Purification process for caprolactam

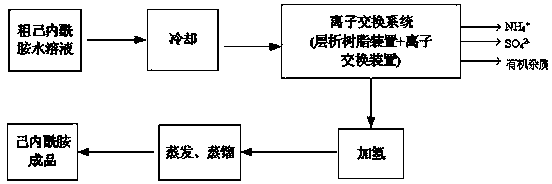

A technology of caprolactam and crude caprolactam, which is applied in the field of refining process of caprolactam, can solve the problems of high processing cost, easily polluted anion exchange resin, resin utilization rate and low resin utilization rate, and achieves reduction of pollution, size reduction and regeneration cycle. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Cool the crude caprolactam aqueous solution flowing out from the extraction process to 43°C;

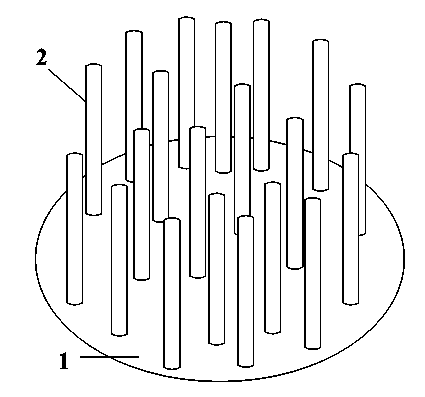

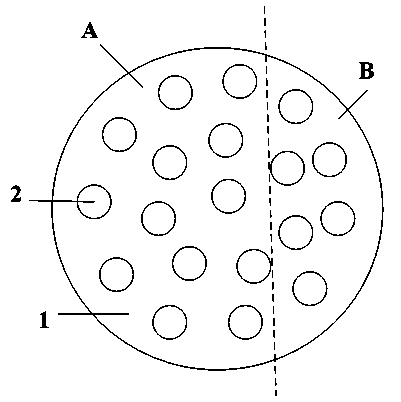

[0027] (2) Pass the cooled crude caprolactam aqueous solution through an ion exchange system composed of a fixed bed chromatography resin device and a fixed bed ion exchange device in series to remove the NH 4 + , SO 4 2- and other trace ions and some organic impurities, the extinction value of the obtained crude caprolactam aqueous solution at 290 nm is stable at about 0.1, which improves the purity of the crude caprolactam aqueous solution. Both the chromatography resin device and the ion exchange resin device are composed of 30 resin columns of the same specification. The filler in the resin column of the chromatography resin device is D101 type macroporous adsorption resin;

[0028] (3) In the ion exchange system, the methanol solution with a mass fraction of 90% is used to regenerate the saturated chromatographic resin; the sodium hydroxide solution with a mass fr...

Embodiment 2

[0033] (1) Cool the crude caprolactam aqueous solution flowing out from the extraction process to 44°C;

[0034] (2) Pass the cooled crude caprolactam aqueous solution through an ion exchange system composed of a fixed bed chromatography resin device and a fixed bed ion exchange device in series to remove the NH 4 + , SO 4 2- and other trace ions and some organic impurities, the extinction value of the obtained crude caprolactam aqueous solution at 290 nm is stable at about 0.1, which improves the purity of the crude caprolactam aqueous solution. Both the chromatography resin device and the ion exchange resin device are composed of 30 resin columns of the same specification. The filler in the resin column of the chromatography resin device is D-101-I macroporous adsorption resin;

[0035] (3) In the ion exchange system, a solution with a mass fraction of methanol of 90% and a mass fraction of hydrochloric acid of 4% was used as the eluent to regenerate the saturated chroma...

Embodiment 3

[0040] (1) Cool the crude caprolactam aqueous solution flowing out from the extraction process to 45°C;

[0041] (2) Pass the cooled crude caprolactam aqueous solution through an ion exchange system composed of a fixed bed chromatography resin device and a fixed bed ion exchange device in series to remove the NH 4 + , SO 4 2- and other trace ions and some organic impurities, the extinction value of the obtained crude caprolactam aqueous solution at 290 nm is stable at about 0.1, which improves the purity of the crude caprolactam aqueous solution. Both the chromatography resin device and the ion exchange resin device are composed of 30 resin columns of the same specification. The filler in the resin column of the chromatography resin device is DA-201 type macroporous adsorption resin;

[0042] (3) In the ion exchange system, use a solution with a mass fraction of ethanol of 90% and a mass fraction of sodium hydroxide of 5% as an eluent to regenerate the saturated chromatogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com