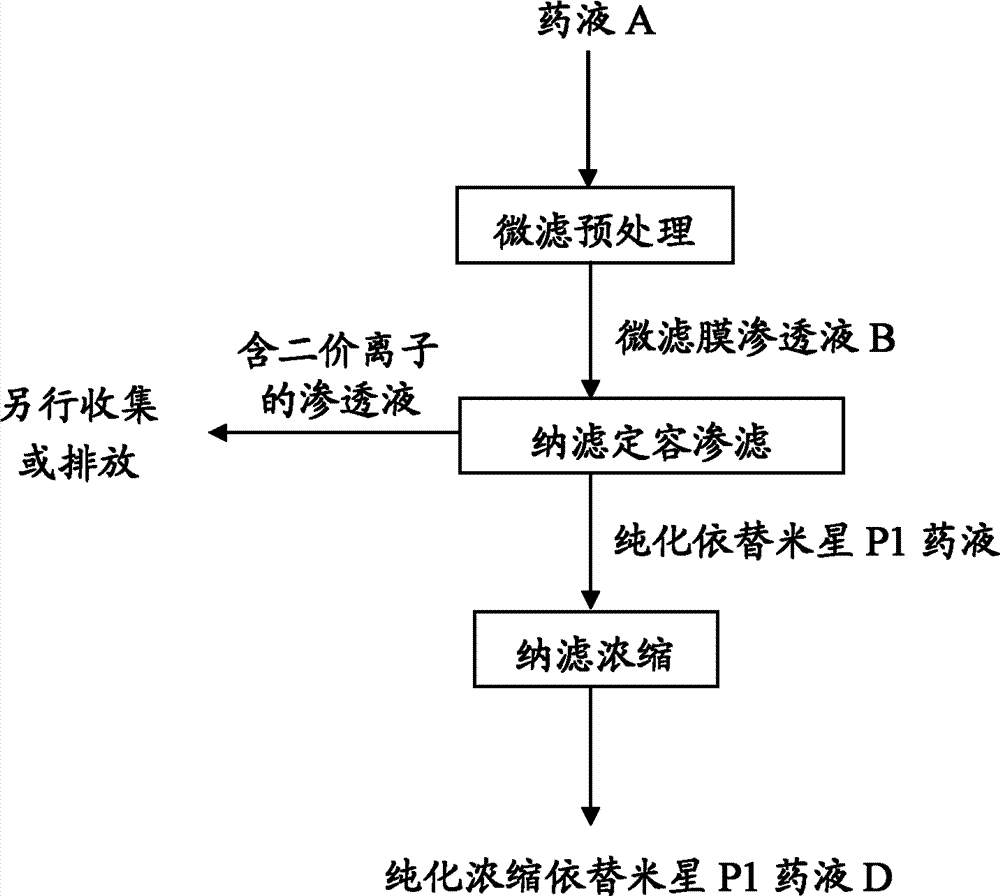

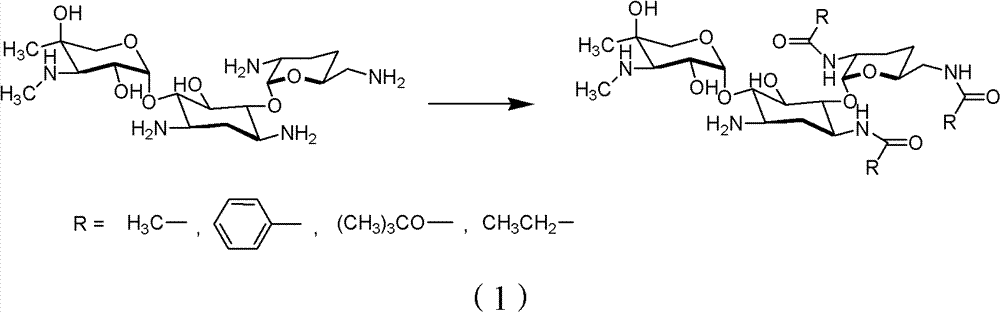

Method for removing divalent metal ion from antibiotic etimicin liquid medicine

A divalent metal ion, etimicin technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve problems such as the removal of divalent metal ions that have not been reported, and achieve significant energy-saving effects. Small loss, the effect of eliminating pollution and harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

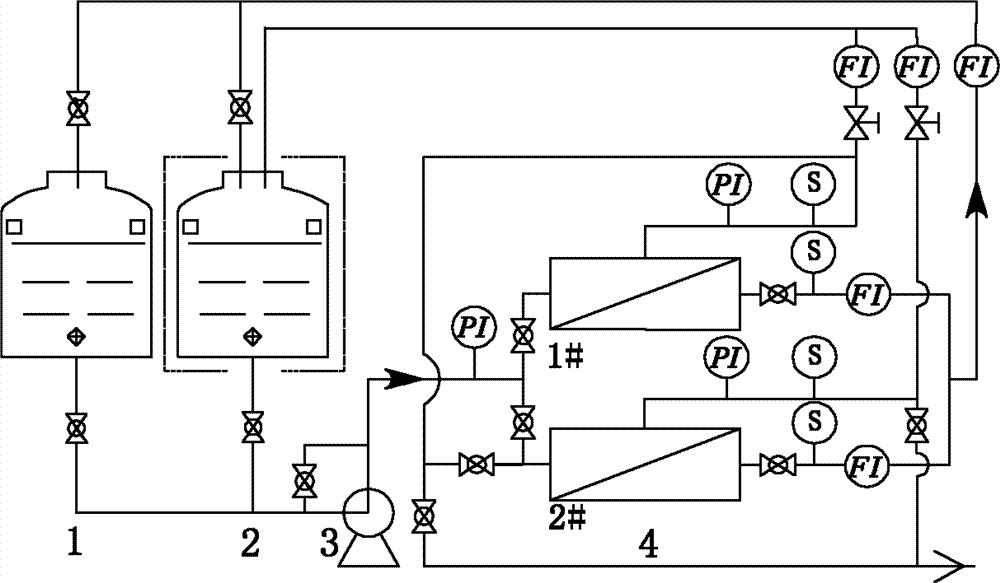

[0035] The medicinal liquid A that separation of the present invention is used is to contain antibiotic etimicin P1 medicine 3.083% (mass concentration), Zn2+ or Co 2+ 1.170% (mass concentration) aqueous solution.

[0036] The operating conditions for nanofiltration purification, concentration and separation of the antibiotic etimicin P1 medicinal liquid are as follows: feed liquid temperature 5-40°C, feed pressure 0.5-1.2 MPa. The purification and concentration separation effects of etimicin P1 drug liquid nanofiltration process were characterized by purification factor (α) and concentration factor (β) respectively.

[0037] Nanofiltration purification factor (α) expression:

[0038] α = Y P 1 / Y M 2 + ...

Embodiment 2

[0049] The same amount of etimicin P1 drug solution A as in Example 1 was used, and the microfiltration membrane permeate B obtained by pretreatment of the microfiltration membrane with a membrane pore size of 0.01 μm was placed in the feed liquid box 2 . At a feed liquid temperature of 40°C and an operating pressure of 0.5 MPa, the liquid medicine B was pumped into the nanofiltration membrane module 4 to carry out the same nanofiltration membrane diafiltration operation as in Example 1 to obtain purified etimicin P1 liquid medicine C, Its purification factor is 31.283. Then, the medicinal liquid C stored in the material liquid tank 1 is concentrated and operated in the same manner as in Example 1 to obtain purified and concentrated medicinal liquid D. The mass fraction of etimicin P1 in the medicinal liquid reaches 7.091%. The liquid concentration factor is 2.307.

Embodiment 3

[0051] The 25l microfiltration membrane permeate B obtained by the method of embodiment 1 is sent into the feed liquid tank 2, and then in the feed liquid tank 2, 25l purified water is added, that is, the feed liquid used as the nanofiltration membrane percolation and that of embodiment 1 for subsequent use In comparison, the drug solution B was diluted 1-fold. At a feed liquid temperature of 25° C. and an operating pressure of 0.8 MPa, the same operation method as in Example 1 was adopted to successively perform the diafiltration and concentration operations of the nanofiltration membrane. At this time, the purification factor of etimicin P1 liquid medicine was 31.072, and the concentration factor was 2.287.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com