Patents

Literature

204results about How to "Save cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

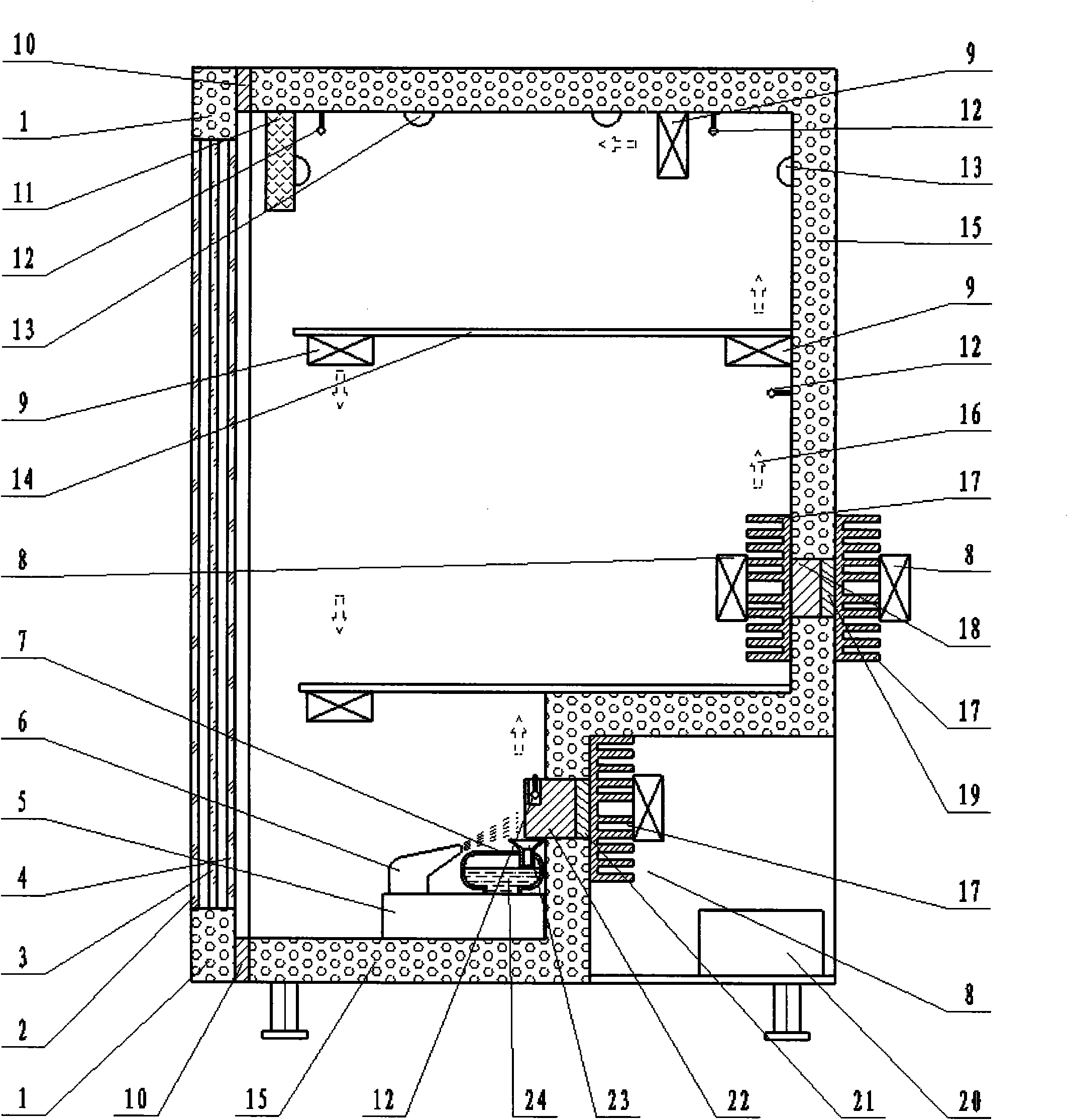

High-precision and constant temperature and humidity cabinet

InactiveCN101898658AEliminate leakage hazardsSmall thermal inertiaSpace heating and ventilation safety systemsLighting and heating apparatusDisplay deviceEngineering

The invention relates to a high-precision and constant temperature and humidity cabinet, which is used for storing special articles. The temperature and humidity in the cabinet can be controlled within designated scope automatically and constantly. In the invention, a cooling / heating semiconductor high-temperature stacking is used as a temperature control and dehumidification executive component, an ultrasonic wave humidifier is used as a humidification executive component, and an electric temperature / humidity sensor, a series of fans, keys, a display, a controller and the like are mounted, thereby realizing constant temperature and humidity. When temperature inside the cabinet is higher than preset target temperature, the temperature control semiconductor high-temperature stacking generates forward current to reduce the temperature inside the cabinet; when temperature inside the cabinet is lower than the preset target temperature, the temperature control semiconductor high-temperature stacking generates reverse current to raise the temperature inside the cabinet to the preset target temperature; when humidity inside the cabinet is higher than preset target humidity, the dehumidification semiconductor high-temperature stacking generates forward current to reduce the temperature of a condensation block in the cabinet to be below the dew point, so as to enable moisture in the cabinet to condensate and flow into a water tank to realize dehumidification effect; and when humidity inside the cabinet is lower than preset target humidity, an ultrasonic wave humidifier sprays water mist to raise the humidity in the cabinet to the preset target humidity.

Owner:邢刚

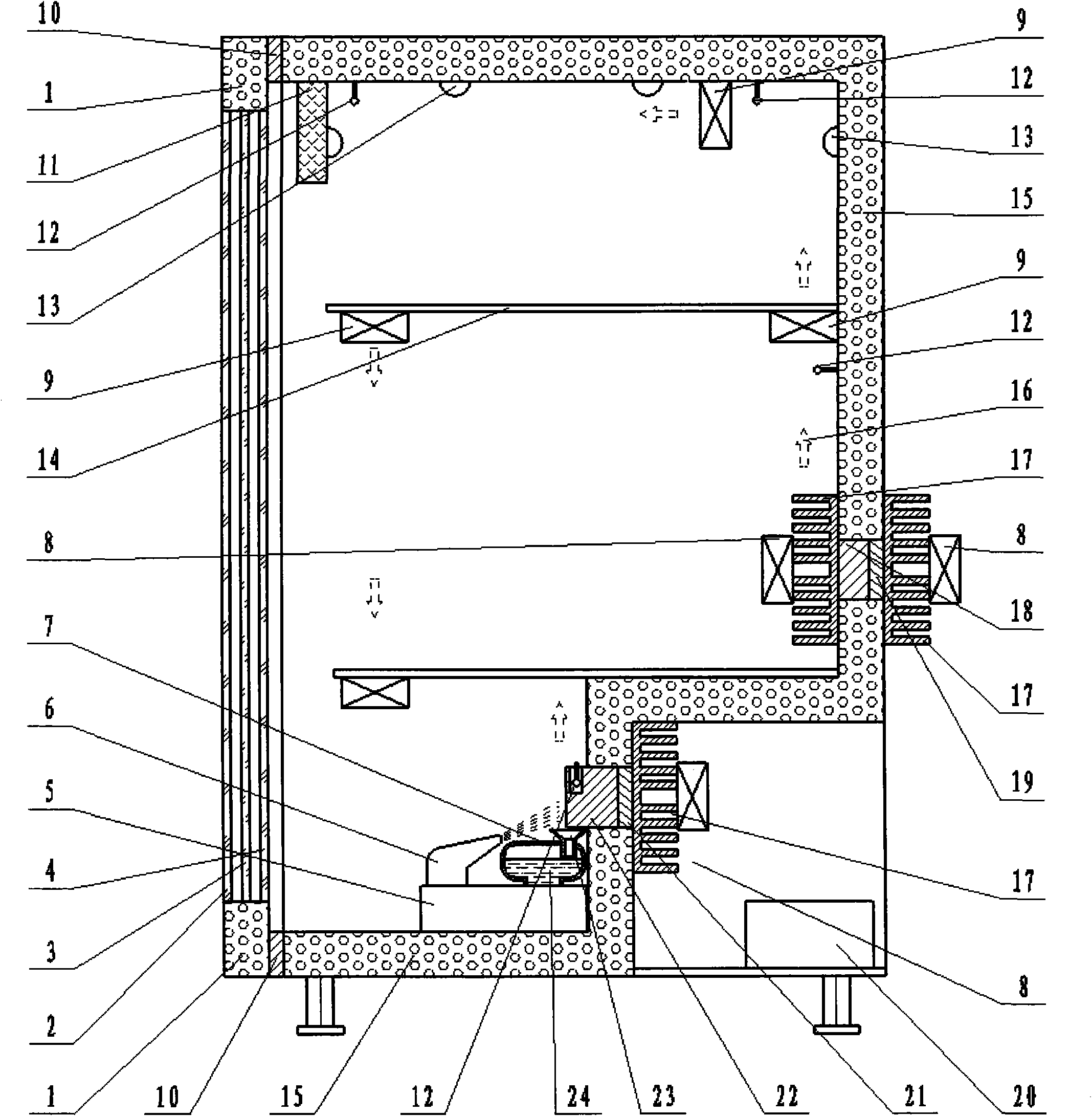

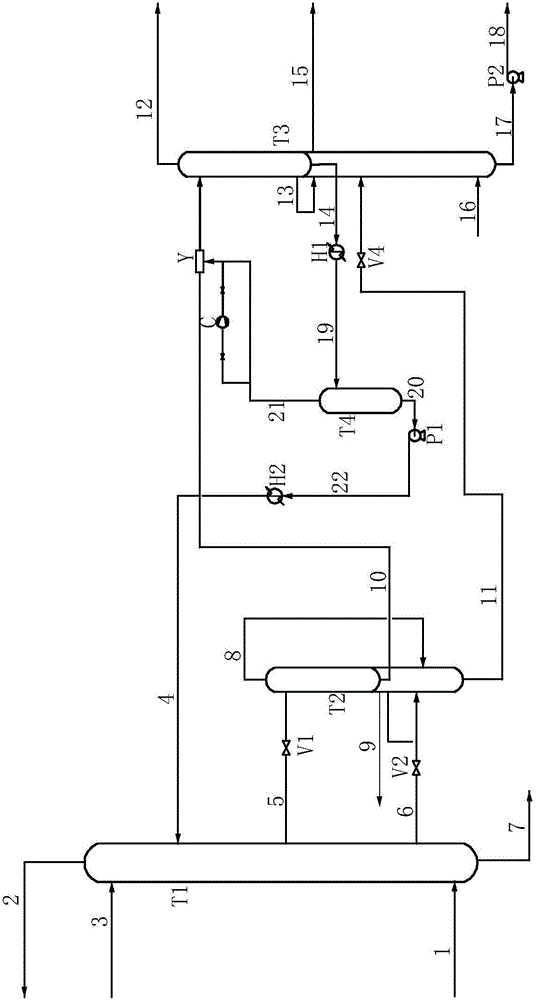

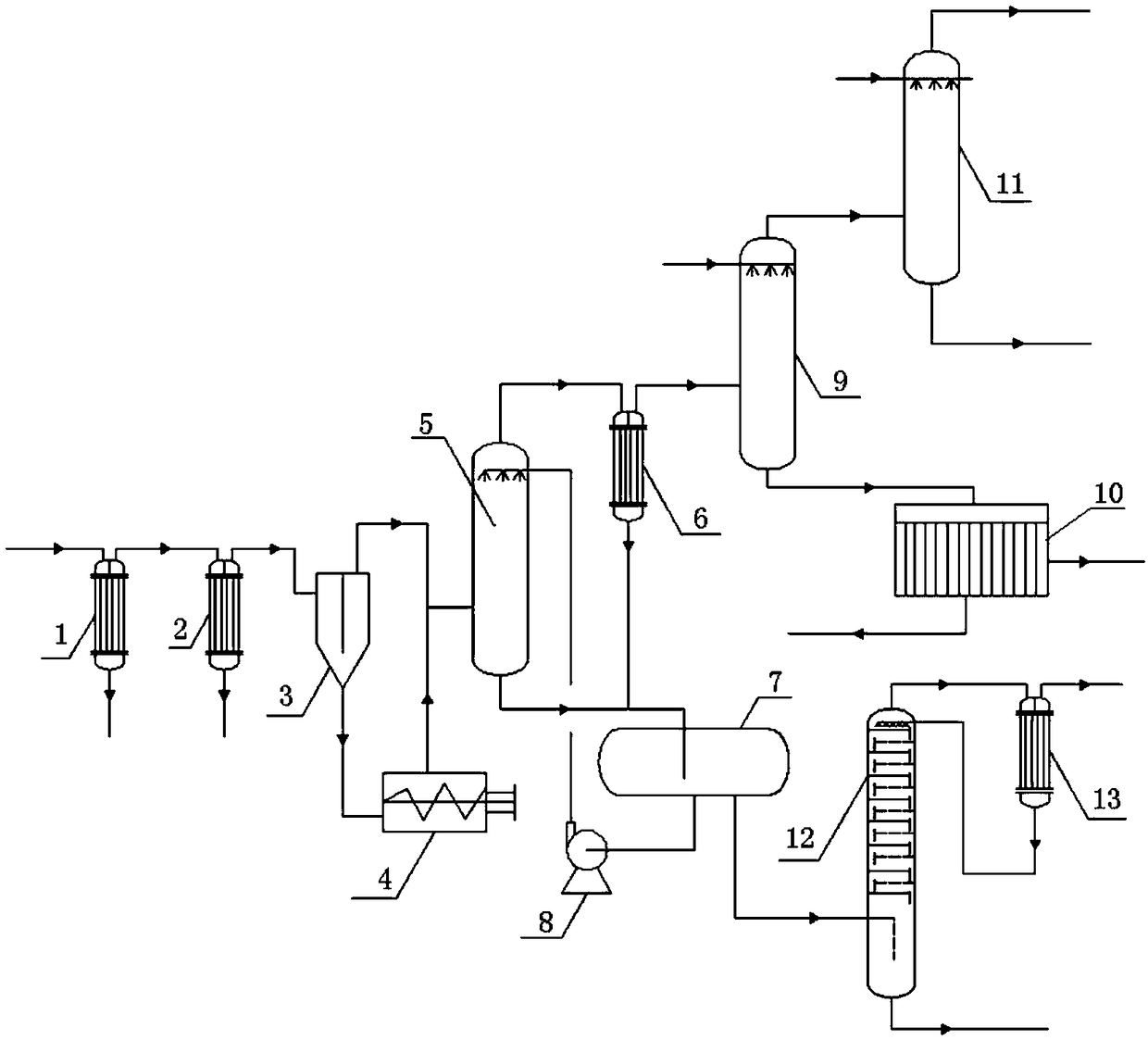

Method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen

ActiveCN102942446ALow costReduce heating effectOrganic compound preparationEnergy inputGas phaseProduct gas

The invention relates to a method for preparing ethanol via hydrogenation of acetic ester based on recirculating of recovered hydrogen. The method comprises the steps of: recycling hydrogen in the gas phase of a product by using a pressure swing adsorption (PSA) device and then increasing the pressure for recirculating; heating the mixed gas of acetic ester, circulated hydrogen and fresh hydrogen by using reaction heat; heating the preheated raw material gas by medium-pressure steam and then importing into a reactor so as to realize high acetic ester conversion rate and high ethanol selectivity in the presence of a catalyst; and carrying out gas-liquid separation on the product gas obtained via the reaction, and liquefying and separating the reaction principal product ethanol, a small amount of byproducts and unreacted acetic ester to obtain an initial product. According to the method, hydrogen is recycled and recirculated via PSA so that the use of the raw material hydrogen can be greatly reduced, the reaction raw materials are preheated by fully utilizing the reaction heat so that the energy consumption of the heating and the cooling is decreased, the flow is simple and the control is simple and convenient.

Owner:DATANG INT CHEM TECH RESINST

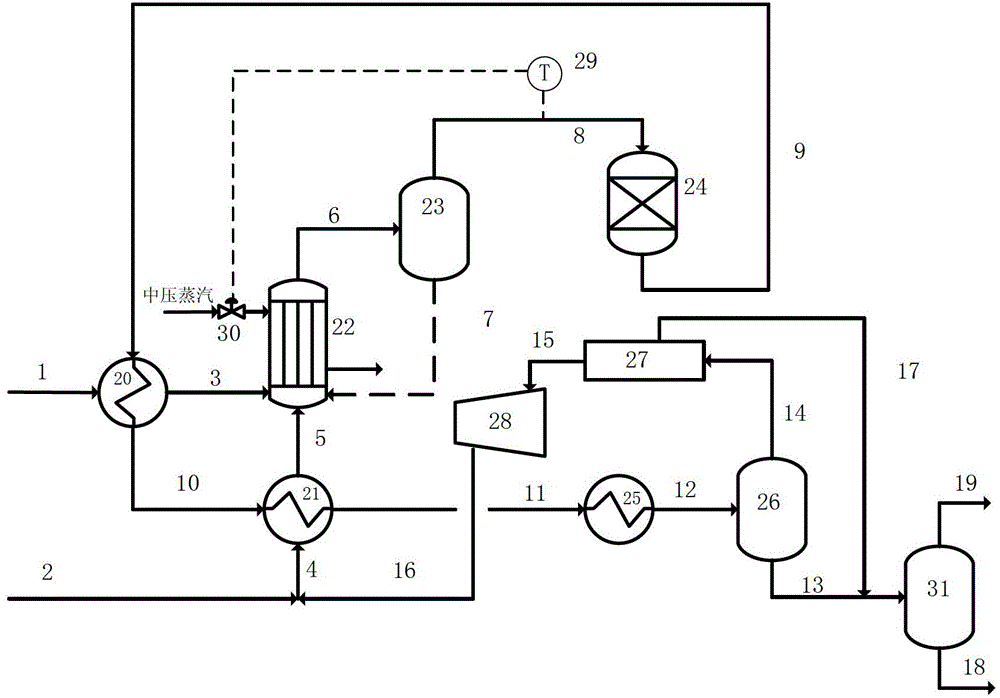

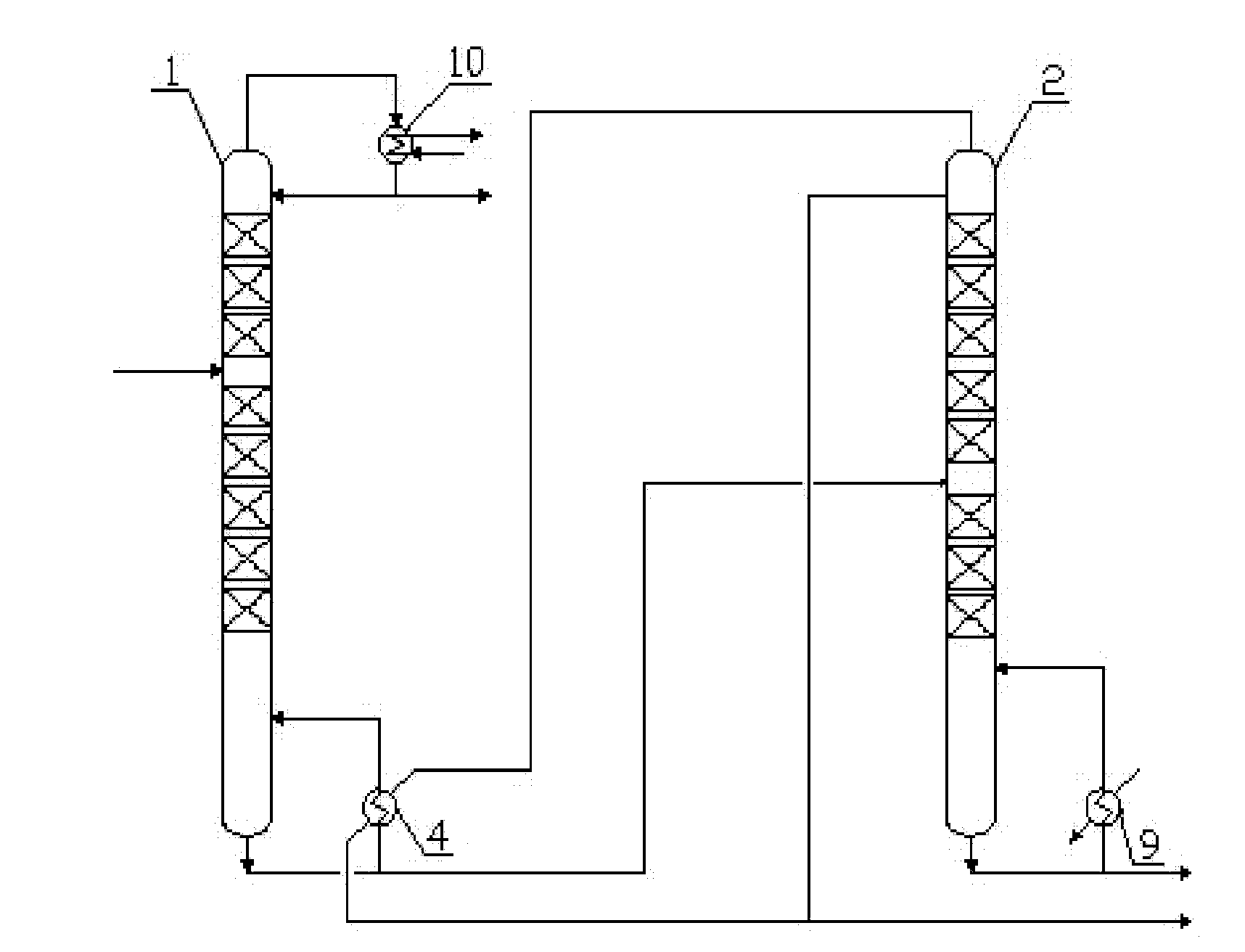

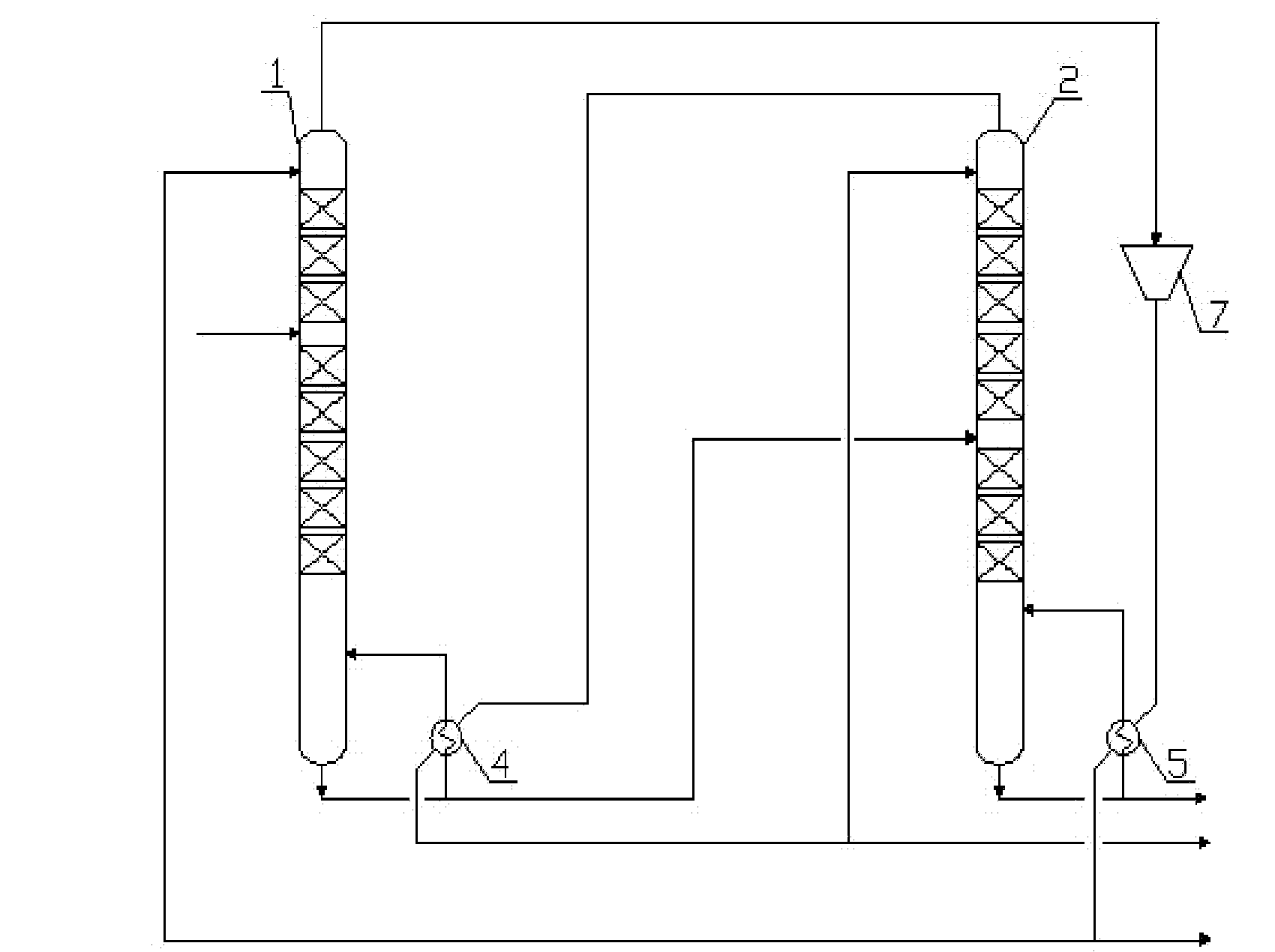

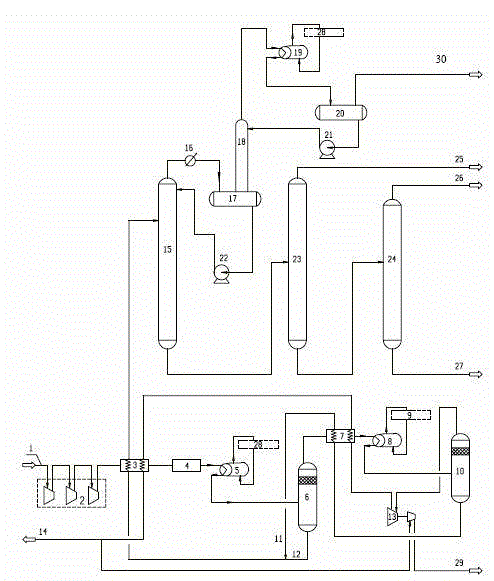

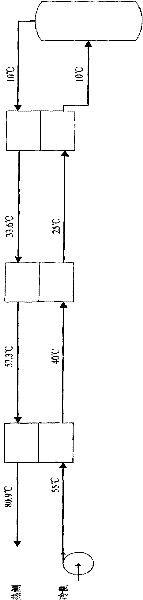

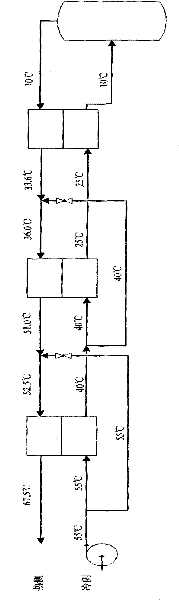

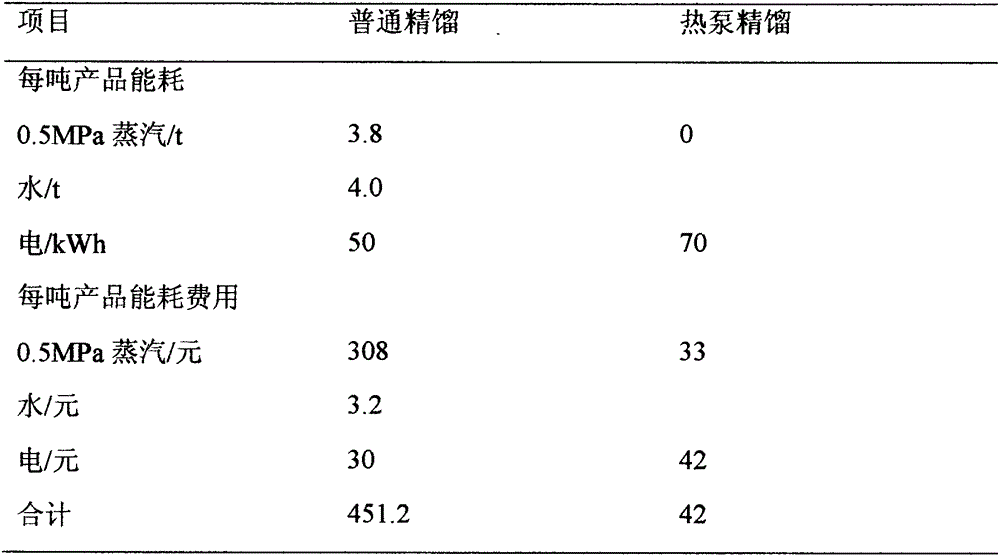

Heat pump distillation and multi-effect distillation integrated device and process for purifying trichlorosilane

InactiveCN102153092AReduce energy consumptionIncrease power consumptionEnergy inputHalogenated silanesElectricityReboiler

The invention discloses a heat pump distillation and multi-effect distillation integrated device and process for purifying trichlorosilane. The steam at the top of a high-pressure tower which is a high-boiling-fraction removal column is used to heat liquid at the bottom of a low-pressure tower which is a low-boiling-fraction removal column, the steam at the top of the high-boiling-fraction removal column is condensed, and the process is a multi-effect distillation process; meanwhile, the steam at the top of the low-boiling-fraction removal column is subjected to pressure and temperature rise through a compressor and then is used for heating the liquid at the bottom of the high-boiling-fraction removal column, the steam at the top of the low-boiling-fraction removal column is condensed, and the process is a heat pump distillation process; and the integration of the heat pump distillation and multi-effect distillation can be realized in the whole process. In the whole process flow, one compressor is additionally arranged, the heat exchange process inside a rectification system is realized by two heat exchangers and condensers and reboilers are saved simultaneously, that is to say, small amount of electricity consumption of one compressor is added and a large amount of cold energy and heat public works are saved, and thereby the energy consumption for the whole rectification and purification process of the trichlorosilane is greatly reduced.

Owner:TIANJIN UNIV

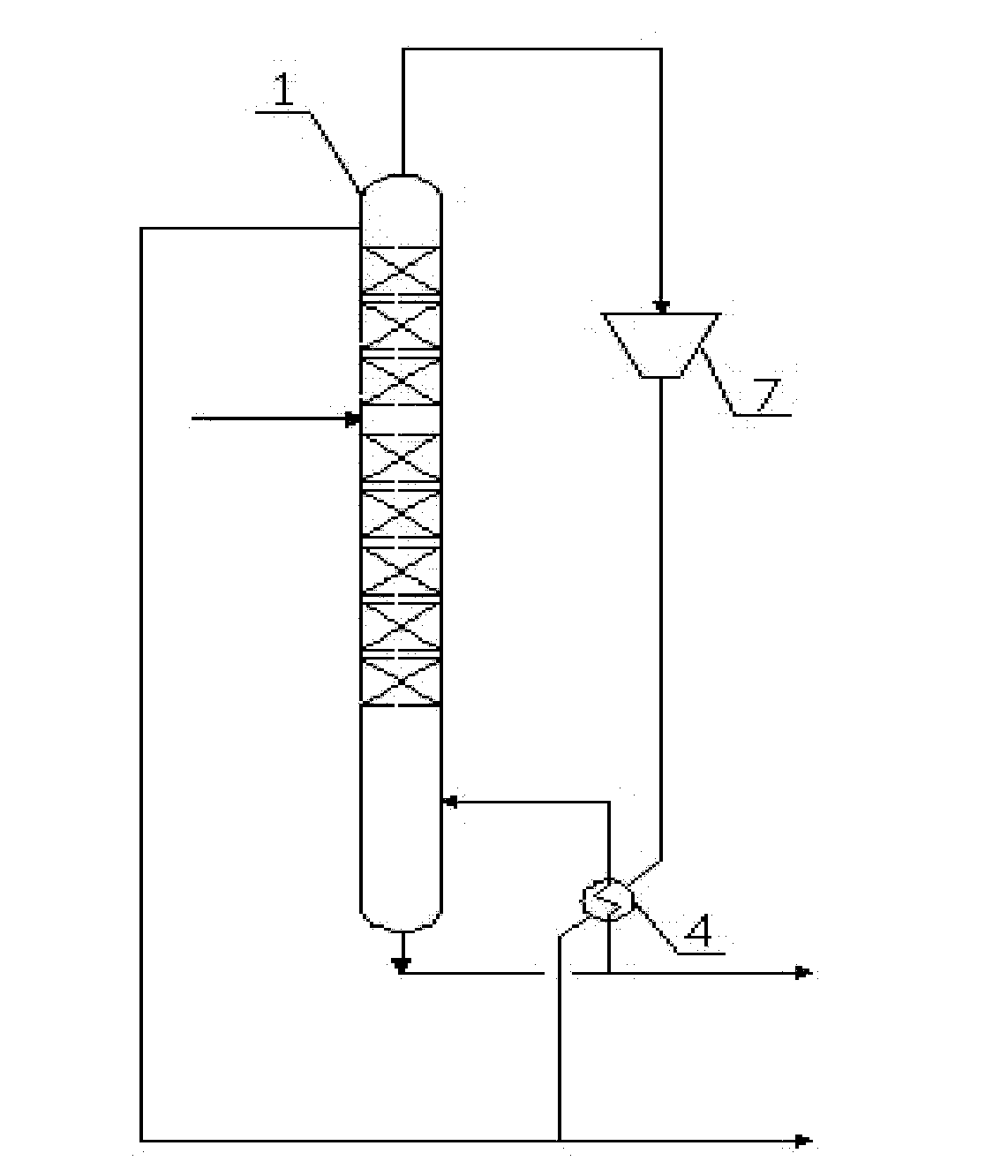

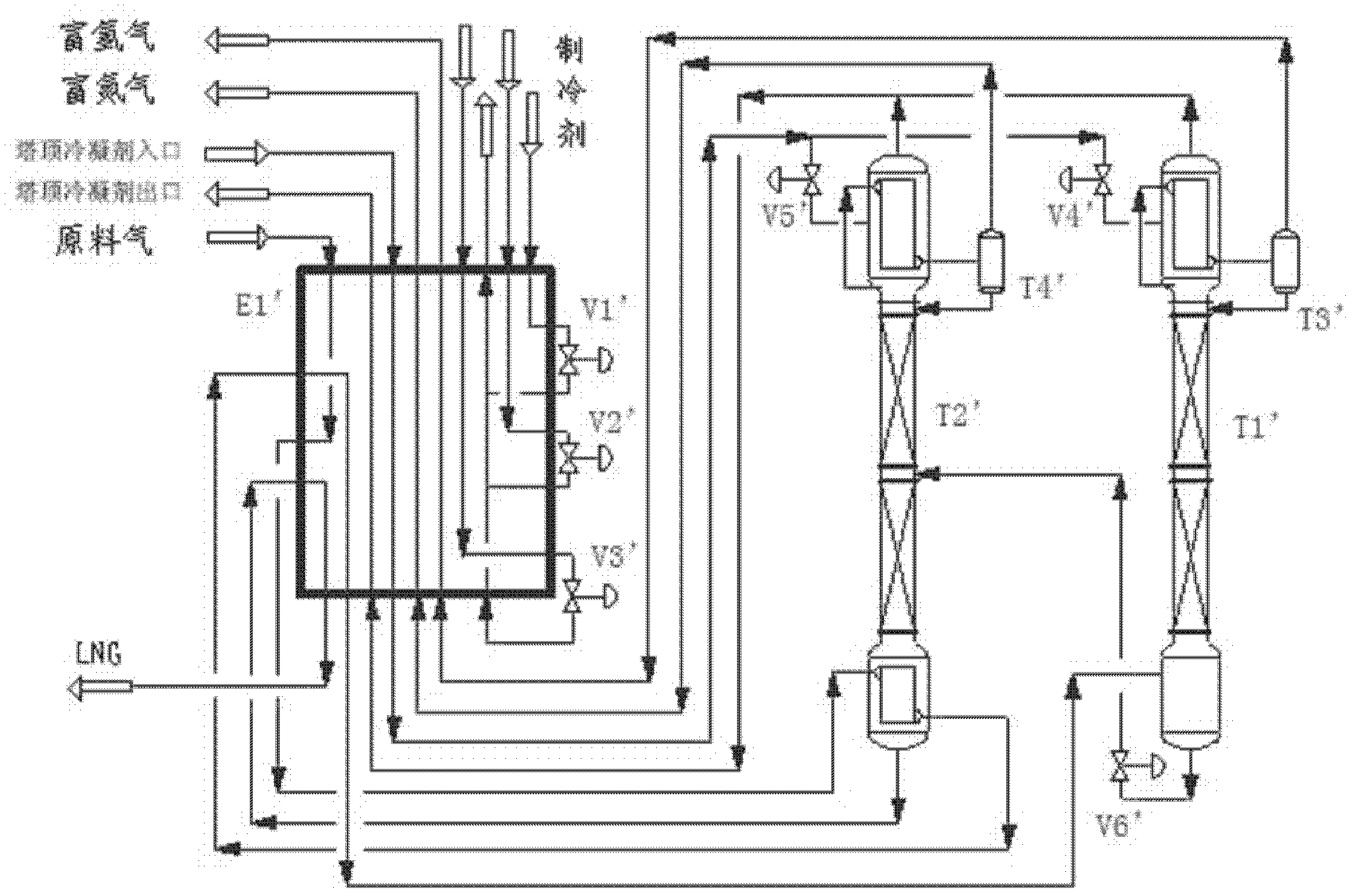

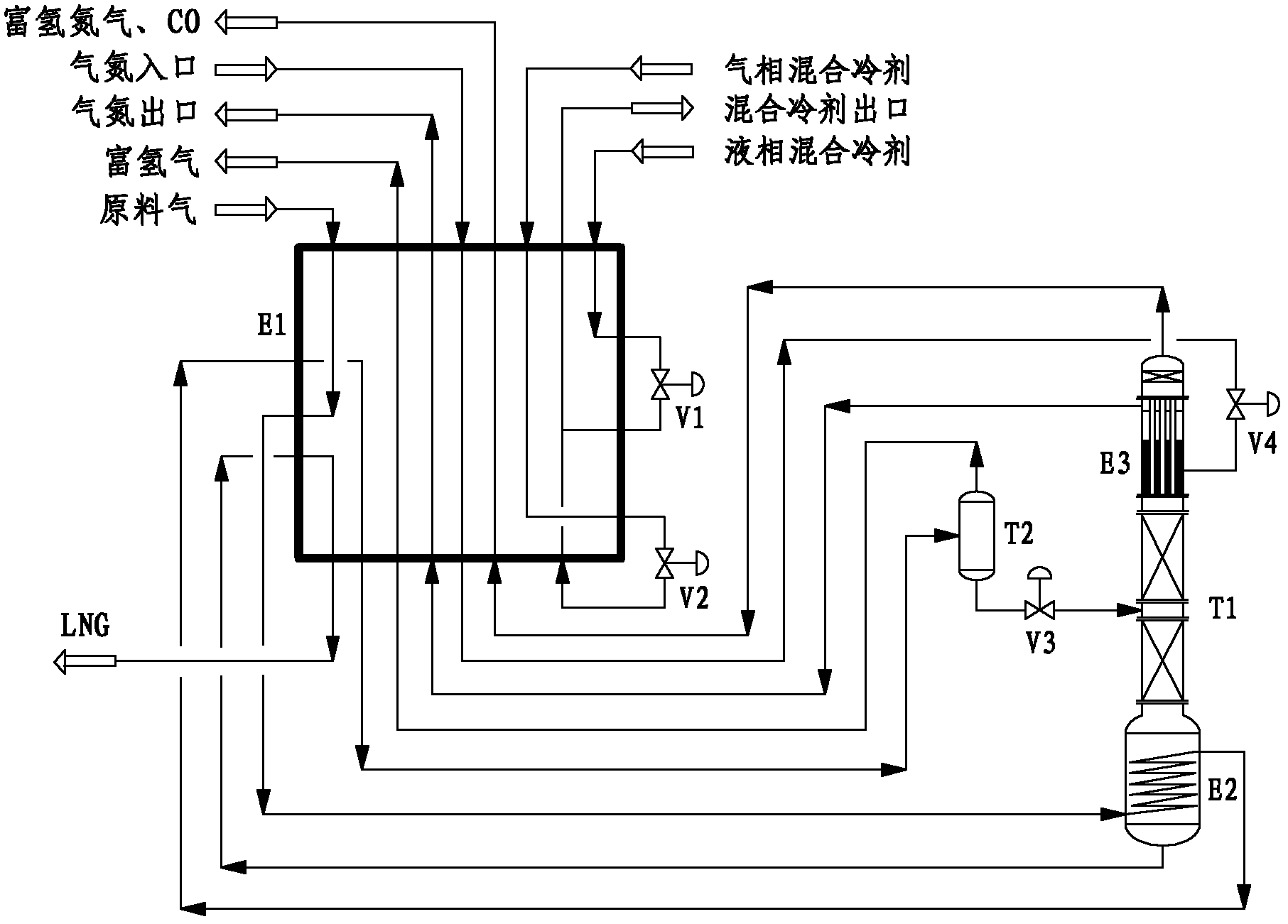

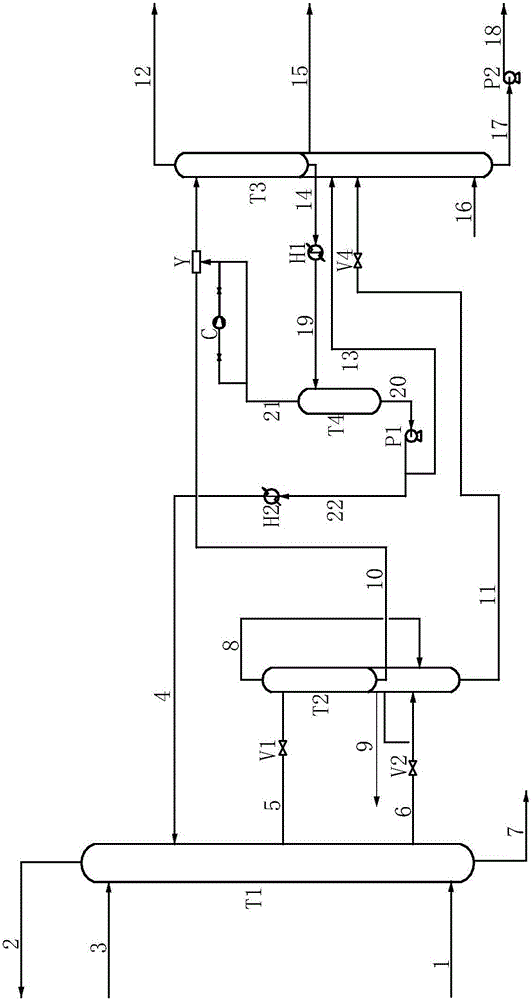

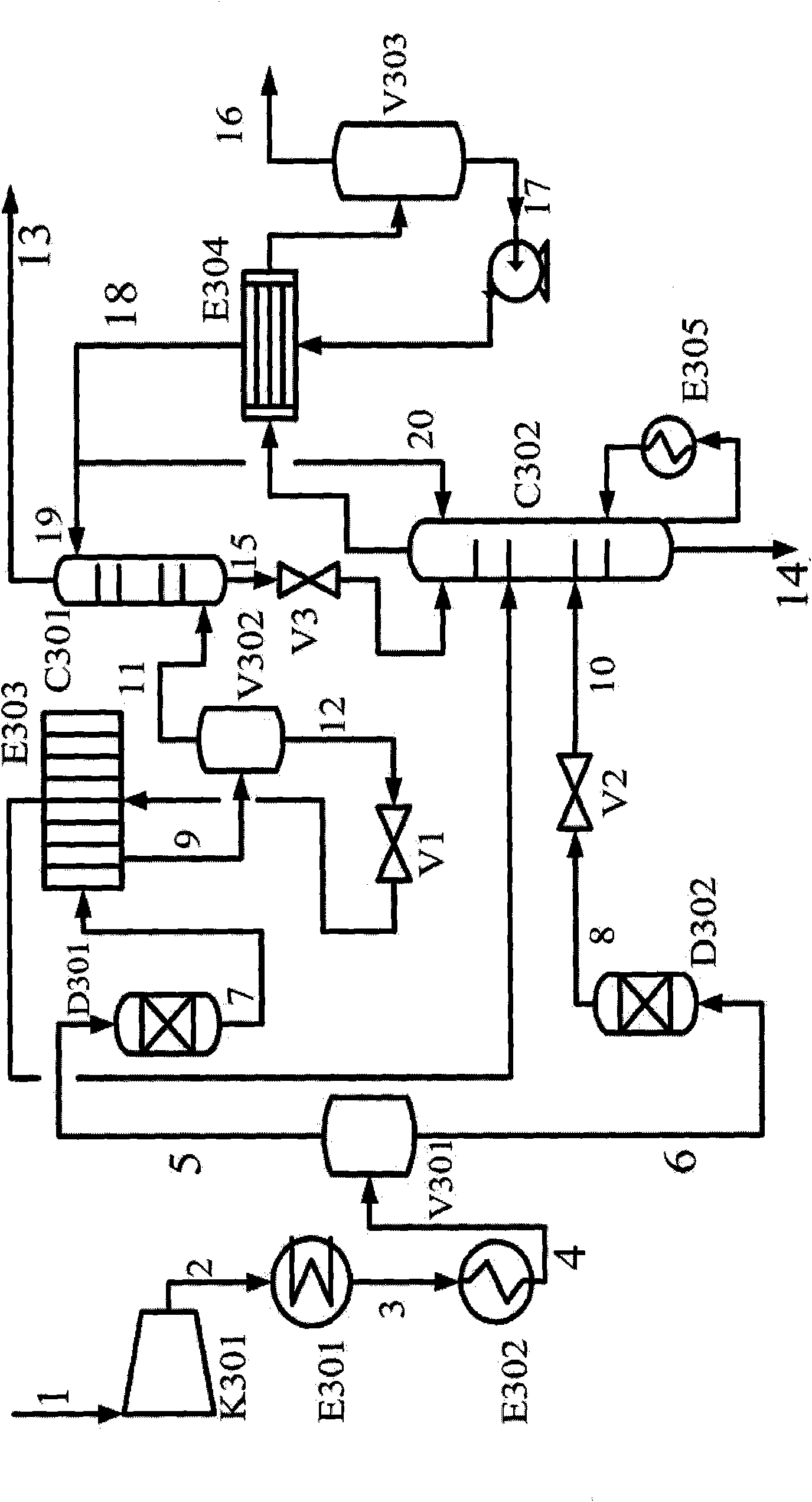

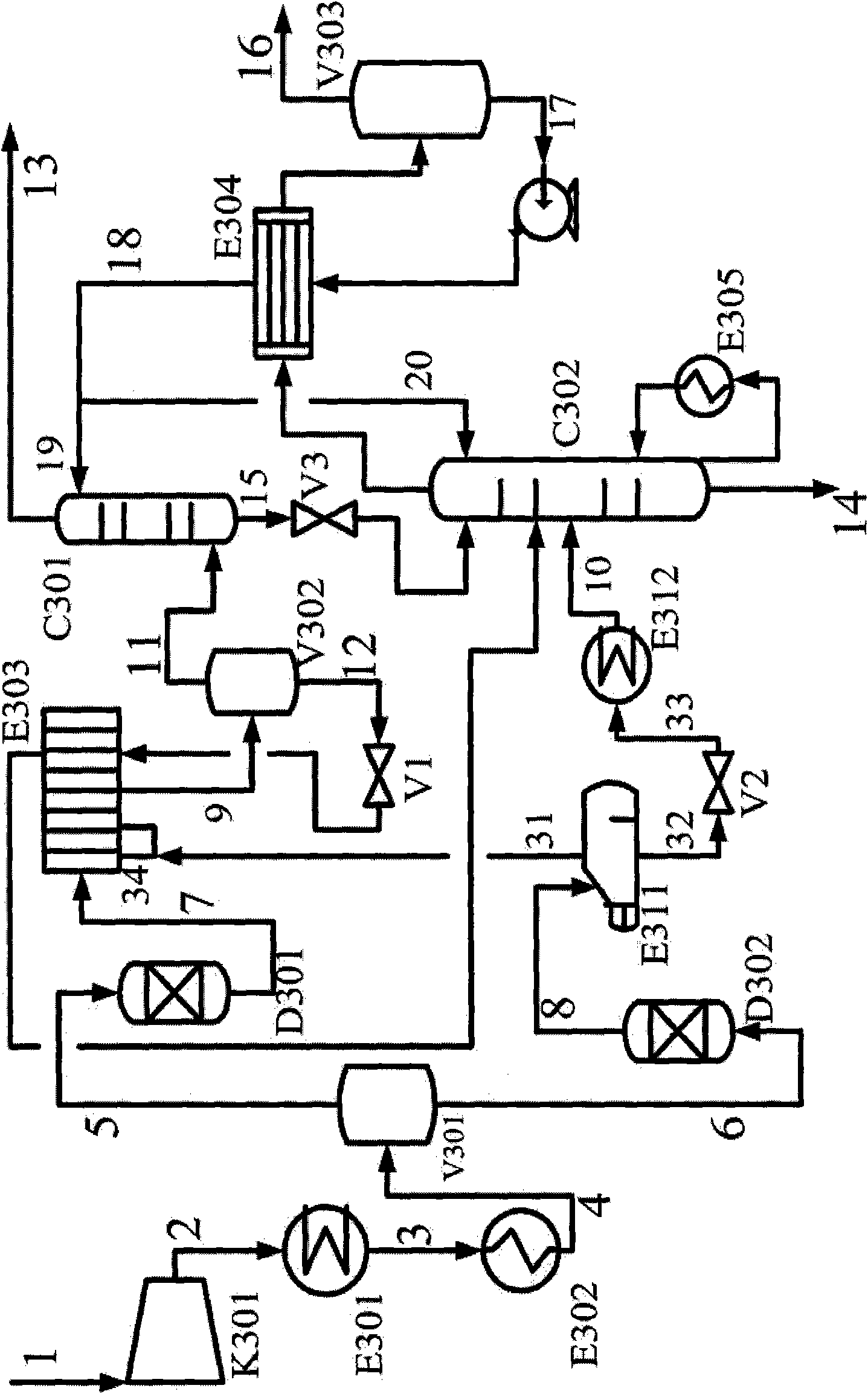

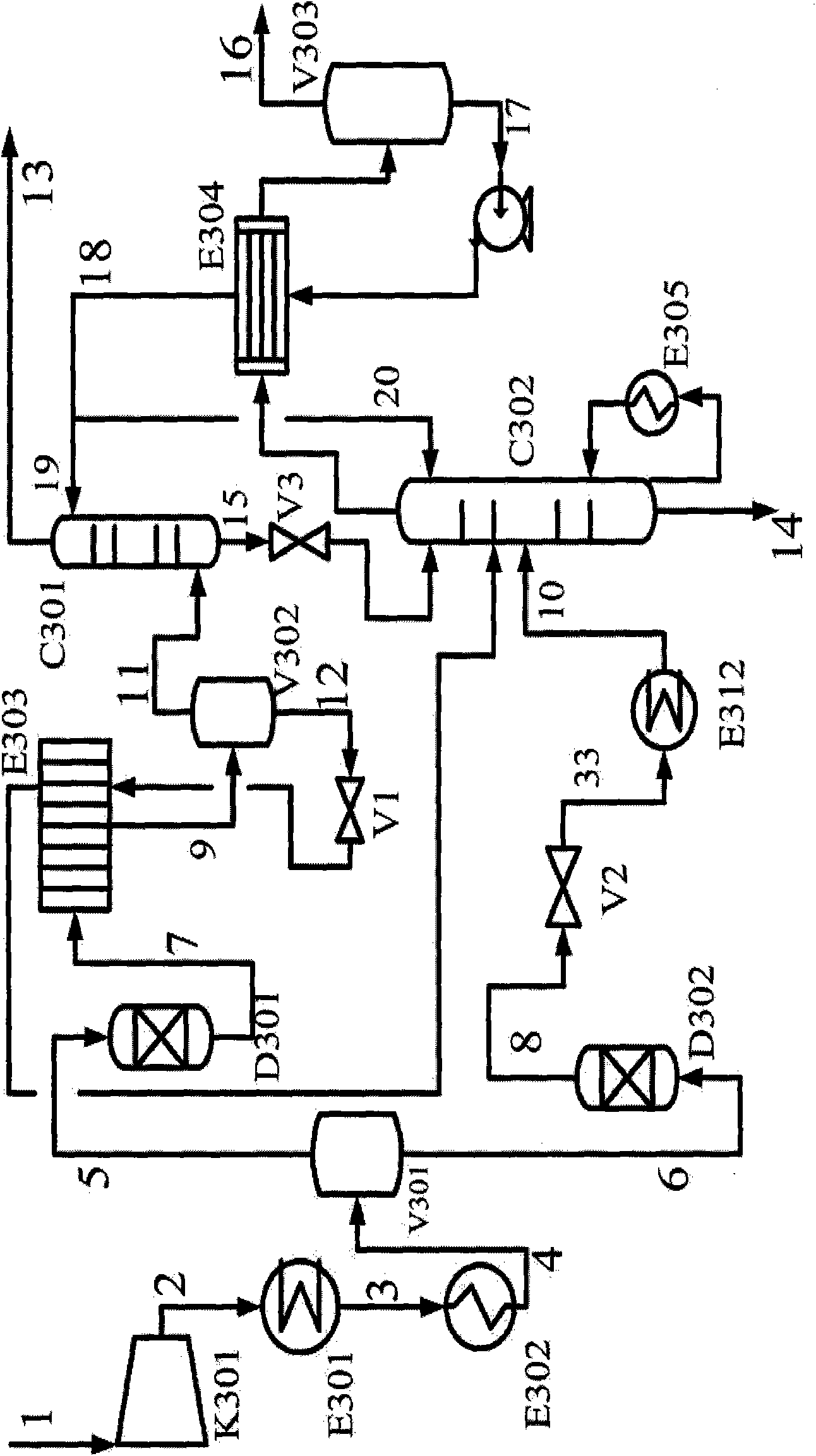

Technology and device for removing hydrogen and nitrogen from methane rich gas and producing liquefied natural gas

ActiveCN102620521AReduce energy consumptionReduce loadSolidificationLiquefactionNitrogen gasMixed gas

The invention discloses a technology and a device for removing hydrogen, nitrogen and carbon monoxide from methane rich gas and producing liquefied natural gas (LNG). The technology comprises two parts, namely low-temperature liquefaction and rectification separation after flash evaporation; the low-temperature liquefaction part is finished in a cold box by using cold flow supplied by a mixed refrigerant; in the rectification separation part after flash evaporation, the hydrogen, the nitrogen and the carbon monoxide are removed by adopting a flash evaporation and rectification flow; and after the methane rich mixed gas containing the hydrogen and the nitrogen sequentially passes through the cold box, a re-boiler at the bottom of a rectification tower and the cold box and the methane components are liquefied, the methane rich mixed gas enters a rectification separation system, and the hydrogen, the nitrogen and the carbon monoxide are removed, wherein the obtained LNG product contains less than or equal to 2,000ppm of hydrogen, less than or equal to 4 percent of nitrogen and less than or equal to 6 percent of carbon monoxide. By the natural gas liquefaction technology for the methane rich gas containing the hydrogen, the nitrogen and the carbon monoxide, the hydrogen, the nitrogen and the carbon monoxide are removed, and the LNG is obtained at the same time; the technology is advanced in process route; and compared with the conventional technology, the technology has the advantage that the investment cost of equipment and the energy consumption of the system are remarkably reduced.

Owner:XINDI ENERGY ENG TECH +1

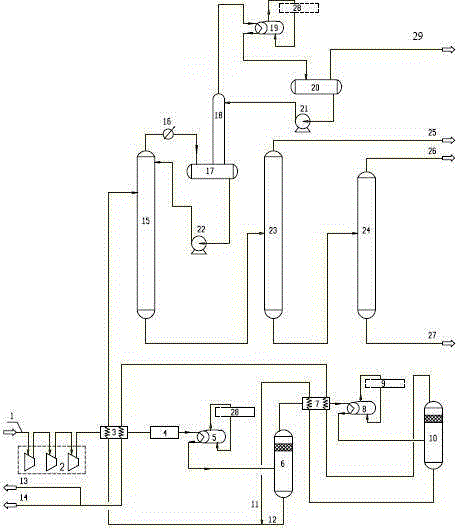

Separation method for reaction product of propane dehydrogenated propylene preparation

InactiveCN106316760AEasy to operateReduce contentDistillation purification/separationHigh energyPetrochemical

The invention discloses a separation method for a reaction product of propane dehydrogenated propylene preparation and belongs to the field of petrochemical industry. The method comprises the following steps: (1) the reaction product of propane dehydrogenated propylene preparation is pretreated, then, the pretreated reaction product enters a propylene and ethylene cascaded refrigeration system with an expander, and then, a liquid phase is fed to a deethanizer; (2) top oil gas of the deethanizer is condensed and then enters a reflux tank of the deethanizer, tank bottom liquid of the reflux tank of the deethanizer totally returns to the deethanizer, tank top gas of the reflux tank of the deethanizer enters a top condensation section of the deethanizer and is fractionated by the condensation section, and top gas of the condensation section is condensed by a refrigerator of the top condensation section of the deethanizer under the action of a propylene refrigerating system and then enters a deep freezing tank of the deethanizer; (3) tank top gas of the deep freezing tank of the deethanizer is delivered out of a device as fuel gas, and bottom liquid of the deethanizer enters a propylene refiner; and (4) a refined propylene product is fractionated from the top of the propylene refiner, a bottom liquid phase of the propylene refiner enters a depropanizer, and a bottom product C4+ cut of the depropanizer is delivered out of the device. By adopting the separation method, the problems, i.e., large absorbent circulating rate and high energy consumption in the prior art can be solved.

Owner:SINOPEC GUANGZHOU ENG +1

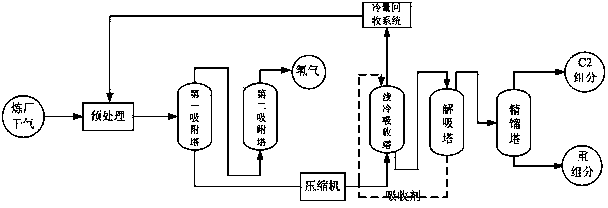

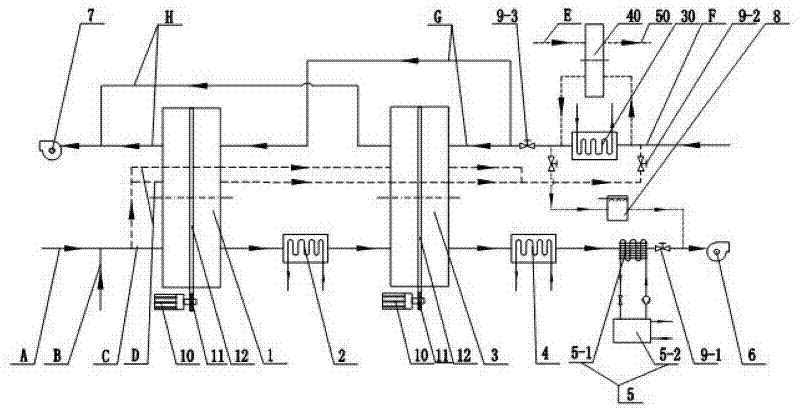

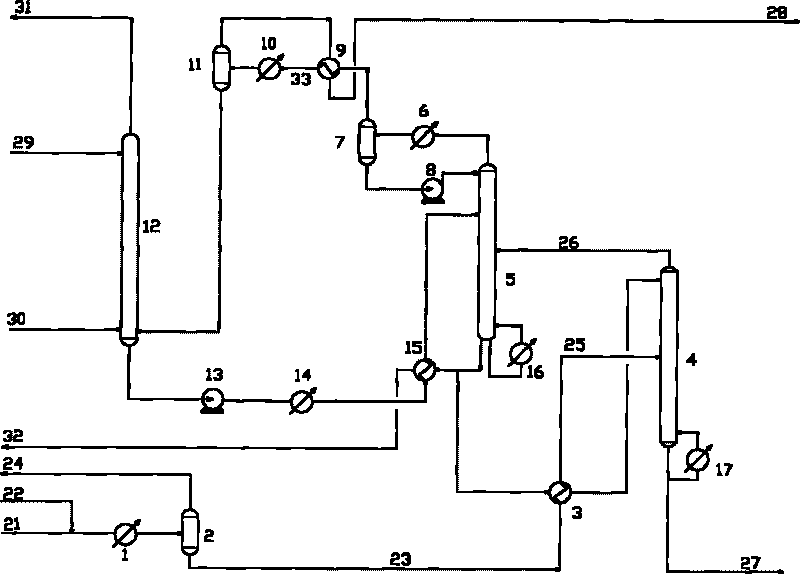

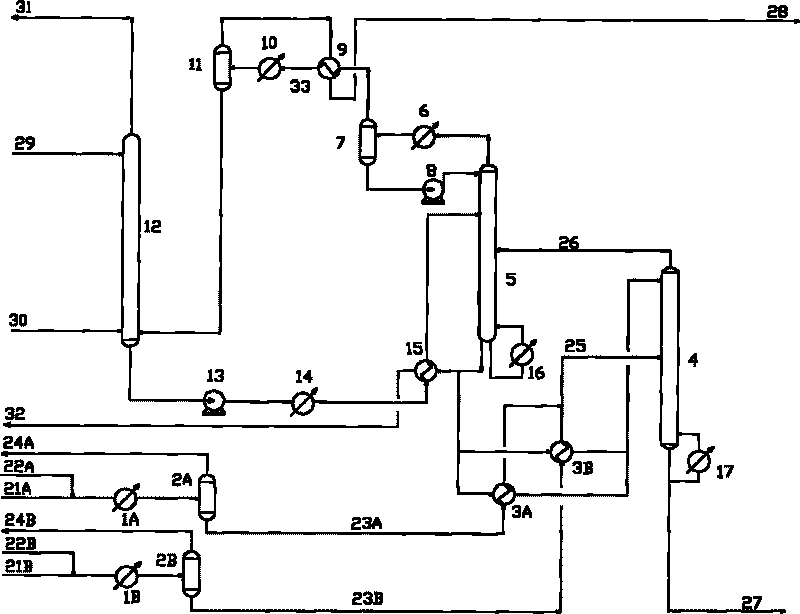

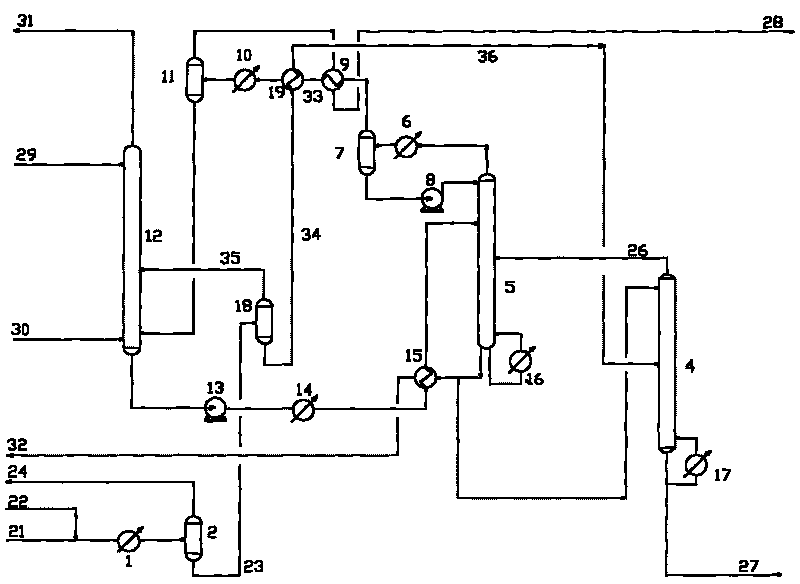

Method and device for separating hydrogen and ethylene from refinery dry gas by shallow condensing adsorption-absorption

ActiveCN104031682ASave coolingReduce energy consumptionHydrogen separationChemical industryHydrogenDesorption

The invention relates to a method for separating and extracting hydrogen and ethylene from refinery dry gas by shallow condensing adsorption-absorption. The method comprises the steps of: S1, carrying out adsorption for the first time on pretreated refinery dry gas of which the pressure is 0.5MPa; S2, pressurizing ethylene-enriched dry gas in the step S1 to 1-2MPa and carrying out shallow condensing absorption; and S3, enabling absorbing liquid obtained by shallow condensing absorption in the step S2 to be subjected to desorption. The invention also discloses a device for separating hydrogen and ethylene from refinery dry gas by shallow condensing adsorption-absorption. The device comprises a first adsorption tower, a second adsorption tower, a shallow condensing absorption tower, a desorber, an expander, a compressor and a pretreatment unit. According to the method and device disclosed by the invention, since C2 is separated and concentrated by virtue of carrying out shallow condensing absorption and low pressure adsorption absorption prior to the shallow condensing absorption, non-condensable gases, such as hydrogen are prevented from entering into the shallow condensing absorption unit, and thus the operating load and energy consumption of absorption are reduced and the investment of cost is decreased.

Owner:SICHUAN TECHAIRS

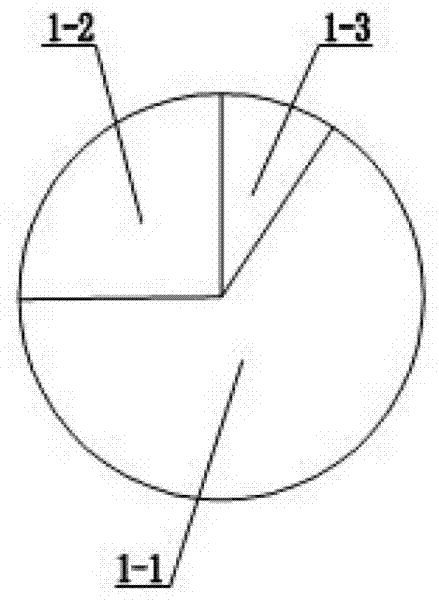

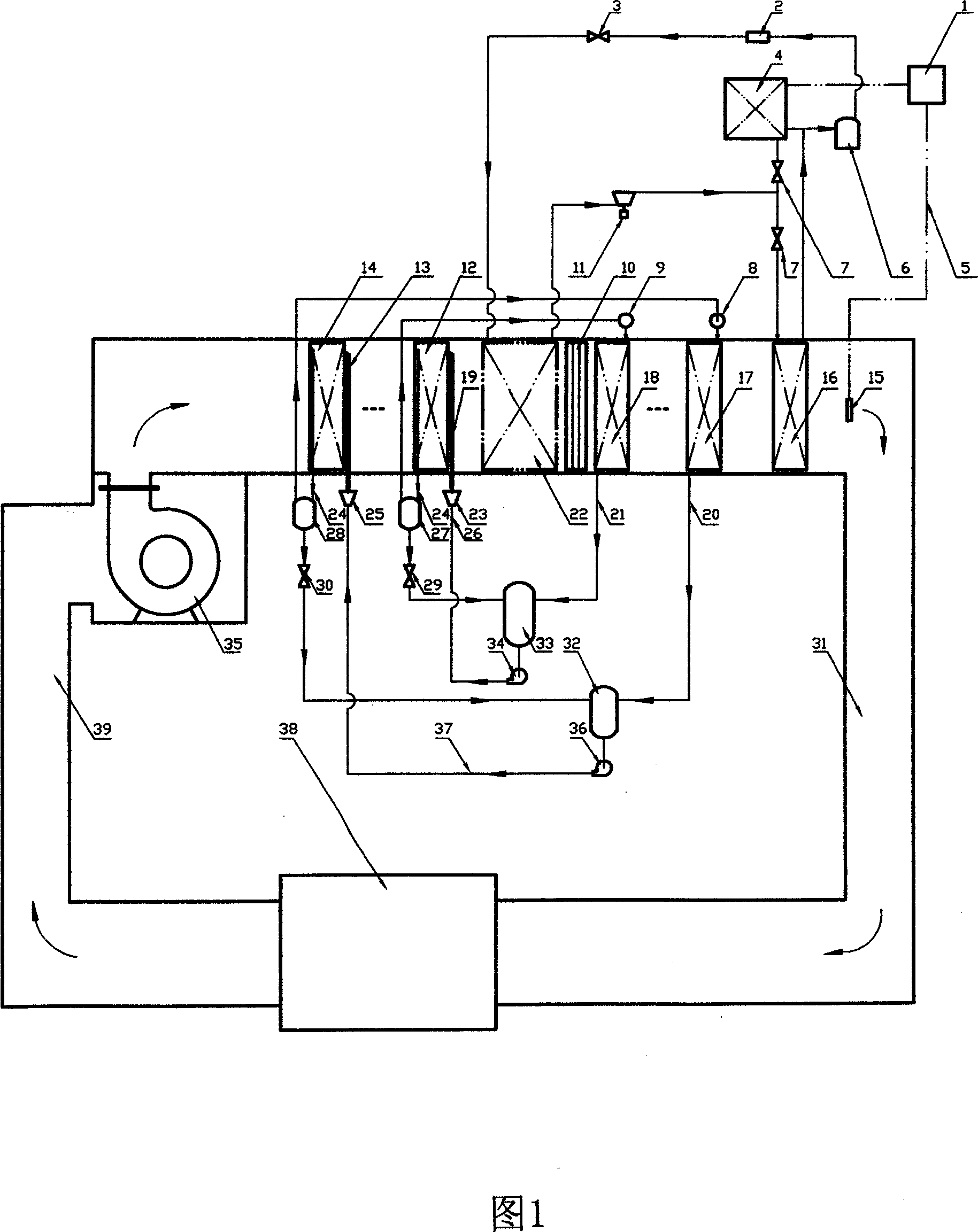

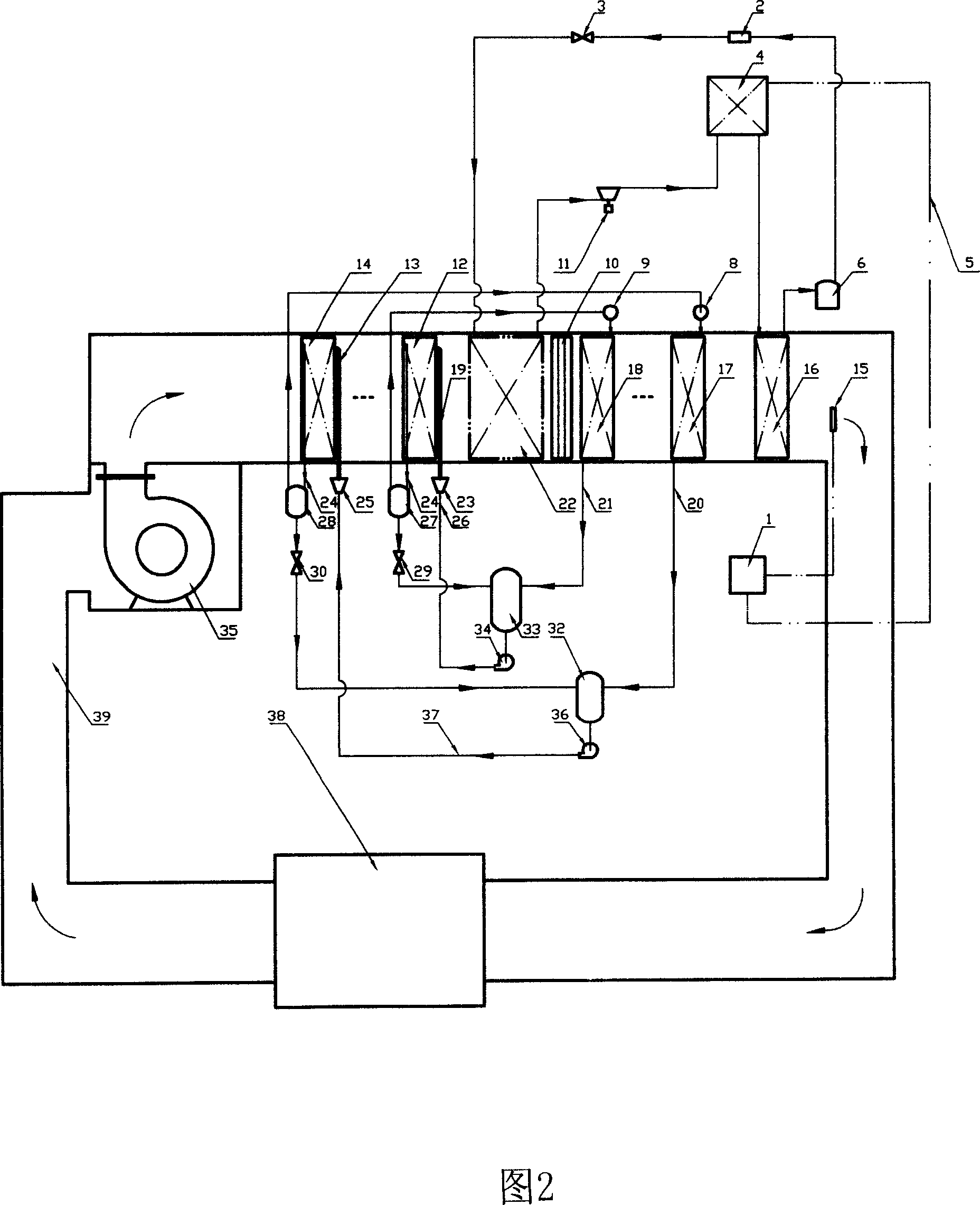

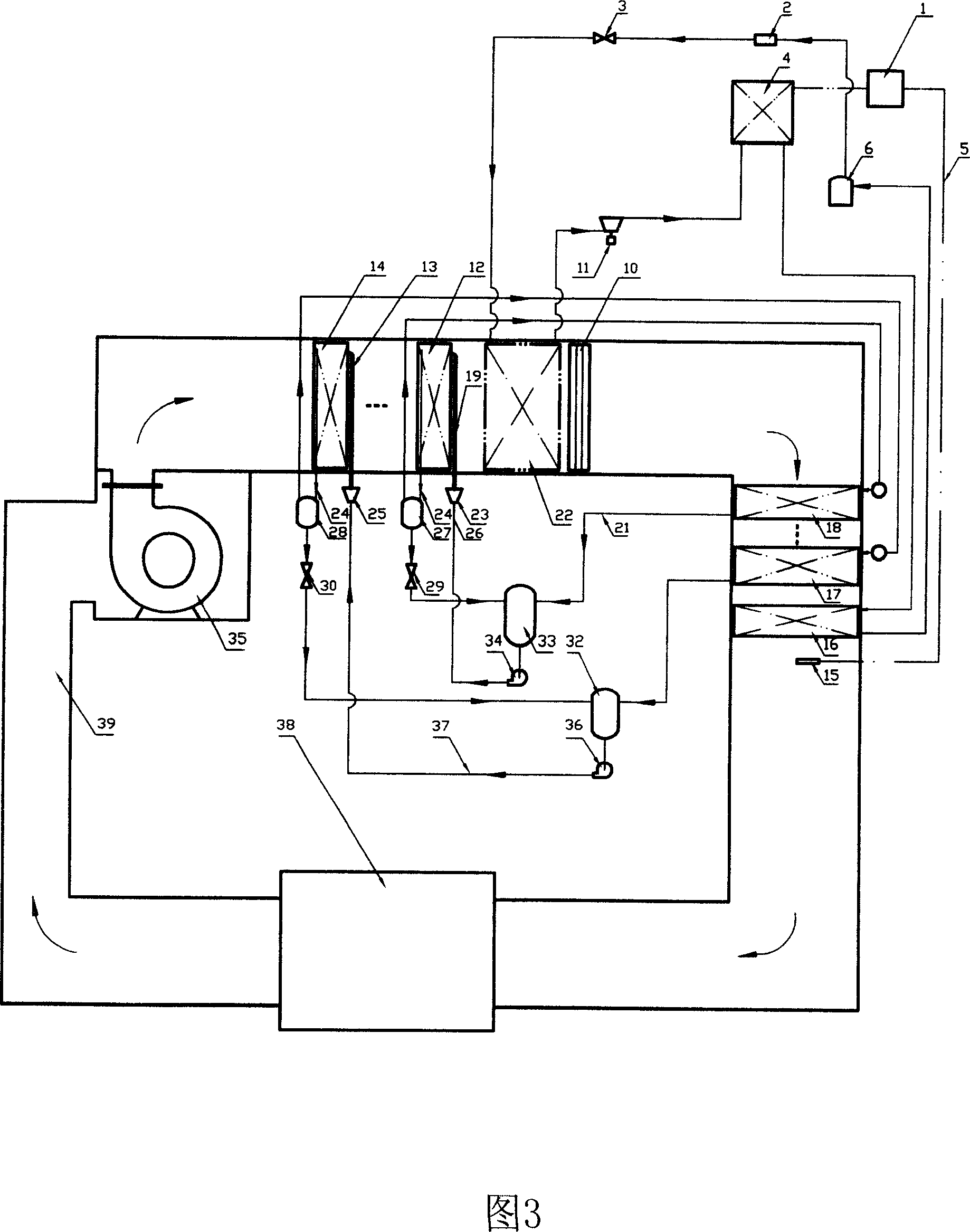

Marine two-stage dehumidification and air-conditioning system with rotary wheels and its operation method

ActiveCN102287882AAvoid the disadvantages of being greatly influenced by the outside worldEmission reductionLighting and heating apparatusSpace heating and ventilation detailsProcess engineeringIntercooler

The invention discloses a marine two-stage rotating-wheel dehumidifying air-conditioning system and an operating method thereof. The marine two-stage rotating-wheel dehumidifying air-conditioning system comprises a dehumidifying rotating wheel, a first-stage intercooler, a second-stage intercooler, a compression-type air-conditioner set, a humidifier, a processing fan and a regenerating fan whichare together connected in series. The adopted dehumidifying rotating wheel comprises a dehumidifying area, a regenerating area and a preprocessing area, and the preprocessing area is positioned between the regenerating area and the dehumidifying area of the dehumidifying rotating wheel. The waste heat of a ship is utilized as a heat source in the regenerating process of the dehumidifying rotatingwheel, and a waste-heat heater or a waste-gas heat-exchanging rotating wheel is adopted to heat regenerative air; and the dehumidified processed air is preliminarily cooled by utilizing seawater witha lower temperature. Because the preprocessing area is additionally arranged in the dehumidifying rotating wheel, the high-temperature high-humidity air remaining in the regenerating process of a dryer can be blown out of a rotating-wheel air passage at the preprocessing area, and the marine two-stage rotating-wheel dehumidifying air-conditioning system is favorable to the proceeding of the dehumidifying process at the dehumidifying area.

Owner:海英荷普曼船舶设备(常熟)有限公司

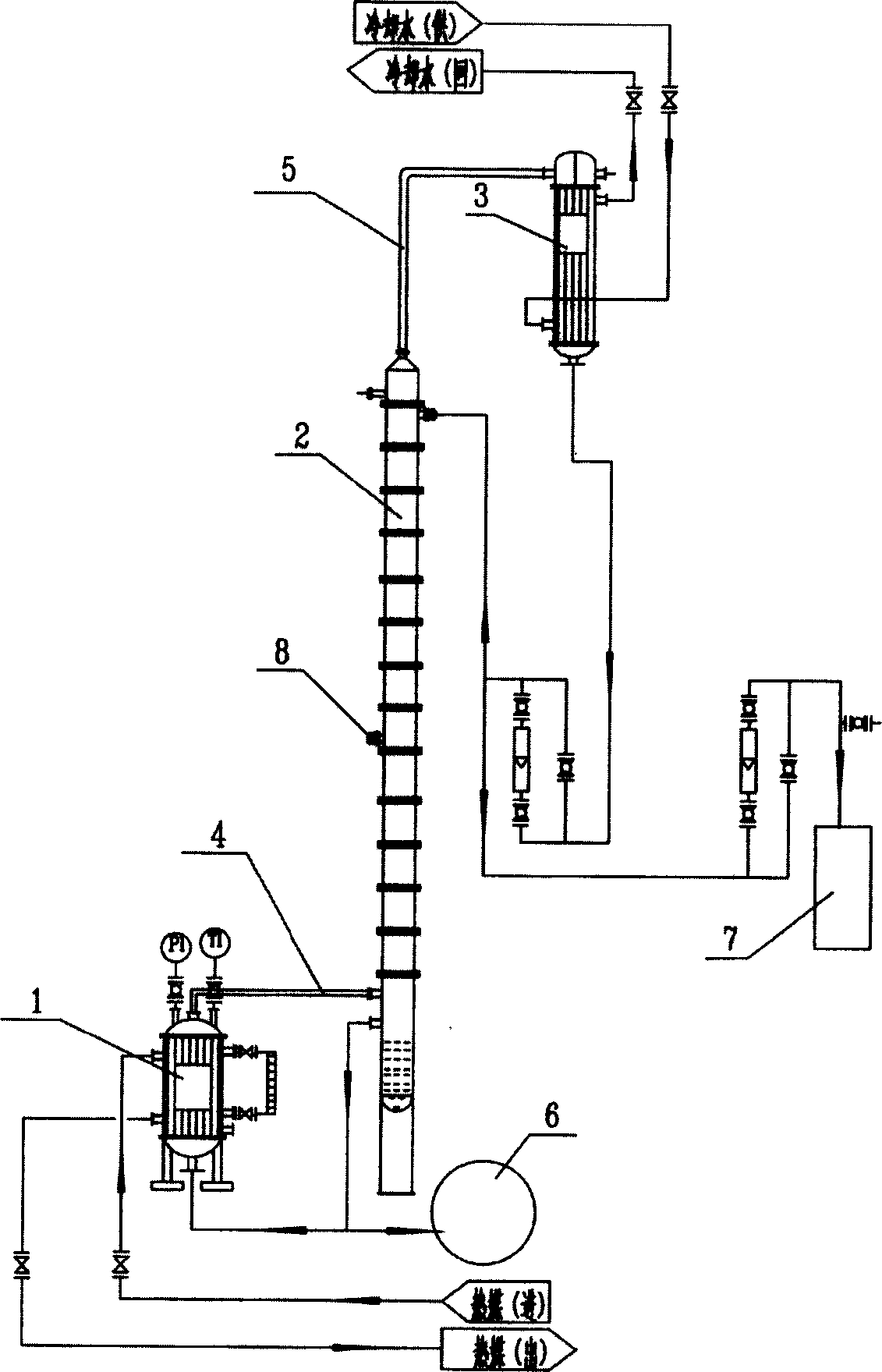

Process for pressure purification of silicon trichlorohydrgen and apparatus thereof

ActiveCN1693192AIncreased operating temperature rangeHigh densityHalogenated silanesBoiling pointTower

A process and apparatus for pressure purifying of trichlorosilane is disclosed. Said process includes such steps as distilling the mixed liquid of trichlorosilane, SiCl4 and chlorosilane at 70-200 deg.C under 0.15-1.5 MPa, sending the vapor derived from distilled into purifying tower for the exchange and separation of heat and components at 40-150 deg.C, enriching the low-boiling-point trichlorosilane in vapor phase and the high-boiling-point SiCl4 in liquid phase, evaporating and condensaing several times to obtain trichlorosilane vapor, and condensing to obtain liquid-phase trichlorosilane.

Owner:CHINA ENFI ENG CO LTD

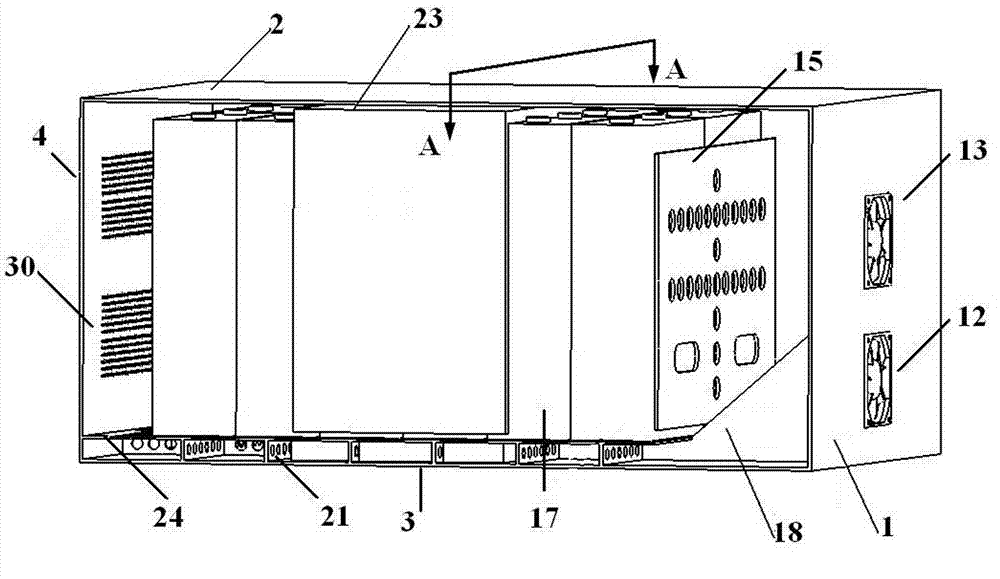

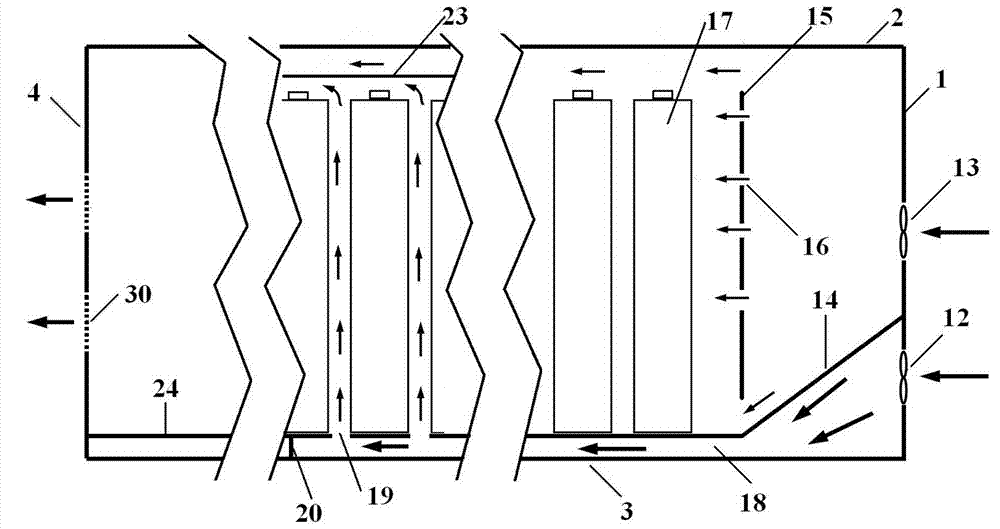

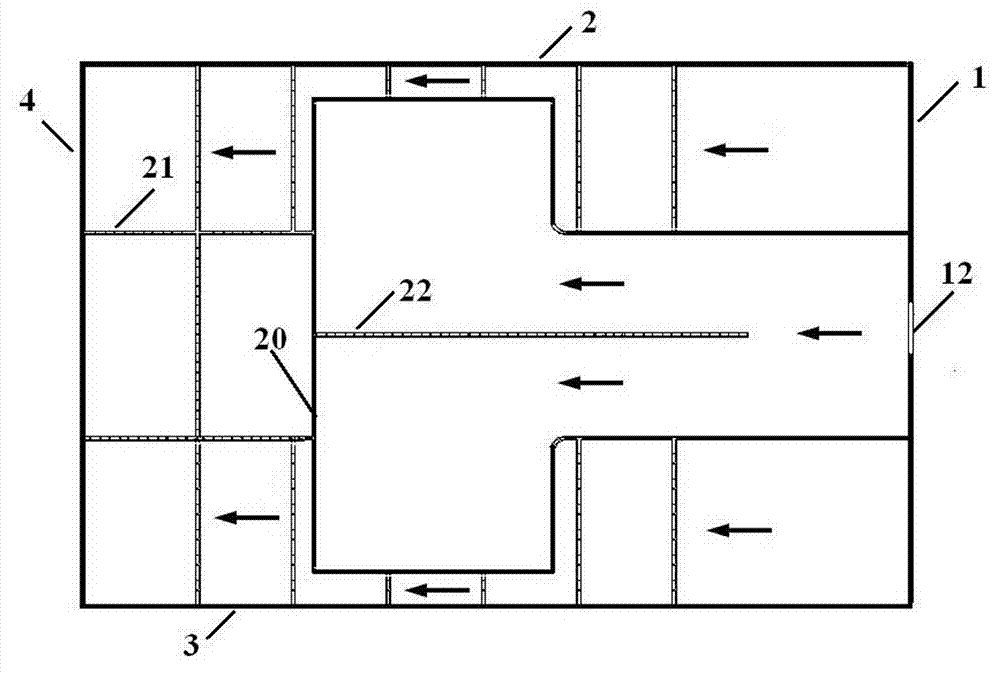

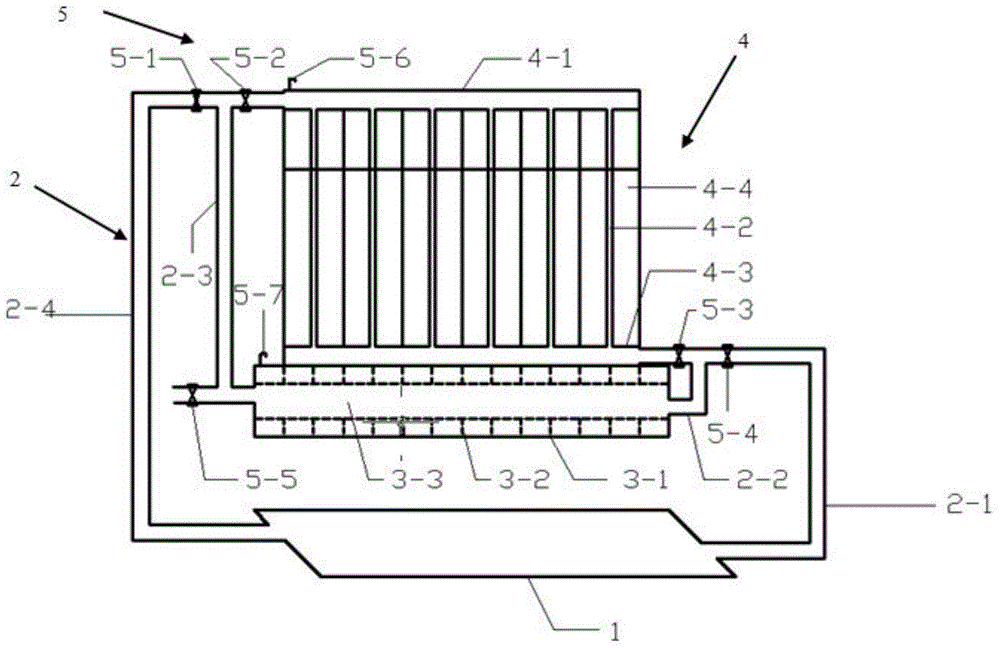

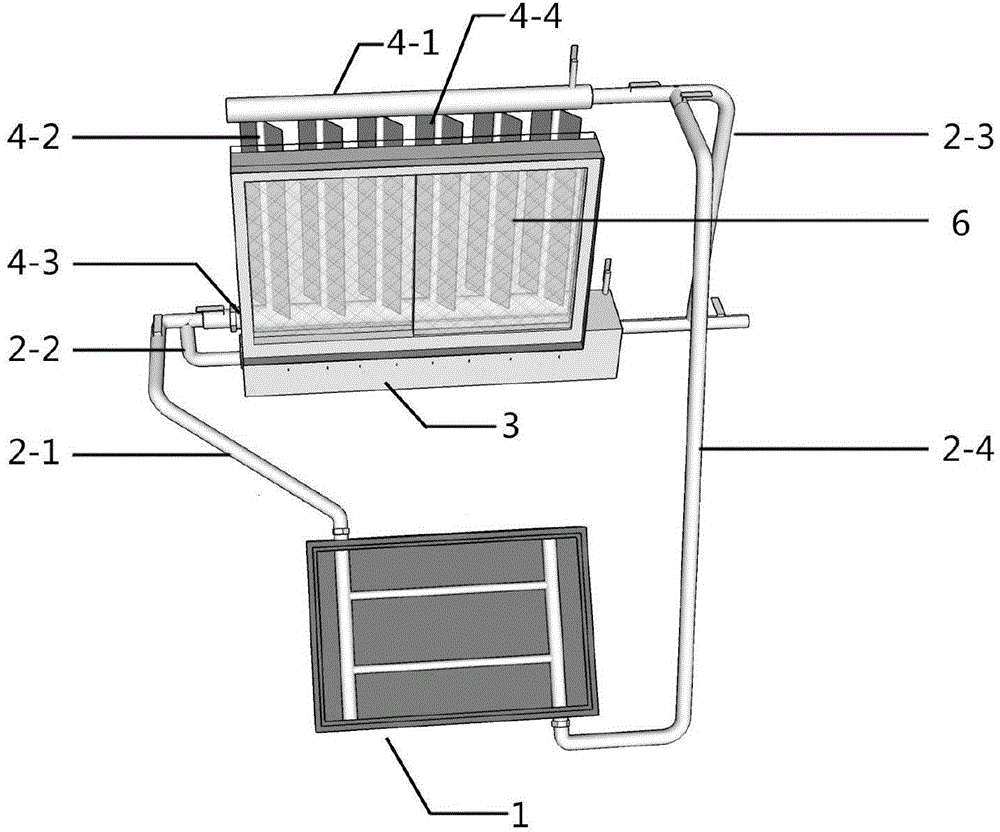

Lithium ion power battery box

ActiveCN103199203ACool evenlyObvious temperature differenceSecondary cellsCell component detailsLithiumPower battery

The invention relates to a lithium ion power battery box, which comprises a battery box body for alternately arranging batteries inside the body along a set arrangement direction, and a base air channel arranged in the battery box body, wherein the flow direction of the base air channel is consistent with the set arrangement direction; the battery box is also provided with a reinforced cooling air channel for delivering cooling air separated from the base air channel; the reinforced cooling air channel is provided with jet holes for directing the cooling air into a set cooling area in the battery box body; and the cooling area is a gap between front and back adjacent batteries along the battery arrangement direction in set positions or batteries in the set positions. By adopting the lithium ion power battery box, the problem in the prior art that cooling capacity distribution in various parts in the battery box body is non-uniform because the batteries are successively cooled along a single base air channel is solved; and the lithium ion power battery box of the invention can uniformly cool the batteries and improve the overall discharge performance and the service life of the batteries in the battery box.

Owner:CALB CO LTD

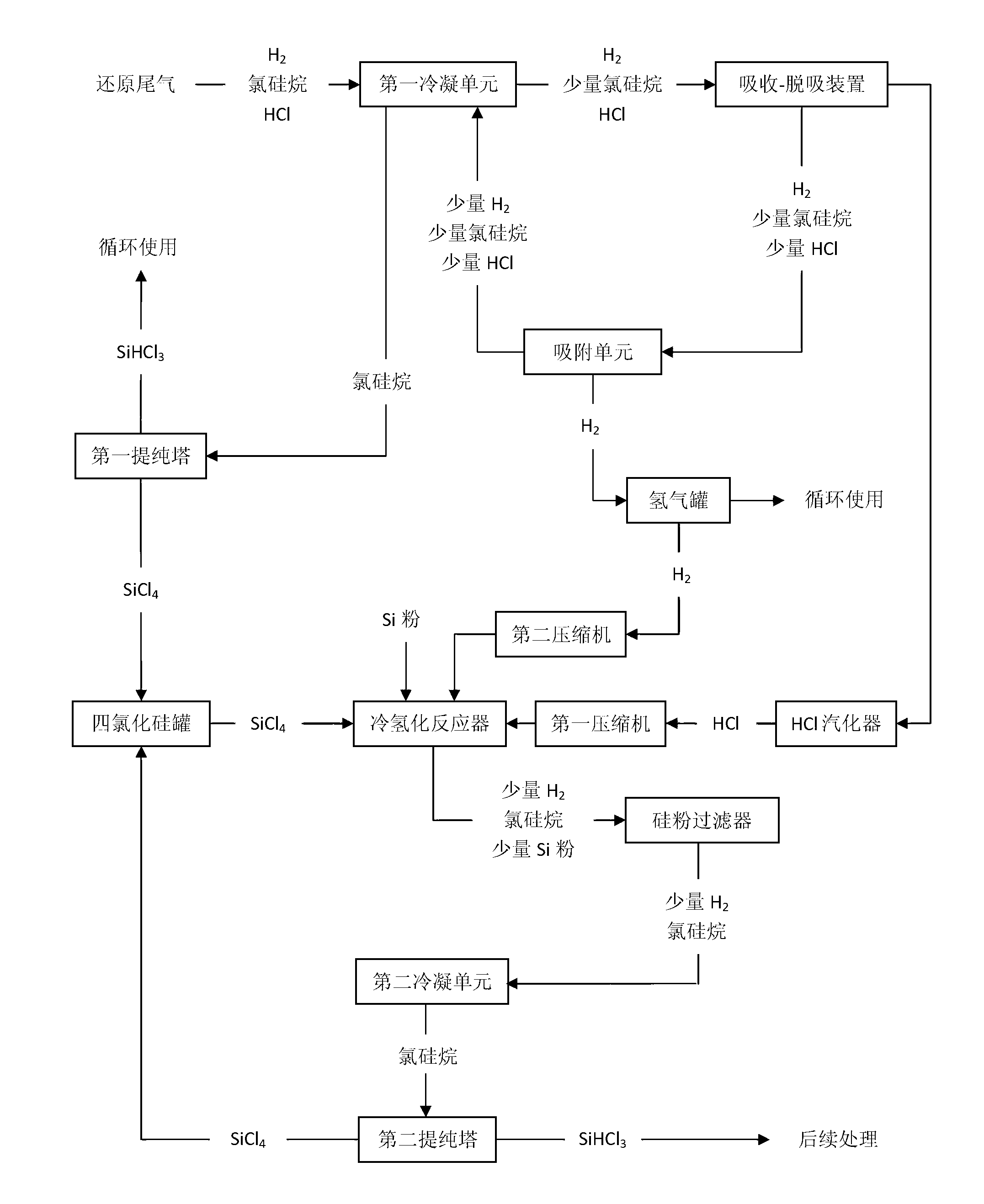

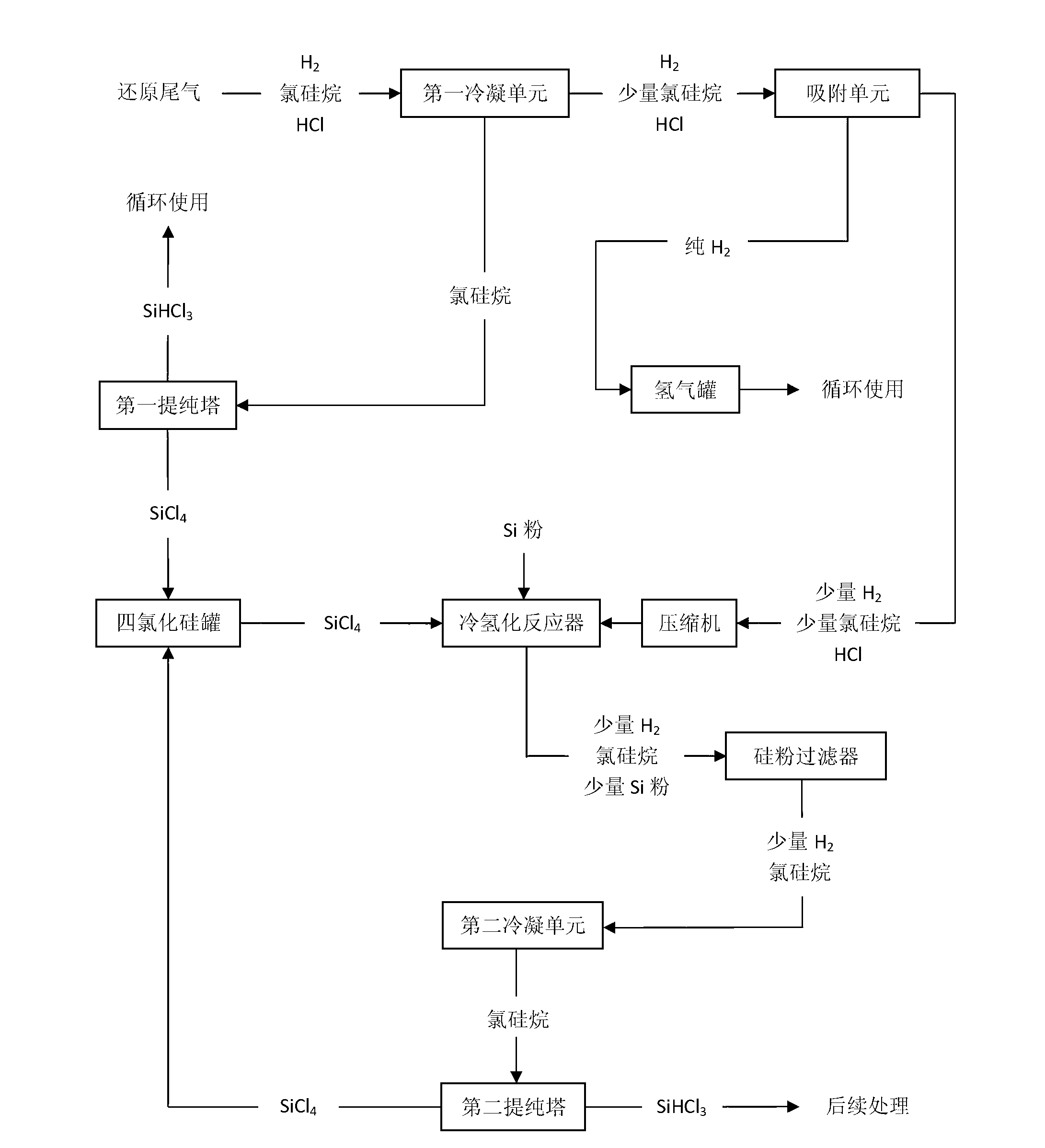

Recovery system and recovery method of by-product in polycrystalline silicon production

ActiveCN103058140ASave heat and coolSave on cooling or heatingChlorine/hydrogen-chloride purificationHydrogen separation using solid contactExhaust gasChemistry

The invention discloses a recovery system and a recovery method of a by-product in polycrystalline silicon production. The system and the method are used for recycling the hydrogen, chlorosilane and chlorine hydride gas in the reducing tail gas produced during the polycrystalline silicon production. The recovery method comprises the following steps: a condensing step for separating most of chlorosilane from the reducing tail gas; an adsorption step for removing all chlorine hydride and the rest chlorosilane from the reducing tail gas by using an absorption unit after the condensing step to obtain the pure hydrogen; a regenerating step for regenerating the absorption unit by using the hydrogen so as to remove the chlorosilane and chlorine hydride absorbed by the absorption unit, and obtaining the regenerative gas containing hydrogen, chlorosilane and chlorine hydride; and a cold hydrogenating step for directly feeding the regenerative gas as the raw material of the cold hydrogenation reaction to a cold hydrogenation reactor. According to the system and method provided by the invention, the HCl can be singly separated from the tail gas without an adsorption-de-adsorption device so as to prevent the HCl from being condensedly separated and gasified, and a great number of heat and cooling capacity is saved.

Owner:巴彦淖尔聚光硅业有限公司

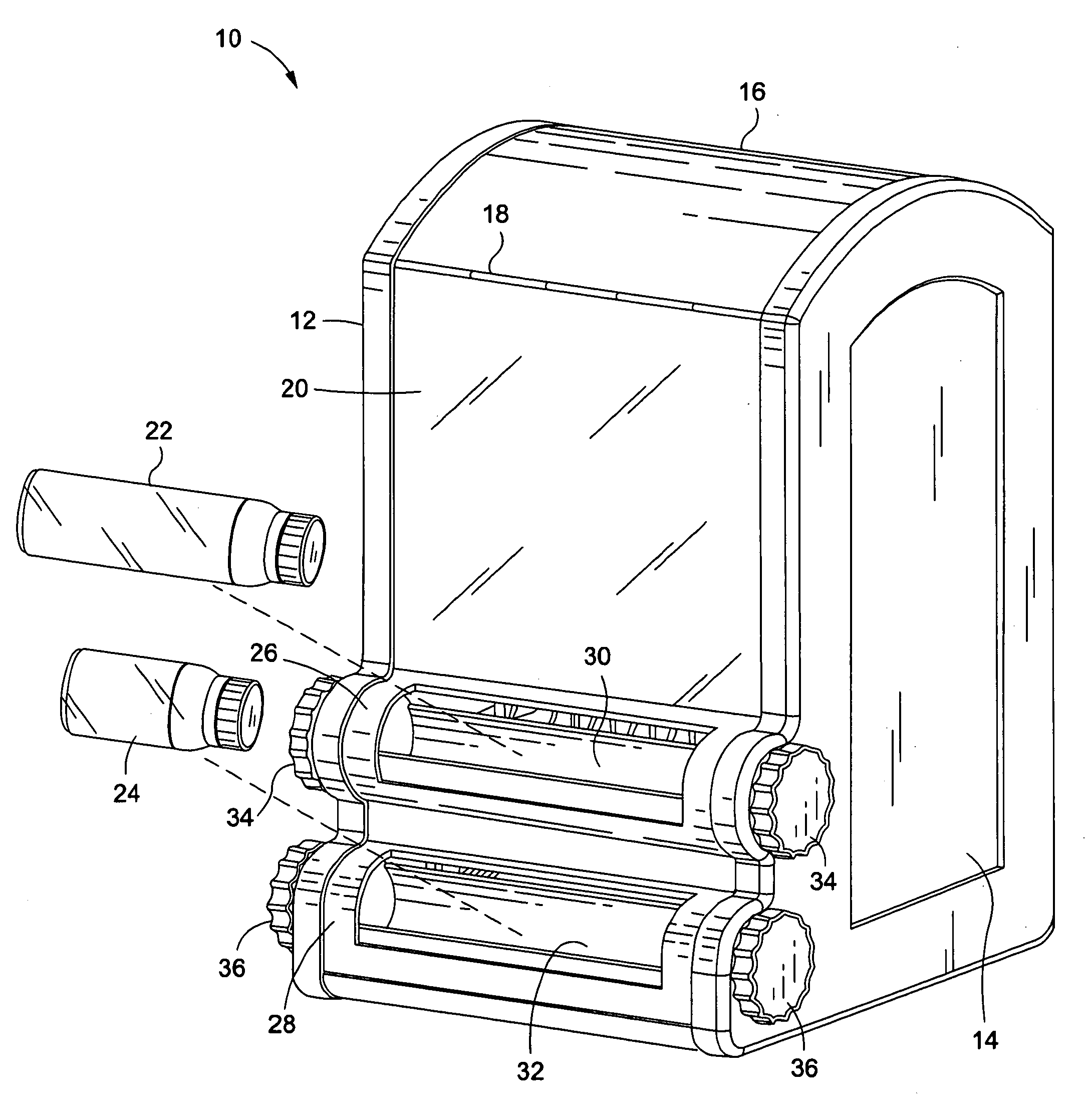

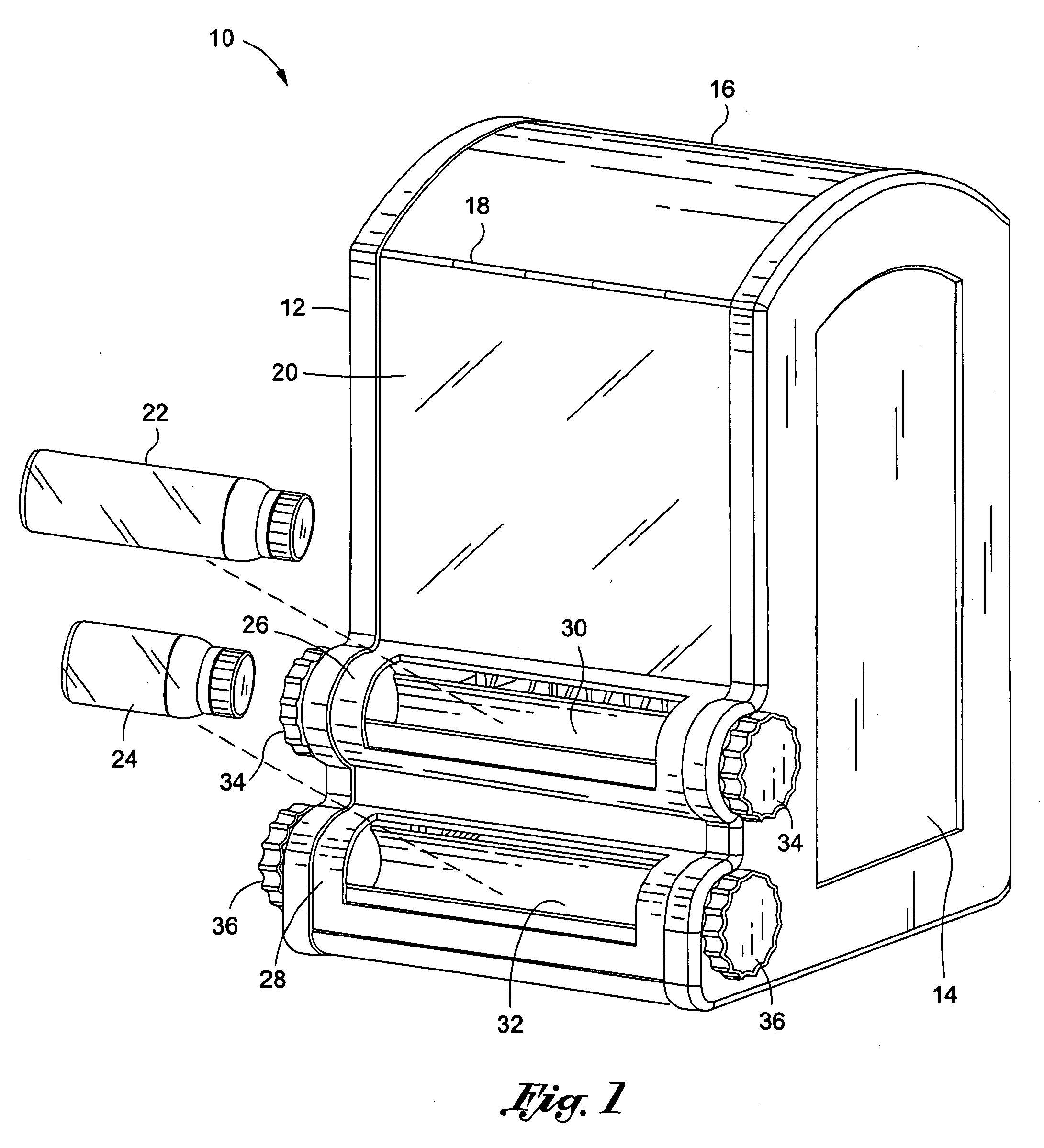

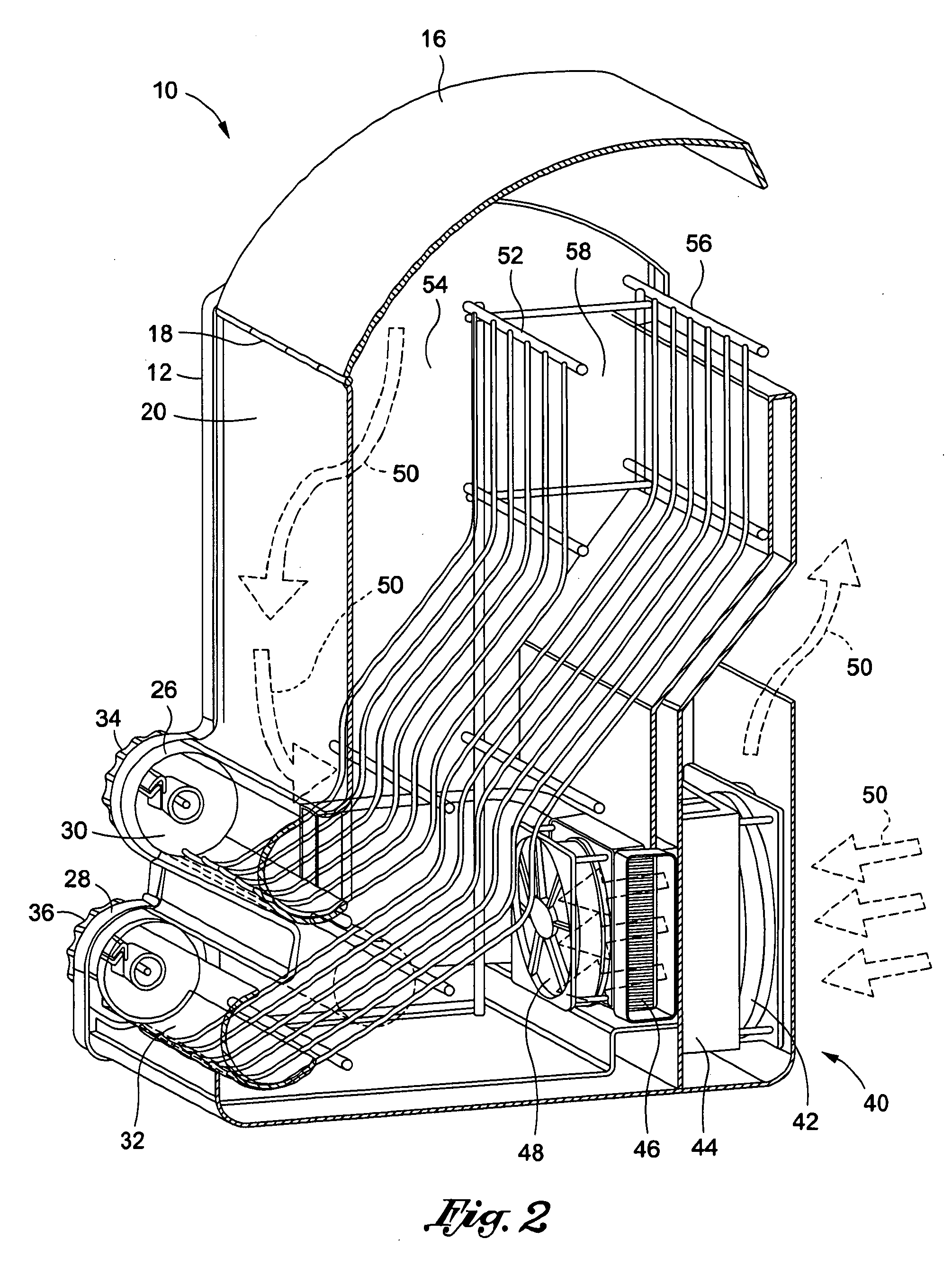

Compact countertop cooler

A compact, countertop cooler for use in dispensing cold, energy-shot beverages at point-of-purchase retail locations. The cooler comprises a housing operative to store and selectively dispense individual containers of beverages through a gravity feed system. Preferably, the cooler will include an outwardly-facing window to facilitate the consumer's ability to see the contents and further, will preferably include a ratchet-type dispensing system to selectively dispense each beverage container individually so as to serve as an anti-theft mechanism, and further dispense at least one and preferably two containers of dissimilar size. The housing will further include a cooling system to provide cooling for the beverages and further, may be provided with decorative indicia to facilitate advertising and the display of product information.

Owner:LINDER NATHAN

Energy-saving gas washing process

ActiveCN105920978AReduce concentrationReduce energy consumptionDispersed particle separationSulfurGas phase

The invention relates to an energy-saving gas washing process, comprising the following steps: subjecting raw gas to countercurrent contact with methanol in an absorbing column, and washing out acidic gas from the raw gas; delivering obtained carbon-rich methanol to the upper portion of a medium-pressure flashing column, and delivering rich methanol to the lower segment of the medium-pressure flashing column; delivering via an ejector, liquid carbon-rich methanol in the medium-pressure flashing column to the upper part of a re-absorbing column, and delivering sulfur-rich methanol at the bottom of the medium-pressure flashing column to the lower part of the re-absorbing column for flashing; returning two parts of liquid flashed from the upper part of the re-absorbing column respectively to the re-absorbing column and a negative-pressure flashing column; using flashed liquid rich methanol as main washing methanol, delivering flashed gas to a suction ejector, and delivering flashed sulfur-rich methanol to a subsequent heat regeneration system.

Owner:SINOPEC NINGBO ENG +2

Method for separation of products of reaction for preparation of propylene from propane by dehydrogenation

InactiveCN106316761AEasy to operateSave coolingDistillation purification/separationPetrochemicalHigh energy

The invention discloses a method for separation of products of reaction for preparation of propylene from propane by dehydrogenation, and belongs to the field of petrochemical industry, by the way of combination of a propylene and ethylene cascade refrigeration process with an expansion machine and a deethanization process with a deethanizer top condensation section, the products of reaction for preparation of propylene from propane by dehydrogenation can be separated, propane can be obtained by fractional distillation on depropanizator top, and is used as a reaction cycle material flow to return to the part of the reaction for preparation of propylene from propane by dehydrogenation for further reaction, and a depropanizator bottom product C4 + fraction is sent out of a device. The method can overcome the problems of a large circulation amount of an absorbent and high energy consumption in the prior art.

Owner:SINOPEC GUANGZHOU ENG +1

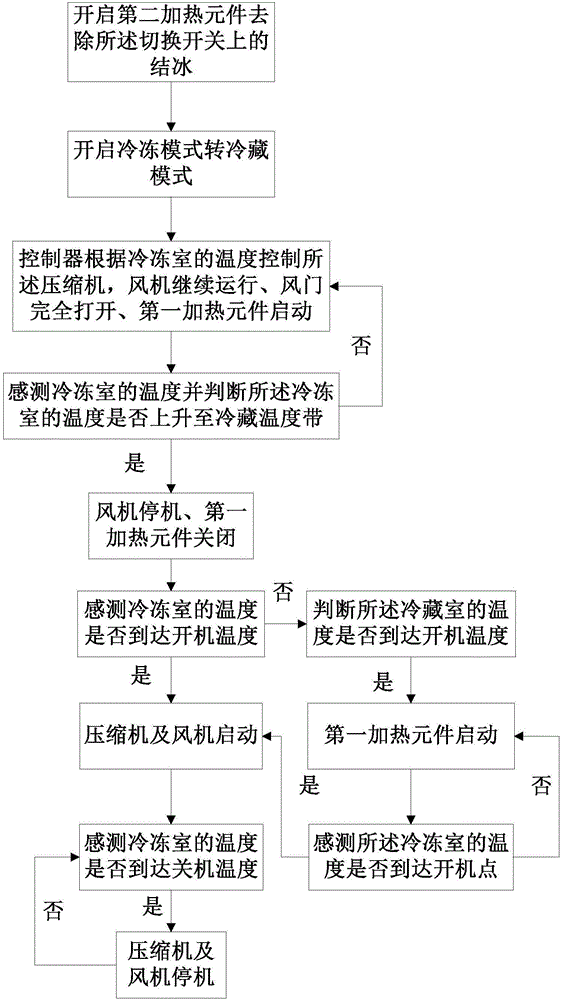

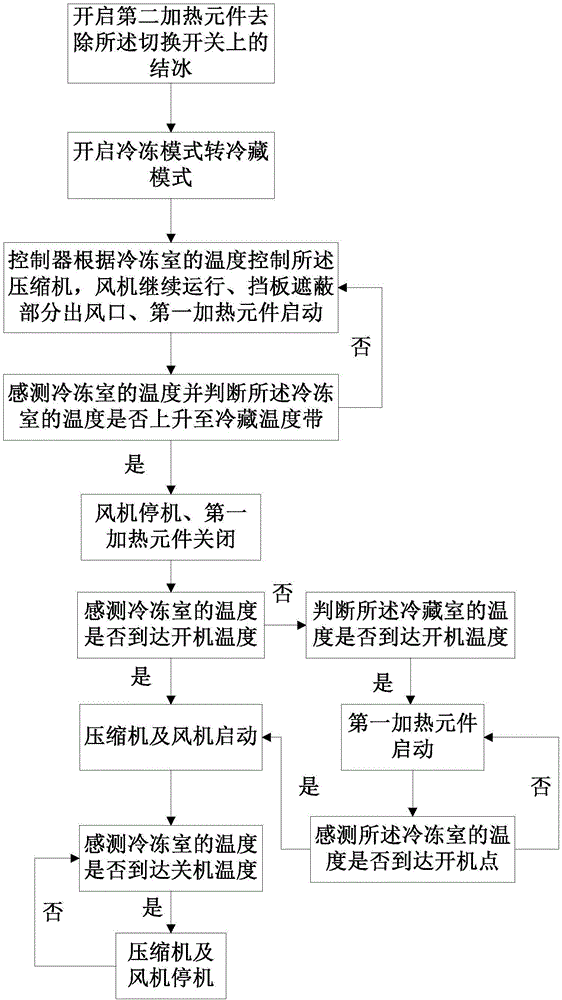

Refrigerator and control method of refrigerator

ActiveCN106247753AIncrease temperatureSave coolingLighting and heating apparatusCooling fluid circulationEngineeringRefrigeration

The invention provides a refrigerator and a control method of the refrigerator. The refrigerator comprises a first refrigeration chamber and a second refrigeration chamber, wherein the second refrigeration chamber can be switched between a freezing mode and a refrigeration mode; after an operation of converting the freezing mode to the refrigeration mode is started, a controller controls the start and stop of a compressor according to the temperature of the second refrigeration chamber; meanwhile, a fan continuously runs. On one hand, the controller controls the start and stop of the compressor according to the temperature of the second refrigeration chamber; an evaporator cannot generate new cold energy for cold supply of the second refrigeration chamber; the indoor temperature rise of the second refrigeration chamber is favorably realized; on the other hand, the fan maintains the running state, so that the cold energy residual on the evaporator is partially conveyed to the first refrigeration chamber; the cold energy conveyed to the indoor space of the second refrigeration chamber is reduced; the indoor temperature rise of the second refrigeration chamber is accelerated, so that the second refrigeration chamber can be fast switched from the freezing mode to the refrigeration mode.

Owner:HAIER SMART HOME CO LTD

Front-end deethanizing separation process method for ethylene device

ActiveCN101967077ASave coolingReduce consumptionHydrocarbon purification/separationHydrocarbonsReboilerGas phase

The invention relates to a front-end deethanizing separation process method for an ethylene device. Liquid phase material flow from pyrolysis gas condensate drier is heated for evaporating in a condensate preheater by using chilled water at the evaporating temperature of between 25 and 35 DEG C, a small amount of evaporated gaseous phase material flow containing hydrogen, methane and carbon-2-components is merged with gaseous phase material flow formed by part of pre-cooled gaseous phase pyrolysis gas at the temperature of between -10 DEG C and -12 DEG C which flows into a plate heat exchanger directly from the pyrolysis gas drier, and the mixed material flow is conveyed to the plate heat exchanger to be pre-cooled; and after being subjected to throttling through a valve under the reducedpressure, condensate material flow from the bottom of the condensate preheater is heated again in the condensate heater by using the chilled water, and gas-liquid phase material flow at the temperature of between 45 and 65 DEG C is conveyed to the middle part of a deethanizing tower. Through the method, the low-pressure steam consumption of a reboiler at the tower bottom of the low-pressure deethanizing tower is reduced, the circulating water volume of the cooling chilled water is reduced, and the comprehensive energy consumption of ethylene per ton produced by the ethylene device is reduced by 125 to 190 MJ.

Owner:PETROCHINA CO LTD

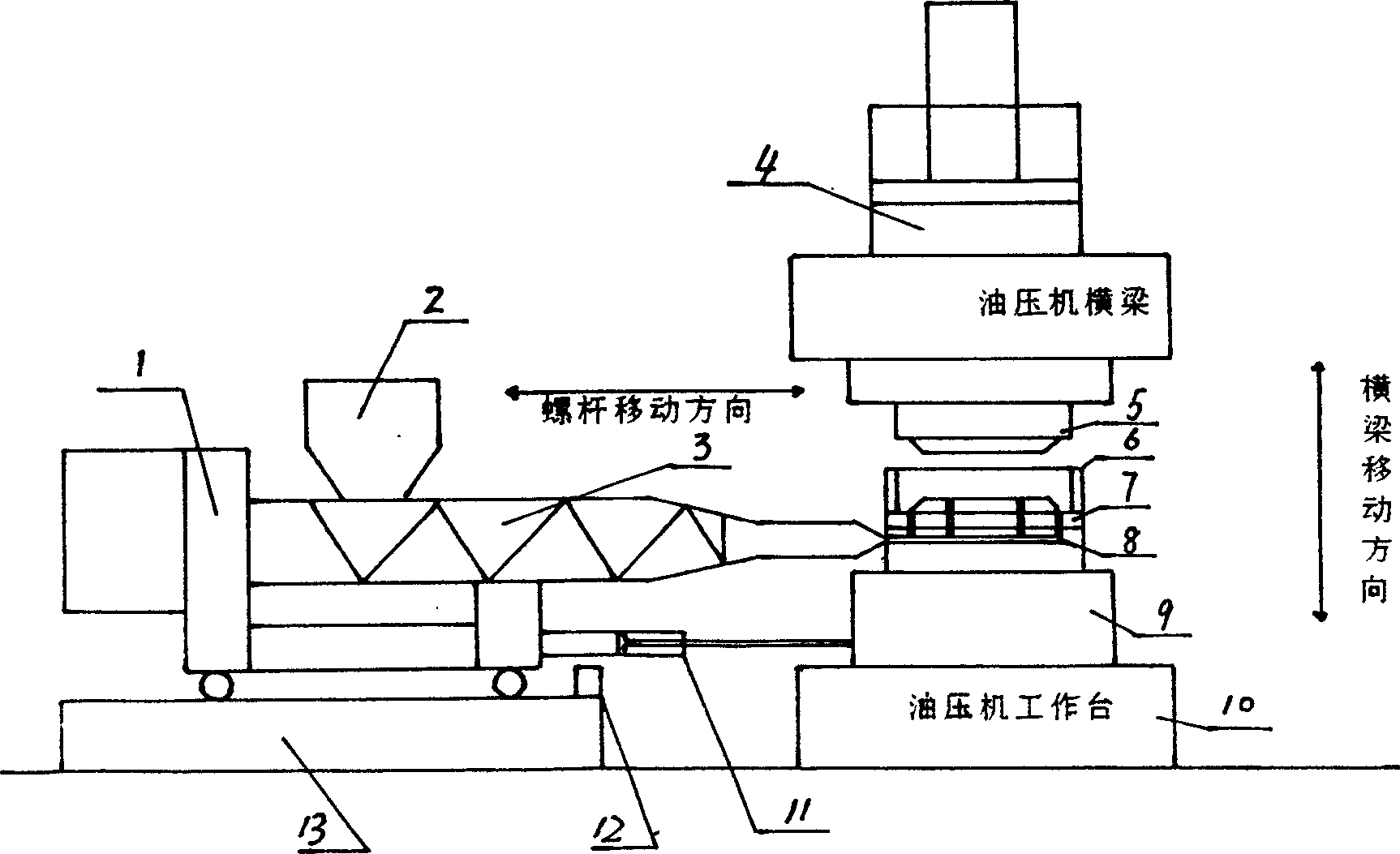

Plastic filtering board or board forming process

A process for preparing the plastic filter plate or plastic plate features that its mould is controlled by hydraulic press, its heat channel is positioned at the bottom of lower mould and communicated with said lower mould, and the plasticized plastics is injected in said mould via heat channel.

Owner:ZHEJIANG LONGYUAN ENVIRONMENTAL TECH CO LTD

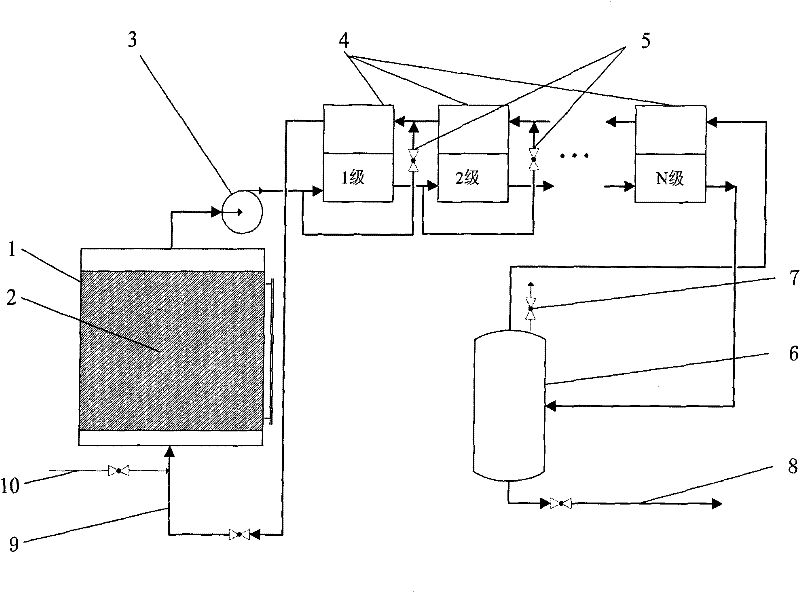

A plant essential oil gradient extraction device

ActiveCN102295992ARational use of energyLow running costEssential-oils/perfumesEvaporatorSemiconductor

The invention provides a plant essence gradient extraction device, which comprises an evaporator with a built-in raw material bed layer, an exhaust pump, a gas condensing device, a circulating gas heating device and a product collecting tank, wherein the gas condensing device and the circulating gas heating device are formed by coupling a semiconductor cooling device; the cold side of the semiconductor cooling device serves as a gas condensing device and the hot side of the semiconductor cooling device serves as a circulating gas heating device; and the semiconductor cooling device is formed by connecting N stages of semiconductor cooling units in series; return crossing lines with valves are arranged at the cold side material outlet openings of the semiconductor cooling units from the 1st stage to the N-1th stage and are connected to the hot side material outlet openings of the semiconductor cooling units to regulate the temperature difference between the cold sides and the hot sidesof the semiconductor cooling units. Based on the requirements of the gradient extraction of the distillates of the plant essence, the device can provide cold energy and heat energy according to the required cooling and heating temperature, so that the device has high energy efficiency, is reasonable in energy utilization and low in cost.

Owner:新疆天然芳香农业科技有限公司

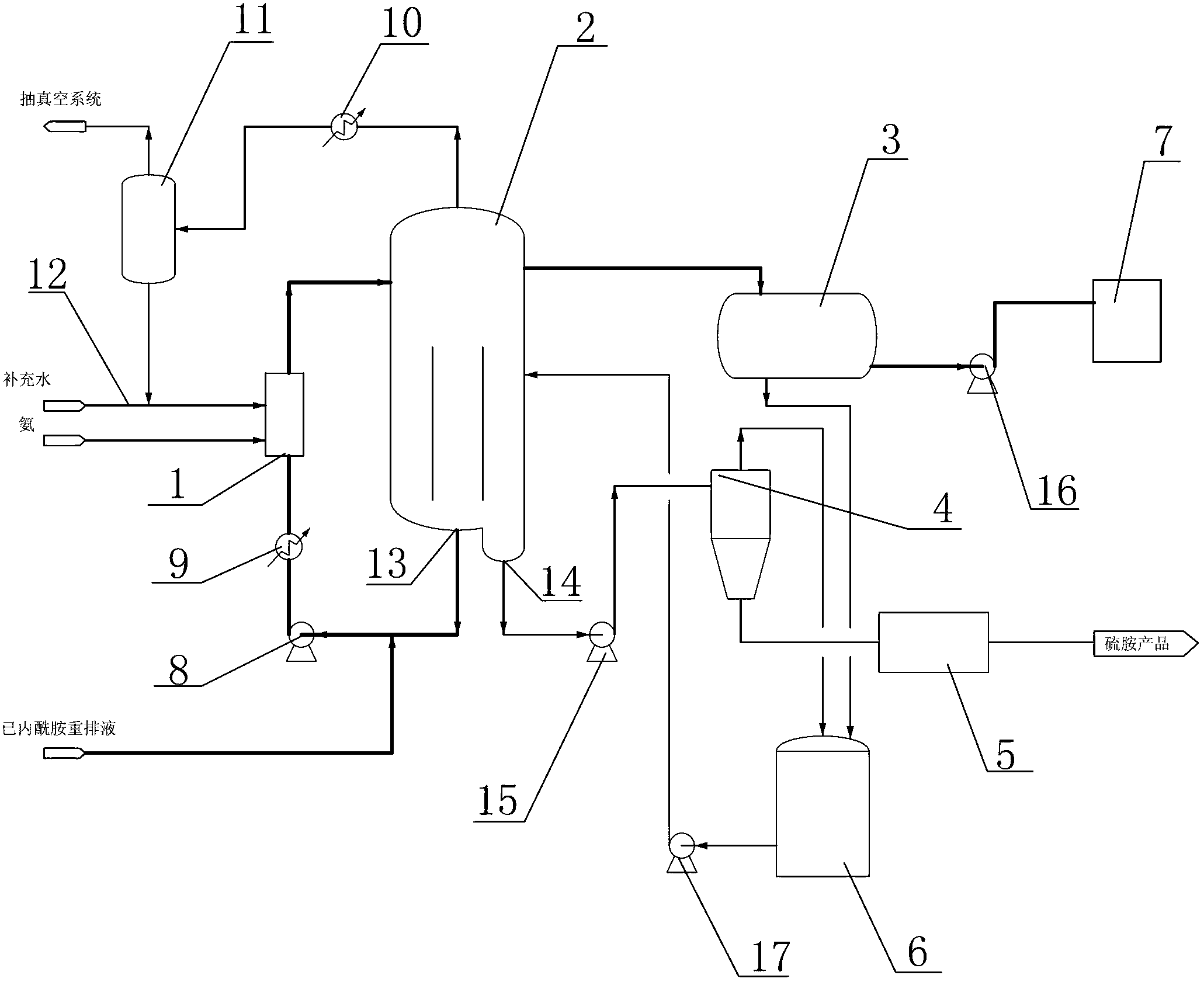

Neutralized crystallization system and method of preparing caprolactam through caprolactam rearrangement solution

InactiveCN103012273ASave on cooling or heatingShorten equipment investment and process flowLactams separation/purificationAmmonia compoundsAmmonium sulfateChemistry

The invention discloses neutralized crystallization system and method of preparing caprolactam through caprolactam rearrangement solution. The neutralized crystallization system is characterized in that a feeding mixer is connected with an inlet in the upper part of a neutralized crystallization reactor, an upper-layer organic phase outlet of the neutralized crystallization reactor is connected with an inlet of a caprolactam oil layer separator, a lower-layer heavy organic phase outlet of the neutralized crystallization reactor is connected with an inlet of an ammonium sulfate centrifugal machine, an outlet at one end of the caprolactam oil layer separator is connected with a caprolactam collecting tank, an outlet at the other end of the caprolactam oil layer separator is connected with an ammonium sulfate mother liquor collection tank, an outlet at the lower end of the ammonium sulfate centrifugal machine is connected with an ammonium sulfate washing dryer, an outlet at the upper end of the ammonium sulfate centrifugal machine is connected with the ammonium sulfate mother liquor collection tank which is connected with the neutralized crystallization reactor through a mother liquor circulating pump. The neutralized crystallization system and method have the advantages that the heating and cooling capacities are integrated in reaction process, the energy consumption is low, the process is simple, and the purity of the product is high.

Owner:SEDIN NINGBO ENG

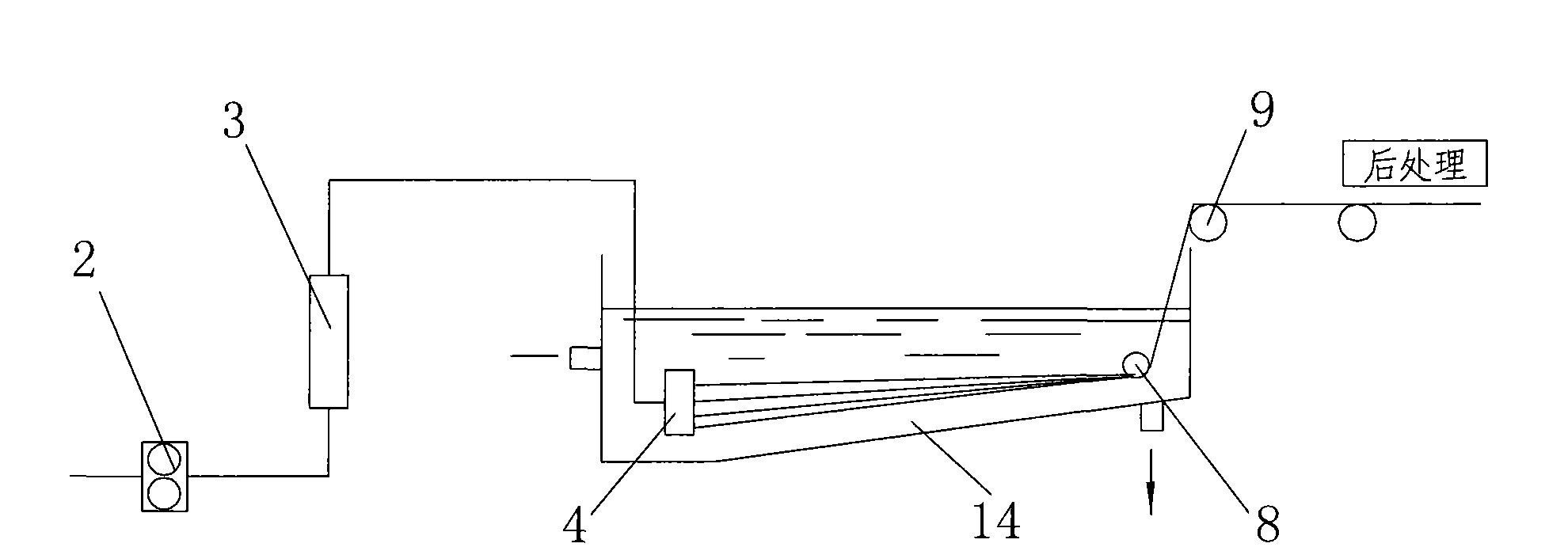

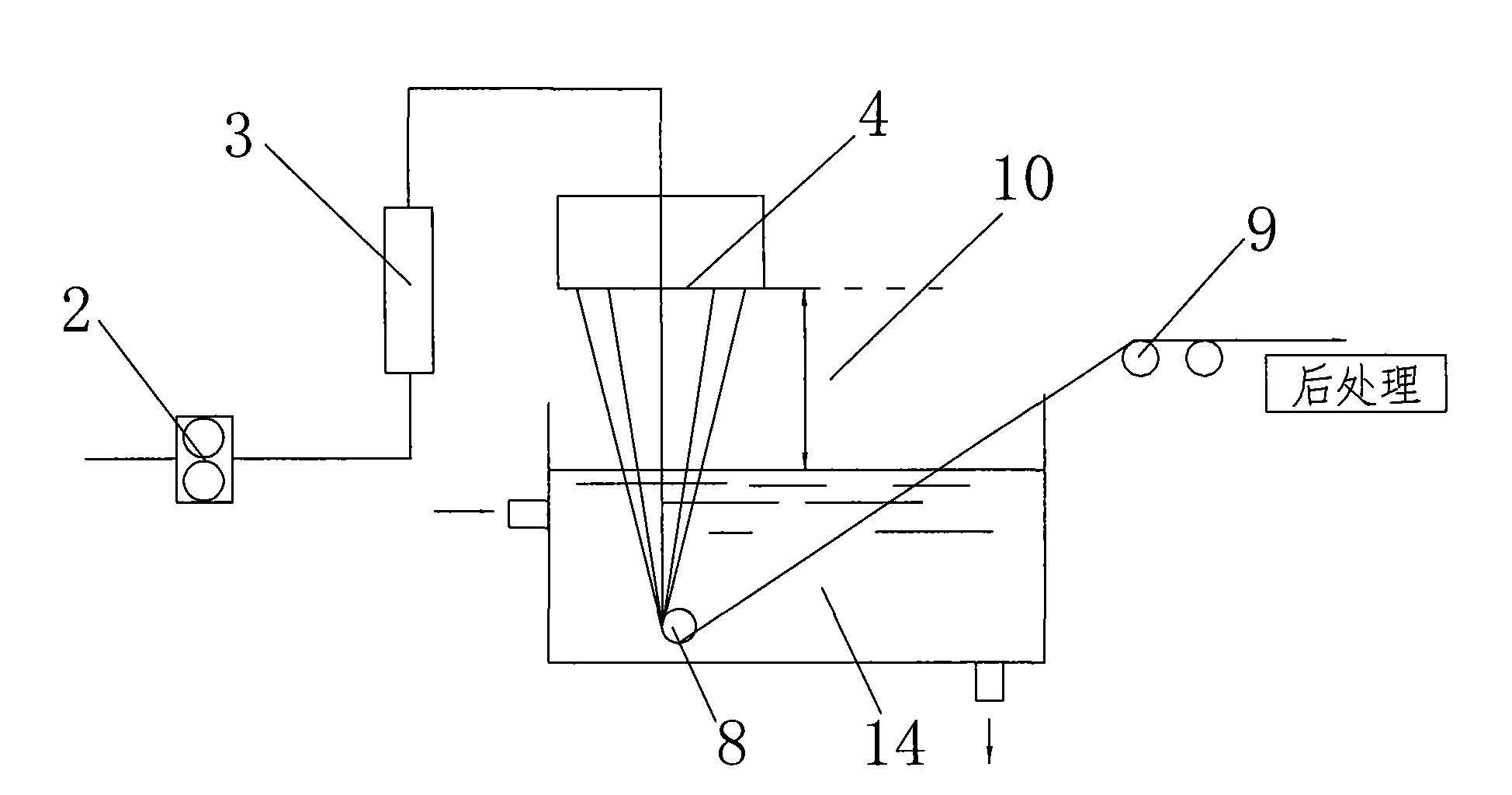

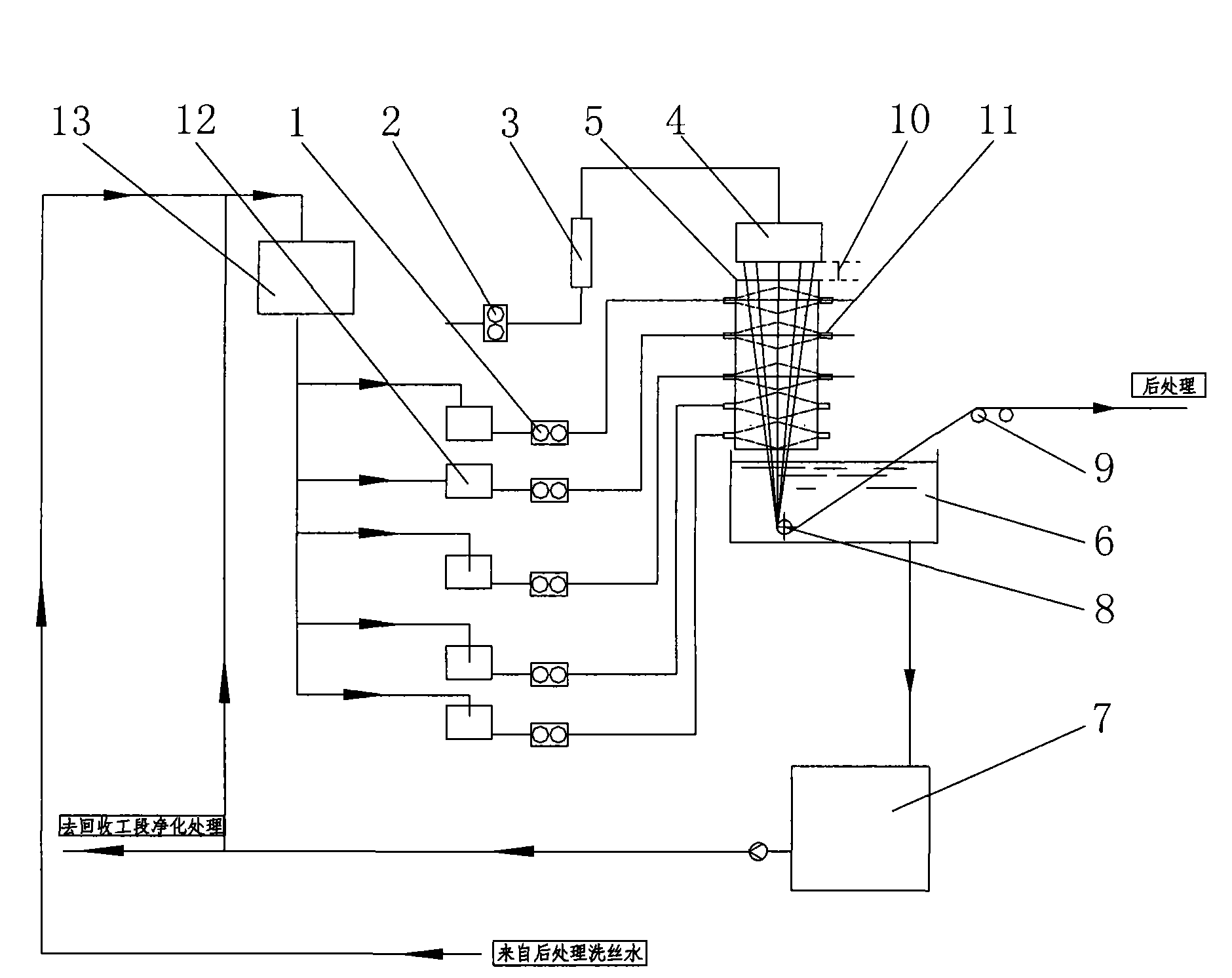

Vertical atomized chemical fiber molding method

InactiveCN101988217AEasy to operateIncrease spinning speedArtificial filament physical treatmentArtificial thread manufacturing machinesFiberMetering pump

The invention belongs to the field of manufacturing of chemical fibers and particularly relates to a vertical atomized chemical fiber molding method. The vertical atomized chemical fiber molding method comprises the following steps that: 1, spinning raw materials enter a spinneret plate of a spinning assembly after passing through a distributing pipe, a metering pump and a filter; 2, an air gap is used for cooling; 3, cooling and solidification is carried out in a solidification chamber; 4, bunching bath is carried out; and 5, post processing is carried out. In the invention, the cooling and solidification are uniform so as to avoid causing fibrillation. The mechanical property of the obtained strand silk is special. A distance from the surface of the spinneret plate to the surface of bunching solution is more than 500mm and the making-up operation is convenient. The spinning speed can reach 200 to 350m per minute so as to greatly improve the productivity, save equipment investment and civil engineering investment and reduce operation cost. The vertical atomized chemical fiber molding method can be popularized and applied to the cooling and molding of heavy denier melt spun fibers (more than 20 deniers per piece) which cannot be spun by the conventional air serving as a cooling medium.

Owner:SHANGHAI PACIFIC TEXTILE COMPLETE EQUIP

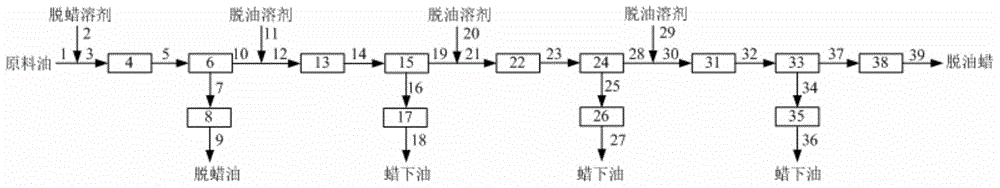

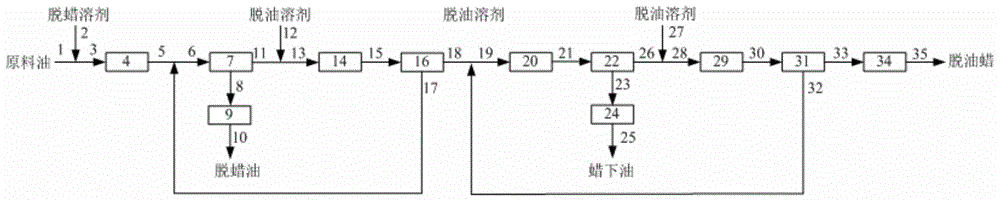

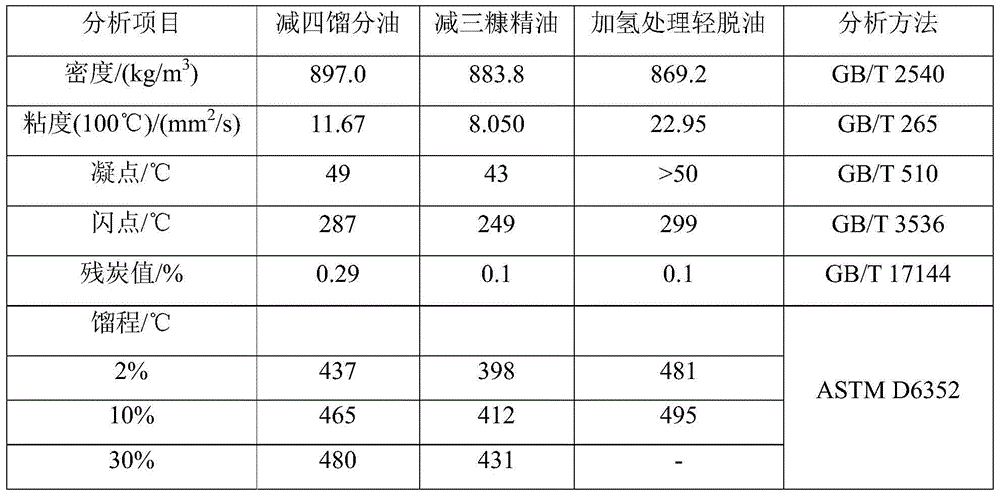

Method for preparing deoiled wax

ActiveCN104560196AReduce usageReduce production energy consumptionPetroleum wax recoveryHydrocarbon oils treatmentSolventWax

The invention discloses a method for preparing deoiled wax. The method comprises the following steps: under a dewaxing condition, performing solvent dewaxing on a mixture of raw oil and a dewaxing diluting solvent to obtain dewaxed filtrate and dewaxed cerate; performing a first stage of solvent deoiling on a mixture of the dewaxed cerate and a first deoiling slurrying solvent at a temperature lower than a dewaxing temperature to obtain first-stage deoiled cerate and first-stage deoiled filtrate; performing a second stage of solvent deoiling on a mixture of the first-stage deoiled cerate and a second deoiling slurrying solvent at a temperature higher than the first-stage deoiling temperature to obtain second-stage deoiled cerate and second-stage deoiled filtrate; and performing a third stage of solvent deoiling on a mixture of the second-stage deoiled cerate and a third deoiling slurrying solvent at a temperature lower than the second-stage deoiling temperature to obtain third-stage deoiled cerate and third-stage deoiled filtrate. The method disclosed by the invention has the advantages of increasing the yield of deoiled wax and the yield of dewax oil on the premise of satisfying the standard requirements of oil content of the deoiled wax, reducing the amount of a used fresh solvent and reducing the energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

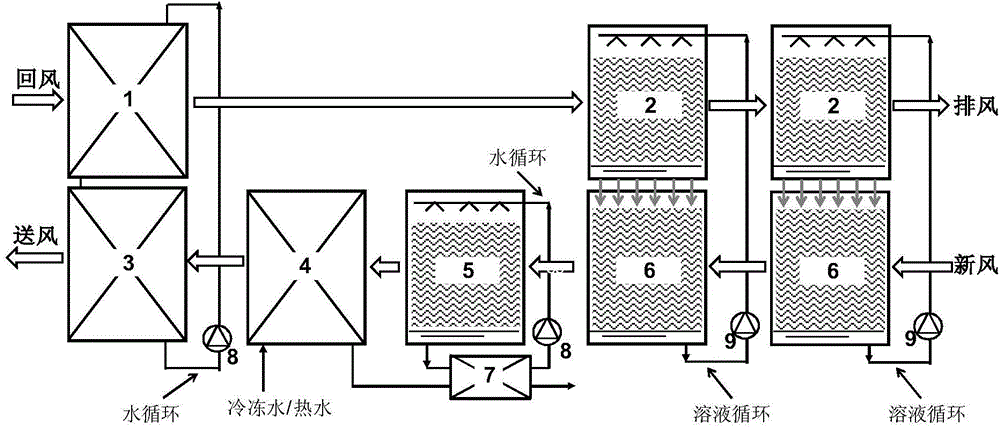

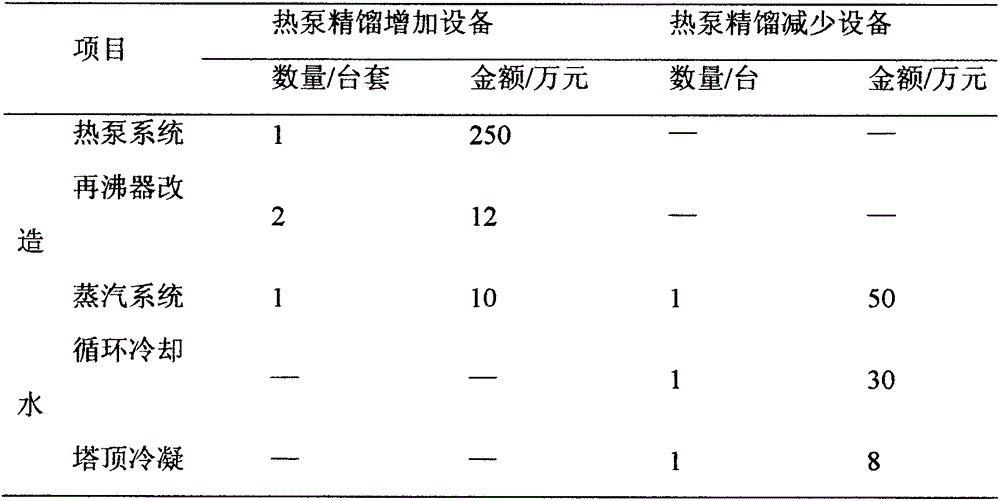

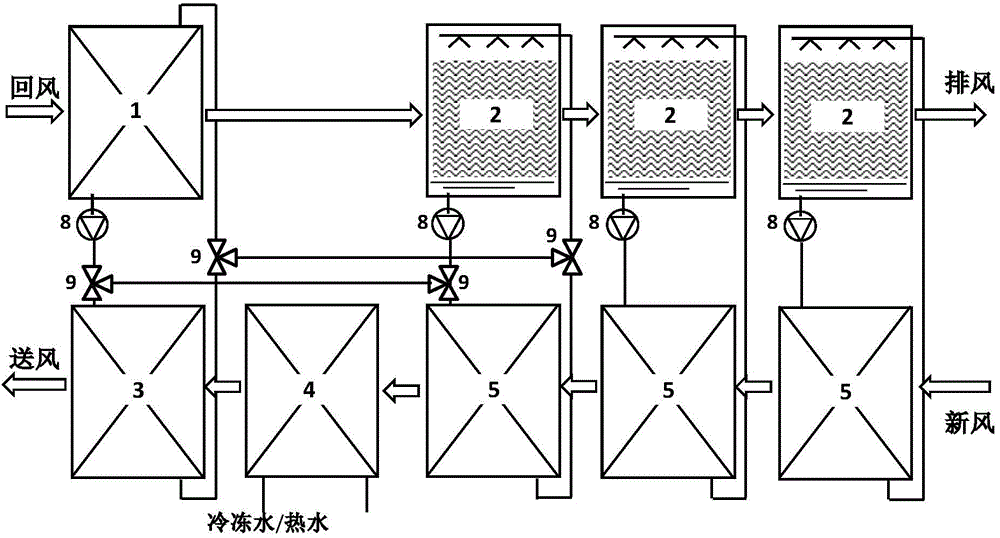

Solution total heat recovery and condensation dehumidification compound fresh air processing device

ActiveCN104807116ASolve the problem of humidificationSuitable temperatureEnergy recovery in ventilation and heatingLighting and heating apparatusProcess engineeringEngineering

The invention discloses a solution total heat recovery and condensation dehumidification compound fresh air processing device, which comprises a return air processing system and a fresh air processing system, wherein a sensible heat exchange device is adopted, supply air with lower temperature is utilized for lowering the temperature of indoor return air, meanwhile, the supply air temperature of fresh air is also raised, and the fresh air can be directly supplied into a room. The state point of return air before entering a total heat recovery device approaches to a saturation line, the return air and the fresh air are subjected to total heat recovery in the solution total heat recovery device, the recovered energy of the return air is fully utilized, the input cold quantity of a cold source is reduced, and the energy efficiency of the fresh air processing device is improved. In addition, the fresh air processing device has the advantage that through work condition switching, the return air heat recovery and fresh air heating and dehumidification functions in winter can be realized.

Owner:SOUTHEAST UNIV

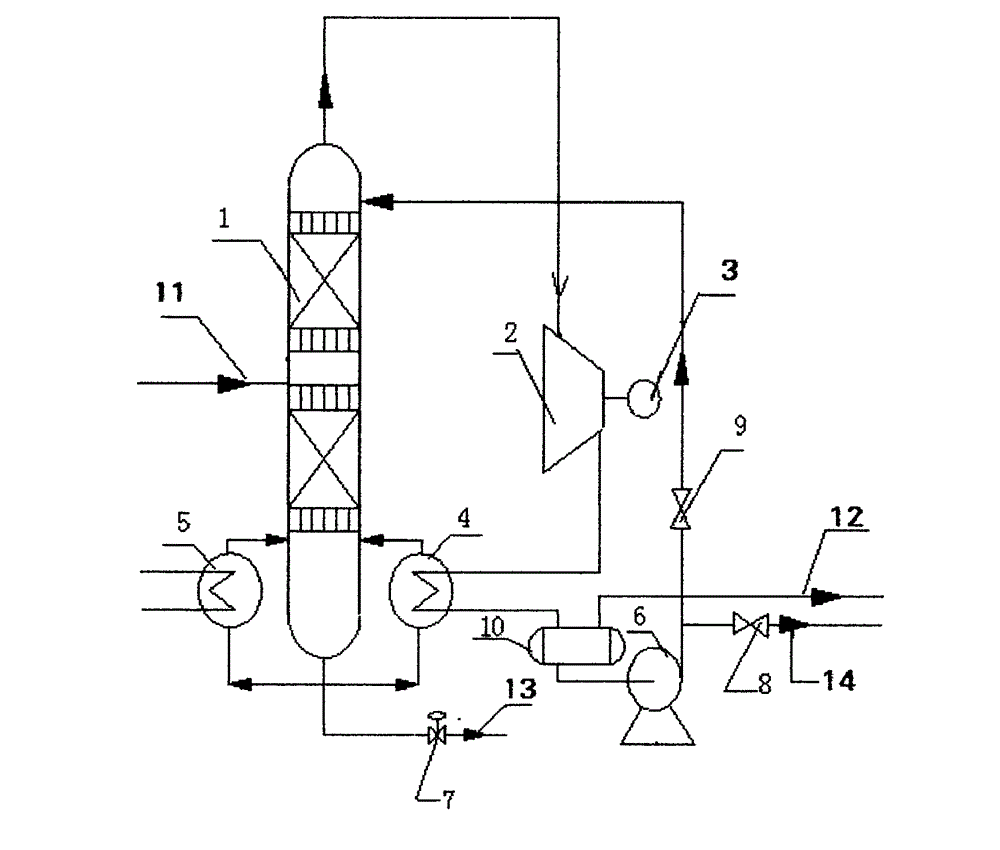

Process and device for distilling and separating isoamylol isomeride by heat pump

InactiveCN102875329AReduce heatingSave heatOrganic compound preparationChemical industryRefluxReboiler

The invention relates to a process and a device for distilling and separating isoamylol isomeride by a heat pump. The device comprises a distilling tower, the heat pump, a reboiler, a buffer tank, a driving heat exchanger and a reflux pump. The distilling tower is provided with a tower top vapor phase port and a tower top discharge outlet, the tower top vapor phase port is hermetically connected with an inlet of the heat pump through a pipeline, the reboiler is provided with a shell pass inlet, a shell pass outlet, a pipe pass inlet and a pipe pass outlet, the shell pass inlet is hermetically connected with the heat pump through a pipeline, the pipe pass inlet of the reboiler is hermetically connected with a tower bottom of the distilling tower, the pipe pass outlet is connected with a vapor phase port on the lower portion of the distilling tower through a pipeline, and the shell pass outlet is connected with the buffer tank. The bottom of the buffer tank is provided with a liquid phase discharge outlet which is connected with an inlet of the reflux pump. An outlet of the reflux pump is divided into two material flows, one is connected with a tower top reflux port of the distilling tower through a pipeline, and the other one is used as discharge on the tower top.

Owner:山东凯利生物科技有限公司

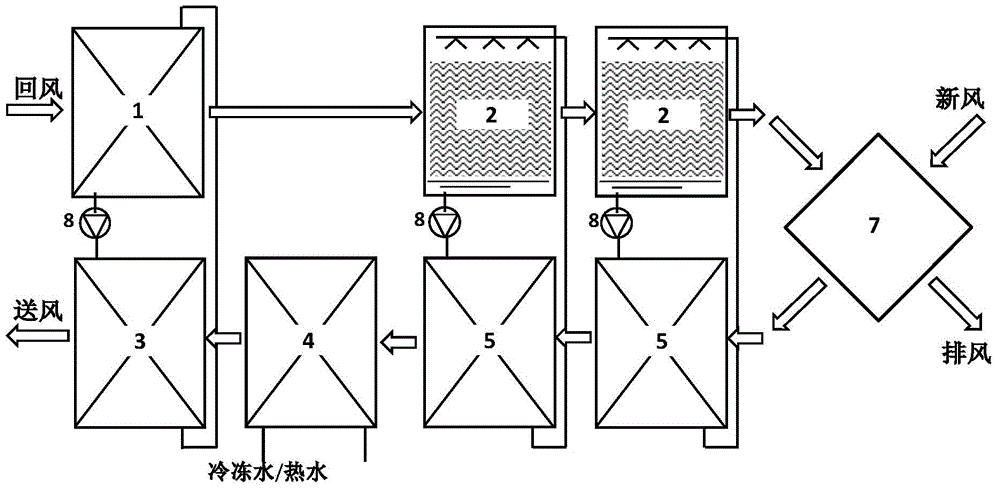

Fresh air treatment device for indirect evaporative cooling return air total heat recovery

ActiveCN104456875ARaise the supply air temperatureImprove energy efficiencyEnergy recovery in ventilation and heatingHeat recovery systemsAir treatmentFresh air

The invention discloses a fresh air treatment device for indirect evaporative cooling return air total heat recovery. The fresh air treatment device is composed of a sensible heat recovery device for supply air and return air, a return air total heat recovery device, an air treatment device and the like. The sensible heat recovery device is adopted for the fresh air treatment device, the supply air low in temperature is used for cooling the indoor return air, a state point of the return air is close to a saturation line before the return air enters the total heat recovery device, and therefore the total heat recovery process of fresh air and the return air is close to the saturation line, and the efficiency of the total heat recovery device is improved. Meanwhile, the supply air temperature of the fresh air is increased, and the fresh air can be fed indoors directly. Through the fresh air treatment device, recoverable energy of the return air is fully used, the input cooling capacity of a cold source is reduced, and the energy efficiency of the fresh air treatment device is improved. In addition, through working condition switching, the fresh air treatment device can have the functions of recovering heat of the return air and heating and humidifying the fresh air in winter.

Owner:SOUTHEAST UNIV

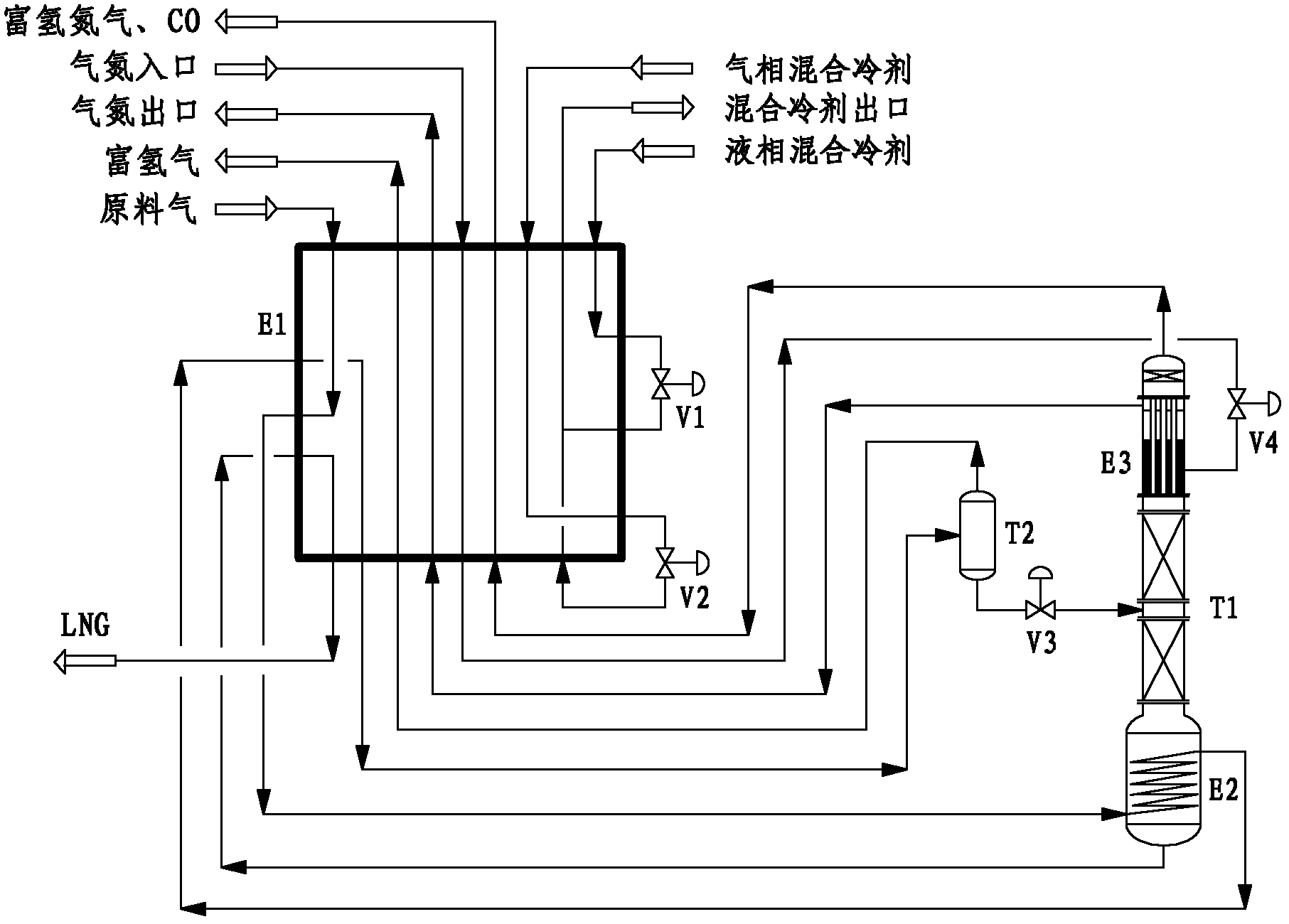

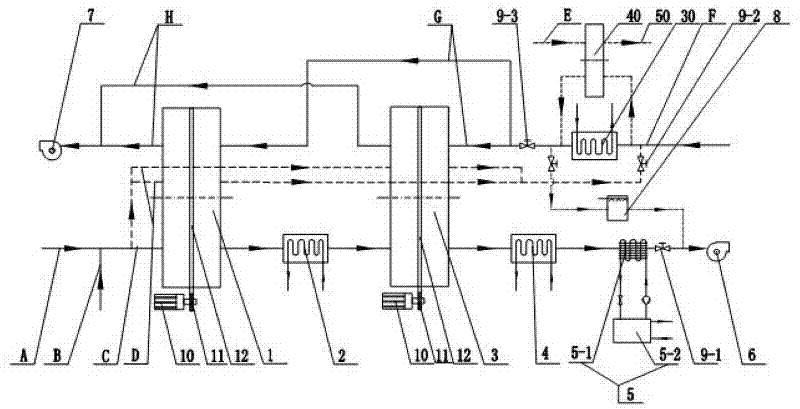

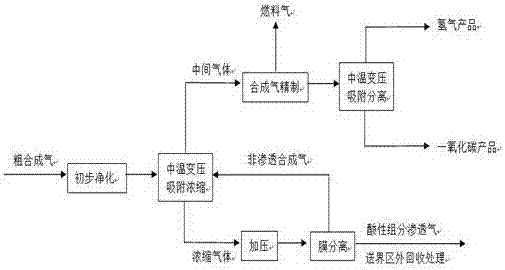

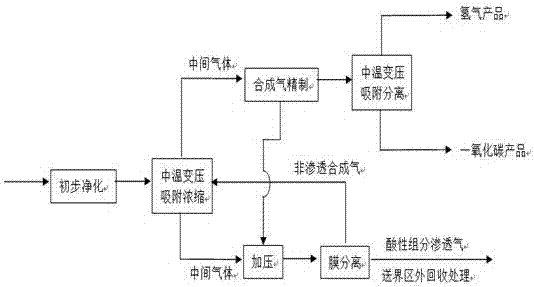

Purification and separation method of syngas by full temperature range-pressure swing adsorption (FTrPSA)

ActiveCN107285279ASave the cooling capacity required for the operating temperature of -75~-34°CSave coolingHydrogen separation using solid contactHydrogen/synthetic gas productionSeparation technologyImpurity

The invention discloses a purification and separation method of a syngas by FTrPSA, and relates to the technical field of H2 production, CO production and purification and separation for a PSA gas. Compared with the prior art, the purification and separation method of the syngas by FTrPSA disclosed by the invention separates coarse removal and refined removal of impurities of acidic components and the like in the syngas purification process, an intermediate gas is refined by the syngas and subjected to an intermediate temperature PSA separation process to obtain a qualified syngas product or H2 and CO products, the operating temperature and operating pressure are the same as those of an intermediate temperature PSA concentration process, so that the load and energy consumption of the syngas in the refining and intermediate temperature PSA separation are reduced, the integration degree of purification and separation process and the purity of the produces are improved, furthermore, a concentrated gas is subjected to a membrane separation process to obtain further recycled syngas and remove the acidic components, so that the load of the membrane separation process is reduced and the yield of the products is improved.

Owner:SICHUAN TECHAIRS

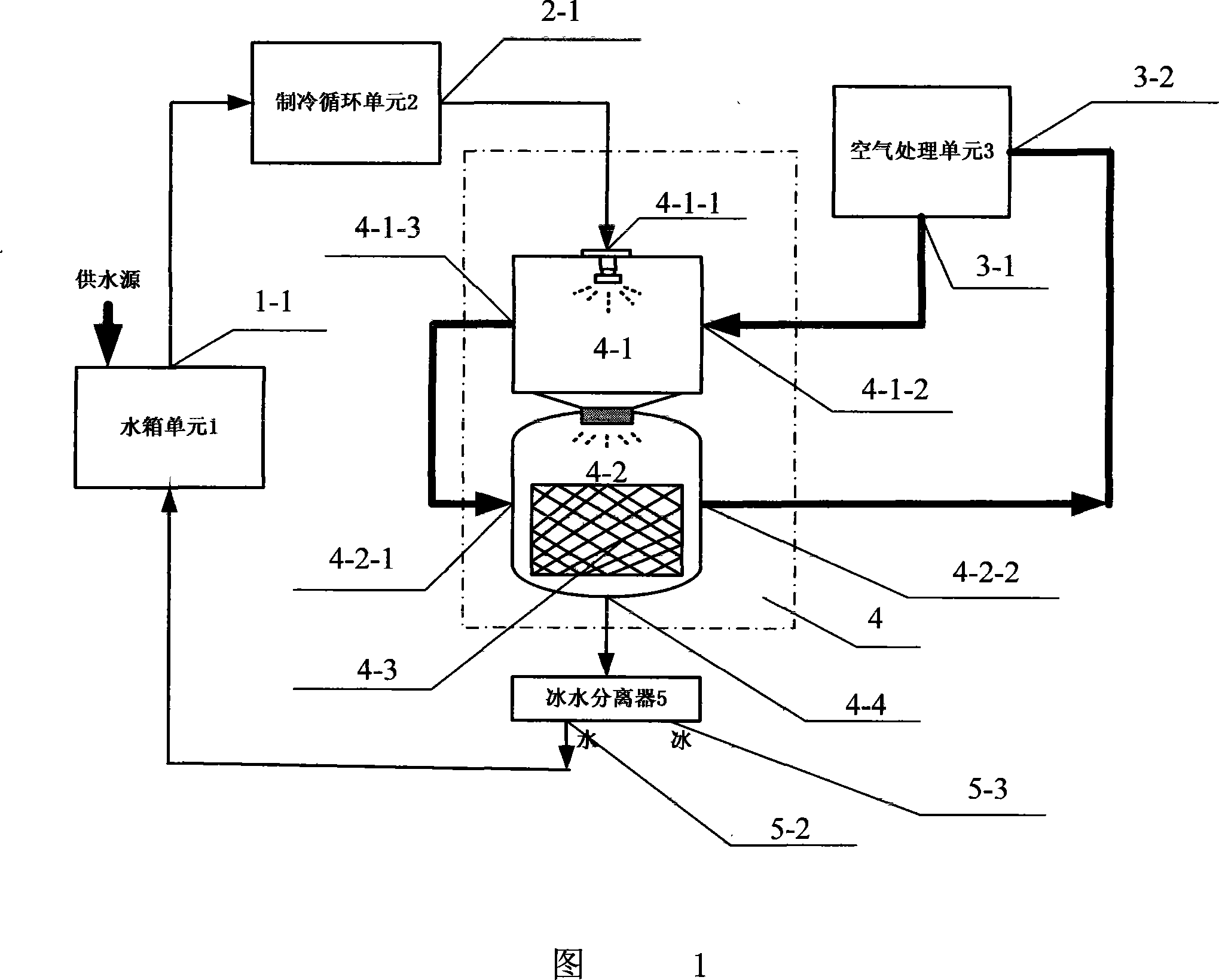

Method for preparing fluid ice by double layer evaporation type supercooled water and the preparing device

InactiveCN101216232AImprove stabilityImprove reliabilityLighting and heating apparatusIce productionWater vaporAir treatment

The invention relates to a method for producing fluid ice using supercooled water and a device thereof, specifically to a double-layer evaporative method for producing fluid ice using supercooled water and a device thereof. The invention comprises the following steps of: primarily cooling the water for producing ice via a refrigerating cycle unit, sprinkling the cooled water for producing ice on an evaporation supercooled layer, and introducing the treated air for producing ice into the evaporation supercooled layer, wherein the water vapor partial pressure is lower than water three-phase saturated vapor pressure 611.7Pa; introducing the treated water into a supercooling relieving and ice producing layer and sprinkling the treated water on a supercooling relieving device for generate a mixture of ice crystal and water; introducing the ice for producing ice from the evaporation supercooled layer to the supercooling relieving and ice producing layer to keep relatively low surrounding temperature of the second layer, and returning the ice for producing ice to an air treatment unit; separating the mixture of ice crystal and water via a ice and water separator to obtain fluid ice; and returning the separated water to a water tank unit. The invention has the advantages of low energy loss, high ice producing efficiency and no ice blockage.

Owner:JIANGSU FOCUS NEW ENERGY TECH +1

Heat pipe hot pump composite drying power source system

InactiveCN1924498AIncrease temperatureAdjustable temperatureHeat recovery systemsHeating arrangementTemperature controlWater block

This invention relates to energy saving technique field and to one heat tube pump compound dying and power system, which comprises m pieces of heat pump sub systems, n heat tube heat recycle sub system, water block board, air flow sub system, wind temperature control sub system, drying chamber, wherein, the heat tube cooling recycle sub system vapor device is fixed in front of heat pump sub system and water block board is fixed behind heat pump sub system.

Owner:QINGDAO UNIV

Regeneration process for washing and spraying methanol by low-temperature methanol

ActiveCN101735010ASave coolingReduce loadOrganic compound preparationHydroxy compound preparationExhaust gasChemistry

The invention relates to a regeneration process for washing and spraying methanol by low-temperature methanol, which comprises the following steps of: spraying the methanol by virgin gas, cooling the virgin gas, carrying out gas-liquid separation on the virgin gas, carrying out flash evaporation on the methanol and a water condensate, reheating the methanol and the water condensate, rectifying and regenerating the methanol, carrying out flash evaporation on the methanol sprayed by the virgin gas and the water condensate by a flash tank, delivering the flashed vapor of the condensate into an H2S concentration tower, delivering into tail gas finally, carrying out heat exchange between the decompressed methanol, the decompressed water condensate and H2S gas at an outlet of an H2S distillate heat exchanger, delivering the reheated methanol and the reheated water condensate into a methanol water knockout tower for separation, delivering methanol gas at the top of the methanol water knockout tower into a methanol regeneration tower and carrying out rectification and regeneration. Compared with the prior art, the invention has the advantages of low energy consumption, low operating pressure of the heat exchanger, high concentration of H2S in acid gas and the like.

Owner:WISON ENG +1

Separation method and device of zirconium tetrachloride synthesis gas

ActiveCN109019684AReduce separation costsReduce the temperatureSilicaCarbon monoxideTetrachloridePhysical chemistry

The invention discloses a separation method of zirconium tetrachloride synthesis gas. The zirconium tetrachloride synthesis gas is prepared from zirconium tetrachloride by a chlorination method. The method comprises the following steps of (1) lowering the temperature of the zirconium tetrachloride synthesis gas to 150 to 180 DEG C; separating out first coarse zirconium tetrachloride to obtain first synthesis gas; (2) lowering the temperature of the first synthesis gas to 80 to 120 DEG C; separating out second coarse zirconium tetrachloride to obtain second synthesis gas. The separation methodand device of zirconium tetrachloride synthesis gas provided by the method have the advantages that according to the method, the first coarse zirconium tetrachloride and the second coarse zirconium tetrachloride are respectively cooled and separated through stepped temperature reduction; the first coarse zirconium tetrachloride and the second coarse zirconium tetrachloride can be respectively usedas a coarse product to be used; the temperature used for separating out the first coarse zirconium tetrachloride through temperature reduction is lower; most zirconium tetrachloride in the zirconiumtetrachloride synthesis gasis separated out; the cold quantity is greatly saved; the separation cost of the zirconium tetrachloride synthesis gas is reduced.

Owner:XINTE ENERGY +1

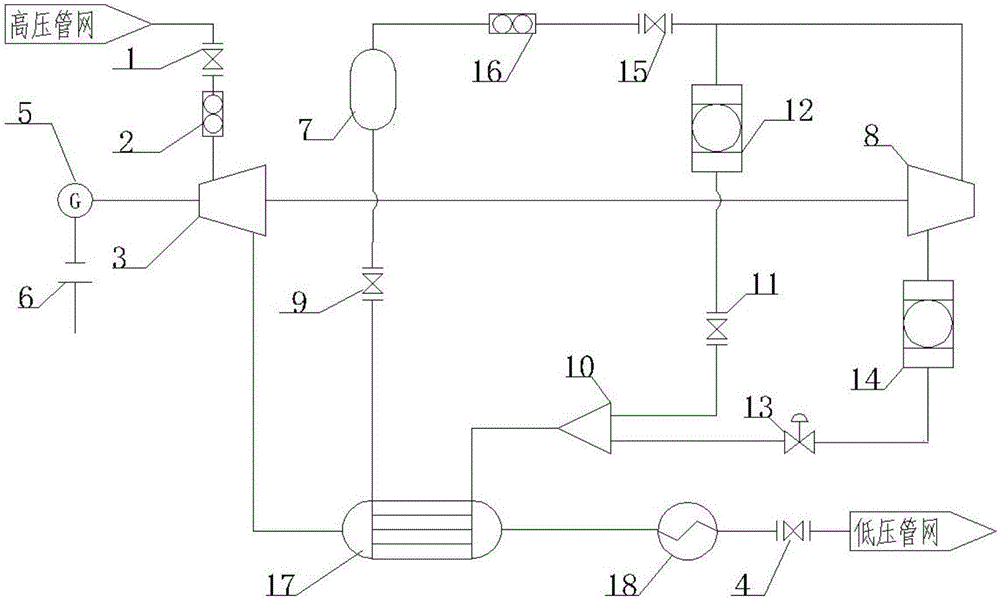

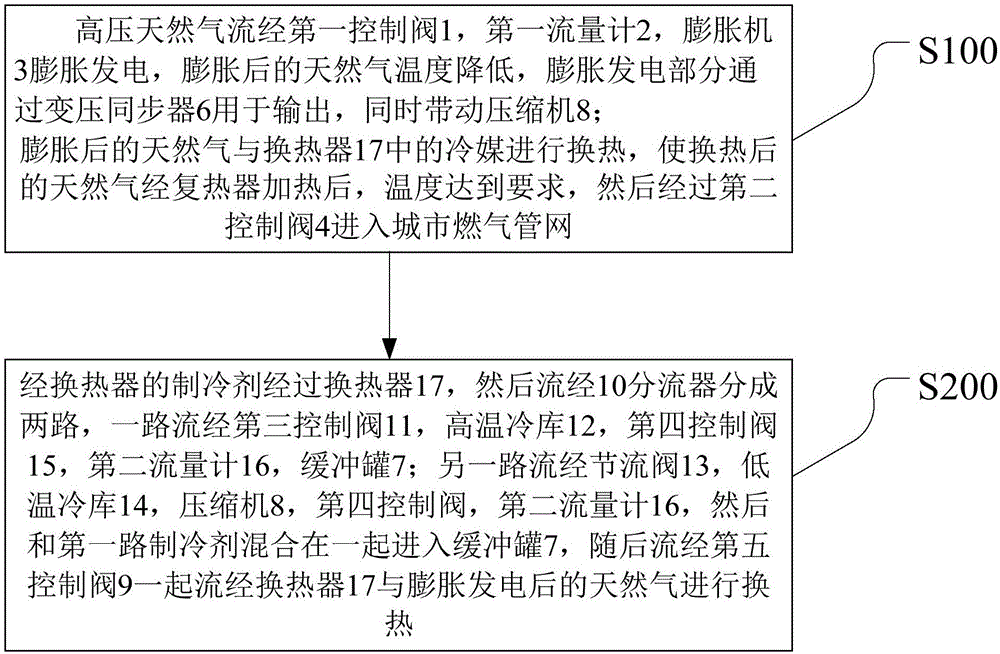

Natural gas pipe network pressure energy power generation and refrigeration house method and device

InactiveCN106640241AEfficient use ofSave coolingStationary refrigeration devicesFluid circulation arrangementShunt DeviceEngineering

The invention discloses a natural gas pipe network pressure energy power generation and refrigeration house method and device. The device comprises an expansion power generation system and a coolant refrigeration system, wherein the expansion power generation system and the coolant refrigeration system realize power generation and refrigeration integration; the expansion power generation system is that high-pressure natural gas generates power through an expander, then exchanges heat with a coolant, and enters an urban gas pipe network; after exchanging heat with low temperature natural gas, the coolant in the coolant system passes through a distributor; and one stream is directly supplied to a high temperature refrigeration house, and the other stream is supplied to a low temperature refrigeration house after being throttled, so as to realize refrigeration house freshness retaining at different temperature levels. According to the device disclosed by the invention, the expander, a power generator and a compressor operate continuously, so that pressure energy of the pipe network is recycled for generating power and driving the compressor to rotate, externally required energy during independent use of the compressor is reduced, and cooling of two refrigeration houses at different temperature levels is realized; and the device has extremely high economical and social benefits.

Owner:SHENZHEN GAS CORP

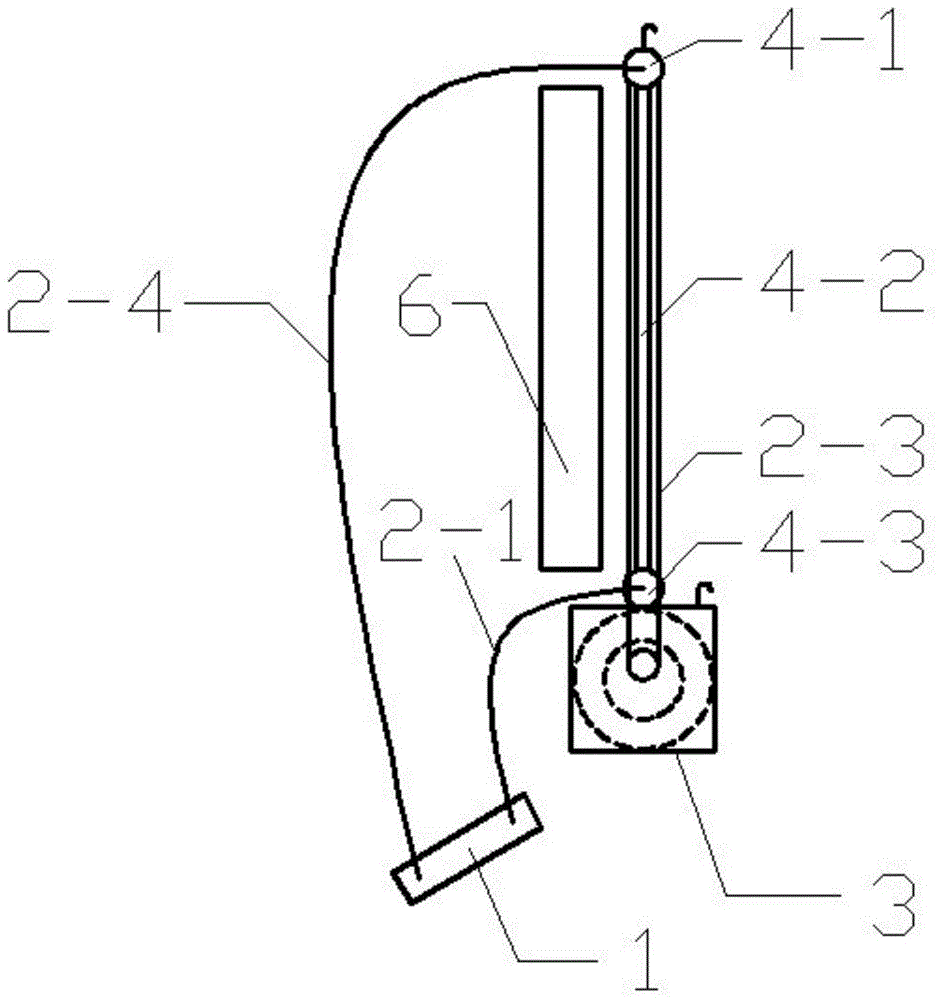

Heat-storing and energy-saving window device coupled with solar heat source

ActiveCN104963621AIncrease useClose to lifeSolar heat devicesLight protection screensEngineeringPhase-change material

The invention relates to a heat-storing and energy-saving window device coupled with a solar heat source. The heat-storing and energy-saving window device coupled with the solar heat source comprises a heat dissipation shutter. The heat-storing and energy-saving window device coupled with the solar heat source is characterized by further comprising a plate-type solar heat collector, a heating medium water pipeline and a phase-change material heat storage tank; the solar heat collector is of a plate-type structure and is installed on the upper portion of an outdoor lower window, the included angle between the heat collecting surface of the solar heat collector and the horizontal direction ranges from 10 degrees to 50 degrees, the length of the solar heat collector is the same as that of a window on which the solar heat collector is installed, and the width of the solar heat collector is one third to one second of the height of the window; the heat dissipation shutter comprises a water separator, heat dissipation water pipes, a water collector and heat conduction slats; the water separator and the water collector are horizontally arranged over and under the window on which the water separator and the water collector are installed respectively; the heat dissipation water pipes are evenly distributed between the water separator and the water collector, and each heat dissipation pipe is fixed with a heat conduction slat which can rotate by 360 degrees by taking the corresponding heat dissipation pipe as the axis.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com