Round sleeve type memory alloy actuator

A memory alloy, circular sleeve technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve the problems of large volume occupied by the structure, limited working space, and uncompact structure, and achieve a simple structure. Compact, saving cooling or heating devices, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

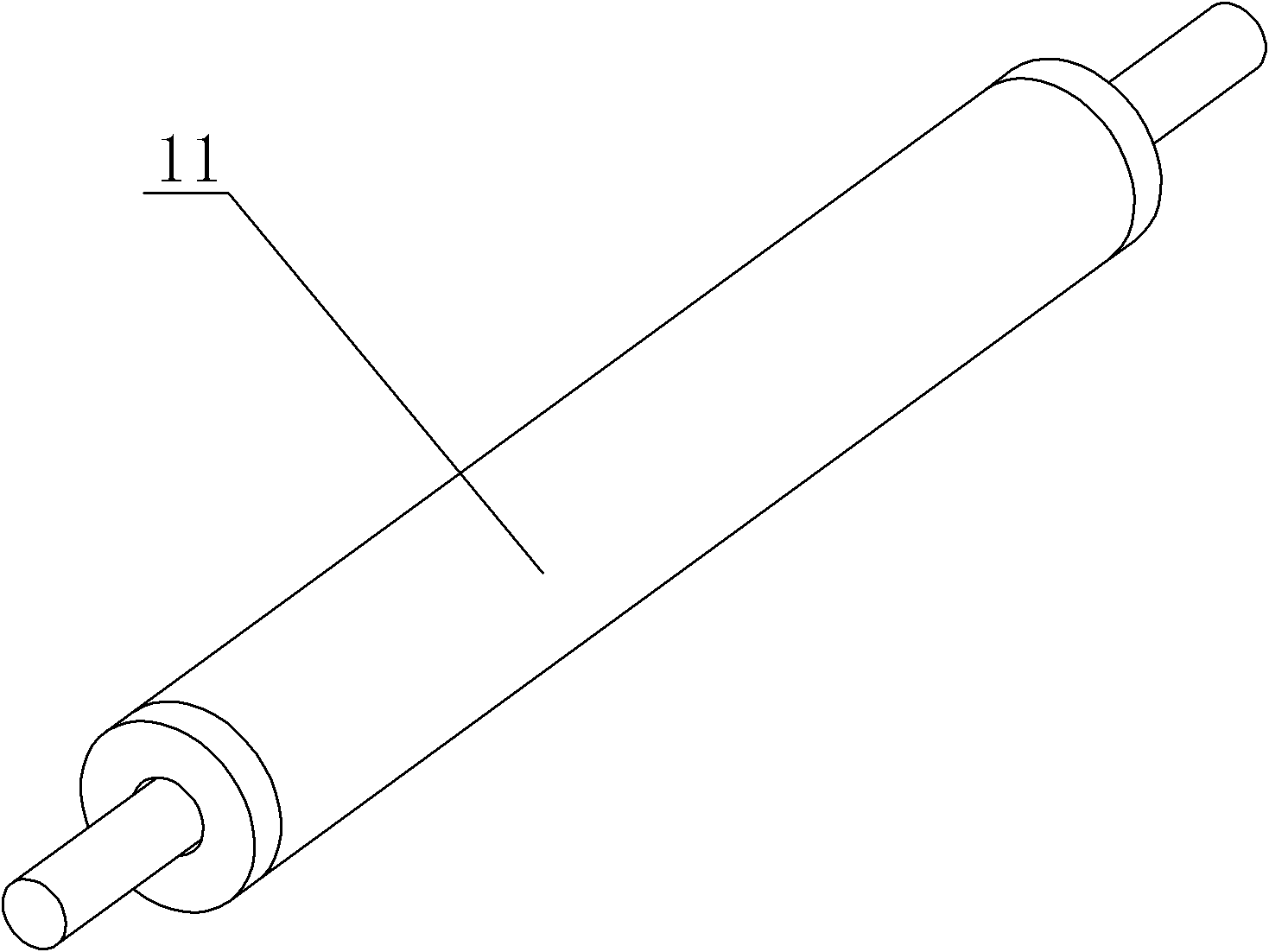

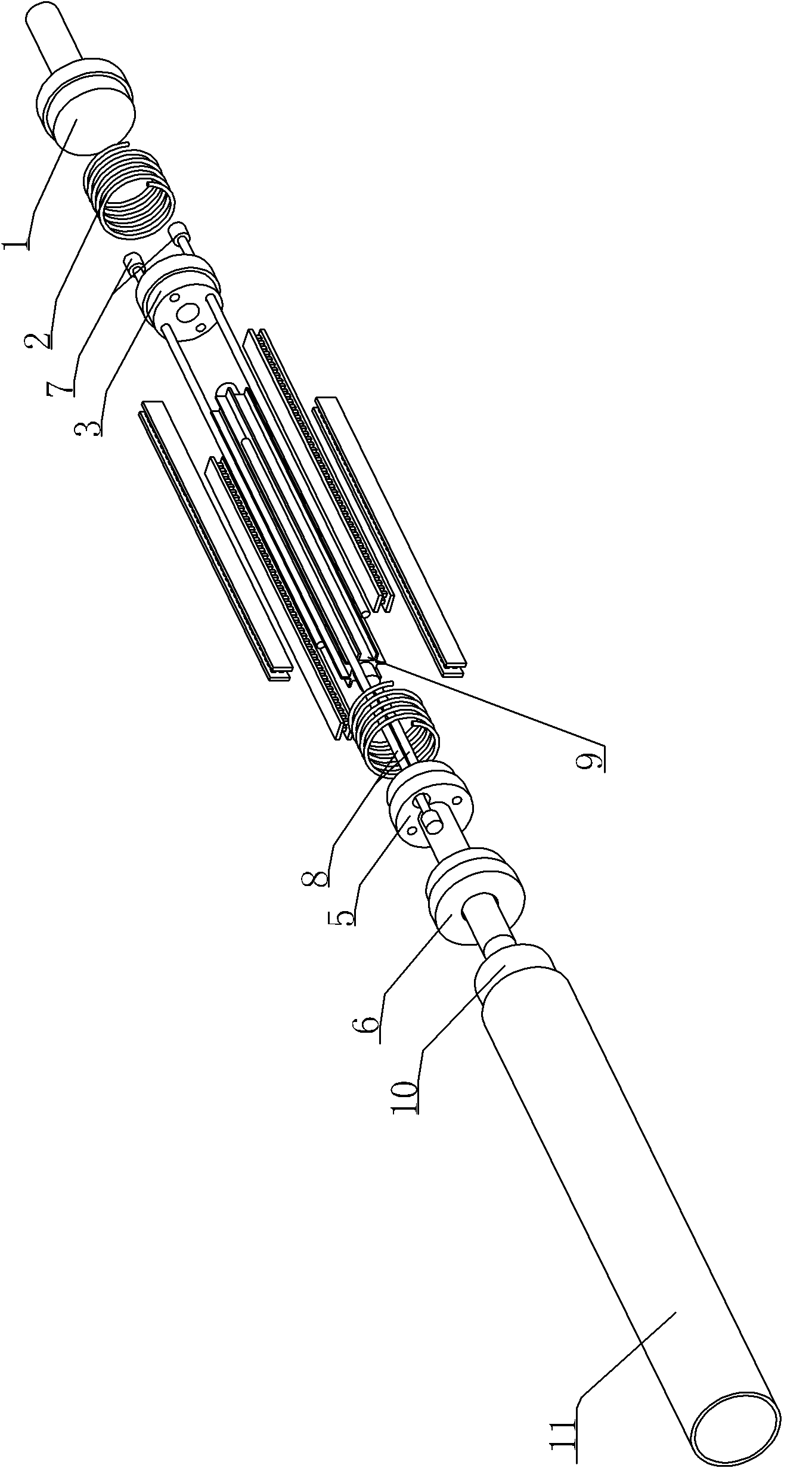

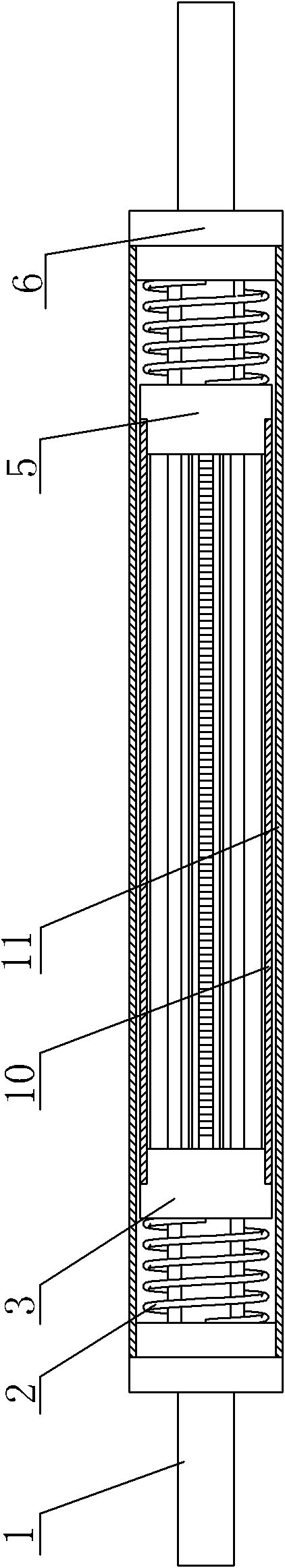

[0007] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the actuator device in this embodiment includes the first end of the outer cylinder 1, two buffer springs 2, the first end of the inner cylinder 3, four semiconductor cooling chips 4, the second end of the inner cylinder Head 5, the second end of the outer cylinder 6, two first memory alloy wires 7, two second memory alloy wires 8, a cooling plate fixing frame 9, a circular inner cylinder 10 and a circular outer cylinder 11, and a circular outer cylinder The two ends of cylinder 11 are respectively equipped with outer cylinder first end 1 and outer cylinder second end 6, and circular inner cylinder first end 3, inner cylinder second end 5 and circular inner cylinder 10 are located in the circle In the shape outer cylinder 11, the two ends of the circular inner cylinder 10 are respectively equipped with the first end 3 of the inner cylinder and the second end 5 of the inner cylinder, a...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, each peltier 4 of this embodiment is bonded in the square groove 9-1, and this structure is stable. Other components and connections are the same as those in the first embodiment.

[0009] Working principle: firstly, the memory alloy wire is pretreated, such as Figure 5 The memory alloy wire is in a shrinking state at the austenite temperature, and when it is cooled to the martensite temperature, the memory alloy wire is elongated by applying tension. The memory alloy wire of the present invention is in when not working Figure 5 In the intermediate state at medium ambient temperature, the square inner cylinder 10 is located in the middle of the square outer cylinder 11 . When the action controller sends out a control signal to energize the four semiconductor refrigeration chips 4, the switching between the heating surface and the cooling surface of the semiconductor refrigeration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com