Heat pump distillation and multi-effect distillation integrated device and process for purifying trichlorosilane

A heat pump rectification and multi-effect rectification technology, applied in the field of rectification, can solve the problems such as the shortage of introduction of heat pump rectification and multi-effect rectification technology, and achieve the effect of saving refrigeration and heat public works and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

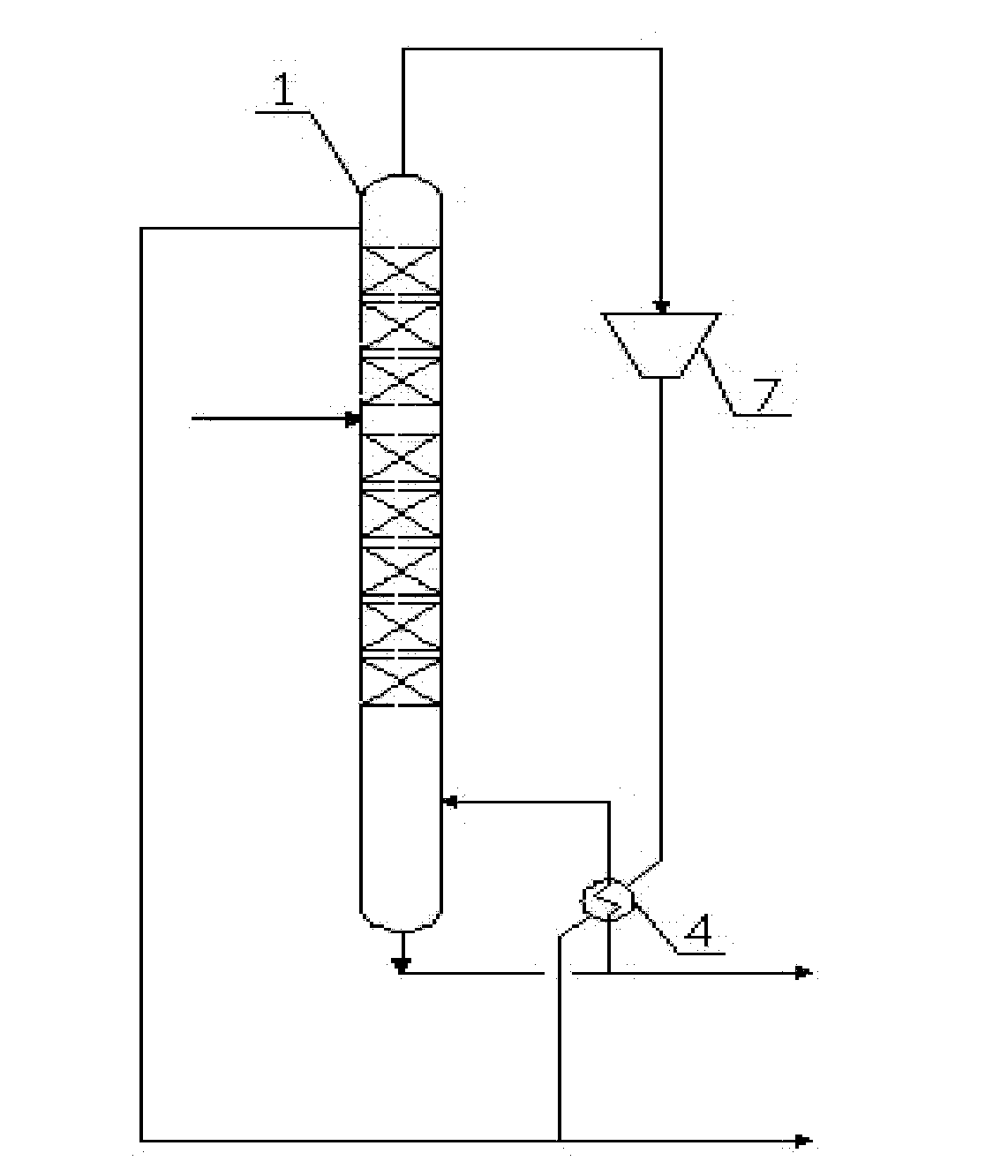

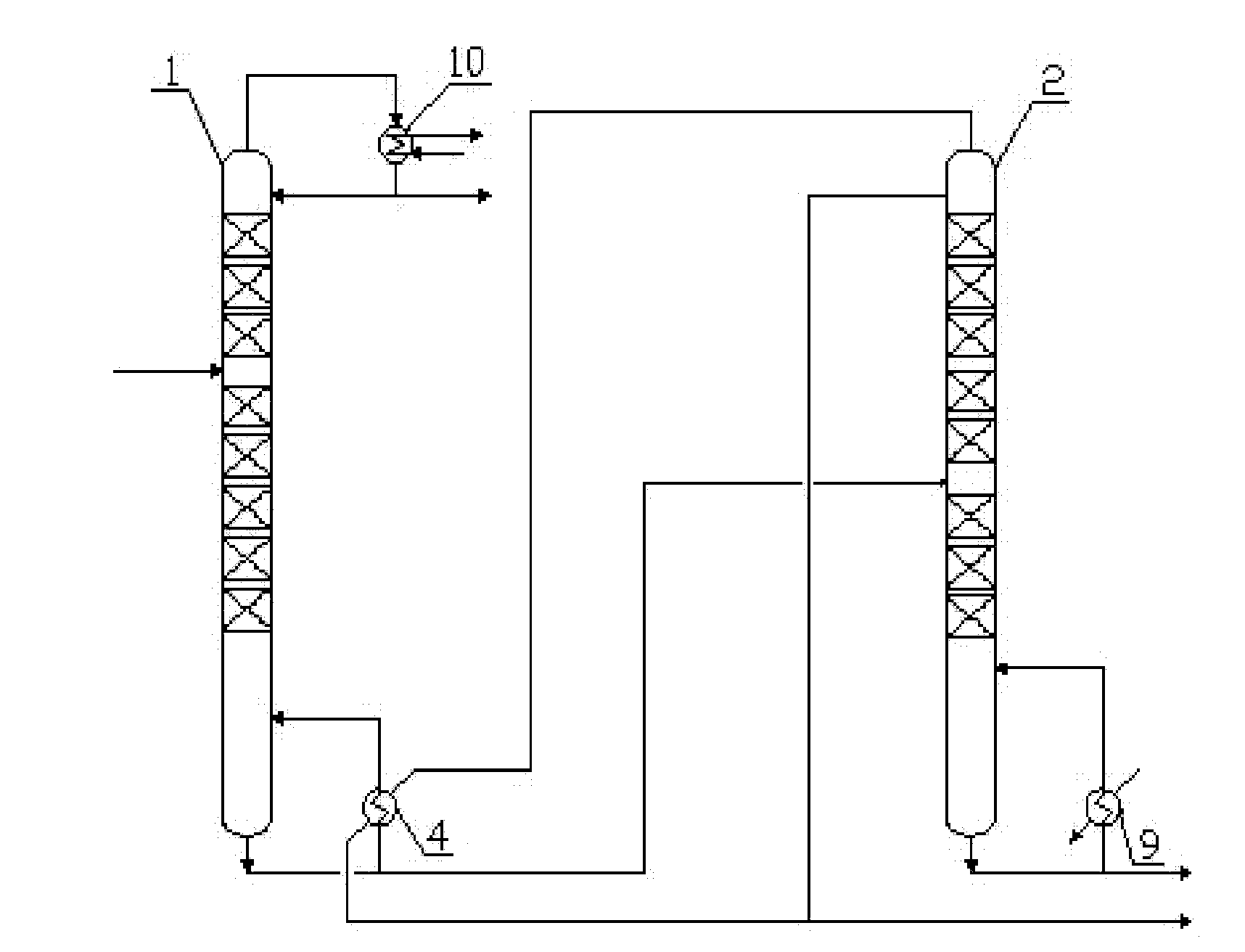

[0023] Embodiment 1: as image 3 As shown, the heat pump rectification and double-effect rectification are integrated to purify the production device and process flow of trichlorosilane, including light removal tower 1, weight removal tower 2, compressor 7, heat exchanger 14, heat exchanger II 5 and several material pipelines, etc. The middle part of the light removal tower 1 is provided with a feed inlet, and one of the discharge pipelines at the bottom of the tower returns to the inner bottom of the light removal tower 1 after being heated up through the heat exchanger 14, and the other pipe is connected with the middle part of the weight removal tower 2 as the inlet of the weight removal tower. material; the discharge pipeline at the top of the light removal tower 1 first passes through the compressor 7 to boost the temperature and then passes through the heat exchanger II 5 to exchange heat with the discharge pipeline at the bottom of the light removal tower 2, and then a ...

Embodiment 2

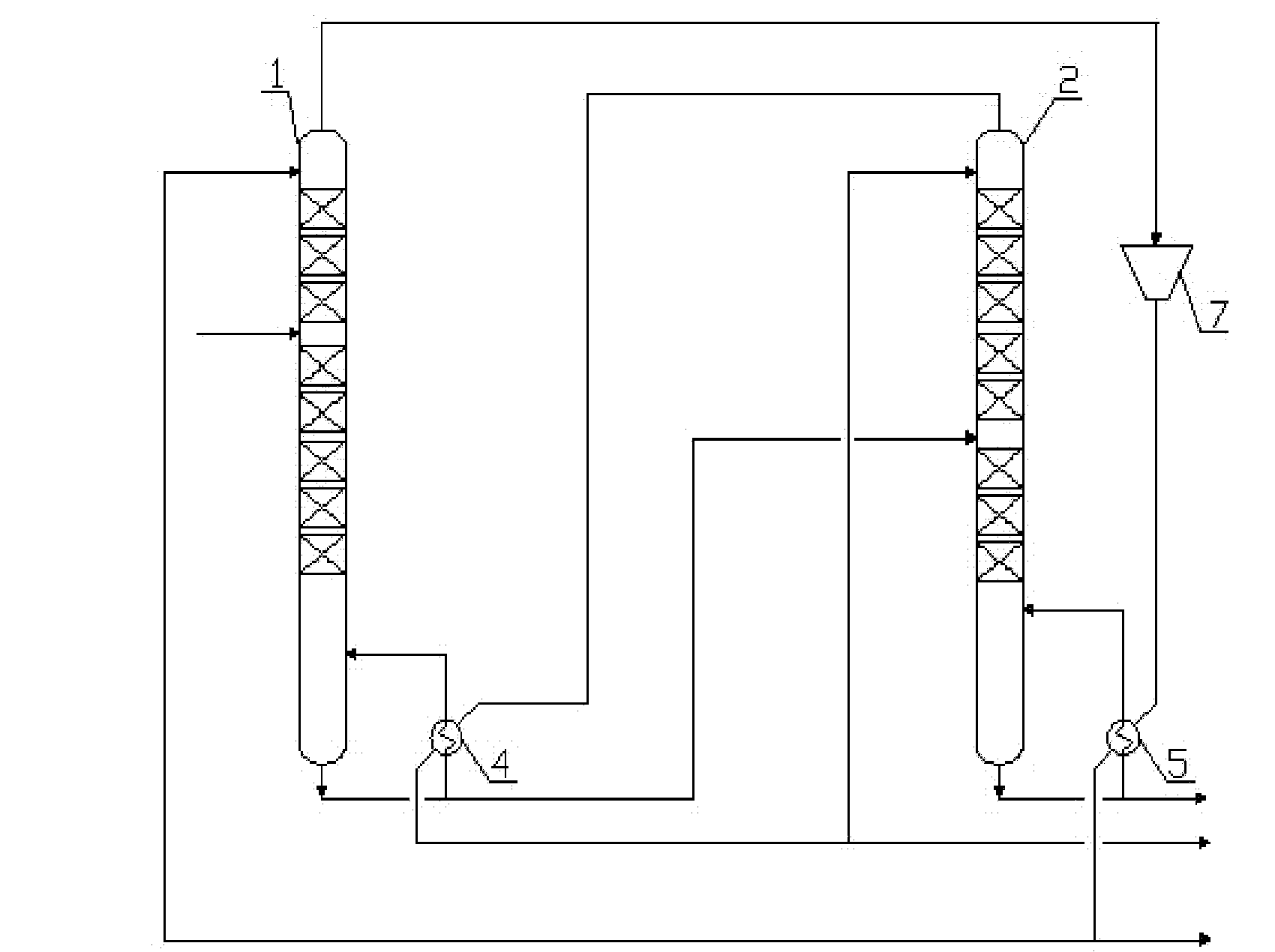

[0025] Embodiment 2: as Figure 4 As shown, the heat pump rectification and three-effect rectification are integrated to purify trichlorosilane process and its production equipment, including light removal tower 1, weight removal tower 2, secondary light removal tower 3, compressor 7, heat exchanger I 4, heat exchanger II 5, heat exchanger III 6 and several material pipelines. Among them, the pressure level of the three towers is the highest in the second light removal tower 3, followed by the second light removal tower 2, and the lowest in the light removal tower 1. The middle part of light removal tower 1 is equipped with a feed inlet, and the steam at the top of the tower is boosted by compressor 7 and then heated through heat exchanger III 6 to heat the liquid flowing out of the second light removal tower 3, and at the same time, the steam at the top of light removal tower 1 is condensed Finally, one pipeline returns to the top of the light removal tower for reflux, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com