Recovery system and recovery method of by-product in polycrystalline silicon production

A recovery method and technology of a recovery system, applied in the purification of halogenated silicon compounds, halogenated silanes, chlorine/hydrogen chloride, etc., can solve problems such as energy consumption reduction, save heat and cooling, save heat and cooling, and save one time Sexual investment and its effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

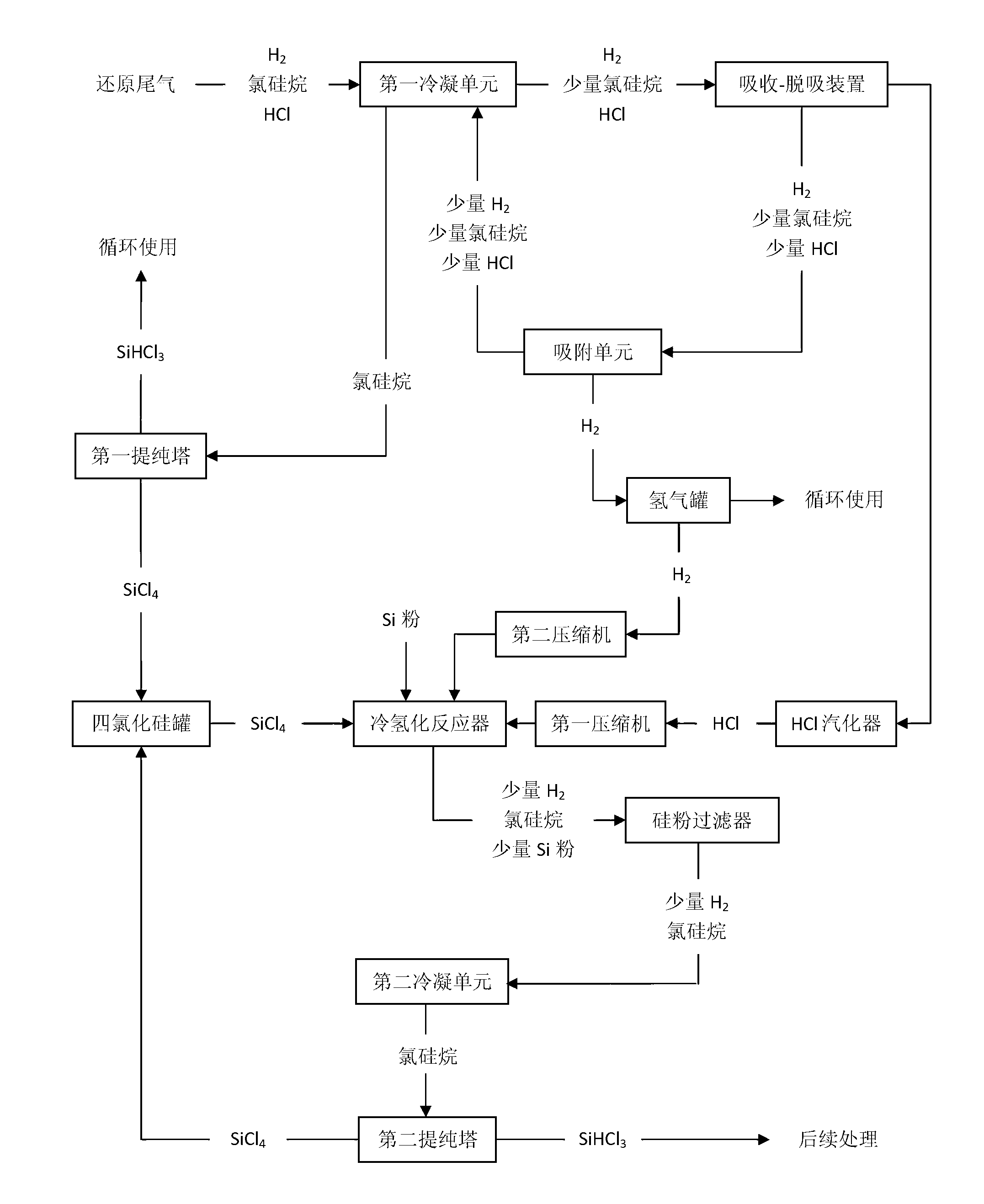

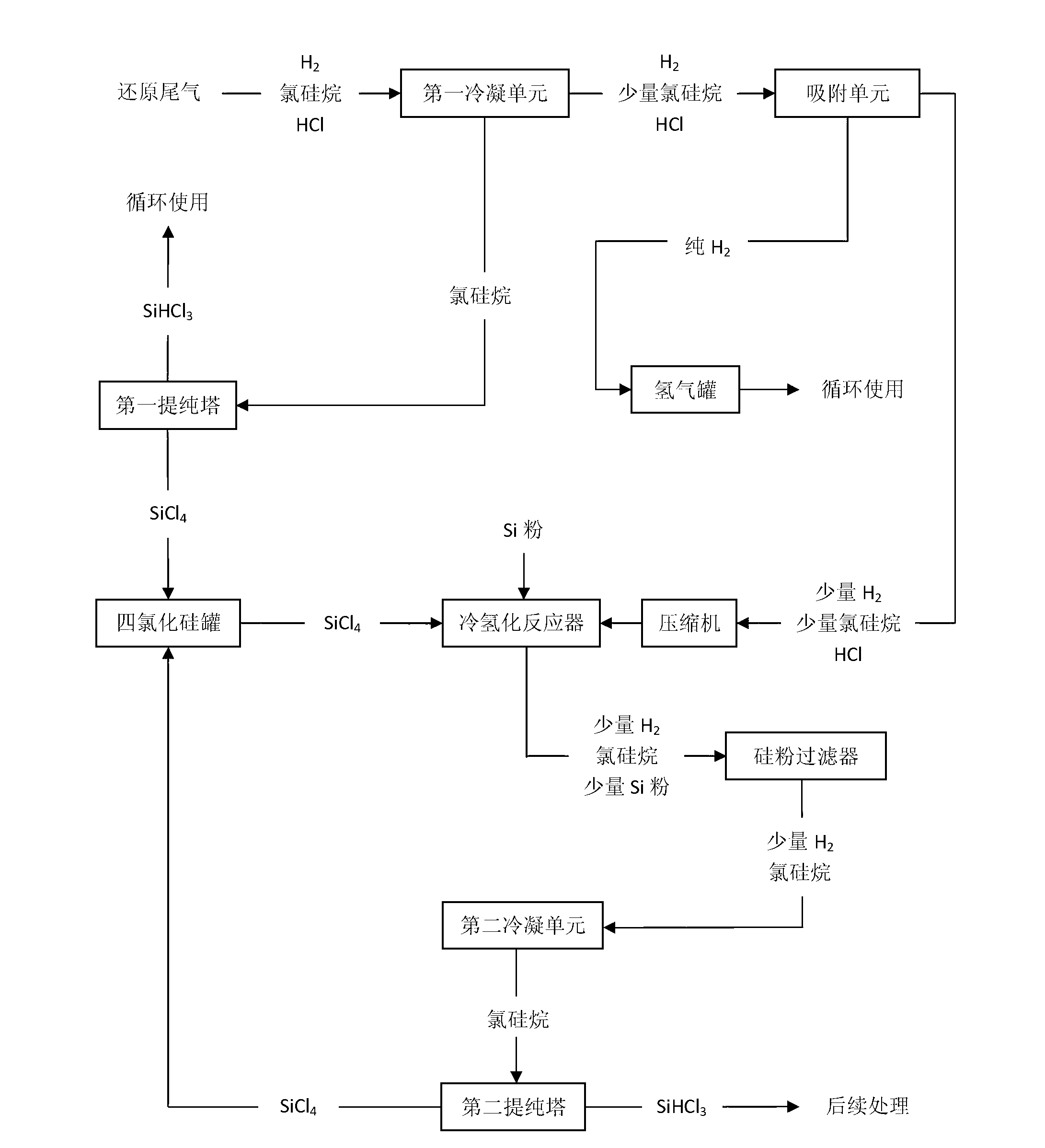

[0035] The recovery system of the invention is used to recover and utilize the hydrogen, chlorosilane and hydrogen chloride gases in the reduction tail gas produced during polysilicon production. Such as figure 2 As shown, the recovery system of the present invention may include: a first condensation unit, an adsorption unit directly connected to the first condensation unit, and a cold hydrogenation reactor connected to the adsorption unit. The first condensation unit can separate most of the chlorosilanes in the reduction tail gas through condensation. The reduced tail gas from which most of the chlorosilanes have been removed in the first condensation unit passes into the adsorption unit. After removal of residual chlorosilanes and all hydrogen c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com