Patents

Literature

86results about How to "Easy to drive and park" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

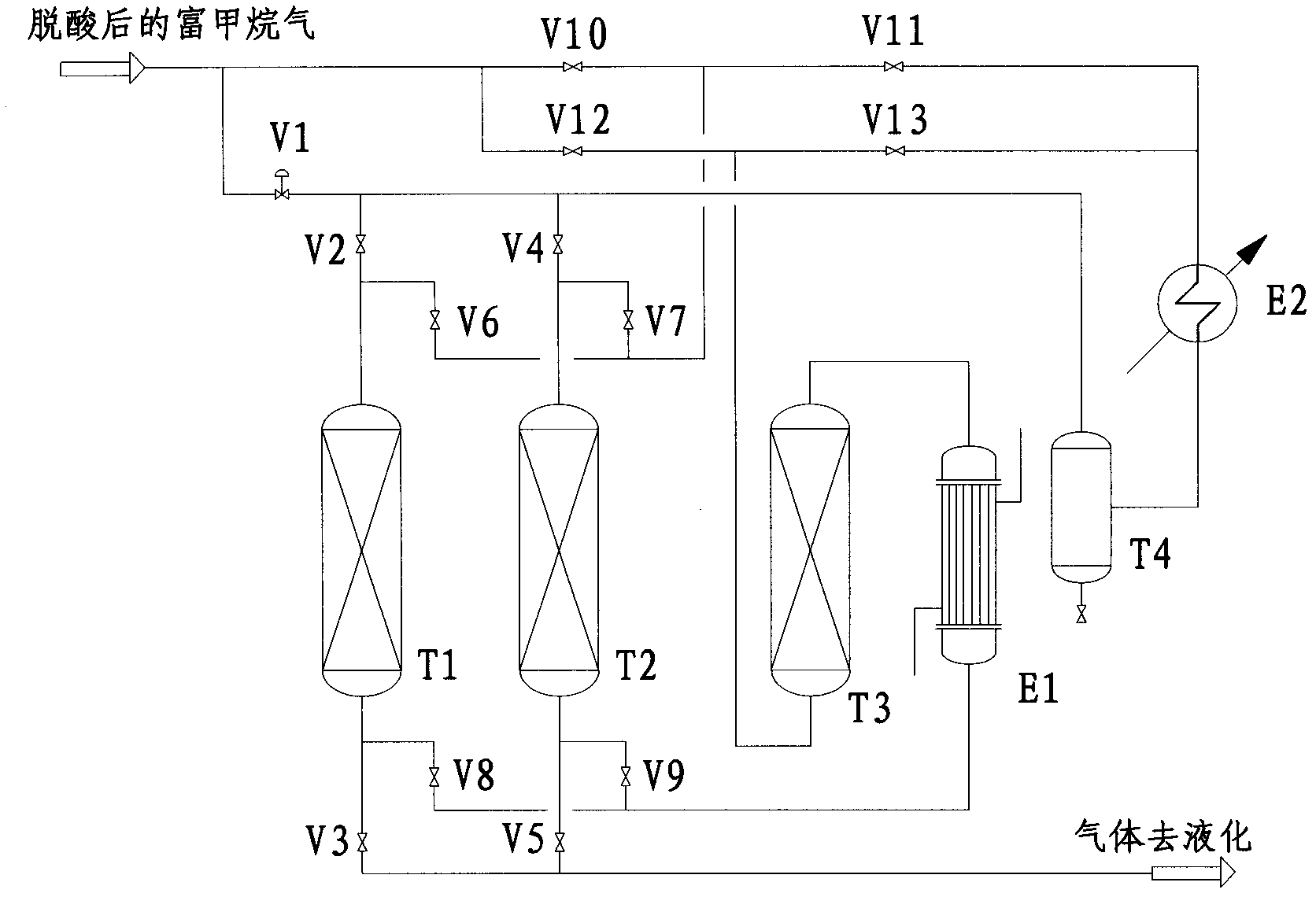

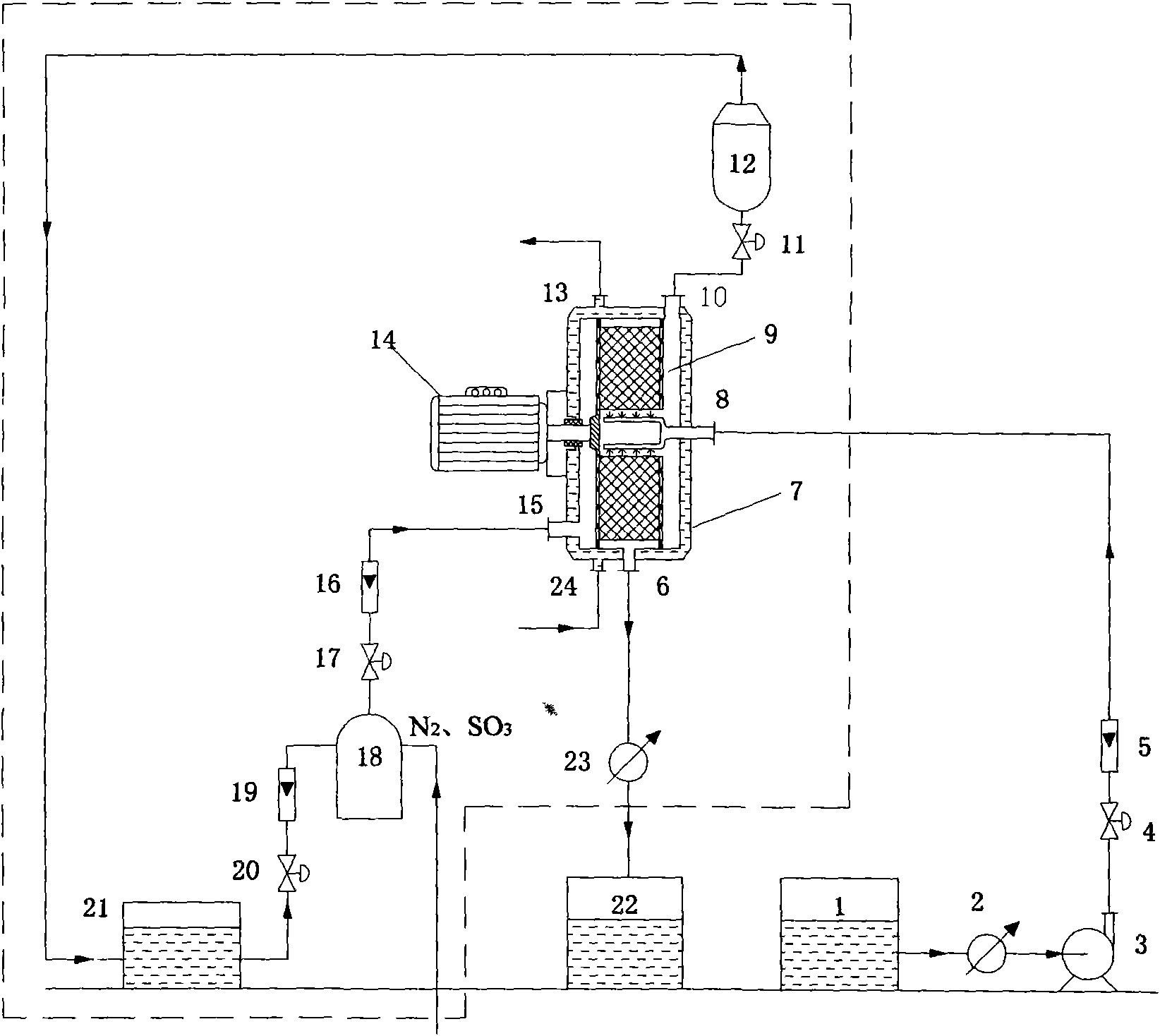

Pyrolysis device and method for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis

ActiveCN102718383ASolve the difficulty of large-scale collectionSolve the inconvenience of storage and transportationSludge treatment by pyrolysisByproduct vaporizationSlagChar

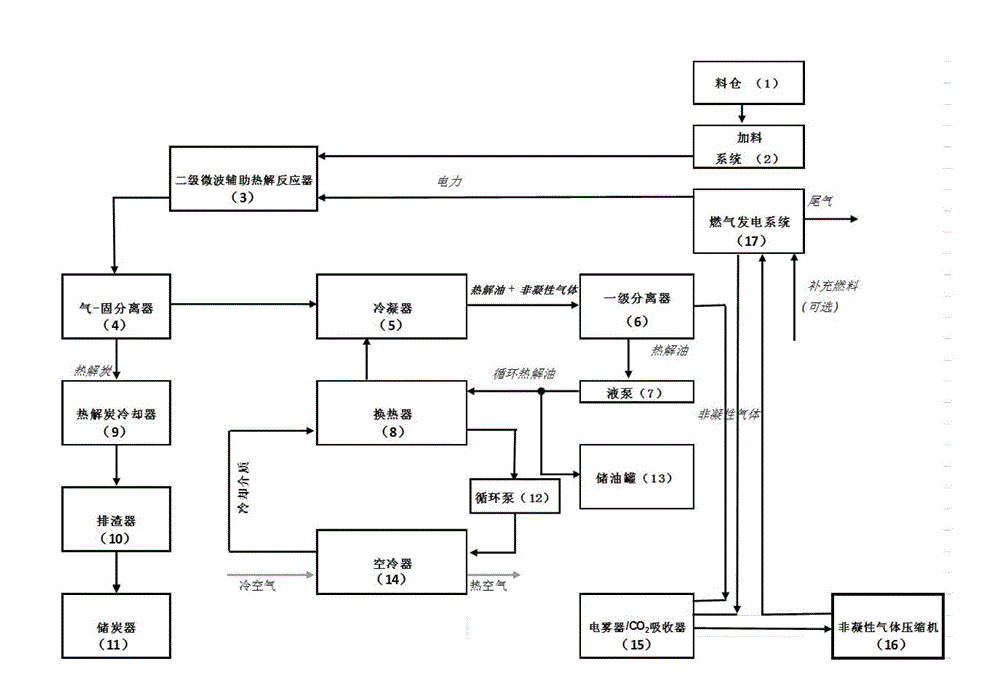

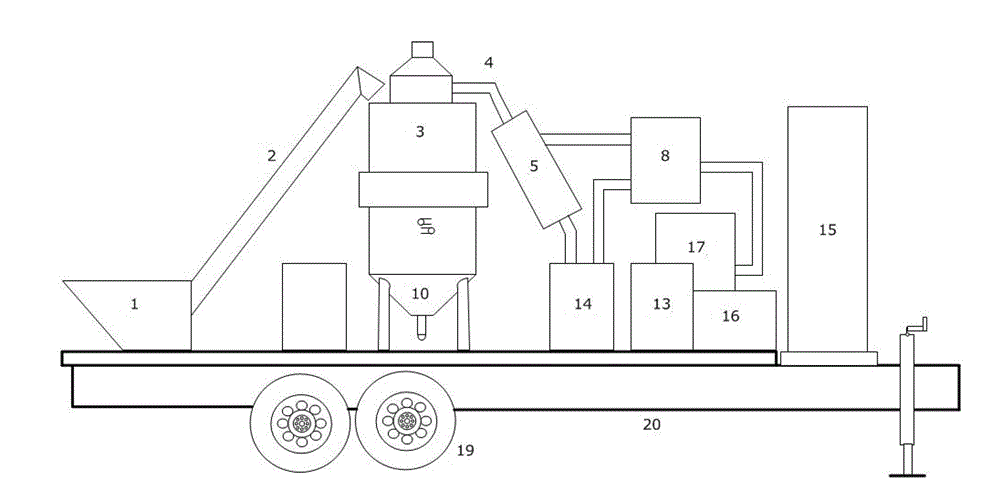

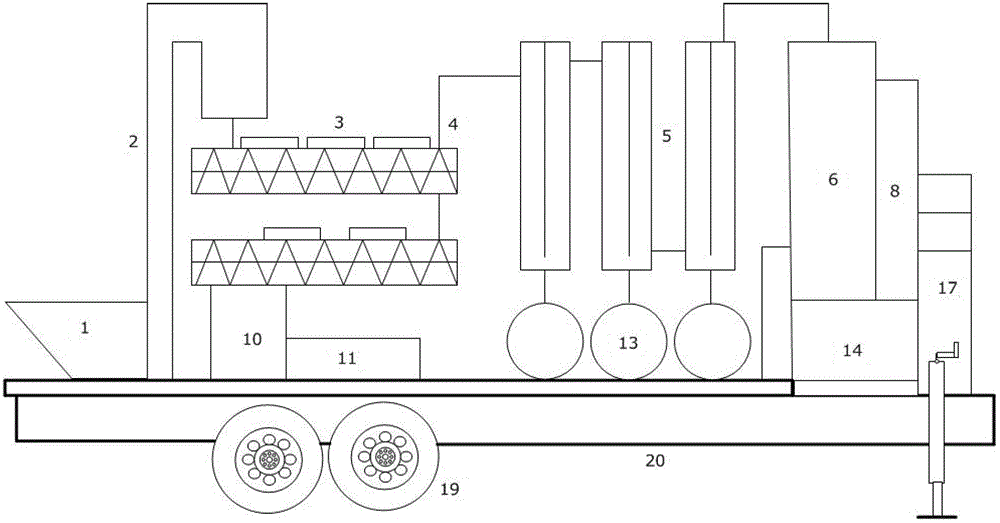

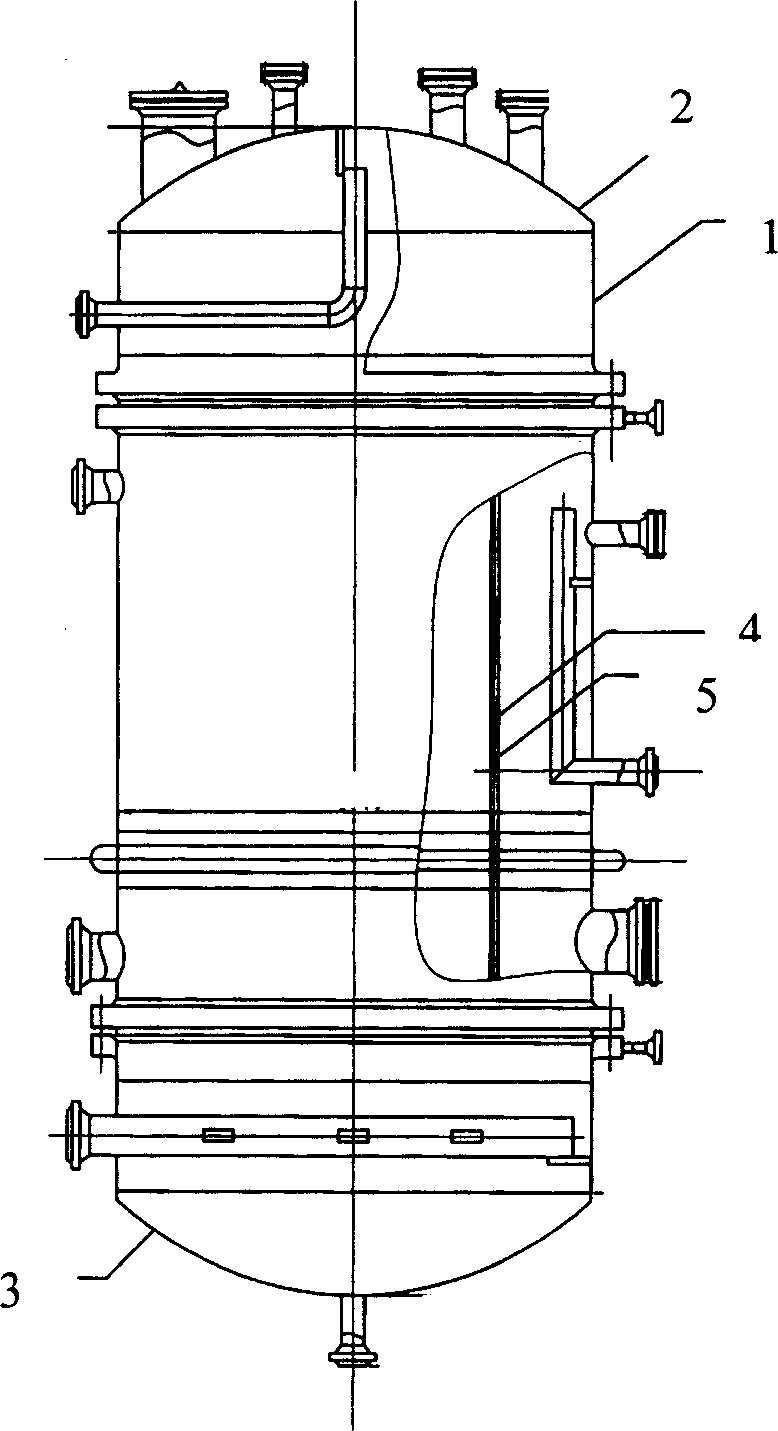

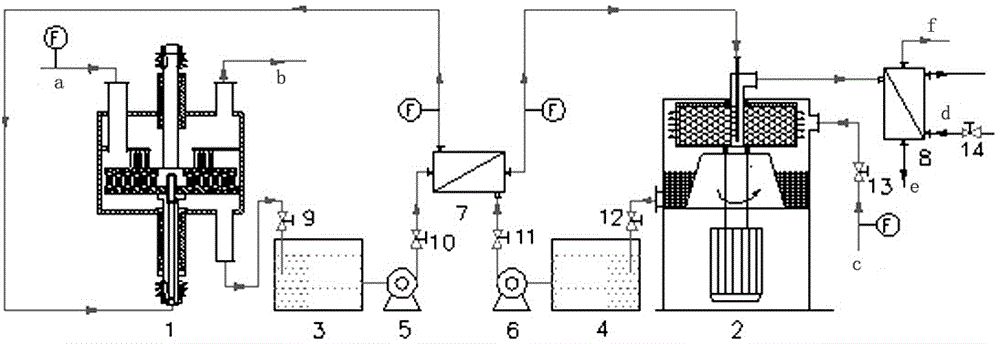

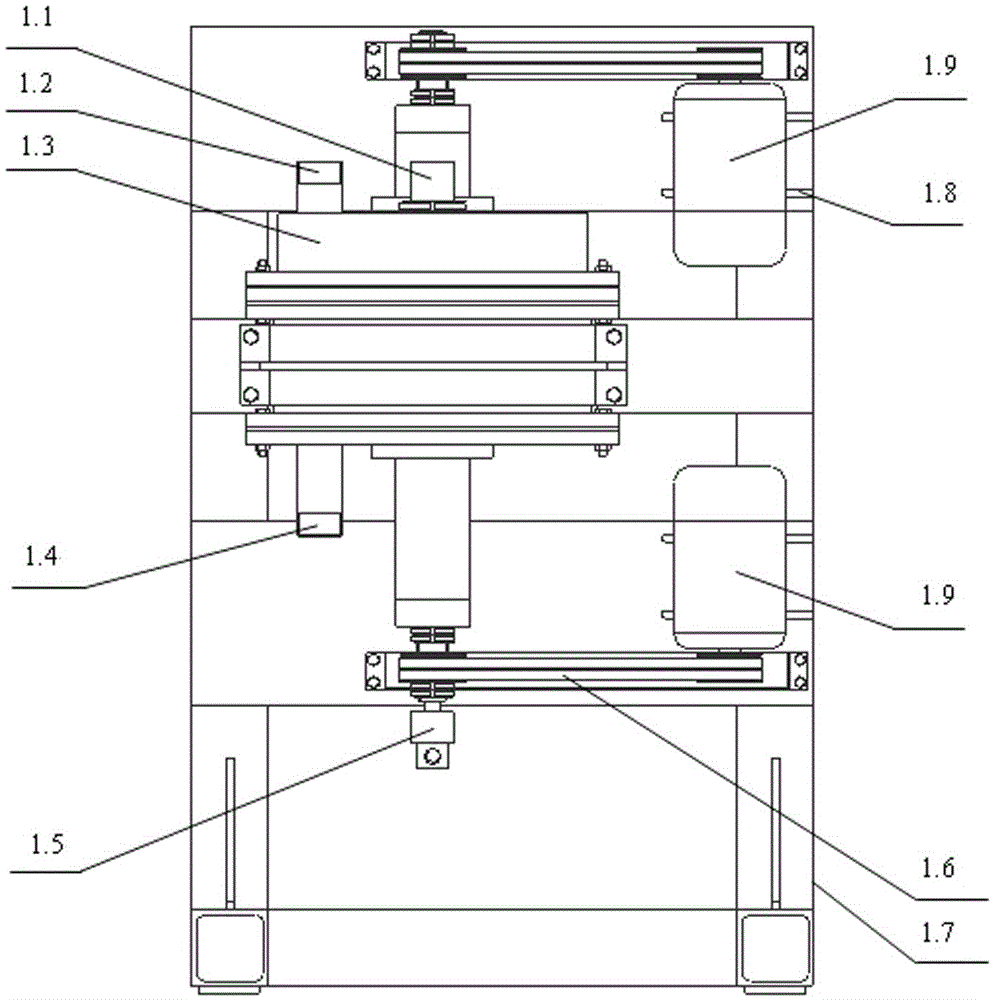

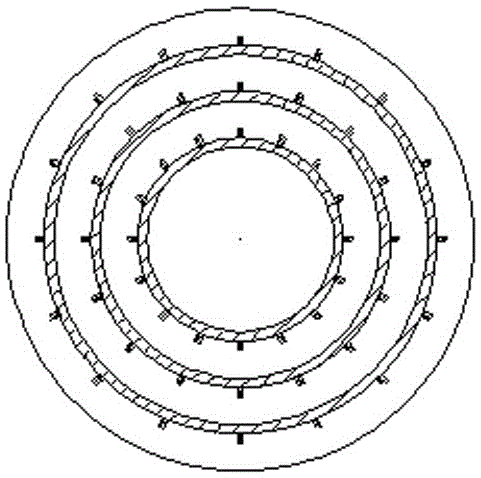

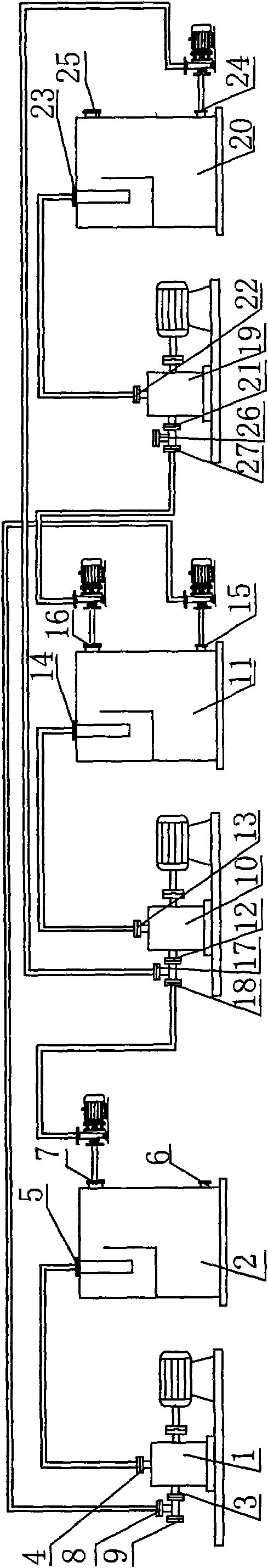

The invention discloses a pyrolysis device for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis. The device comprises a microwave-assisted pyrolysis reactor, a solid outlet of the reactor is connected with an inlet of a pyrolytic carbon cooler, an outlet of the pyrolytic carbon cooler is connected with a slag storer through a deslagging machine, a gas outlet of the reactor is connected with an inlet of a condenser through a pipeline, the condenser is provided with a gas-liquid separator, a gas outlet of the condenser is connected with a gas purifier, an outlet of the gas purifier is connected with a gas compressor, a liquid outlet of the condenser is connected with a liquid circulating pump, then one branch of the condenser is connected with an oil storage tank, and the other branch of the condenser is connected back to the condenser through a cooling medium circulating system. The invention further discloses a method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis. By the pyrolysis device and the method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis, various low-grade carbon-containing resources can be collected, stored and continuously produced at an economic scale.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

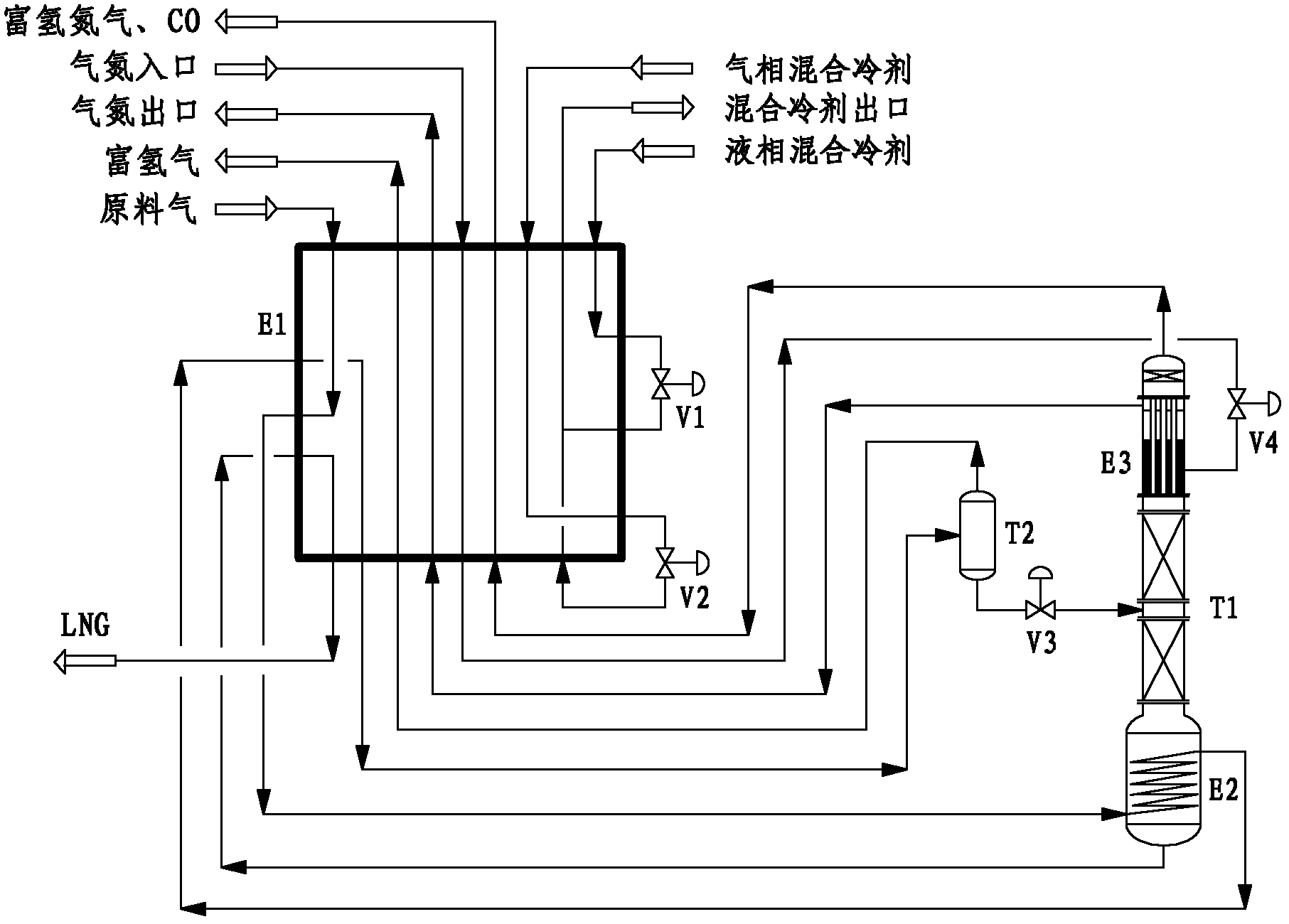

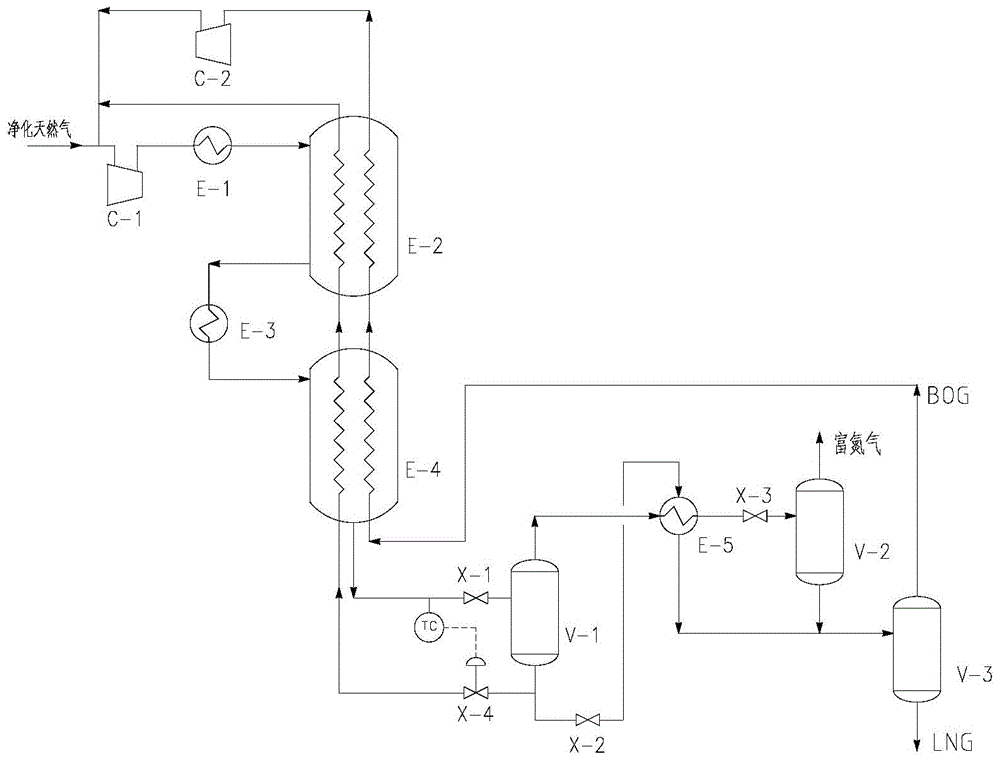

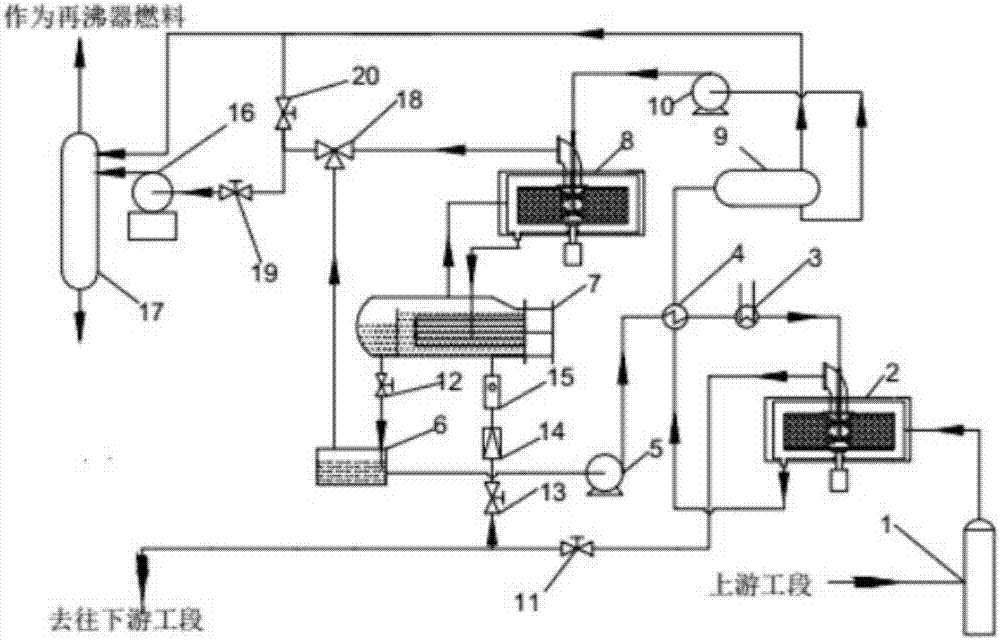

Technology and device for removing hydrogen and nitrogen from methane rich gas and producing liquefied natural gas

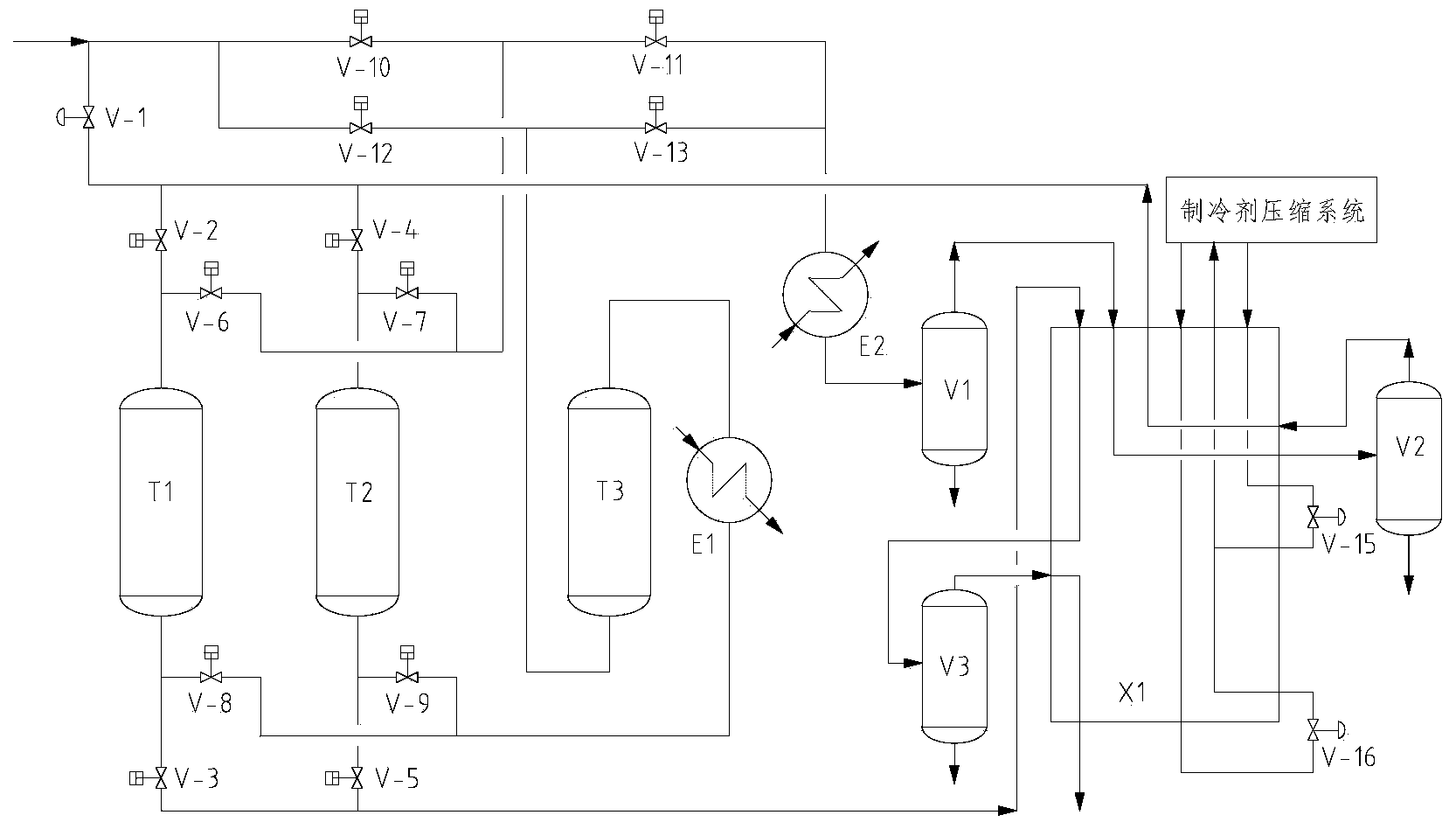

ActiveCN102620521AReduce energy consumptionReduce loadSolidificationLiquefactionNitrogen gasMixed gas

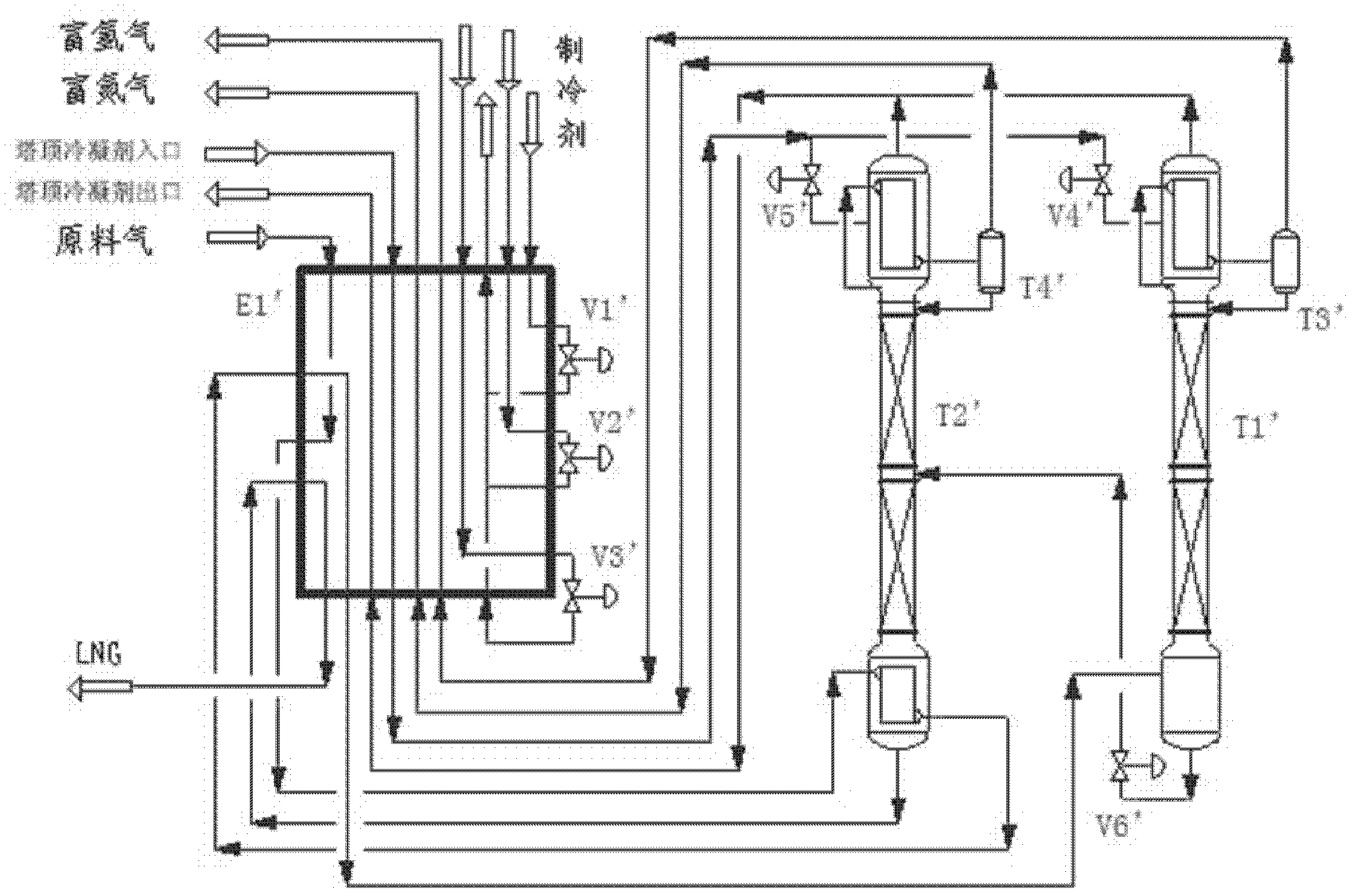

The invention discloses a technology and a device for removing hydrogen, nitrogen and carbon monoxide from methane rich gas and producing liquefied natural gas (LNG). The technology comprises two parts, namely low-temperature liquefaction and rectification separation after flash evaporation; the low-temperature liquefaction part is finished in a cold box by using cold flow supplied by a mixed refrigerant; in the rectification separation part after flash evaporation, the hydrogen, the nitrogen and the carbon monoxide are removed by adopting a flash evaporation and rectification flow; and after the methane rich mixed gas containing the hydrogen and the nitrogen sequentially passes through the cold box, a re-boiler at the bottom of a rectification tower and the cold box and the methane components are liquefied, the methane rich mixed gas enters a rectification separation system, and the hydrogen, the nitrogen and the carbon monoxide are removed, wherein the obtained LNG product contains less than or equal to 2,000ppm of hydrogen, less than or equal to 4 percent of nitrogen and less than or equal to 6 percent of carbon monoxide. By the natural gas liquefaction technology for the methane rich gas containing the hydrogen, the nitrogen and the carbon monoxide, the hydrogen, the nitrogen and the carbon monoxide are removed, and the LNG is obtained at the same time; the technology is advanced in process route; and compared with the conventional technology, the technology has the advantage that the investment cost of equipment and the energy consumption of the system are remarkably reduced.

Owner:XINDI ENERGY ENG TECH +1

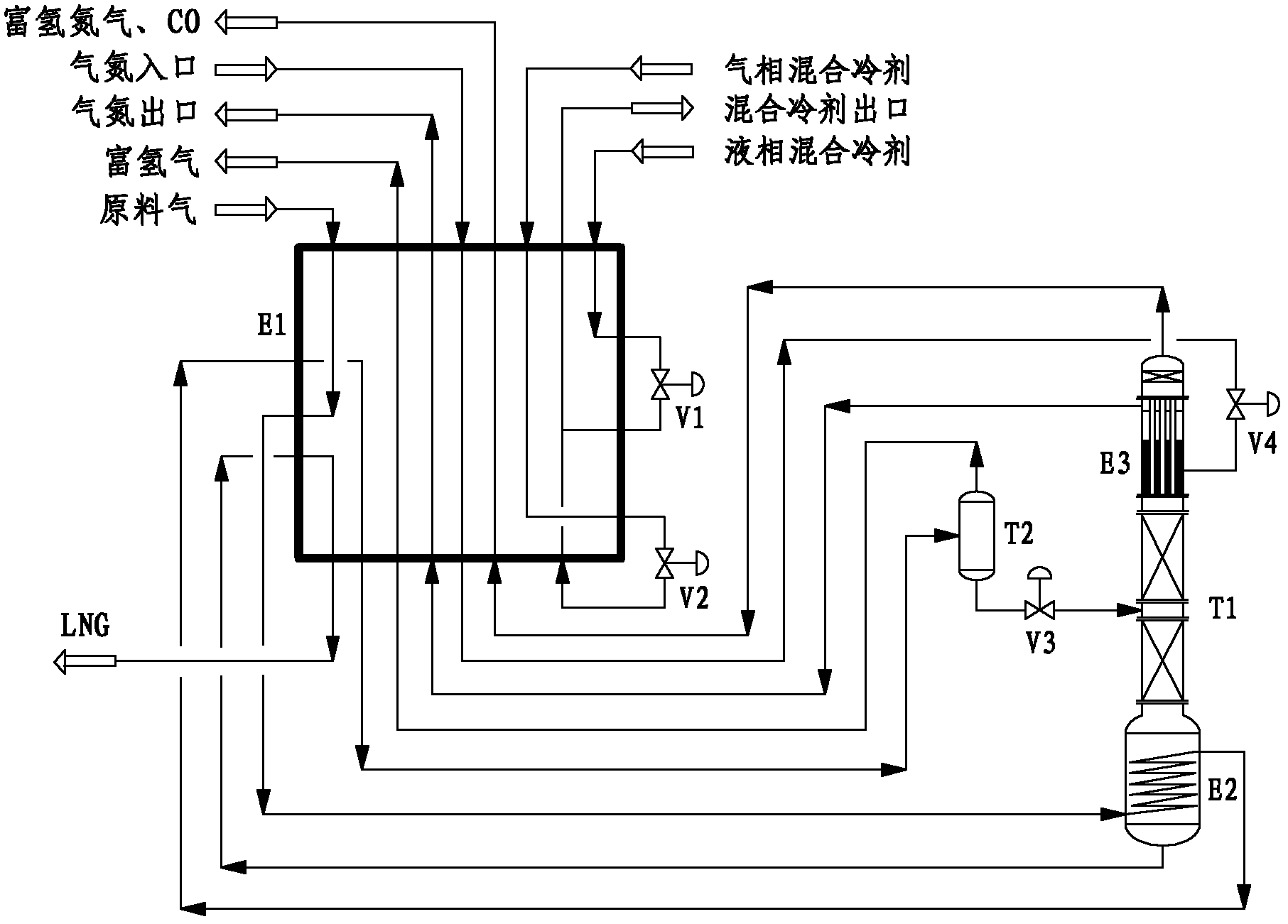

Dehydration and de-heavy hydrocarbon technology for production of liquefied natural gas from methane-rich mixed gas

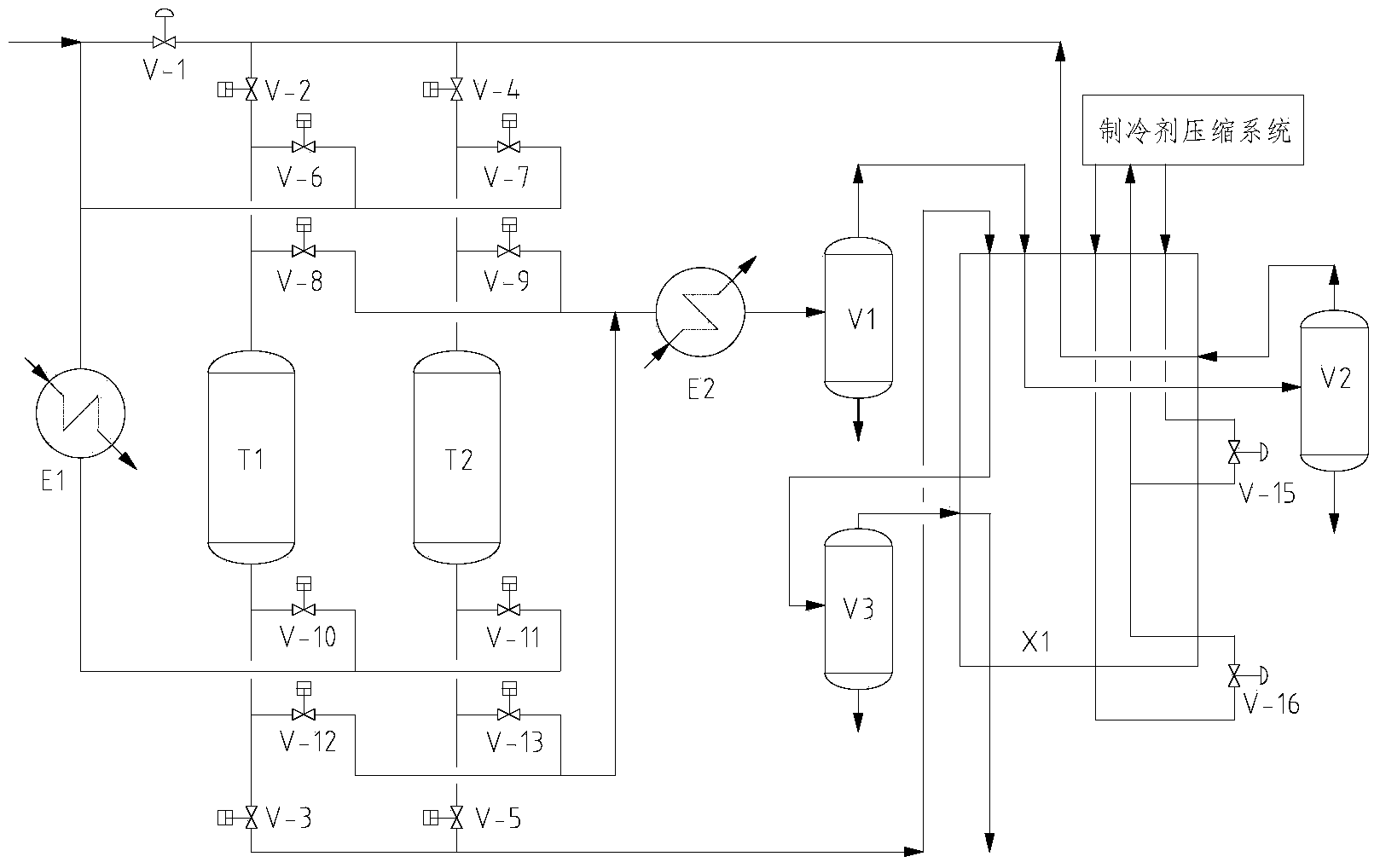

ActiveCN103031168ALow investment costReduce energy consumptionSolidificationLiquefactionSorbentMoisture

The invention relates to a dehydration and de-heavy hydrocarbon technology for production of liquefied natural gas from a methane-rich mixed gas. The technology is characterized in that: after a deacidification treatment, the methane-rich mixed gas falls into two parts, one part enters a drying process, and the other part enters a regeneration process. The methane-rich mixed gas entering the drying process undergoes a drying treatment to remove moisture and heavy hydrocarbons from the gas simultaneously in a drying tower adsorbent composite bed, the moisture is removed till an atmospheric dew point lower than or equal to -76DEG C, and the heavy hydrocarbons above C6 are removed till a content of less than or equal to 217ppm. The methane-rich mixed gas entering the regeneration process serves as a regeneration gas of a drying tower regeneration process, and when the regeneration process is completed, the regeneration gas part returns to the process gas of the system. The invention can achieve a good purification effect, and compared with conventional process routes, the equipment investment and the later stage system energy consumption are reduced, the raw material utilization rate is improved, and the operation indexes of each part become clearer and are easier to control. The invention also relates to equipment used by the technology.

Owner:XINDI ENERGY ENG TECH

Method for producing coal gas by staged gasification of pulverized coal

InactiveCN102277200AAchieve desulfurizationAdaptableGranular/pulverulent flues gasificationCycloneSuperheated steam

The invention relates to a method for producing coal gas by staged gasification of pulverized coal. The steps are as follows: the pulverized coal fed into the furnace is mixed with rapidly fluidized high-temperature particles and gasification gas in a fluidized bed, and the pulverized coal of small and medium particles flows upwards. Pyrolysis at a high temperature of 900-1000°C, enter the cyclone separator through the gas-solid mixing pipeline for separation, the medium particles return to the lower part of the main body of the circulating fluidized bed through the first-stage feeder, and the gas carries small particles out of the upper port of the cyclone separator, and passes through the high temperature The gas pipeline enters the superheated steam heat exchanger for heat exchange and separation, and then enters the circulation separator, and the gas is discharged from the gas outlet for users. The invention has the characteristics of integrated circulating fluidized bed and entrained flow bed, high gasification intensity, flexible adjustment of production load, stable and reliable operation, high operation rate, reduced gas production cost, and no phenolic water pollution.

Owner:舒克孝

Flue gas desulfurization and dust removal technology and integrated apparatus applicable to ship

ActiveCN104492210AEnhanced mass transferIncrease capture rateCombination devicesGas treatmentFlue gasDust control

The invention belongs to the technology of flue gas desulfurization and dust removal, and in particular relates to a flue gas desulfurization and dust removal technology and an integrated device applicable to ships, and solves the problems in the flue gas desulphurization technology and equipment for ships of the prior art. The flue gas desulfurization and dust removal apparatus includes a multi-stage cross flow rotating packed bed, a barren liquor tank, a barren liquor circulating pump and an aeration tank. The flue gas desulfurization process includes an open seawater method flue gas desulphurization technology and a enclosed alkali method flue gas desulfurization technology. Two technologies can be combined with the rotating packed bed, and the invention has the advantages of high desulfurization efficiency, low energy consumption, simple process, low investment and operation cost, stable operation, convenient startup and shutdown, and integrated desulphurization and dust removal.

Owner:ZHONGBEI UNIV

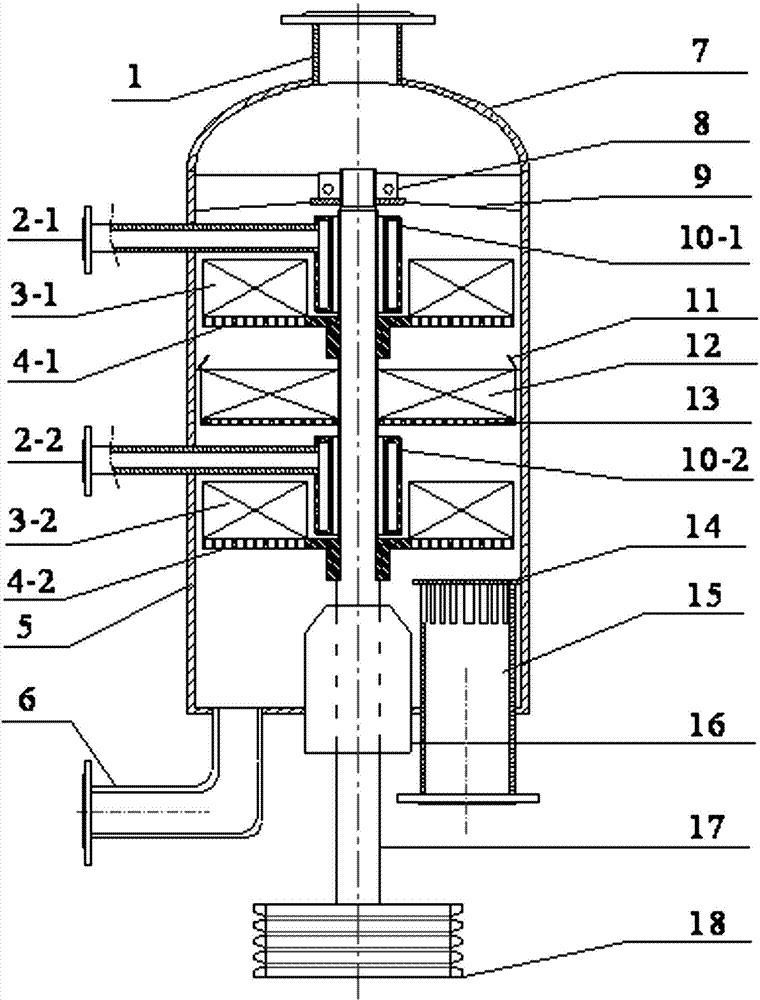

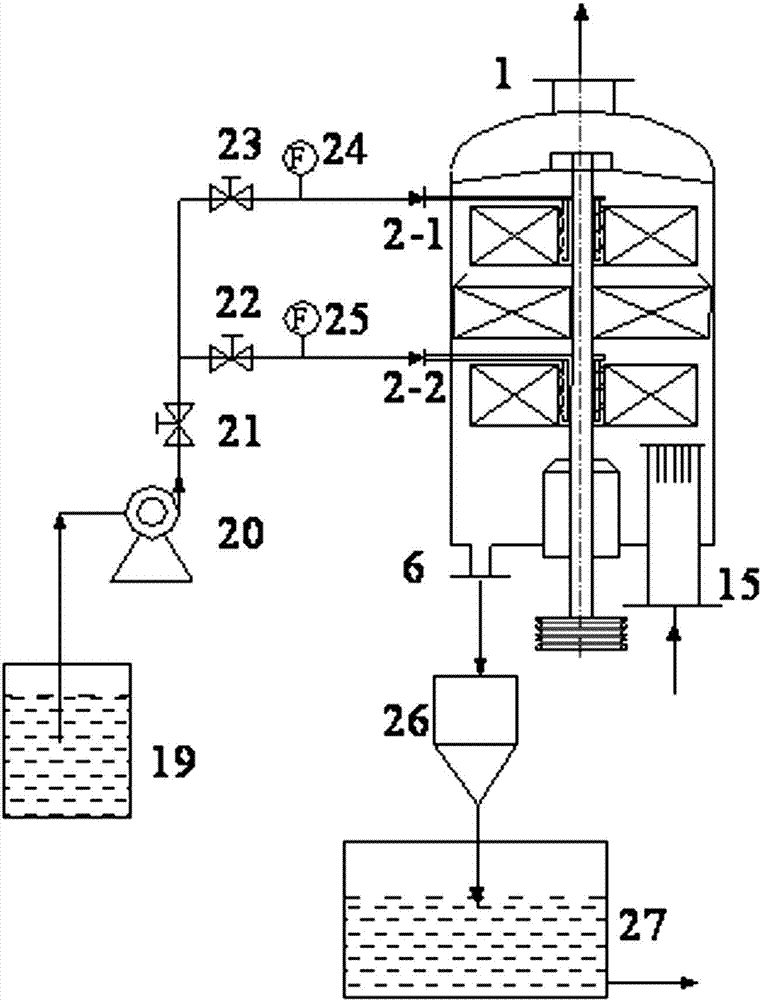

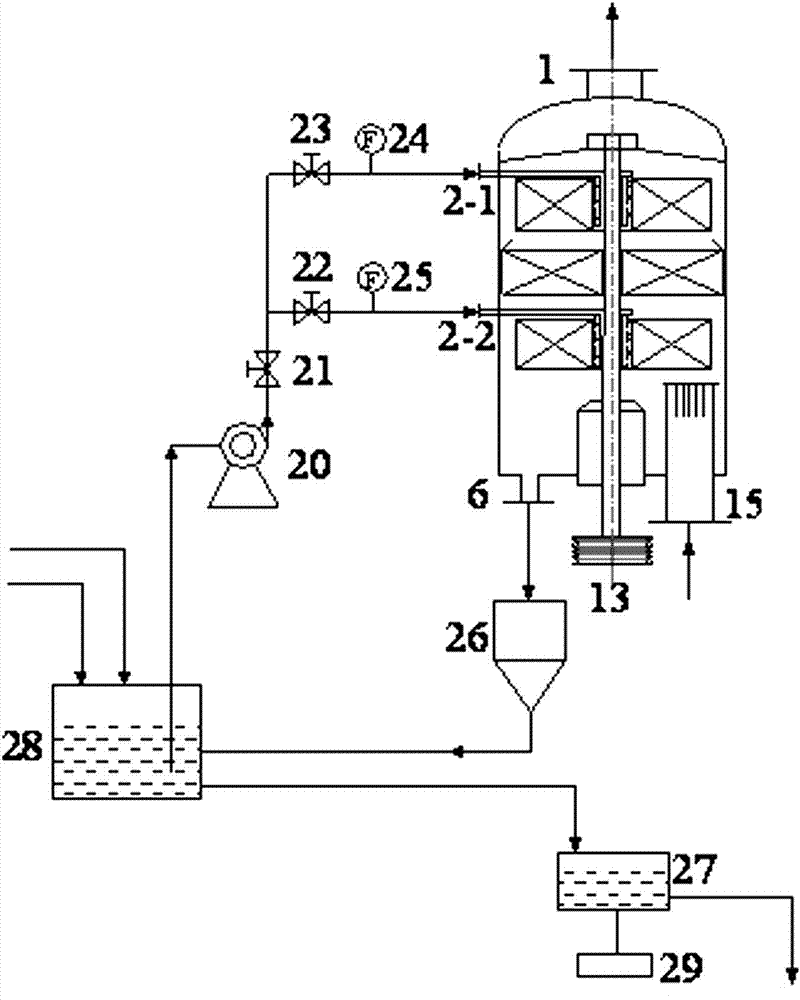

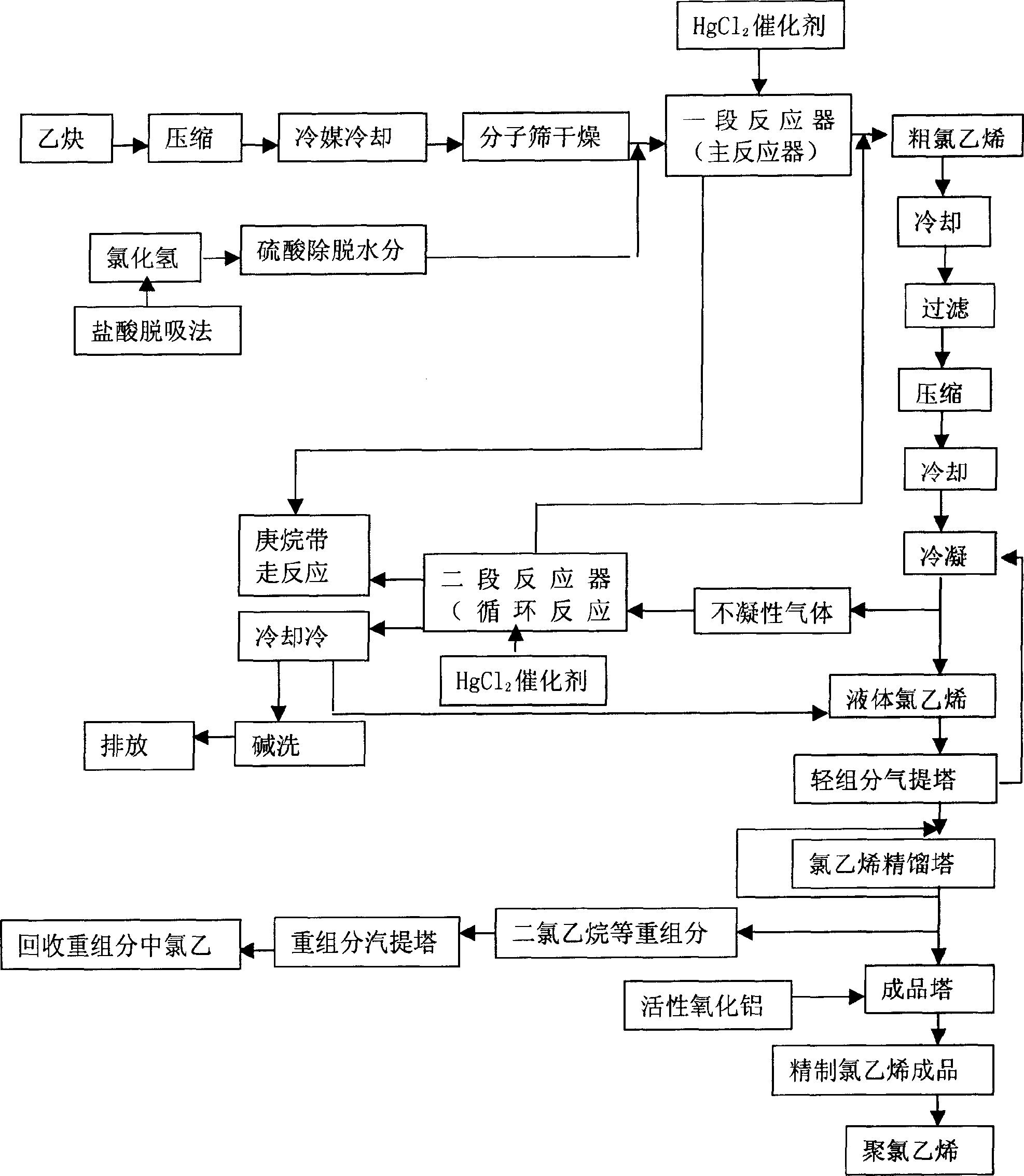

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

Heavy hydrocarbon removing process and device of natural gas

The invention relates to a heavy hydrocarbon removing process of natural gas, i.e. a heavy hydrocarbon removing process by adopting the combination of an adsorbent and low-temperature separation. According to the heavy hydrocarbon removing process disclosed by the invention, most heavy hydrocarbons in the natural gas are removed by an adsorbent bed layer of a heavy hydrocarbon removing tower, then the natural gas enters a cold box for further low-temperature separation to remove residual heavy hydrocarbons, and C6 and C6<+> heavy hydrocarbon components in the natural gas after treating are removed until the soluble degree of LNG (Liquefied Natural Gas); regeneration gas used for regeneration of the heavy hydrocarbon removing tower is taken from process gas, and is regenerated by sequentially pre-cooling, partial heavy hydrocarbon separation and low-temperature heavy hydrocarbon separation in the cold box, so that excessive heavy hydrocarbons are not carried when the regeneration gas is returned to the process gas, the load of the heavy hydrocarbon removing tower and the device investment cost are lowered, and the source and destination problems of the regeneration gas are solved. In addition, with the adoption of the heavy hydrocarbon removing process, the purification effect is good, and an operation index of each part is clearer and is easily controlled. The invention also relates to a device used by the process.

Owner:XINDI ENERGY ENG TECH

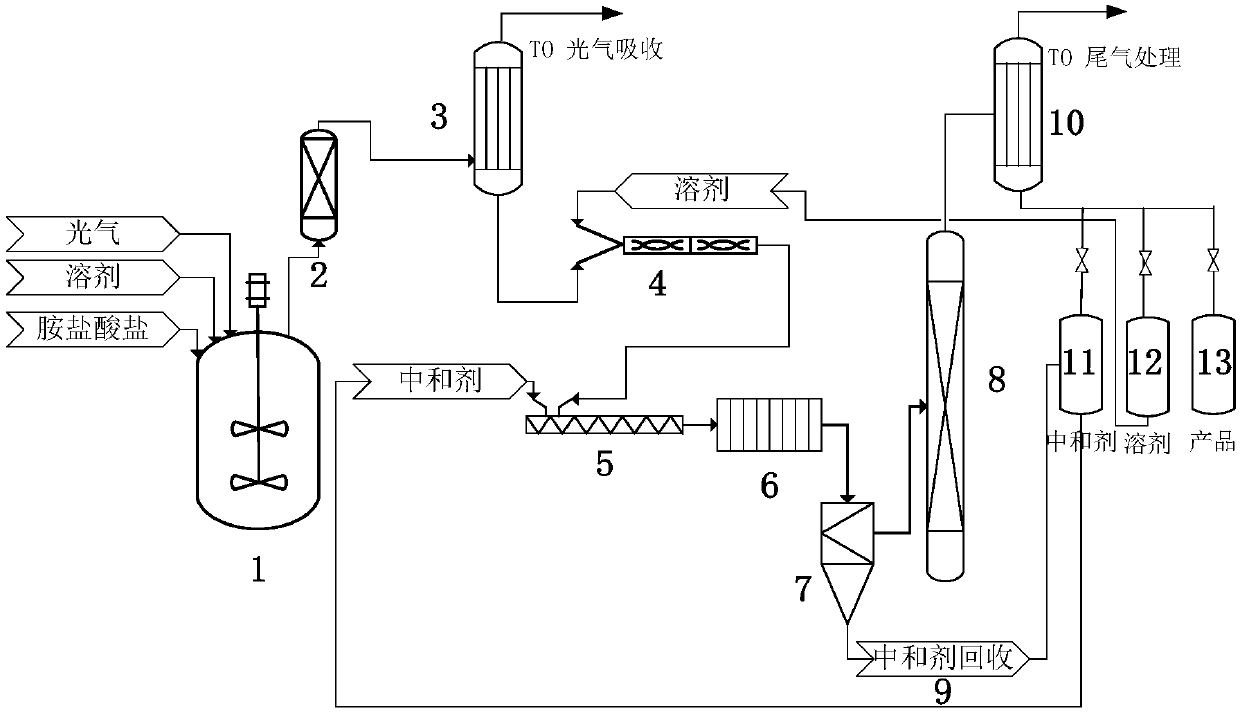

Method for preparing isocyanate monomer

ActiveCN104945283AIncrease profitIncrease contact areaIsocyanic acid derivatives preparationOrganic compound preparationGas liquid reactionMixing effect

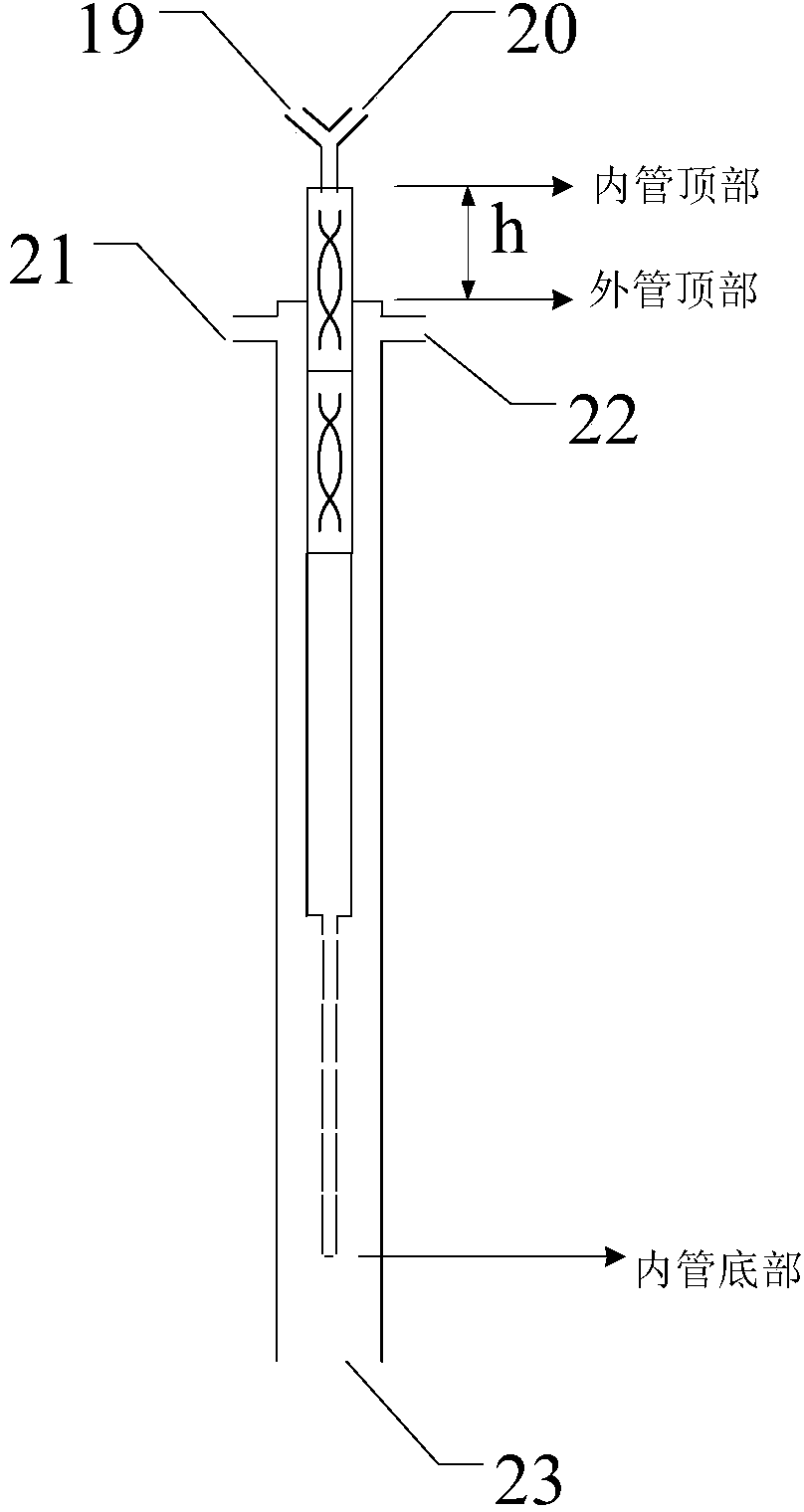

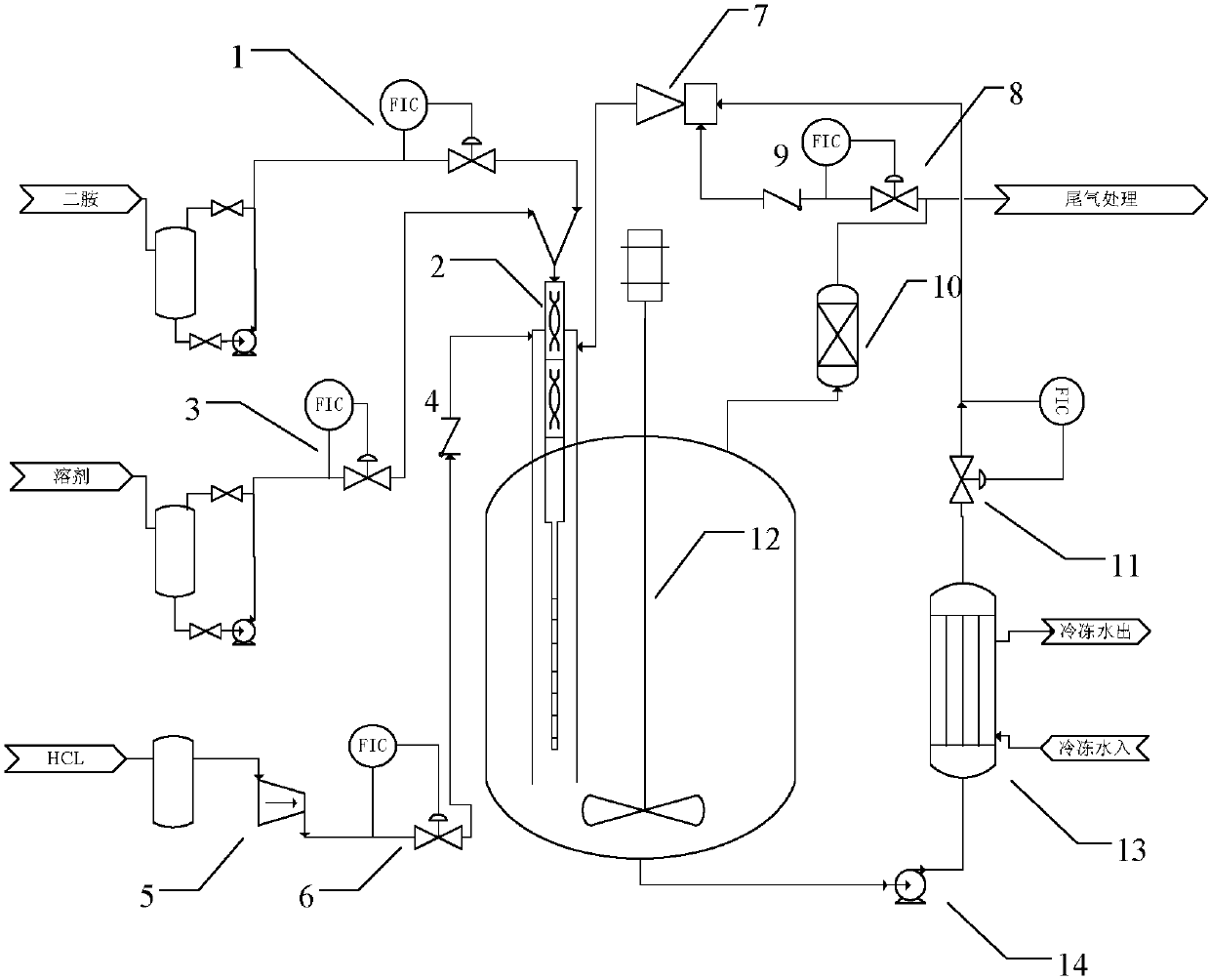

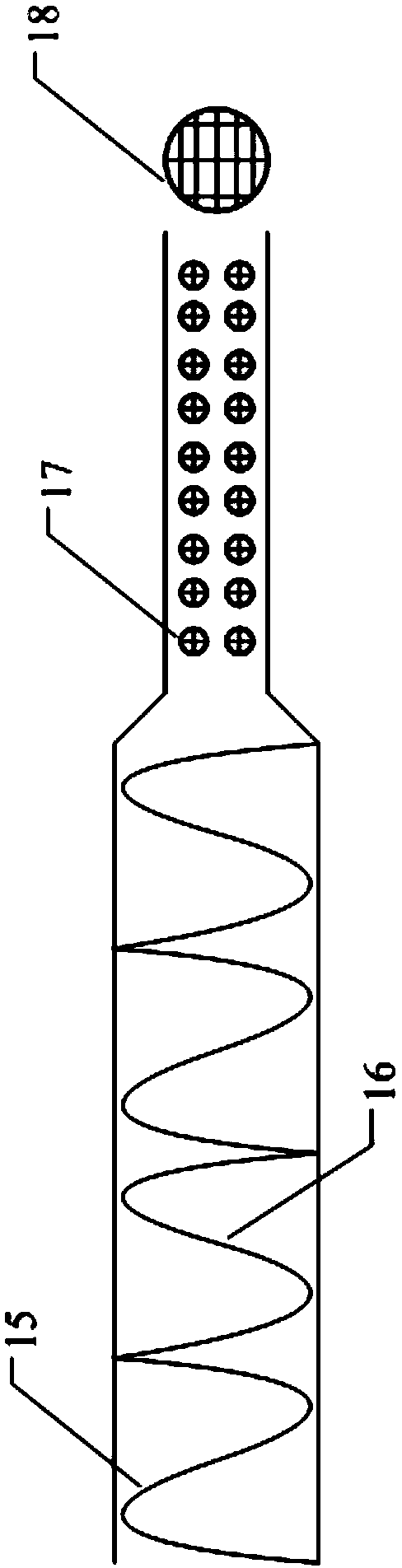

The invention discloses a method for preparing an isocyanate monomer. The method comprises the following steps: adding a first batch of solvents in a reaction kettle and circulating; compressing HCl, conveying HCl in a salt-forming reaction kettle through the outer tube of a mixer, carrying out gas-liquid separation and then circulating HCl in a system through a Venturi mixer; mixing diamine with the residual solvents in the inner tube of the mixer, then mixing the mixture with HCl in the outer tube, and then conveying the mixture in the salt-forming reaction kettle and reacting to obtain a diamine hydrochloride solution; reacting the diamine hydrochloride solution with phosgene under a pressurization condition to obtain an isocyanate photochemical solution. The mixer comprises the inner tube and the outer tube, wherein a spiral plate is installed in the thick-diameter part of the inner tube, a hole is formed in the tube wall of the thin-diameter part of the inner tube, and the bottom of the inner tube is a detachable bottom plate; the outer tube sleeves outside the inner tube, and the bottom of the outer tube is a mixer outlet. The method disclosed by the invention reinforces the mixing effect of the gas-liquid reaction, the obtained hydrochloride particles are uniform, the use efficiency of HCl is high, the energy consumption is low, and the purity of the photochemical solution after a phosgenation reaction is high.

Owner:WANHUA CHEM GRP CO LTD +1

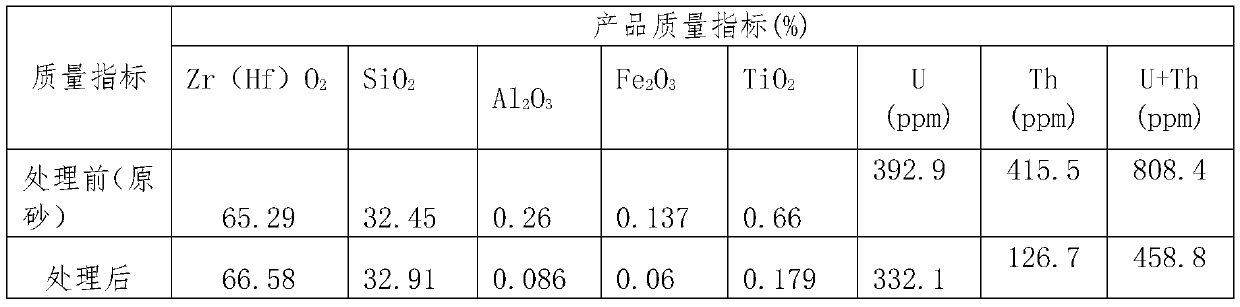

Method for producing high-grade zircon sand

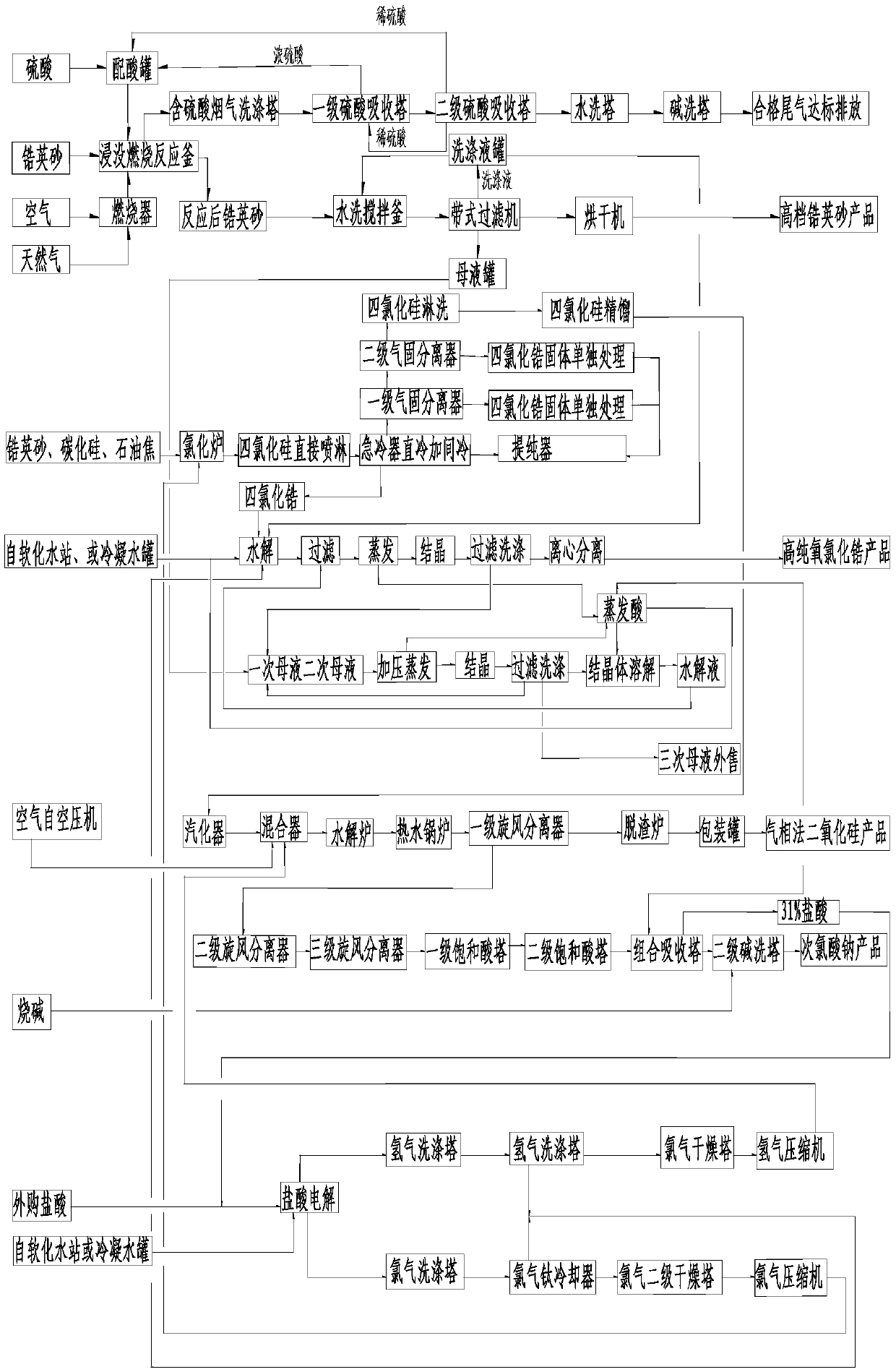

InactiveCN105502423AImprove product qualityReduce energy consumptionSilicaElectrolysis componentsChemical reactionCombustion

The invention relates to a method for preparing zircon sand, in particular to a method for producing high-grade zircon sand. The method comprises the following steps: adding zircon sand and sulfuric acid at the mass ratio of (0.4-0.9): 1 into an immersion combustion reaction still; introducing smoke at 800-1000 DEG C after natural gas combustion to enable a chemical reaction to be carried out for 6-8 hours at 100-350 DEG C in the reaction still; removing impurities in the zircon sand; then carrying out stirring washing; filtering, washing and drying to obtain the high-grade zircon sand. High-purity zirconium oxychloride, gas-phase method silicon dioxide and high-grade zircon sand can be co-produced by using the production method disclosed by the invention, the method is a green, cyclic and economical industry chain, and the obtained product is good in quality, low in production cost and free of pollution.

Owner:郭志斌

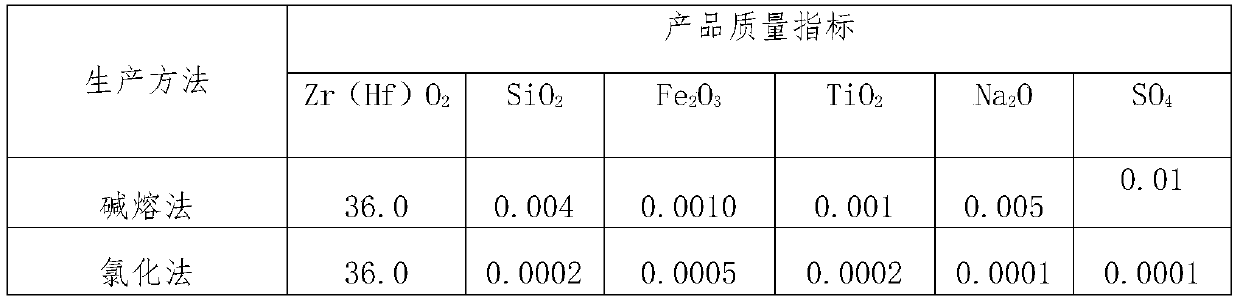

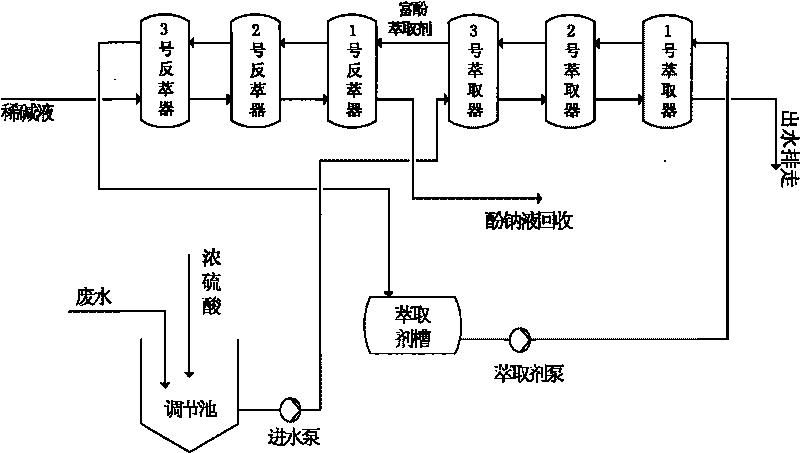

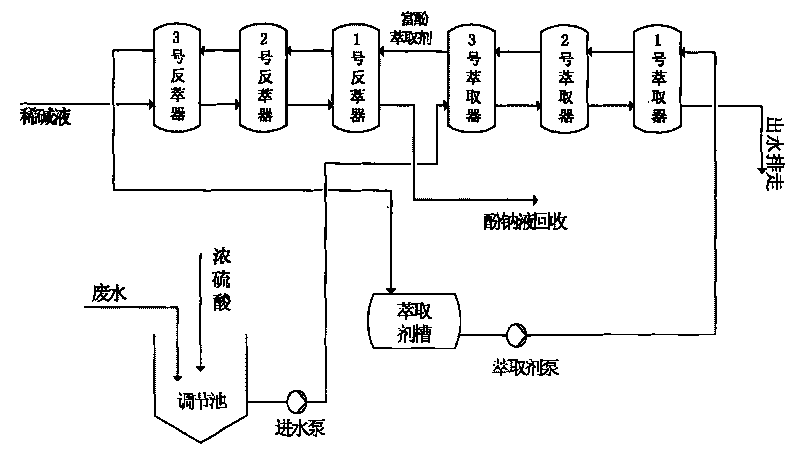

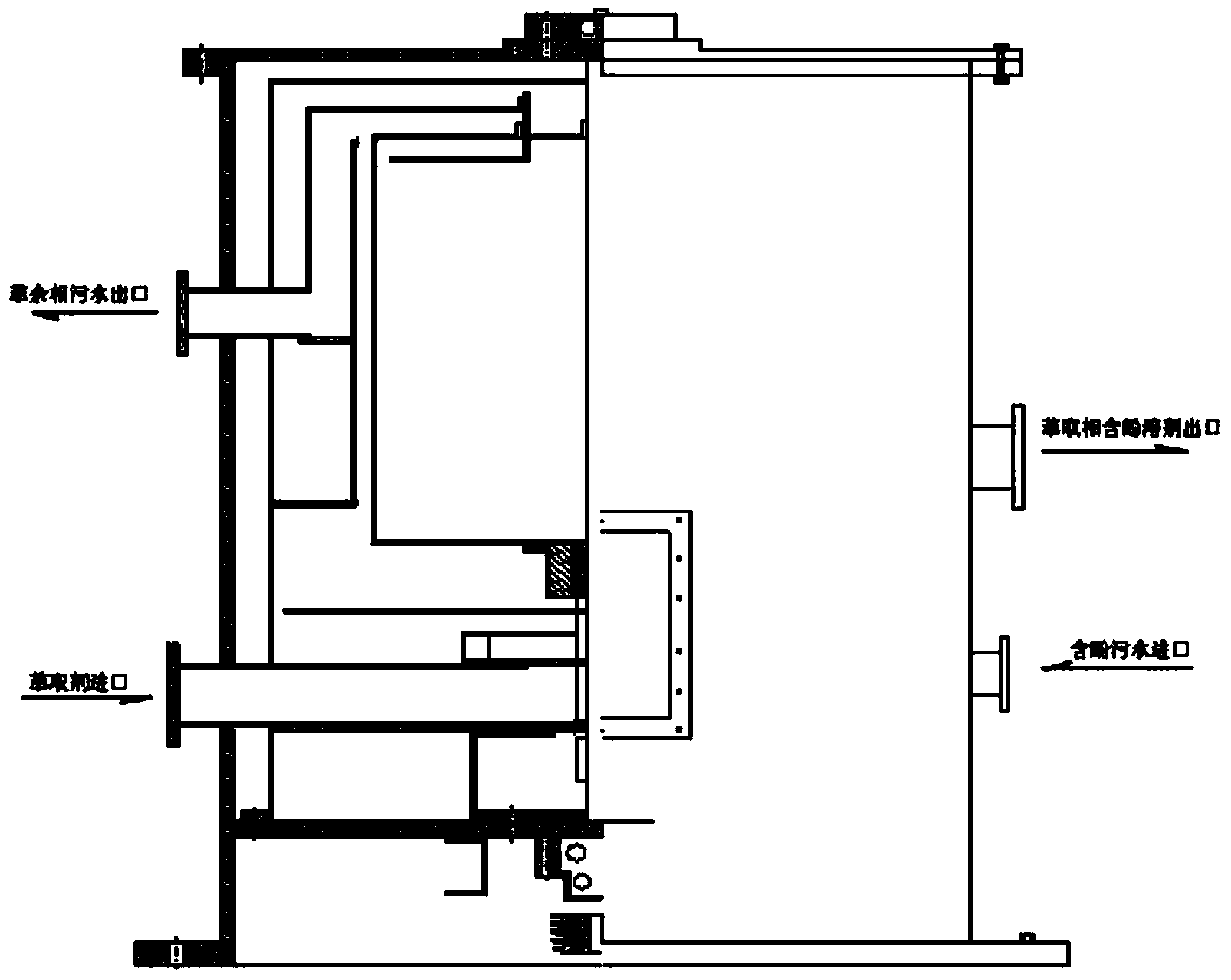

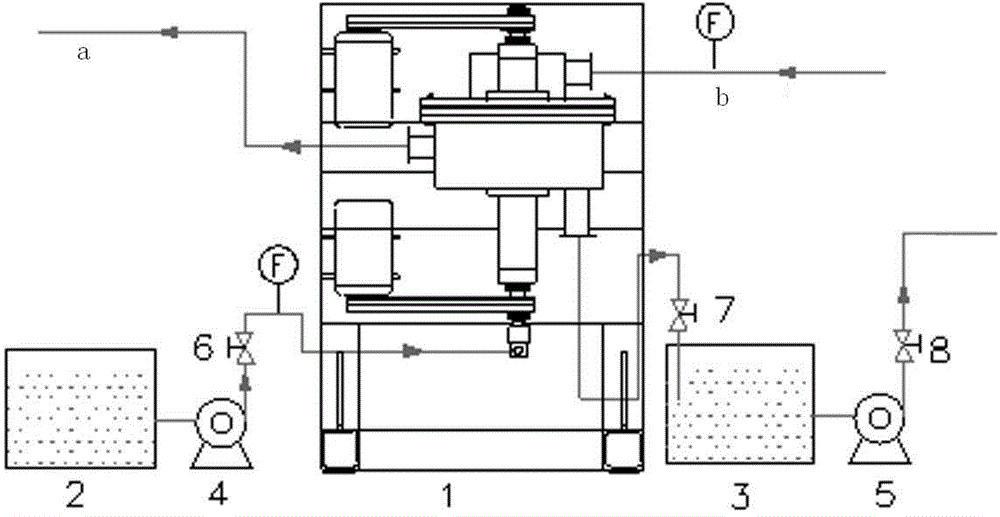

Complexing centrifugal extraction method of high-concentration phenolic wastewater

InactiveCN101723528ALarge extraction and dephenolization coefficientForward and reverse reactions are easyWater contaminantsMultistage water/sewage treatmentHigh concentrationWastewater

The invention provides a complexing centrifugal extraction method of high-concentration phenolic wastewater, which utilizes an efficient extractor and a back wash extractor to process high-concentration phenolic wastewater. The method of the invention comprises the following steps: 1) pretreating the phenolic wastewater; 2) leading the extracting agent to flow to each extractor in turn; 3) leading the phenolic wastewater to flow reversely into each extractor which is flown with extracting agent for extraction reaction; 4) discharging the wastewater from the extractor after dephenolizing; 5) discharging the extracting agent rich in phenol from the extractor which is filled with wastewater firstly; 6) leading the extracting agent rich in phenol to flow reversely to each back wash extractor, leading the thin alkali solution to flow into each back wash extractor which is flown with extracting agent rich in phenol for backextraction reaction; and 7) discharging the phenolate generated in the backextraction reaction from the back wash extractor which is flown with extracting agent rich in phenol firstly, and discharging the extracting agent after backextraction from the back wash extractor which is flown with thin alkali solution. The invention has low cost, small floor area, great flexibility of device operation, low consumption, the phenol content of the processed water is reduced to below 200ppm, the phenol removal rate is above 99%, thus achieving the biochemical treatment water quality standard, recovering the phenol in the waste water in the form of phenolate to return to the system for reuse, and lowering environmental pollution.

Owner:山西焦化股份有限公司

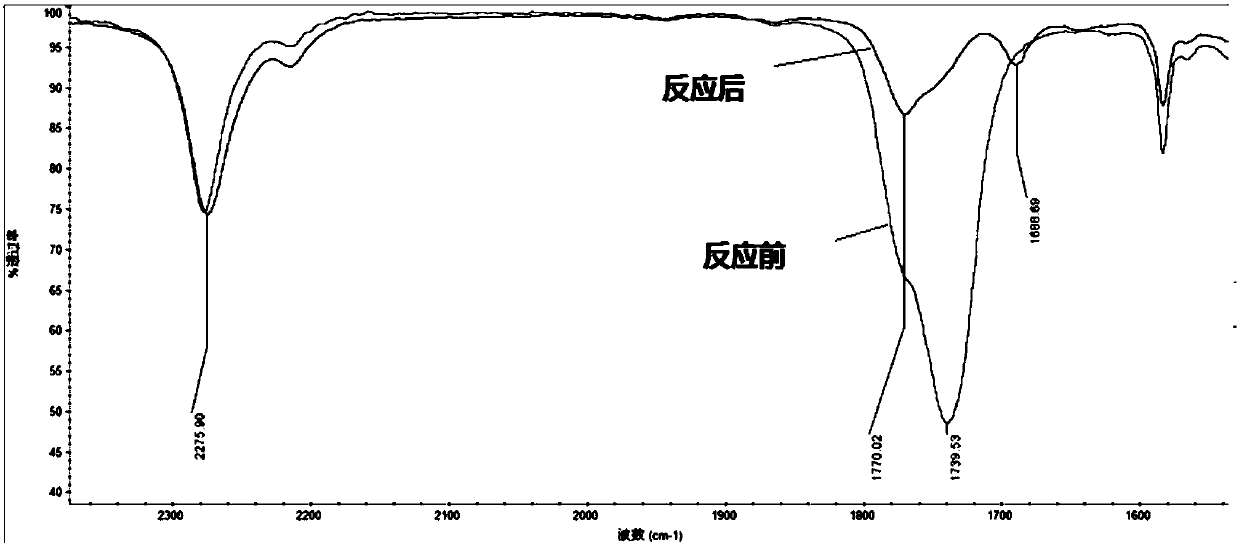

Gas phase SO3 film-scrapping sulfonating technology

InactiveCN101445418ALess investmentReduce energy consumptionLiquid-gas reaction of thin-film typeSulfo/sulfonyldioxy group formation/introductionGas phaseProduct gas

The invention relates to a gas phase SO3 film-scraping sulfonating technology which belongs to the technical field of production technology which prepares anionic surfactant by using gas phase SO3 film-scraping sulfonating liquid organic materials. The invention is carried out according to the following steps: A: liquid SO3 is vaporized to gas phase SO3, the gas phase SO3 is sucked in a mixer shaft through a turbo-blower, the gas phase SO3 is mixed with inert gases recycled in a sulfonating reactor to reaction gas with the volume concentration being 0.1 to 10 percent, and then the reaction gas goes into a reaction cylinder body through reaction gas distribution holes on the upper part of the scraping plate shaft; B: the organic materials go into the sulfonating reactor and downwards flow along the inner wall of the reaction cylinder body, a scraping plate is rotated along with the mixer shaft under the action of a transmission system, the organic materials are continuously suffered with film scaping-spread coating-film scaping in the inner wall of the reaction cylinder body, the organic material are alternately updated and uniformly coated on the inner wall of the reaction cylinder body, and the organic materials are completely contacted and reacted with the reaction gas which goes from the reaction gas distribution holes to form reaction products. The design of the technology is reasonable, and the invention can be suitable for sulfonating or sulphating materials with various viscosities.

Owner:ZANYU TECH GRP CO LTD

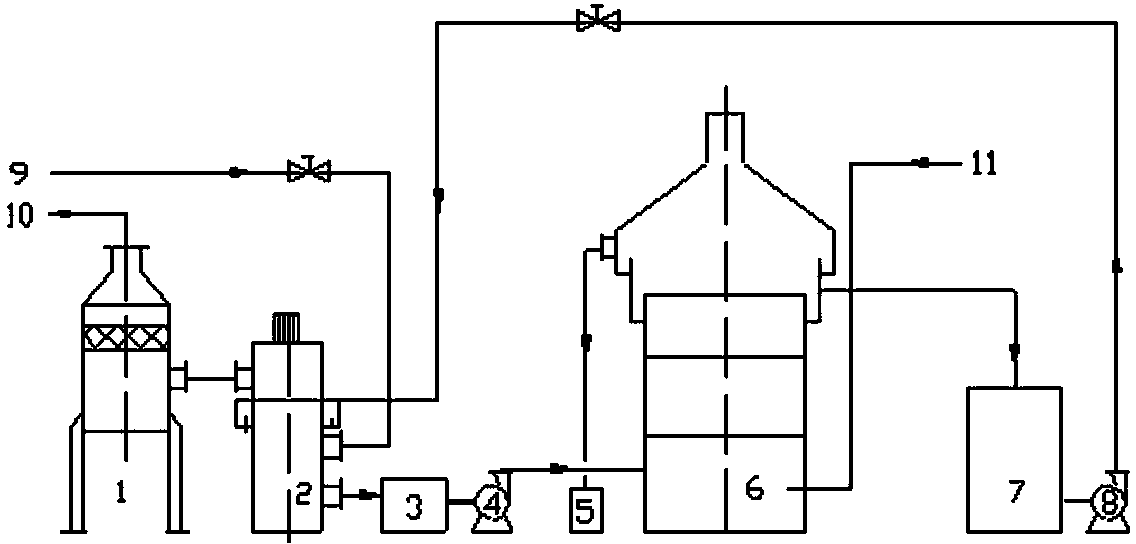

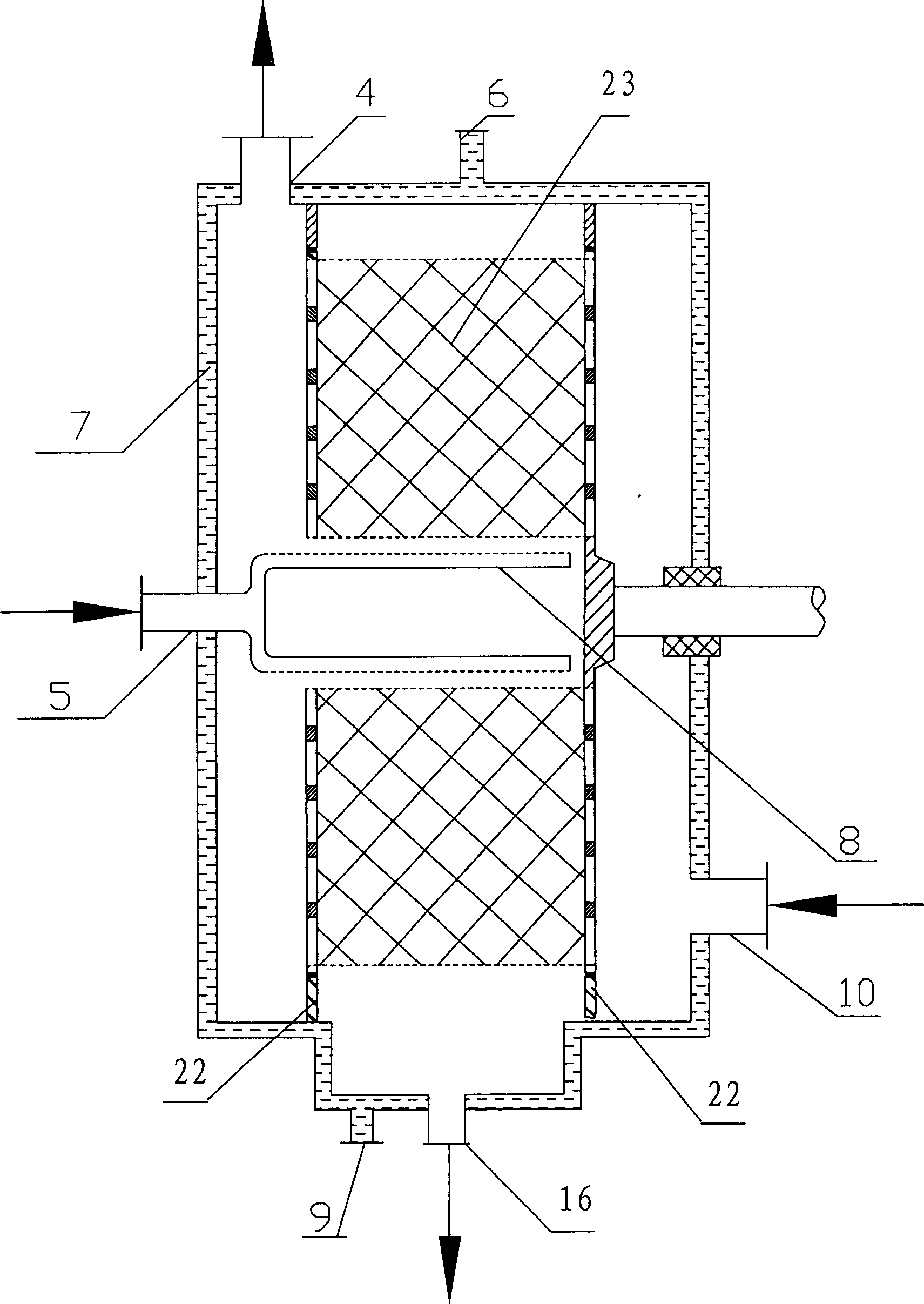

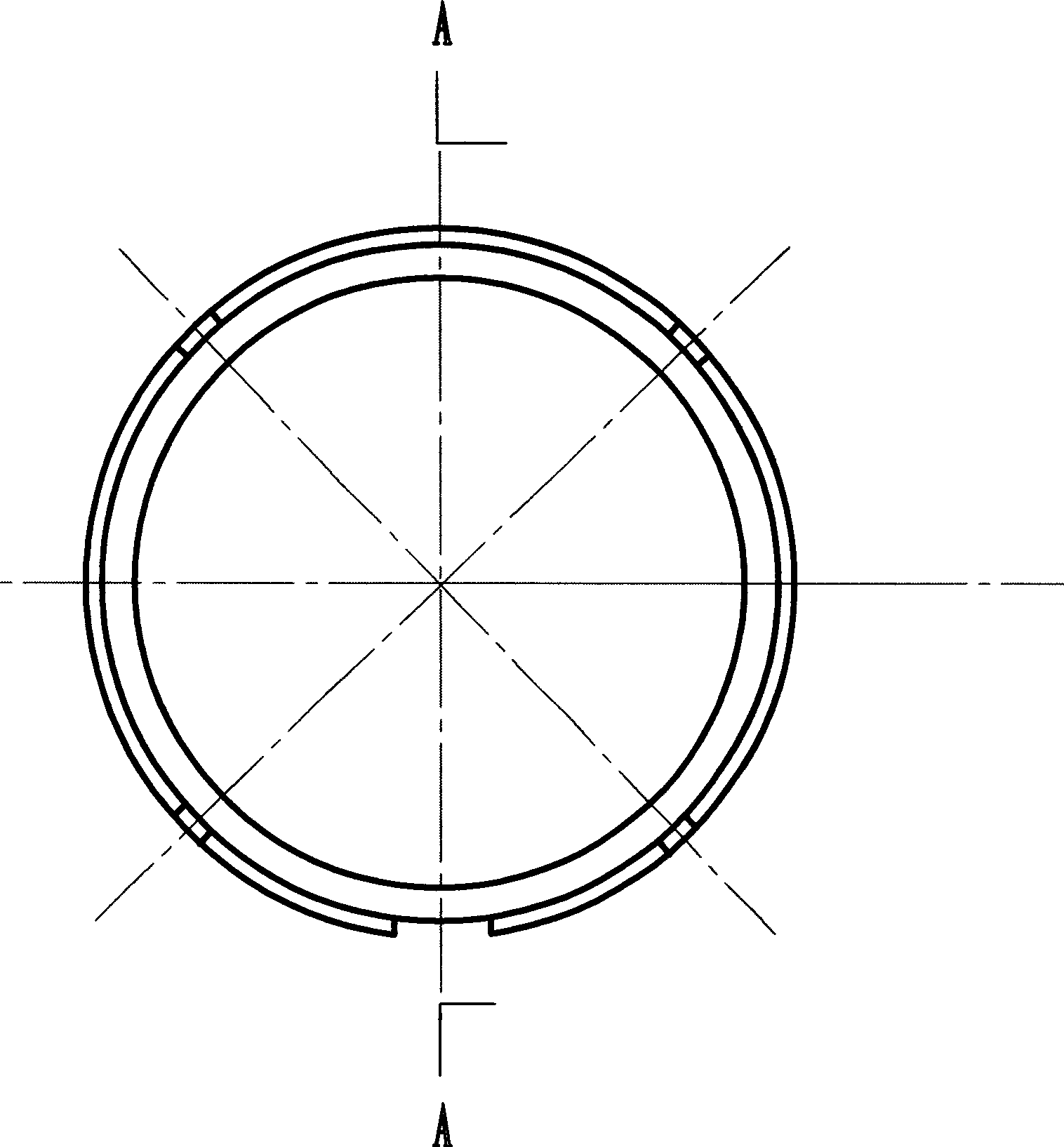

Device and process for removing hydrogen sulfide contained in industrial gas

ActiveCN103463954ASmall footprintReduce circulationDispersed particle separationProcess systemsIndustrial gas

The invention belongs to the technical field of removal of hydrogen sulfide contained in gases, and particularly relates to a device and a process for removing the hydrogen sulfide contained in an industrial gas, aiming at providing high-efficiency rotating packed bed equipment applicable to occasions with large flux and high treatment requirements. The device comprises a rotating packed bed and a regeneration system, wherein the liquid inlet pipe of the rotating packed bed is connected with a barren solution tank through a barren solution pump, and an air inlet pipe is connected with a sulfurous gas; the liquid discharge pipe of the rotating packed bed is connected with a pregnant solution tank, and an air outlet pipe is connected with a demister. The process comprises the following steps: preparing a desulfurizing solution; respectively introducing the desulfurizing solution and the gas which contains the hydrogen sulfide into the rotating packed bed; introducing a liquid discharged from the rotating packed bed into the regeneration system for recovery. The device and the process which are disclosed by the invention have the advantages of good desulfurization effect, small occupied area, high mass transfer efficiency, small liquid circulating amount, small gas-phase pressure drop, low operation cost and convenience for start and stop. According to the invention, the integral process system can be stable within a few minutes.

Owner:ZHONGBEI UNIV

Method and equipment for preparing aromatic sulfonic acid by gas-phase sulphonation of aromatic organic compound

ActiveCN101570500AImprove mass transfer efficiencyQuick contact mixChemical industrySulfonic acid preparationLiquid productSimple Organic Compounds

The invention relates to a method and equipment for preparing aromatic sulfonic acid by the gas-phase sulfuric anhydride sulphonation of aromatic organic compounds with a rotating packed bed. The method solves the problems of the existing method in which the aromatic sulfonic acid is prepared by the sulphonation of aromatic organic compounds using sulfuric anhydride gas as sulphonating agent. The method is as follows: the aromatic organic compounds and the mixed sulfuric anhydride gas enter the started rotating packed bed and come into contact to produce partial sulphonation reaction; the liquid product after reaction enters a tubular heat exchanger and the reaction proceeds; and the aromatic sulfonic acid is obtained. The equipment comprises the rotating packed bed; the liquid inlet of the rotating packed bed is connected with a raw material storage tank; the gas inlet of the rotating packed bed is connected with the mixed sulfuric anhydride gas source; and the liquid outlet of the rotating packed bed is connected with a product storage tank through the tubular heat exchanger. The invention has the advantages of easy control of reaction temperature, reduction of the possibility of subsidiary reaction, enhancement of reactive selectivity, avoidance of environmental pollution, energy saving, small equipment volume, light weight, convenient installation and maintenance, and convenient starting and shutdown.

Owner:ZHONGBEI UNIV

Isocyanate monomer preparation method and system

ActiveCN109748822AStable controlThe reaction process is stableOrganic compound preparationIsocyanic acid derivatives purification/separationReaction temperaturePhosgene

The invention discloses an isocyanate monomer preparation method and system. The method includes that amine hydrochloride and phosgene are continuously added into a reaction kettle, a reaction temperature is controlled, and generated isocyanate, HCl, acyl chloride and the like are gasified prior to entering an intermediate product kettle; after the gas flows through a condenser, intermediates suchas acyl chloride are condensed and participate in neutralization reaction, acyl chloride is subjected to organic alkali catalytic reaction to obtain isocyanate, and then a pure product is obtained through separation; phosgene and HCl enter secondary condensation, and condensed phosgene is recycled in the reaction kettle. Compared with a traditional pyrolyzing process, the method and the system have advantages that stability in system control, high yield, low energy consumption and low equipment investment are realized; pyrolyzing procedures are reduced, pyrolyzer cleaning is avoided, and material leakage and personnel safety risks are reduced.

Owner:WANHUA CHEM GRP CO LTD +1

Separation technique for low pressure oxygen-enriched air

InactiveCN102213537AReduce energy consumptionLower pressure ratioSolidificationLiquefactionAir filtrationInterference factor

The invention belongs to the field of air separation technology and in particular relates to a separation technique for low pressure oxygen-enriched air, comprising the steps of impurity removal by means of air filtration, compression to 0.33-0.44MPa with an air compressor, purification, heat exchange, rectification, liquid oxygen vaporization and pressurization. The technique has the characteristics of being simple in technological process, convenient in operation, stable and reliable in running, stable in oxygen purity of the product, less in outside interference factors, long in continuous running period, low in power consumption for oxygen generation, low in equipment cost, high in automation degree and convenient in engine start and stop.

Owner:开封黄河空分集团有限公司

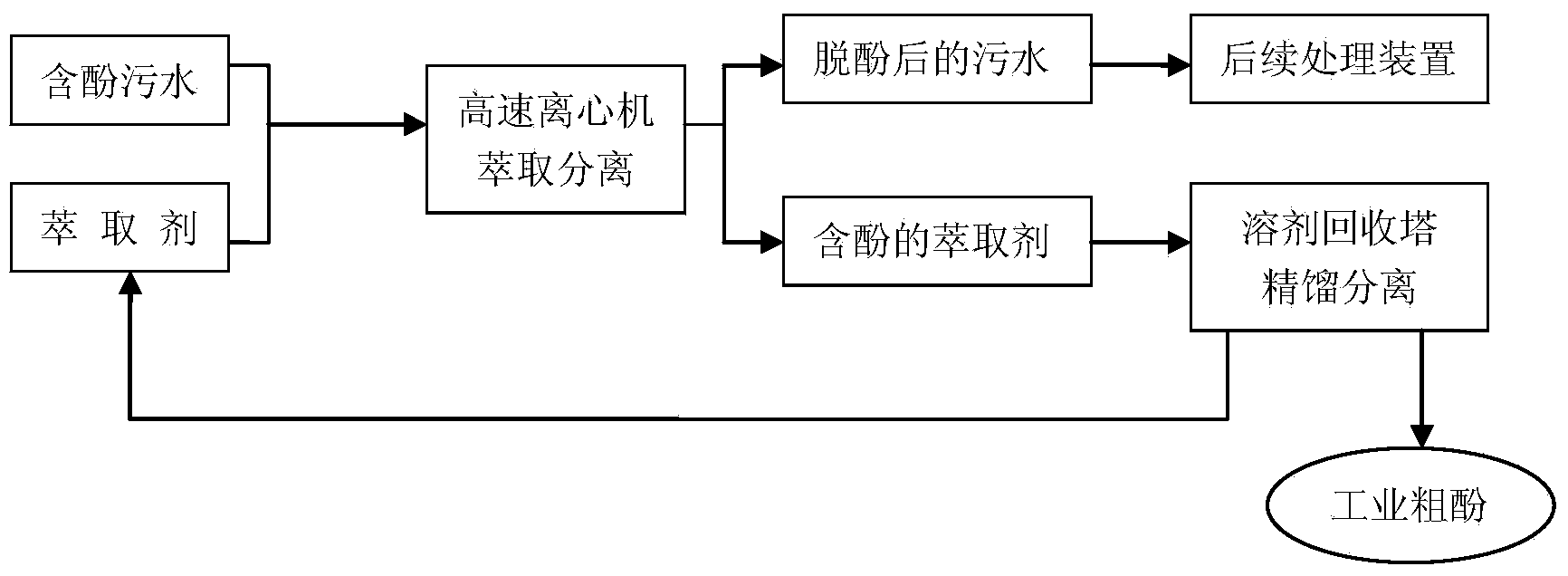

Centrifugal extracting wastewater dephenolization technology

ActiveCN103818982AReduce holdupShort stayWater/sewage treatment by centrifugal separationWater/sewage treatment by extractionWastewaterSmall footprint

The invention relates to a centrifugal extracting wastewater dephenolization technology. A high-speed centrifuge is used as an extraction device to perform centrifugal extraction separation. The technology comprises the steps as follows: phenol wastewater and an extraction agent enter the centrifuge simultaneously for centrifugal extraction separation, an extract phase phenol solvent and extract phase wastewater are produced after separation, the extract phase phenol solvent enters a solvent recovery tower for rectification separation, and a solvent and crude phenol are recovered; the extraction agent extracted at the top of the tower enters the centrifuge again to be recycled, and the crude phenol is recovered at the bottom of the tower. Compared with the prior art, the technology has the benefits as follows: the technology is low in investment, small in occupied area, simple and reliable in technological process, high in dephenolization efficiency and capable of realizing recovery of the industrial crude phenol.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

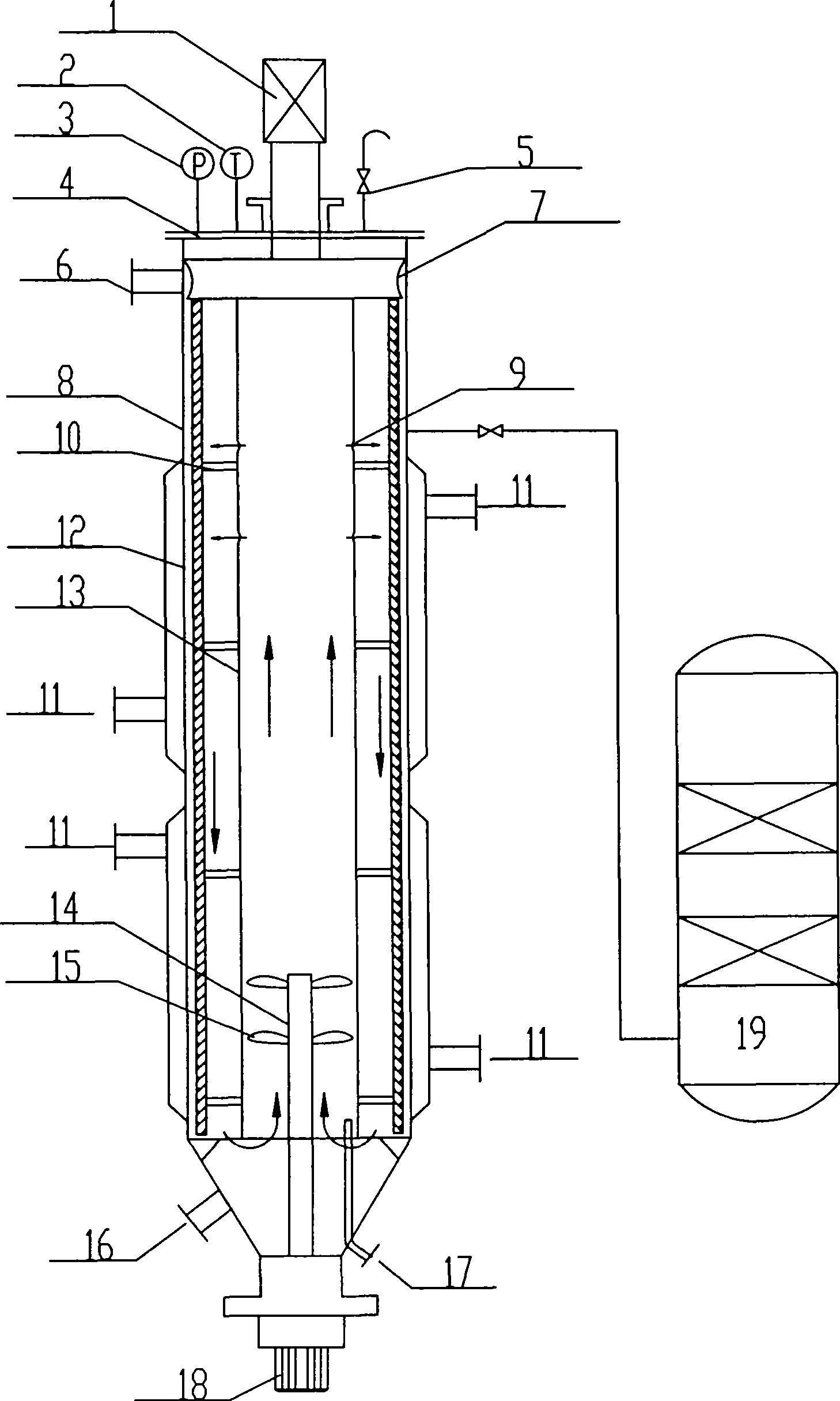

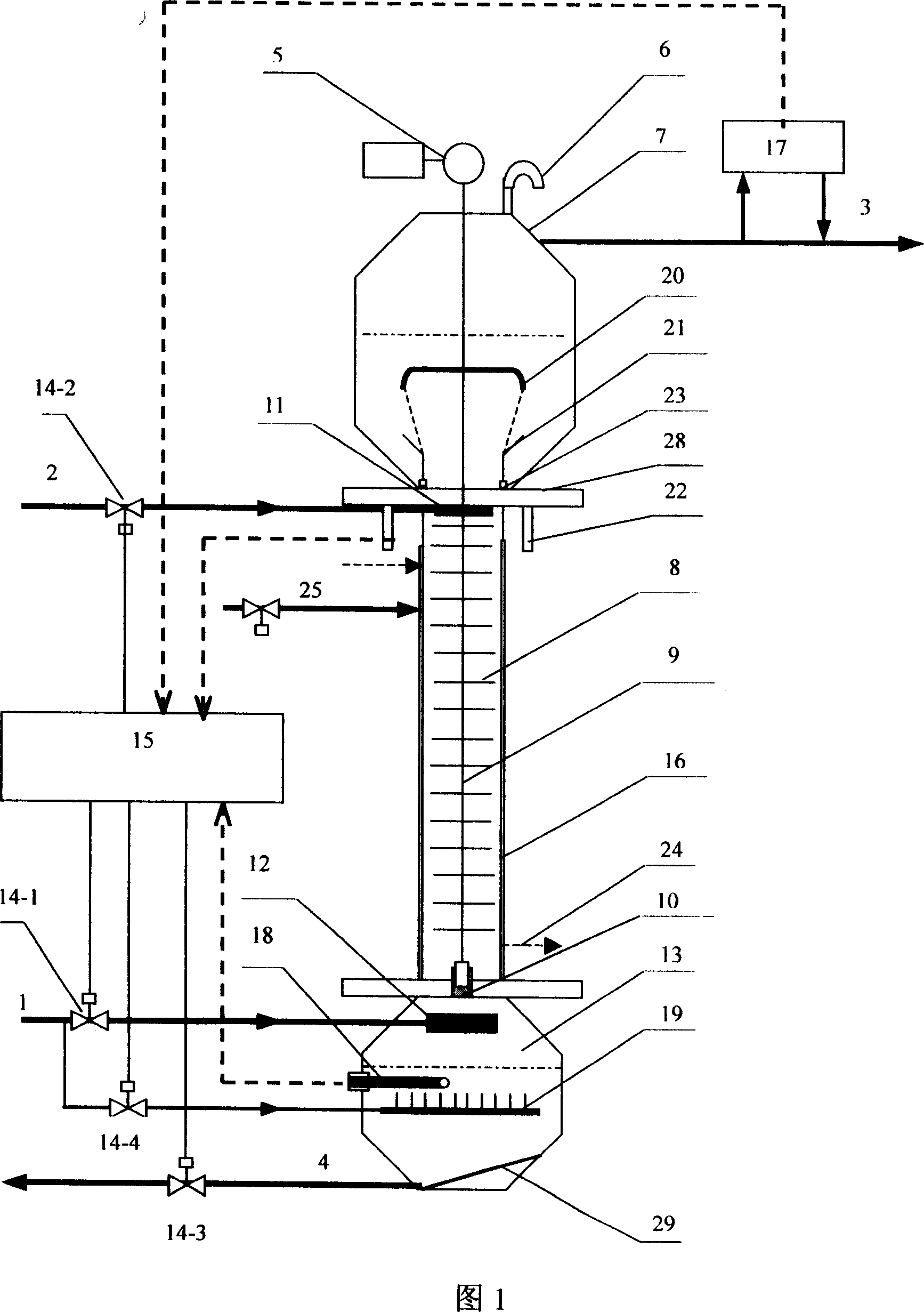

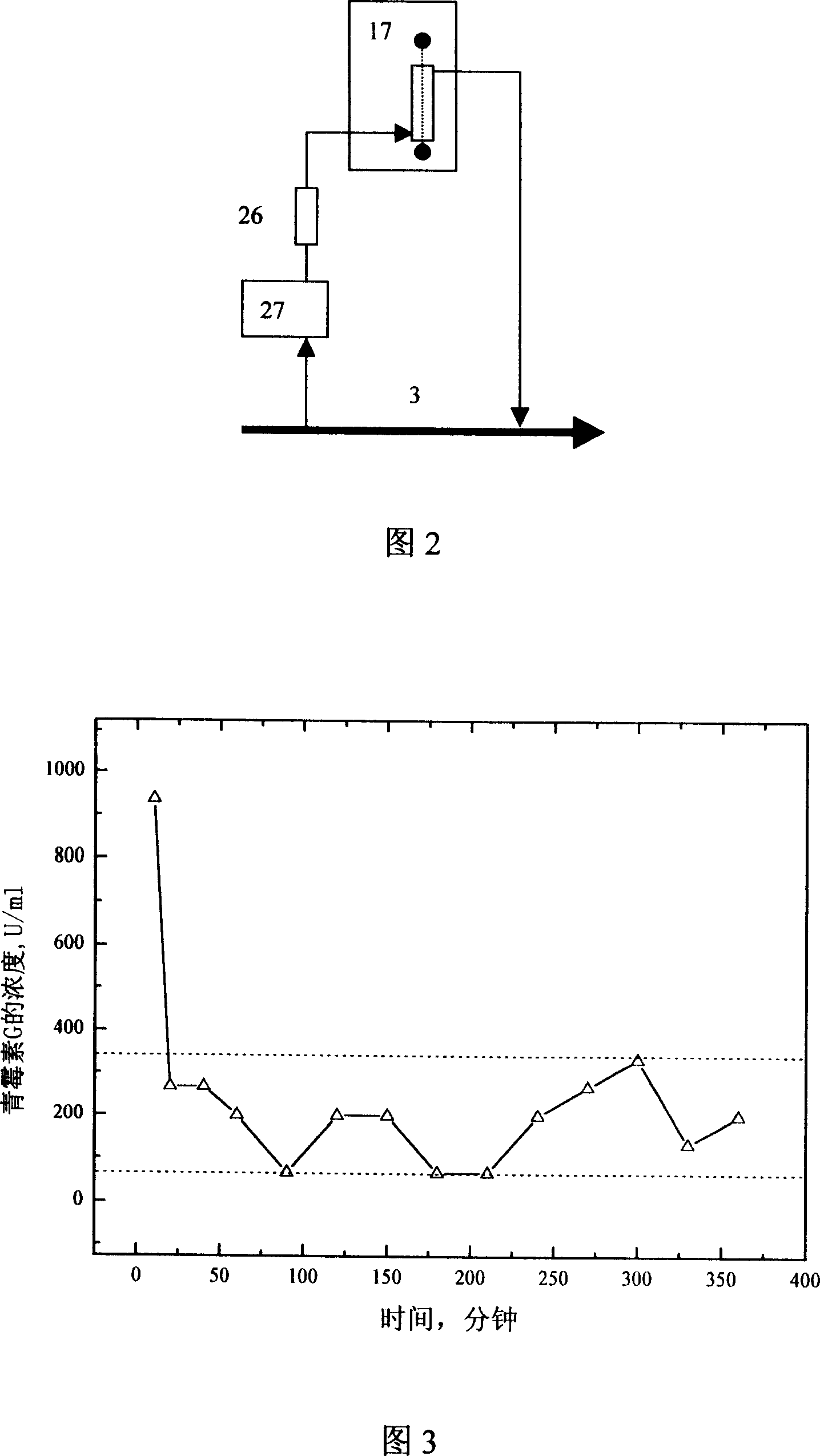

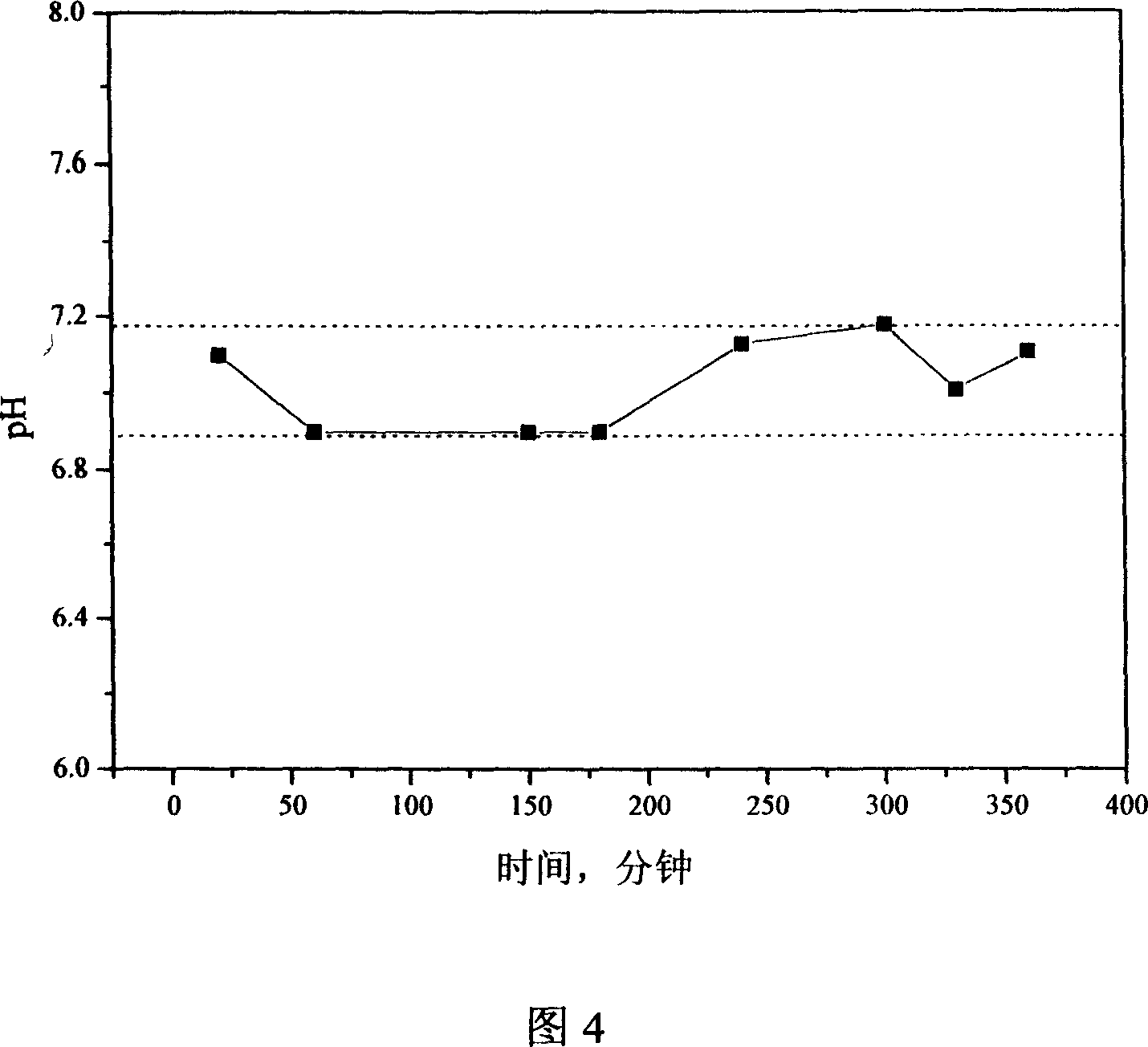

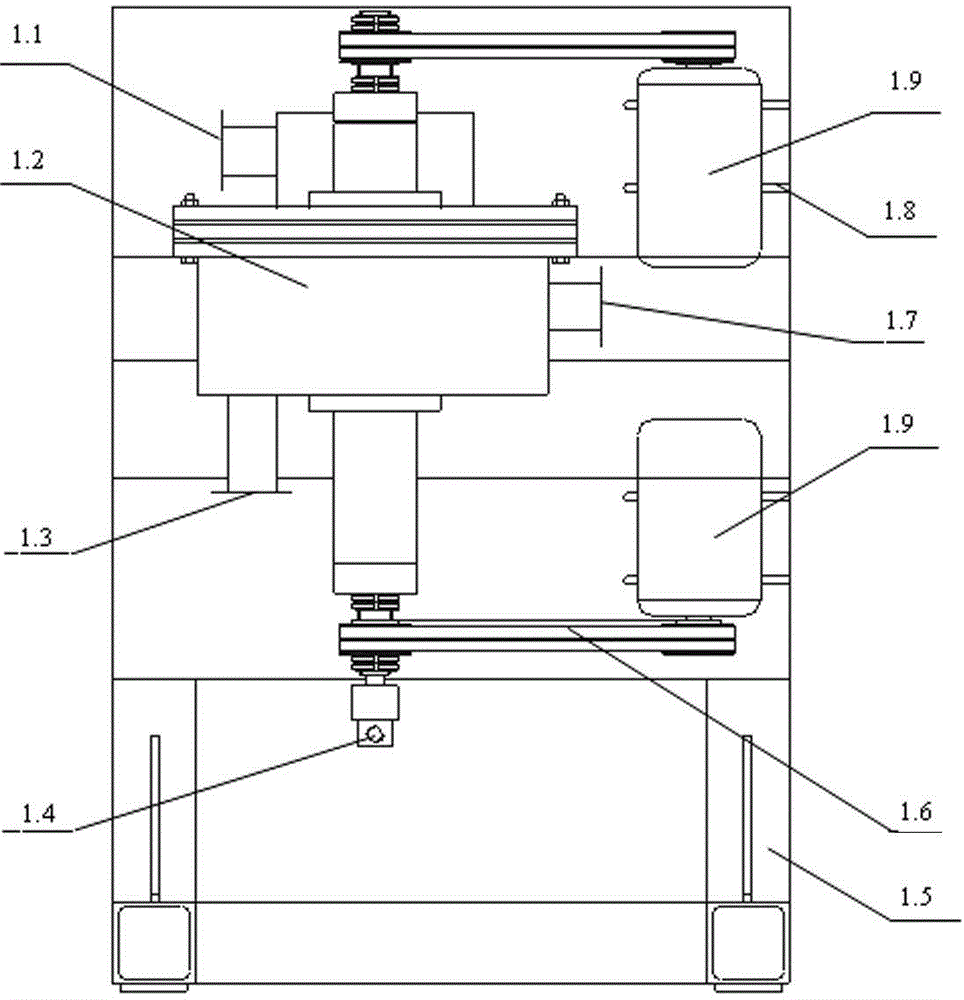

Device and method for continuously back extracting penicillin

The present invention relates to an equipment and the operation method for continuous penicillin stripping. An extraction tower is controlled by a computer control system; a cylindrical tower reaction extraction section adopts a jacketed structure; a clarification section container on the upper end of the tower body is larger than a clarification section container on the lower end of the tower body; a tower body extension section that extends into the upper clarification section container is bended outwards after a certain length of extension; a reflux hole is arranged on a straight tower body on the tower body extension section; an arc-shaped baffle plate with a downward arc core is arranged over the tower body extension section; a central shaft with a tower plate enters into the top of the upper clarification section container to make the bottom of the central shaft landed in a central shaft slot; a light phase distributor, a pH meter probe and a light phase in a heavy phase clarification area are arranged in the lower clarification section container; a laser particle size analyzer is arranged on a flange which connects the upper clarification section container with the tower body; a polarimeter is arranged on a pipe on an organic extraction raffinate phase exit. The invention can effectively inhibit the problems of penicillin degradation and milk slag handling, which can be applied to large-scale penicillin production through on-line automation control.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

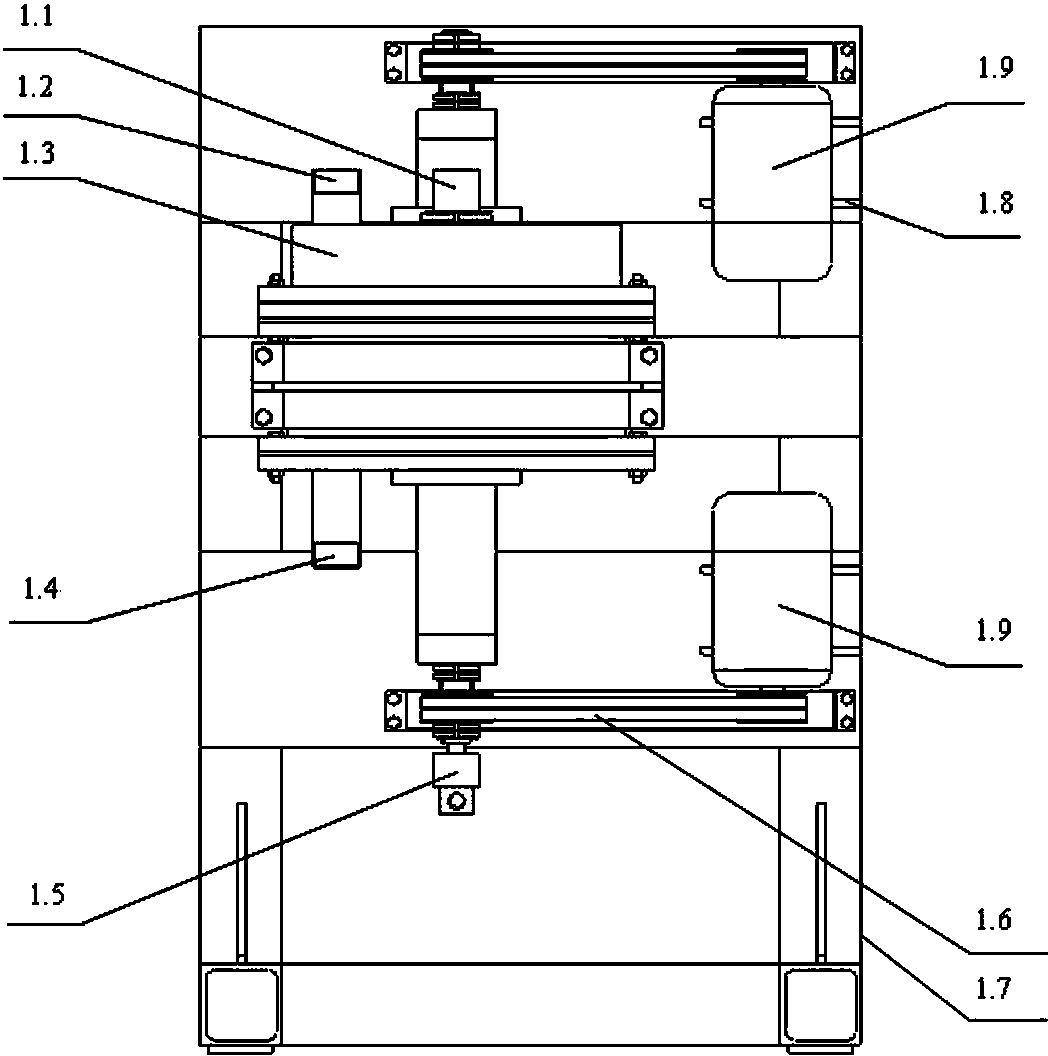

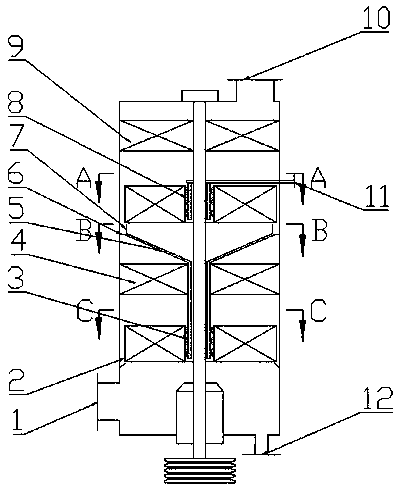

Device and method for removing methanol from methyl tert-butyl ether cracking product

InactiveCN108159844AEvenly distributedAdequate mass transferDispersed particle separationProduct gasMethyl tert-butyl ether

The invention discloses a device and a method for removing methanol from a methyl tert-butyl ether cracking product. The MTBE cracking product and absorption liquid undergo cross flow-counterflow contact in a multistage airflow shear cross-flow bed; under the shear action of high-speed rotating filler, cracked gas and the absorption liquid are dispersed, coalesced and redispersed for multiple times, so that multistage absorption is realized; cracking gas is introduced to a gas inlet in the side bottom of a multistage airflow shear cross flow bed; a gas outlet in the top of the multistage airflow shear cross flow bed is connected with a purified gas section; the absorption liquid is introduced to a liquid inlet in the side top of the multistage airflow shear cross flow bed; a liquid outletin the bottom of the multistage airflow shear cross flow bed is used for draining the absorption liquid; the liquid inlet is connected with a pump; the liquid outlet of the multistage airflow shear cross flow bed is connected with a liquid-rich tank; the multistage airflow shear cross flow bed comprises a liquid distributor, a liquid collecting and redistributing device, a rotor, a stator, a driving device and a casing. According to the equipment, the gas and the absorption liquid generally make counterflow contact, so that a gas-liquid mass transfer propulsion force is greater, the purification degree of the cracking gas is improved, and the concentration of methanol in the rich solution and the utilization rate of the absorption liquid are improved.

Owner:ZHONGBEI UNIV

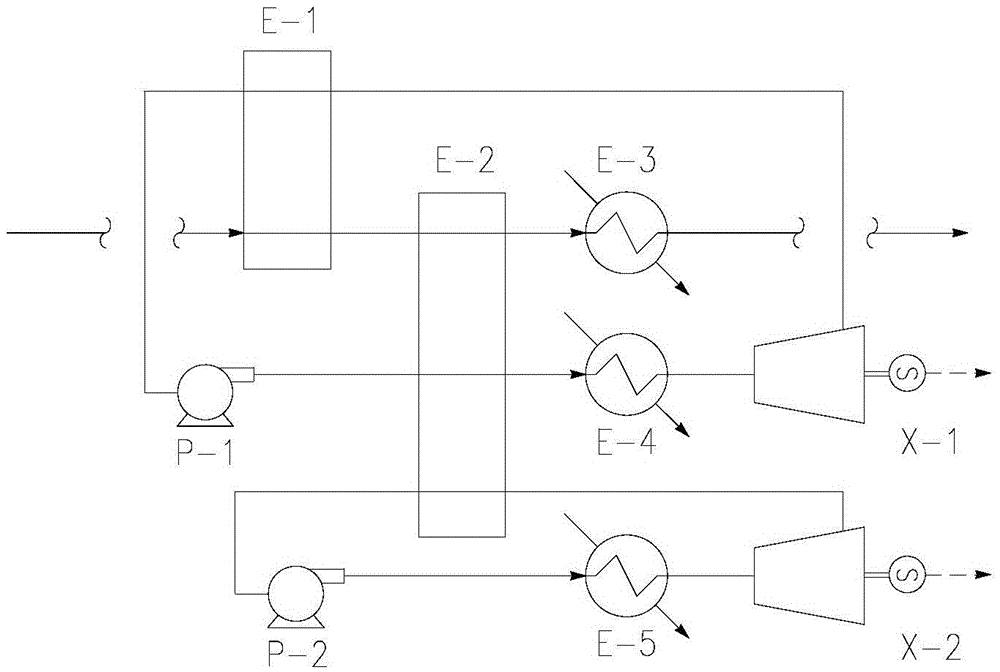

Process and device for generating electricity by using LNG cold energy

ActiveCN105569752AImprove utilization efficiencyReduce heat transfer temperature differenceSteam engine plantsElectricityEconomic benefits

The invention relates to a process and device for generating electricity by using LNG cold energy. A lot of cold energy is released in the process of supplying vaporized LNG to a downstream pipe network; and the process uses two independent cycles to recover the cold energy for generating electricity, so that the loss of the cold energy is prevented, the economic benefit of enterprises is promoted, the pollution problem caused by power generation of a power plant is prevented in power generation, and the requirements of energy conservation and environmental protection are accorded with.

Owner:XINDI ENERGY ENG TECH

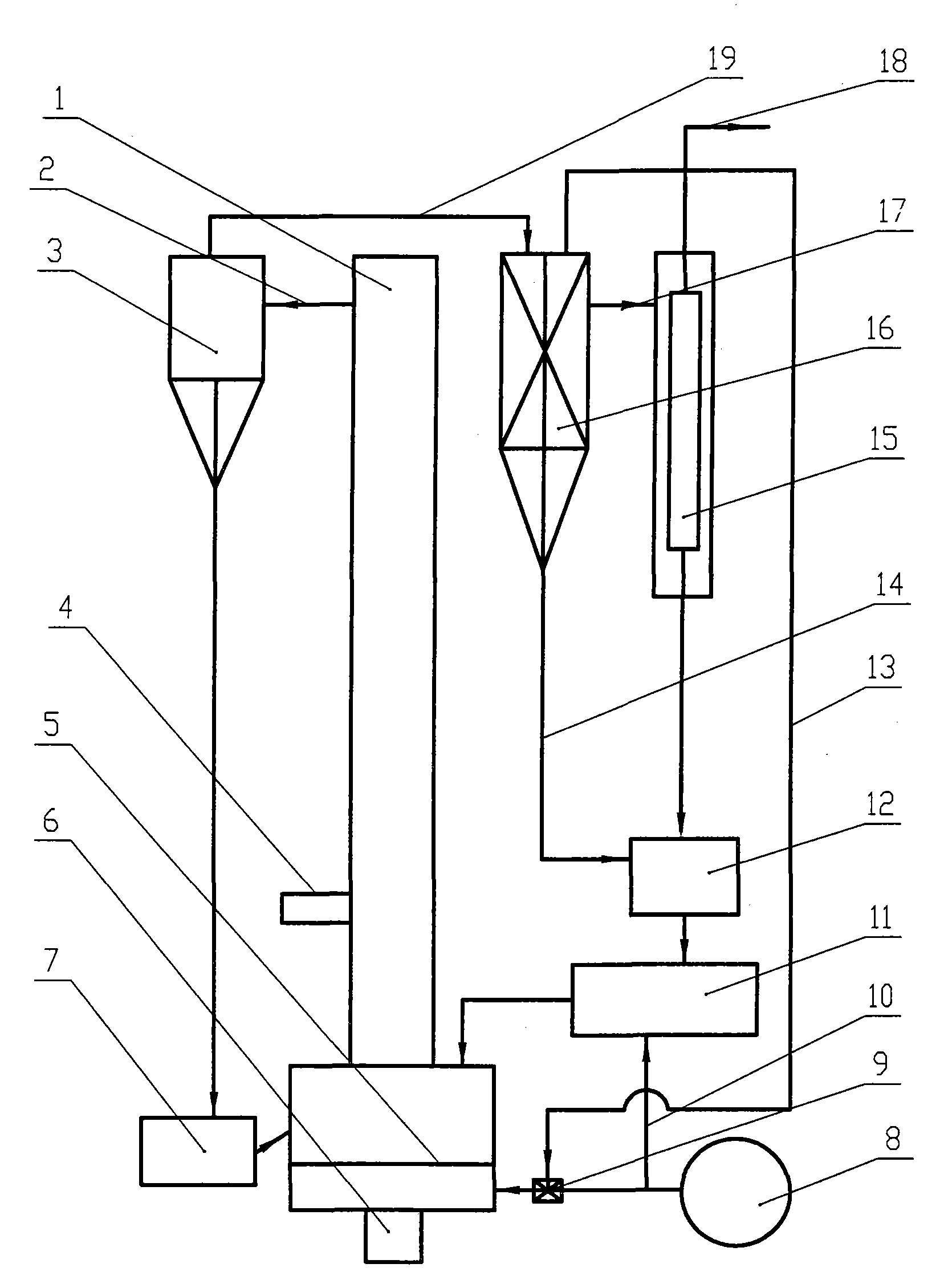

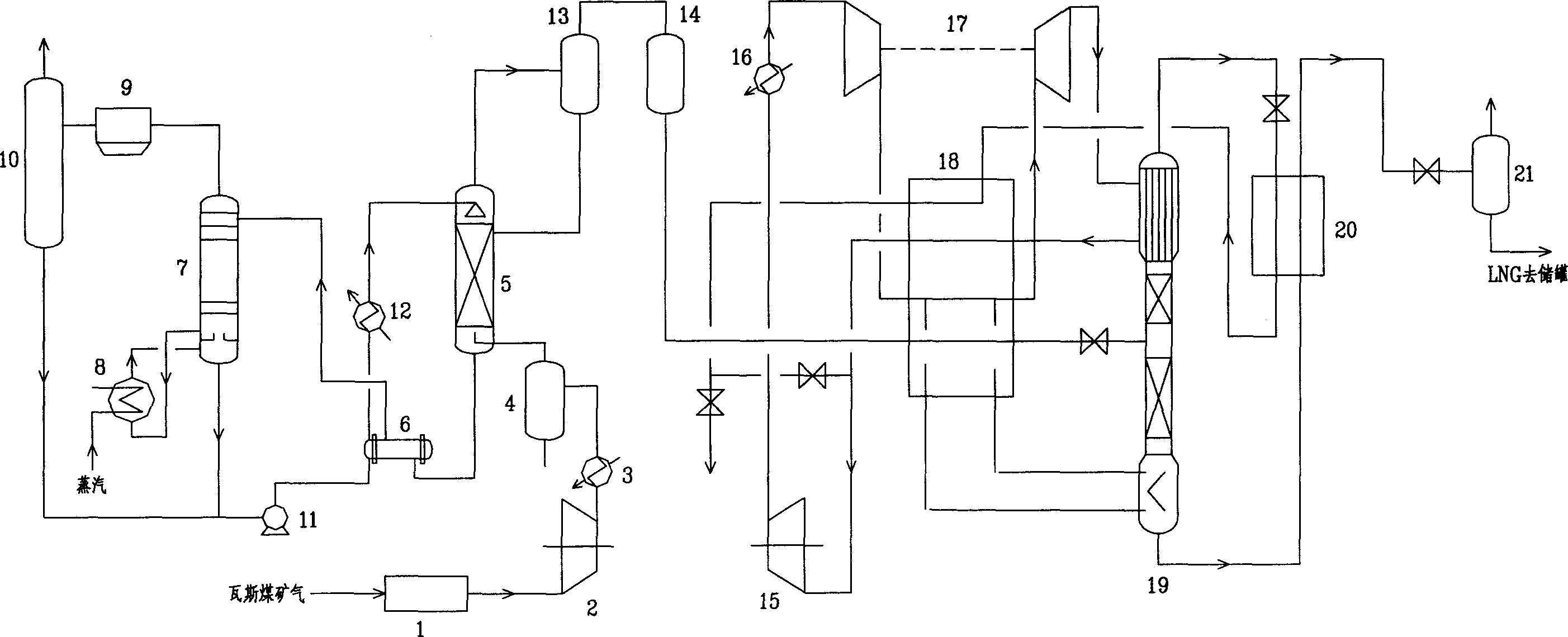

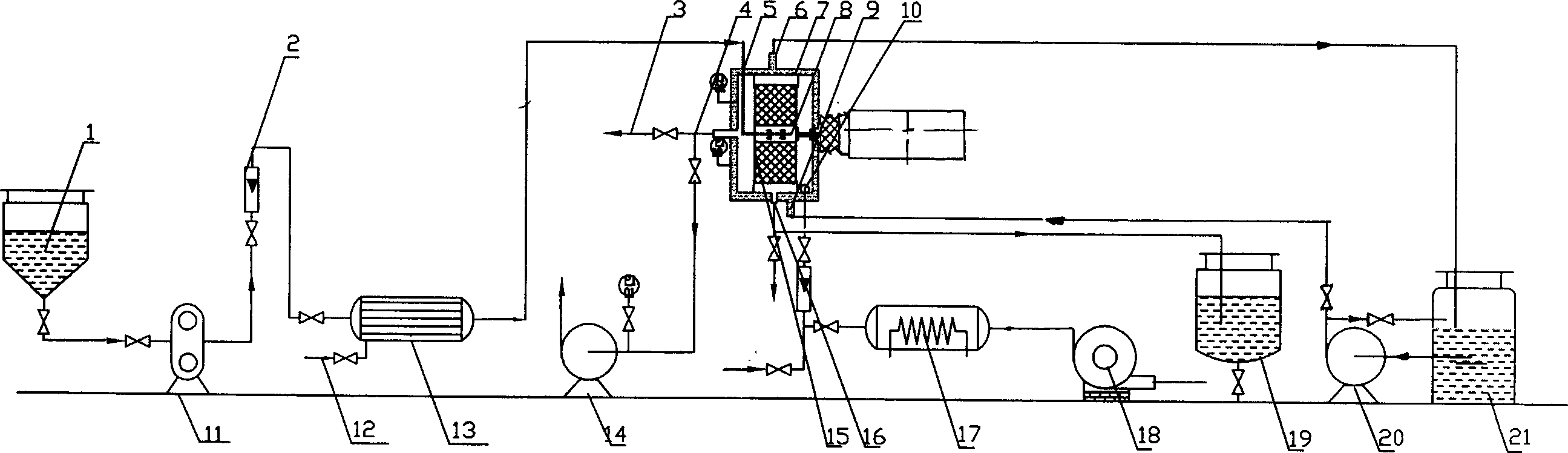

Process technology for preparing liquefied natural gas with coal-mine gas as crude material

InactiveCN1970702AEnsure safetySafe and stable operationGaseous fuelsMolecular sieveCoal mine methane

The invention discloses a making method of liquefied natural gas (LNG), which is characterized by the following: adopting coal gas as raw material; predisposing coal gas; liquefying under low temperature; making oxygen content in the gas lower than 0.5%; pressurizing; entering into composite purifying device of solvent and molecular sieve; reducing the content of CO2, H2S and H2O to preset scale; cooling gas in the plate-fin heat exchanger to liquefy; rectifying in the fractional tower; separating methane at LNG pattern; cooling to enter LGN product reserving tank; obtaining LNG product; fitting for automobile fuel or powering.

Owner:熊世平 +3

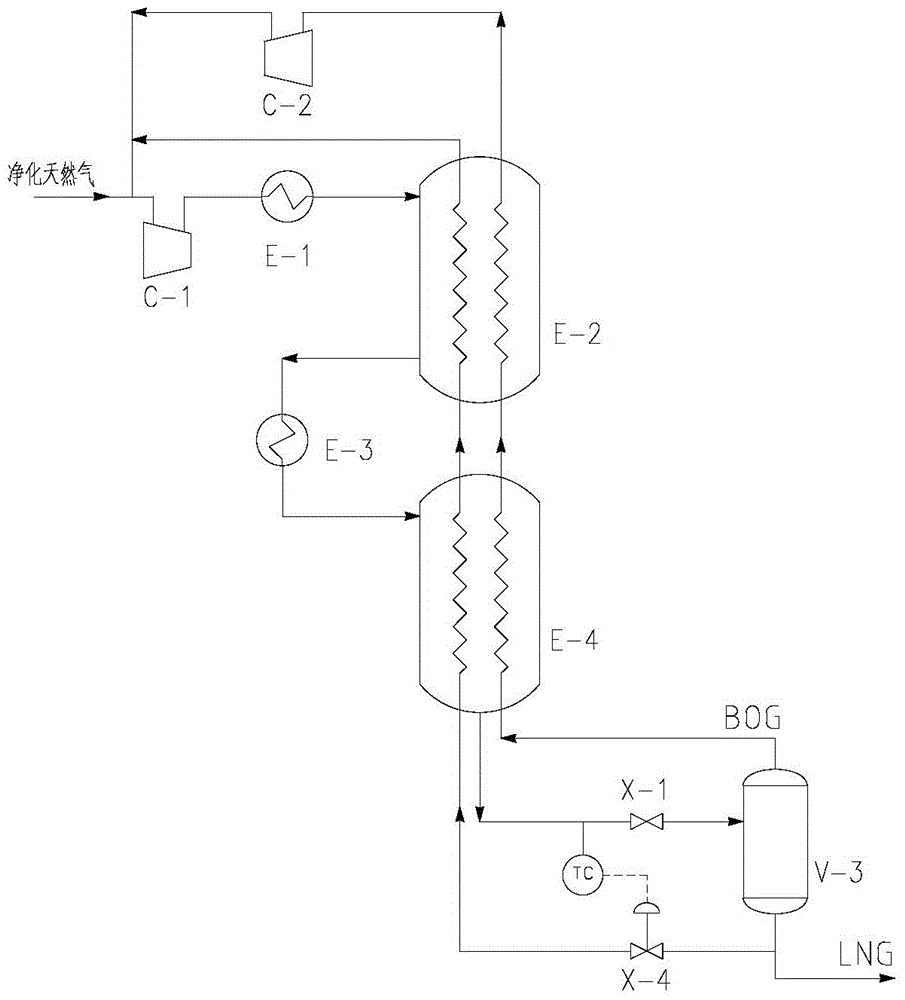

Small natural gas liquefying technology

ActiveCN104913592ASimple processThere is no problem of matchingSolidificationLiquefactionCompressed natural gasNitrogen

The invention relates to a small natural gas liquefying technology or device. The technology is characterized in that purified natural gas is pressurized and liquefied through the technology that the high-pressure natural gas is refrigerated in advance and then refrigerated in a throttling mode, the refrigerating capacity for refrigerating the high-pressure natural gas in advance is provided by a single refrigerant provided by a refrigerating machine and part of LNG generated through liquefying of the natural gas, the technology process is simple, the problem of the ratio of the refrigerant does not exit, the device runs stably, and a machine can be started and stopped conveniently; furthermore, the nitrogen content in the LNG can be removed and reduced to be 1% or lower through a throttling flash approach.

Owner:XINDI ENERGY ENG TECH

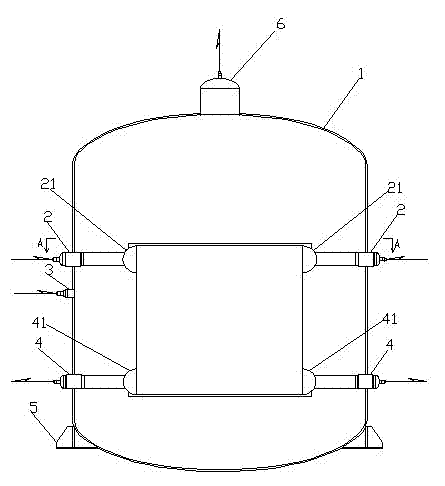

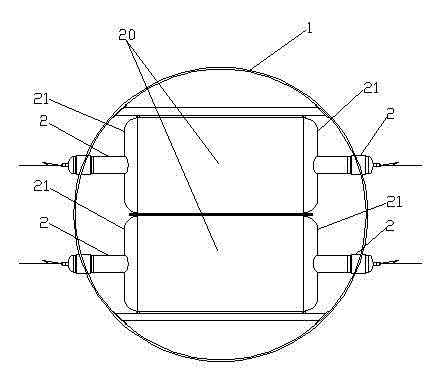

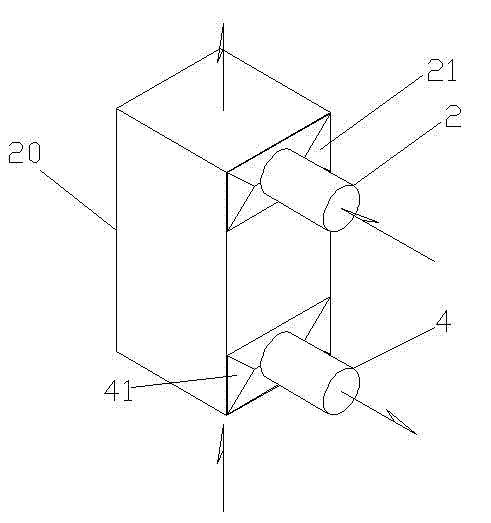

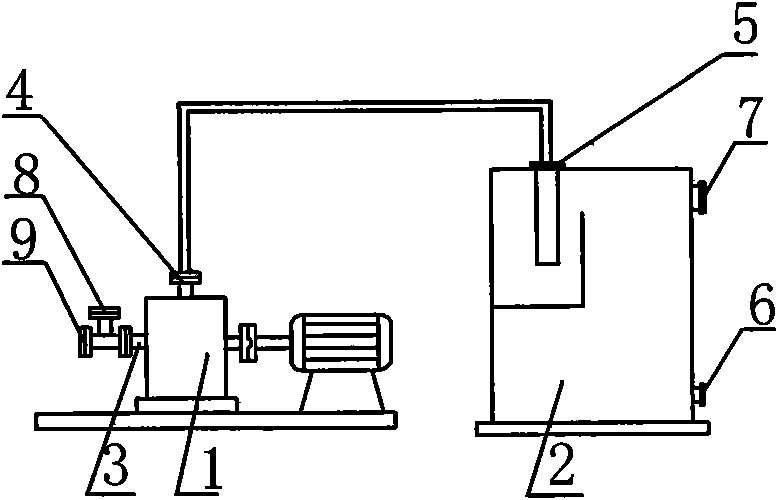

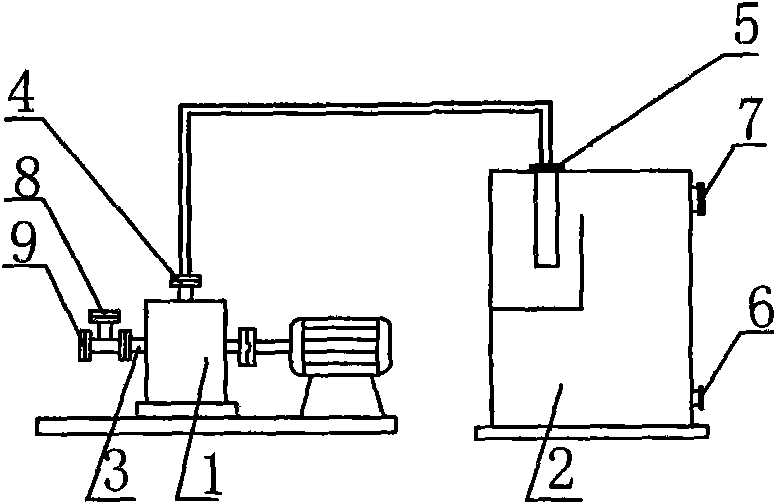

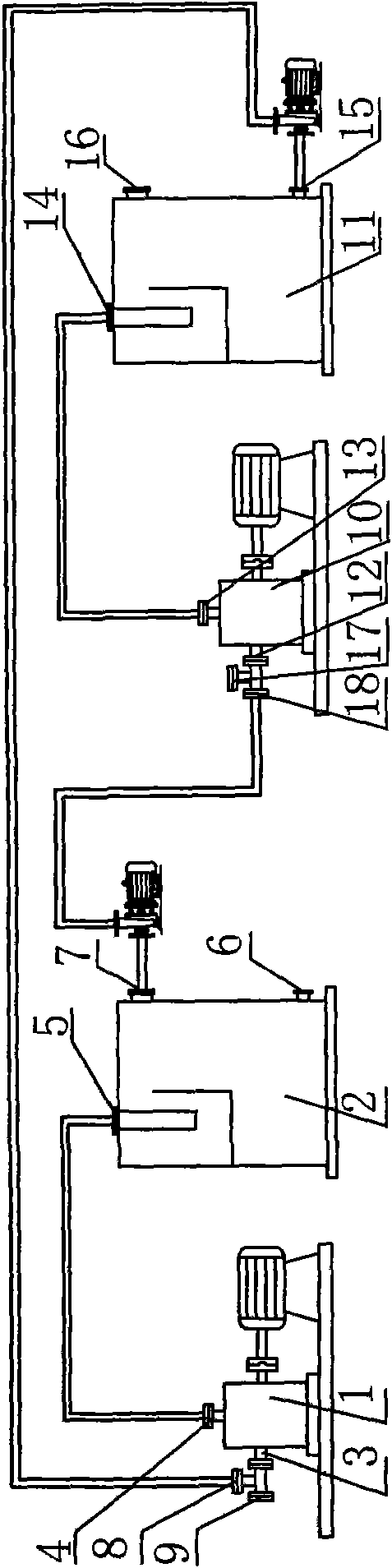

Extraction device

InactiveCN101898048ALarge mass transfer areaEasy to phaseLiquid solutions solvent extractionPhase splittingEngineering

The invention discloses an extraction device comprising an emulsifying machine (1) and a phase-splitting apparatus (2). The emulsifying machine (1) is provided with an emulsifying machine inlet (3) and an emulsifying machine outlet (4), the phase-splitting apparatus (2) is provided with a mixed phase inlet (5), a heavy phase outlet (6) and a light phase outlet (7), the emulsifying machine inlet (3) is connected with an extracted object inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed phase inlet (5) of the phase-splitting apparatus. When multistage extraction devices are combined, the light phase outlet of the phase-splitting apparatus in the extraction device at the current level is connected with the solvent inlet of the extraction device at the next level through a pipeline provided with a pump, and the heavy phase outlet of the phase-splitting apparatus in the extraction device at the next level is connected with the extracted object inlet of the extraction device at the current level through the pipeline provided with the pump. The invention has high extraction efficiency, small size, less occupied area, simple operation and capability of saving apparatus investment and running cost.

Owner:WENGFU (GRP) CO LTD

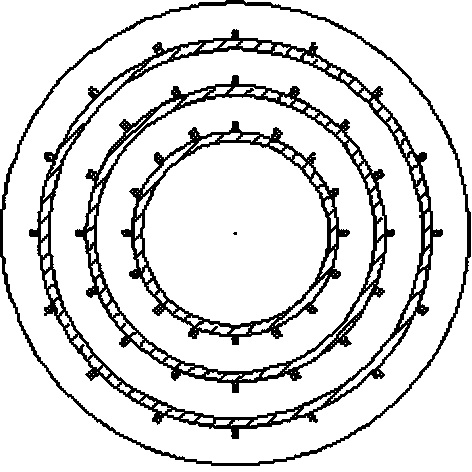

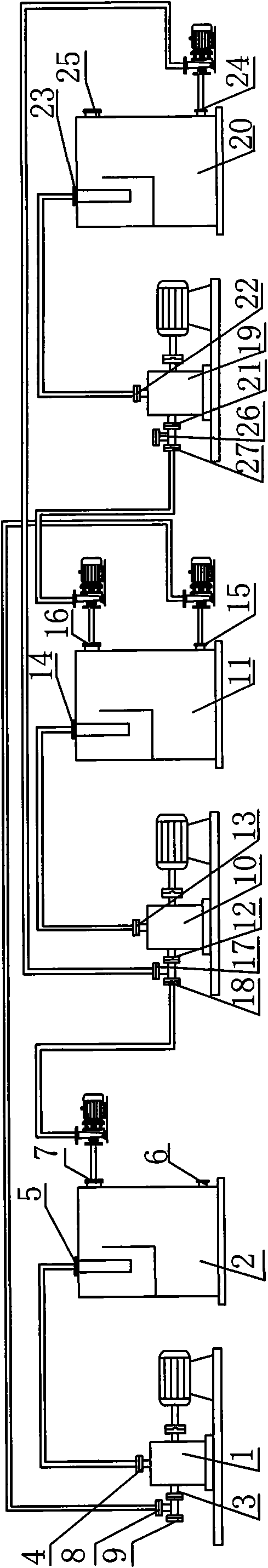

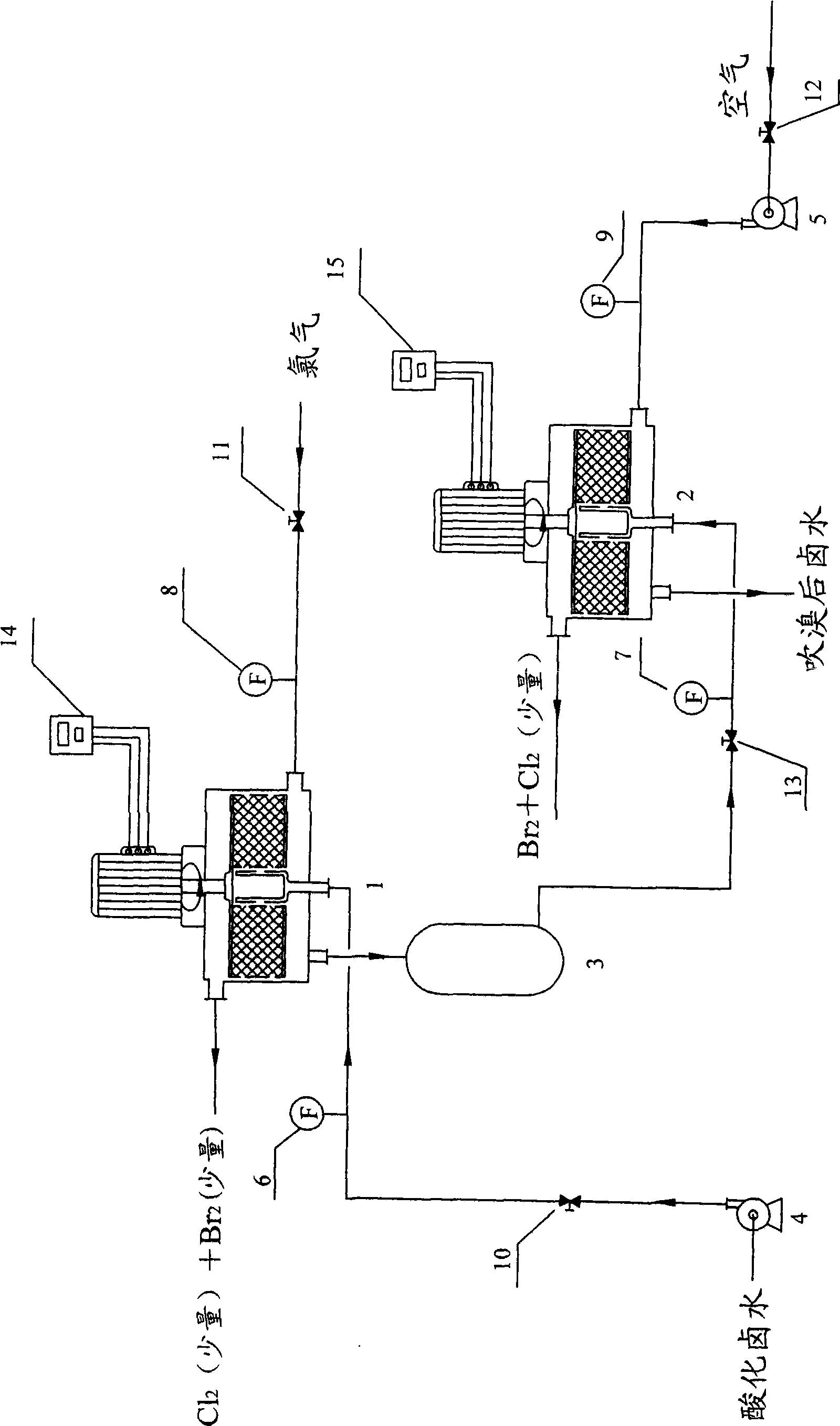

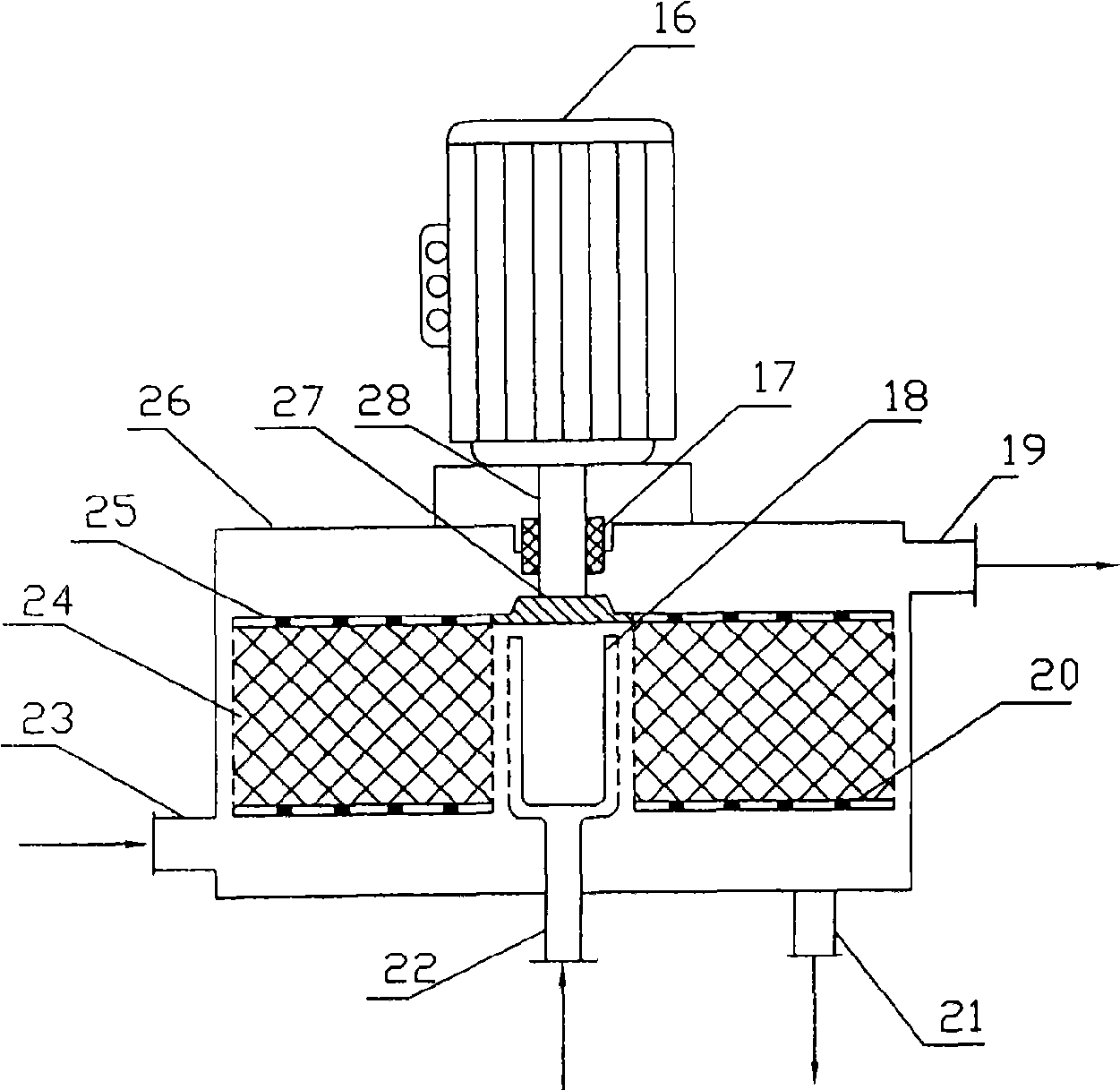

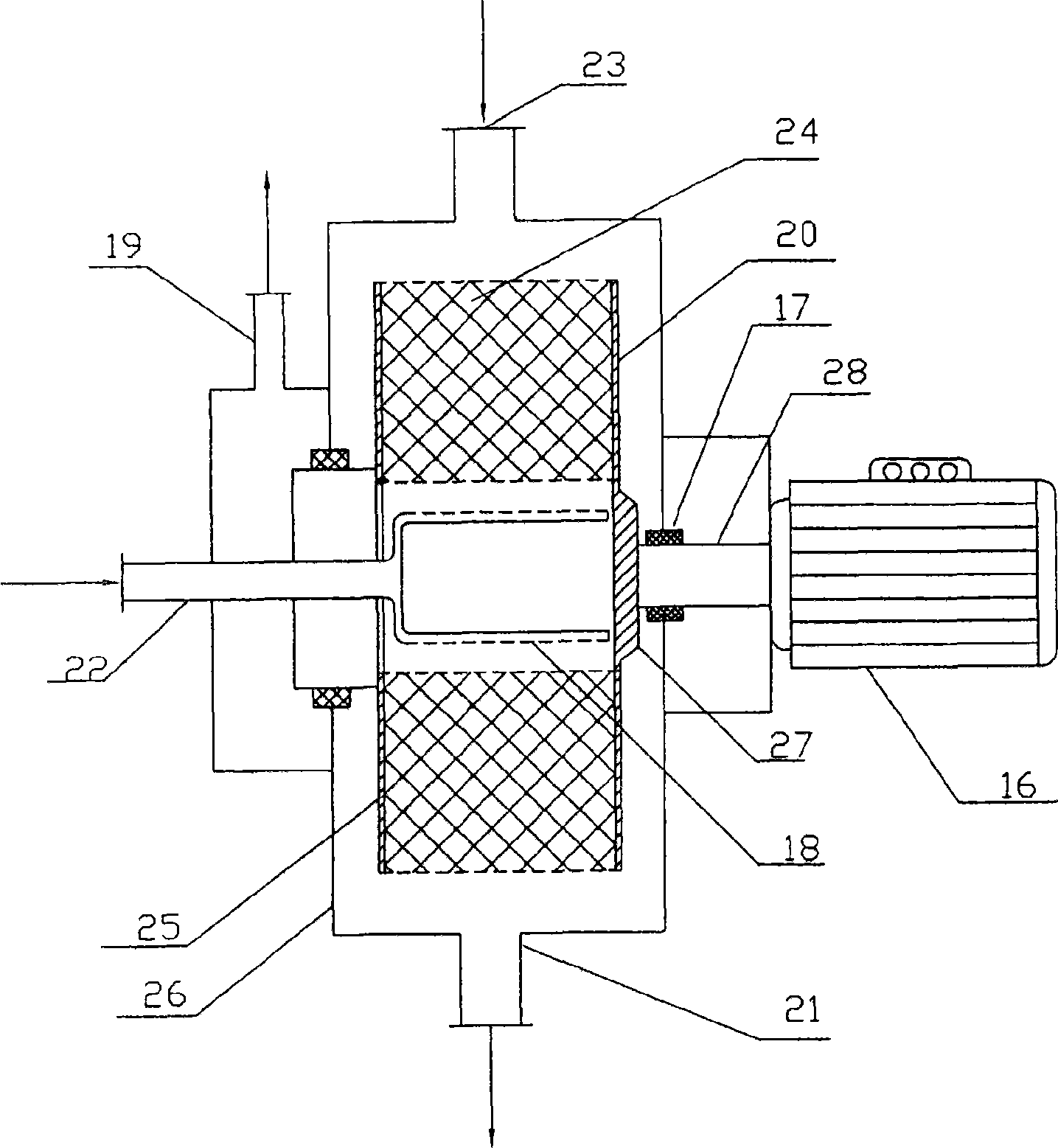

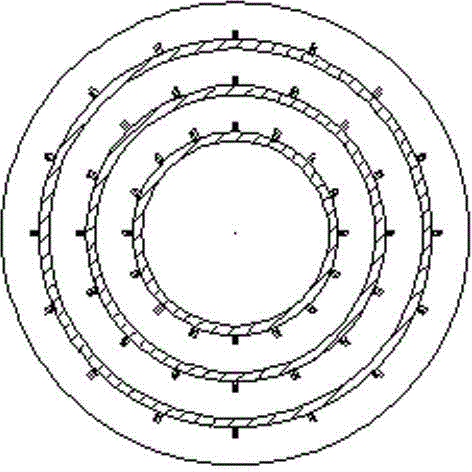

Oxidation and blowout technological process and apparatus for bittern bromine process

ActiveCN101486445AIncrease the specific surface area of contactEnhanced mass transferBromine/hydrogen-bromideLiquid ratioBromine

The invention pertains to the technical field of extraction of bromine from brine, more particularly relates to the technique of oxidation and blow-out during the process of extraction of bromine from brine, and a device thereof, which improve the oxidation rate and blow-out rate of bromine during the extraction process and reduce energy consumption. The method is as follows: acid brine and chlorine are introduced into a rotating packed bed I, and the formed oxidation solution and air enter a rotating packed bed II to blow out free bromine. The device comprises two rotating packed beds, the liquid inlet of the rotating packed bed I is connected with a pump and the gas inlet thereof is connected with a chlorine pipe; the rotating packed bed I and the rotating packed bed II are connected by a storage tank; and the gas inlet of the rotating packed bed II is connected with a fan. The method has the advantages of improving the oxidation rate of bromonium ions, the utilization ratio of chlorine and the blow-out rate of free bromine, and reducing chlorine adding ratio, chlorine consumption amount, the causticity of the device during the process after the extraction of bromine and the process of salt extraction, gas-liquid ratio and operation cost; and the device occupies less land and is easy to be start and shut off and maintained.

Owner:ZHONGBEI UNIV

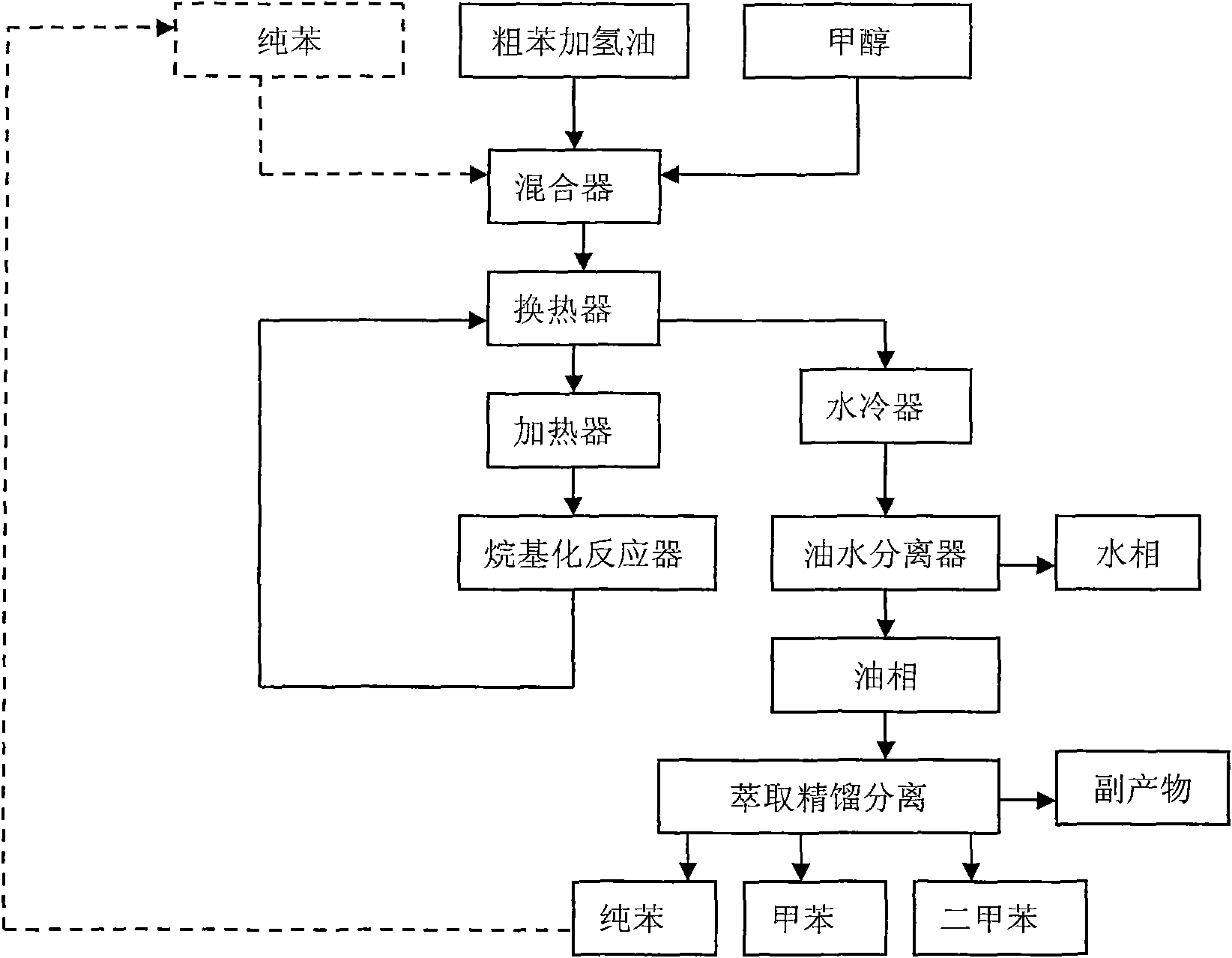

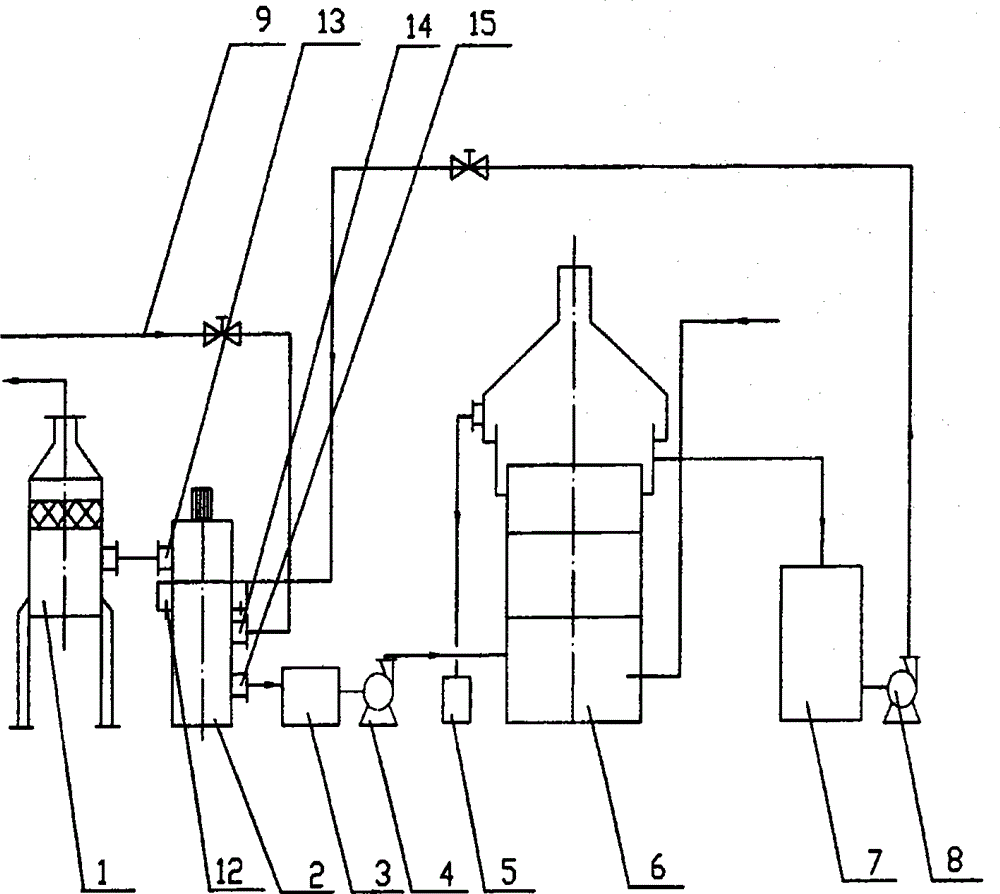

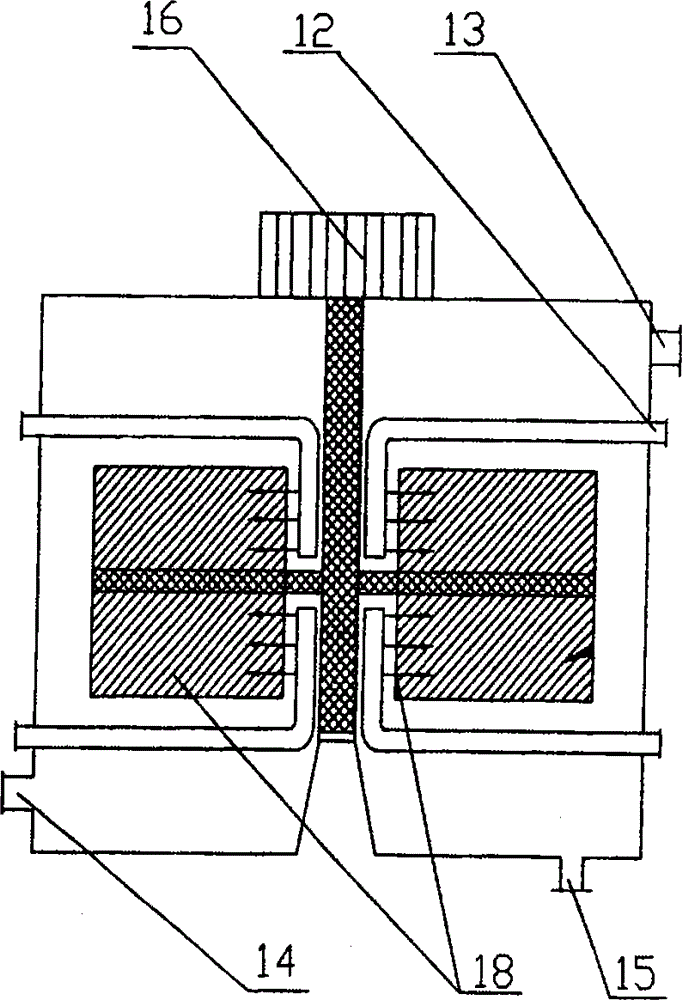

Method for adjusting product composition during coked crude benzene refining

InactiveCN101628846AIncrease productionReduce outputMolecular sieve catalystsDistillation purification/separationAlkyl transferMolecular sieve

The invention relates to a method for adjusting product composition during coked crude benzene refining. Coked crude benzene hydrogenated oil is premixed with alkylation reagent methanol. The mixture undergoes heat exchange with a material leaving an alkylation reactor and then is heated. After the temperature of the mixture reaches a reaction temperature, in the presence of a molecular sieve based catalyst, the mixture undergoes alkylation reaction so as to obtain a product. After the alkylation reaction is completed, the product is cooled by water and then undergo extraction, rectification and separation so as to obtain benzene, toluene and xylene, which leave the reaction system as target products. The method has simple procedures and can achieve the aim of reducing the benzene production amount and increasing the production amount of the toluene and the xylene by only increasing an alkylation unit without changing the main low-temperature hydrofining procedures of coked crude benzene.

Owner:山西恒扬科技有限公司 +1

Device for removing hydrogen sulfide in industrial gas

InactiveCN105879628ASmall footprintReduce circulationDispersed particle separationGas phaseSmall footprint

The invention relates to a device for removing hydrogen sulfide in industrial gas; a rotary packing bed is adopted as a gas-liquid mass transfer device; a gas inlet of the rotary packing bed is connected with sulfur-containing gas; a liquid inlet is connected with a barren liquid trough through a barren liquid pump, and an exhaust port of the rotary packing bed is connected with a defogger. The device for removing the hydrogen sulfide in the industrial gas has good desulfurization effect, and has the desulfurization rate reaching 98% or more. The device has small floor space, and the volume of the hypergravity rotary packing bed device is about 1 / 10 that of a traditional tower device; the mass transfer efficiency is high, the liquid circulation amount is small, the gas-phase pressure dropping amount is small, and the operation cost is low; the car driving and parking is convenient, and the whole technical system can be stabilized within several minutes; the hydrogen sulfide gas in an acid system is removed, the selectivity is high, and the alkaline consumption can be greatly reduced. The type and material of rotary packing can be chosen arbitrarily without restriction.

Owner:CHONGQING AOGEMEI GAS CO LTD

Deep dehydrating system device for natural gas and dehydrating method

InactiveCN107460015AHigh dehydration depthWide range of applicationsGas treatmentDispersed particle separationReboilerProcess engineering

The invention discloses a deep dehydrating system device for natural gas. The device is characterized by comprising a filter separator, a first super-gravity machine, a condenser, a poor / rich liquor heat exchanger, a pressurizing pump, a buffer tank, a reboiler, a second super-gravity machine, a flash tank, a conveying pump, a first stop valve, a second stop valve, a third stop valve, a fourth stop valve, a fifth stop valve, a reducing valve, a flowmeter, a vacuum pump, a gas-liquid separator and a three-way valve. The invention discloses a dehydrating method. According to the device, the purity of regenerated triethylene glycol poor liquor can be improved to 99.99wt%. By using the triethylene glycol poor liquor as an absorbent, the water dew-point at the natural gas outlet after water absorption in an absorption system is reduced to be below 35 DEG C below zero, preferably 45 DEG C below zero. The problem that the dehydrating depth of natural gas in the absorption system is low as triethylene glycol is not high in purity is solved, and the dehydrating treatment demand on low water dew point natural gas is met.

Owner:BEIJING UNIV OF CHEM TECH

A flue gas desulfurization device and process

ActiveCN103480259BOvercome surface tensionEnhanced mass transferDispersed particle separationDesorptionLiquid circulation

The invention belongs to the technical field of flue gas desulfurization, and particularly relates to a flue gas desulfurization process and device, which aim to solve the problems of an existing flue gas desulfurization process and device. The flue gas desulfurization device comprises a retrograde rotation packed bed absorber, a rotation packed bed desorber, a barren liquid storage groove, a rich liquid storage groove, a barren liquid circulation pump, a rich liquid circulation pump, a heat exchanger and a condenser. The flue gas desulfurization process comprises an absorption process and a desorption process. The device provided by the invention is small in size, has a wide in treatment gas quantity range, and is simple in structure and easy to operate. The process has the advantages of high desulfurization rate, low energy consumption, simple process, low investment and running expense, running stability, convenience in starting and stopping and the like.

Owner:ZHONGBEI UNIV

Method and device for removing free formaldehyde in urea-formaldehyde resin

The method of removing free formaldehyde from urea-formaldehyde resin includes: preheating rotary packing bed to 50-80 deg.c, starting the rotary packing bed and regulating rotation speed to 200-2500 rpm, feeding preheated urea-formaldehyde resin into the rotary packing bed, introducing air, water vapor or nitrogen as gas stripping gas via the gas inlet, and diffusing the free formaldehyde to the gas stripping gas for taking out of urea-formaldehyde resin. The present invention has greatly lowered technological cost and great treating amount. The formaldehyde removing apparatus of the present invention has simple structure, easy operation, high formaldehyde removing rate, low power consumption, and other advantages.

Owner:ZHONGBEI UNIV

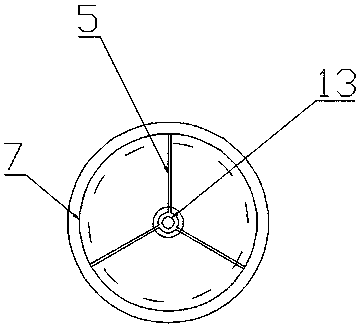

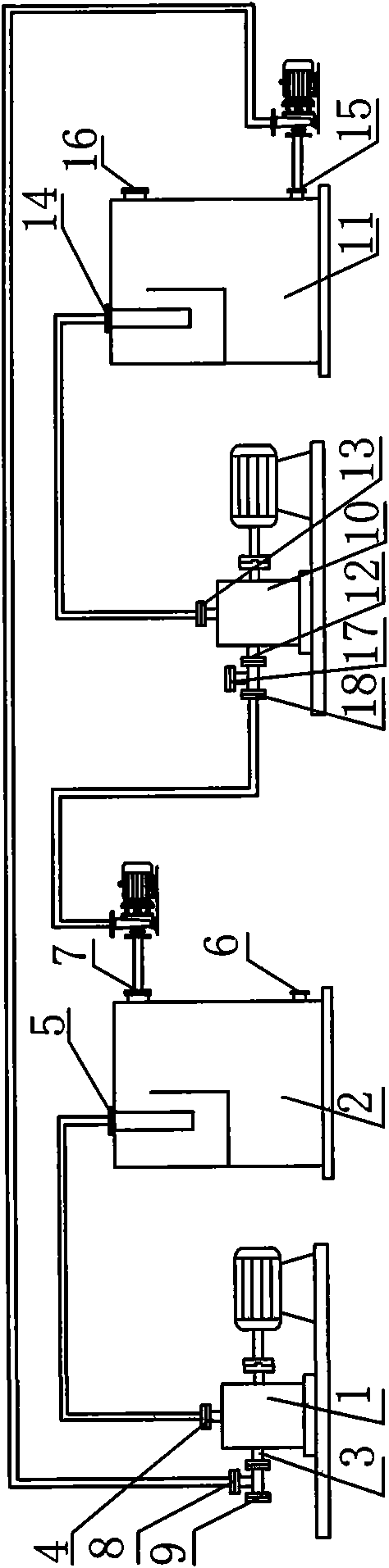

Stripping device

ActiveCN101898049ALarge mass transfer areaImprove stripping efficiencyLiquid solutions solvent extractionPhase splittingSolvent

The invention discloses a stripping device which comprises an emulsifying machine (1) and phase splitting equipment (2), wherein an emulsifying machine inlet (3) and an emulsifying machine outlet (4) are arranged on the emulsifying machine (1), a mixed-phase inlet (5), a heavy-phase outlet (6) and a light-phase outlet (7) are arranged on the phase splitting equipment (2), the emulsifying machine inlet (3) is connected with a stripping agent inlet (8) and a solvent inlet (9), and the emulsifying machine outlet (4) is connected with the mixed-phase inlet (5) of the phase splitting equipment. When multiple stages of stripping devices are combined, the light-phase outlet of the phase splitting equipment in the stage of stripping device is connected with the solvent inlet in the next stage of stripping device through a pipeline provided with a pump; and the heavy-phase outlet of the phase splitting equipment in the next stage of stripping device is connected with the stripping agent inlet in the stage of stripping device through the pipeline provided with the pump. The invention can strengthen the mass transfer performance, improve the stripping efficiency and lower the stripping equipment investment and the operating cost.

Owner:WENGFU (GRP) CO LTD

Device and method for removing sulfur dioxide in waste gas

ActiveCN103463936BOvercome surface tensionEnhanced mass transferDispersed particle separationAir quality improvementGas phaseTower

The invention belongs to the field of waste gas desulfurization, and particularly relates to a device and a method for removing sulfur dioxide contained in a waste gas. The device and the method can be used for solving the problems of the traditional waste gas desulfurization technology. The device for removing the sulfur dioxide contained in the waste gas comprises an inverse shearing rotation packed bed, a barren solution storage tank, a pregnant solution storage tank, a barren solution circulation pump and a pregnant solution circulation pump, wherein an inverse rotation packed bed absorber is in a parallel flow structure; a gas and a liquid which are positioned in the inverse shearing rotation packed bed contact in a parallel flow way. The method for removing the sulfur dioxide contained in the waste gas comprises the following step: fast transferring SO2 contained in the waste gas to a desulfurization absorbing agent by carrying out multistage parallel flow contact on the desulfurization absorbing agent and the SO2-containing waste gas through multilayer inverse rotation packings and body resistance parts. The device disclosed by the invention has the advantages of small size, width treatment tolerance range, simple structure and easiness for operation. Compared with the traditional tower, the process disclosed by the invention has the advantages of high desulfurization rate, less gas-phase pressure drop, low energy consumption, low investment and operation cost, stability in operation, convenience for start and stop, and the like.

Owner:JIANGSU ZEYU ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com