Technology and device for removing hydrogen and nitrogen from methane rich gas and producing liquefied natural gas

A technology for liquefied natural gas and methane, which is applied in liquefaction, refrigeration and liquefaction, and the petroleum industry, etc. It can solve the problems of difficult start-up and operation of the device, high investment cost, and complicated process flow, and achieves reduced energy consumption, convenient start-up and parking, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

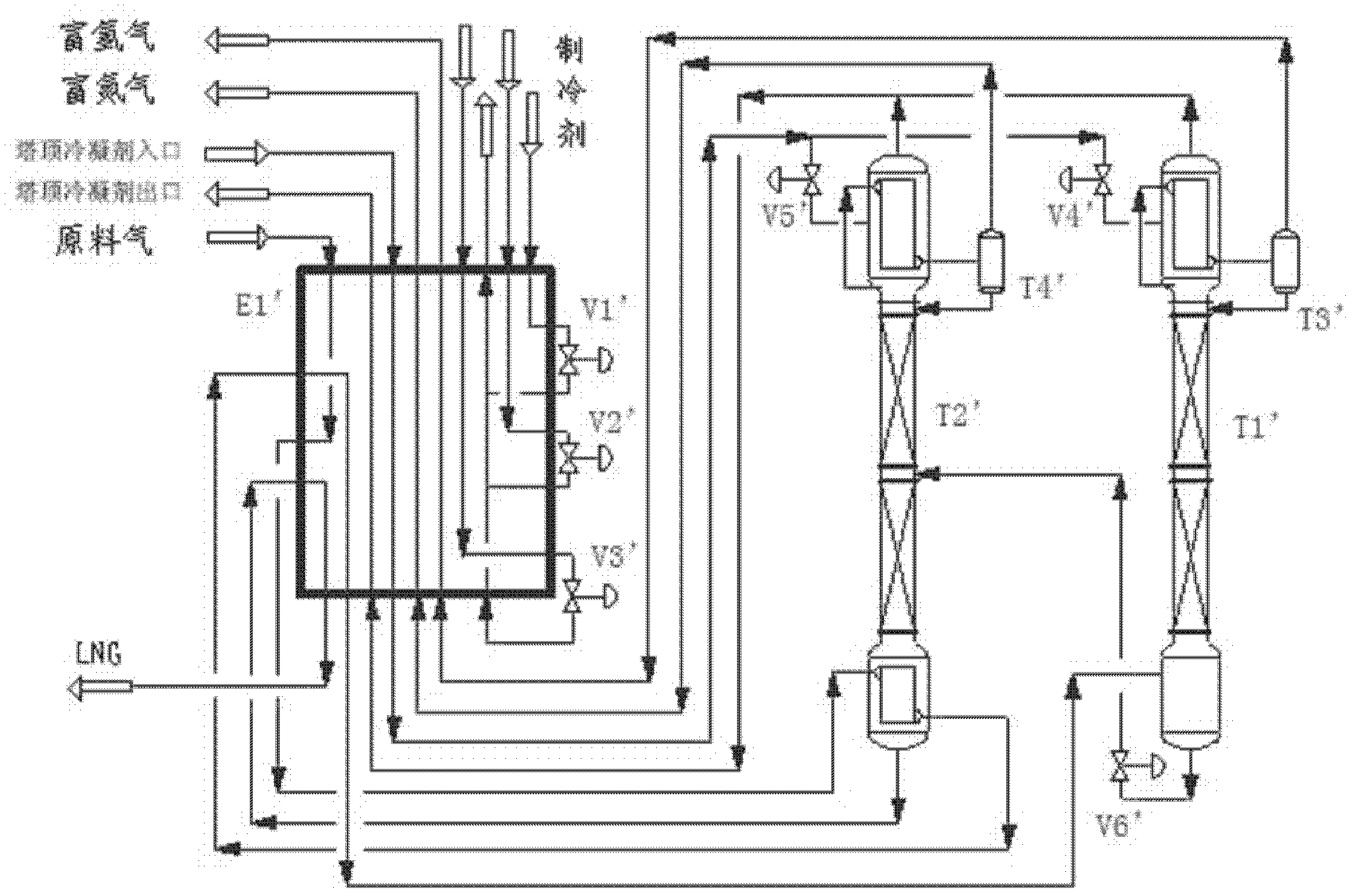

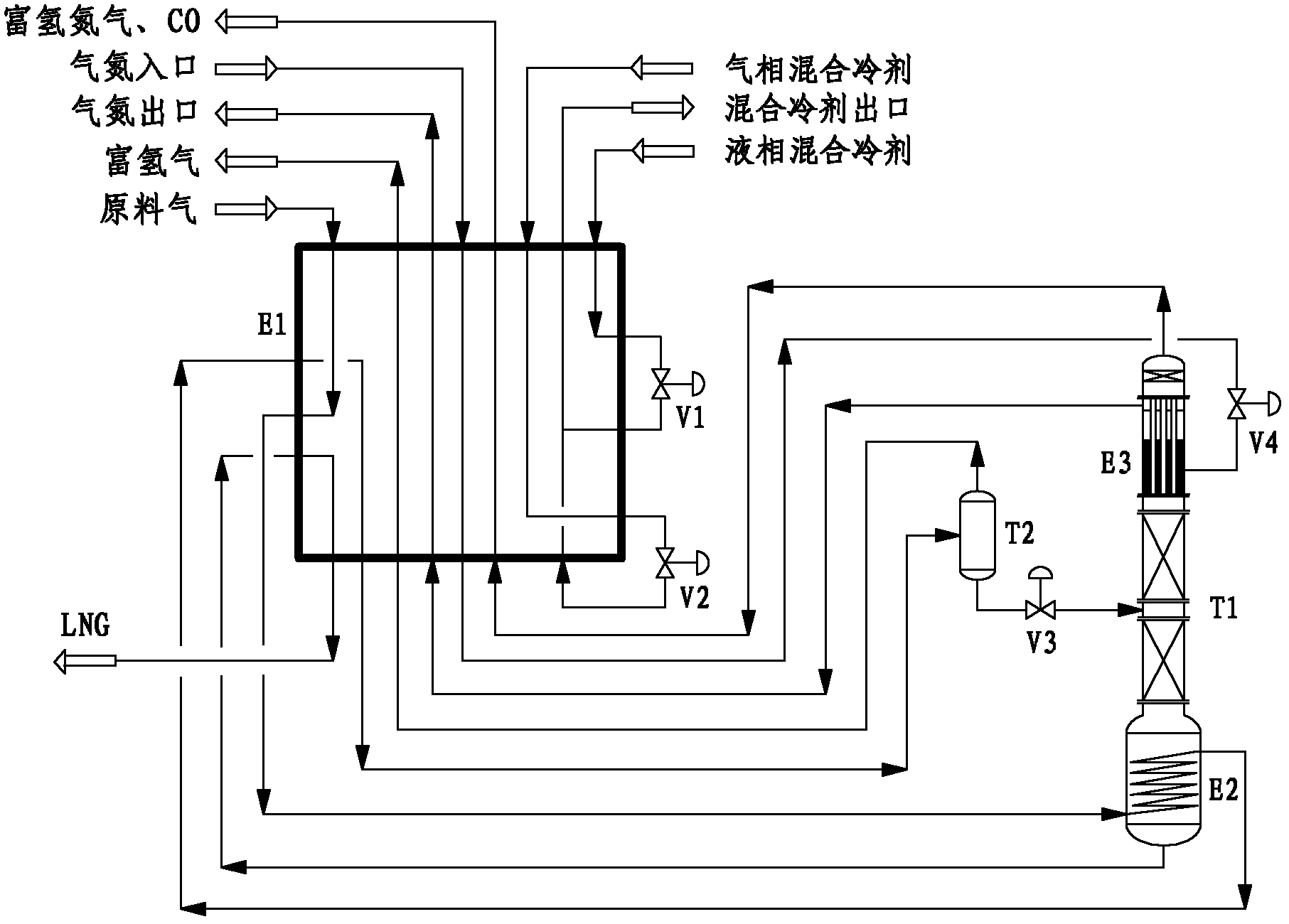

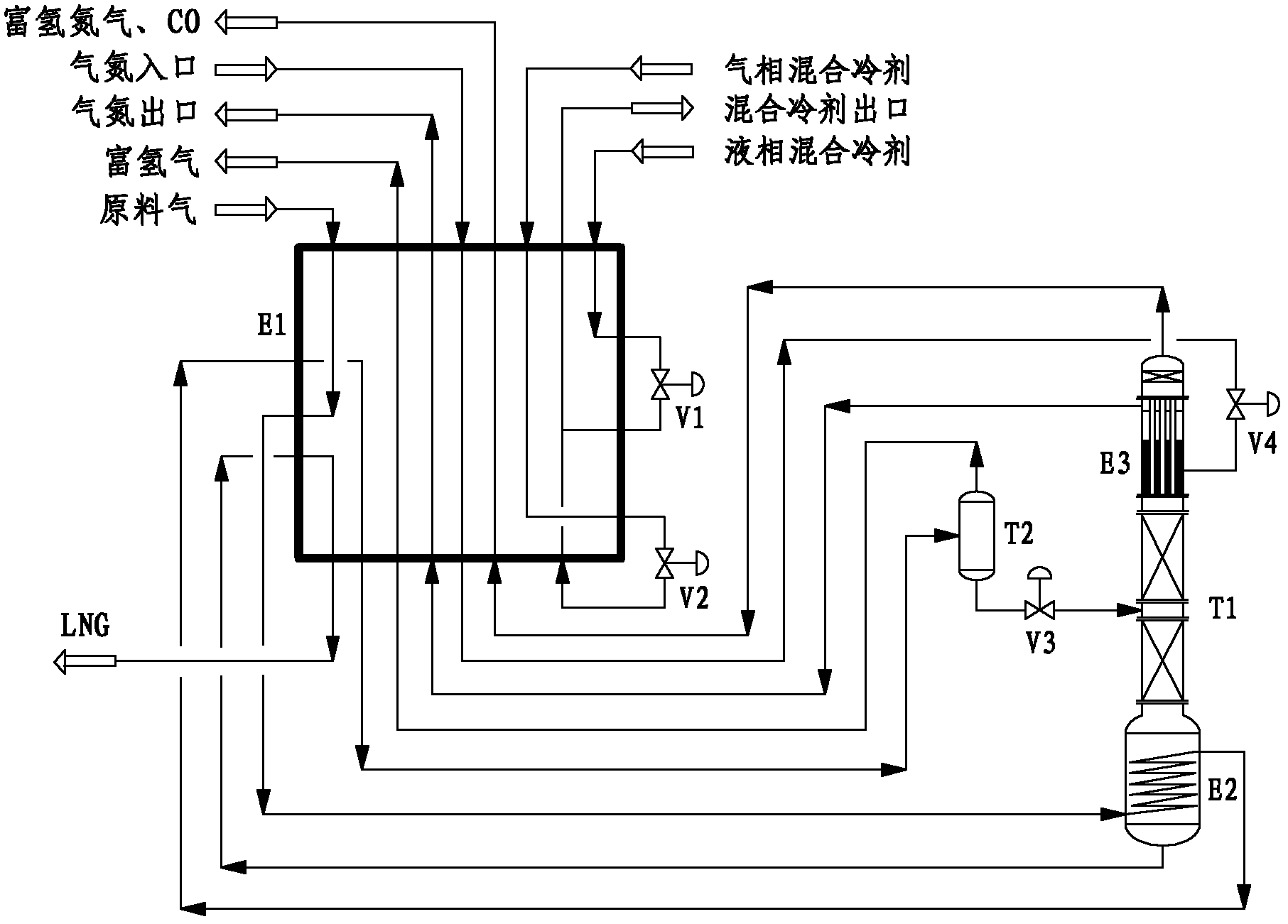

[0033] The process of the present invention includes two parts: a low-temperature liquefaction process and a rectification separation process with flash evaporation before; the low-temperature liquefaction part is completed in a cold box provided by a mixed refrigerant; Distillation process to remove hydrogen, nitrogen and carbon monoxide; the methane-rich mixed gas containing hydrogen, nitrogen and carbon monoxide passes through the cold box, rectification tower bottom reboiler and cold box in turn to liquefy the methane component, and then enters the flash distillation separation system Hydrogen, nitrogen, and carbon monoxide are removed in the process, and the hydrogen content in the obtained LNG product is ≤2000ppm, the nitrogen content is ≤4%, and the carbon monoxide content is ≤6%.

[0034] The low-temperature liquefaction part is completed in the cold box, and the cooling capacity of the cold box is mainly provided by the mixed refrigerant. Refer to attached figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com