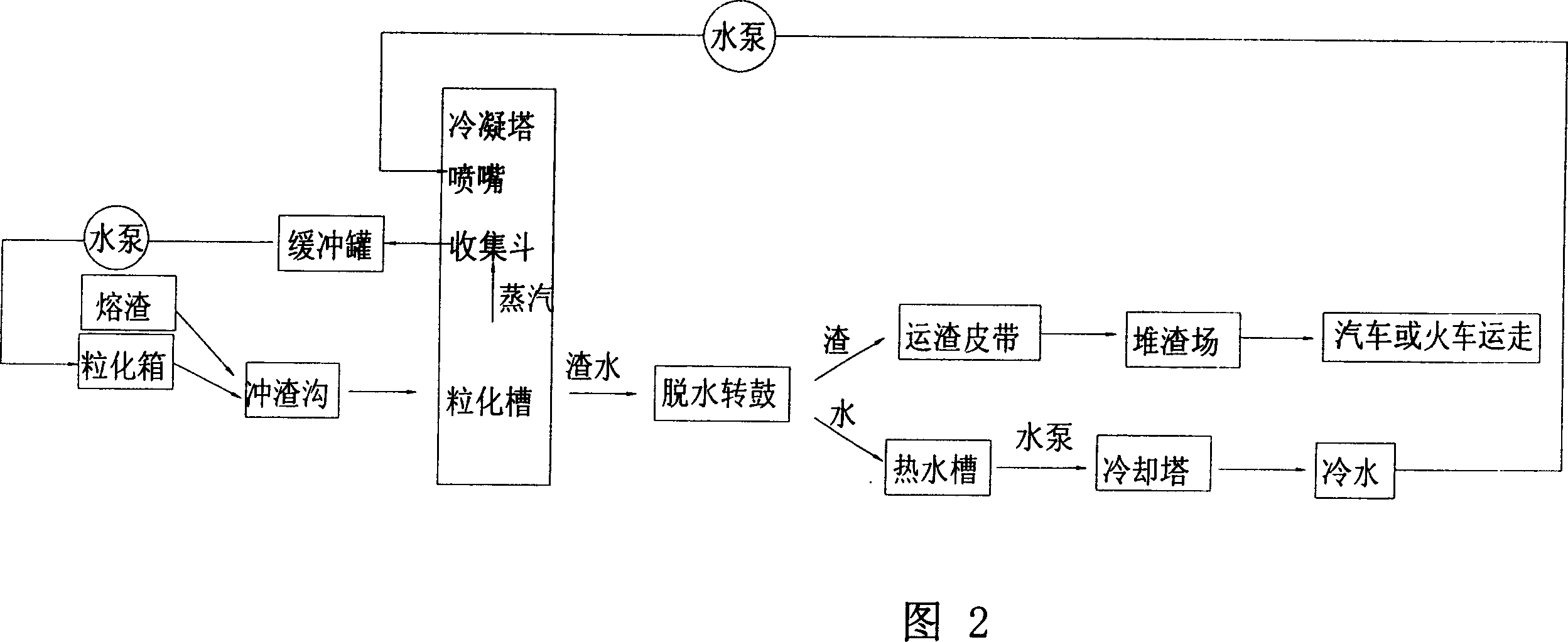

Environment friendly blast furnace slag treating process and system

InactiveCN1986836AImprove protectionReduce trafficRecycling and recovery technologiesCooling towerSteam condensation

The present invention is environment friendly blast furnace slag treating process and system. The blast furnace slag treating process includes water quenching the red slag for fast cooling with the granulating tank sprayed cooling water and collecting in the collecting pipeline; conveying to the distributor of dewatering drum and separating into water granulated slag falling to the belt conveyer for being transported to the slag yard and filtered hot water; collecting hot water, pumping to cooling tower for cooling and condensing through the atomizing nozzle in the condensing tower; and collecting the condensated water and returning through the third water pipe, the buffering tank and the fourth water pipe to the granulating tank for reuse. The present invention has the advantages of simple system composition, environment friendship, low power consumption, etc.

Owner:WISDRI ENG & RES INC LTD

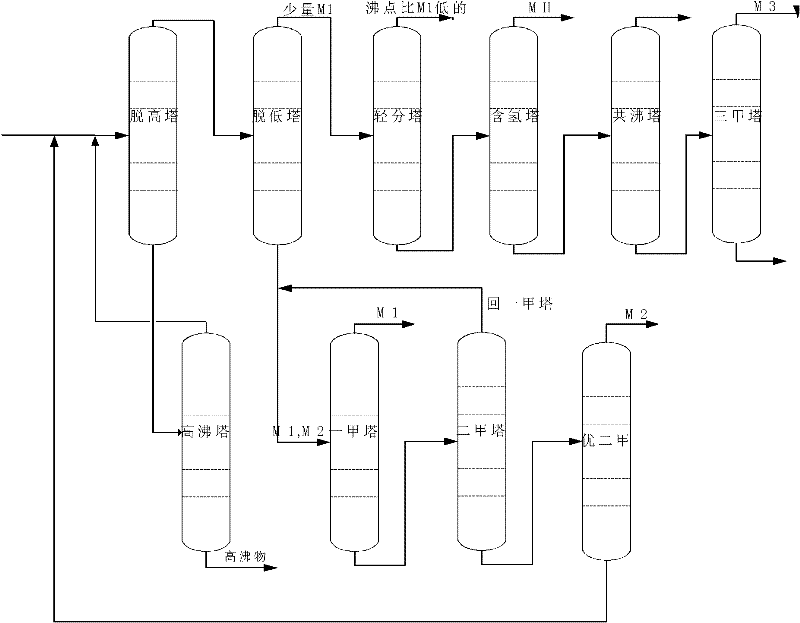

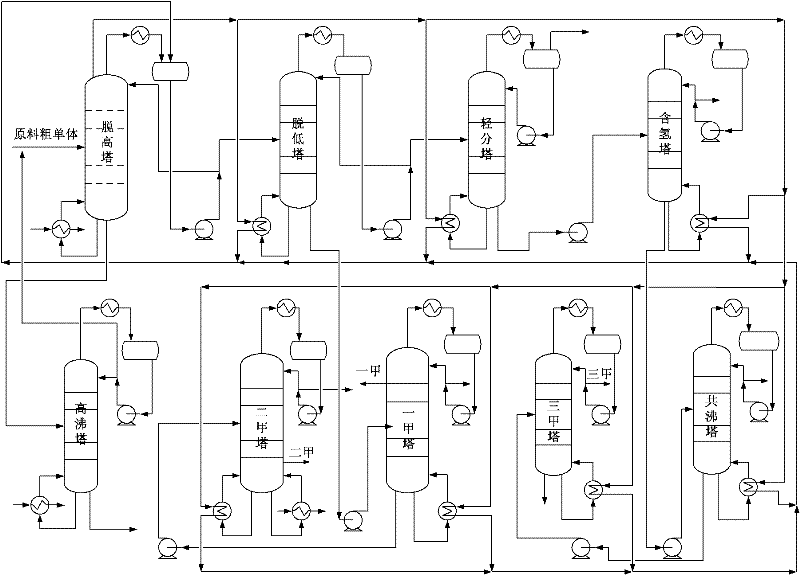

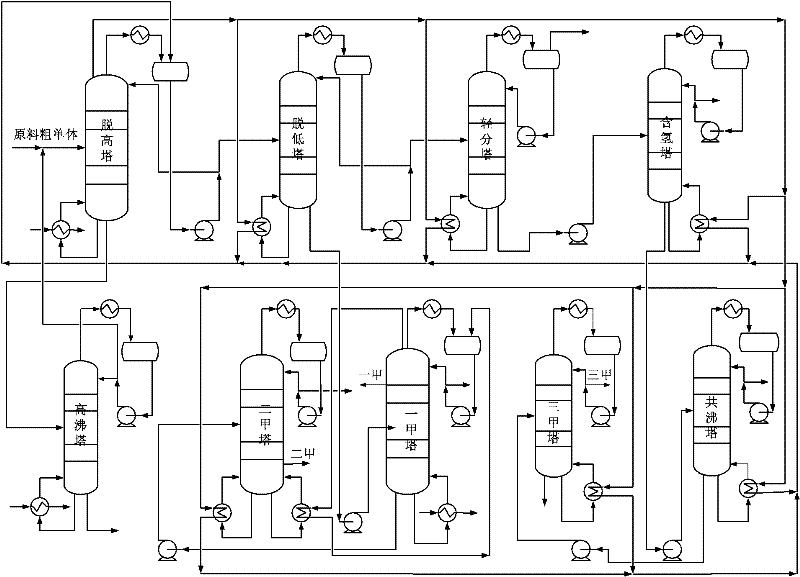

Energy-saving water-saving organic silicon monomer rectifying method

ActiveCN101798322AImprove operational safetyIncrease operating pressureSilicon organic compoundsChemical industryWater vaporReboiler

The invention discloses an energy-saving water-saving organic silicon monomer rectifying method which adopts a cis cleavage multi-tower flow. In the rectifying method, the tower top material steam of a high-boiling component removing tower firstly enters a main distribution manifold, then heat is respectively supplied for tower bottom reboilers of a low-boiling component removing tower, a light component removing tower, a hydrogenous tower, an azeotropic tower, a trimethylchlorosilane separating tower, a methyl trichloro silicane separating tower and a dimethyldichlorosilane separating tower through the main distribution manifold, the tower top material steam of the high-boiling component removing tower after heat supply is condensed into liquid, is then cooled to the reflux temperature through an air cooler and enters a tower top reflux tank of the high-boiling component removing tower, a second reboiler is connected with the tower bottom of the dimethyldichlorosilane separating tower, and vapor is adopted for the heat exchange of the reboiler. By adopting the method, because the operating pressure and the operating temperature of the high-boiling component removing tower and the methyl trichloro silicane separating tower with larger cooling quantity requirements are increased, at least two towers in the flow have the condition of adopting air cooling, thereby reducing the circulating water quantity and decreasing the evaporation loss; and the energy-saving water-saving organic silicon monomer rectifying method has strong operation controllability, flexible mode, multiple control means, smaller pressure increasing amplitude and high operation security.

Owner:TIANJIN UNIV

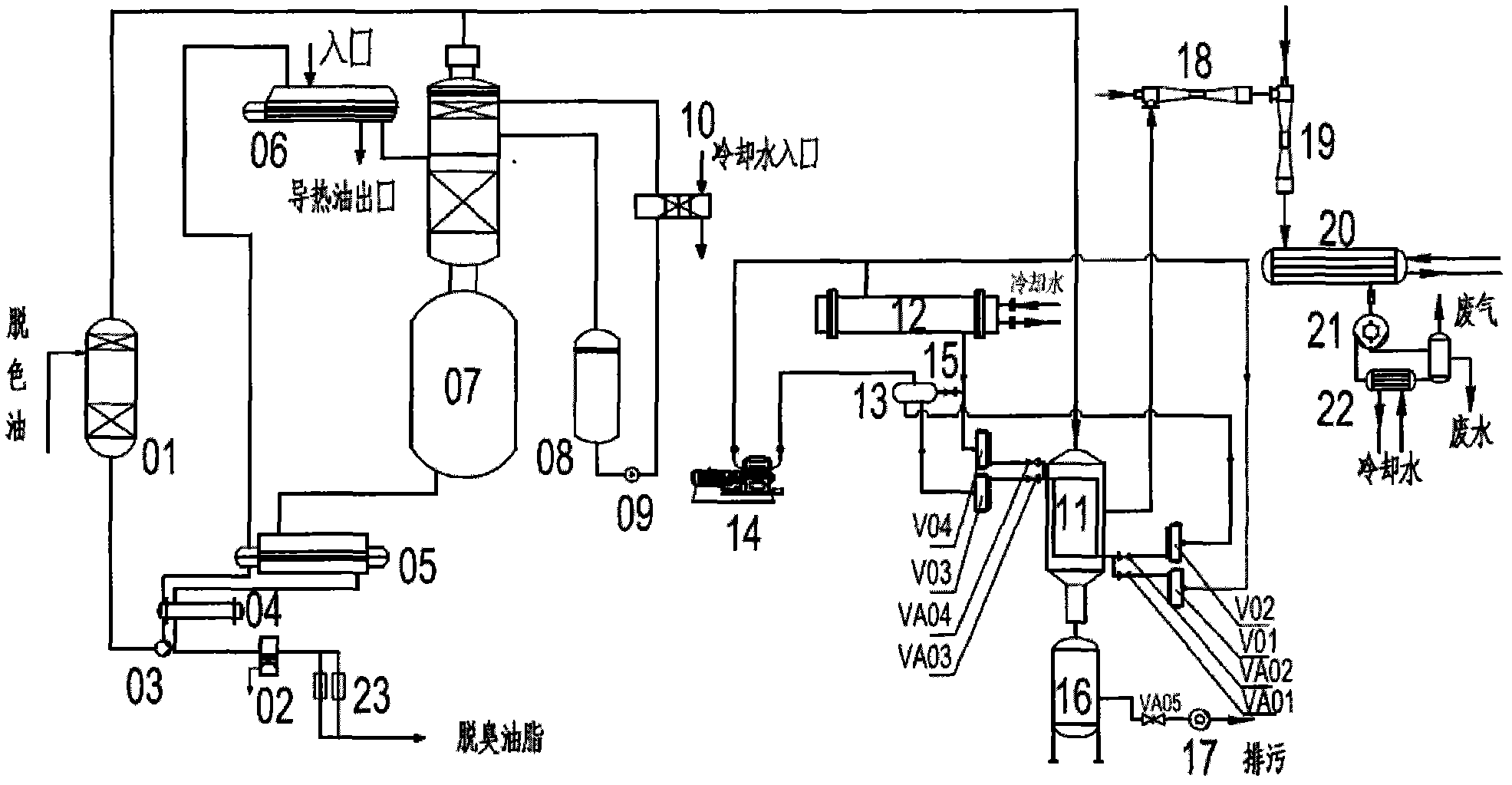

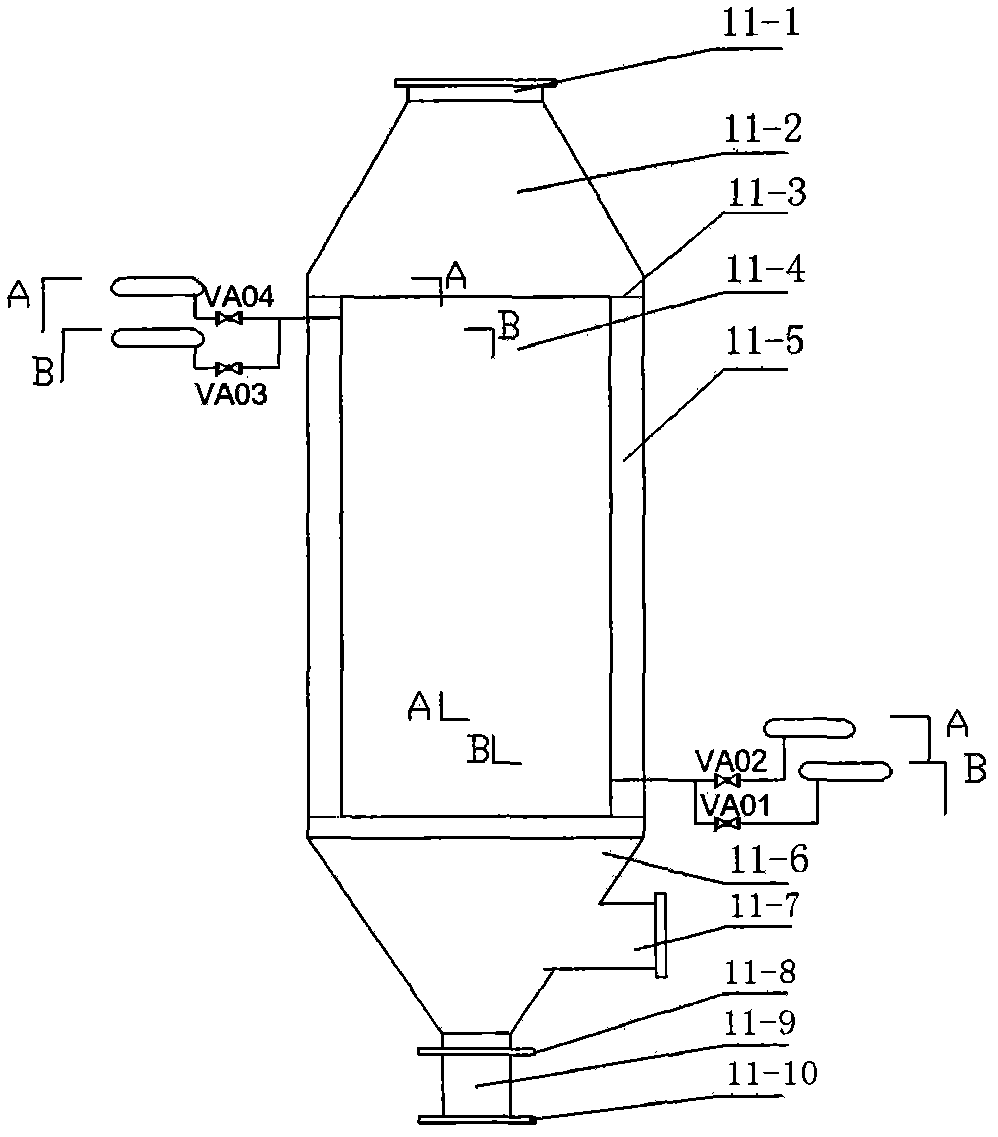

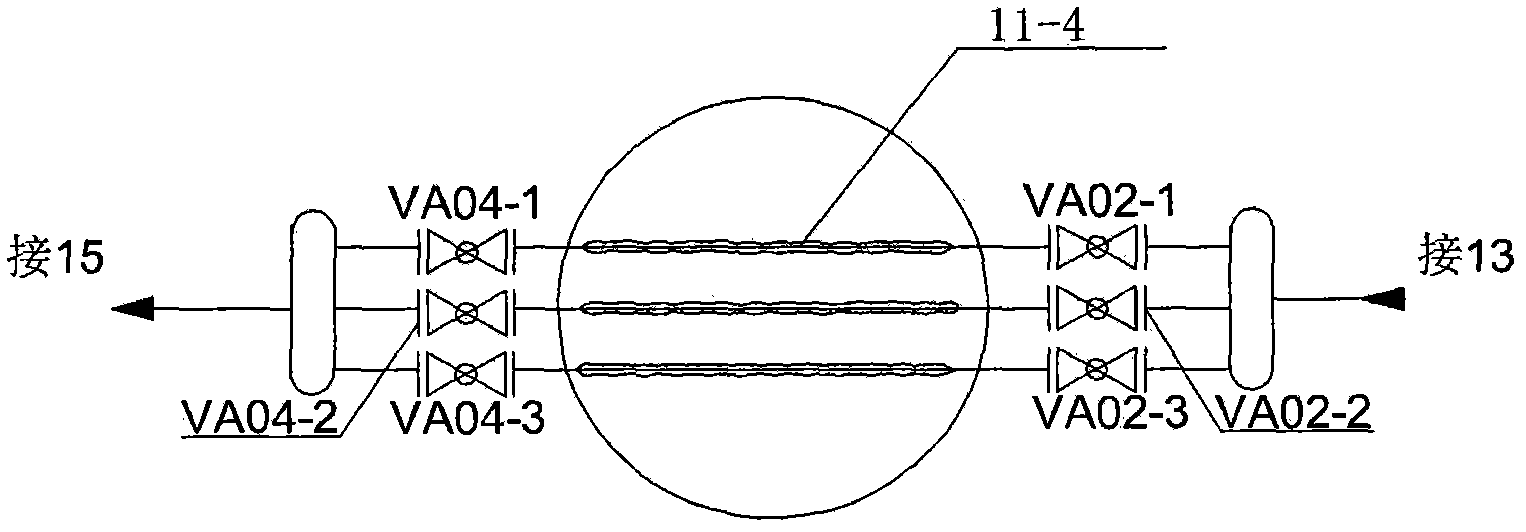

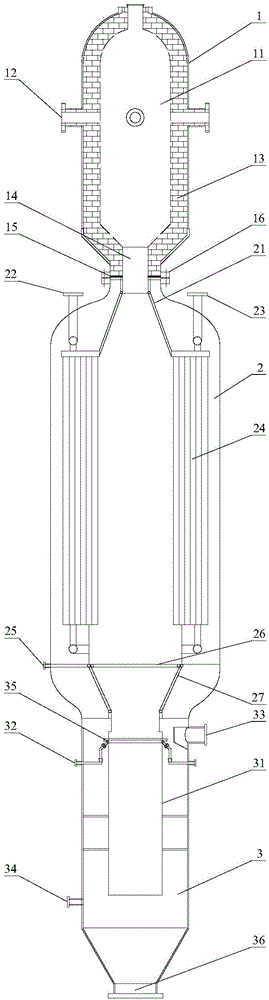

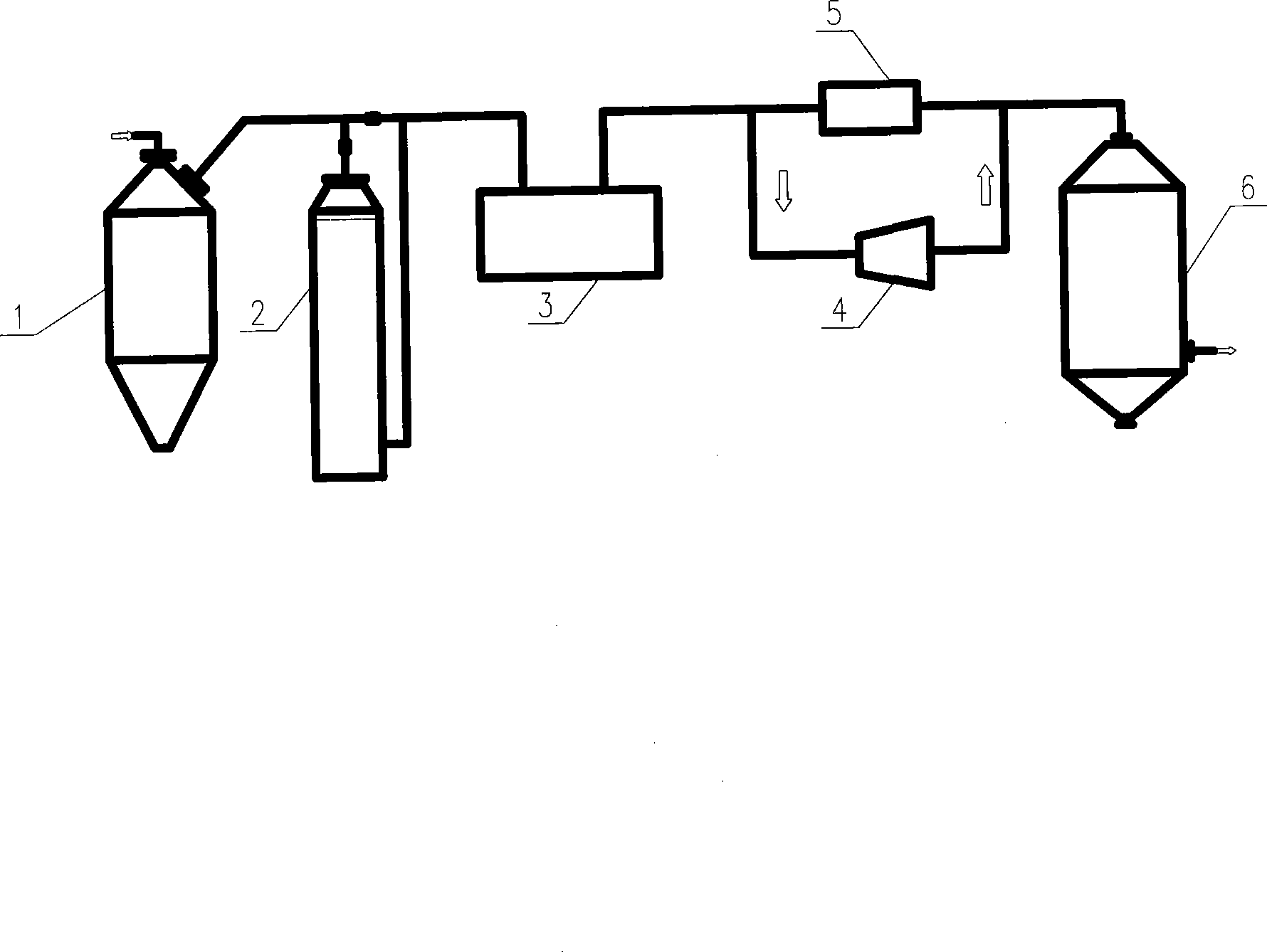

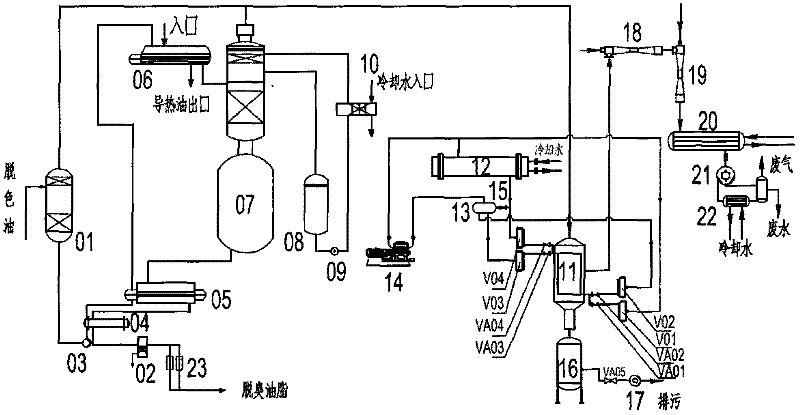

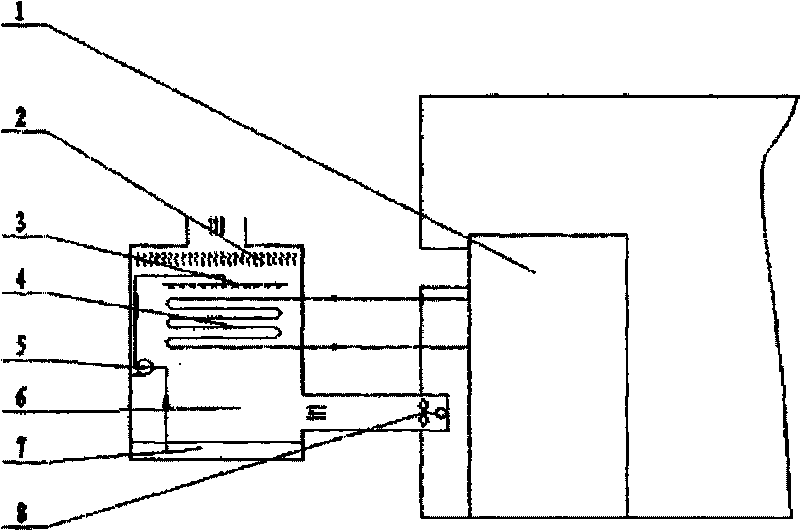

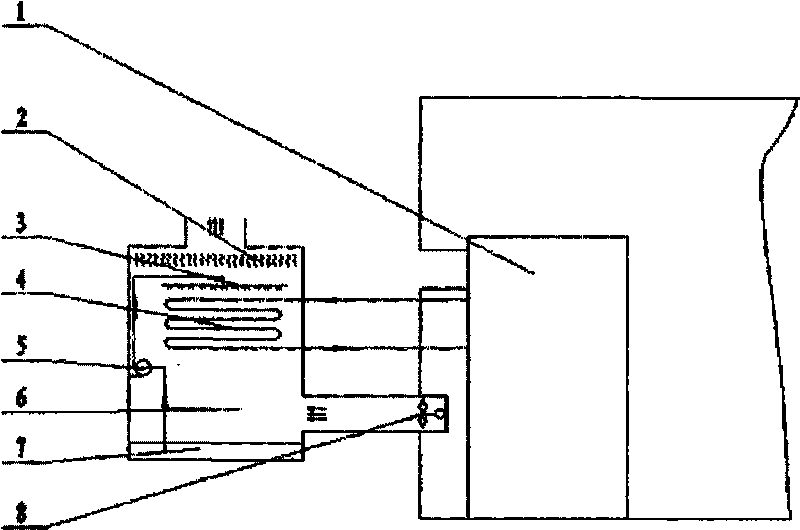

Freeze-condensing vacuum deodorizing method and equipment for fat and oil

The invention relates to a freeze-condensing vacuum deodorizing method for fat and oil. The method is characterized by comprising the following steps of: 1) preparing; 2) performing gassing to remove oxygen; 3) heating; 4) deodorizing; 5) cooling; and 6) freezing, trapping and melting. Equipment using the method is characterized by comprising the following units of: (1) a gassing unit; (2) a heating unit; (3) a deodorizing unit; (4) a fatty acid trapping unit; (5) a vacuum refrigeration unit; (6) a rear vacuum pump unit; and (7) a defrosting unit. When the method and the equipment are used for performing fat and oil deodorizing production, the method and the equipment have the advantages of greatly reducing heating energy, greatly reducing the using amount of injecting steam and the using amount of cooling water and improving production efficiency. Moreover, sealing treatment is performed on a system and no waste gas is discharged, so the method and the equipment also have the advantages of energy conservation, emission reduction, sanitation and environmental protection.

Owner:中机康元粮油装备(北京)有限公司

Chilling process gasifier with high-temperature heat recovery unit

InactiveCN104629807AMeet the requirements of the transformationApplicableEnergy inputCombined combustion mitigationCombustion chamberCooling chamber

The invention discloses a chilling process gasifier with a high-temperature heat recovery unit, which comprises an upper gasification / combustion chamber, a middle radiation waste pot with high-temperature heat recovery function and a bottom washing and cooling chamber, wherein the top of the gasification / combustion chamber furnace body or a certain plane on the periphery of the furnace body or a plurality of planes is / are provided with one or a plurality of nozzles; the radiation waste pot is composed of a flange connected with the gasification / combustion chamber, an interface water cooling coil pipe, a single-channel water cooling wall, a water cooling coil pipe connected with the washing and cooling chamber, and the like; the washing and cooling chamber is mainly composed of a chilling water ring and a down pipe; and the upper part of the side surface of the washing and cooling chamber is provided with a synthetic gas outlet. The chilling process gasifier can enhance the adaptability to coal types, effectively recovers the high-position sensible heat of the gasification product, and is suitable for a process unit for preparing synthetic gas and an integral coal gasification combined cycle generation system. Compared with the traditional waste-pot process gasifier, the chilling process gasifier is simpler in structure and convenient for manufacturing and maintenance, and has higher popularization and application values.

Owner:EAST CHINA UNIV OF SCI & TECH

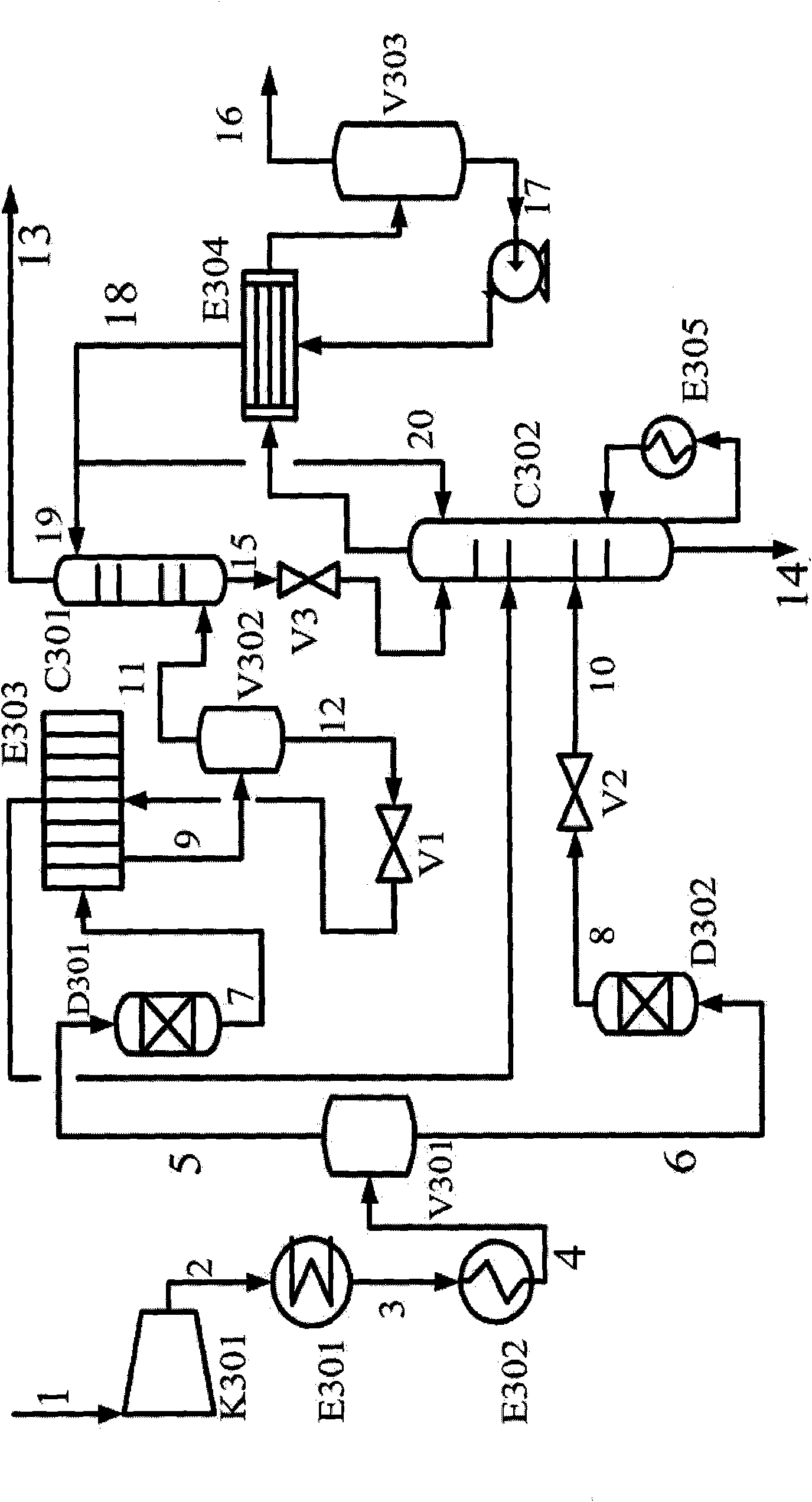

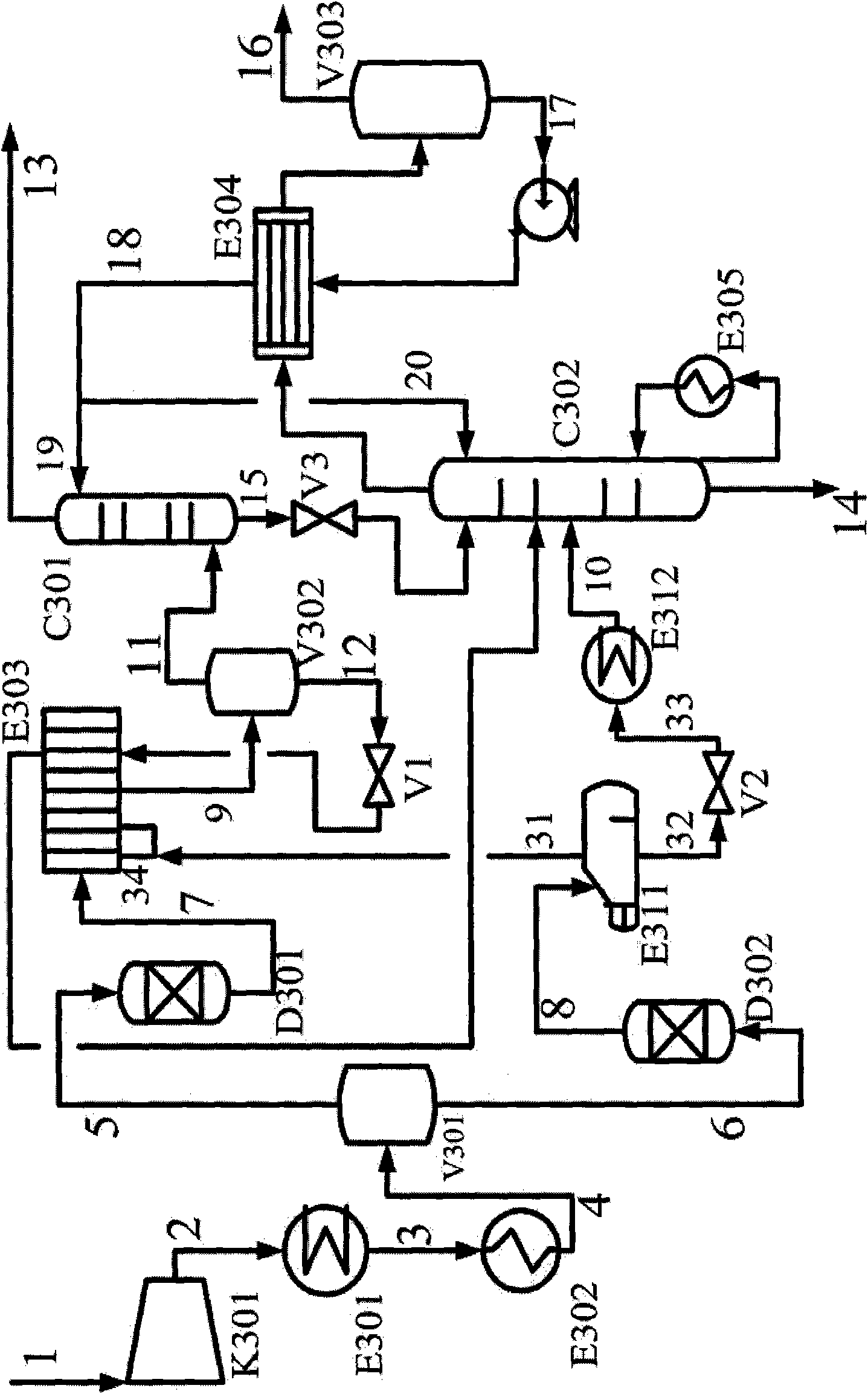

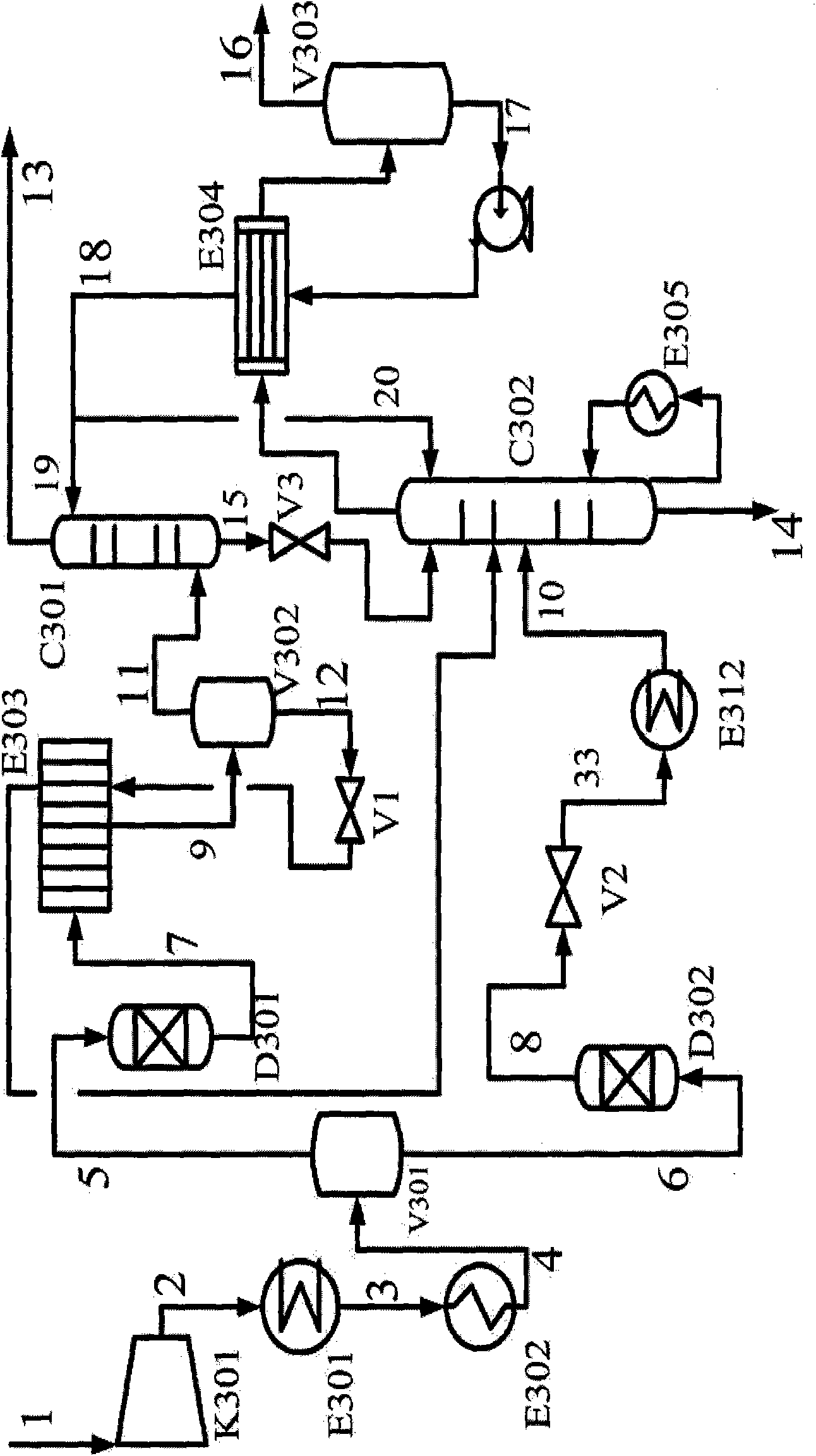

Front-end deethanizing separation process method for ethylene device

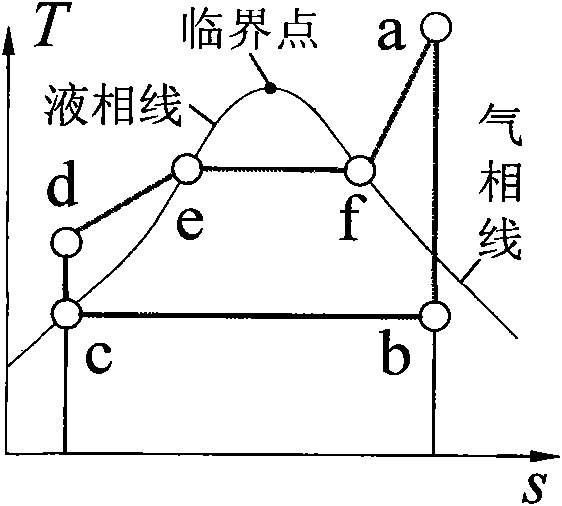

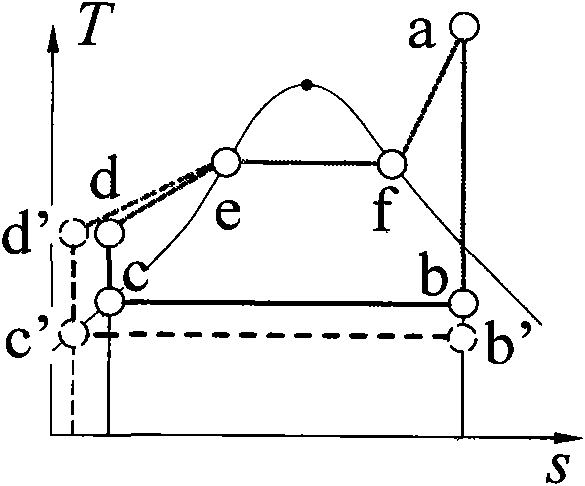

ActiveCN101967077ASave coolingReduce consumptionHydrocarbon purification/separationHydrocarbonsReboilerGas phase

The invention relates to a front-end deethanizing separation process method for an ethylene device. Liquid phase material flow from pyrolysis gas condensate drier is heated for evaporating in a condensate preheater by using chilled water at the evaporating temperature of between 25 and 35 DEG C, a small amount of evaporated gaseous phase material flow containing hydrogen, methane and carbon-2-components is merged with gaseous phase material flow formed by part of pre-cooled gaseous phase pyrolysis gas at the temperature of between -10 DEG C and -12 DEG C which flows into a plate heat exchanger directly from the pyrolysis gas drier, and the mixed material flow is conveyed to the plate heat exchanger to be pre-cooled; and after being subjected to throttling through a valve under the reducedpressure, condensate material flow from the bottom of the condensate preheater is heated again in the condensate heater by using the chilled water, and gas-liquid phase material flow at the temperature of between 45 and 65 DEG C is conveyed to the middle part of a deethanizing tower. Through the method, the low-pressure steam consumption of a reboiler at the tower bottom of the low-pressure deethanizing tower is reduced, the circulating water volume of the cooling chilled water is reduced, and the comprehensive energy consumption of ethylene per ton produced by the ethylene device is reduced by 125 to 190 MJ.

Owner:PETROCHINA CO LTD

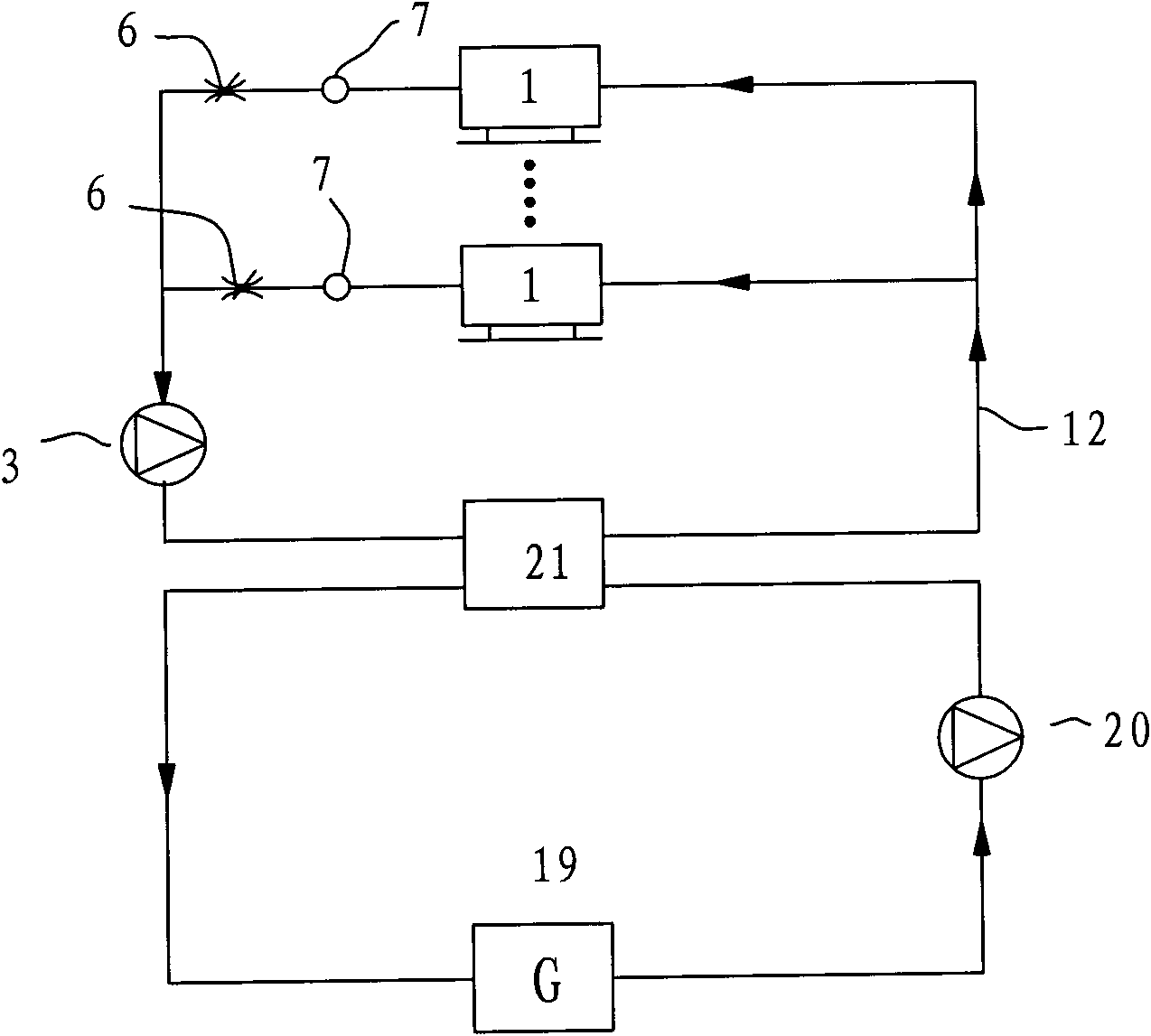

Air-conditioning system and control method thereof

InactiveCN101660815AReduce loadReduce operating frequencySpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerFrequency conversion

The invention discloses an air-conditioning system and a control method thereof. The air-conditioning system comprises a controller, a frequency converter, a circulating pump, a cold water machine set, a hot water machine set and a coil pipe blower group of each user end, wherein the controller is provided with a frequency-conversion protecting device used for refrigeration; the frequency converter is used for controlling the working frequency of the circulating pump; the circulating pump, the cold water machine set, the hot water machine set and the coil pipe blower group of each user end arepositioned on a circulating water loop, the coil pipe blower groups are respectively connected and arranged on the circulating water loop in parallel, a flow rate automatic balance adjusting valve and a temperature sensor which outputs a temperature signal to the flow rate automatic balance adjusting valve are respectively arranged on the connection pipelines of the coil pipe blower groups, the temperature signal output by the temperature sensor is used for switching the maximum flow rate setting value of the flow rate automatic balance adjusting valve under a refrigeration mode and a heatingmode, the controller controls the constancy of the temperature difference of an inlet and an outlet of the cold water machine set or the hot water machine set by adjusting the working frequency of the circulating pump, and the frequency-conversion protecting device used for refrigeration is switched to a bypass under the heating mode. The invention can correspondingly adjust the frequency of thecirculating pump according to the load change of the system, save energy, lower consumption and control the flow rate in the circulating loop accurately.

Owner:谭仲禧 +1

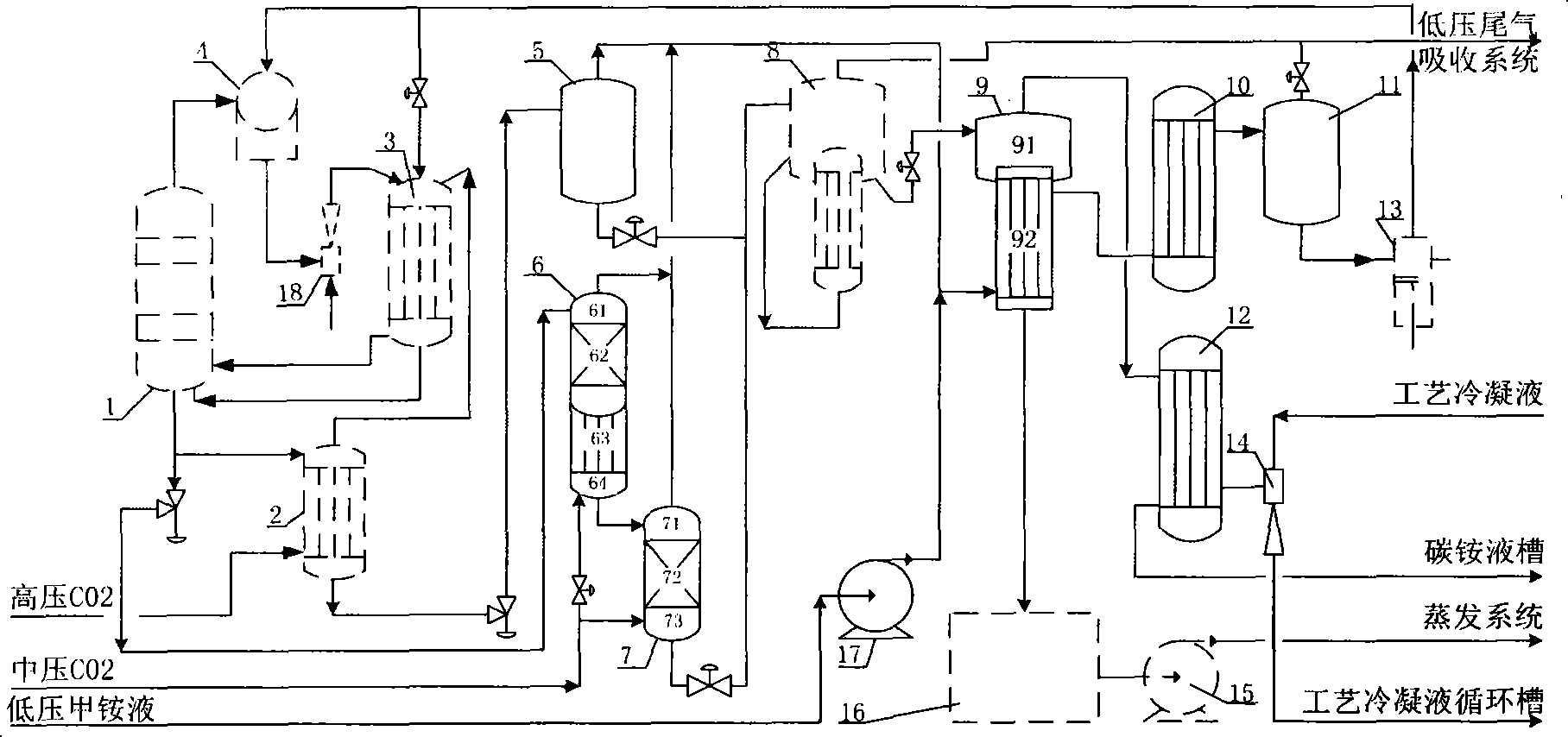

CO2 gas-striping parallel /serial connection medium-pressure urea energy-saving and yield-increasing novel technology

ActiveCN103819365AThe effect of increasing production is obviousGood energy saving effectUrea derivatives preparationOrganic compound preparationUreaDecomposition

The invention provides a CO2 gas-stripping parallel / serial connection medium-pressure urea energy-saving and yield-increasing novel technology. The conventional CO2 gas-stripping urea technology equipment is parallelly connected to a medium-pressure decomposition system, is serially connected to a medium-pressure pre-separator and an evaporation pre-condensation system, and is added with a medium-pressure methylamine recycling system. In a urea synthesis tower, materials are divided into two parts according to a certain ratio, one part of the materials is transported to the medium-pressure decomposition system and is subjected to processes of flash separation, liquid rectification, thermal decomposition, and CO2 air stripping; the other part of the materials is discharged from a CO2 stripping tower, then is decompressed, and finally is subjected to flash separation in the medium-pressure pre-separator; the urine in the medium-pressure system is decompressed and then transported to a low-pressure rectification tower; the medium-pressure decomposition gas phase and the low-pressure methylamine are mixed and transported to the heat utilization section shell pass of an evaporation pre-condensation device, and the urine in the tube pass is heated to evaporate and thus is condensed by utilizing the heat generated by bubbling reactions. The CO2 air-stripping parallel / serial connection medium-pressure urea energy-saving and yield-increasing novel technology can increase the production capacity by 30 to 60% or more compared to that of original CO2 air-stripping urea device, and has the advantages of simple technology process, convenient operation control, reduction on steam and electricity consumption, and high reconstruction investment profit.

Owner:王庆锋 +1

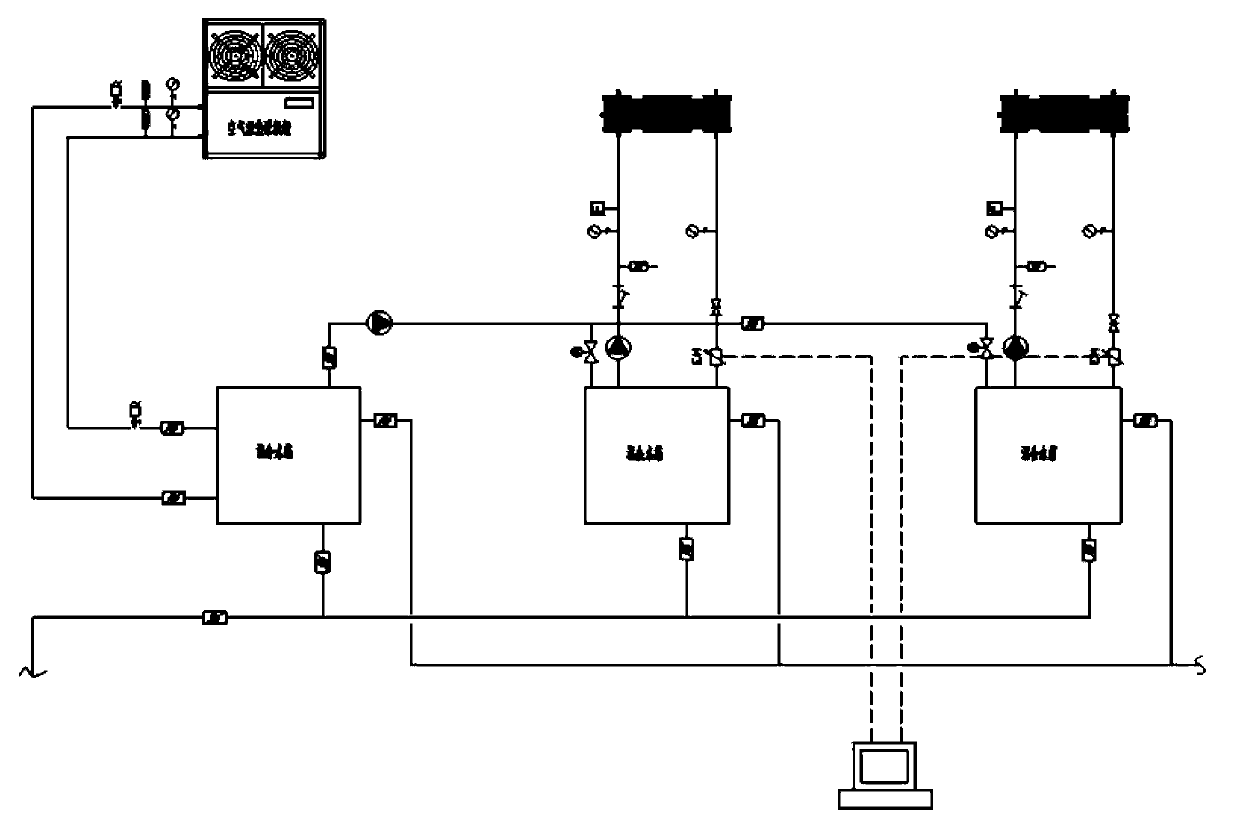

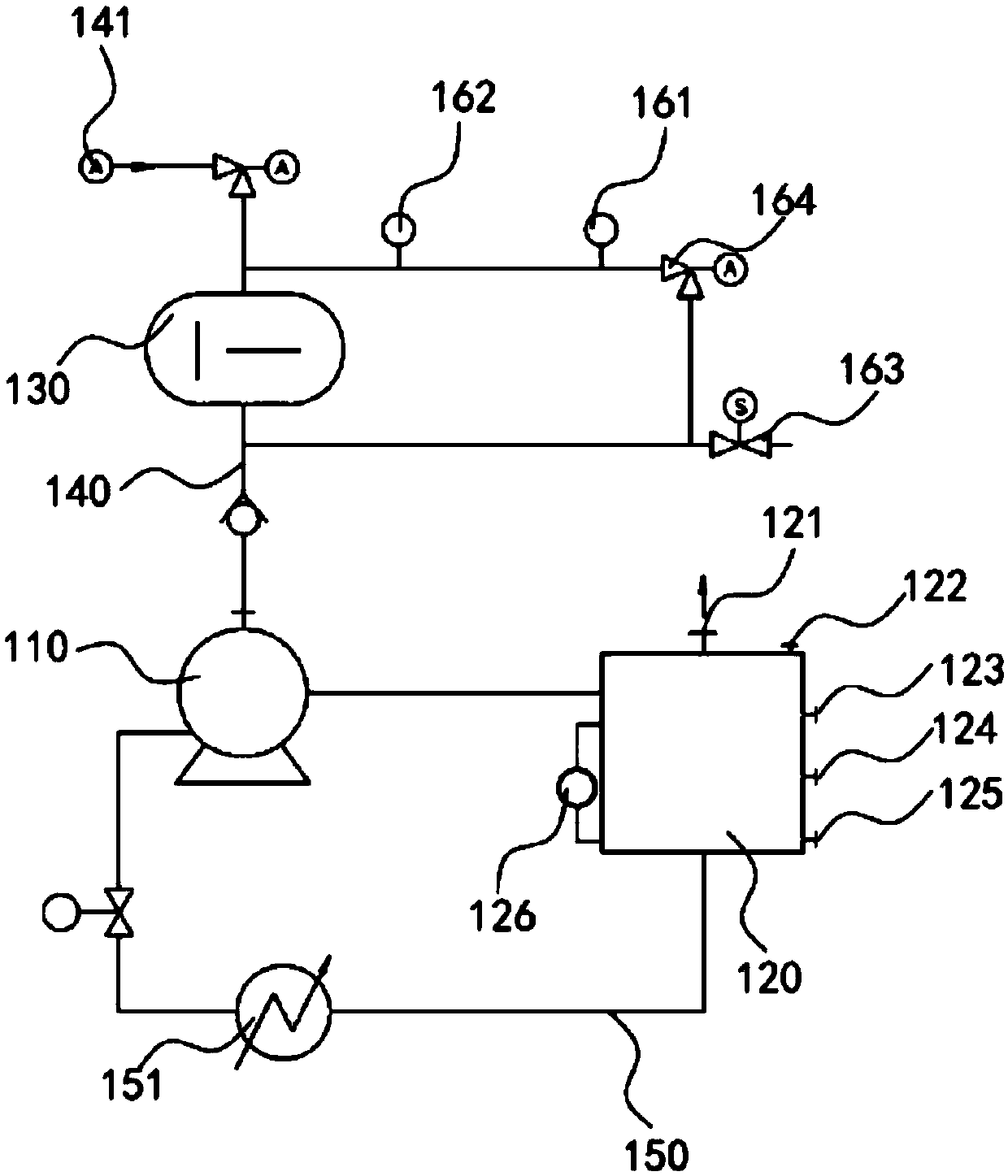

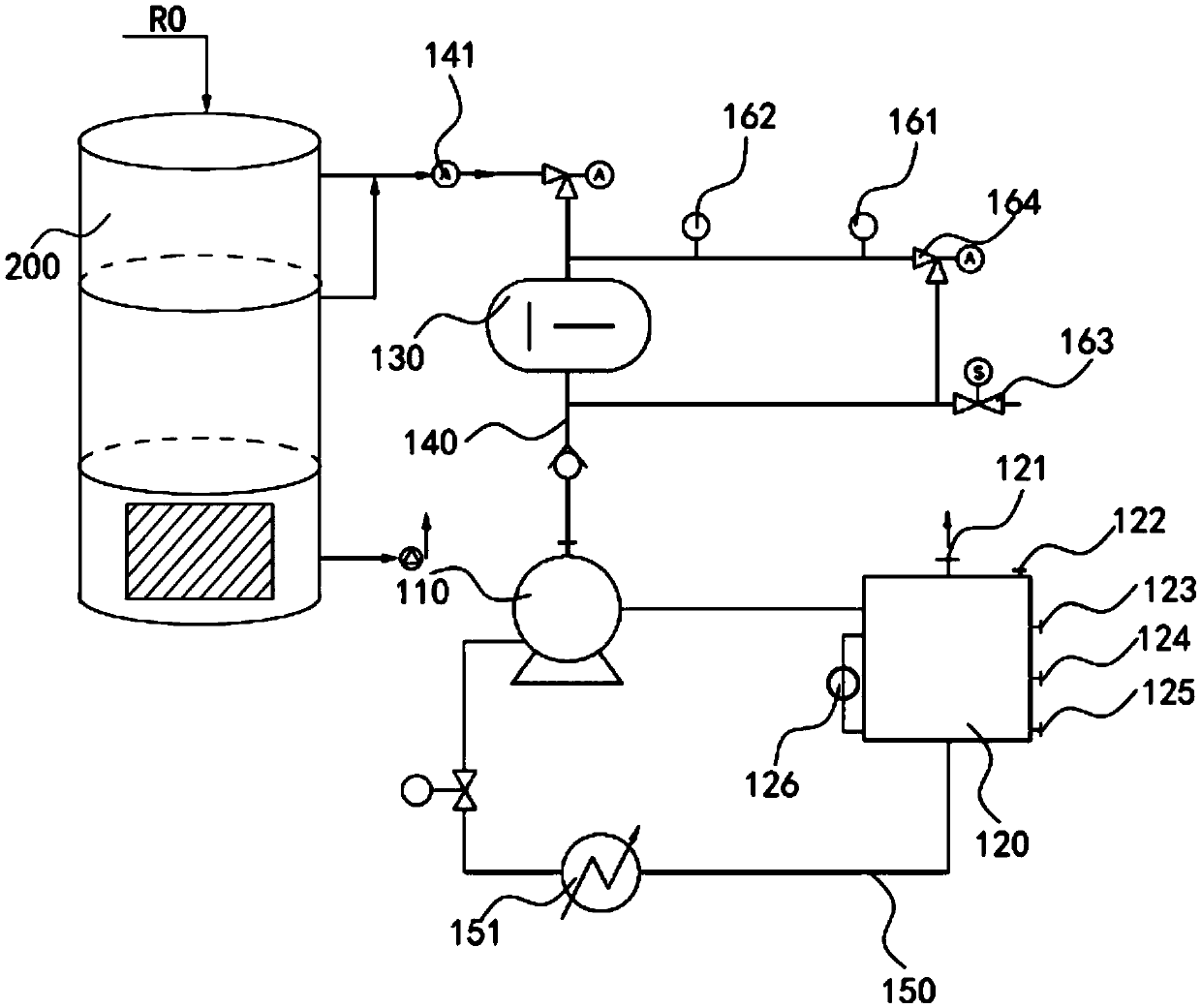

Device for testing energy-saving water source heat pump performance coefficients

InactiveCN102998132ASmall sizeSimple structureStructural/machines measurementWater source heat pumpWater circulation

The invention discloses a device for testing energy-saving water source heat pump performance coefficients. The device comprised a tested unit, a cold water circulation loop, a hot water circulation loop, a mixed water circulation loop and a compensation loop, an evaporator of the tested unit is connected with the cold water circulation loop through a soft connector, a condenser of the tested unit is connected with the hot water circulation loop through a soft connector, and the mixed water circulation loop exchanges heat with the cold water circulation loop and the hot water circulation loop respectively. The device adopts plate-type heat exchangers to respectively replace a hot water tank and a cold water tank, size of a test board is reduced, and the test board is simple and compact in structure. Circulation water quantity is substantially reduced, the temperature of water in cold (hot) plate exchange loops is rapidly achieve needed temperature, time for pre-heating or pre-cooling circulating water is reduced, and accordingly consumption of electrical energy is greatly reduced, and a purpose of saving energy is achieved.

Owner:WUXI INST OF COMMERCE

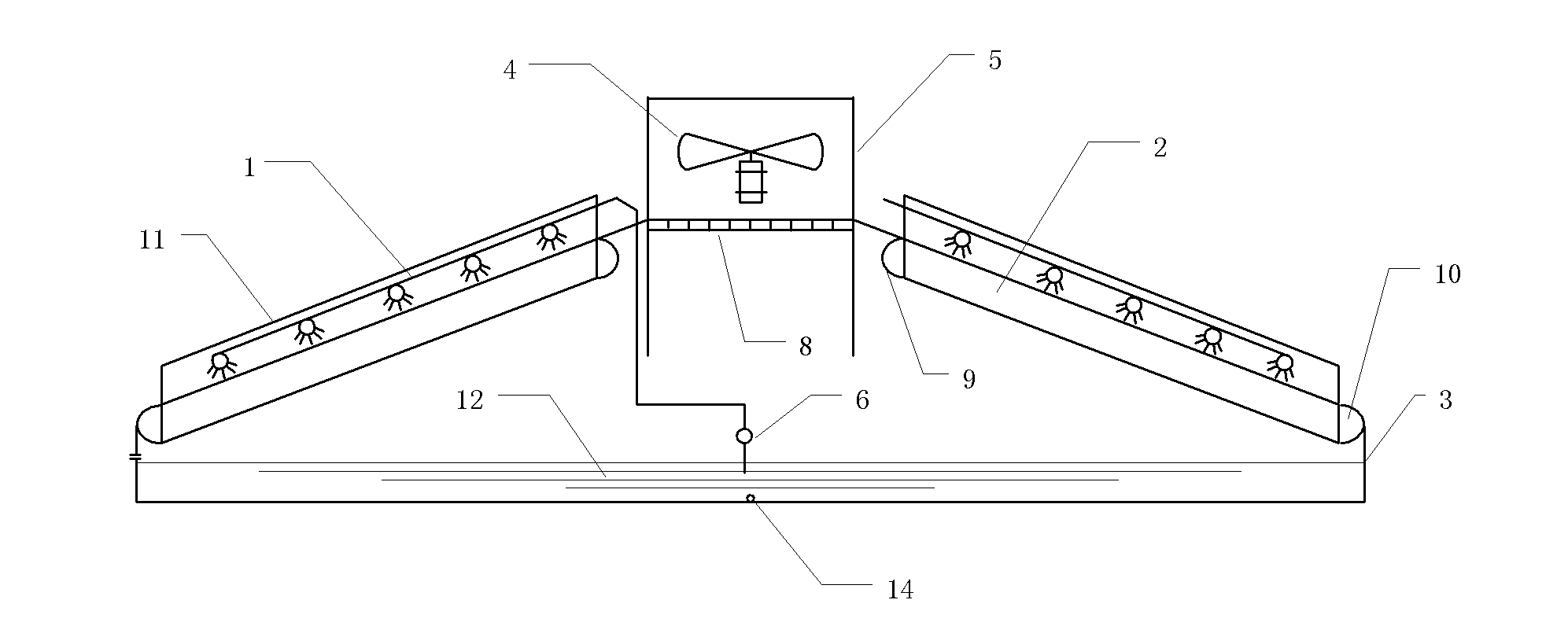

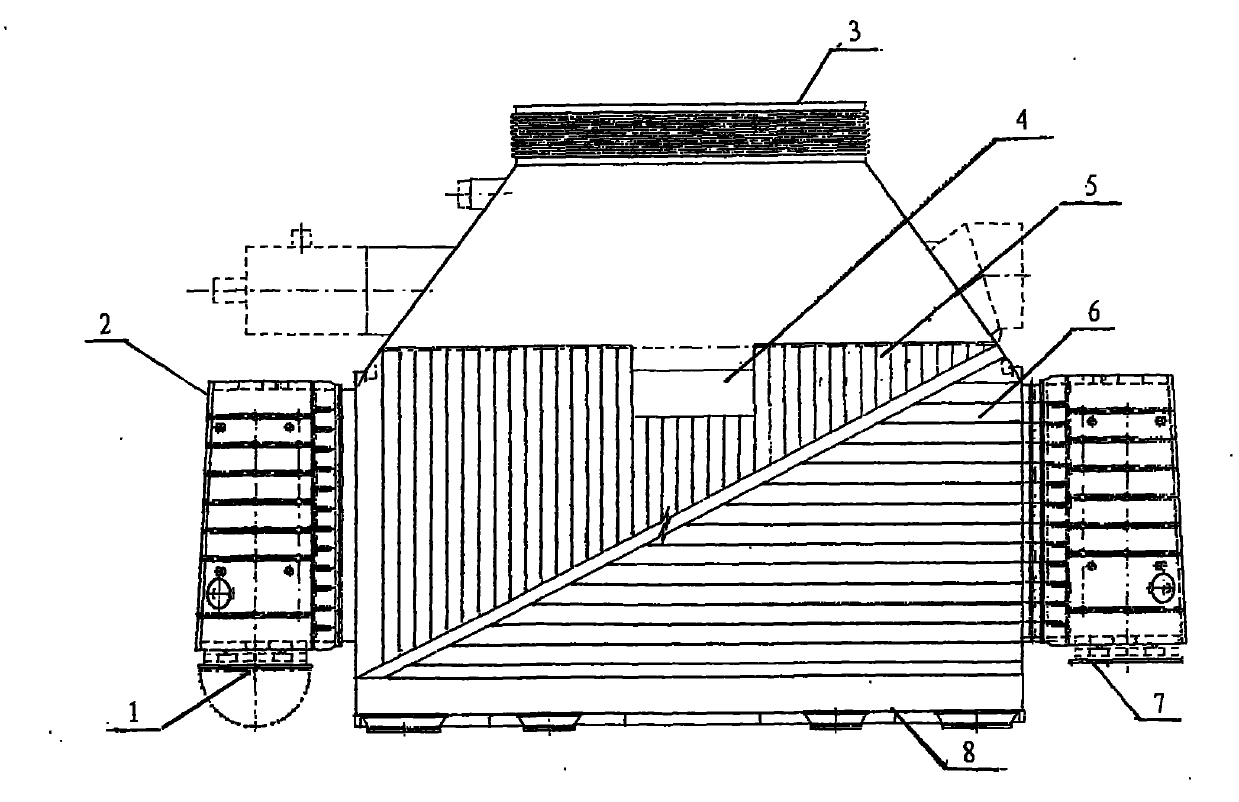

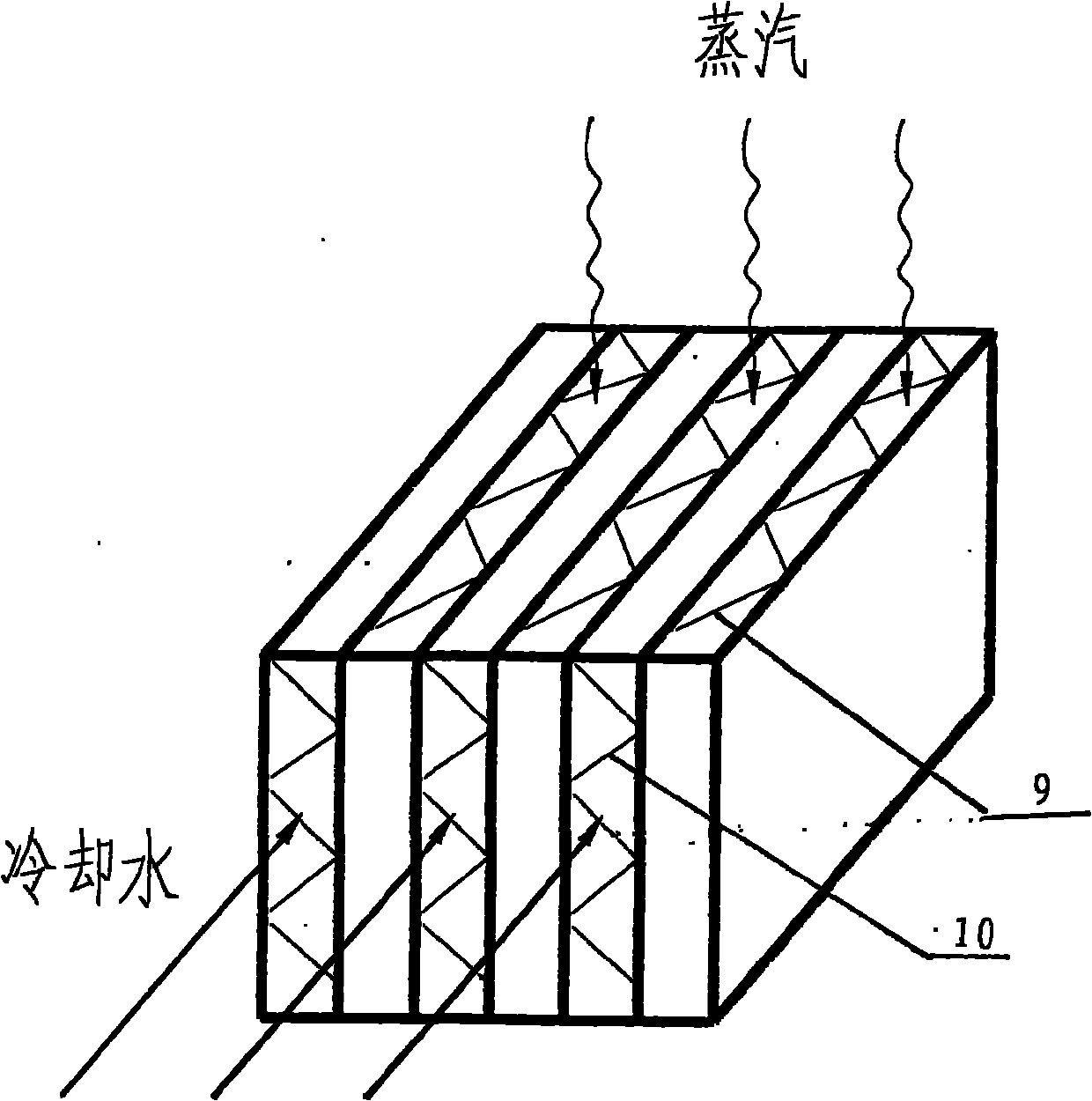

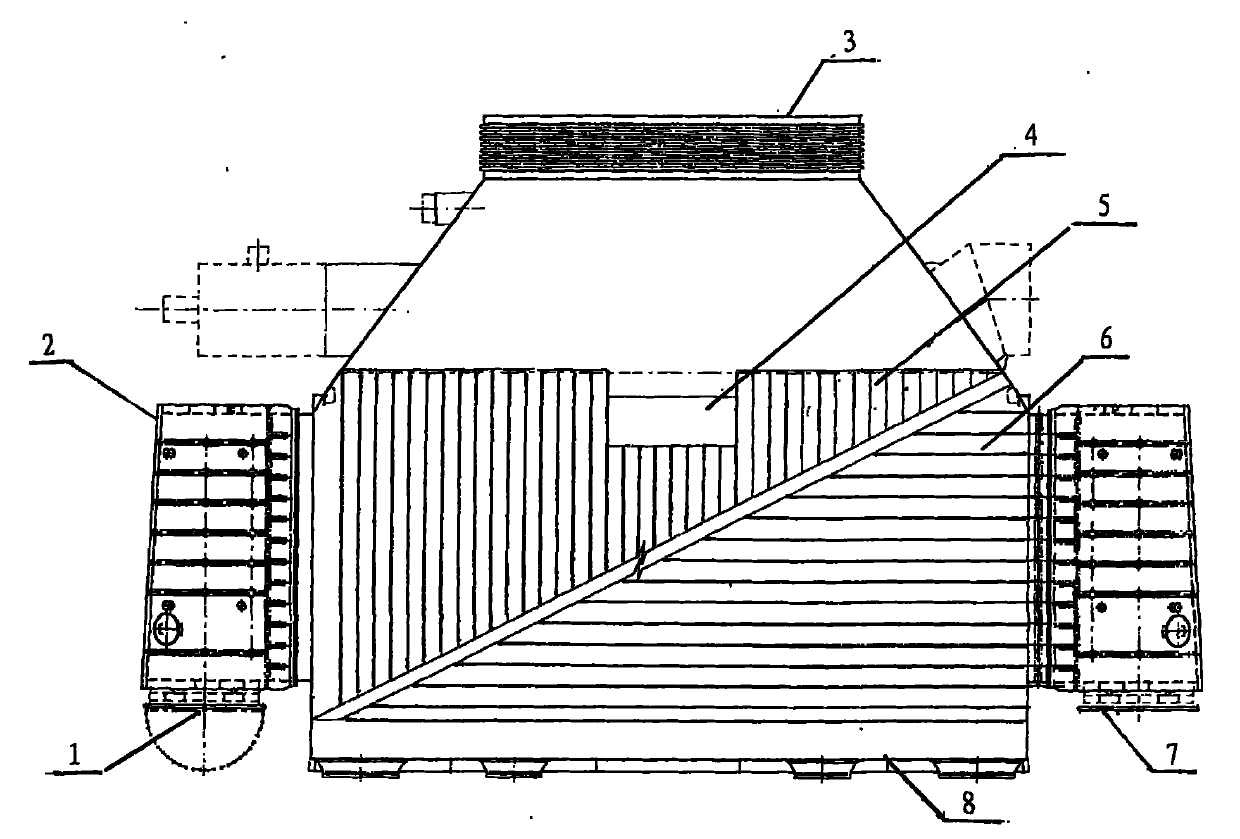

Plate type evaporation air-cooling condenser with obliquely-arranged heat exchange plate bundles

InactiveCN102425957ALow water quality requirementsReduce the impactSteam/vapor condensersHeat transmissionEvaporation

The invention relates to a plate type evaporation air-cooling condenser, in particular to a plate type evaporation air-cooling condenser with obliquely-arranged heat exchange plate bundles. The condenser comprises spraying devices, the heat exchange plate bundles, a box, a fan, an air exhaust barrel and a circulating water pump, wherein the air exhaust barrel is arranged on the top of the box; two groups of heat exchange plate bundles are arranged downwards on the box on the two sides of the air exhaust barrel respectively; an angle of between 110 and 130 DEG is formed between the two groups of heat exchange plate bundles; the upper end and the lower end of each group of heat exchange plate bundles are provided with an upper connecting box and a lower connecting box respectively; the upper connecting boxes and the lower connecting boxes are used as steam inlets and condensed water outlets respectively; the upper sides of the two groups of heat exchange plate bundles are provided with a group of spraying devices respectively; the lower ends of the lower connecting boxes are connected with the box; the fan is arranged in the air exhaust barrel; and the upper end of the circulating water pump is connected with the spraying devices, and the lower end of the circulating water pump is extended to the bottom of the box. The condenser has the advantages of high heat transmission efficiency, energy conservation, small occupied area and the like; and the heat exchange plate bundles are obliquely arranged, so that condensed water is convenient to discharge, thermal resistance is reduced, heat transmission is enhanced, a counter current area is convenient to form, and non-condensed gas is discharged.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

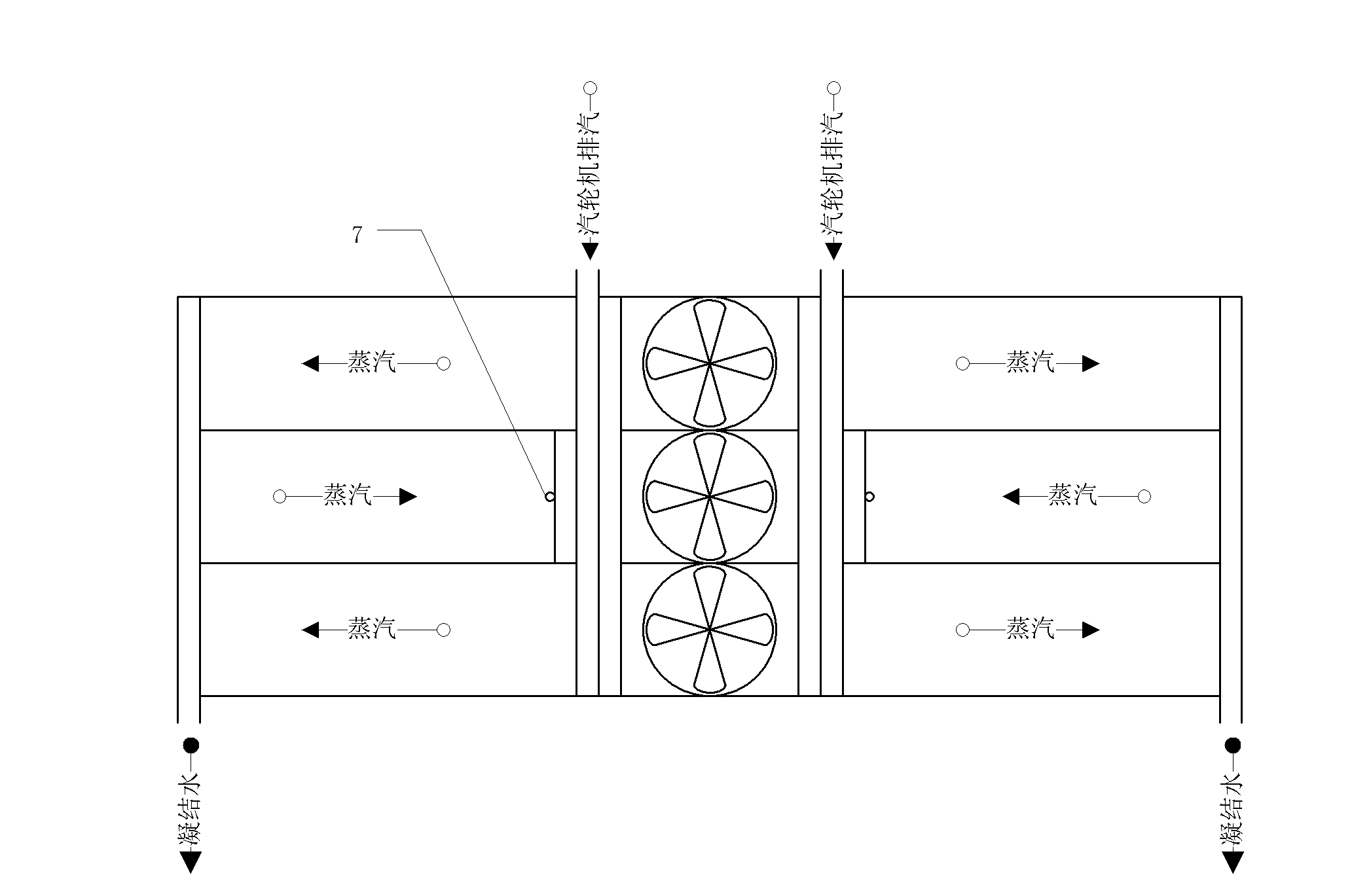

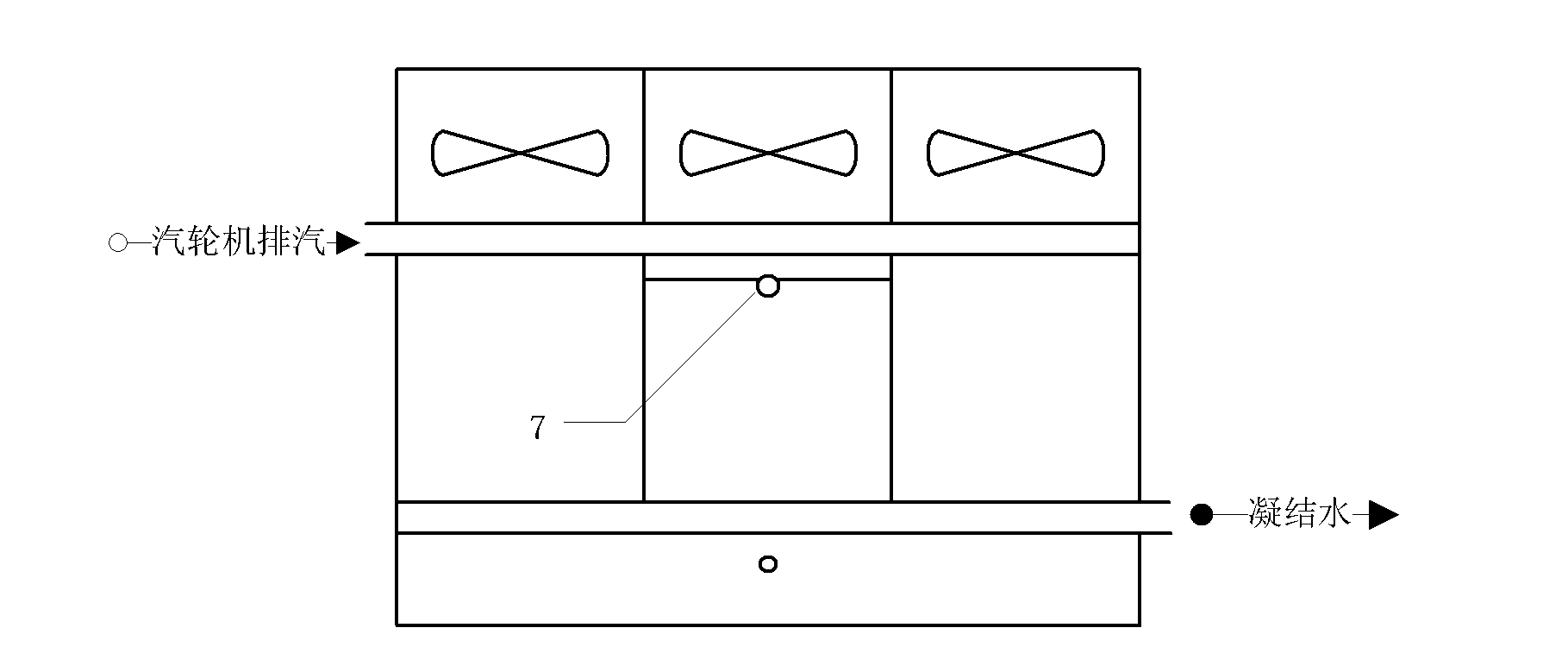

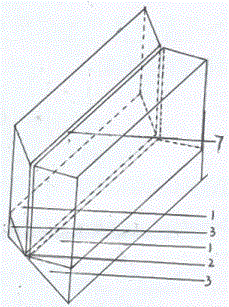

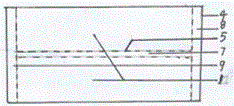

Surface-type indirect air cooling system plate-type condenser of thermal power plant

InactiveCN101907408AImprove heat transfer coefficientIncrease the heat exchange areaSteam/vapor condensersWater channelMaterial consumption

The invention relates to a surface-type indirect air cooling system plate-type condenser of a thermal power plant, which comprises headers that are symmetrically arranged; a steam inlet is arranged above the headers, and a condensate water well is positioned under the headers; the condenser is characterized in that a heat exchanger connected between the headers has plate-type structure which is provided with a plurality of vertical metal plates; a transverse clapboard is arranged between the plate 1 and the plate 2, so that a cooling water channel is formed, and the two ends of the cooling water channel are communicated with the headers; a vertical clapboard is arranged between the plate 2 and the plate 3, so that a steam channel is formed; a transverse clapboard is arranged between the plate 3 and the plate 4, so that a cooling water channel is formed, and so on, a plate-type heat exchanger can be formed. On the premise of maintaining the original design, the plate-type condenser improves the heat transfer coefficient by 20-45%, and reduces the weight, the volume, tubes and other material consumption by 30%, thus greatly reducing the manufacturing cost.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP

Air-cooled steam condensing system with natural ventilation and direct water film evaporation

InactiveCN101776401AImprove cycle efficiencySave electricitySteam/vapor condensersCooling towerSteam condensation

The invention relates to an air-cooled steam condensing system with natural ventilation and direct water film evaporation, which comprises a natural ventilation cooling tower and a direct water film evaporation type air-cooled cluster steam condenser arranged above the water pool of the cooling tower. Waste steam from a steam turbine flows through the tube of the steam condenser to release heat so as to be condensed into water to be discharged; and spray water forms a water film outside of the tube, flowing air sweeps the water film, and the water film absorbs the heat of the waste steam in the tube and transmit sensible heat and the latent heat generated in the evaporation of the water film to the flowing air. The spray water then falls into the water pool of the cooling tower, and is delivered to a spray water distribution device above each tube bundle of the steam condenser by a circulating pump. The system consumes a certain amount of evaporated water, thereby significantly improving the heat cycling efficiency. No fan is applied to consume power, thereby reducing the service power. Moreover, the system can overcome the defect that the direct dry-air-cooled steam condensation can not be completed and realized in the high-temperature environment. Compared with the water-cooled steam condensation, the system can obtain a steam condensation temperature lower than the water-cooled steam condensation, achieve higher heat cycling efficiency, and significantly reduce water consumption. Therefore, the system is applicable to areas with abundant water resources but stricter and stricter water-saving requirements.

Owner:HUAZHONG UNIV OF SCI & TECH

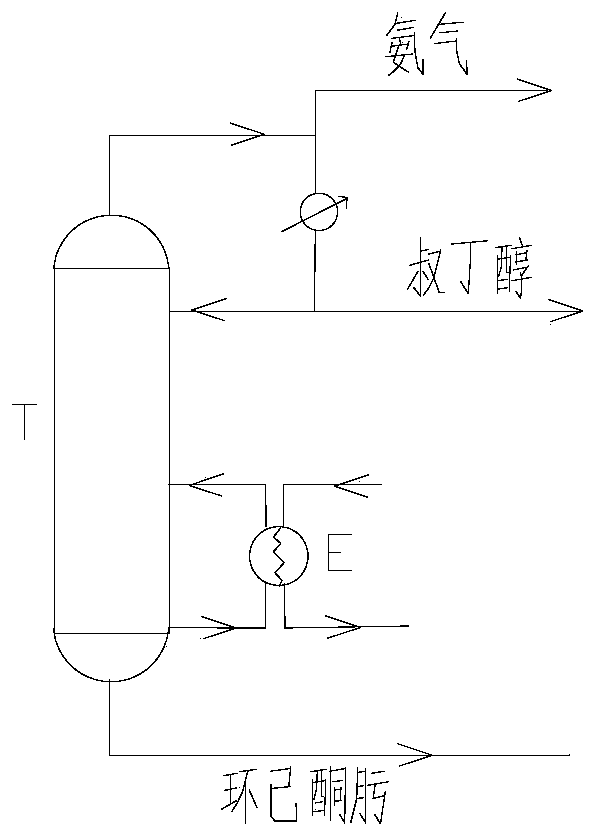

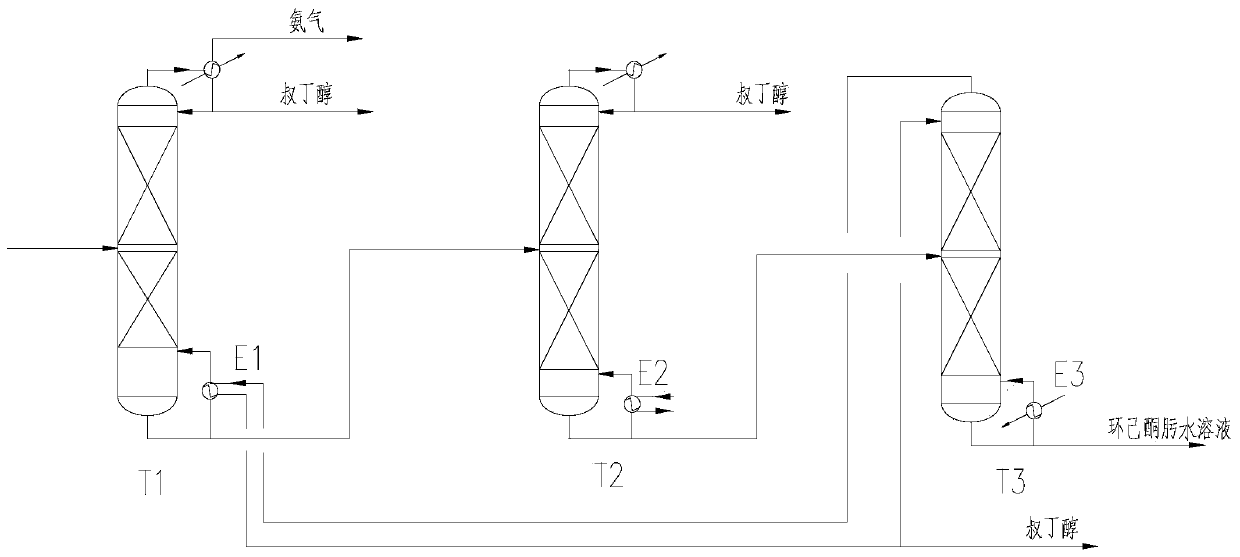

Tert-butanol recovery method by using cyclohexanone ammoximation reaction heat

ActiveCN110218147AReduce energy consumptionReduce circulating waterOrganic compound preparationChemical industryRecovery methodReboiler

The invention discloses a tert-butanol recovery method by using cyclohexanone ammoximation reaction heat. The method comprises the following steps: an ammoximation reaction product containing tert-butanol enters a deamination tower, all ammonia gas and non-condensable gases and part of tert-butanol are separated from the top of the deamination tower, tower kettle materials enter a tert-butanol vacuum tower for secondary separation of tert-butanol, 60-80% of tert-butanol is separated from the top of the vacuum tower, tower kettle materials containing remaining tert-butanol enter a tert-butanolhigh pressure tower for further separation, the remaining entire tert-butanol is distilled out from the tower top of the tert-butanol high pressure tower, the tower top tert-butanol vapor is used as aheat source of a tower kettle reboiler of the deamination tower, part of a tert-butanol liquid after heat exchange backflows to the tert-butanol high pressure tower, and part of the tert-butanol liquid is taken out, a cyclohexanone oxime aqueous solution is taken out from a tower kettle of the tert-butanol high pressure tower, a tert-butanol high pressure tower tower-kettle reboiler is heated byan external heat source, and the heat used in a tert-butanol vacuum tower tower-kettle reboiler comes from the interior reaction heat of a cyclohexanone ammoximation reactor. According to the method,energy consumption of tert-butanol recovery is saved by 60-67% or more compared with a conventional process.

Owner:TIANJIN UNIV

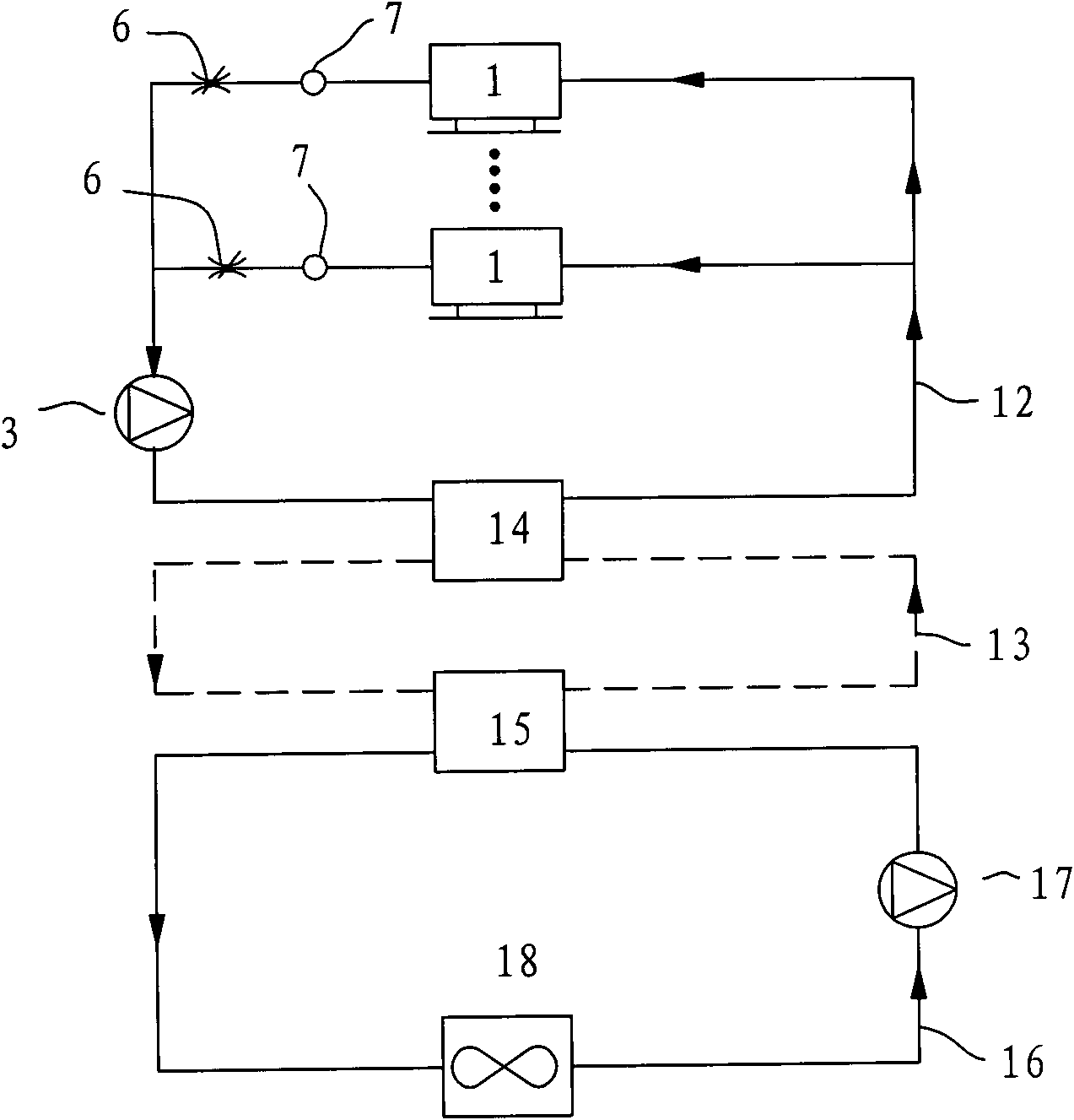

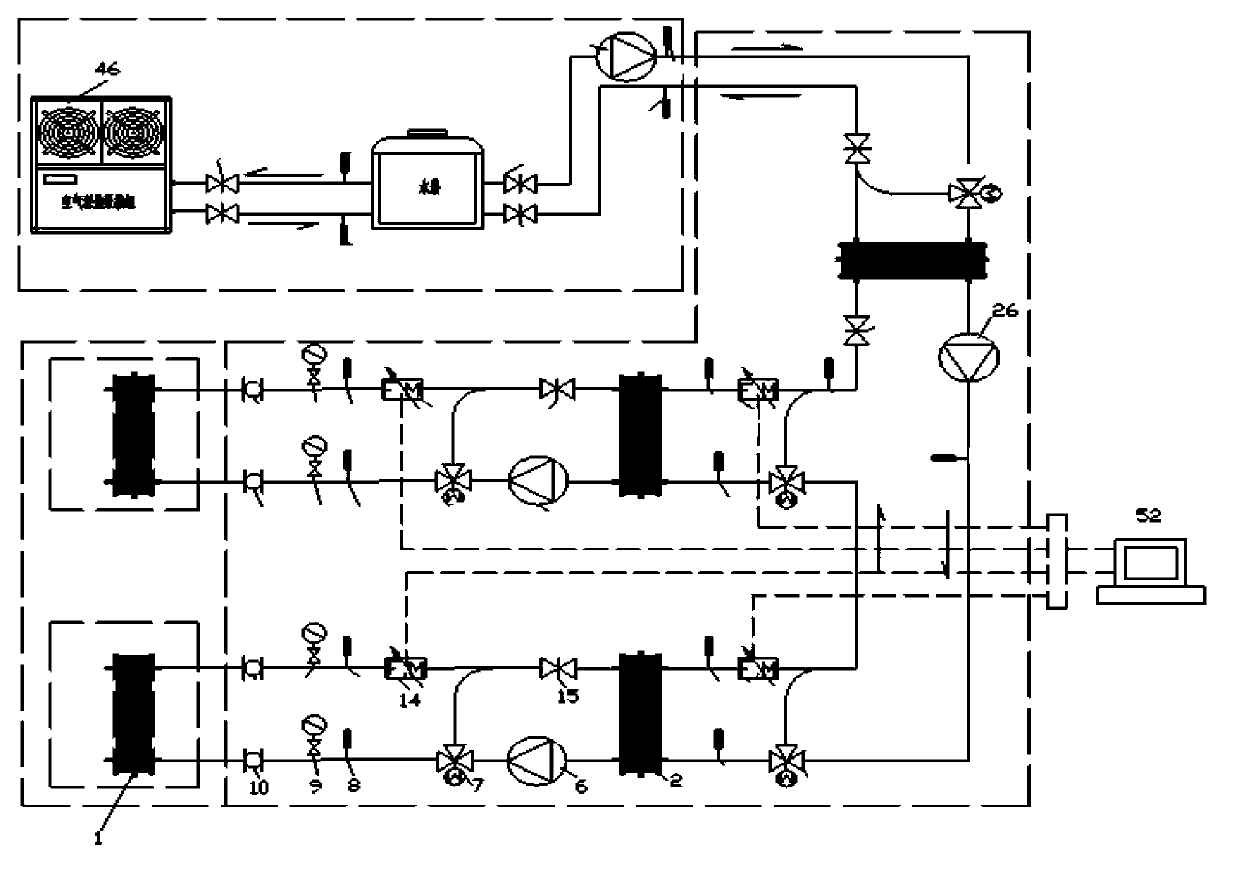

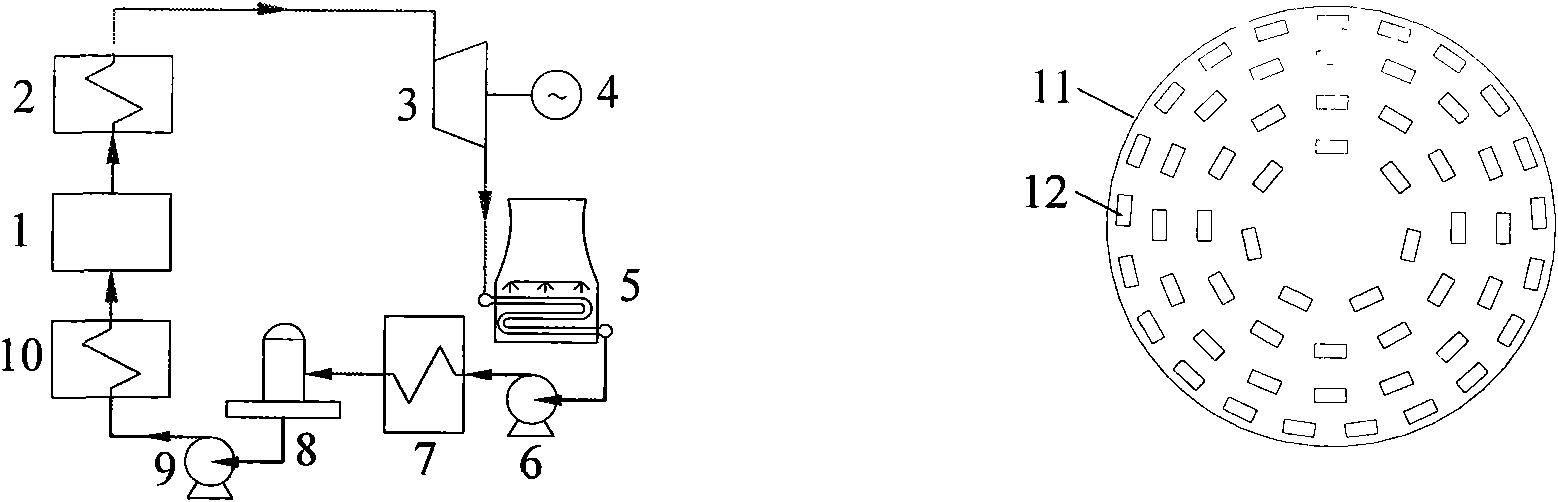

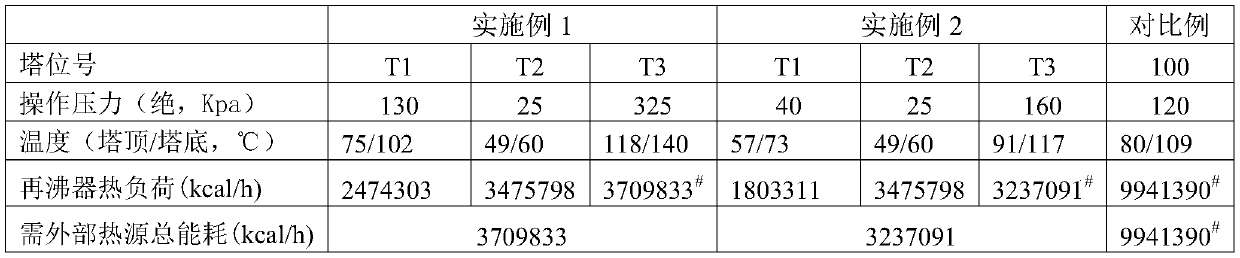

System and method of waste heat utilization of indirect cooling tower circulating water in integrated absorption heat pump

InactiveCN108981222AReduce high back pressureFlexible operationHeat recovery systemsClimate change adaptationAridCooling tower

The invention discloses a system and a method of waste heat utilization of an indirect cooling tower circulating water in an integrated absorption heat pump. The system and the method are mainly applied to an indirect air-cooling coal-fired unit in an arid and water-deficient area of China; the system comprises an turbine, an absorption heat pump and an indirect cooling tower, wherein a main turbine extracts steam to drive the absorption heat pump, an evaporator of the absorption heat pump takes away part of circulating water heat, so as to achieve the effect of reducing the backpressure of the indirect air-cooling coal-fired unit especially in summer high-temperature strong wind weather; condensed water enters an absorber and a condenser of the absorption heat pump to absorb heat, and heat recovery is achieved. By adopting the system, the circulating water temperature can be effectively reduced, and the purpose of reducing the back pressure of the indirect air-cooling coal-fired unitis achieved; and a calculation result shows that the coal consumption of a 660 MW unit can be reduced by 8 g / kWh or above by adopting the system and the method, and relatively high energy-saving and social benefits are achieved.

Owner:XI AN JIAOTONG UNIV

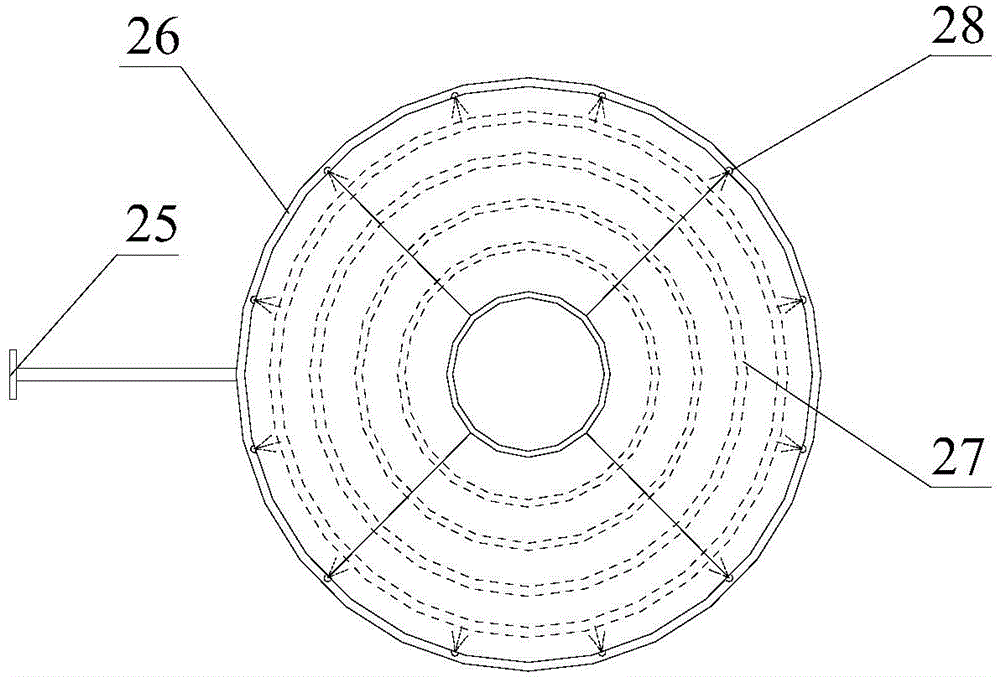

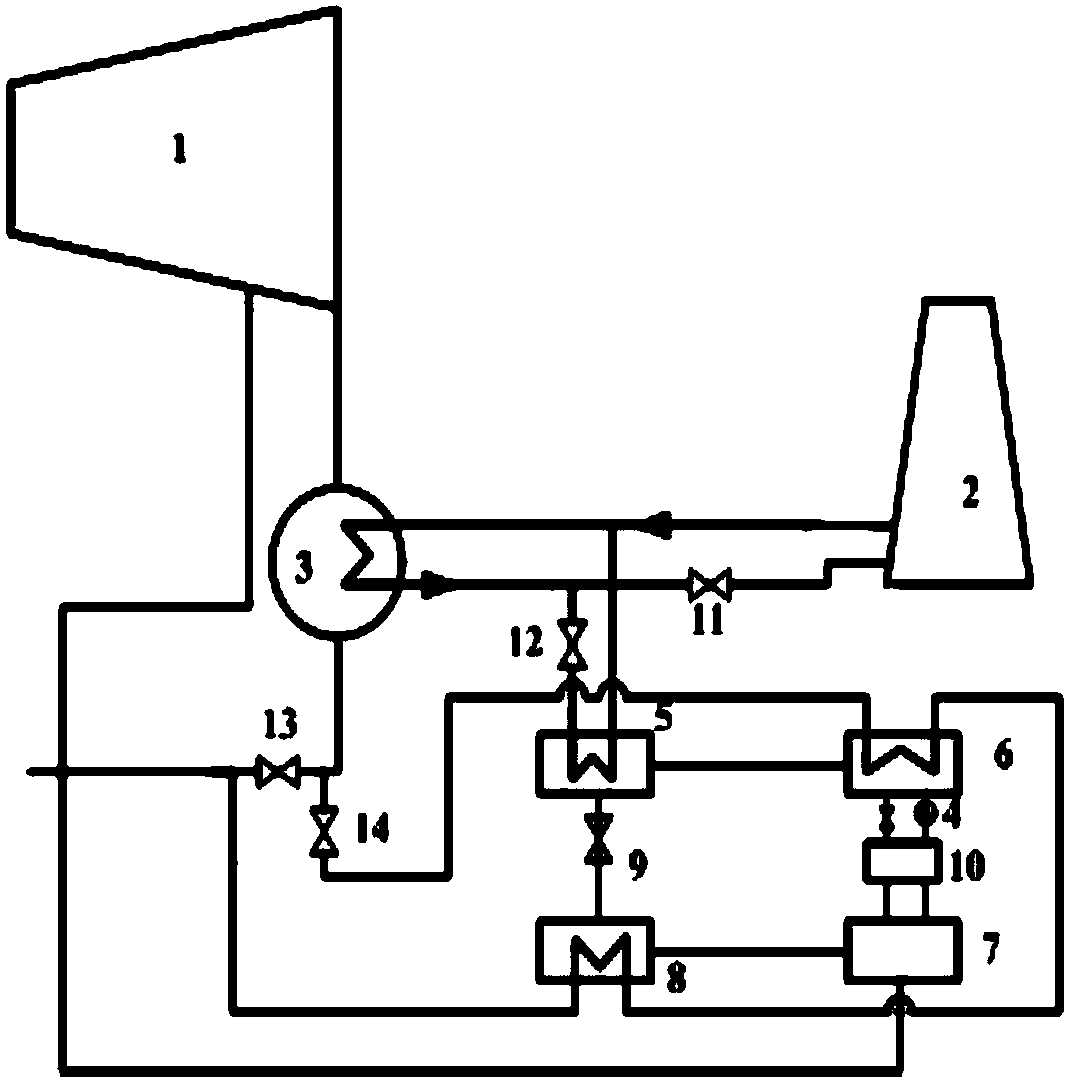

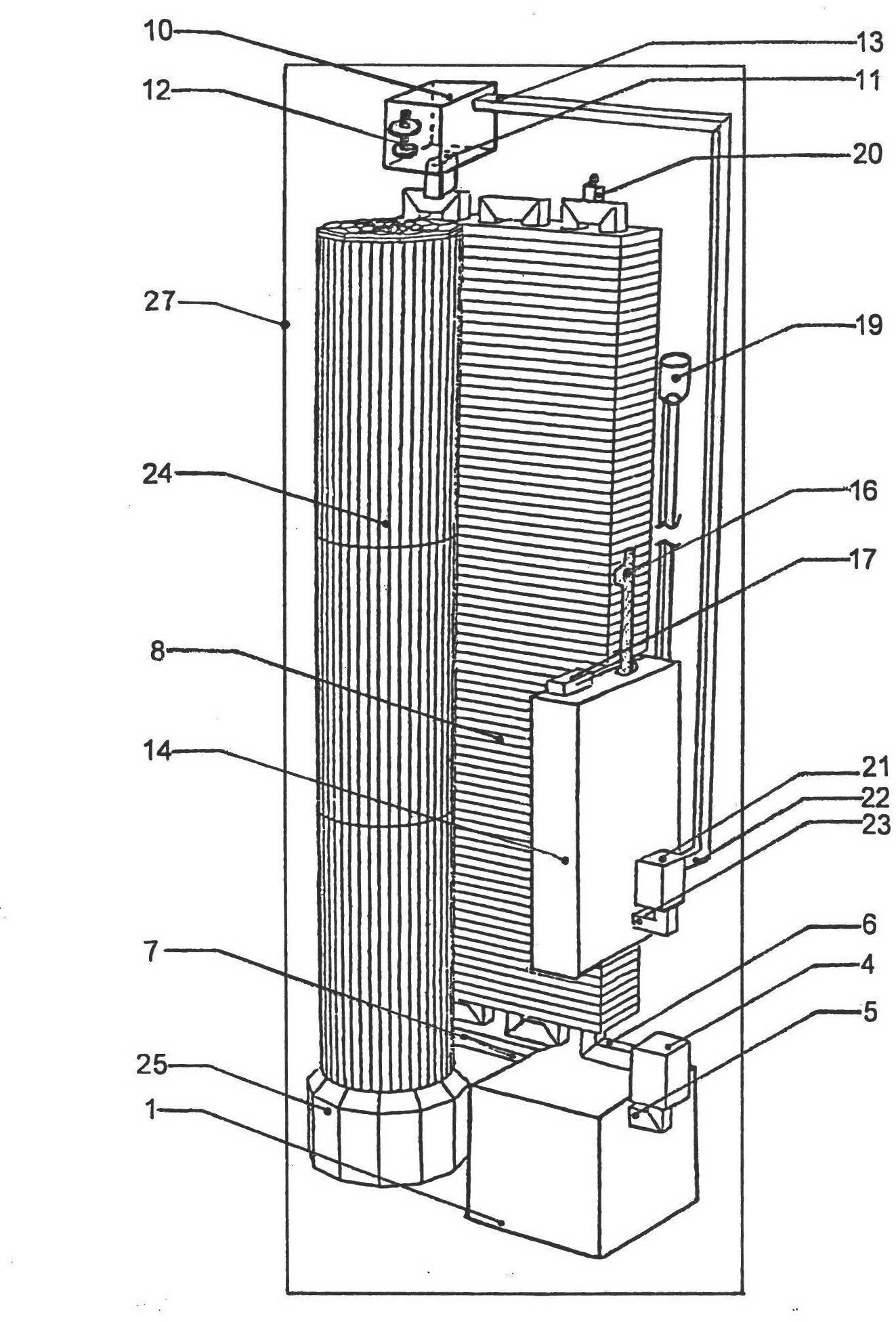

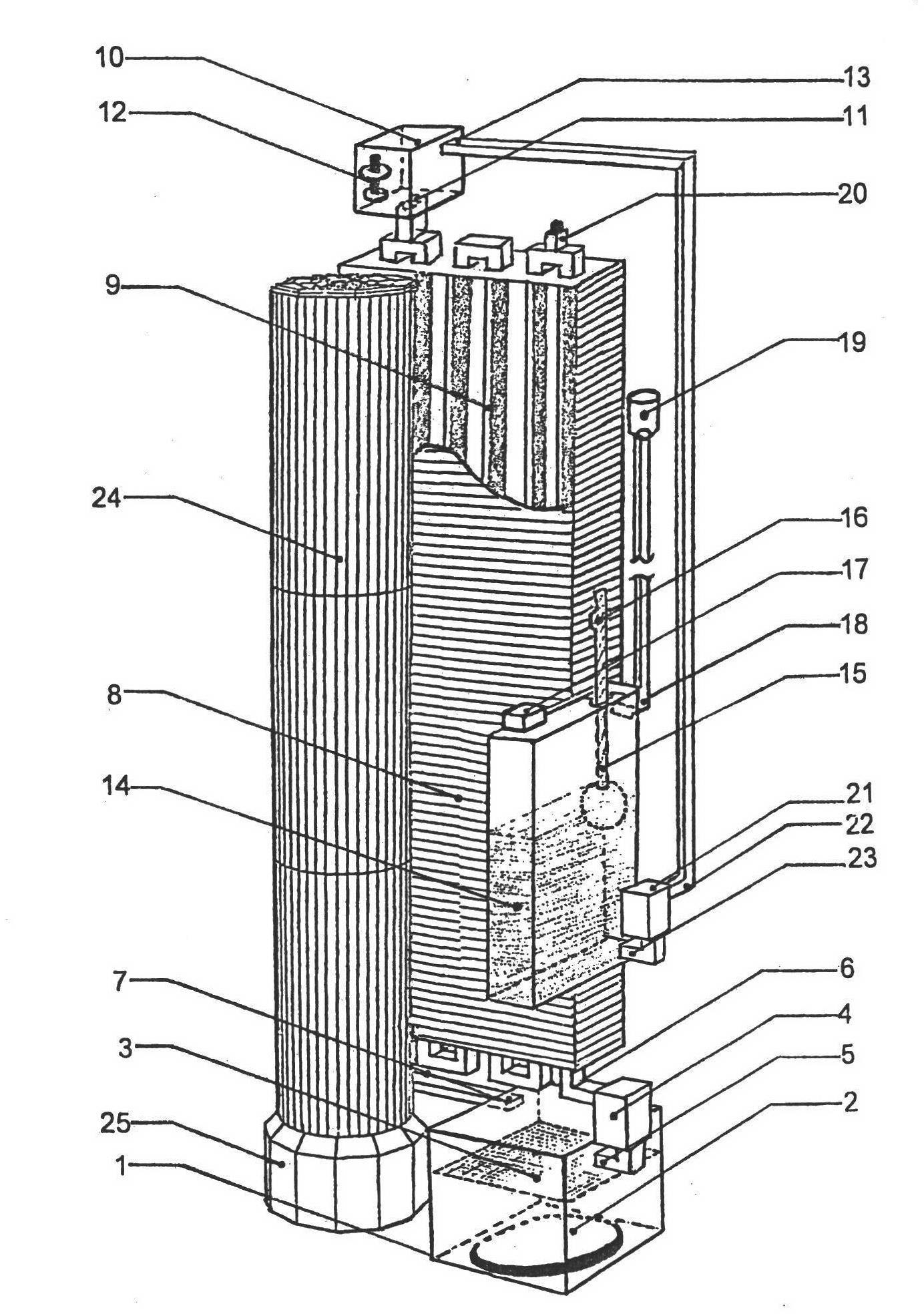

Fixing device of filter disk filter cloth

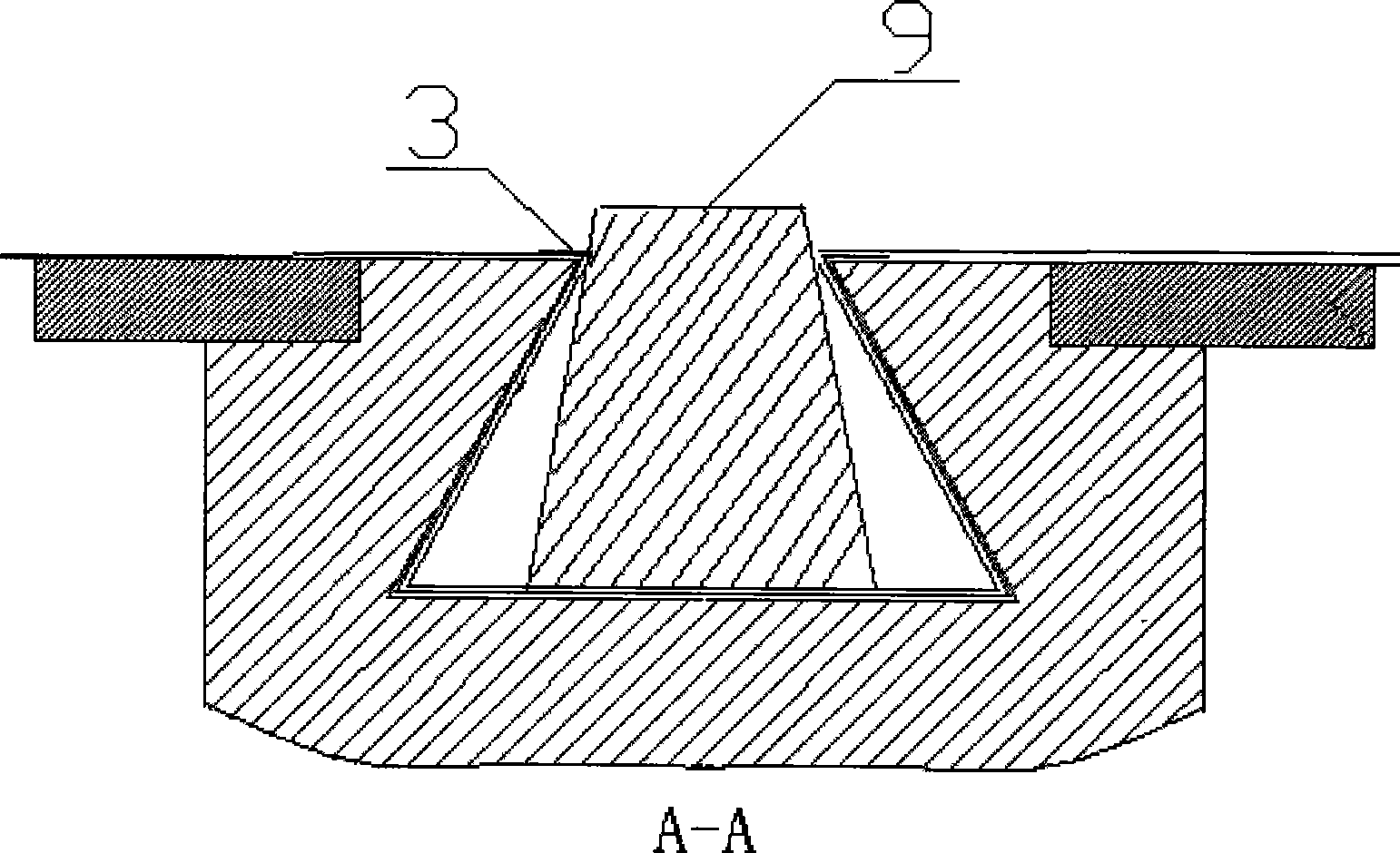

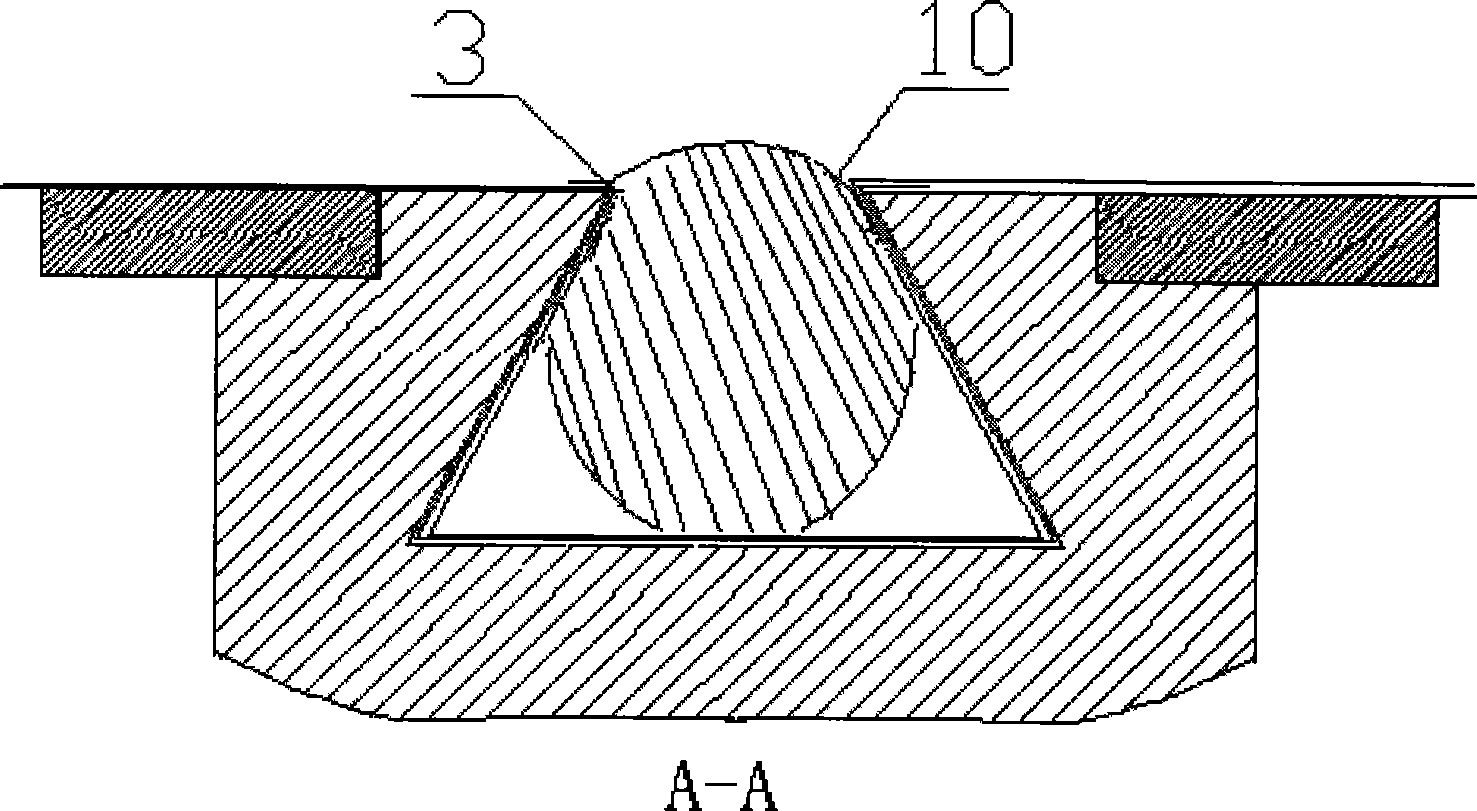

ActiveCN101468266ANo breakageLow priceStationary filtering element filtersMoving filtering element filtersEngineeringBottom pressure

The invention provides a device for fixing filtering cloth on a filter plate surface, which comprises the filter plate surface (1), a linear pressure cloth groove (2), a round pressure cloth groove (8) and the filtering cloth (3), wherein the filter plate surface (1) is provided with the filtering cloth (3) of which the joint part is positioned in the linear pressure cloth groove (2), a bottom pressure strip (5) presses on the joint part of the filtering cloth (3), a trapezoidal pressure tank (4) is positioned above the bottom pressure strip (5), and the trapezoidal pressure tank (4) is connected with the bottom pressure strip (5) through a bolt (6). The device can well fix the filtering cloth on the filter plate surface, solve the technical problems in the prior art that the product yield is decreased, the quality is reduced, the production cost is increased, the installation is difficult, the energy source is wasted and the like because of the ageing and the deformation of rubber strips.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

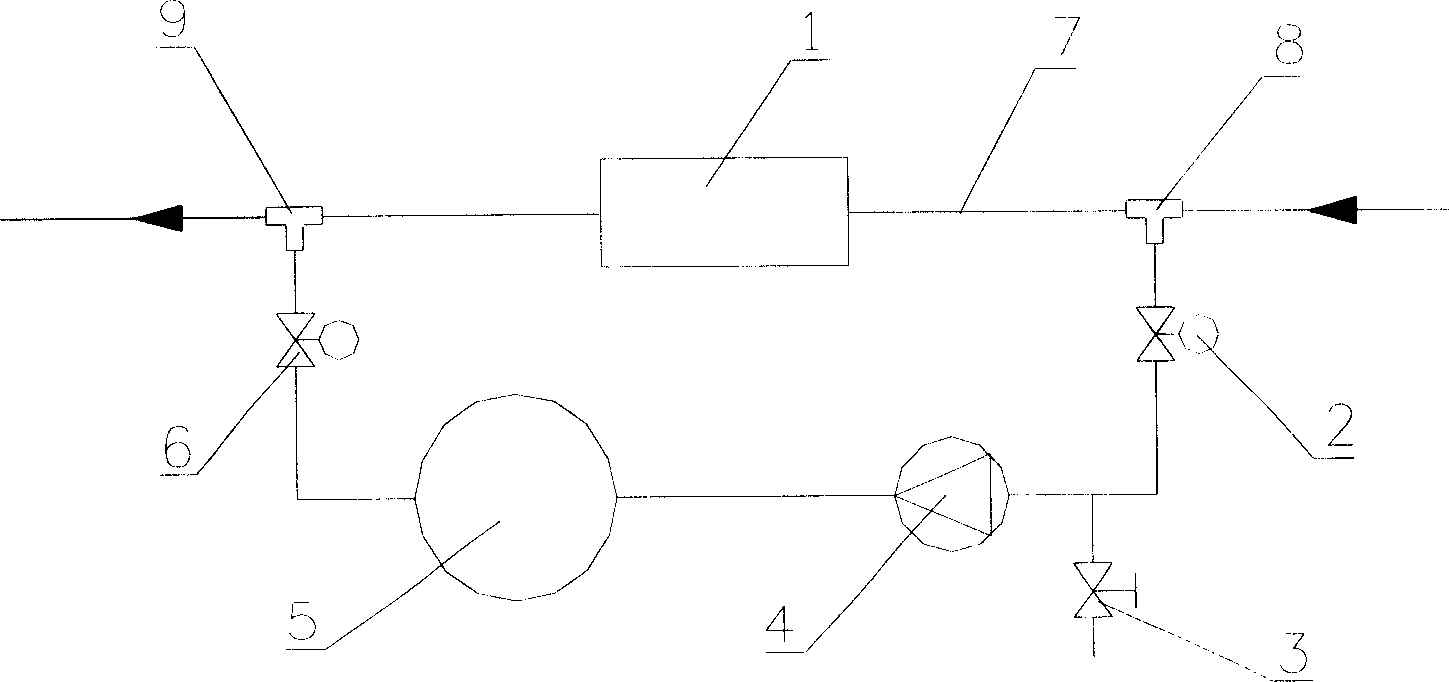

Descaling device used for air conditioner heat pump set water heat exchanger

InactiveCN101131310AReduce consumptionReduce circulating waterFlush cleaningPlate heat exchangerControl system

This invention is descaling device for air conditioner heat pump assembly water heat exchanger. It includes water heat exchanger, circulating water pump, filling tank with scale dissolver, drain valve, three-way valve and magnet valve. The water inlet pipeline and water outlet pipeline of the said water heat exchanger are connected to three-way valve one and three-way valve two respectively. The bypass of the three-way valve one connects to the bypass of the three-way valve two through magnet valve one, circulating water pump, filling tank and magnet valve two. The pipeline between magnet valve one and circulating water pump is connected with drain valve. This invention can automatically remove the scale in the water heat exchanger under the operation of controlling system. Its descaling efficiency is high.

Owner:TONGFANG ARTIFICIAL ENVIRONMENT

Purifying technique for roof gas of COREX melting reducing furnace

ActiveCN101200656AReduce consumption costReduce manufacturing costEnergy inputCombustible gas purificationEconomic benefitsEnergy recovery

The present invention belongs to the operation technical field, discloses an ironmaking furnace coal gas purification technology and especially relates to a technology of purifying the furnace top coal gas of a COREX smelting reduction furnace. The present invention aims at that the furnace top coal gas containing dust which is produced by the COREX smelting reduction furnace during the process of ironmaking is processed for removing partial dust by a primary dust remover; dry dust removing and purifying technology is used to purify coal gas; the coal gas after purification is processed for energy recovery by a TRT device or pressure reduction by a by-pass valve set and is put into a low pressure clean coal gas pipe net through a coal gas cooler for other users to use. The present invention reduces the use of cyclic water at the maximum, reduces the energy consumption and the production cost for reducing and ironmaking and at the same time keeps the quite high temperature of reducing and ironmaking coal gas, which is in favor of matching with the TRT to use the residual heat of coal gas to increase electricity generation and furthermore to improve the economic benefit.

Owner:CISDI ENG CO LTD

Low grade oil shale processing technique

InactiveCN101665707AReduce resistanceReduce circulating waterSpecial form destructive distillationWater contentTar

The invention provides a low grade oil shale processing technique. Shale of a retort furnace is preheated in a dry distillation section on the upper part of the furnace to raise temperature, and the water content and wetted gas on the surface of the shale are removed; the temperature of the shale is increasingly raised in a process of moving the dry distillation section down, and when the temperature is raised to 120 DEG C, the water content on the surface is evaporated completely; when the temperature is raised to between 150 and 180 DEG C, gases adsorbed in the shale are released; when the temperature exceeds 180 DEG C, organic matters in the shale are started to be decomposed to generate water content, gases such as carbon dioxide, sulfureted hydrogen and the like; and when the temperature of the shale is continuously raised to 520 DEG C, tar oil in the shale is fundamentally released; temperatures of various parts of the retort furnace are controlled, and the final temperature of the retort furnace is mainly controlled to 520 DEG C; and a thermometer is arranged under an arch abutment of a mixing chamber, and is inserted in the depth of between 1.0 and 1.5 meters. The low gradeoil shale processing technique has the advantages that: the oil rate of the 5 percent low grade oil shale is over 75 percent, and more shale oil can be extracted from low grade shale ore through themeasure.

Owner:汪清县龙腾能源开发有限公司

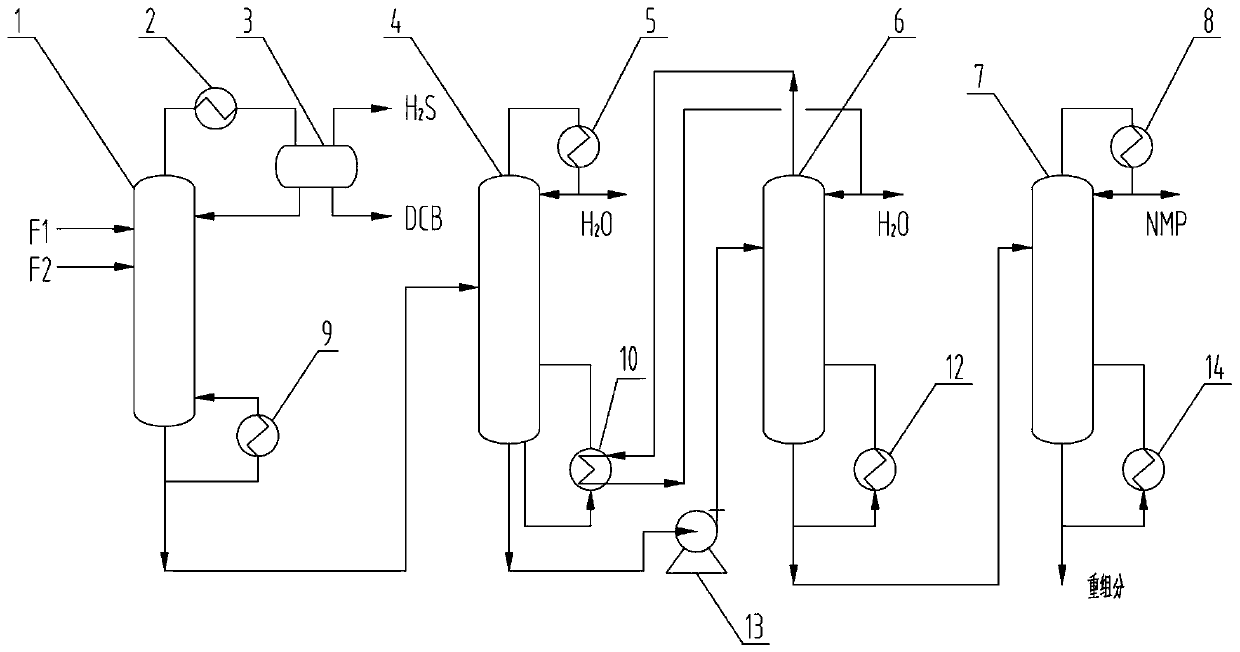

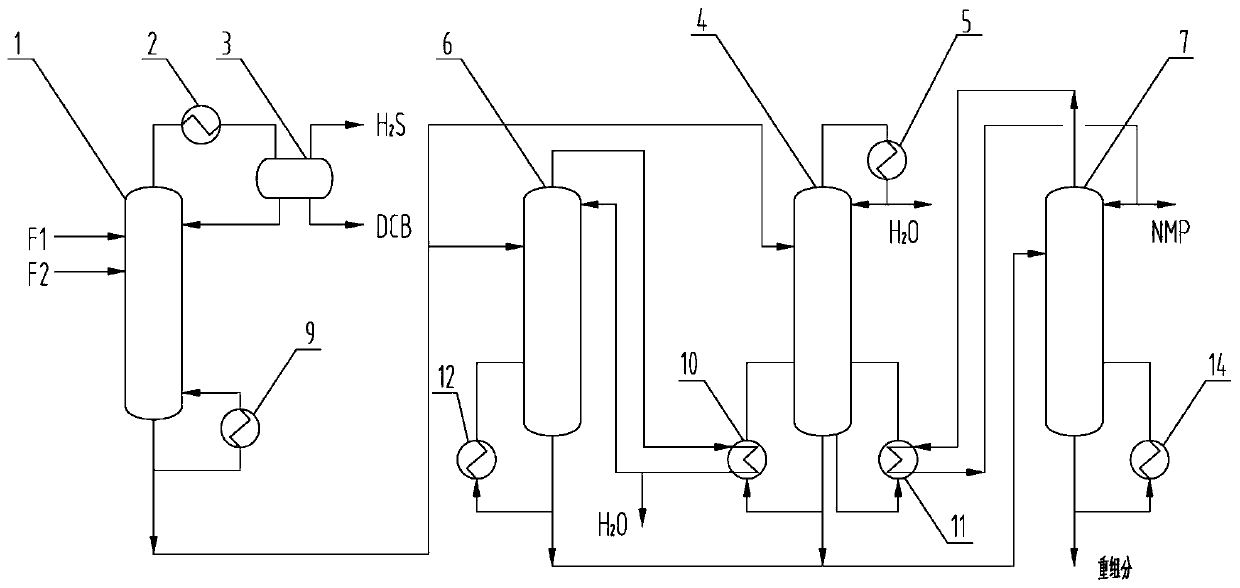

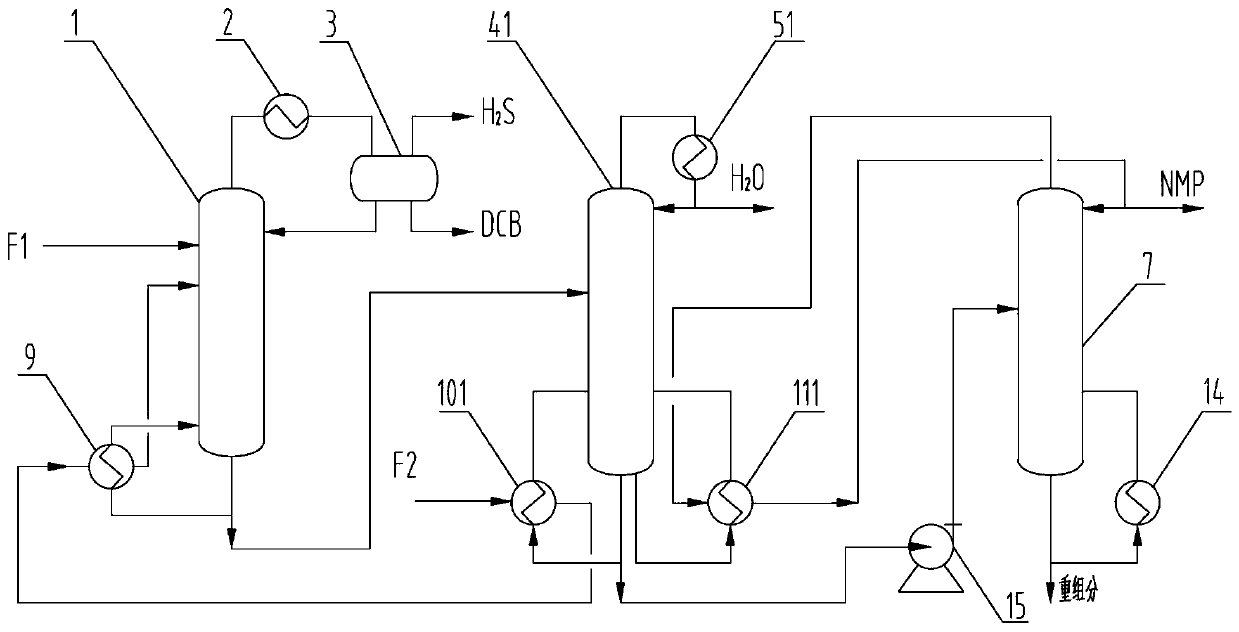

Method and system for energy-saving separation of DCB-NMP mixture

ActiveCN110668989AReduce consumptionReduce dosageChemical industryHalogenated hydrocarbon preparationFractionating columnPollution

The invention belongs to the field of resource recovery, and discloses a method for energy-saving separation of a DCB-NMP mixture. The method comprises the following steps: (1) fractionating: enablingcooled or uncooled gas-phase raw material containing DCB and NMP and / or liquid-phase raw material containing DCB and NMP to enter a fractionating tower, performing azeotropic treatment on water and DCB, condensing a tower top gas phase, allowing the condensed tower top gas phase to enter a phase separation tank for layering to achieve a separation effect and obtain an oil phase and a water phase,and enabling the water phase to flow back into the fractionating tower; (2) dehydrating: feeding a material flow at the bottom of the fractionating tower into a dehydration system, and performing dehydration; and (3) rectifying: feeding the dehydrated mixture into a rectifying tower to separate NMP from heavy components, and obtaining a high-purity NMP product from the top of the rectifying tower. The invention further provides a system for energy-saving separation of the DCB-NMP mixture. The method has the advantages of small investment, low energy consumption, reduction of environmental pollution, and deeply recovery of ultra-pure DCB and NMP products.

Owner:南京佳华科技股份有限公司

Freeze-condensing vacuum deodorizing method and equipment for fat and oil

The invention relates to a freeze-condensing vacuum deodorizing method for fat and oil. The method is characterized by comprising the following steps of: 1) preparing; 2) performing gassing to remove oxygen; 3) heating; 4) deodorizing; 5) cooling; and 6) freezing, trapping and melting. Equipment using the method is characterized by comprising the following units of: (1) a gassing unit; (2) a heating unit; (3) a deodorizing unit; (4) a fatty acid trapping unit; (5) a vacuum refrigeration unit; (6) a rear vacuum pump unit; and (7) a defrosting unit. When the method and the equipment are used for performing fat and oil deodorizing production, the method and the equipment have the advantages of greatly reducing heating energy, greatly reducing the using amount of injecting steam and the usingamount of cooling water and improving production efficiency. Moreover, sealing treatment is performed on a system and no waste gas is discharged, so the method and the equipment also have the advantages of energy conservation, emission reduction, sanitation and environmental protection.

Owner:中机康元粮油装备(北京)有限公司

Evaporative condenser type novel air/water-cooled dehumidifier

InactiveCN101738014ALower condensation temperatureReduce power consumptionEvaporators/condensersCooling towerAgricultural engineering

The invention discloses an evaporative condenser type novel air / water-cooled dehumidifier, which is characterized in that: an air outlet is formed on the top of an evaporative condenser; a water baffle is connected to the lower end of the air outlet; a spray device is connected to the lower end of the water baffle; a heat exchange coil is arranged at the lower end of the spray device; the heat exchange coil is connected with a novel air / water-cooled dehumidifier; and an exhaust fan of the novel air / water-cooled dehumidifier is connected with an air inlet of the evaporative condenser. The evaporative condenser type novel air / water-cooled dehumidifier has the advantages that: 1, the refrigerating efficiency is high and the service life of a compressor is long; 2, the water recirculation rate is small, the power consumption of a water pump is low, and the power consumption of a circulating fan is saved by using the air exhaust of an engineering system; and 3, the evaporative condenser has a compact integral structure without a cooling tower, a water pump and other cooling systems, convenient engineering installation, small occupancy area and low investment cost, and solves the problem that the novel air / water-cooled dehumidifier has large workload of the engineering installation, large occupancy area, high investment cost and high power consumption.

Owner:TELLHOW SCI TECH CO LTD

Power-assisted degassing system, and vacuum degassing tower and pure water system with power-assisted degassing system

PendingCN111068365AReduce circulating waterReduce wear and tearLiquid degasificationWater/sewage treatment by degassingVacuum AssistanceEngineering

The invention provides a power-assisted degassing system, and a vacuum degassing tower and a pure water system with the same. The power-assisted degassing system comprises a water seal pump, a gas-liquid separation circulating barrel and a power-assisted pump, wherein the water seal pump is communicated with the upper portion of the degassing tower through a main pipeline and is used for pumping out mixed water gas in the degassing tower, the gas-liquid separation circulating barrel is circularly communicated with the water seal pump through a circulating pipeline and is used for carrying outgas-liquid separation treatment on the mixed water gas pumped by the water seal pump, and the power-assisted pump is arranged on the main pipeline, located between the water seal pump and the degassing tower and used for providing assistance when the water seal pump pumps out mixed water and gas. The water seal pump and the power-assisted pump form two-section type pumping equipment based on mechanical vacuum assistance, the circulating water amount of the water seal pump is small, the needed motor power is small, and the mixed water gas pumped out by the vacuum tower only needs to be treatedby one water seal pump, so that the equipment load is small, and the blade operation efficiency loss degree of the water seal pump is low.

Owner:CHANGXIN MEMORY TECH INC

Parallel type circulating water culture container system and usage method thereof

PendingCN106069985AWater head reductionReduce energy consumptionPisciculture and aquariaHigh densityWater flow

A parallel type circulating water culture container system and a usage method thereof belong to the aquatic product culture field, and a high density circulating water culture facility fishery equipment system is provided; the system comprises a culture zone, a backflow duct, a night soil settling zone, and a backflow water zone connecting the culture zone with the backflow duct; the culture zone and the backflow duct are isolated by a film and / or plate type and / or dense net material; the backflow water zone is connected with the culture zone, and water flows in one way in the culture zone; the water reversely flows in the backflow duct, thus forming the one-piece enclosed circulating water culture system; the night soil settling zone settles and gathers night soils on one nearby side of the culture zone, thus transferring night soils with high efficiency. The parallel type circulating water culture container system can reduce circulating pipeline system, can reduce construction fee and operational fee, can gather night soils and residual baits with high efficiency, thus solving aquatic product culture non point source pollution problems, promoting technology progress in culture and sewage processing industry, and improving aquatic product culture equipment level.

Owner:SHANGHAI NENGZHENG FISHING TECH DEV CO LTD

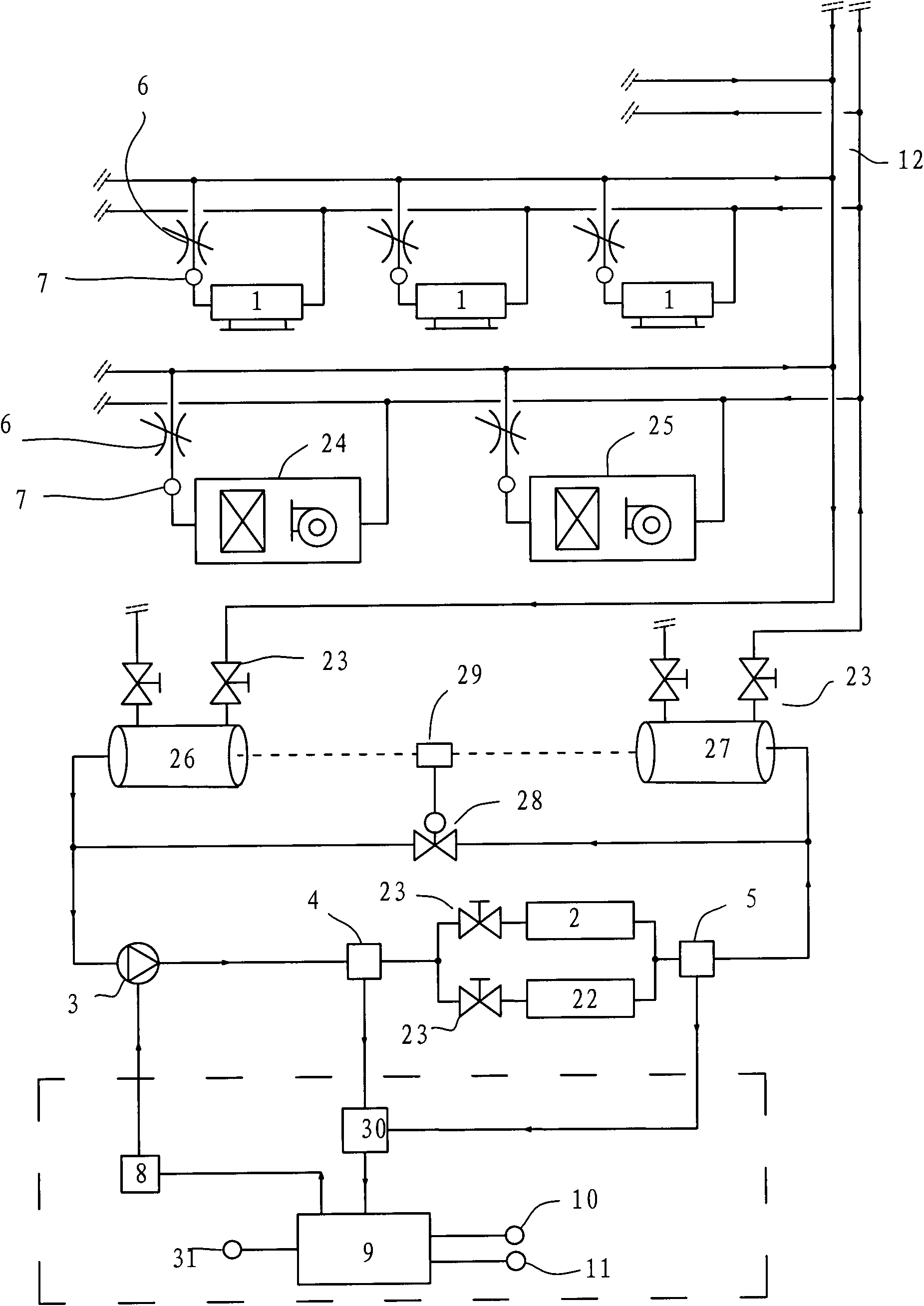

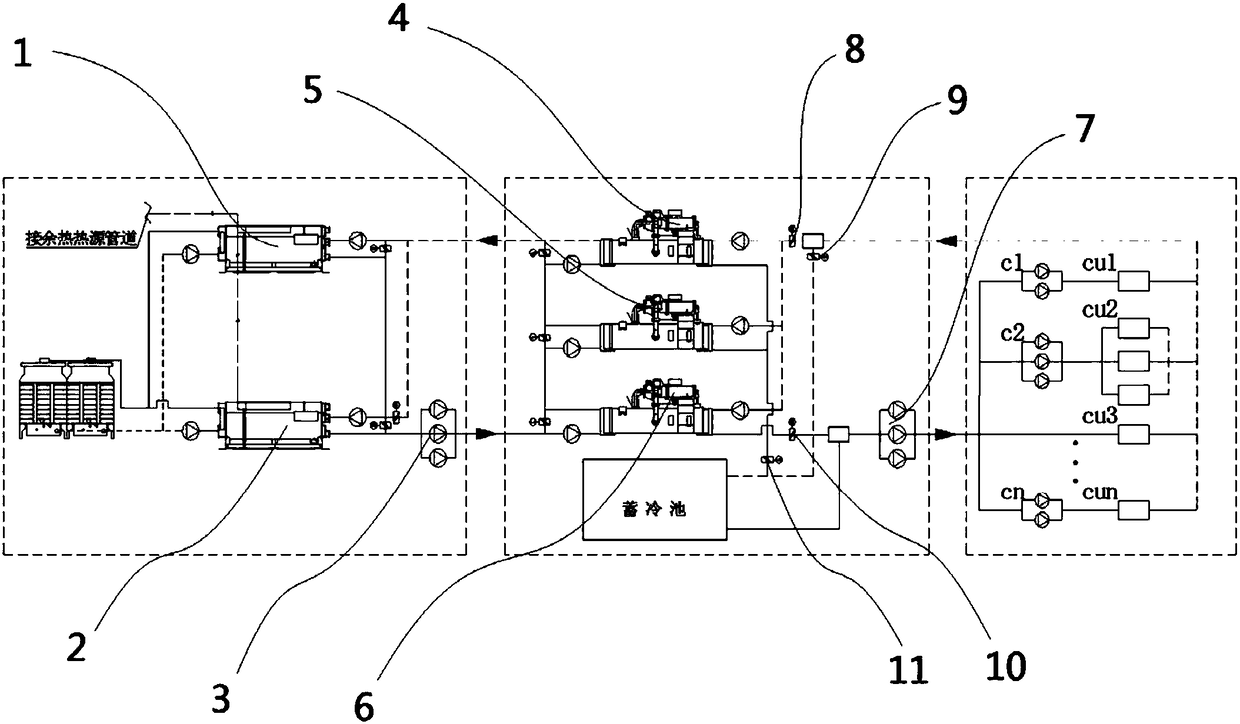

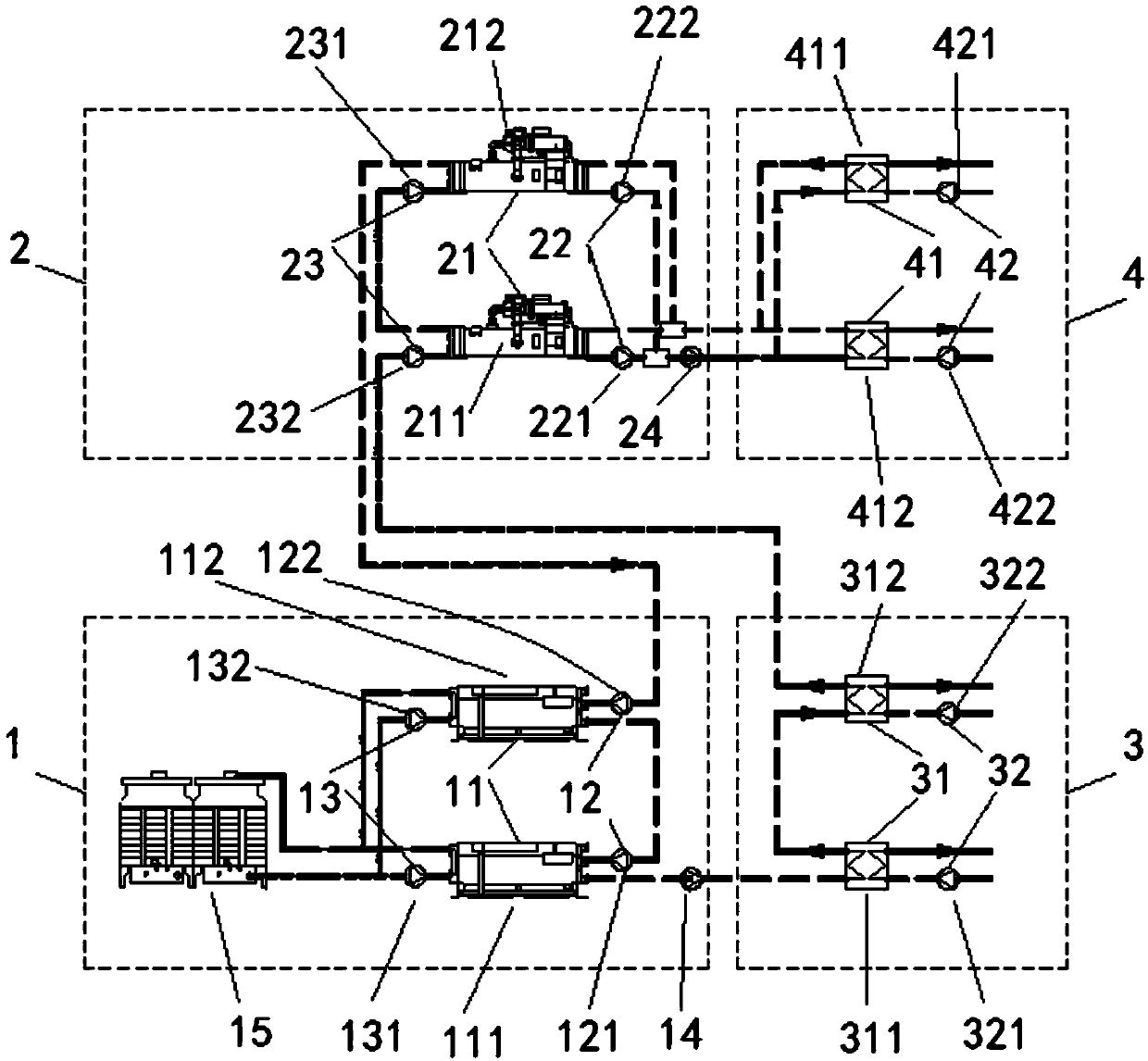

Modular area cooling system

ActiveCN108180674ARelease cooling capacityImprove operational efficiencyHeat pumpsEfficient regulation technologiesElectricityModularity

The invention discloses a modular area cooling system. The cooling system comprises a cooling system, a refrigerating and cold storage system and a variable frequency distribution pump system, whereinthe cooling system comprises a waste heat source pipeline, a waste heat absorption type water chilling unit a1, a cooling system waste heat absorption type water chilling unit a2 and a cooling waterconveying water pump BQ; the refrigerating and cold storage system comprises a water-cooled electric cooling water chilling unit b1, a water-cooled electric cooling water chilling unit b2, a water-cooled electric cooling water chilling unit b3, an electric butterfly valve v1, an electric butterfly valve v2, an electric butterfly valve v3, an electric butterfly valve v4, a cold storage tank, a water distributor and a chilled water secondary pump BL; the cooling water conveying water pump BQ is used for conveying cooling water to a cold supply station, and the water-cooled electric cooling waterchilling units b1, the water-cooled electric cooling water chilling unit b2 and the water-cooled electric cooling water chilling unit b3 are used for extracting cooling water according to requirements by utilizing split cooling water pumps and utilizing the cooling water step by step; and the water-cooled electric cooling water chilling unit b1, the water-cooled electric cooling water chilling unit b2 and the water-cooled electric cooling water chilling unit b3 are connected with the cold accumulation pool in series and in parallel in a switched operation working condition through the electric butterfly valve v1, the electric butterfly valve v2, the electric butterfly valve v3 and the electric butterfly valve v4. According to the system, the installed capacity and the running efficiency of the cold supply station can be improved, and the advantages of intensive cooling, intensive energy utilization and efficient utilization of energy can be brought into full play.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

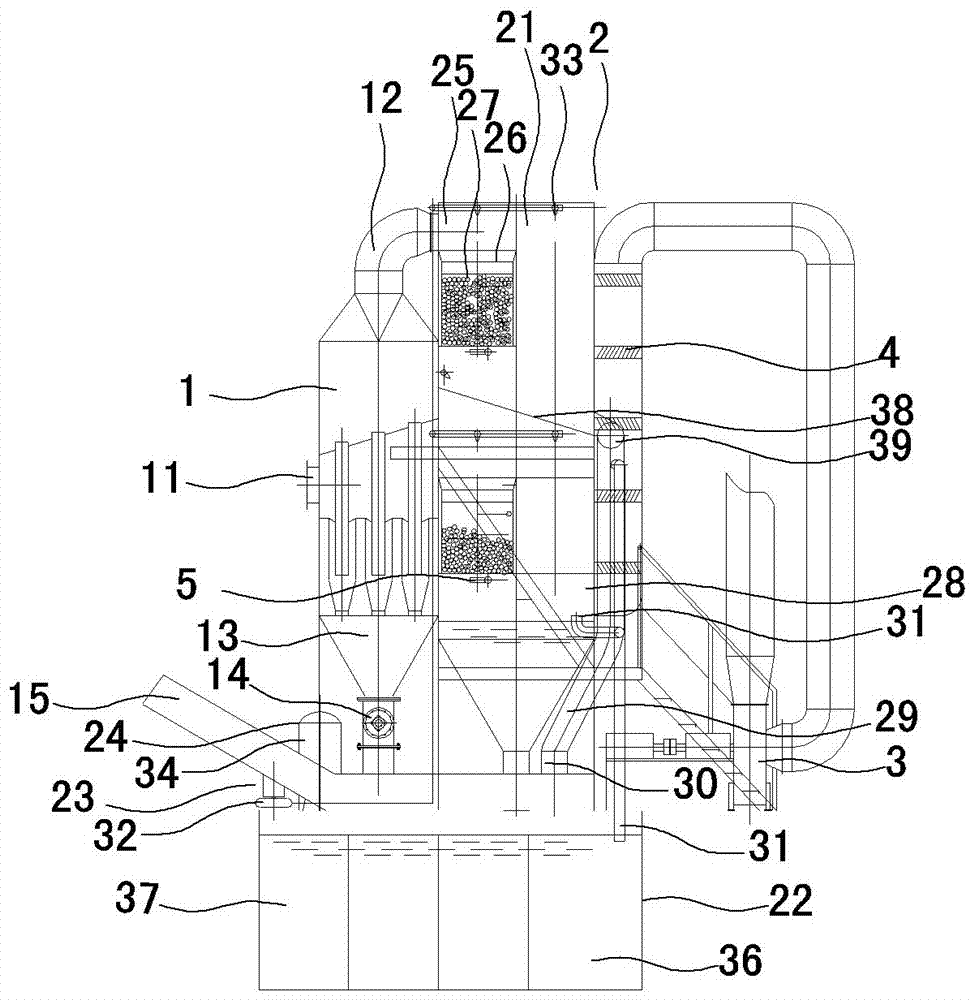

High-efficiency boiler dedusting desulfurization denitrification device

InactiveCN107042033ALow temperature range requirementsLower exhaust gas temperatureGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention relates to a high-efficiency boiler dedusting desulfurization denitrification device. The high-efficiency boiler dedusting desulfurization denitrification device comprises a dedusting device (1), a desulfurization denitrification device (2), and an induced draft fan (3); the desulfurization denitrification device is composed of a desulfurization denitrification tower (21), a circulation sedimentation tank (22), a urea spraying mechanism (23), and a drug adding mechanism (24); a wind outlet (12) of a cyclone multi-tube dust collector is communicated with a flue gas inlet (25) of the desulfurization denitrification tower; a plurality of raschig ring filter subassemblies (26) are arranged in the desulfurization denitrification tower; a flue gas outlet of the desulfurization denitrification tower is communicated with a wind inlet of the induced draft fan (3); the urea spraying mechanism (23) is composed of a circulating pump (32), and a plurality of spray nozzles (33) arranged in the desulfurization denitrification tower (21); the drug adding mechanism (24) is composed of a urea tank (34) and a drug adding pump (35). The high-efficiency boiler dedusting desulfurization denitrification device is high in desulfurization denitrification efficiency, and excellent in dedusting effect, and is capable of reducing boiler flue gas temperature and increasing boiler heat effciency; requirement on flue gas temperature range is low; and production operation cost is low.

Owner:鲍守明 +1

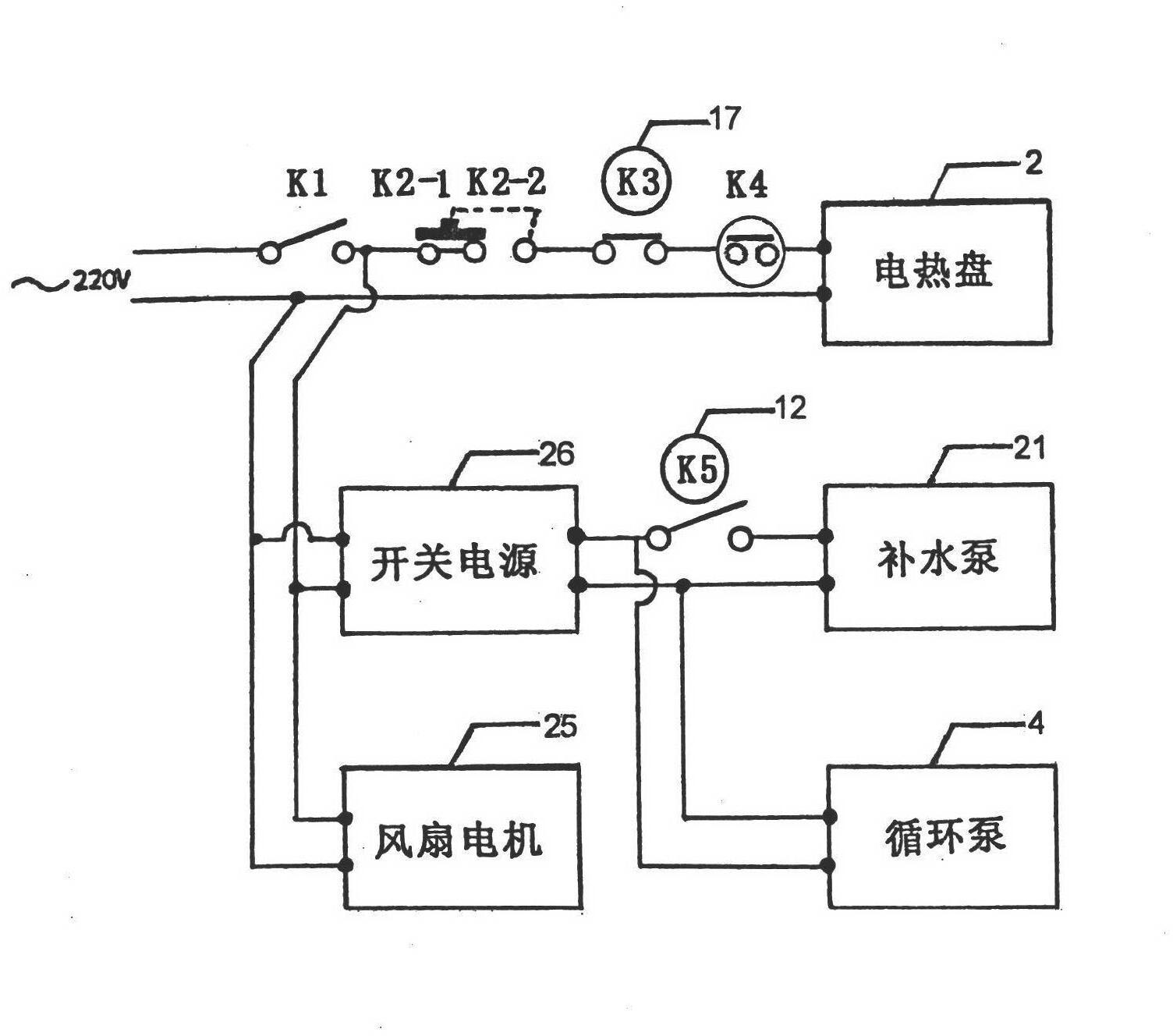

Water-circulation conducting electrically-heated warmer

InactiveCN102434909AIncrease the holding temperatureReduce heat transferLighting and heating apparatusElectric heating systemElectricityWater storage tank

The invention discloses a water-circulation conducting electrically-heated warmer. An electrothermal disk is hermetically embedded at the bottom of an inner box of a heating box container and directly contacted with water so as to heat the water; a heating box filled with water, a water pump and an evaporator are hermetically communicated with one another to form a water-circulation conducting heat channel; the heated swelled water overflows into an overflow bottle; after being cooled, the water is returned to the evaporator communicated with the overflow bottle; if the overflow bottle is lack of water, a water level switch in the overflow bottle is turned on and a water supplementation pump of a water storage tank is started to pump water into the overflow bottle; the water pump pumps the water heated by the electrothermal disk out of the heating box and pumps the heated water into a copper pipe in the evaporator, so circulation of the water is realized; and the air enters a rotary columnar fan blade through the evaporator, and the air heated by the evaporator is fanned out, therefore, the conduction warmer in which electric energy is converted into water heat energy is implemented.

Owner:吴仁麒

Energy-saving water-saving organic silicon monomer rectifying method

ActiveCN101798322BImprove operational safetyIncrease operating pressureSilicon organic compoundsChemical industryWater vaporReboiler

Owner:TIANJIN UNIV

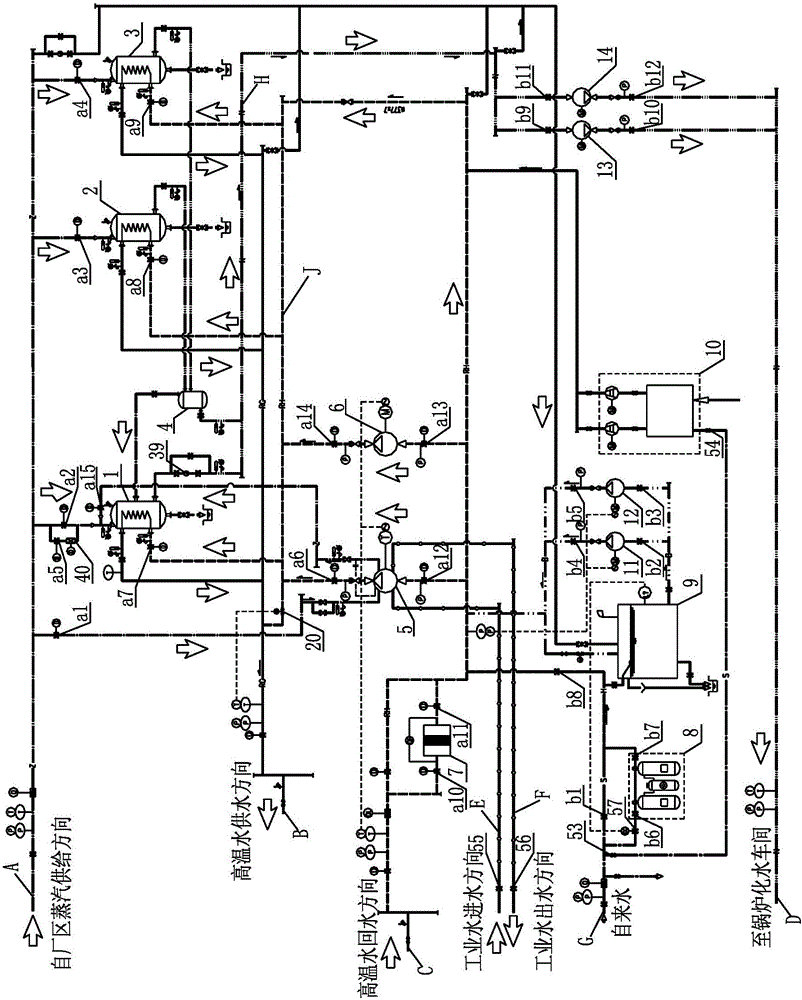

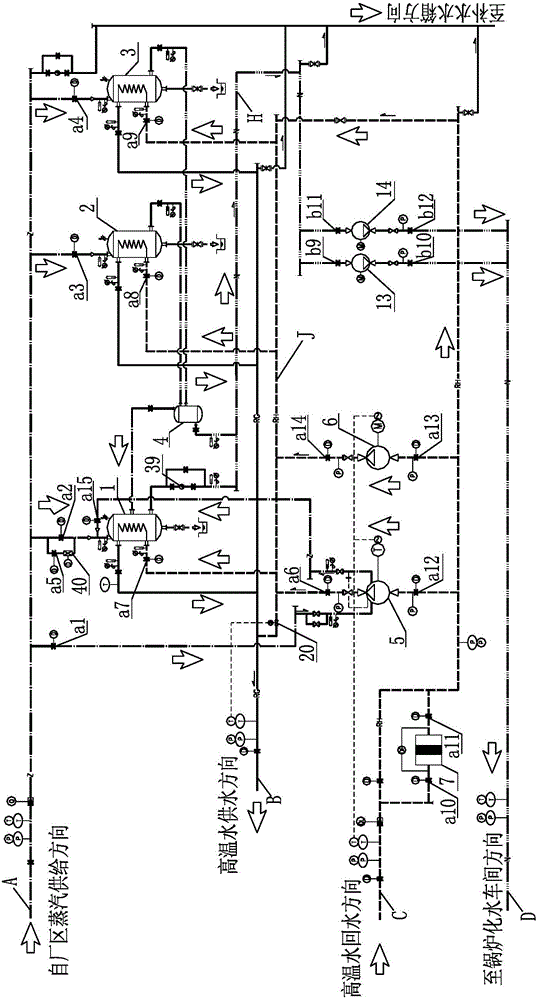

Heat efficiency-optimized first steam-water heat exchange station and running method thereof

ActiveCN105757759ASave electricityReduce heat transfer areaLighting and heating apparatusWaste gas energySteam pressureSteam condensation

The invention discloses a heat efficiency-optimized first steam-water heat exchange station and a running method thereof.A heat source of a first heat exchanger comprises three parts, wherein the third part is achieved by arranging a drain flash tank at a condensation water outlet of a second heat exchanger and a third exchanger of the first steam-water heat exchange station; high-pressure condensation water generated through high-pressure steam condensation heat exchange and steam generated through secondary evaporation are collected and recycled through the drain flash tank respectively and then enter the first heat exchanger for secondary heat exchange, and energy sources are fully utilized.According to the heat efficiency-optimized first steam-water heat exchange station and the running method thereof, an electric control valve arranged on a high-temperature water return pipeline is controlled through a temperature measuring instrument arranged at the head end of a high-temperature water supplying pipeline, and through the design, the temperature of high-temperature supplied water is adjusted in time according to the changes of the heat exchange amount needed by a user of the first steam-water heat exchange station; a pressure regulating valve is only arranged on a standby steam heating bypass pipeline of the first heat exchanger, no pressure regulating valve is arranged on the other steam heating pipelines of the three heat exchangers, therefore, it is guaranteed that the steam pressure drop at inlets of the heat exchangers is small and the heat transfer temperature difference is large, and it is further guaranteed that only the small heat exchange area of the heat exchangers is needed.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

Large-temperature-difference cold water composite gradient utilization system based on waste heat utilization

PendingCN107764122AImprove primary energy utilizationIncrease return water temperatureRecuperative heat exchangersWater circulationWater pipe

The invention discloses a large-temperature-difference cold water composite gradient utilization system based on waste heat utilization. The large-temperature-difference cold water composite gradientutilization system comprises a waste heat absorption type large-temperature-difference gradient refrigeration system, a chilled water gradient utilization system, a cooling water gradient utilizationsystem and a district cooling user system. The waste heat absorption type large-temperature-difference gradient refrigeration system supplies cold water to the chilled water gradient utilization system through a pipeline. The chilled water gradient utilization system supplies cold water to the cooling water gradient utilization system through a pipeline. The cooling water gradient utilization system supplies cold water to the district cooling user system. Hot water of the cooling water gradient utilization system flows back to the waste heat absorption type large-temperature-difference gradient refrigeration system to be cooled. According to the large-temperature-difference cold water composite gradient utilization system, waste heat of a thermal power plant is utilized for carrying out absorption type refrigeration; waste heat and exhaust heat gradient utilization is achieved; the primary energy utilization ratio is increased; the water return temperature is improved; the water supplyand return temperature difference of the district cooling system is increased; the cold water use temperature difference is enlarged; the circulating water amount of cold water is greatly reduced; pipe network conveying energy consumption and cold losses are reduced; and cold water pipe network conveying energy consumption is reduced.

Owner:济南热力集团有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com