Patents

Literature

251results about "Lactams separation/purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation catalyst and preparation method thereof

InactiveCN102430406AWith hydrogen storage functionExtend your lifeLactams separation/purificationMetal/metal-oxides/metal-hydroxide catalystsHydrogenActive component

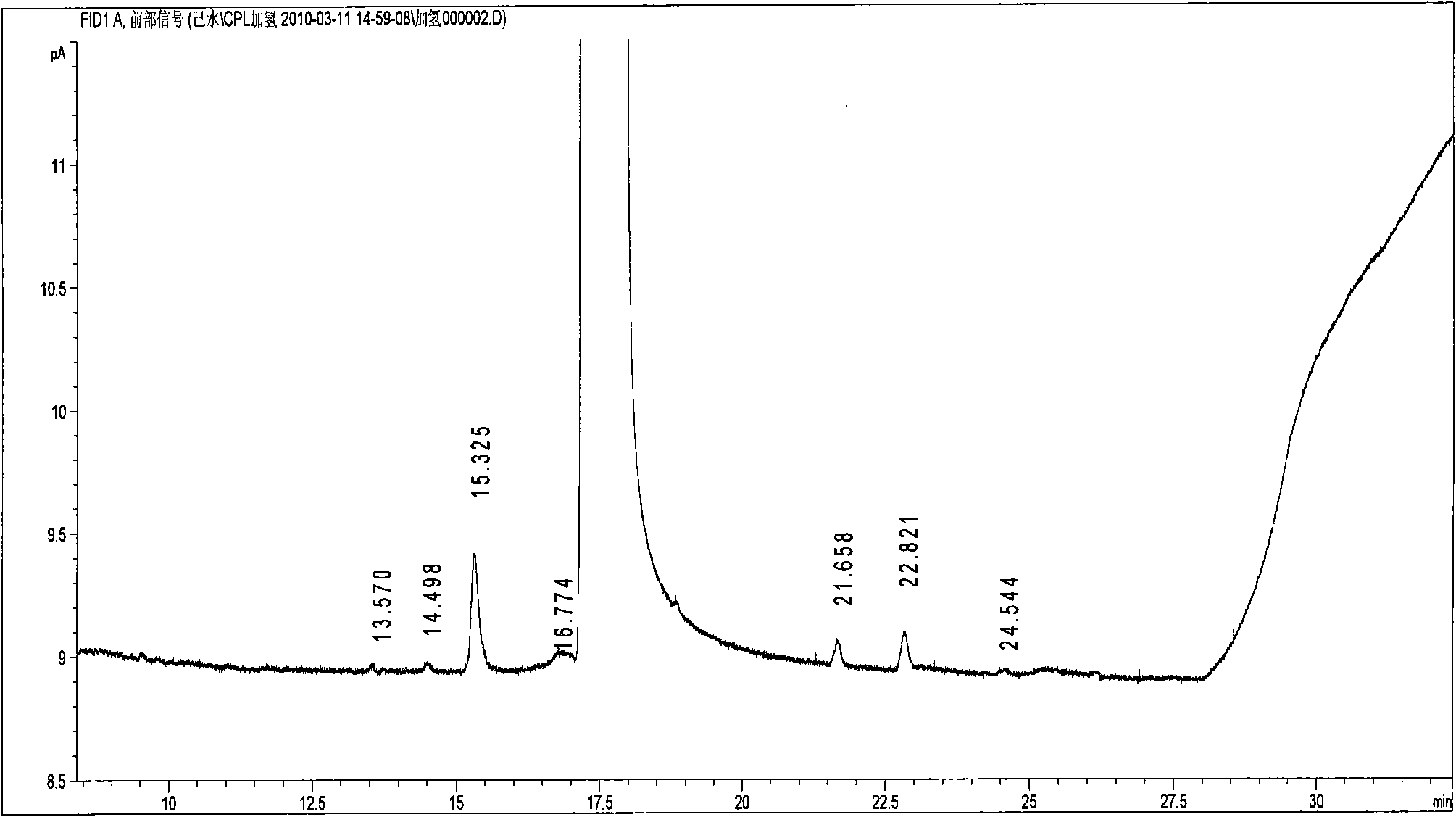

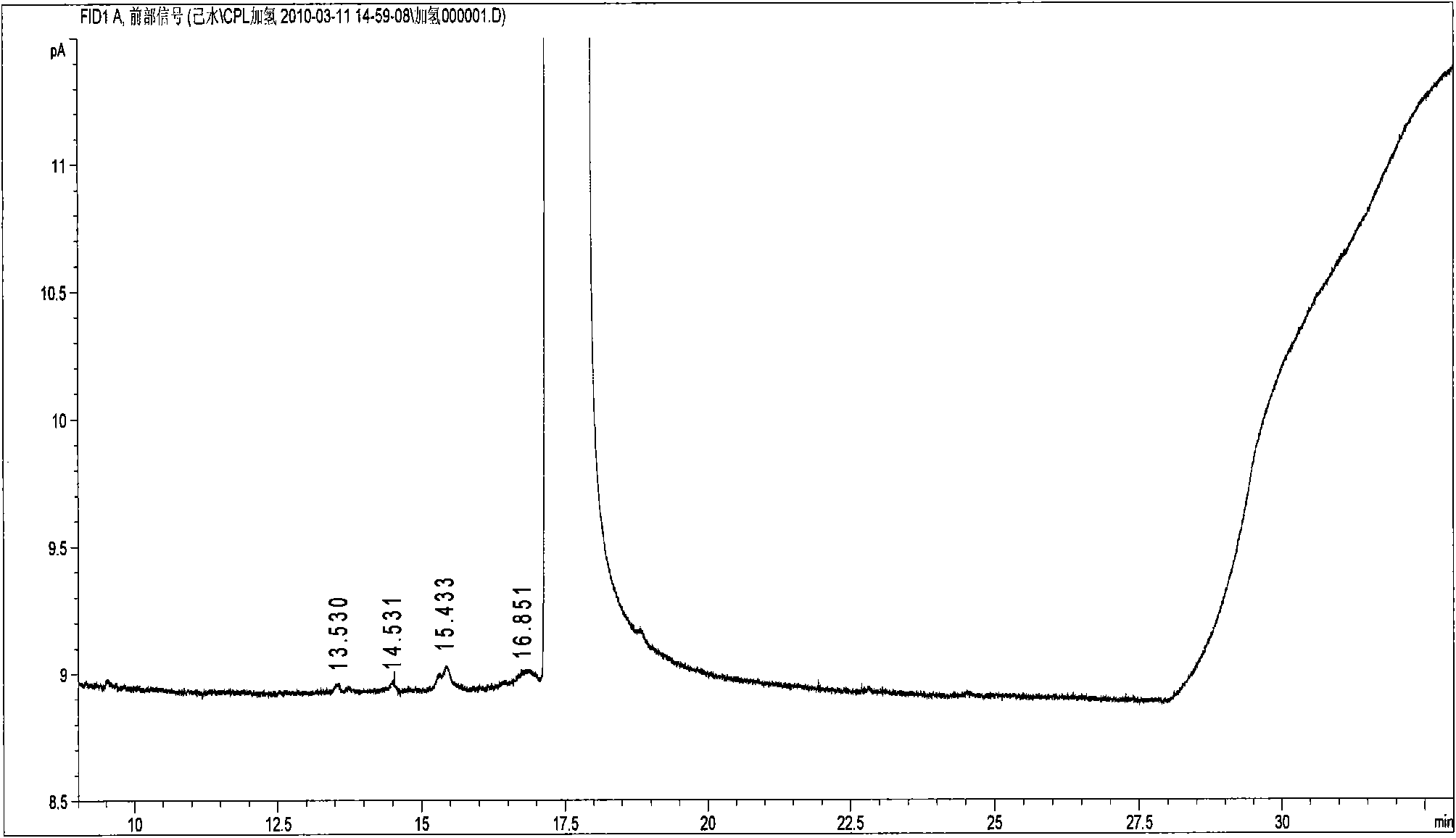

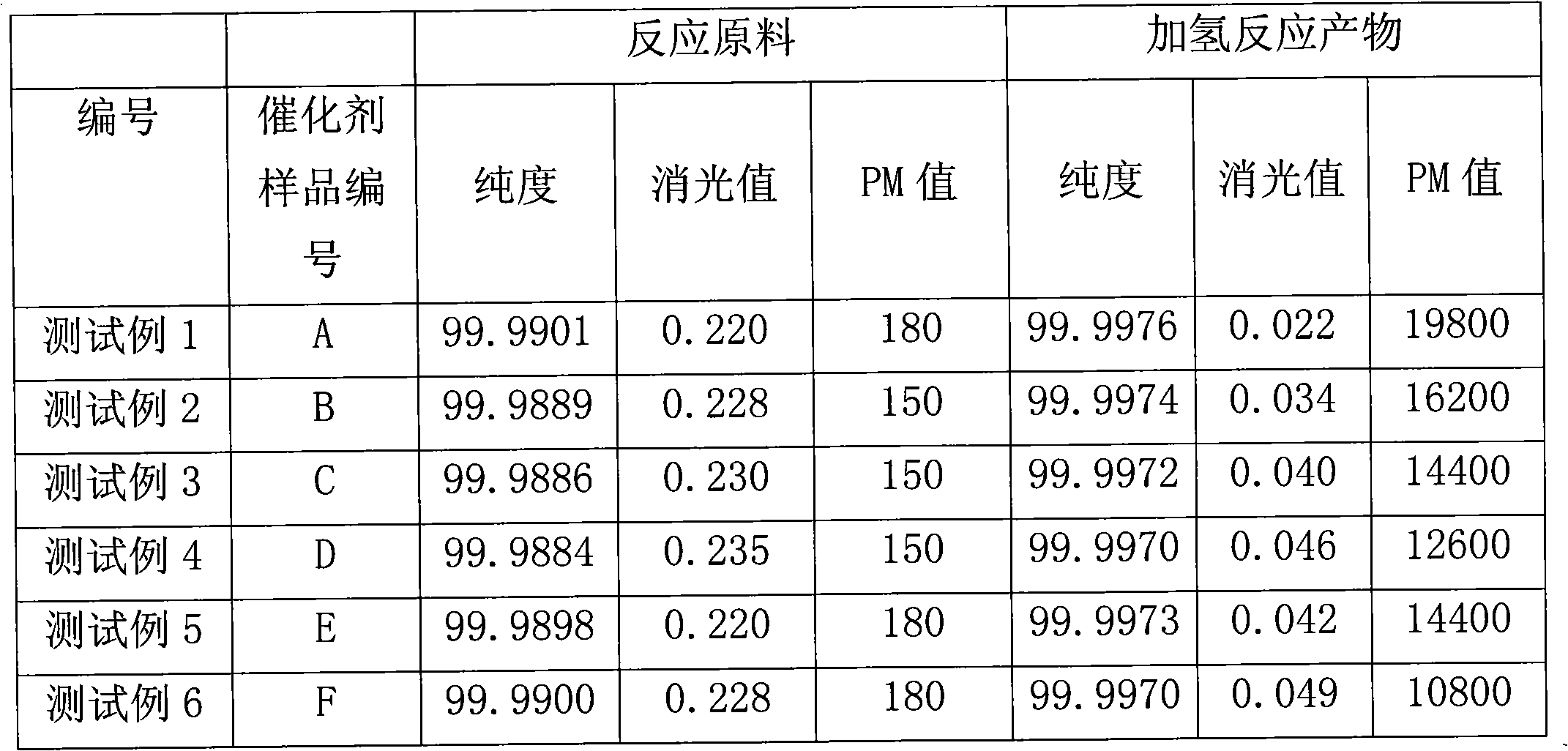

The invention discloses a hydrogenation catalyst, characterized in that: active components are loaded on a carrier, the active components comprise 0.2-5 wt% of metallic palladium and 0.1-2.5 wt% of rare earth oxide. The catalyst is prepared by the following steps: preparing water-soluble palladium-containing compound, water-soluble rare earth compound and water into a palladium-rare earth aqueous solution, dipping a carrier in the palladium-rare earth aqueous solution to loading the palladium-containing compound and rare earth compound on the carrier to obtain a catalyst precursor; drying and roasting the catalyst precursor, then carrying out reduction processing at a temperature of 50-200 DEG C in the presence of hydrogen to reduce oxidative divalent palladium in the palladium compound to metallic palladium.

Owner:CHINA PETROLEUM & CHEM CORP +1

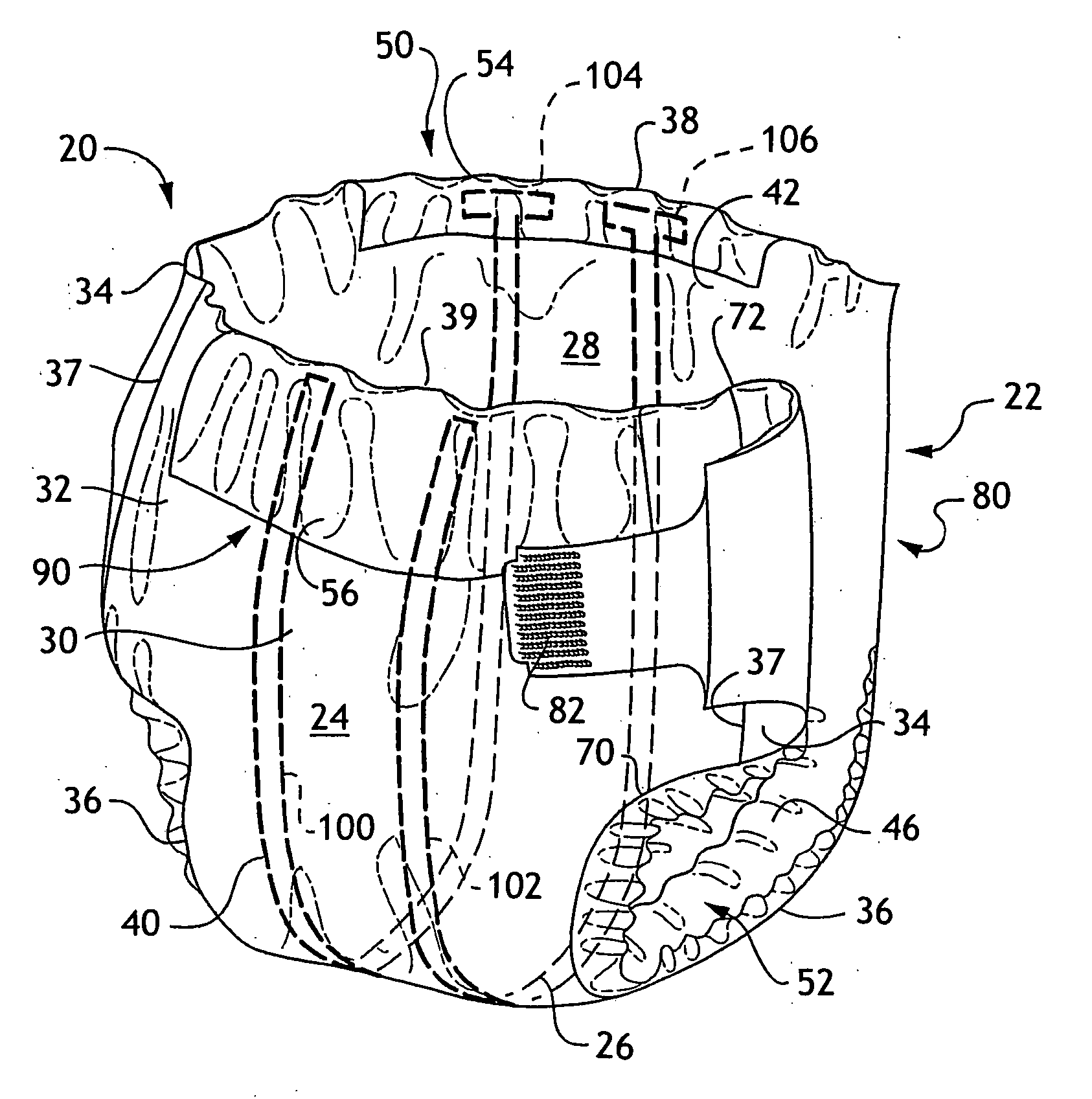

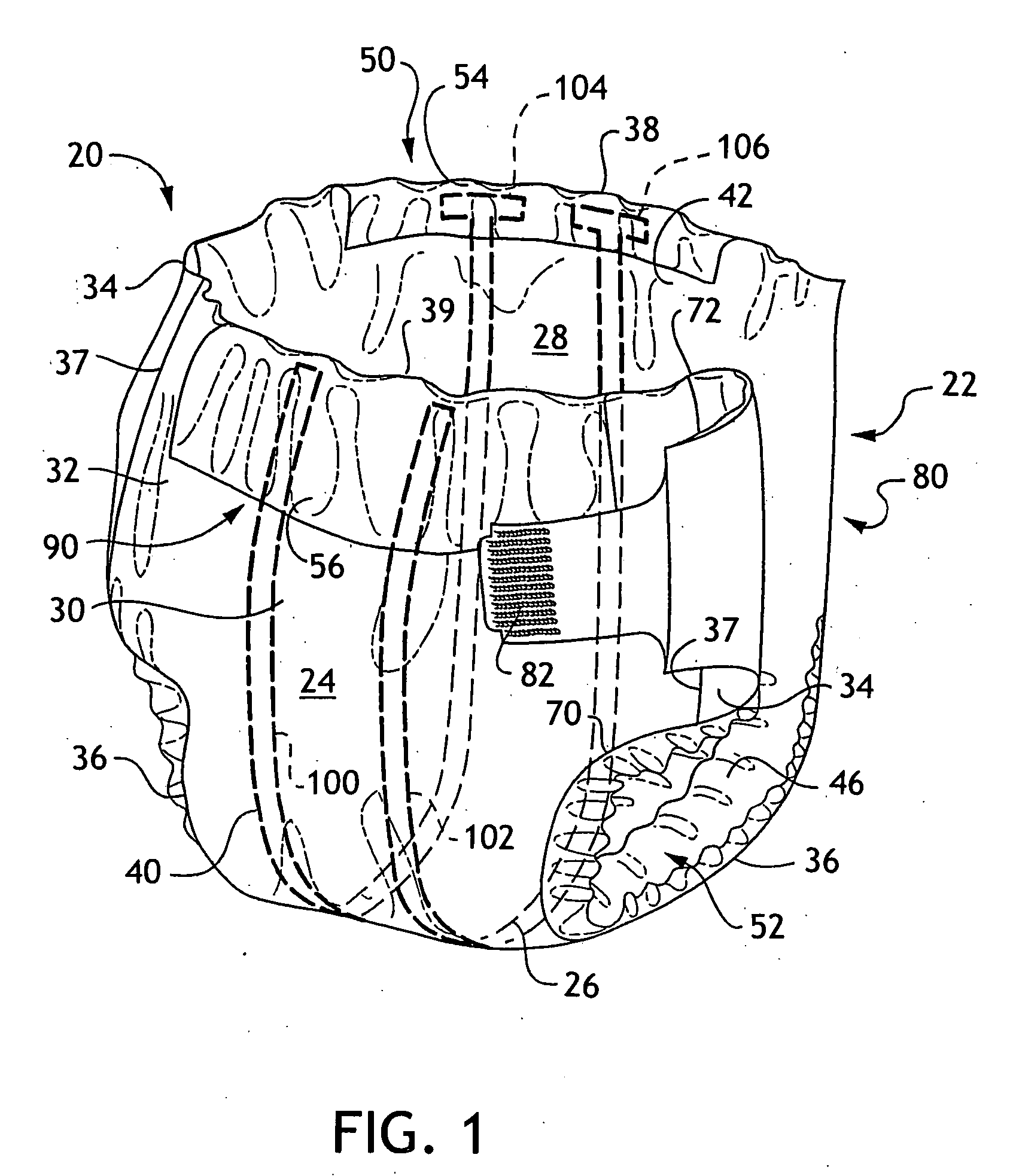

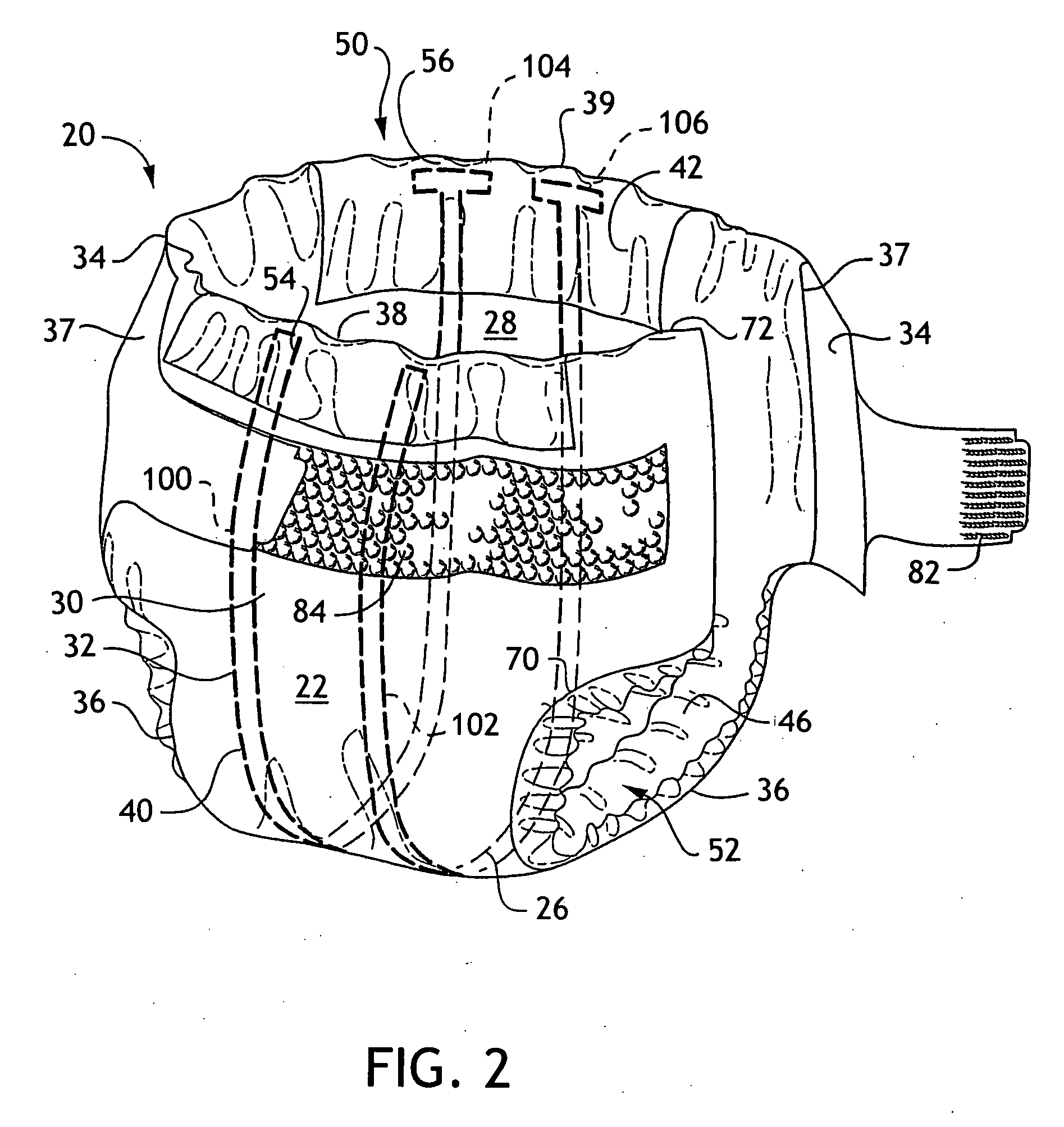

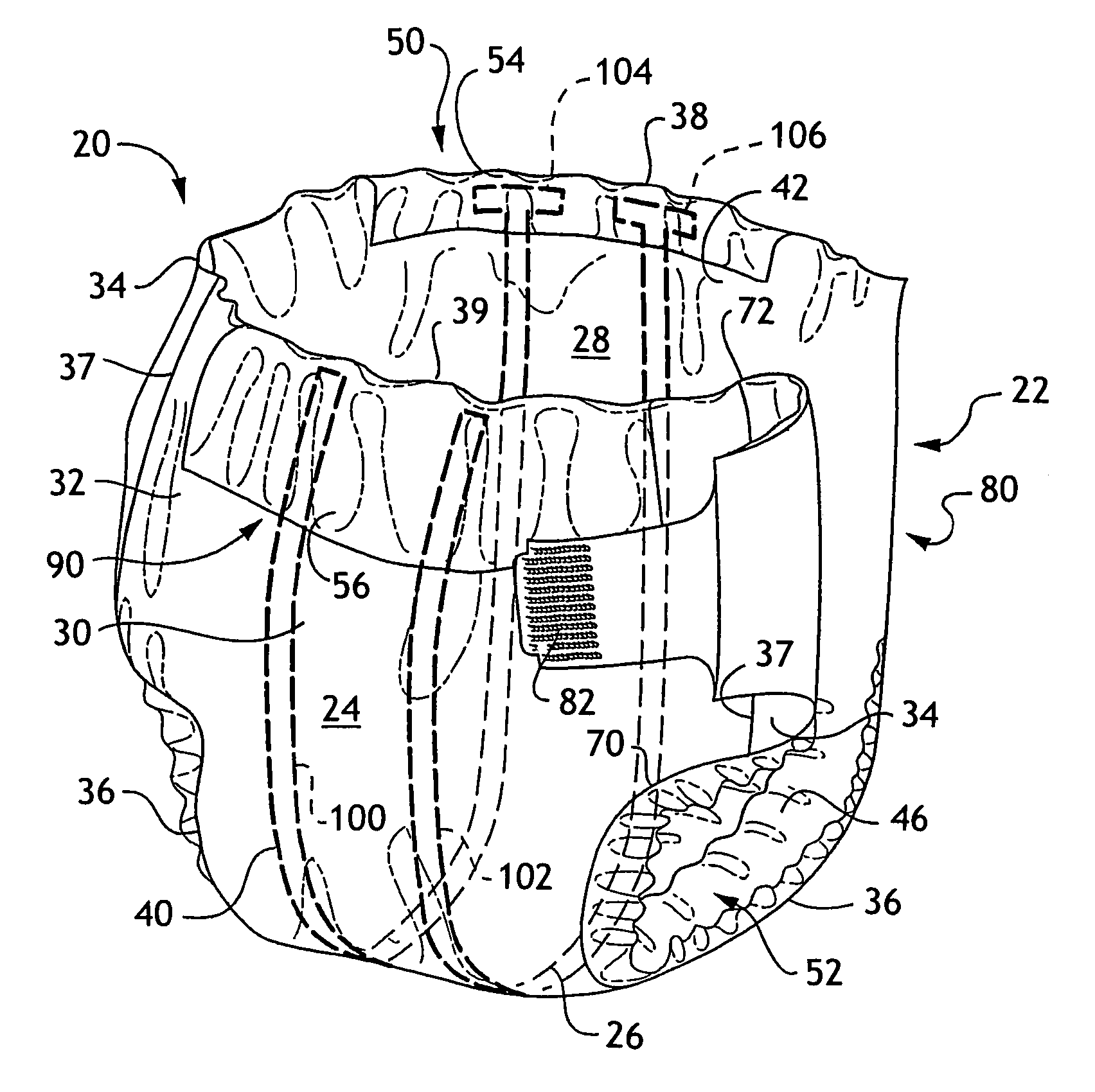

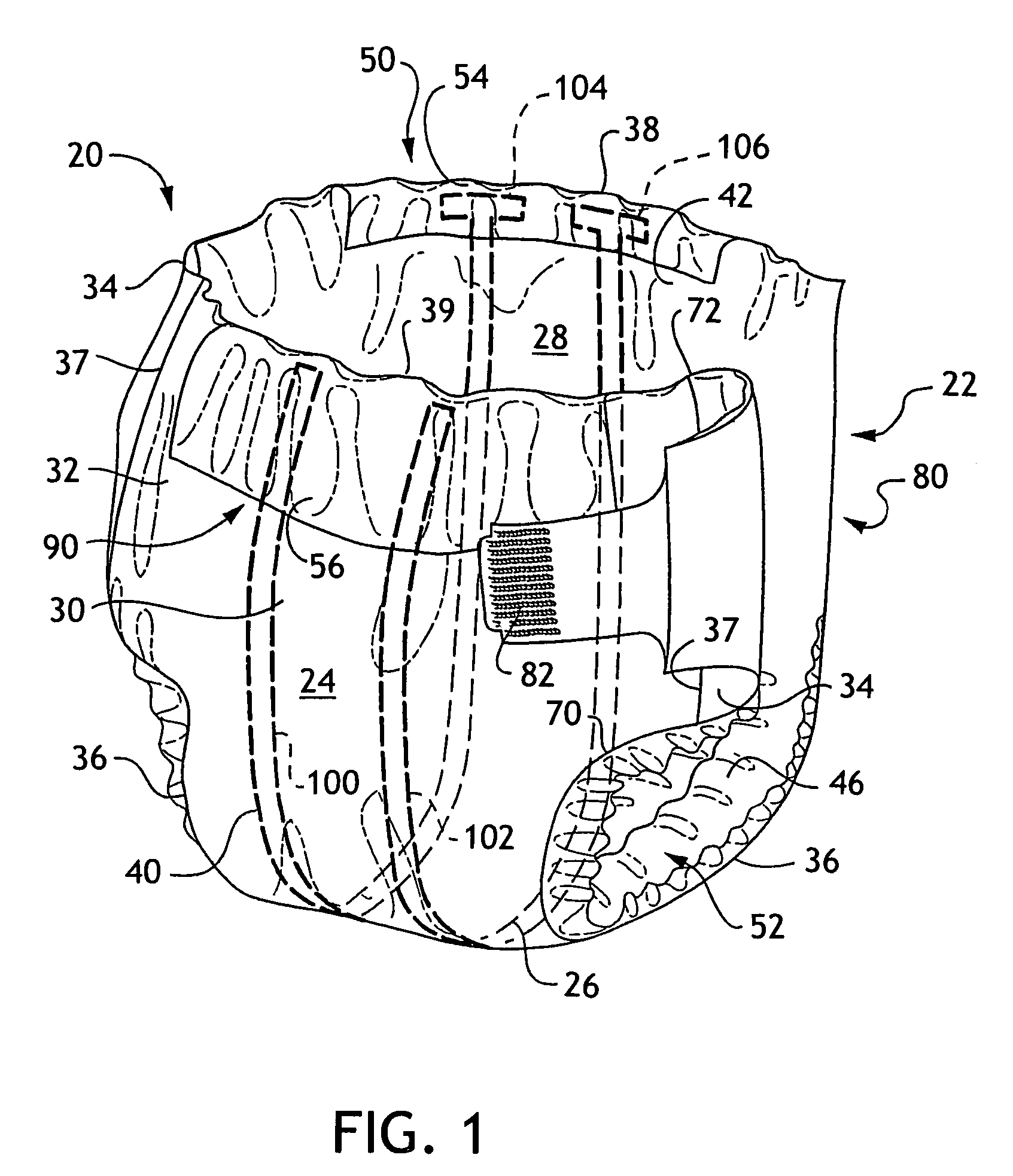

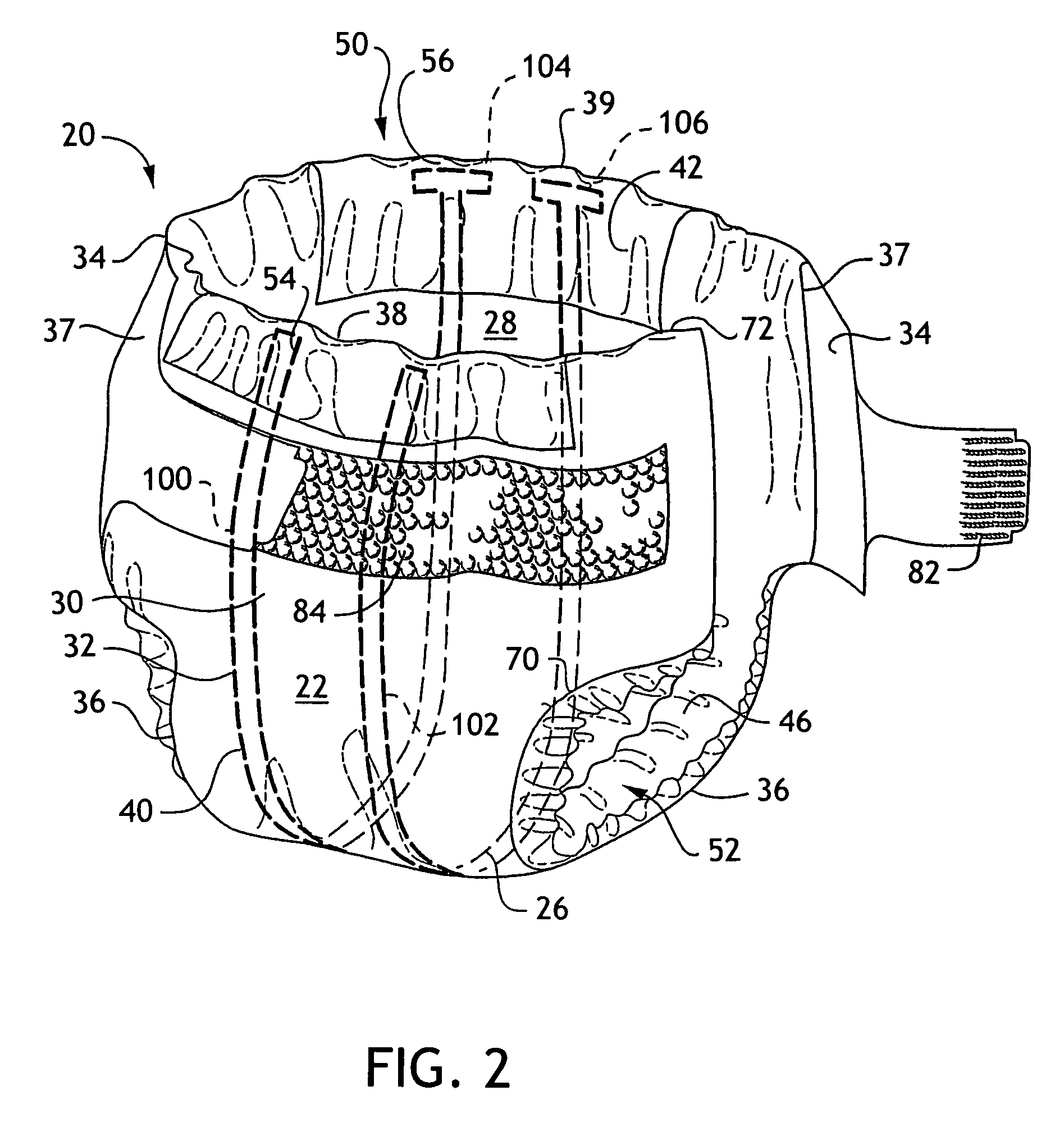

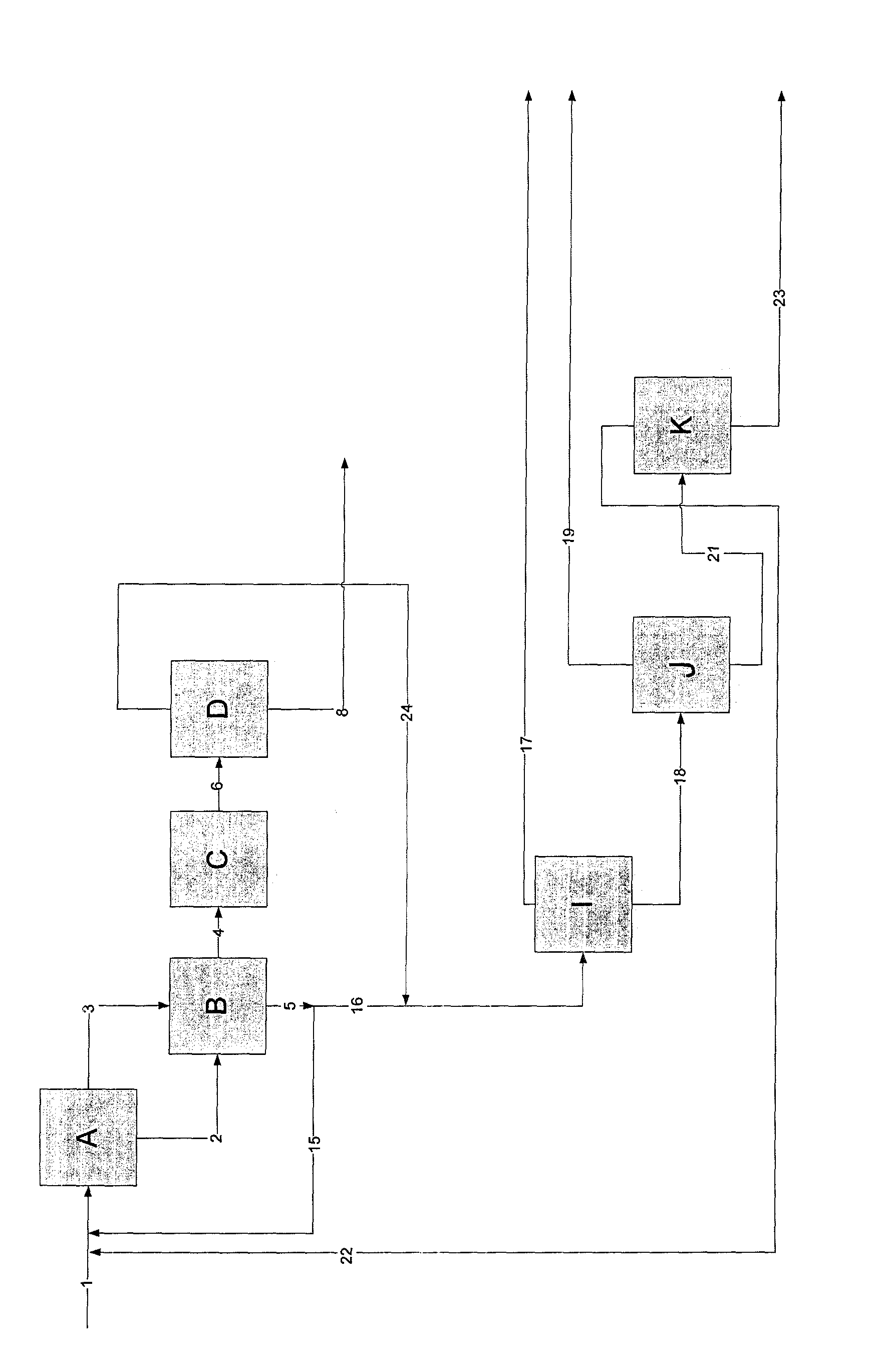

Array of wetness-sensing articles

ActiveUS20070252712A1Good curative effectEnhancing level of interestLactams separation/purificationBaby linensEngineeringHumidity

A wetness sensing system includes a first wetness sensing article; a first signaling device producing a first signal upon sensing wetness in the first wetness sensing article, wherein the first signaling device is compatible with the first wetness sensing article; and a second signaling device producing a second signal upon sensing wetness in the first wetness sensing article, wherein the second signaling device is compatible with the first wetness sensing article. Also, a method for enhancing a wetness sensing system includes producing a wetness sensing absorbent article compatible with at least one component of the wetness sensing system, wherein the wetness sensing system includes as components a wetness sensing article and a first signaling device compatible with the wetness sensing article.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for purifying and refining epsi caprolactam

ActiveCN101070299AMeet the requirements of industrial productsLactams preparationLactams separation/purificationPotassium permanganatePhotochemistry

This invention relates to a refine means of epsilon - caprolactam by separation and purification. The feature of the invention lay in that it includes the step of crystallize epsilon - caprolactam from ethereal solution containing crude epsilon - caprolactam.The product purity can reach 99.98%upwards, absorption value of potassium permanganate is greater than 10000 or more, the extinction value of epsilon - caprolactam at 290nm wavelength is 0.05 or smaller. The invention wholly meet the require of industrial product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for purifying and refining epsi-caprolactam

ActiveCN101070298AMeet the requirements of industrial productsLactams preparationLactams separation/purificationEtherLength wave

This invention relates to a refine means of epsilon - caprolactam by separation and purification. The feature of the invention is that it includes the step of crystallize epsilon - caprolactam from ethereal solution containing crude epsilon - caprolactam. The product purity can reach 99.98%upwards, absorption value of potassium permanganate is greater than 10000 or more, the extinction value of epsilon - caprolactam at 290nm wavelength is 0.05 or smaller. The invention wholly meets the require of industrial product.

Owner:CHINA PETROLEUM & CHEM CORP +1

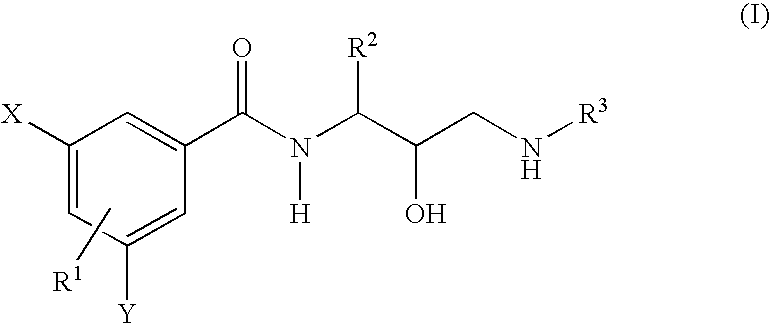

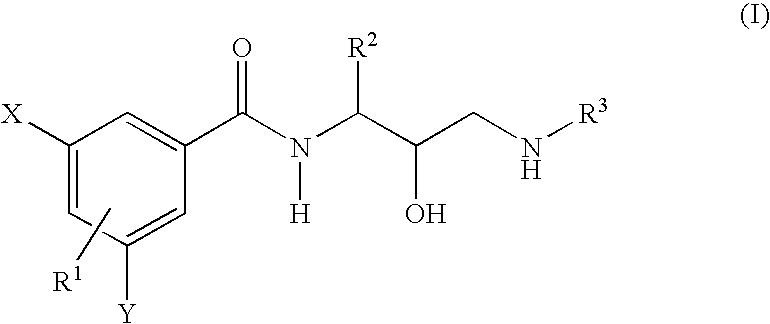

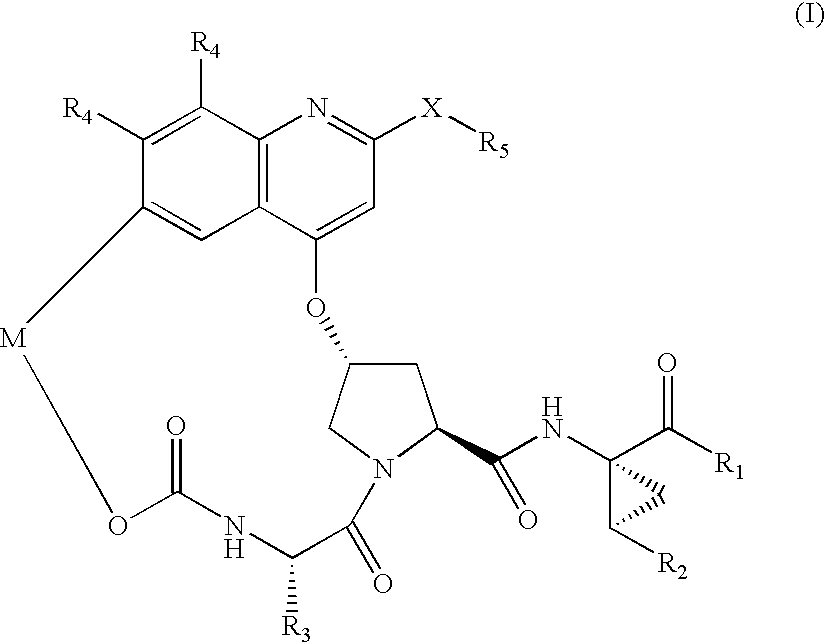

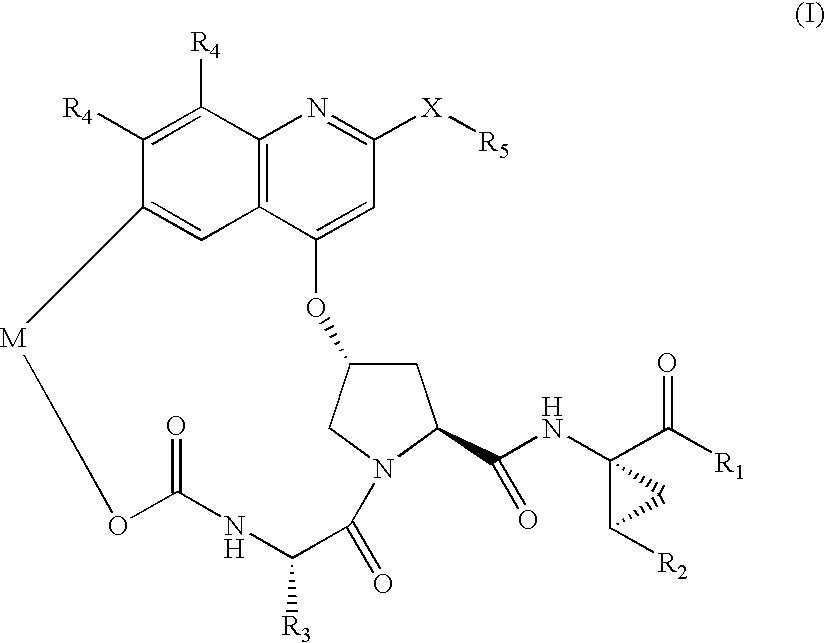

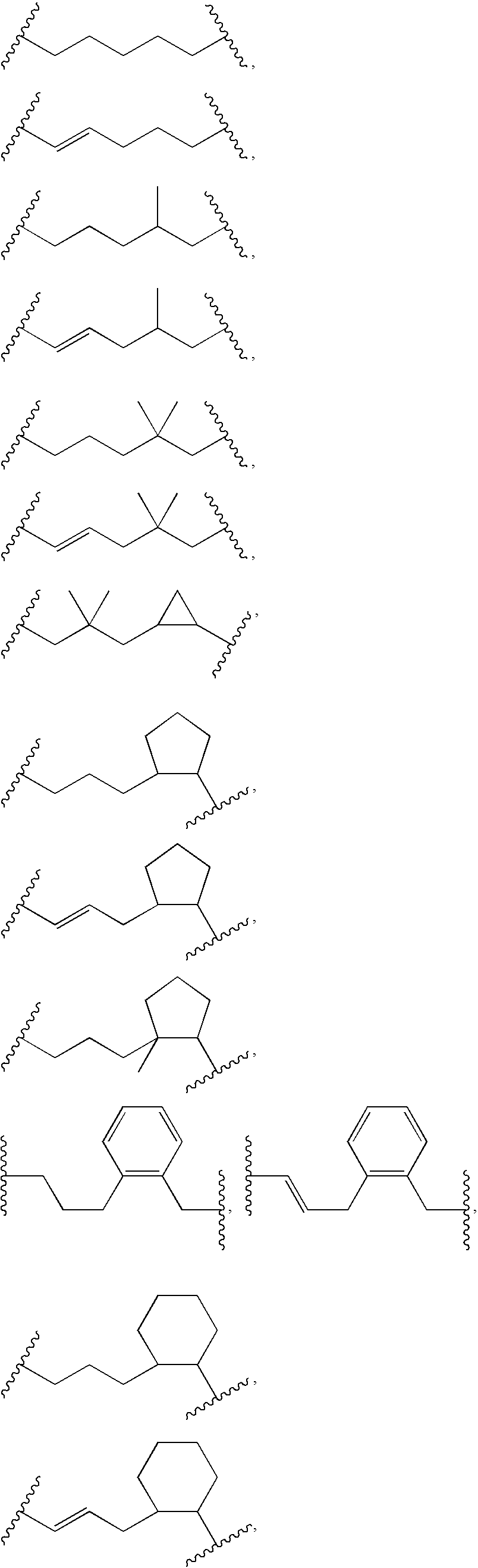

Novel phenylcarboxyamides as beta-secretase inhibitors

There is provided a series of novel phenylcarboxyamides of Formula (I) or a stereoisomer; or a pharmaceutically acceptable salt thereof, wherein R1, R2, R3, X and Y as defined herein, their pharmaceutical compositions and methods of use. These novel compounds inhibit the processing of amyloid precursor protein (APP) by β-secretase and, more specifically, inhibit the production of Aβ-peptide. The present disclosure is directed to compounds useful in the treatment of neurological disorders related to β-amyloid production, such as Alzheimer's disease and other conditions affected by anti-amyloid activity.

Owner:BRISTOL MYERS SQUIBB CO

Array of wetness-sensing articles

ActiveUS8378167B2Good curative effectEnhance interestLactams separation/purificationBaby linensEngineeringHumidity

A wetness sensing system includes a first wetness sensing article; a first signaling device producing a first signal upon sensing wetness in the first wetness sensing article, wherein the first signaling device is compatible with the first wetness sensing article; and a second signaling device producing a second signal upon sensing wetness in the first wetness sensing article, wherein the second signaling device is compatible with the first wetness sensing article. Also, a method for enhancing a wetness sensing system includes producing a wetness sensing absorbent article compatible with at least one component of the wetness sensing system, wherein the wetness sensing system includes as components a wetness sensing article and a first signaling device compatible with the wetness sensing article.

Owner:KIMBERLY-CLARK WORLDWIDE INC

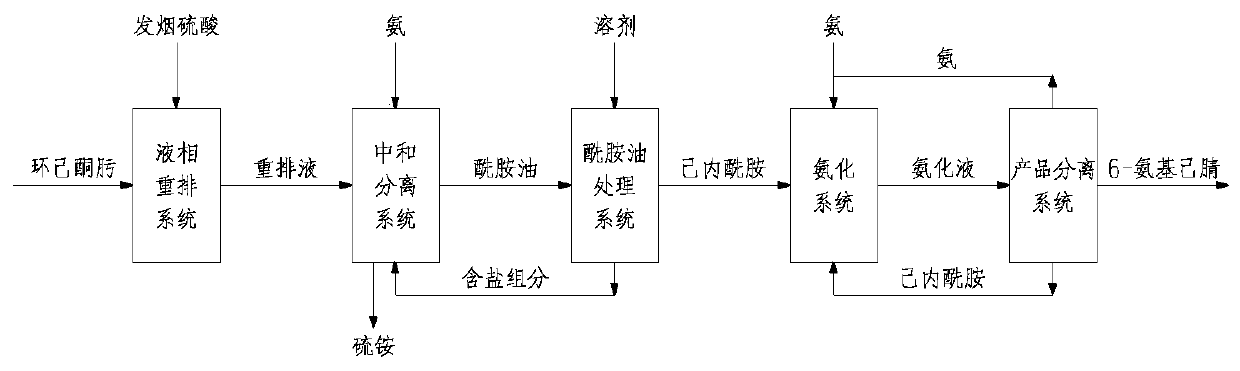

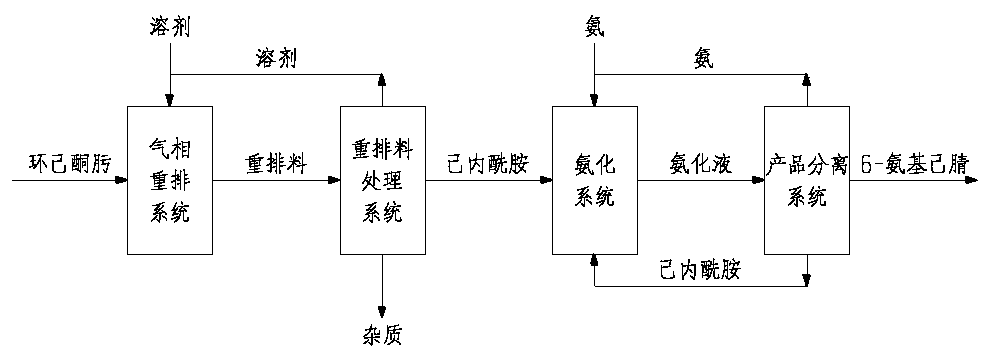

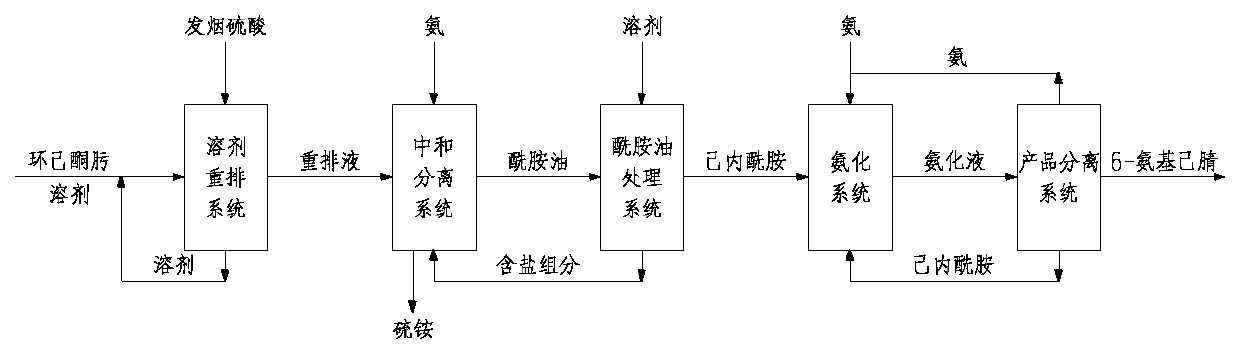

Method for preparing 6-aminocapronitrile from cyclohexanone-oxime

InactiveCN110835311AReduce consumptionReduce processing complexityLactams preparationLactams separation/purificationDistillationIon exchange

The invention discloses a method for preparing 6-aminocapronitrile from cyclohexanone-oxime. The method comprises the following steps: carrying out a rearrangement reaction on cyclohexanone-oxime to obtain a rearranged reaction material; and treating the rearranged reaction material to obtain caprolactam, carrying out an ammoniation dehydration reaction on the caprolactam to obtain an ammoniated dehydrated reaction material, and performing separation to obtain the 6-aminocapronitrile. Compared with the prior art, the method of the invention reduces complex separation and refining processes such as back extraction, ion exchange, hydrogenation, evaporation and distillation required after liquid phase rearrangement of the cyclohexanone-oxime, reduces the processes of crystallization, solventrefining and recovery needed after gas phase rearrangement, and organically combines the caproamide evaporation and rearrangement treatment processes in the ammoniation dehydration reaction process. The steam consumption can be reduced by 2.0-3.0 t / t 6-aminocapronitrile, and the cyclohexanone-oxime consumption is reduced by 20-50 kg / t 6-aminocapronitrile.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

Processes for obtaining sterols and polar lipids from vegetable oil lecithin fractions

InactiveUS20050130281A1Reduce contentHigh purityLactams separation/purificationUltrafiltrationVegetable oilUltrafiltration

Processes for the simultaneous production of sterols and polar lipids, in which preparations of vegetable oil lecithin fractions are subjected to ultrafiltration and, on the one hand, the sterols in the permeate and, on the other hand, the polar lipids in the retentate are enriched. The permeate and retentate can subsequently be worked up by methods known per se.

Owner:COGNIS IP MANAGEMENT GMBH

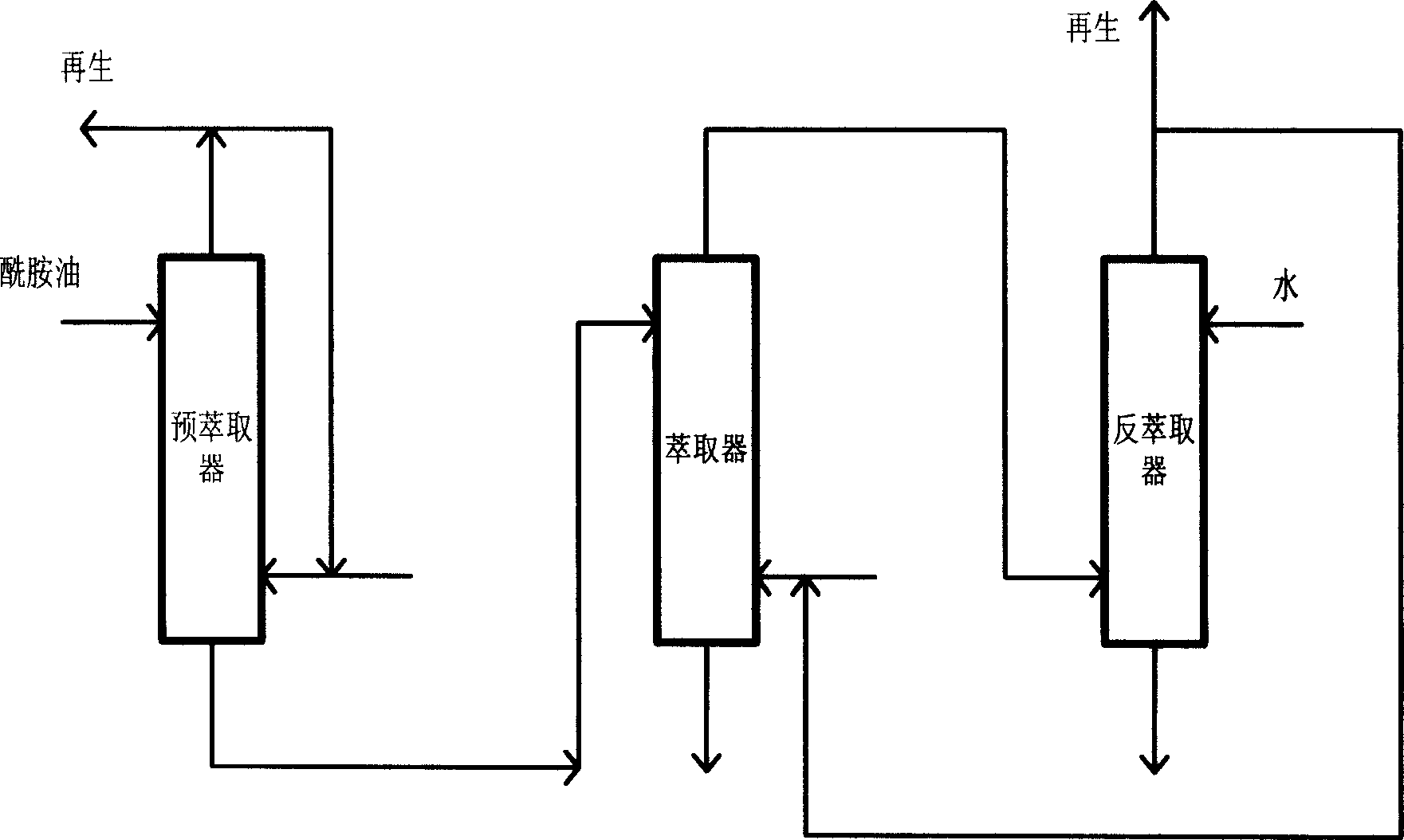

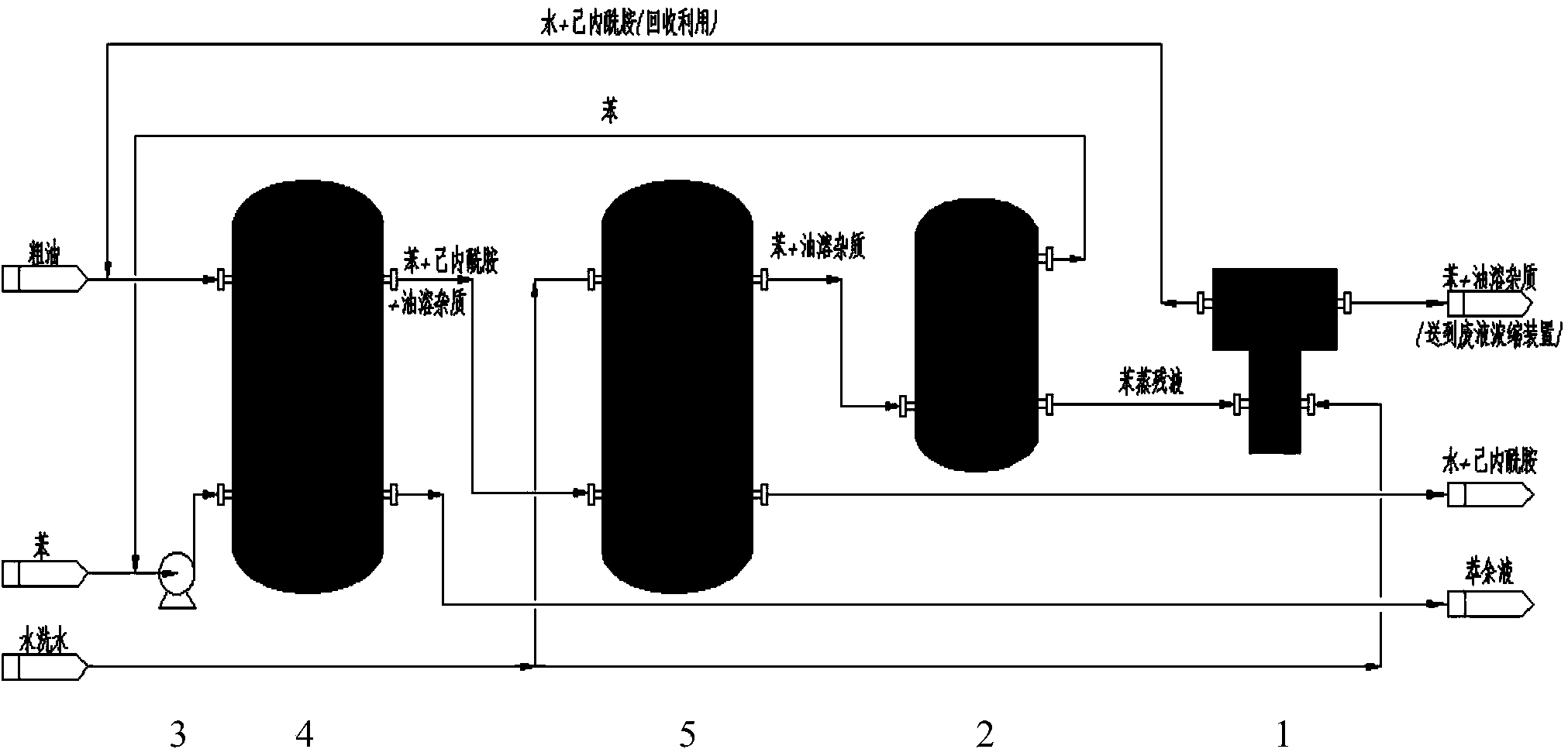

Process for extracting and separating caprolactam from amide oil

The invention provides a process for extracting and separating caprolactam from amide oil which comprises, using cyclohexane or the mixed solvent of cyclohexane and benzene to pre-extract amide oil and remove part of the impurity, then using benzene or the mixed solvent of cyclohexane and benzene to extract the dense phase obtained from the pre-abstraction, finally back washing the light phase with water to obtain the water solution of caprolactam.

Owner:CHINA PETROLEUM & CHEM CORP +2

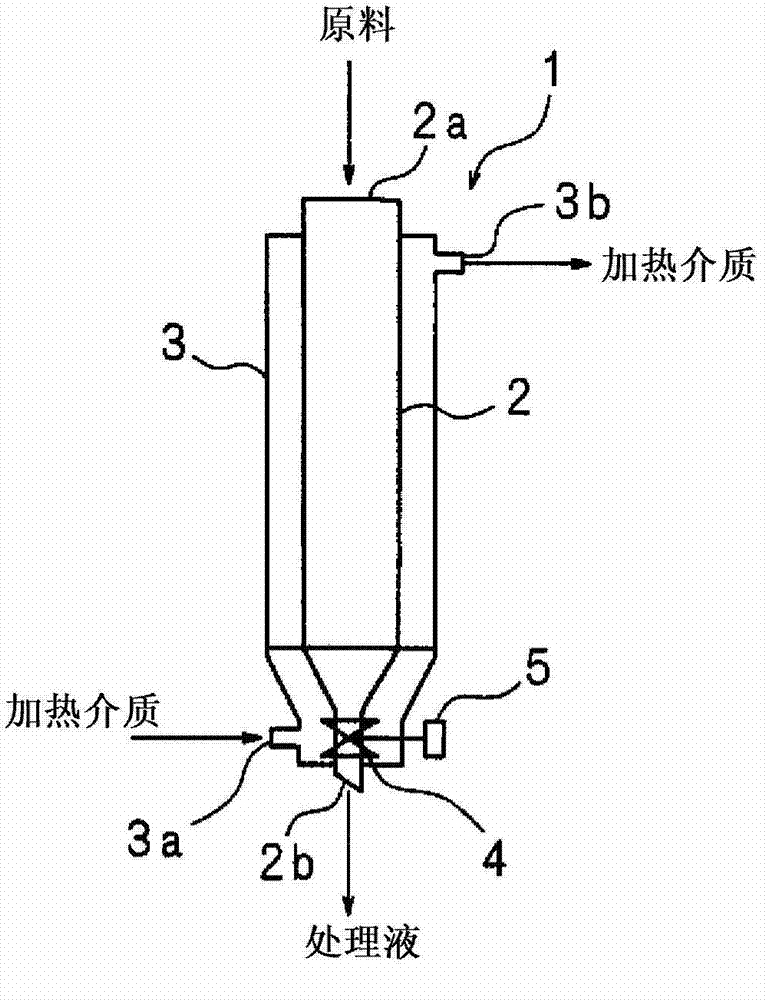

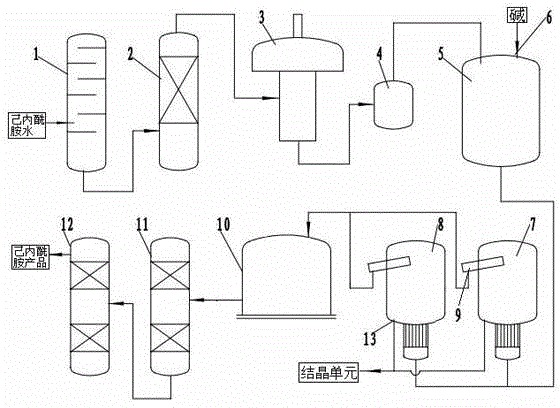

Process for refining aqueous hexanolactam solution by hydrogenation

ActiveCN1552698ALess investmentReduce volumeLactams separation/purificationAqueous solutionLiquid solid

A process for hydrorefining the aqueous solution of caprolactam includes such steps as gas-liquid-solid hydrorefining reacting between the raw aqueous solution of caprolactam, H2 and ferromagnetic catalyst while dissolving H2 in said aqueous solution, and liquid-solid hydrorefining reacting between said aqueous solution and catalyst in magnetically stabilized-bed reaction. Said catalyst can be reused. Its advantages are high reaction efficiency and less consumption of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for comprehensive utilization for benzene extracting concentrated solution of residue wastewater

InactiveCN101049980AInhibit aggregationLow viscosityLactams separation/purificationWater contaminantsBenzeneWastewater

This invention relates to a method for comprehensive utilization of concentrated waste solution after benzene extraction. The method comprises: evaporating the concentrated waste solution, adding solvent to precipitate ammonium sulfate, performing solid-liquid separation to obtain ammonium sulfate crystals, distilling the separated liquid phase to recover solvent and remove water, and cooling to obtain organic crystals containing caprolactam.

Owner:徐明光

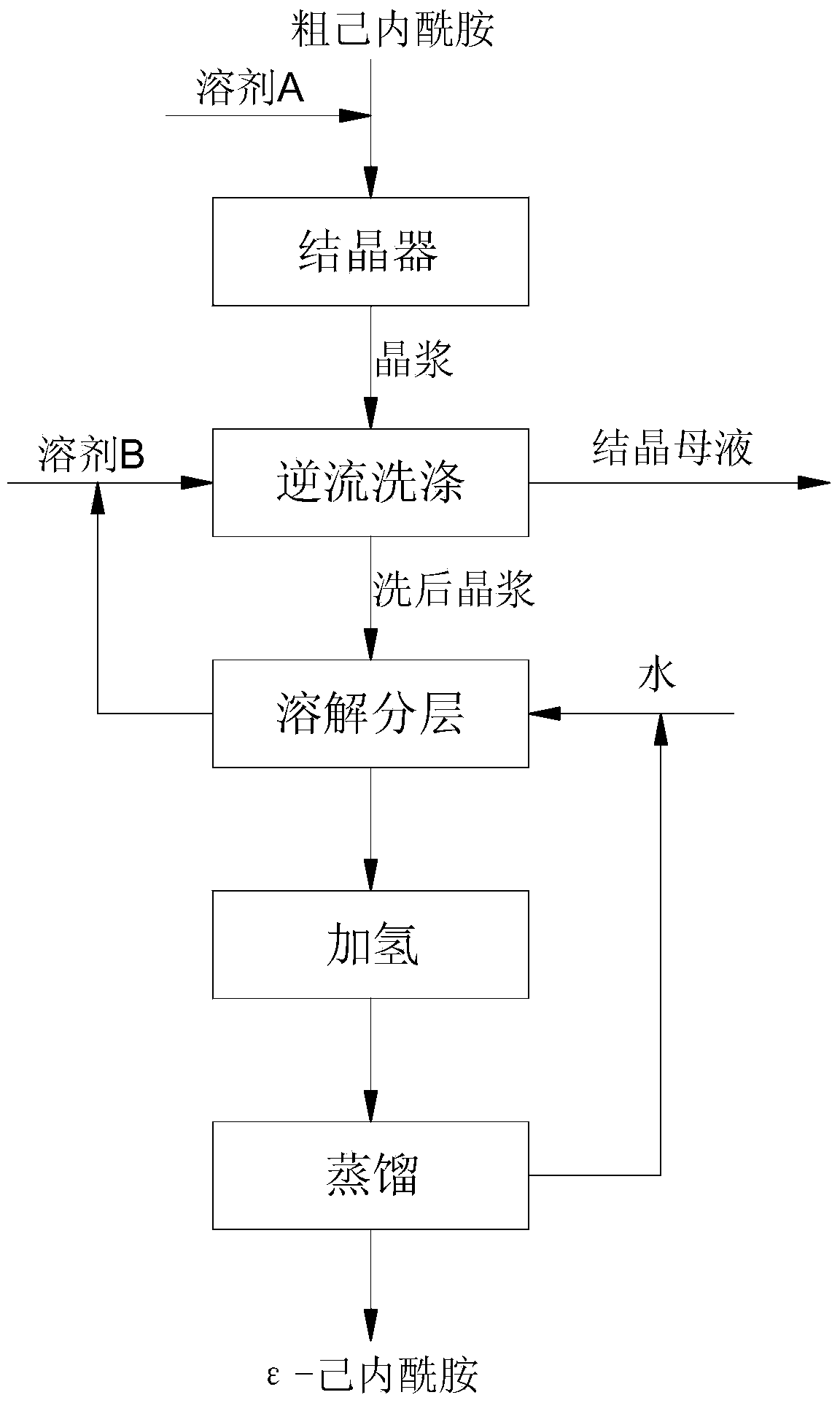

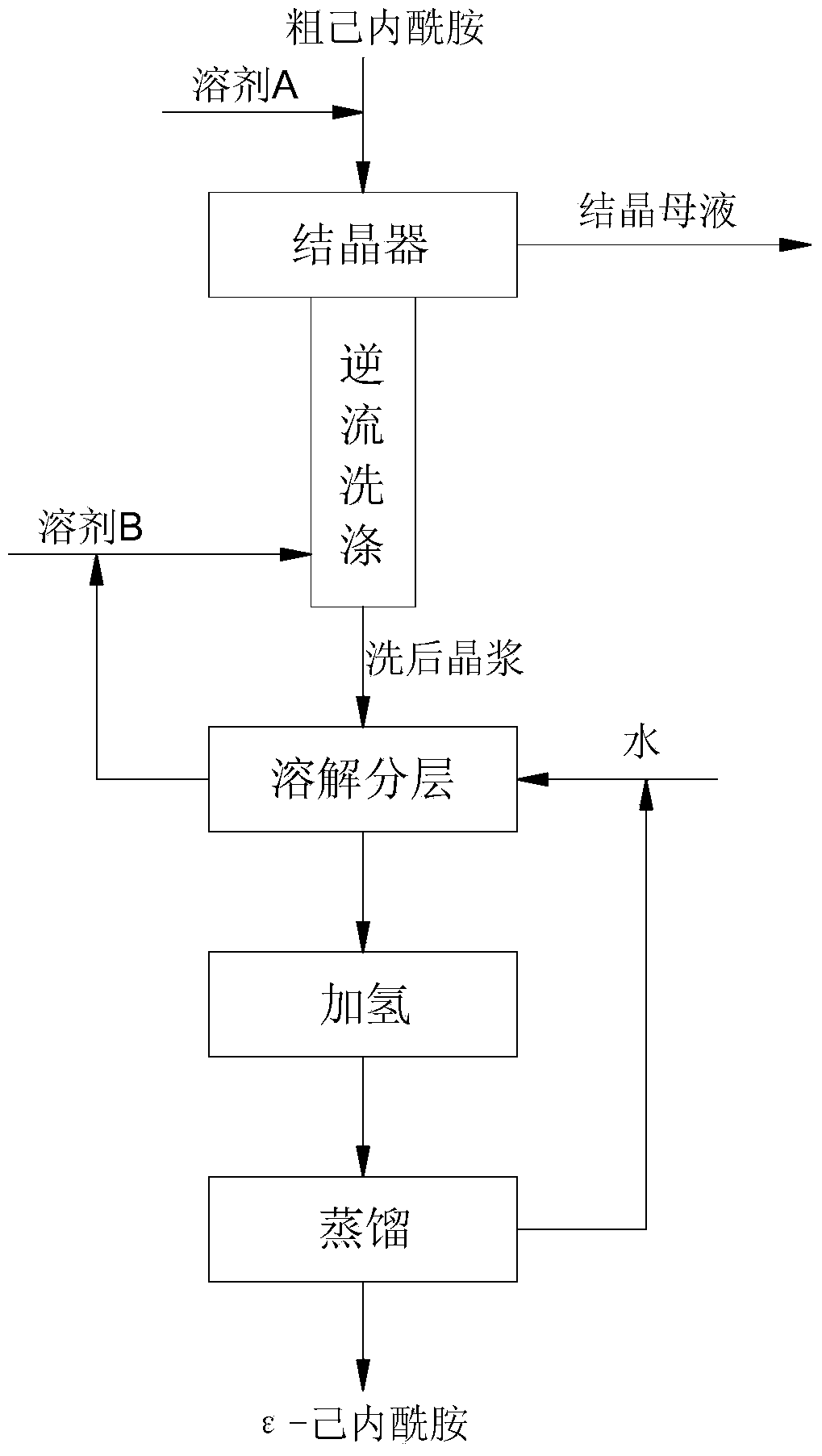

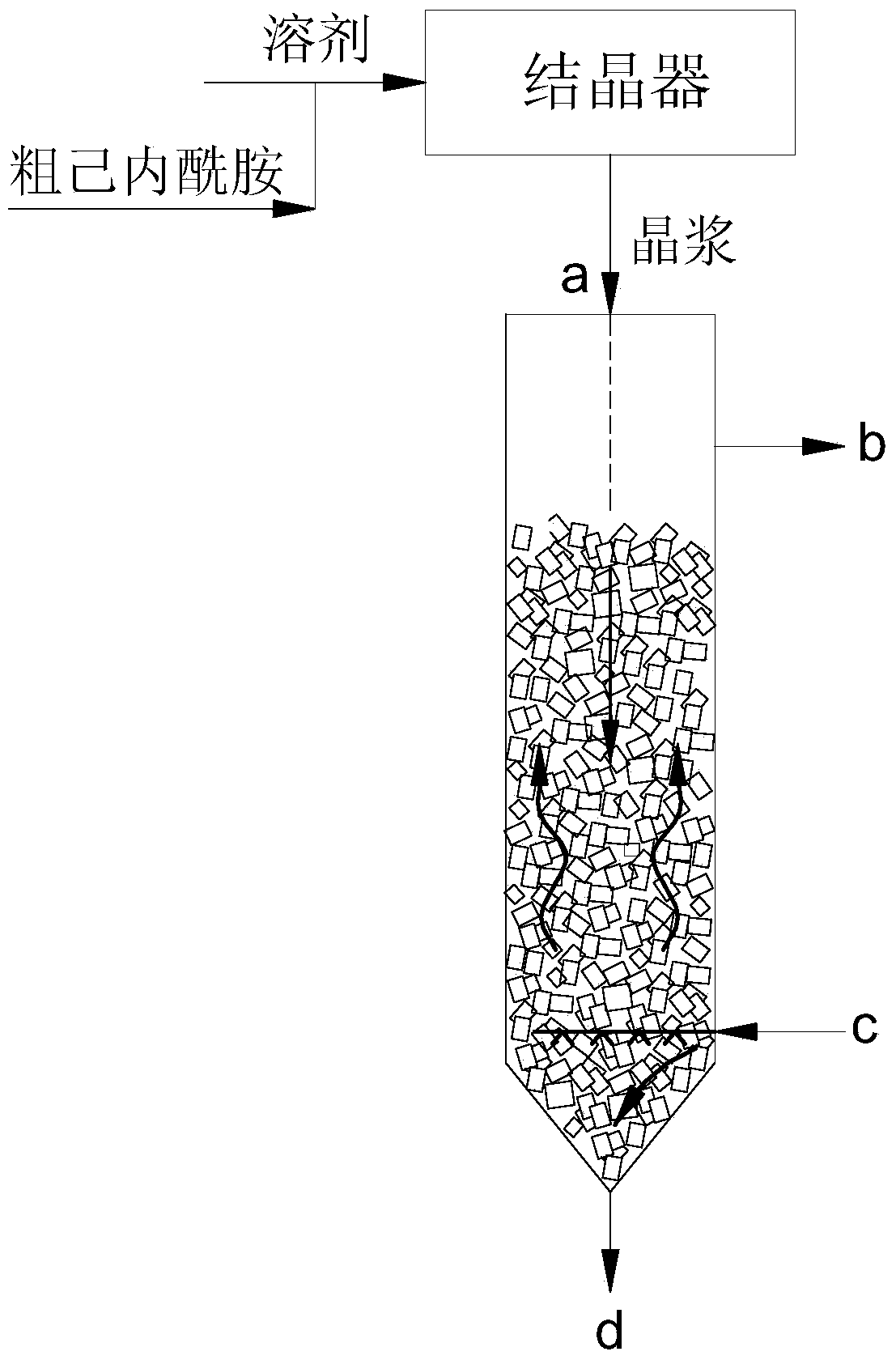

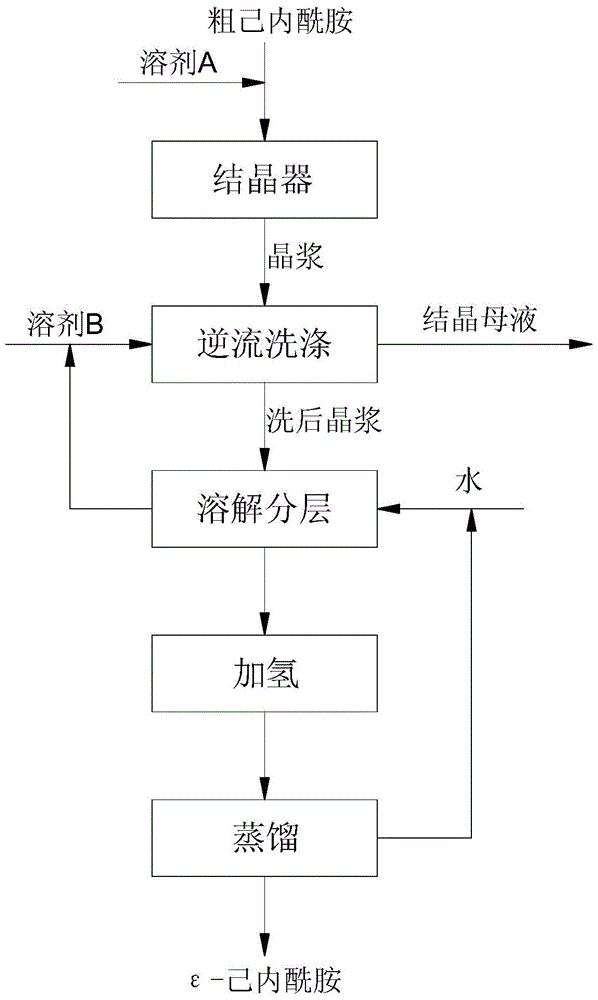

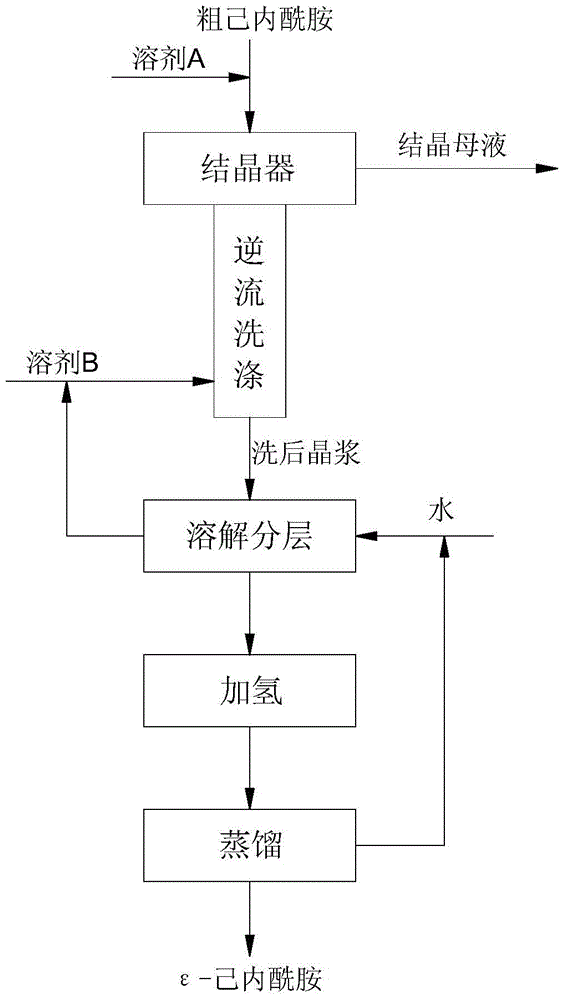

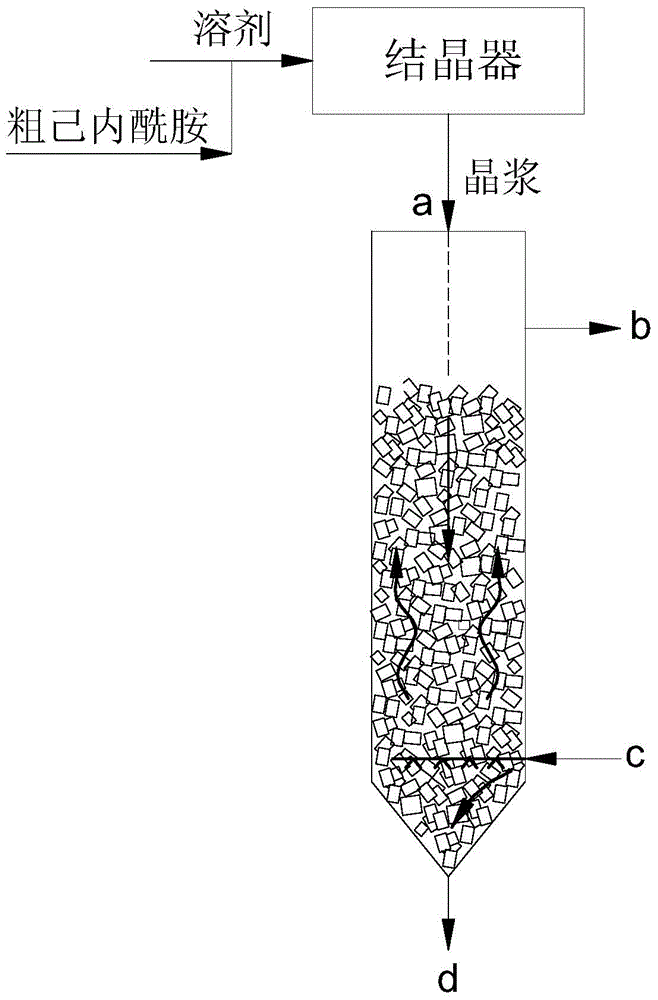

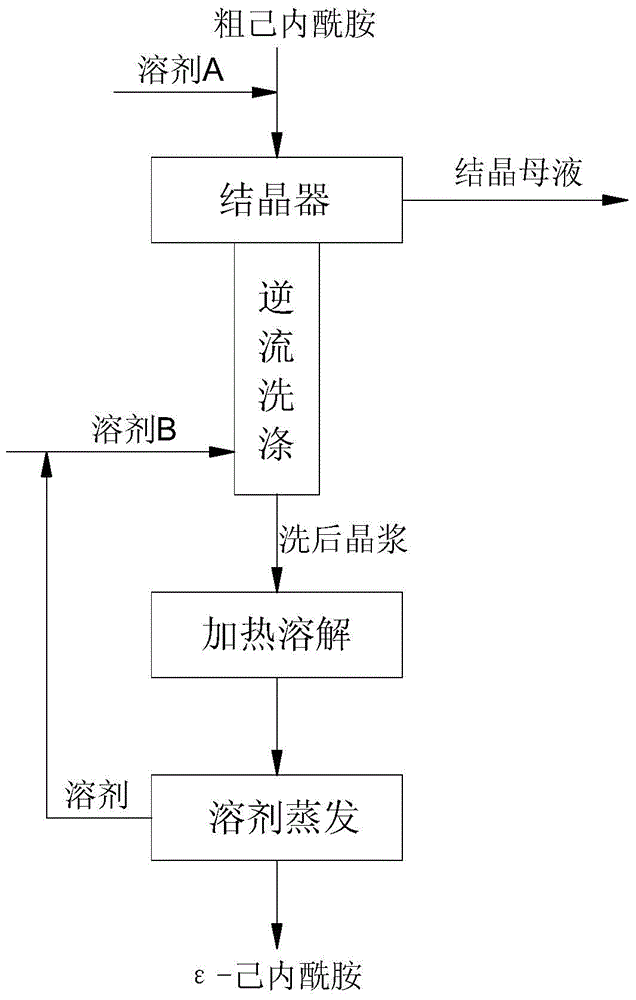

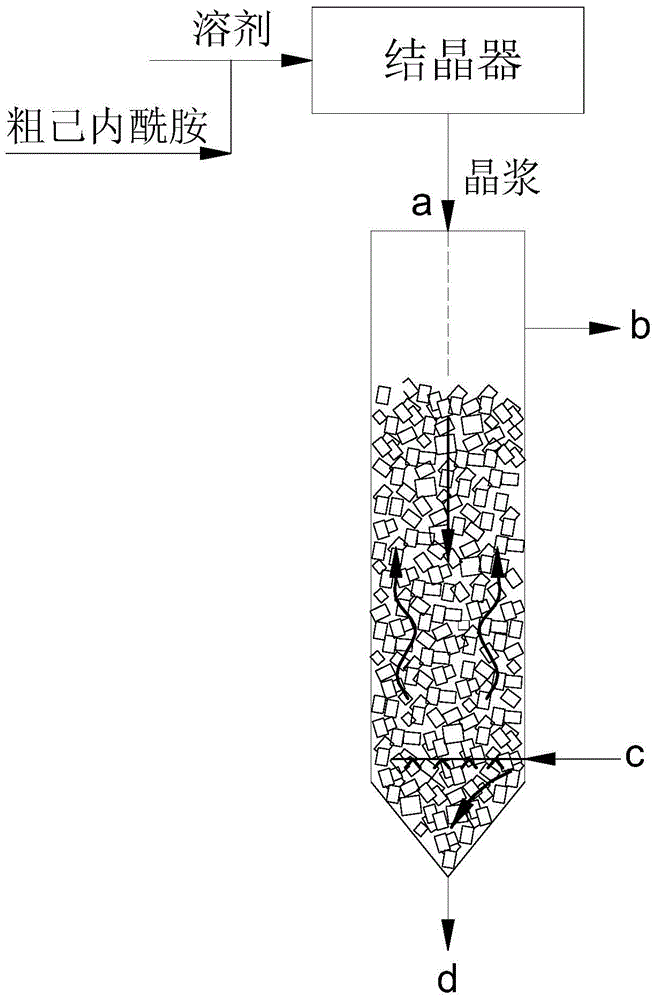

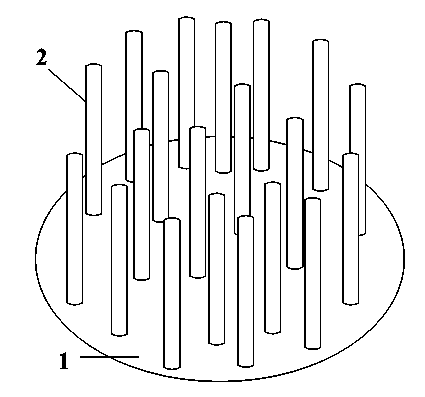

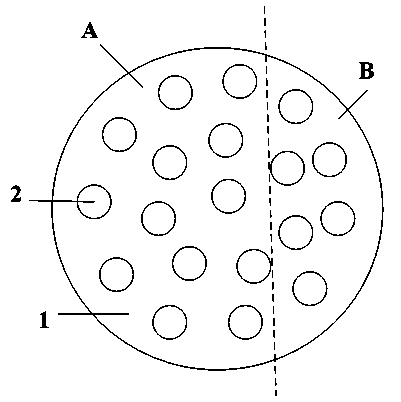

Purification method and purification device of caprolactam

ActiveCN104072419AQuality improvementSimple structureLactams separation/purificationPurification methodsGas phase

The invention discloses a purification method and a purification device of caprolactam. The method comprises process of crystallization, extraction in water, hydrogenation and evaporation dehydration, no solid-separation is needed, a high-quality epsilon-caprolactam product can be produced, and thus the method is particularly applicable to refining of crude epsilon-caprolactam obtained through gas phase rearrangement. The caprolactam purification device disclosed by the invention comprises a crystallizer, a countercurrent washer, a phase separator, a hydrogenation reactor and distillation equipment which are connected in sequence. The device is simple in structure, capable of continuous operation and applicable to a purification process of crude caprolactam.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of purification method and purification device of caprolactam

ActiveCN104072419BQuality improvementSimple structureLactams separation/purificationPurification methodsGas phase

The invention discloses a purification method and a purification device of caprolactam. The method comprises process of crystallization, extraction in water, hydrogenation and evaporation dehydration, no solid-separation is needed, a high-quality epsilon-caprolactam product can be produced, and thus the method is particularly applicable to refining of crude epsilon-caprolactam obtained through gas phase rearrangement. The caprolactam purification device disclosed by the invention comprises a crystallizer, a countercurrent washer, a phase separator, a hydrogenation reactor and distillation equipment which are connected in sequence. The device is simple in structure, capable of continuous operation and applicable to a purification process of crude caprolactam.

Owner:CHINA PETROLEUM & CHEM CORP +1

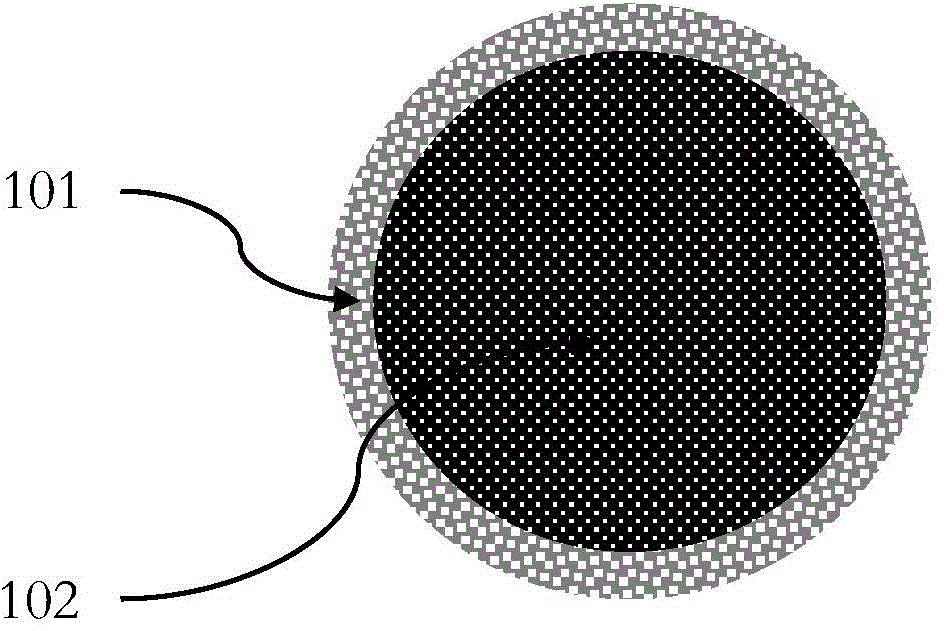

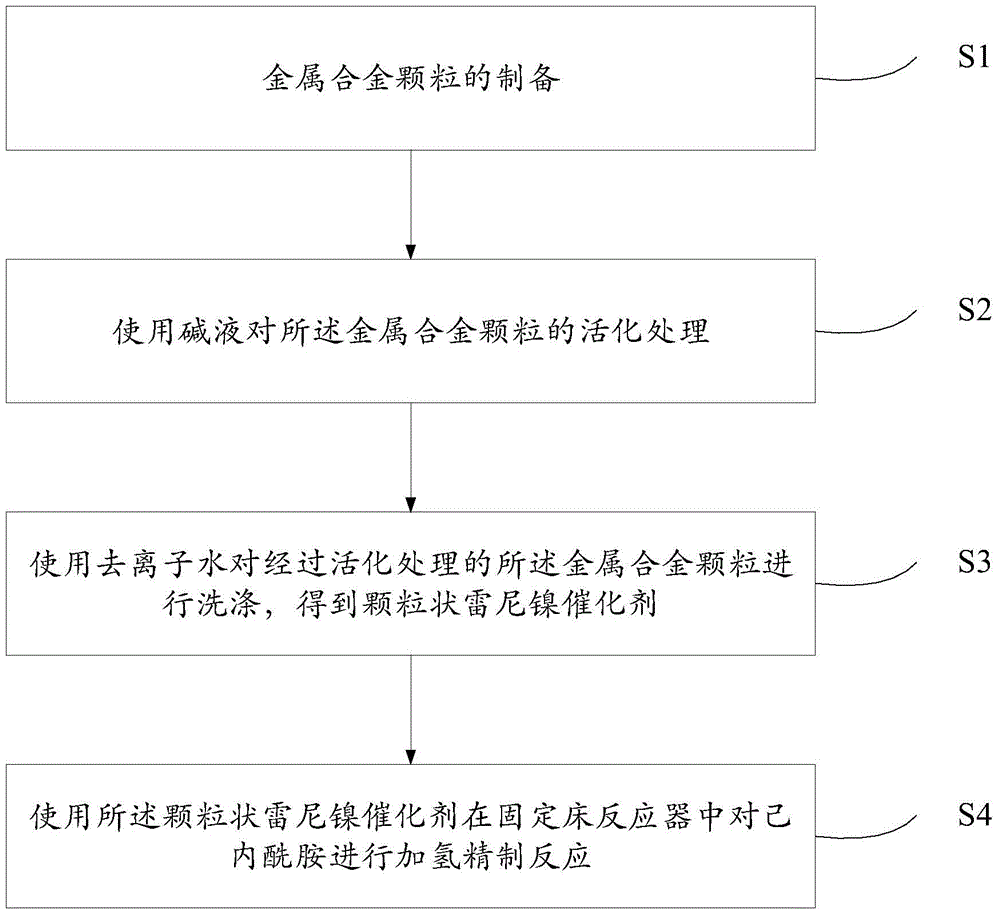

Caprolactam hydrofining catalyst and method

ActiveCN106140195AEasy to prepareHigh activityLactams separation/purificationBulk chemical productionParticulatesMetallurgy

The invention discloses a caprolactam hydrofining catalyst and method. The method comprises the steps of preparing metal alloy particles, activating the metal alloy particles with alkali liquor, washing the activated metal alloy particles with deionized water to obtain a particulate raney nickel catalyst, and conducting hydrofining on caprolactam in a fixed bed reactor by means of the particulate raney nickel catalyst. Operation is easy, hydrofining effect is improved greatly, application prospects are broad, and economic benefits are great.

Owner:SHANGHAI XUNKAI NEW MATERIAL TECH

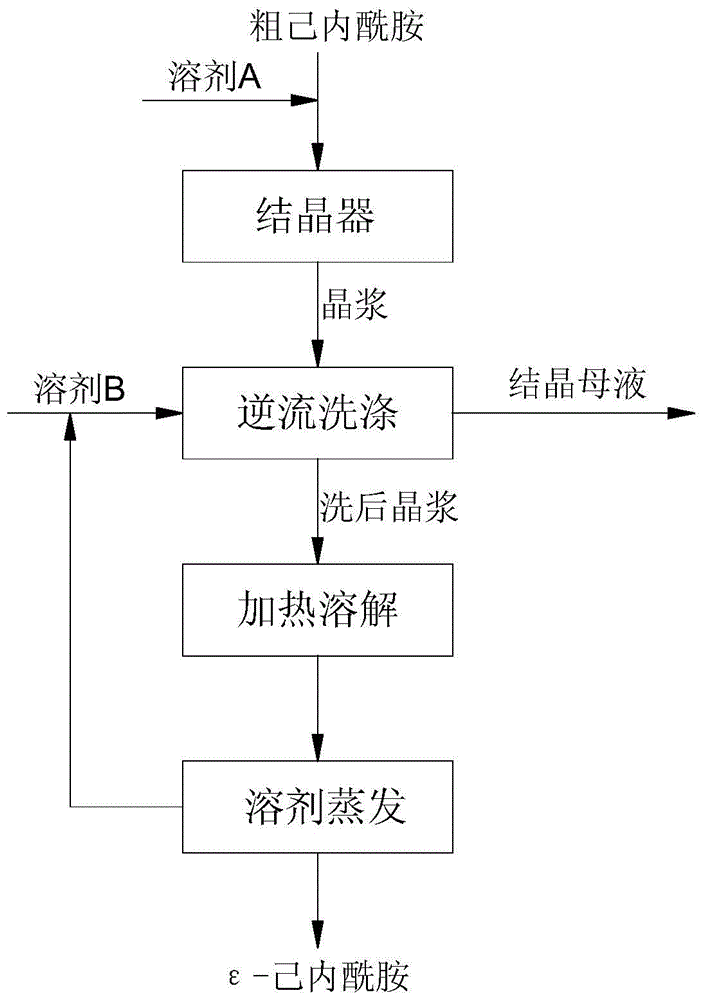

A kind of purification method and device of caprolactam

ActiveCN104059018BQuality improvementSimple structureLactams separation/purificationPurification methodsSolvent evaporation

The invention provides a caprolactam purification method and device, and the method includes crystallization, countercurrent washing, solvent evaporation and other processes, is in no need of solid-liquid separation, can produce high-quality epsilon-caprolactam refining products, and is especially suitable for refinement of crude epsilon-caprolactam obtained by gas phase rearrangement. The caprolactam purification device includes a crystallizer, a countercurrent scrubber, a heater and distillation equipment which are sequentially communicated, has the advantages of simple structure and capability of continuous operation, and is applicable to the purification process of crude caprolactam.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for isolation of laurolactam from a laurolactam synthesis process stream

A process for purifying laurolactam by means of integrated connection of distillation and crystallization is provided. The crystallization is performed as a solution or melt crystallization. The process reduces thermal stress applied to the laurolactam stream and improved yields are obtained. Raw materials are recovered and recycled in the production sequence.

Owner:EVONIK OPERATIONS GMBH

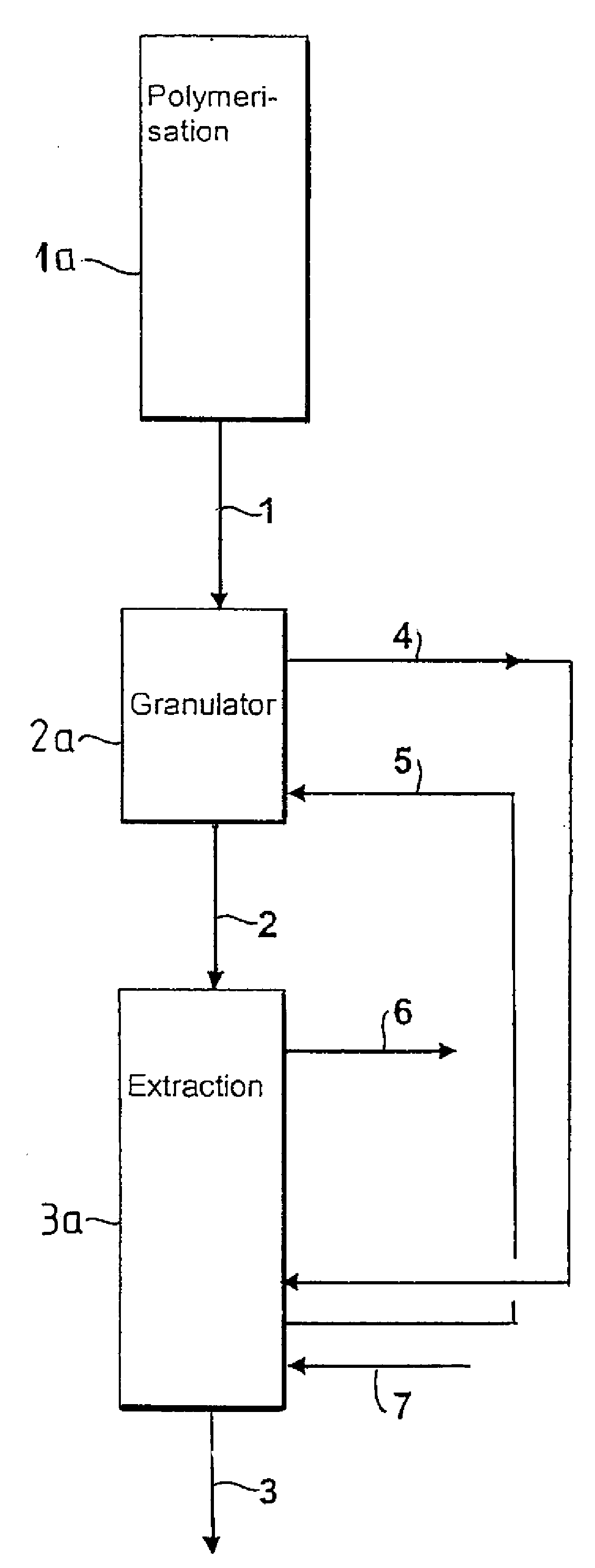

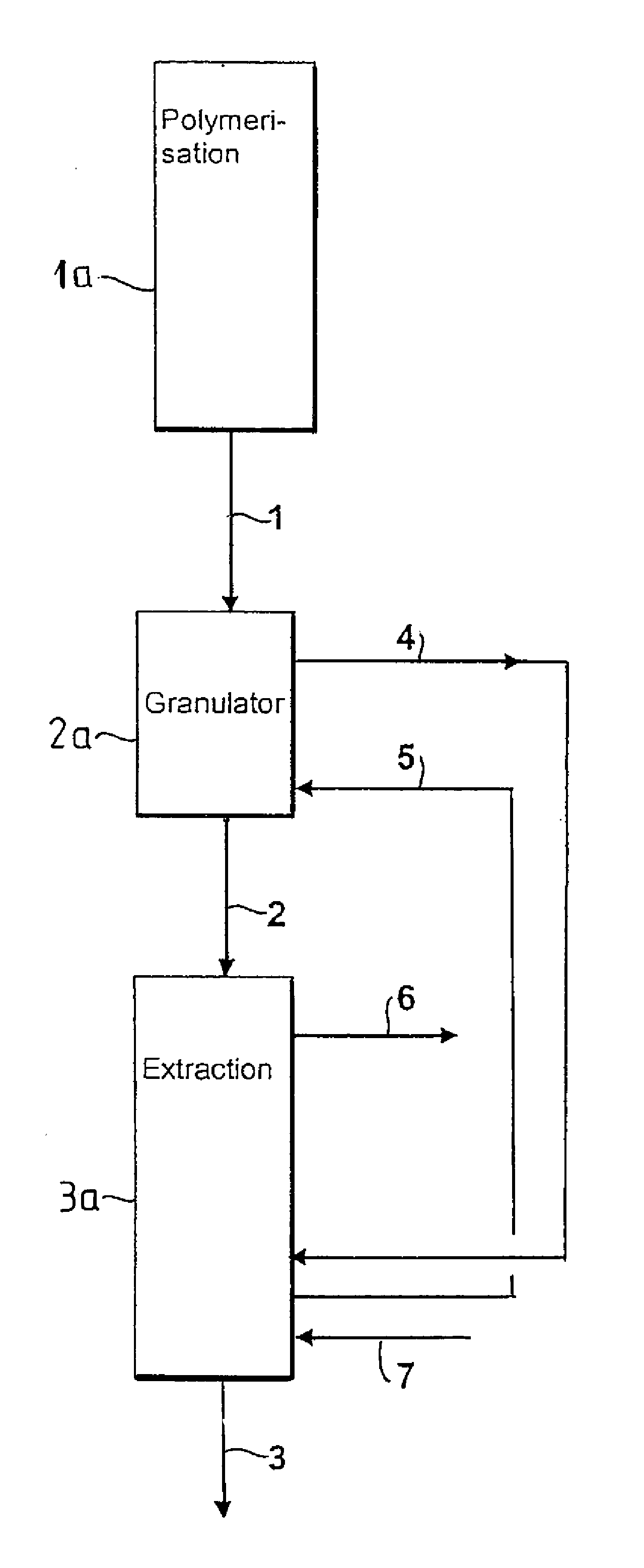

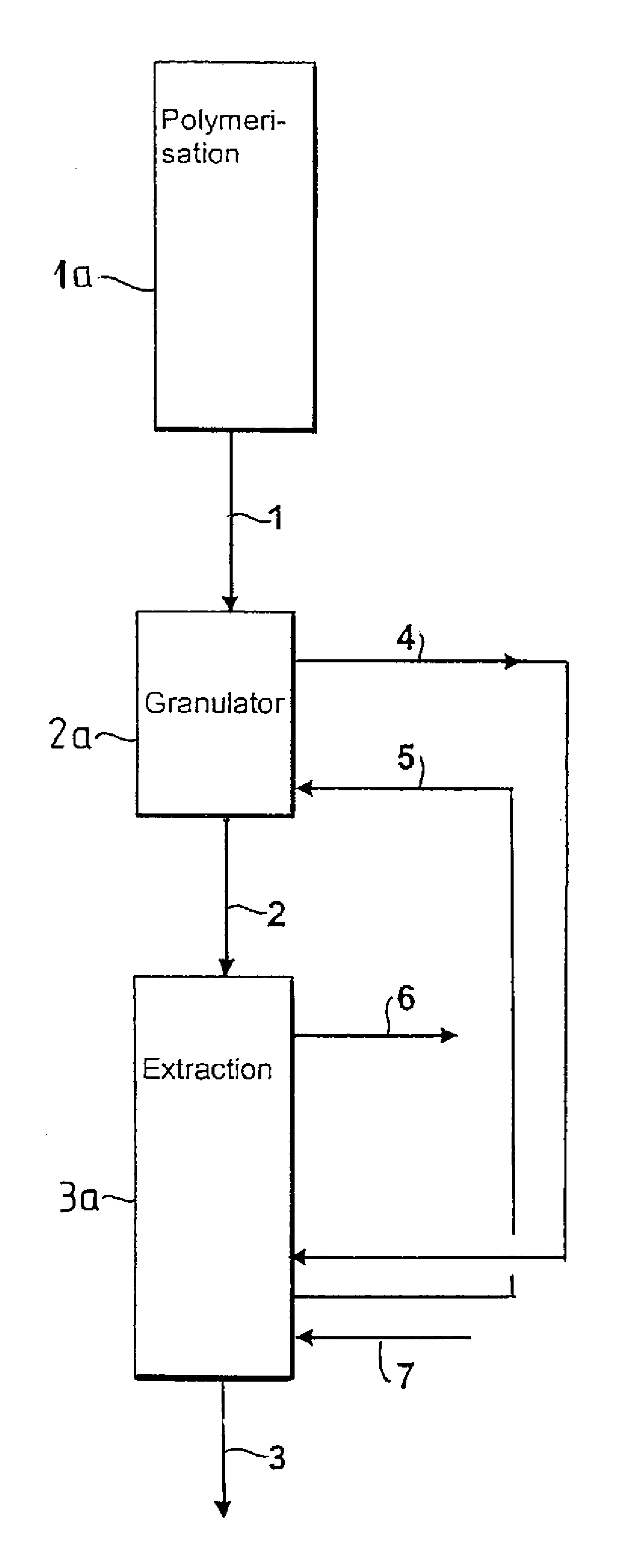

Continuous process for the extraction of polyamide-6

ActiveUS20100048860A1Reduce consumptionSolve the large energy consumptionLactams separation/purificationChemical recyclingOligomerPolyamide

A continuous process is disclosed for the extraction of monomeric caprolactam and its oligomers as the raw polymer product obtained in the polymerization of polyamide-6 in which no fresh water, but processing water or previously used extraction water is used for the granulation.

Owner:LURGI ZIMMER GMBH

Method for purifying epsilon-caprolactam and method for preparing epsilon-caprolactam

ActiveCN102452982AFully removedNo foulingLactams preparationLactams separation/purificationBeckmann rearrangementMolecular sieve

The invention provides a method for purifying a crude epsilon-caprolactam product, which comprises the following steps of: dissolving the crude epsilon-caprolactam product in halogenated hydrocarbon to obtain a halogenated hydrocarbon solution of epsilon-caprolactam; and performing evaporative crystallization on the solution at the temperature of between -10 and 50 DEG C under reduced pressure to separate an epsilon-caprolactam crystal. The invention also provides a method for preparing the epsilon-caprolactam, which comprises the following steps of: performing Beckmann rearrangement reaction on gas-phase cyclohexanone-oxime in the presence of a molecular sieve catalyst with a melt flow index (MFI) structure, and distilling a reaction product to obtain the crude epsilon-caprolactam product; and performing crystallization purification by the method for purifying the crude epsilon-caprolactam product, and performing hydrogenation reaction on the epsilon-caprolactam crystal obtained after purification in the presence of a hydrogenation catalyst. By the method for purifying the crude epsilon-caprolactam product, the epsilon-caprolactam which meets the industrial product requirement can be obtained, and the phenomenon of scale formation in the crystallization process is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

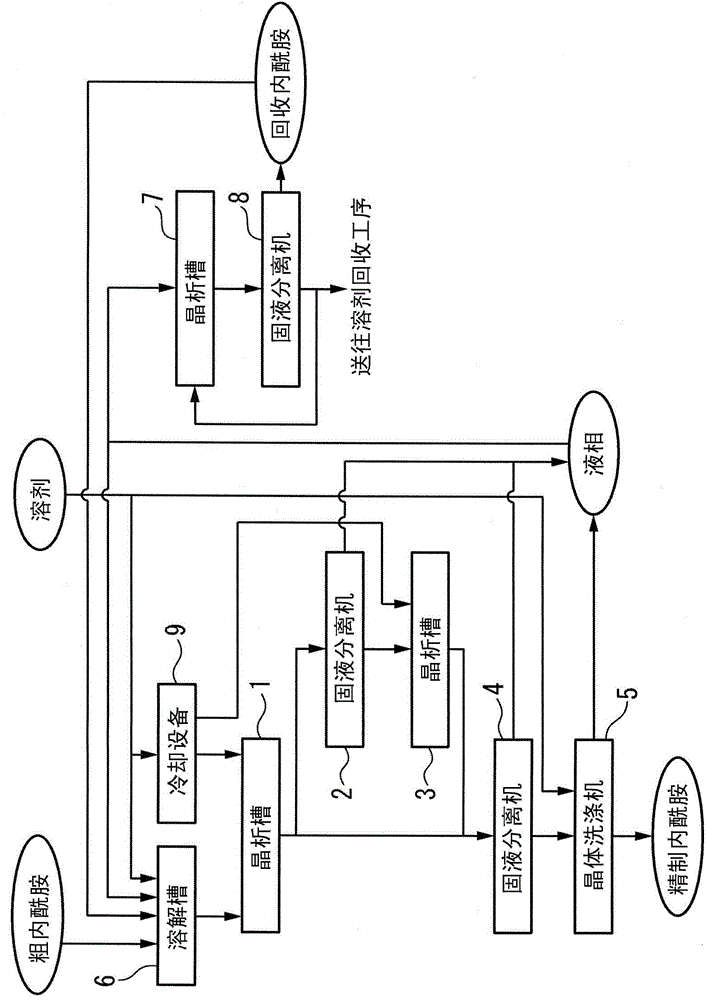

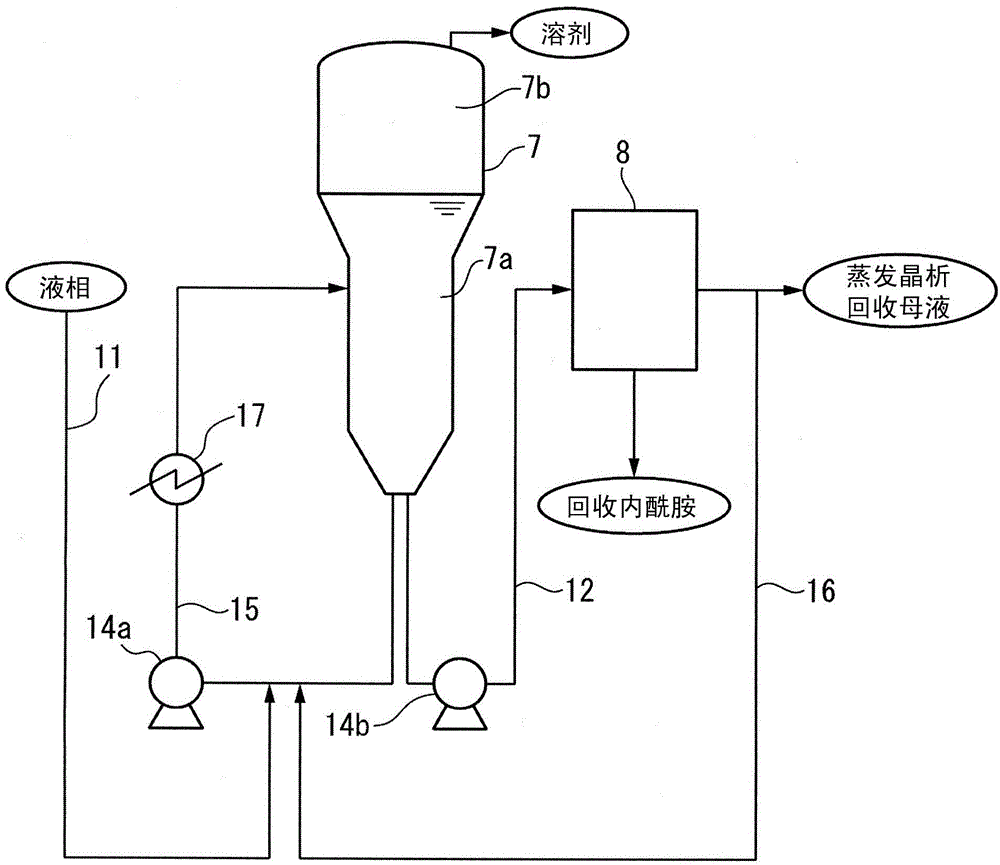

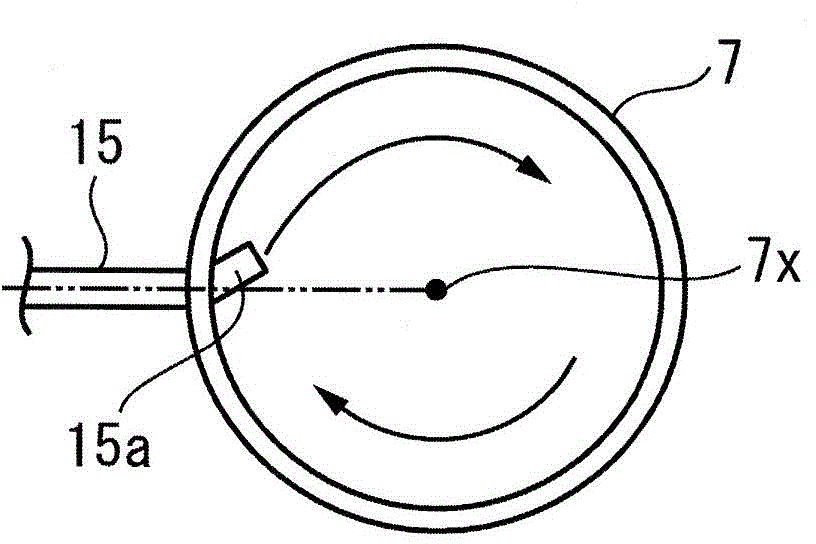

Method for producing high-quality epsilon-caprolactam

ActiveCN104024221APrevent scalingImprove qualityOrganic chemistry methodsLactams separation/purificationBeckmann rearrangementOrganic solvent

A method for producing high-quality epsilon-caprolactam, comprising: a purification step of allowing epsilon-caprolactam to be crystallized from a mixed solution that is prepared by mixing crude epsilon-caprolactam produced by the Beckmann rearrangement of cyclohexanoneoxime with an organic solvent and then subjecting the resultant solution to solid / liquid separation to produce high-quality epsilon-caprolactam and a drop crystallization-collected mother liquor; and a collection step of evaporating an evaporative crystallization mother liquor containing the drop crystallization-collected mother liquor to cause the crystallization of epsilon-caprolactam and then subjecting the resultant solution to solid / liquid separation to produce collected epsilon-caprolactam and an evaporative crystallization-collected mother liquor. In the method, prior to the collection step, the following steps are involved: a step of mixing the drop crystallization-collected mother liquor with at least a portion of the evaporative crystallization-collected mother liquor, at least a portion of an evaporative crystallization mother liquor that is removed from a vessel in which evaporative crystallization is to be carried out, or both of at least a portion of the evaporative crystallization-collected mother liquor and at least a portion of the evaporative crystallization mother liquor to prepare a mixed solution; and a step of introducing the mixed solution into the vessel and mixing the mixed solution with the evaporative crystallization mother liquor that is stored in the vessel.

Owner:SUMITOMO CHEM CO LTD

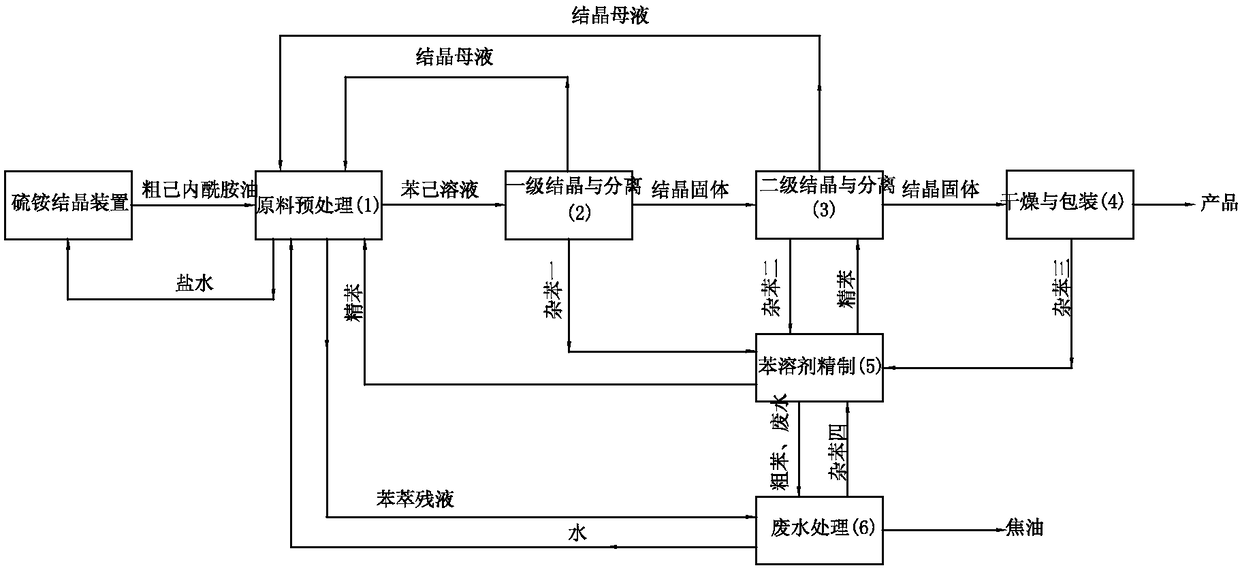

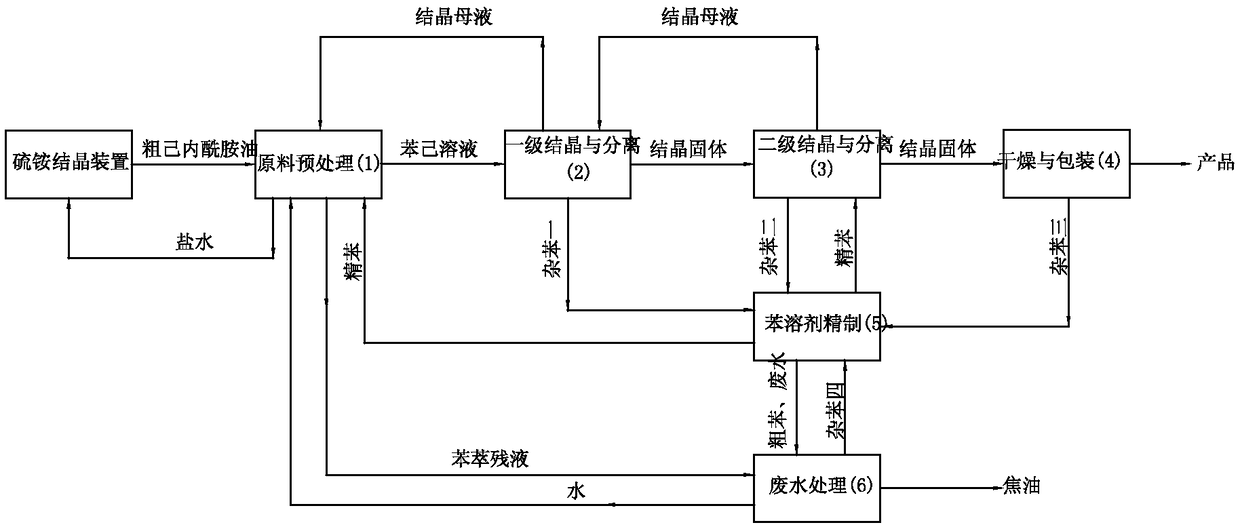

Method for refining caprolactam by organic solvent crystallization

InactiveCN108358823AQuality improvementLow energy consumption for crystallizationLactams separation/purificationWater/sewage treatment by heatingUltraviolet absorptionSolvent

The invention discloses a method for refining caprolactam by organic solvent crystallization. The method is concretely characterized in that solvent crystallization and recrystallization are used; a impurity-containing caprolactam water solution is subjected to benzene extraction to obtain a caprolactam solution; the caprolactam solution is subjected to evaporative crystallization and recrystallization to obtain high-quality caprolactam; benzene is refined to be cyclically used. The solvent crystallization and recrystallization are used for realizing impurity-containing caprolactam refining and purification; the process energy consumption is low; the product yield is high; the technological process is short; the equipment investment is low; the product quality is good; various items of indexes such as the chromaticity, the acidity and alkalinity, the volatile alkali content, the ultraviolet absorption value and potassium permanganate oxidation value of the finished product can stably reach national standard premium grade requirements; meanwhile, the discharge of three wastes (waste water, waste gas and waste solid) is little; the environment pollution is little.

Owner:陕西宏元化工技术有限公司

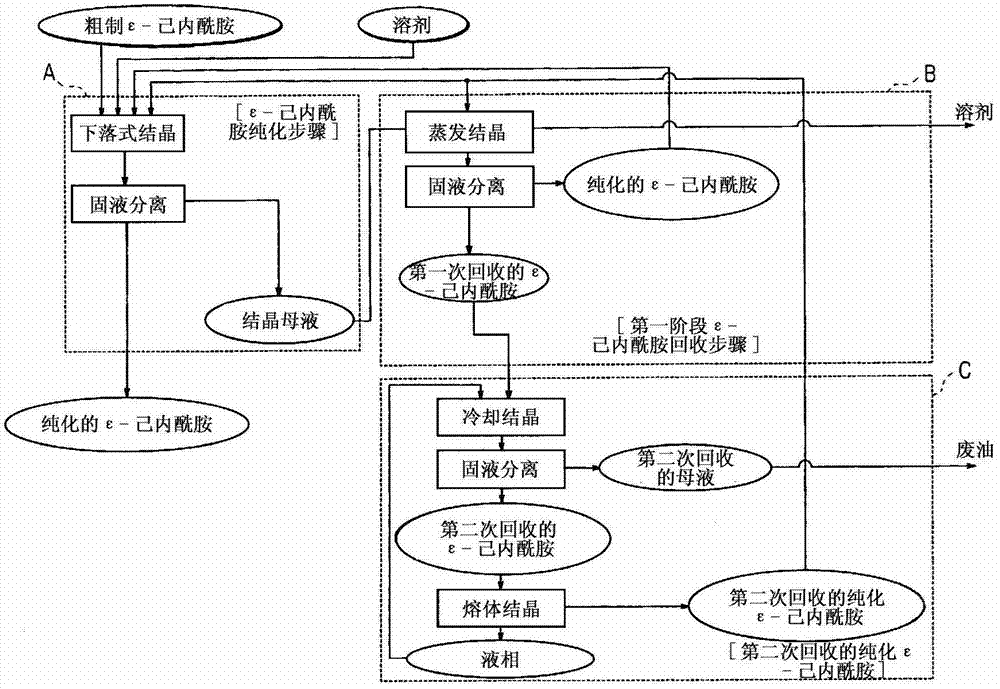

Method of manufacturing epsilon-caprolactam

InactiveCN102781913AEfficient preparationHigh yieldLactams preparationOrganic chemistry methodsCaprolactamImpurity

An epsilon-caprolactam manufacturing method capable of manufacturing in good yield, high-quality epsilon-caprolactam containing less impurity has an epsilon-caprolactam purification step A of obtaining purified epsilon-caprolactam from raw epsilon-caprolactam by applying a drop crystallization method, a first-stage epsilon-caprolactam recovery step B of obtaining first recovered epsilon-caprolactam and a first recovered mother liquor by applying an evaporative crystallization method to a crystallization mother liquor obtained in the epsilon-caprolactam purification step A, and a second-stage epsilon-caprolactam recovery step C of obtaining second recovered purified epsilon-caprolactam by applying a melt crystallization method to the first recovered mother liquor, first recovered epsilon-caprolactam being recovered as a raw material for the epsilon-caprolactam purification step A and second recovered purified epsilon-caprolactam being recovered as a raw material for the epsilon-caprolactam purification step A and / or the first-stage epsilon-caprolactam recovery step B.

Owner:SUMITOMO CHEM CO LTD

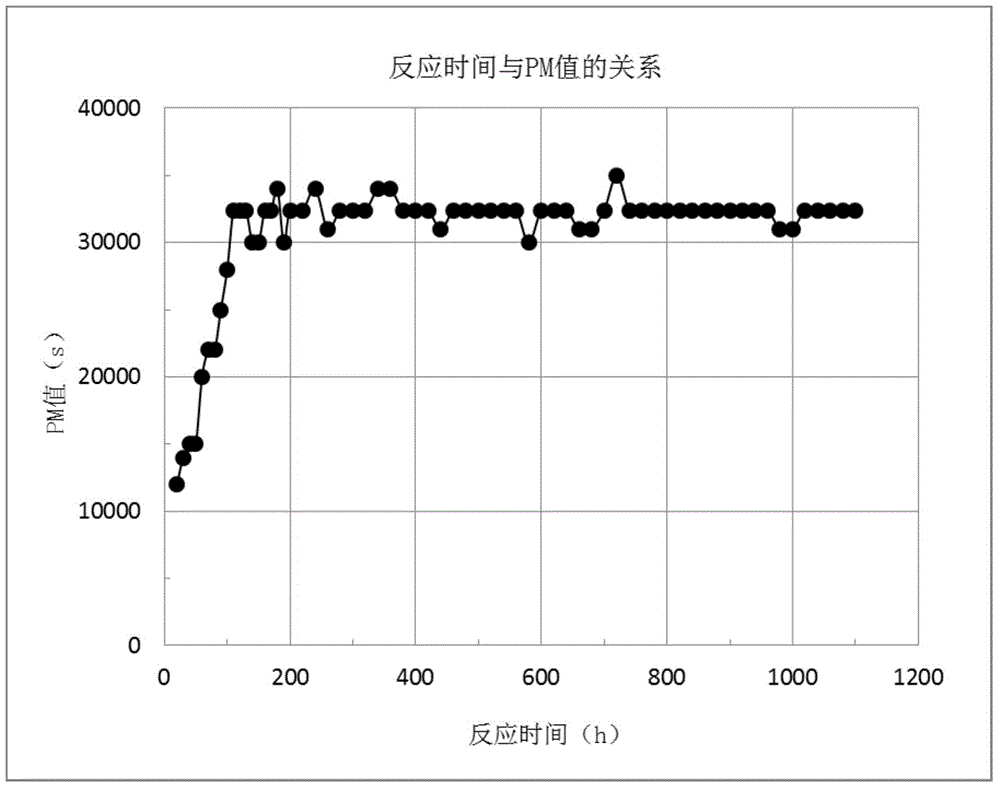

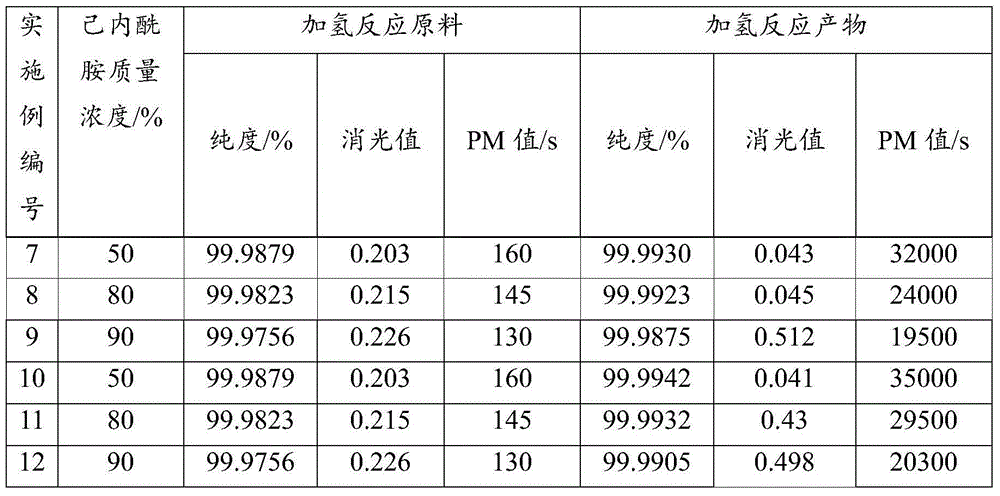

Caprolactam hydrofining method

ActiveCN104557706AReduce contentLactams preparationLactams separation/purificationMolten stateHydrogen

The invention relates to a caprolactam hydrofining method. The caprolactam hydrofining method is characterized in that an organic solution of caprolactam is in contact with hydrogen in the presence of a hydrogenation catalyst under hydrofining reaction conditions. In the catalytic hydrogenation reaction conditions, the reaction temperature is 50 DEG C-150 DEG C, the pressure is 0.1-5MPa, and the molar ratio of caprolactam to hydrogen is 1:(0.001-0.25). By adopting the caprolactam hydrofining method provided by the invention, under the situation of upgrading the PM (particulate matter) value of a product to the same extent, the shortcomings of using a caprolactam water solution or molten-state caprolactam to perform hydrofining in the prior art can be overcome, the problems that water enters a system, high energy consumption is caused by subsequent water evaporation and polymerization of caprolactam is initiated by the water in the system are avoided, and after hydrofining, the purity of caprolactam is above 99.9950%, the PM value is more than 10000s and the extinction value is less than 0.05.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous process for the extraction of polyamide-6

ActiveUS8541540B2Avoid the needReduce consumptionLactams separation/purificationChemical recyclingOligomerPolyamide

A continuous process is disclosed for the extraction of monomeric caprolactam and its oligomers as the raw polymer product obtained in the polymerization of polyamide-6 in which no fresh water, but processing water or previously used extraction water is used for the granulation.

Owner:LURGI ZIMMER GMBH

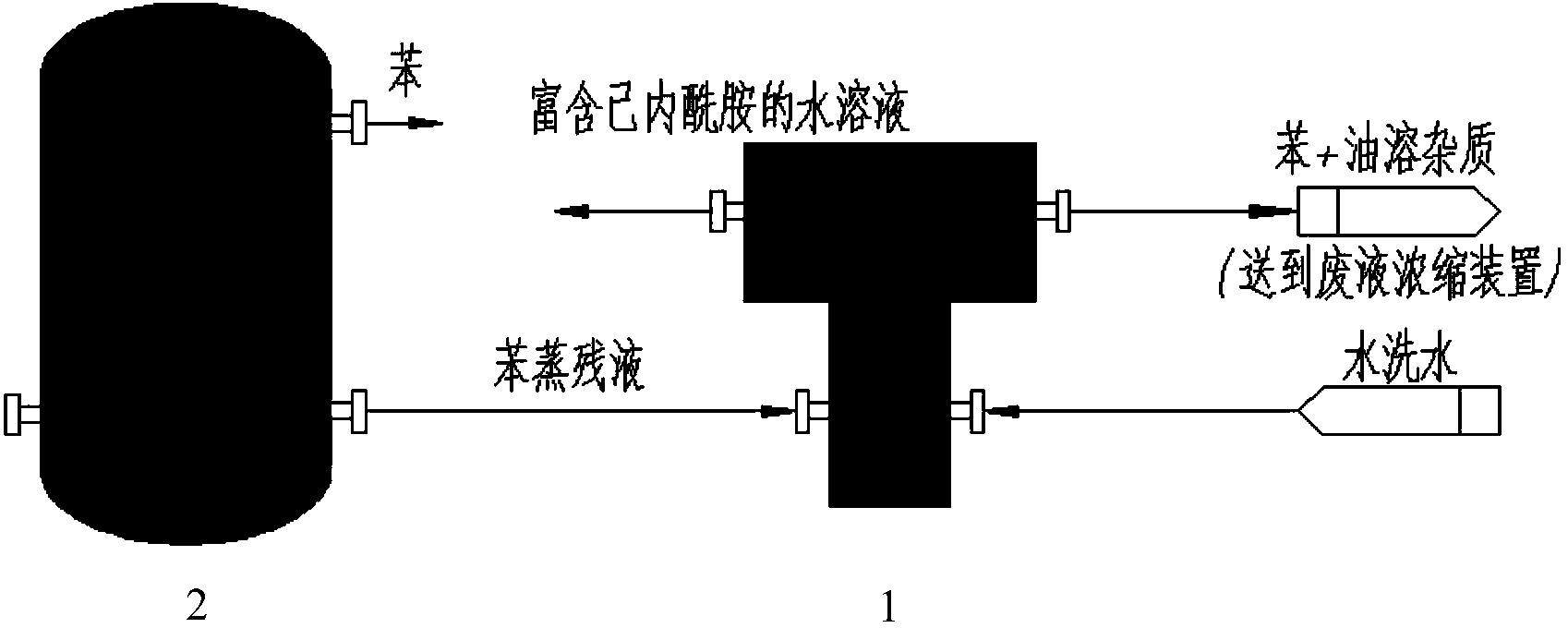

Method and device for recovering caprolactam in benzene distillation residue

InactiveCN103539738AAvoid churnIncrease productionLactams separation/purificationLiquid solutions solvent extractionBenzeneDistillation

The invention relates to a method and device for recovering caprolactam in benzene distillation residue, and provides a method for recovering caprolactam in the benzene distillation residue. The method comprises the following steps: (a) respectively feeding the benzene distillation residue and water obtained by distilling in a benzene distillation column into a centrifugal extractor; (b) enabling the benzene distillation residue and water to fully mix and be subjected to mass transfer in the centrifugal extractor, in order to extract caprolactam in benzene distillation residue into the water; (c) performing liquid-liquid separation on the mixed solution of the benzene distillation residue and water through the centrifugal extractor in order to separate out an aqueous solution rich in caprolactam and the benzene distillation residue in which the caprolactam is removed; and (d) recycling the aqueous solution rich in caprolactam, separated out in step (c), and treating the benzene distillation residue in which the caprolactam is removed, by incineration. The invention also provides the device for recovering the caprolactam in the benzene distillation residue.

Owner:EAST CHINA UNIV OF SCI & TECH

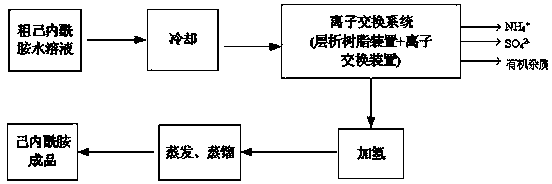

Purification process for caprolactam

ActiveCN104193663AShort regeneration periodTotal charge reductionLactams separation/purificationDistillationIon exchange

The invention discloses a purification process for caprolactam. The purification process comprises the following steps: cooling crude caprolactam aqueous liquor obtained in an extracting process to 43-45 DEG C; then, passing the cooled crude caprolactam aqueous liquor through an ion exchange system which is composed of a chromatography resin device and an ion exchange device; and carrying out hydrogenation, evaporation and distillation to prepare a caprolactam finished product. The chromatography resin device is introduced to the ion exchange system, so that the problem that anion exchange resin is easy to pollute and difficult to regenerate is solved. The resin impurity removal and the resin regeneration are realized by continuously moving the bed-layer chromatography resin device and bed ion exchange resin, the regeneration period of the resin is shortened, and the stability of the discharge purity of the caprolactam aqueous liquor in an ion exchange process is guaranteed. Moreover, the number of resin columns is increased and the size of the resin columns is reduced, so that the total filling amount in the continuous ion exchange system is reduced, and the dosage of acid and alkaline in the regenerating process is also correspondingly reduced, and thus, the cost is saved and the secondary pollution is lowered.

Owner:河北美邦工程科技股份有限公司 +1

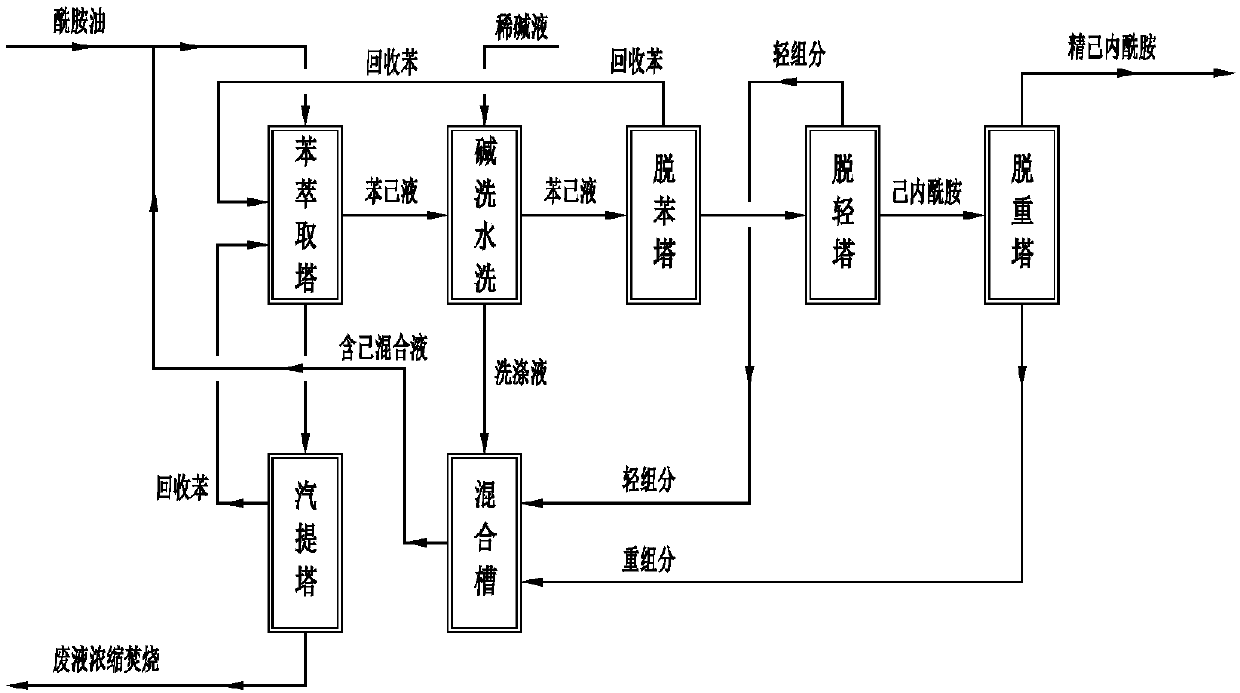

Caprolactam refining method and system

ActiveCN107556240AEliminates water strippingEliminate ion exchangeLactams separation/purificationBenzeneWater soluble

The invention relates to a caprolactam refining method. The method comprises the steps as follows: 1) amide oil enters a benzene extraction tower, and benzene is used as an extraction agent to extractcaprolactam in the amide oil; 2) a benzene-caprolactam solution obtained after extraction is subjected to alkali washing and water washing for removal of alkali-soluble and water-soluble substances;3) a product in the step 2) sequentially passes through a benzene removal tower, a light component removal tower and a heavy component removal tower, wherein the benzene removal tower removes a benzene solvent, the light component removal tower removes light component impurities, the heavy component removal removes heavy component impurities, and refined caprolactam is obtained. The invention alsorelates to a caprolactam refining system.

Owner:沧州旭阳化工有限公司

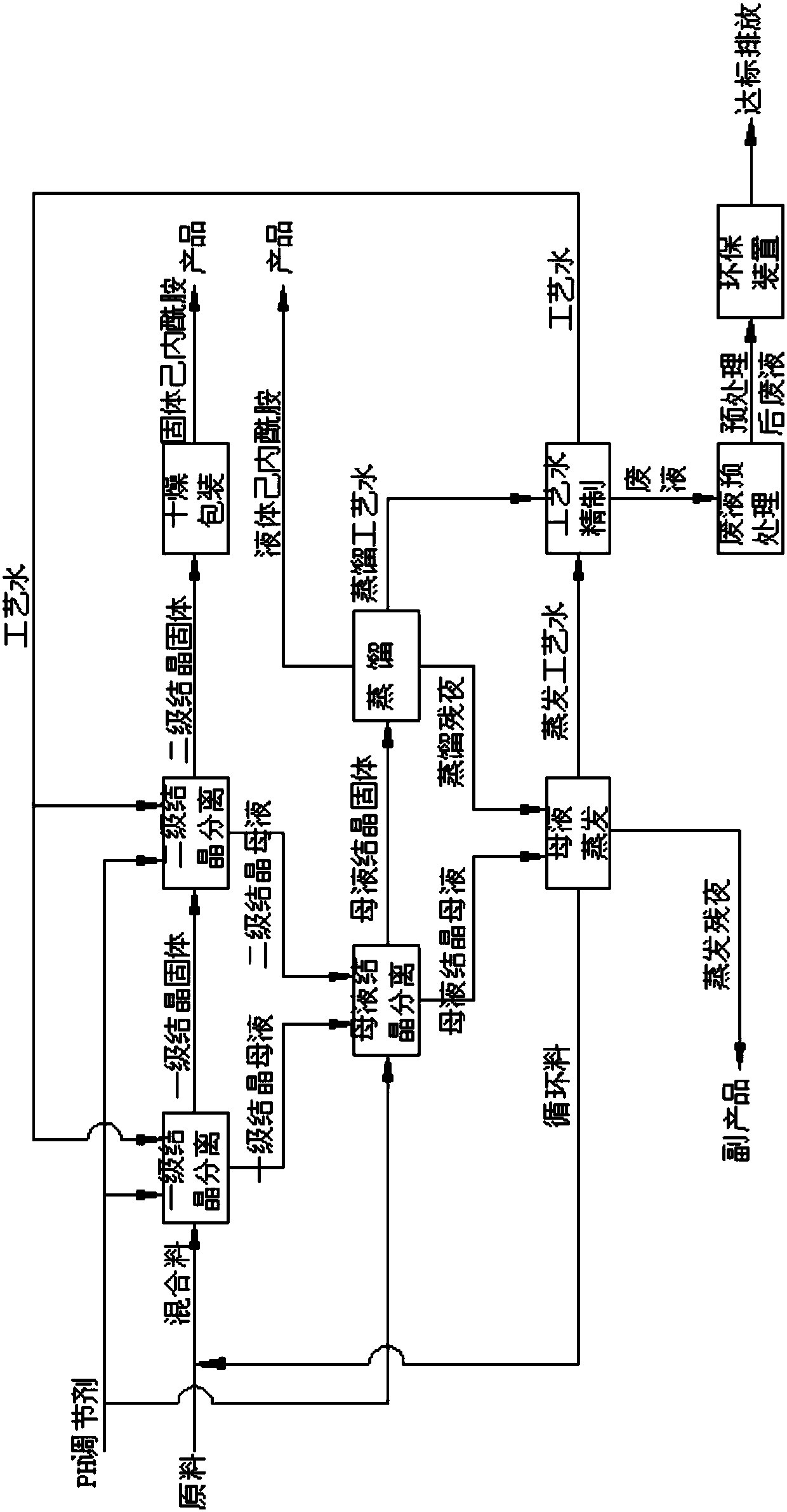

Method for refining and purifying caprolactam

ActiveCN107778244AEmission reductionGood chromaLactams separation/purificationDistillationEvaporation

The invention discloses a method for refining and purifying caprolactam. Through crystallizing low-water-content crude caprolactam at a constant temperature, one part of caprolactam with high qualityis obtained, through crystallizing room-temperature-crystallization high-water-content mother liquor at a low temperature and then performing distillation, the other part of caprolactam with high quality is obtained, wherein the low-temperature-crystallization mother liquor is evaporated to obtain circulation materials which participate in constant-temperature crystallization. A constant-temperature and low-temperature combined crystallization way is adopted and is matched with distillation and evaporation processes to realize the efficient refining and purification of the caprolactam. The constant-temperature and low-temperature crystallization has the advantages of low energy consumption, small effluent discharge, lowered production cost and improved safety. The method has the advantagesof high product yield, short technical process and low equipment investment. No inorganic solvent is used, the process is simple, and production cost is greatly lowered. The obtained caprolactam hasgood quality, each index is superior to the standard of a national standard premium grade; three waste (waste gas, waste water, industrial residue) discharge amount is small, and environment pollutionis low.

Owner:SHAANXI KEYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING TECH

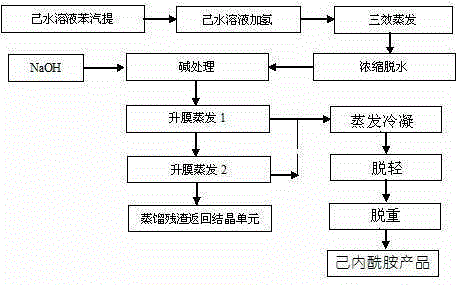

Method and device for refining caprolactam

ActiveCN104557705ASolving Corrosion ProblemsSimple processLactams separation/purificationBenzeneDistillation

The invention relates to a method and a device for refining caprolactam. The device comprises a stripping tower, a hydrogenation tower, a triple-effect evaporator, a dehydration tank, a concentration buffer tank, a No. 1 climbing film evaporator, a No. 2 climbing film evaporator, an evaporation and condensation tank, a light component removal tower and a heavy component removal tower. Amide oil is subjected to caustification and extraction processes to remove most of byproducts, and a separated caprolactam water solution is subjected to benzene stripping, hydrogenation, triple-effect evaporation, concentration and dehydration processes and then enters the concentration buffer tank. Alkali is added into the buffer tank for performing alkali treatment, and the caprolactam water solution after alkali treatment enters the climbing film evaporators for climbing film evaporation. Residues after evaporation return into a crystallization device for treatment. The caprolactam water solution evaporated by climbing film evaporation enters the light component removal tower and the heavy component removal tower for rectification to obtain a caprolactam product. The climbing film evaporators are used for replacing thin film evaporators, and the alkali treatment process is performed in the concentration buffer tank in advance, so that the corrosion problem of the evaporators is solved; meanwhile, the alkali distillation process in an alkali tower is canceled, the process flow is simplified and the energy consumption and the production cost are reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Process for producing epsi-caprolactam

InactiveUS6252068B1Low costQuality improvementLactams separation/purificationBeckmann rearrangementHydrogen

A high purity epsi-caprolactam is prepared by crystallizing an epsi-caprolactam from a hydrocarbon solution containing a crude epsi-caprolactam, and allowing the crystallized epsi-caprolactam in contact with hydrogen in the presence of a hydrogenation catalyst. This process can effectively remove impurities from a crude epsi-caprolactam, which is obtained by subjecting cyclohexanone oxime to the Beckmann rearrangement, and provide a high purity epsi-caprolactam.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com