Caprolactam hydrofining method

A caprolactam, hydrofining technology, applied in the field of caprolactam hydrofining treatment, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

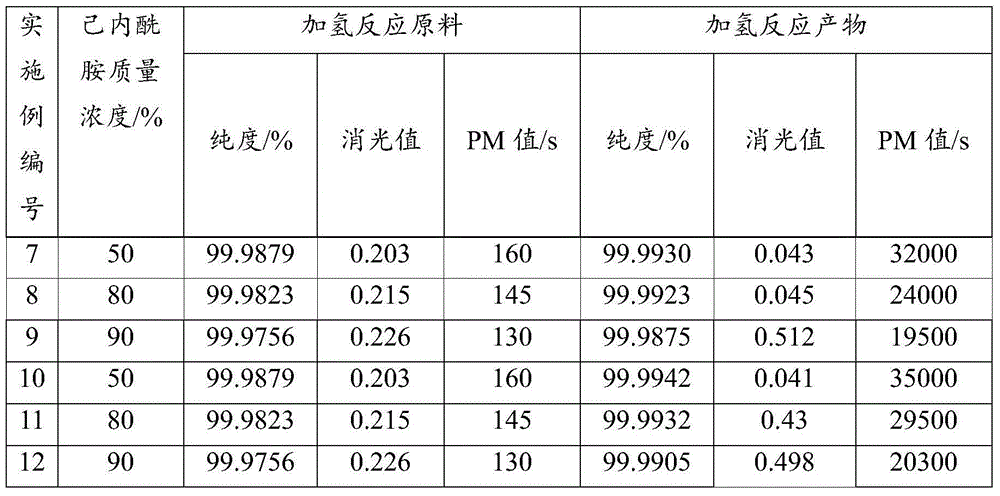

Examples

Embodiment 1

[0025] Put 150g of caprolactam crystals (see Table 1 for specifications) and 150g of isopropyl ether into a 500ml pressure reactor, then add 40-100 mesh 2%Pd-1%La 2 o 3 / Activated carbon strip catalyst 1.5g, close the reactor, replace it with hydrogen, raise the temperature of the reactor to 90°C at a heating rate of 2°C / min, the hydrogen flow rate is 200ml / min, and the pressure of the reaction system is controlled at 0.7MPa, at 90°C Keep the temperature constant for 60 minutes. After the reaction is completed, stop stirring and heating, and take off the insulation cover to quickly cool down. When the temperature is lowered to 55°C, the reactor is opened, the solvent is evaporated to dryness, and then it is made into a 50% aqueous solution of ethyl alcohol, which is then filtered and then analyzed and evaluated for product quality.

Embodiment 2-3

[0027] The hydrogenation conditions are the same as in Example 1, but the hydrogenation solvent is changed, and the hydrogenation solvents in Examples 2 and 3 are replaced by a mixed solvent of n-heptane, n-heptane and isopropyl ether (mass ratio is 3:1), and the hydrogenation product See Table 1 for quality.

Embodiment 4

[0029] Embodiment 4 conditions are the same as embodiment 1, difference is that used hydrogenation catalyst is 1%Pd-3.5%La 2 o 3 / Activated carbon strip catalyst. The quality of hydrogenation products is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pm value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com