Front-end deethanizing separation process method for ethylene device

A technology of ethylene plant and process method, which is applied in the field of chemical engineering, and can solve problems such as rising low-pressure steam consumption and increasing heat load of deethanizer bottom reboiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

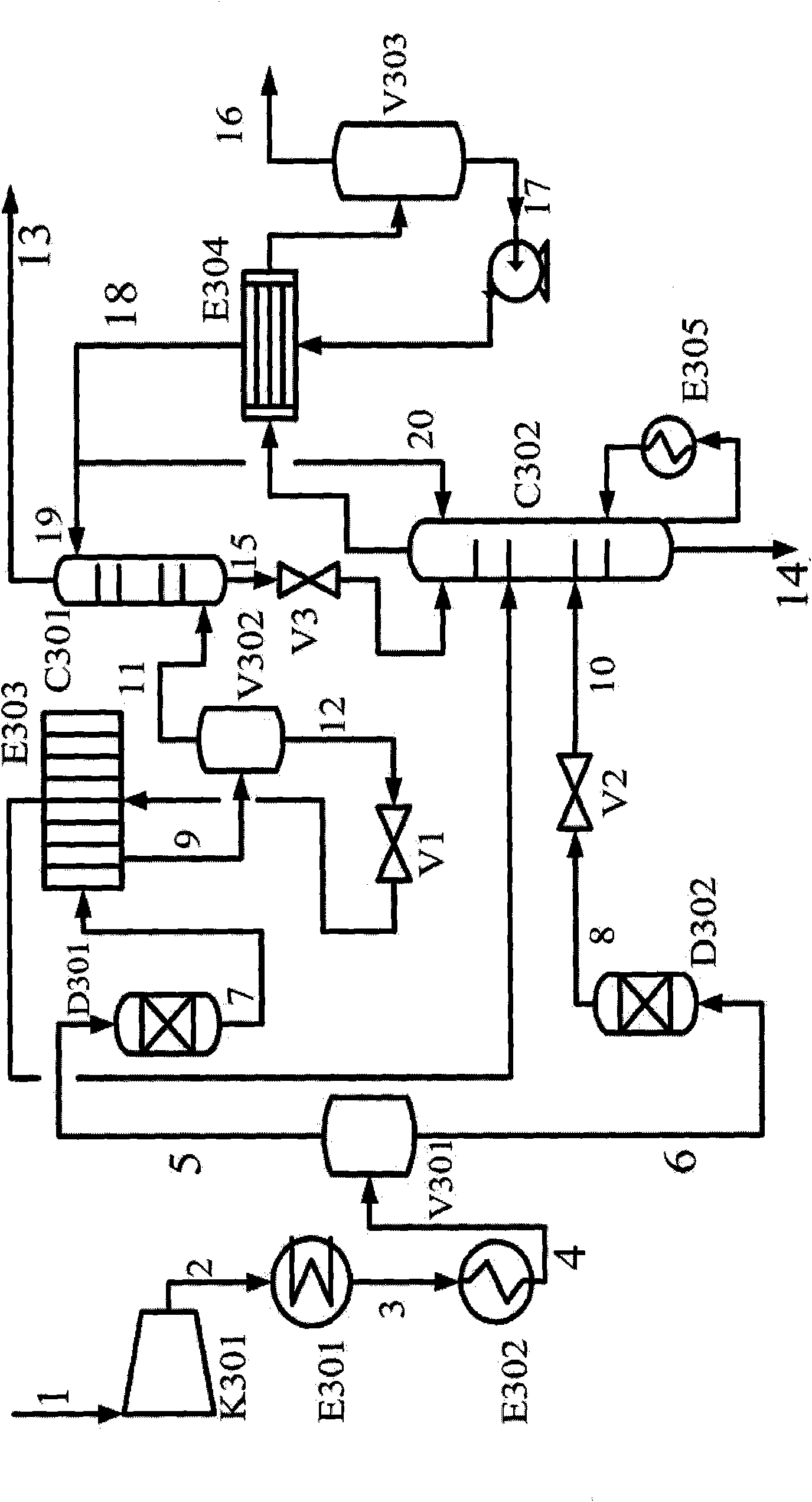

Method used

Image

Examples

Embodiment 1

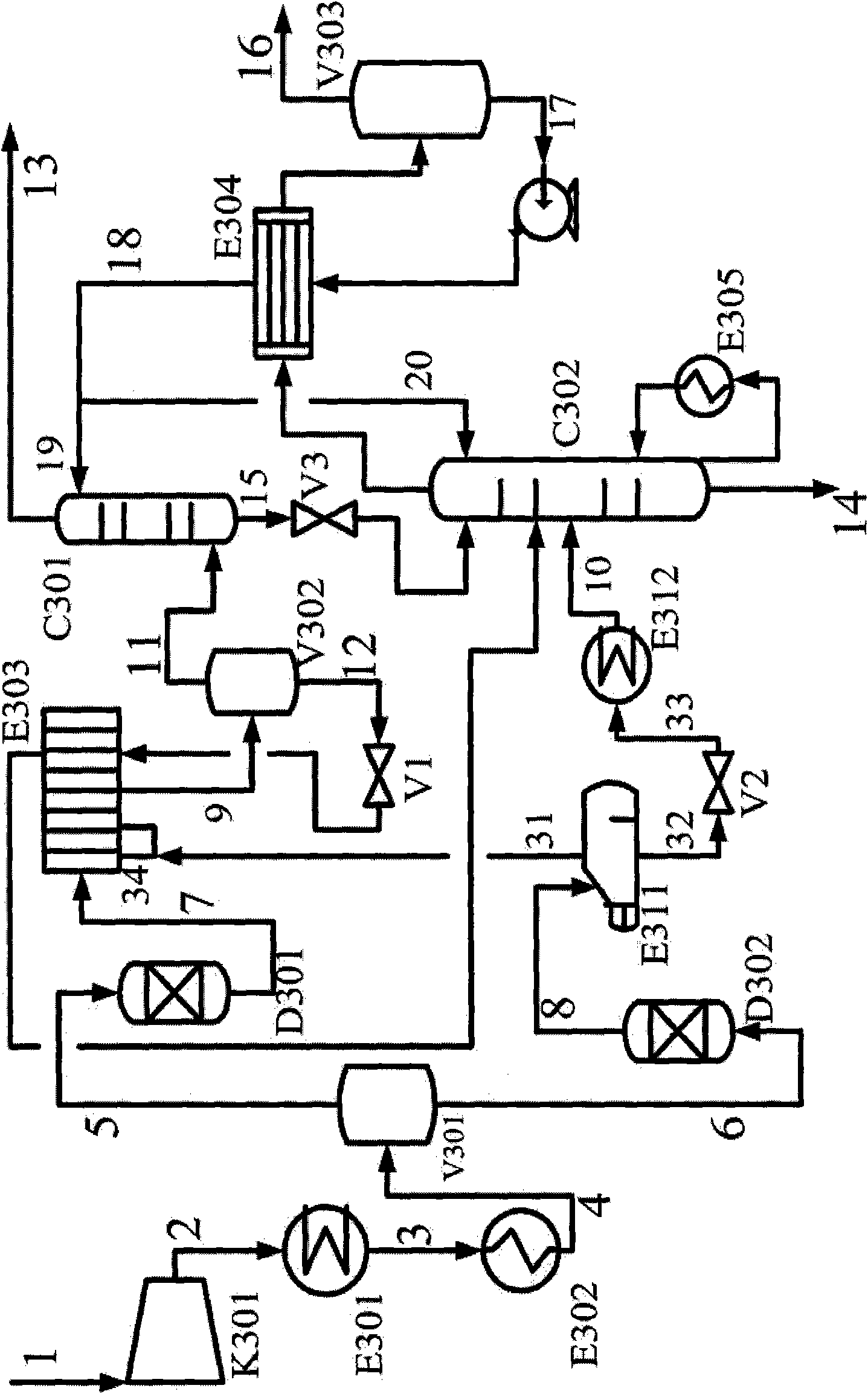

[0030] exist figure 2 Among them, the evaporation temperature of the condensate pre-heater E311 is selected to be 30°C, and the condensate heater E312 heats the process flow 33 to 60°C. implement the present invention figure 2 Example typical data are listed in Table 2. It can be seen from Table 2 that the implementation figure 2 After the invention, the cooling capacity required by the top condenser of the deethanizer was reduced by 10kw, the uncondensed gas flow rate was reduced by 456kg / h, and the final power of the cracked gas compressor was reduced by 16kw at the same time. implement figure 2After the invention, the ethylene unit further utilizes the surplus quench water heat to reduce the heat load of the reboiler at the bottom of the deethanizer and the circulating water volume for cooling the quench water. It can be seen from Tables 1 and 2 that the heat load of the reboiler at the bottom of the deethanizer decreased by 14410.8MJ / h, and the consumption of low-p...

Embodiment 2

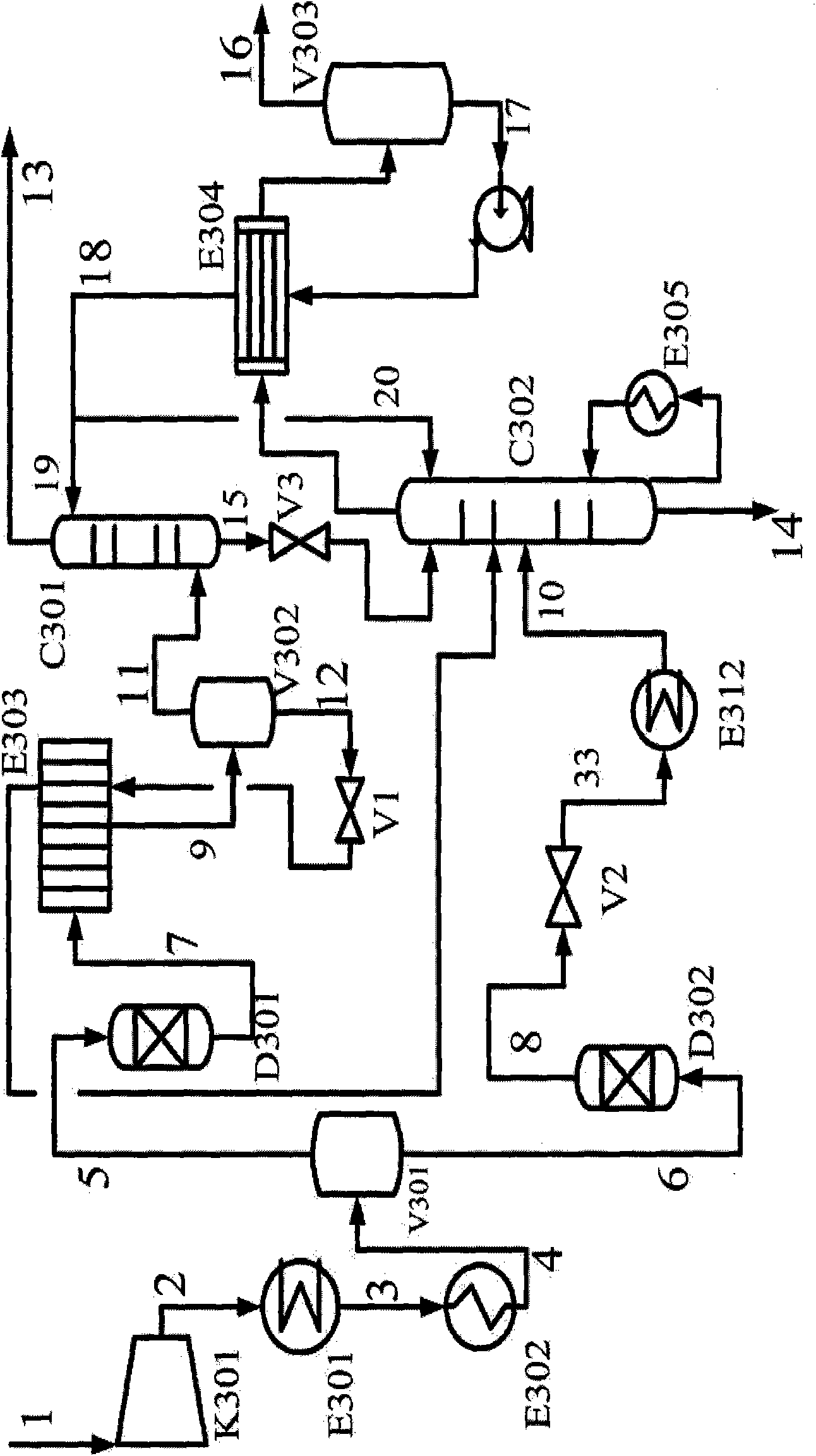

[0034] exist image 3 Among them, the condensate pre-heater E311 is canceled, and the condensate heater E312 heats the process stream 33, 10 at 10.7°C to 50°C. implement the present invention image 3 Example typical data are listed in Table 3. As can be seen from Table 3, the implementation image 3 After the invention, the cooling capacity required by the top condenser of the deethanizer was reduced by 38kw, but the flow rate of uncondensed gas was increased by 206kg / h, and the power of the cracked gas compressor was increased by 5kw at the same time. The cooling capacity required by the pre-cooling section An increase of 9kw has little effect on cracked gas compressors and propylene refrigeration compressors. implement image 3 After the invention, it can be seen from Tables 1 and 3 that the heat load of the reboiler at the bottom of the deethanizer decreased by 11696.8MJ / h, and the consumption of low-pressure steam was reduced by 5023kg / h; the amount of circulating wat...

Embodiment 3

[0038] Will image 3 The condensate heater E312 in is moved to the deethanizer tower as an intermediate reboiler, and the heat load of the intermediate reboiler is the same as in Scheme 2 image 3 The heat load of the condensate heater E312 is the same in the example. After implementing this, with image 3 Compared with the typical data in Table 3 of the example, only the cooling data of the deethanizer overhead condenser increased from 38kw to 150kw, and other data remained almost unchanged, indicating that adding the middle reboiler of the deethanizer further reduced the Cooling capacity required by the tower overhead condenser. The comprehensive energy consumption per ton of ethylene produced by the ethylene plant decreased by 158MJ, that is, 3.78 kg standard oil / ton of ethylene.

[0039] According to the results of the examples, after applying the present invention, the comprehensive energy consumption per ton of ethylene produced by large and medium-sized ethylene plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com