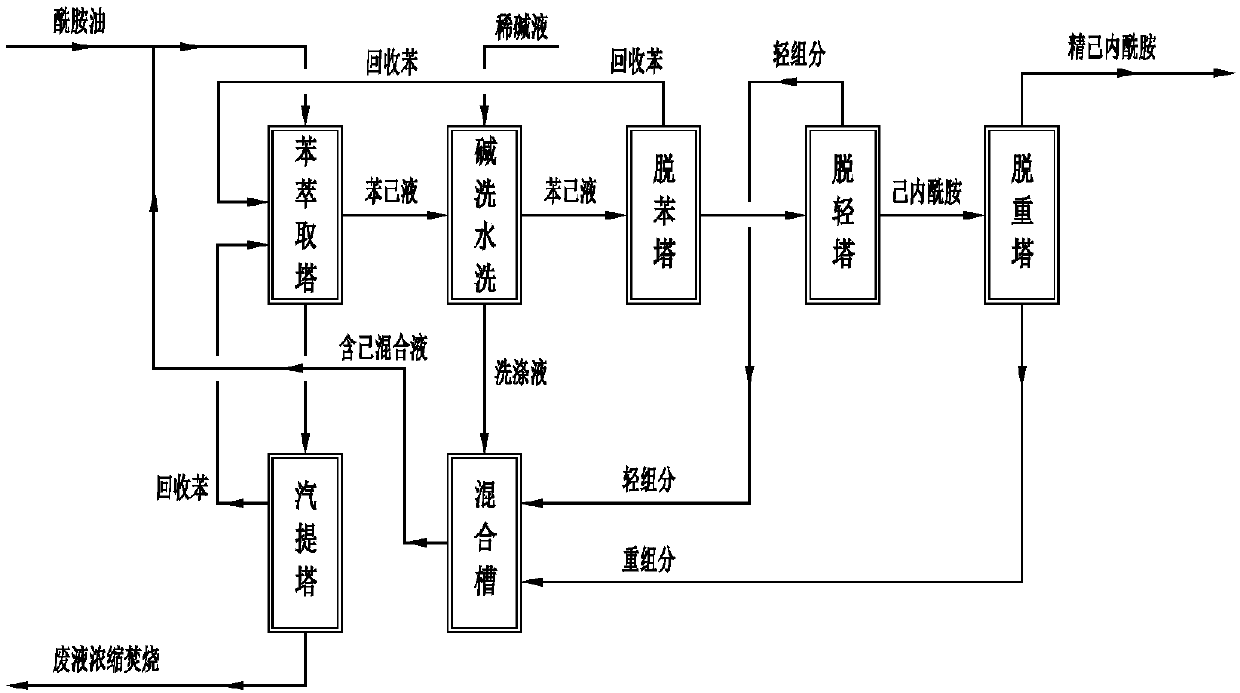

Caprolactam refining method and system

A technology of caprolactam and refining method, which is applied in the field of chemical refining, and can solve the problems of complex process control, long process flow, and shortened life of ion exchange resins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The benzene ethyl alcohol liquid formed after the amide oil is extracted by benzene is washed with 0.2wt% NaOH to remove the alkali-soluble substances, ammonium sulfate and esters and other impurities; The debenzene tower removes the benzene solvent therein, and its operating conditions are tower top temperature 70°C, tower bottom temperature 100°C, tower top pressure 90kpaA, tower bottom pressure 100kpaA; then enter the light removal tower to remove light component impurities therein, The condition is that the temperature at the top of the tower is 80°C, the temperature at the bottom of the tower is 100°C, the pressure at the top of the tower is 0.1kpaA, and the pressure at the bottom of the tower is 0.3kpaA; finally, it enters the weight removal tower to remove the heavy component impurities. The temperature at the bottom is 100°C, the pressure at the top of the tower is 0.1kpaA, and the pressure at the bottom of the tower is 0.7kpaA, and the caprolactam that meets the...

Embodiment 2

[0028] The benzene ethyl alcohol liquid formed after the amide oil is extracted by benzene is subjected to alkali washing with 5wt% NaOH to remove impurities such as alkali-soluble substances, ammonium sulfate and esters therein; The benzene tower removes the benzene solvent therein, and its operating conditions are tower top temperature 100°C, tower bottom temperature 150°C, tower top pressure 120kpaA, tower bottom pressure 120kpaA; The condition is that the temperature at the top of the tower is 120°C, the temperature at the bottom of the tower is 140°C, the pressure at the top of the tower is 0.5kpaA, and the pressure at the bottom of the tower is 1.0kpaA; finally, it enters the deweighting tower to remove the heavy component impurities. The temperature is 140°C, the pressure at the top of the tower is 0.6kpaA, and the pressure at the bottom of the tower is 1.2kpaA, and the caprolactam that meets the national standard GBT13254-2008 is obtained.

Embodiment 3

[0030] The benzene ethyl alcohol liquid formed after the amide oil is extracted by benzene is subjected to alkali washing with 2.6wt% NaOH to remove impurities such as alkali-soluble substances, ammonium sulfate and esters; The debenzene tower removes the benzene solvent therein, and its operating conditions are tower top temperature 85°C, tower bottom temperature 125°C, tower top pressure 105kpaA, tower bottom pressure 110kpaA; then enter the light removal tower to remove the light component impurities therein, The condition is that the temperature at the top of the tower is 100°C, the temperature at the bottom of the tower is 120°C, the pressure at the top of the tower is 0.3kpaA, and the pressure at the bottom of the tower is 0.65kpaA. The temperature at the bottom is 120°C, the pressure at the top of the tower is 0.35kpaA, and the pressure at the bottom of the tower is 0.95kpaA, and the caprolactam that meets the national standard GBT13254-2008 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com