Process for extracting and separating caprolactam from amide oil

A technology of caprolactam and amide oil, applied in the separation/purification of lactam, chemical instruments and methods, organic chemistry, etc., can solve the problems of limited processing capacity, low extraction capacity, high boiling point, etc., achieve less solvent consumption and improve purity , the effect of high purity

Active Publication Date: 2005-06-22

CHINA PETROLEUM & CHEM CORP +2

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with benzene, toluene has a lower extraction capacity for caprolactam and a higher boiling point, which limits the processing capacity of a single set of equipment, and the problem of energy and material consumption in the extraction process is more prominent

However, due to selectivity reasons, the use of benzene instead of toluene has proven to be inadvisable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025] sample discription

Embodiment 2

[0027] project

[0028] Note: √, means there is this step; ×, means there is no such step; comparison refers to the volume ratio of solvent phase to water phase (or amide oil).

Embodiment 3

[0030] project

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

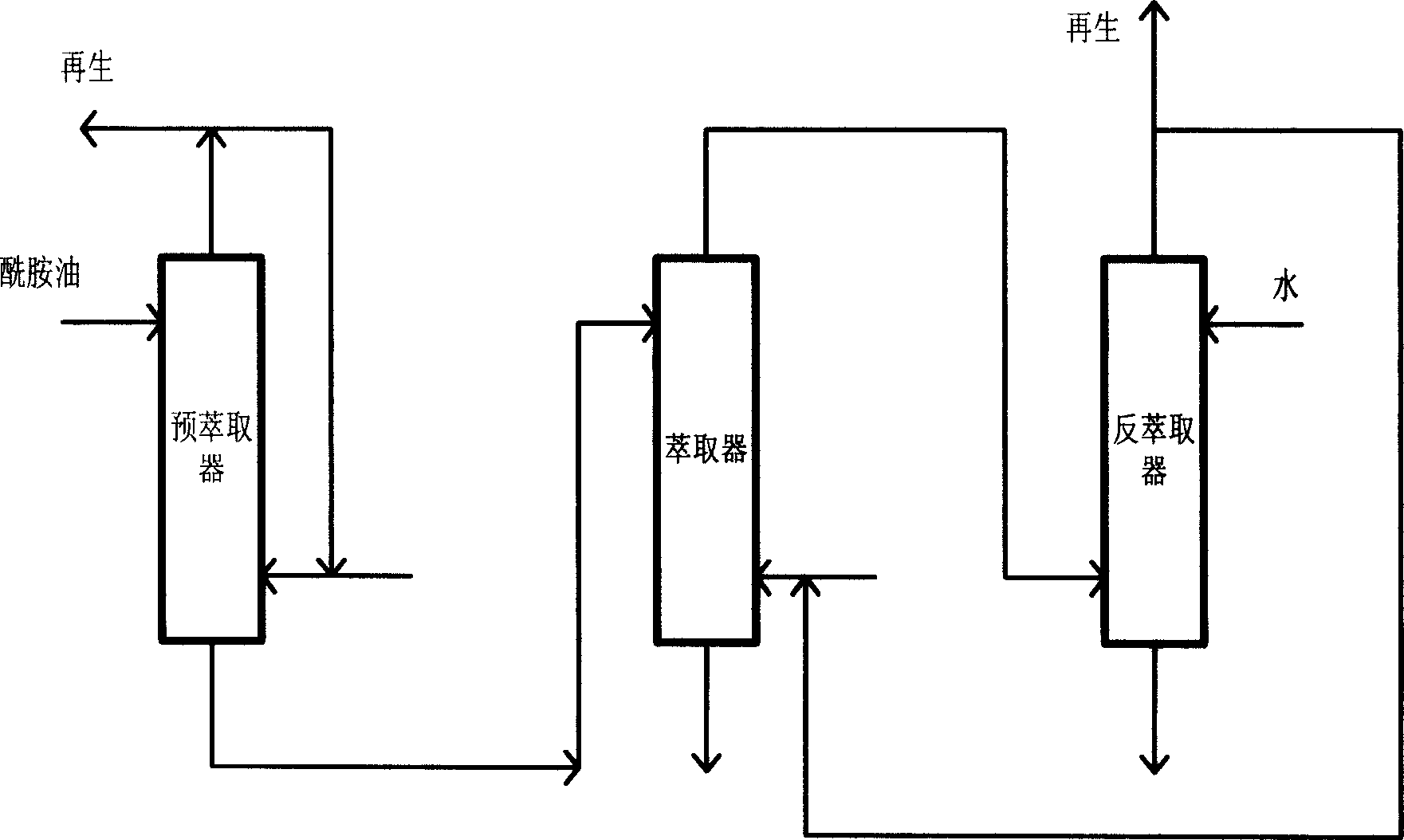

The invention provides a process for extracting and separating caprolactam from amide oil which comprises, using cyclohexane or the mixed solvent of cyclohexane and benzene to pre-extract amide oil and remove part of the impurity, then using benzene or the mixed solvent of cyclohexane and benzene to extract the dense phase obtained from the pre-abstraction, finally back washing the light phase with water to obtain the water solution of caprolactam.

Description

technical field [0001] The invention relates to a method for extracting and purifying caprolactam from amide oil, which belongs to the technical field of chemical mass transfer and separation. Background technique [0002] Caprolactam is an important organic chemical raw material, mainly used in the production of nylon fiber and nylon resin. It is also an excellent solvent and has a wide range of applications. [0003] There are many industrial preparation methods of caprolactam, such as cyclohexane-hydroxylamine method, toluene method and so on. Due to the long reaction route, the amide oil obtained by the reaction contains various impurities. To obtain the caprolactam product, a series of physical and chemical refining methods must be adopted, such as extraction, chemical treatment and multi-effect distillation. Solvent extraction is the most effective means for the preliminary purification of caprolactam from amide oil, and benzene and toluene are the most commonly used ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D201/16C07D223/10

Inventor 吕阳成骆广生赵承军寇建朝曹志广

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com