Caprolactam hydrofining catalyst and method

A caprolactam and hydrorefining technology, applied to the separation/purification of lactam, Raney-type catalysts, chemical instruments and methods, etc., can solve the problems of low precision of hydrorefining, and achieve obvious impurity removal effect and good application prospect. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

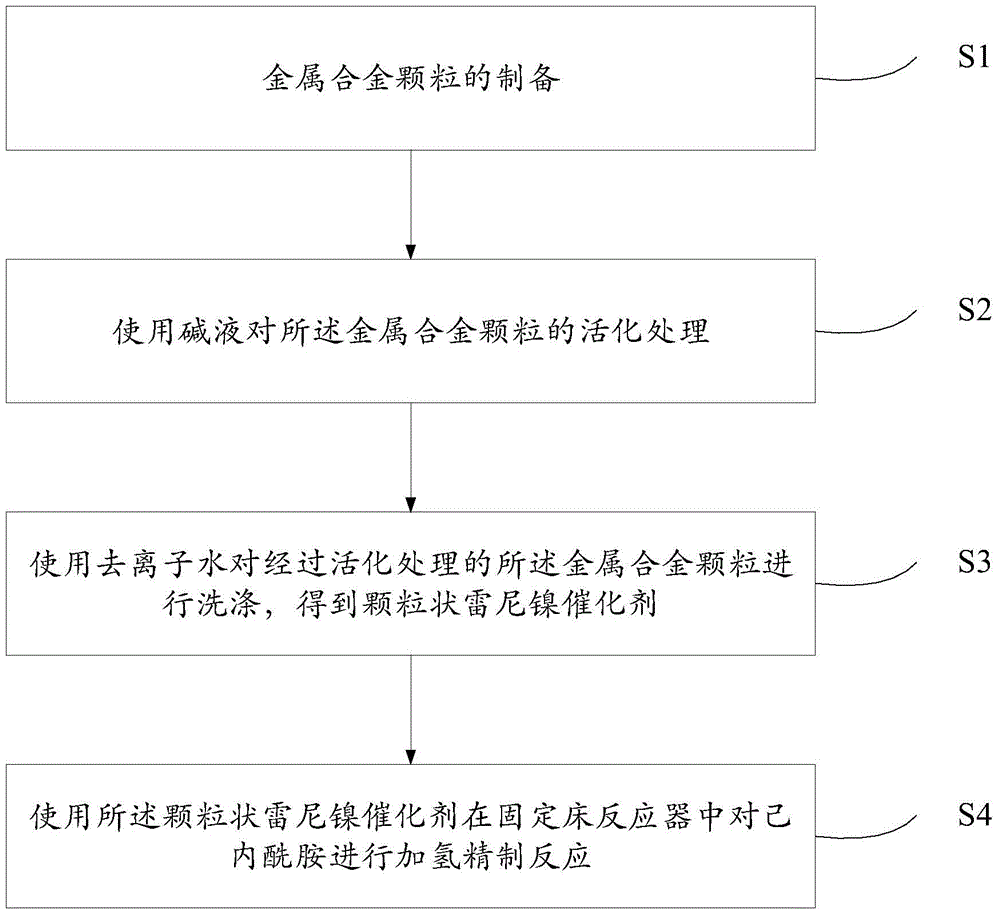

[0051] S1. Preparation of metal alloy particles;

[0052] S2. Using lye to activate the metal alloy particles;

[0053] S3. Washing the activated metal alloy particles with deionized water to obtain a granular Raney nickel catalyst;

[0054] S4. Using the granular Raney nickel catalyst in a fixed-bed reactor to perform hydrofining reaction on caprolactam.

[0055] Among them, S1-S3 are the preparation process of the granular Raney nickel catalyst. The specific implementation method can refer to the description of the caprolactam hydrogenation catalyst, so it will not be repeated here.

[0056] S4 is specifically: placing the granular Raney nickel catalyst in a fixed-bed reactor, purging with nitrogen, and co-flowing the caprolactam aqueous solution and hydrogen into the fixed-bed reactor for gas-liquid-solid three-phase hydrogenation refining reaction.

[0057] Specifically, the concentration of the caprolactam aqueous solution is 5-60 wt%, more preferably 10-50 wt%.

[005...

Embodiment 1

[0064] This embodiment shows that the average particle size is 3mm, and the composition is Ni 40 Al 60 The preparation process of granular Raney nickel catalyst prepared by alkali solution activation treatment of metal alloy particles.

[0065] In a specific embodiment, it is accurately weighed that the average particle diameter is 3 mm and the composition is Ni 40 Al 60 500g of metal alloy particles, placed in a quartz glass tube with an inner diameter of 50mm, the NaOH alkali solution with a concentration of 1wt% flows from the bottom of the quartz glass tube through the metal alloy particle bed at a rate of 10L / h and then flows out from the top, NaOH alkali The weight space velocity of the liquid is 20h -1 . The bed temperature is 70°C, and the activation treatment time is 2h. After lye activation treatment, wash with deionized water at 50° C. until the pH of the solution after washing is 7-9. The average composition of the prepared granular Raney nickel catalyst is N...

Embodiment 2

[0067] This embodiment shows that the average particle size is 3mm, and the composition is Ni 40 Al 60 The preparation process of granular Raney nickel catalyst prepared by alkali solution activation treatment of metal alloy particles.

[0068] In a specific embodiment, the preparation of the granular Raney nickel catalyst is carried out according to the method described in Example 1, the difference is that the NaOH lye concentration is 2wt%, the average of the prepared granular Raney nickel catalyst Composed of Ni 56.6 Al 43.4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com