Purification method and purification device of caprolactam

A technology of caprolactam and purification method, applied in the directions of separation/purification of lactam, chemical instruments and methods, organic chemistry, etc., can solve the problems of fragility, low washing efficiency, large investment, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

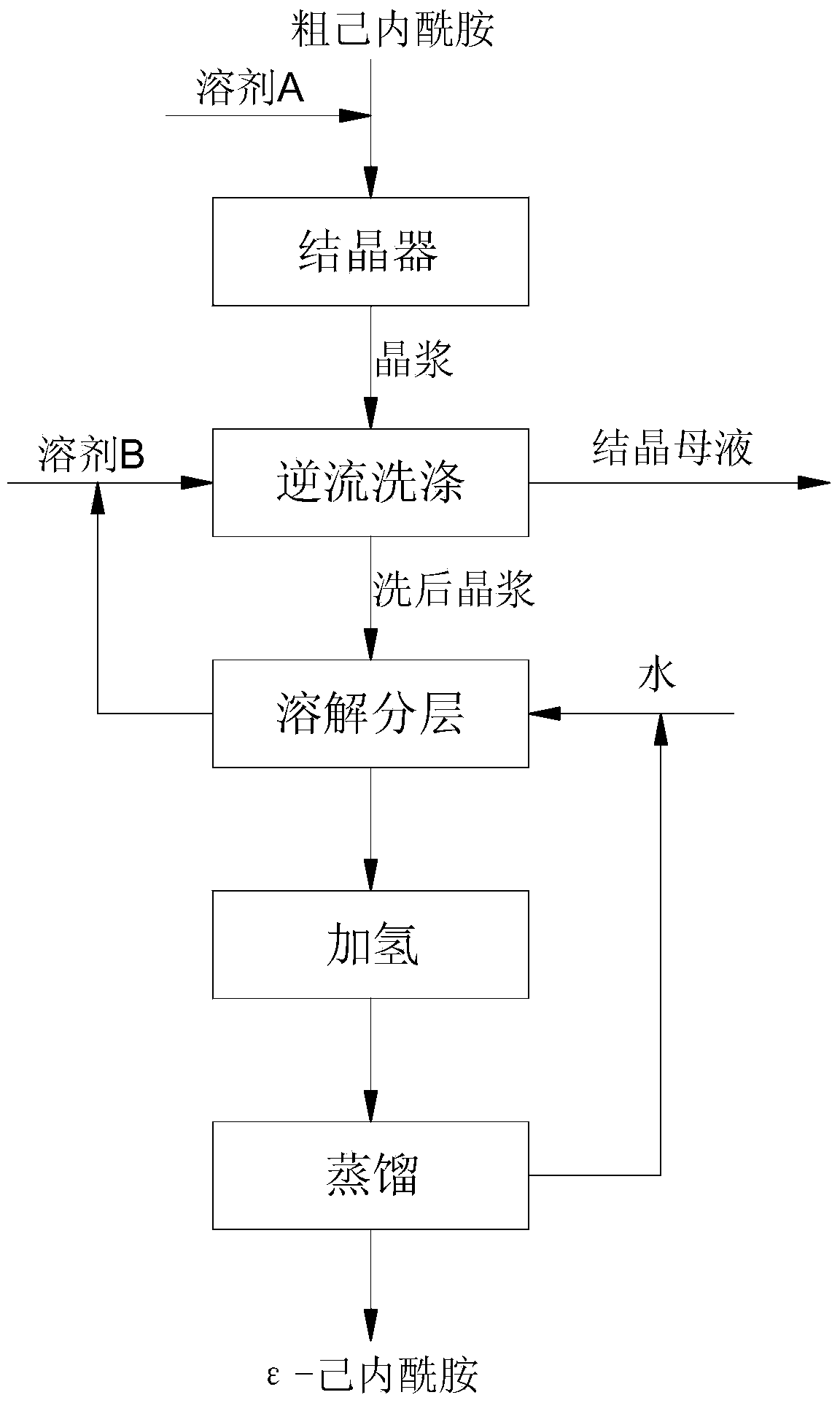

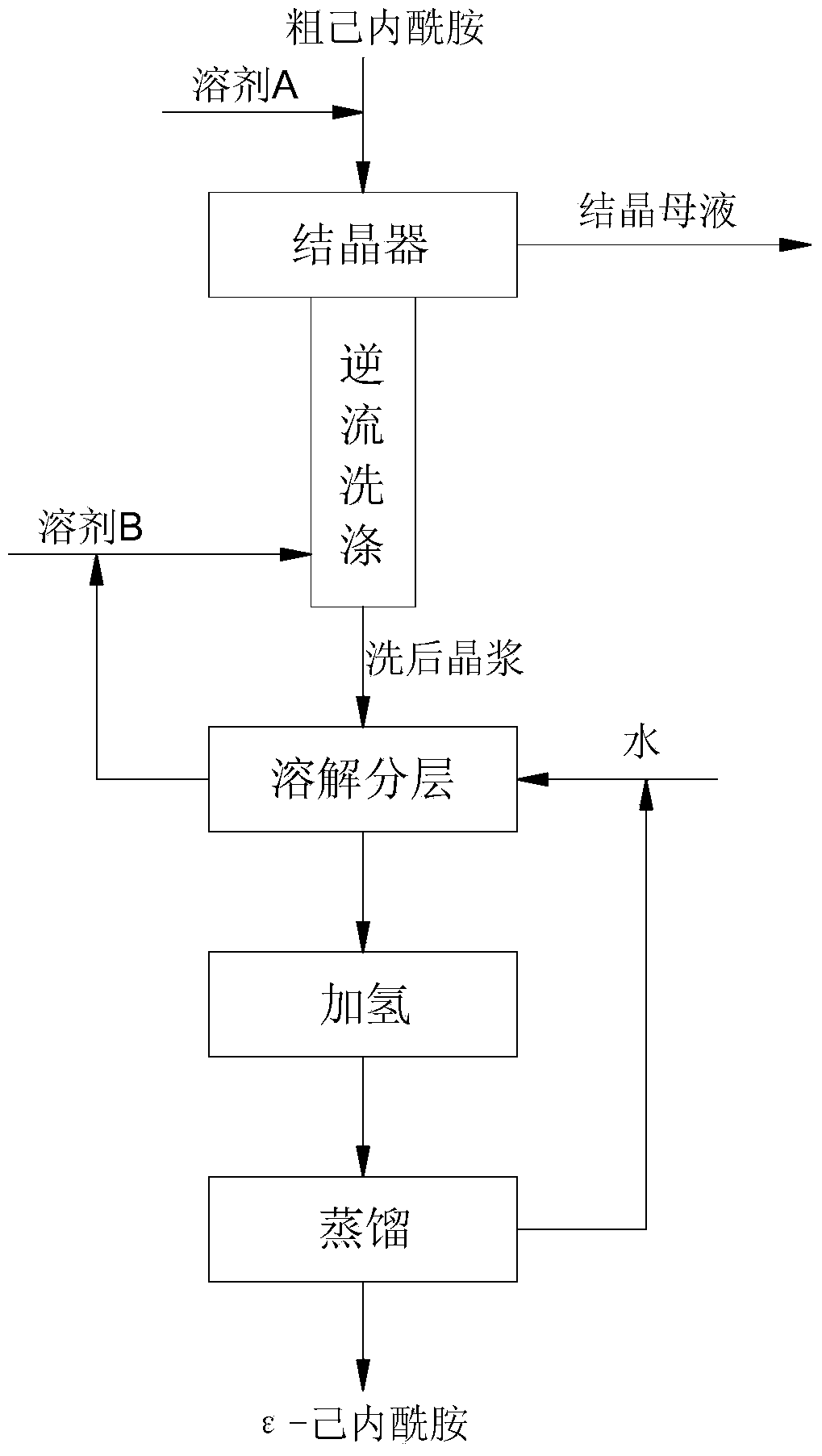

[0037] A method for purifying ε-caprolactam, comprising:

[0038] (1) Crystallizing crude ε-caprolactam containing impurities in the presence of solvent A to obtain a crystal slurry containing solvent A;

[0039] (2) washing the crystal slurry obtained in step (1) with solvent B to obtain the washed crystal slurry and mother liquor containing solvent B;

[0040] (3) Add water to dissolve the washed crystal slurry obtained in step (2), and separate phases to obtain an organic phase and an aqueous solution of ε-caprolactam;

[0041] (4) In the presence of a hydrogenation catalyst, the ε-caprolactam aqueous solution is contacted with hydrogen, and the water is removed by distillation to obtain ε-caprolactam.

[0042] Preferably, the organic phase obtained in step (3) is preferably returned to step (2) for reuse; the water recovered in step (4) is preferably returned to step (3) for reuse.

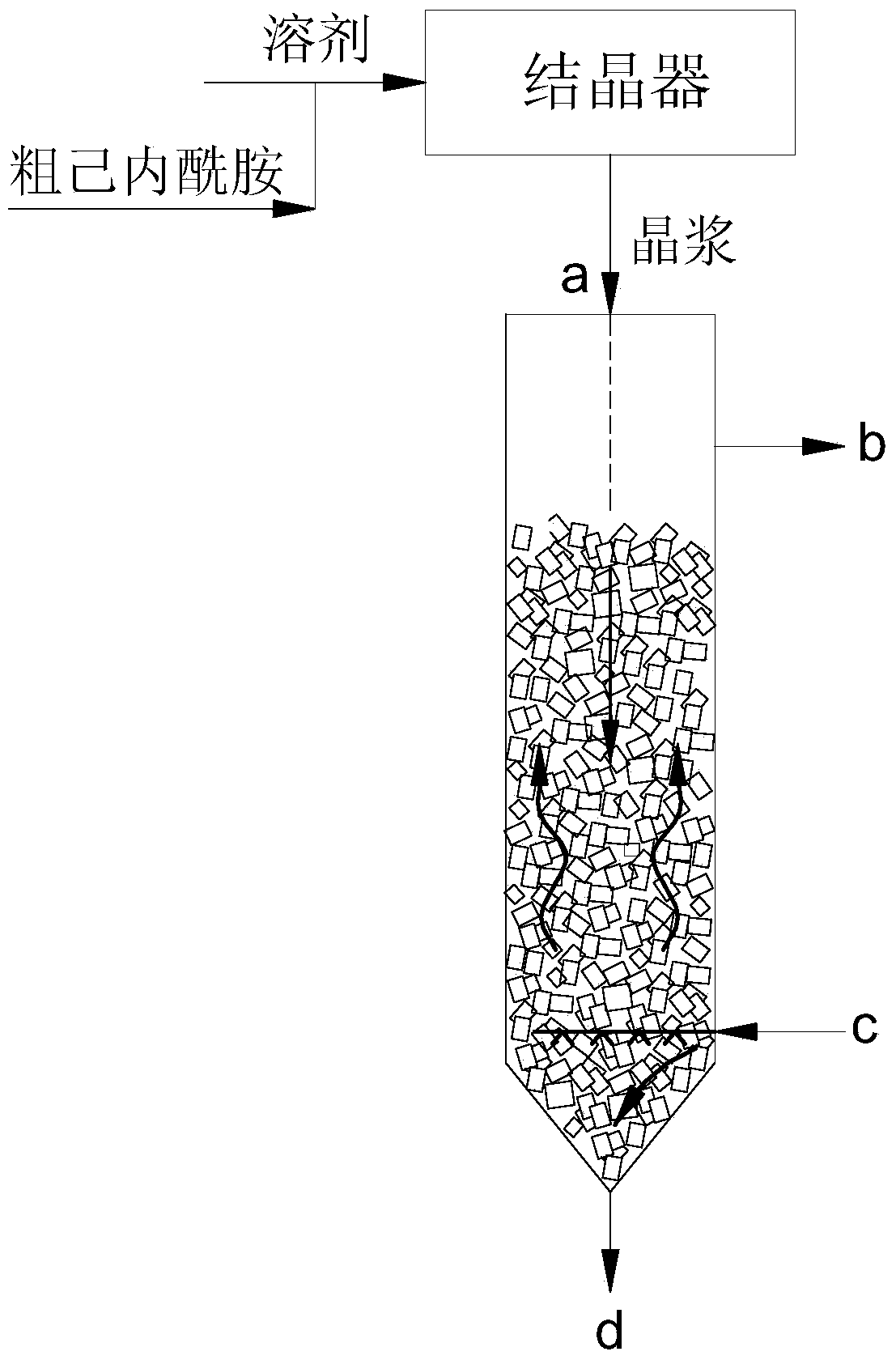

[0043] In the method provided by the present invention, step (1) is to continuously feed...

Embodiment 1

[0088] Take 600 grams of crude caprolactam and 600 grams of isopropyl ether and add them to a 2L glass kettle with stirring and a jacket. Heat hot water in the jacket to 70 degrees until the caprolactam is completely dissolved. Under stirring, adjust the jacket The temperature of the water inside is gradually lowered to 20° C. to obtain a crystal slurry of caprolactam.

[0089] Transfer the above crystal slurry into a jacketed washing column with a diameter of 20 mm and a height of 200 mm, continuously inject 1140 g (2 times the solvent) of normal temperature n-heptane from the bottom for countercurrent washing, and extract the mother liquor from the top.

[0090] The concentration of the crystal slurry after washing is about 50%. Transfer it to a 2L separatory funnel, add water and mix evenly, let it settle at room temperature, separate the caprolactam aqueous solution from the bottom, transfer it to a 2L autoclave, and add 5 grams of powder loaded with 2% palladium. Shaped h...

Embodiment 2

[0092] Make a mixed solvent of 150 grams of isopropyl ether and 450 grams of n-heptane, take 200 grams of the mixed solvent and add it to a 2L crystallization kettle with stirring and a jacket, and heat the jacket to raise the temperature in the kettle to 80°C , take 400 grams of crude caprolactam and 400 grams of mixed solvent and mix them uniformly at 40° C., and gradually drop them into a crystallization kettle under stirring to obtain crystal slurry of caprolactam.

[0093] Put hot water at 40°C into the jacket of the washing column, transfer the above crystal slurry into the washing column, take 380 grams (1 times the solvent) of n-heptane and 11 grams of pure caprolactam, and make a saturated solution at 40°C, from the bottom of the washing column Continuous feeding is performed for countercurrent washing, and the mother liquor is drawn out from the top.

[0094] Follow-up operations were carried out in the same manner as in Example 1 to obtain 383 grams of purified capr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com