Method for preparing fluid ice by double layer evaporation type supercooled water and the preparing device

A supercooled water and evaporative technology, which is applied in the field of making fluid ice, can solve the problems of system stability reduction, freezing in the supercooled water pipe, and failure to operate, so as to reduce the dependence on electric energy, avoid ice blockage, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

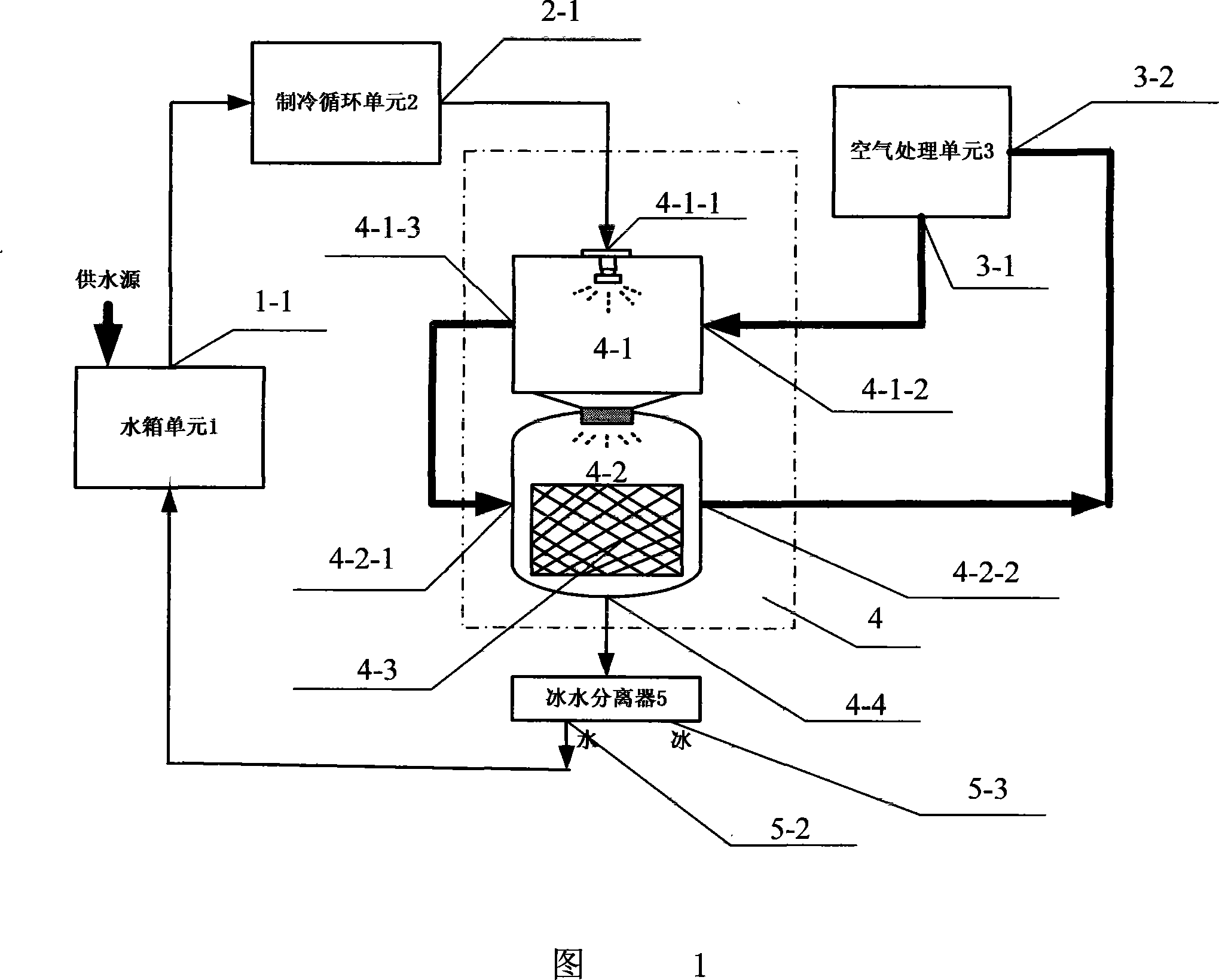

[0022] The present invention includes the following steps:

[0023] Step 1: The water used for refrigeration is preliminarily cooled by the refrigeration cycle unit 2, and the temperature of the water after cooling is above 0°C;

[0024] Step 2: The above-mentioned cooled water is sprayed into the evaporative supercooling layer 4-1, and the ice making air processed by the air processing unit 3 is passed into the evaporative supercooling layer 4-1. The partial pressure of water vapor is lower than the saturated vapor pressure of the triple point of water 611.7Pa;

[0025] The third step: the above-mentioned water after evaporating the ice making layer 4-1 passes into the supercooling deicing layer 4-2, and is sprayed on the supercooling deicing device 4 in the supercooling deicing layer 4-2 3, produce a mixture of ice crystals and water;

[0026] Step 4: While completing the above third step, the ice making air from the evaporated supercooling layer 4-1 is passed into the supercool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com