A kind of purification method and device of caprolactam

A caprolactam and purification method technology, applied in the separation/purification of lactam, chemical instruments and methods, organic chemistry, etc., can solve the problems of fragility, low washing efficiency, large investment, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

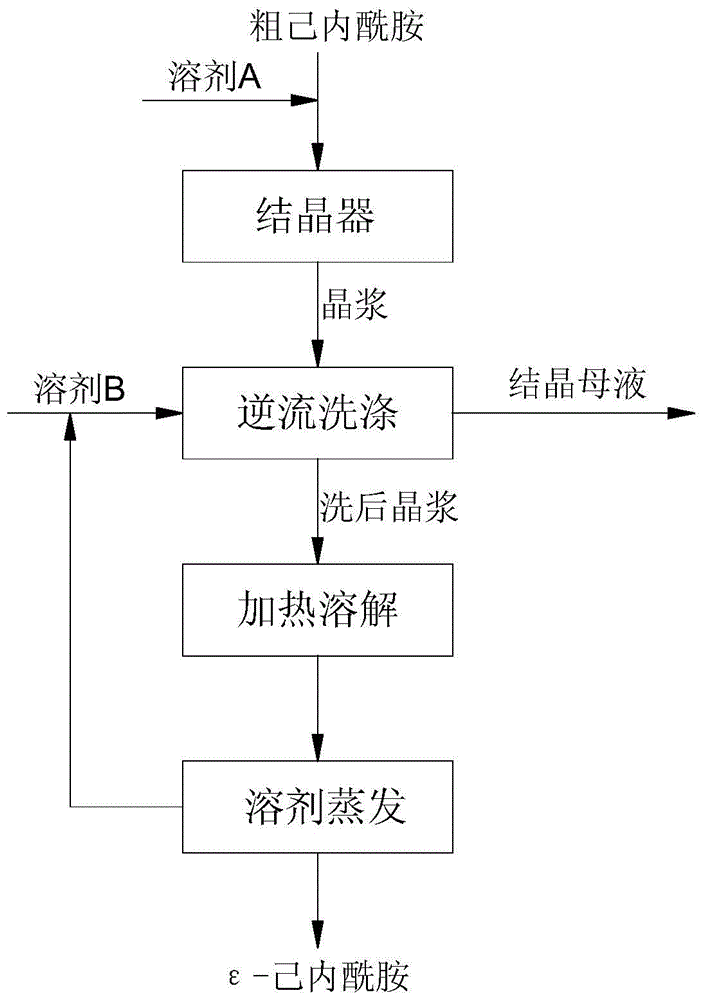

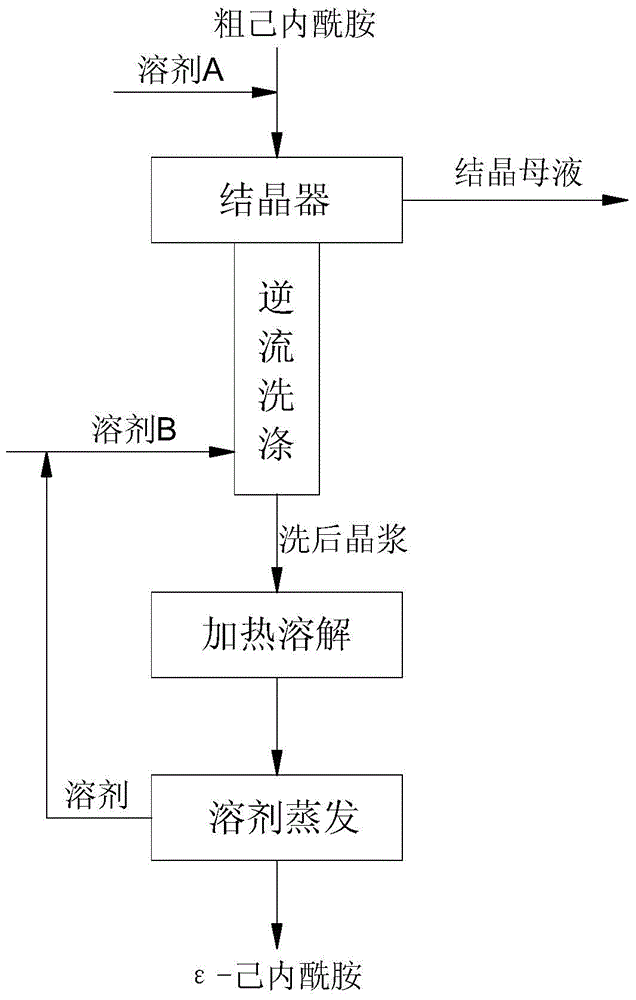

[0038] A method for purifying ε-caprolactam, comprising:

[0039] (1) Crystallizing crude ε-caprolactam containing impurities in the presence of solvent A to obtain a crystal slurry containing solvent A;

[0040] (2) washing the crystal slurry obtained in step (1) with solvent B to obtain the washed crystal slurry and mother liquor containing solvent B;

[0041] (3) Separate the solvent B in the magma after washing in step (2) to obtain ε-caprolactam.

[0042] Preferably, the step (3) includes:

[0043] (4) heating and dissolving the washed crystal slurry obtained in step (2) to obtain ε-caprolactam solution;

[0044] (5) Distilling off the solvent B in the ε-caprolactam solution in step (4) to obtain ε-caprolactam.

[0045] Preferably, the solvent B recovered by distillation in step (4) is returned to step (2) for reuse.

[0046] In the method provided by the present invention, step (1) is to continuously feed the crude caprolactam containing impurities and solvent A into...

Embodiment 1

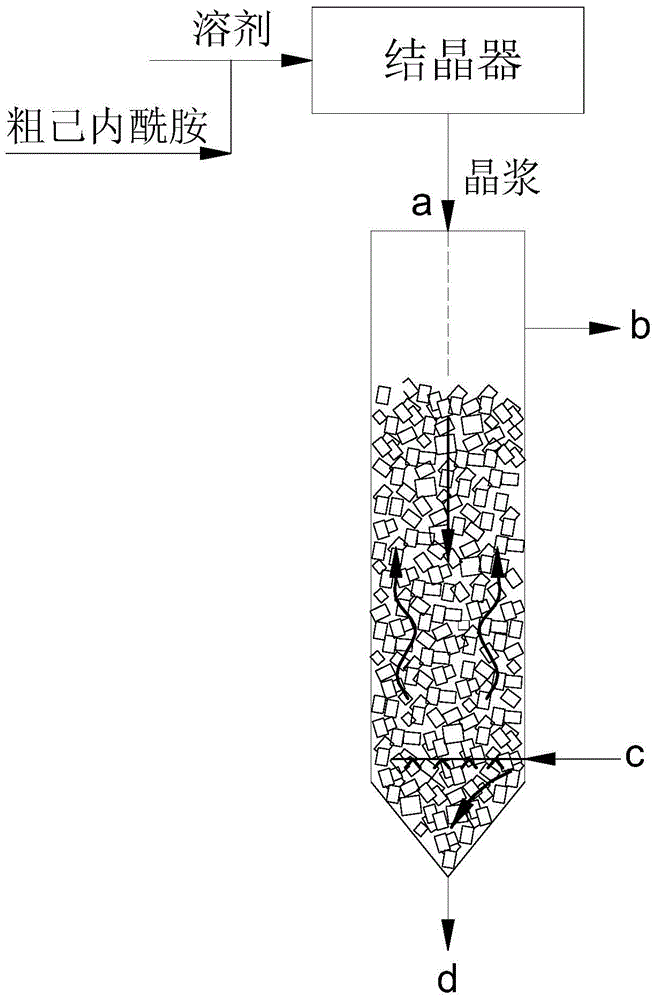

[0096] Take 600 grams of crude caprolactam and 600 grams of isopropyl ether and add them to a 2L glass kettle with stirring and a jacket. Heat hot water in the jacket to 70 degrees until the caprolactam is completely dissolved. Under stirring, adjust the jacket The temperature of the water inside is gradually lowered to 20° C. to obtain a crystal slurry of caprolactam.

[0097] The above-mentioned magma is transferred into a washing column with a jacket of 50 mm in height and 800 mm in length, and 1140 grams of normal temperature n-heptane are continuously fed from the bottom for countercurrent washing, and the mother liquor is drawn out from the top.

[0098] The concentration of the crystal slurry after washing is about 50%, and it is transferred to a distillation kettle and heated to 85°C for dissolution.

[0099] 456g of solvent was distilled off under normal pressure, and then the remaining solvent was distilled off under reduced pressure to 1.3kPa, and 558g of purified c...

Embodiment 2

[0101] By the same method as in Example 1, the difference is that 1092 g of isopropyl ether solution in which 4.2% caprolactam is dissolved is used as a solvent for backwashing. 592 grams of purified caprolactam were obtained from the still of the distillation tower. A small amount of purified caprolactam was taken for chromatographic analysis. The purity of caprolactam was 99.98%. Cyclohexanone oxime and swahydrophenazine were not detected. N-methyltetrahydrobenzimidazole: 4 μg / g. The PM value is 120s, the V.B value is 0.34mmol / kg, and the E value is 0.150.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com