Method for preparing isocyanate monomer

A technology of isocyanate and monomer, which is applied in the field of diisocyanate preparation based on salt-forming phosgenation reaction, can solve the problems of incomplete salt-forming reaction hydrochloride particles, low utilization rate of HCl, many side reactions, etc., and achieve stable product quality , full salt-forming reaction, easy to start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

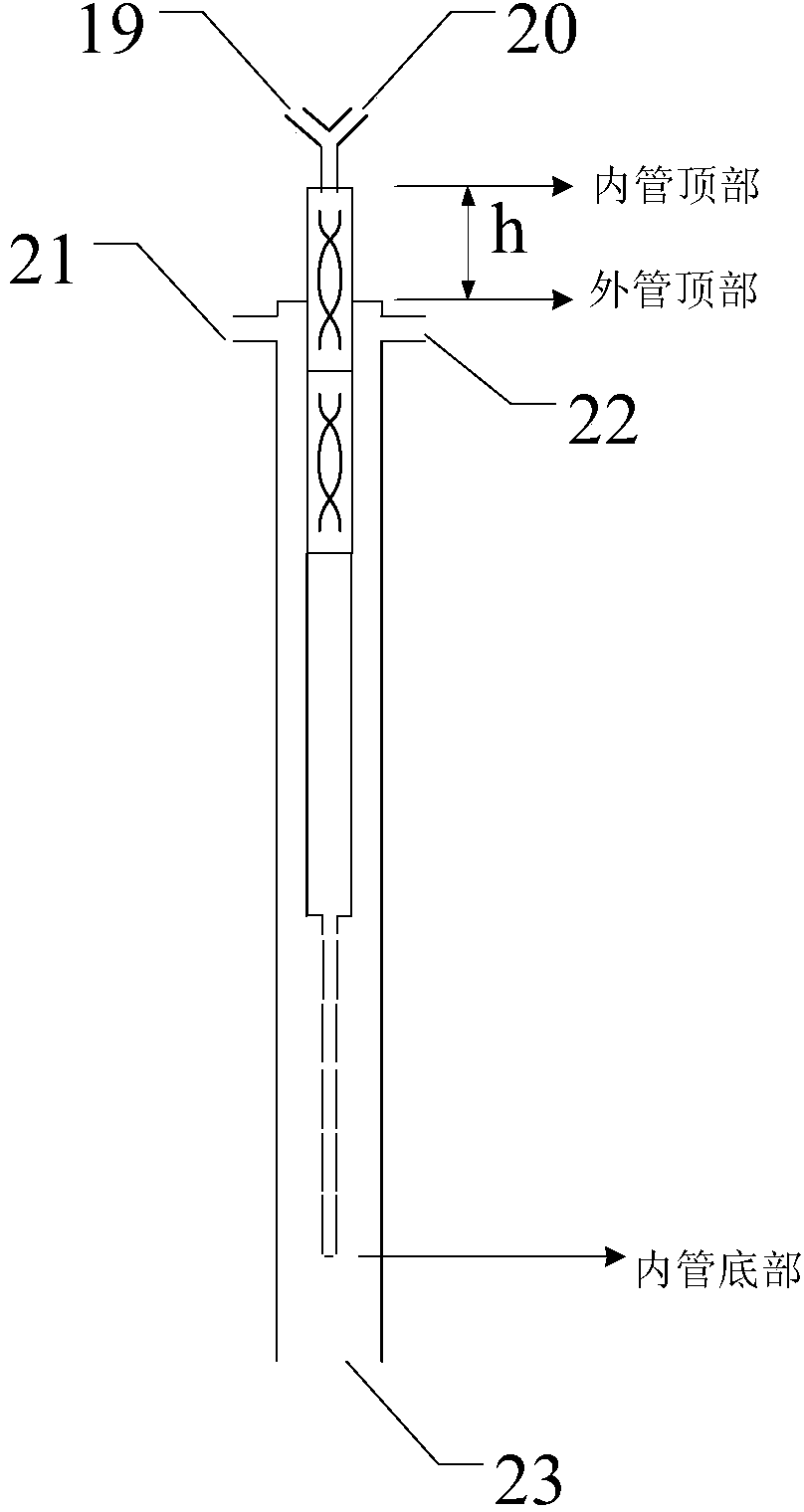

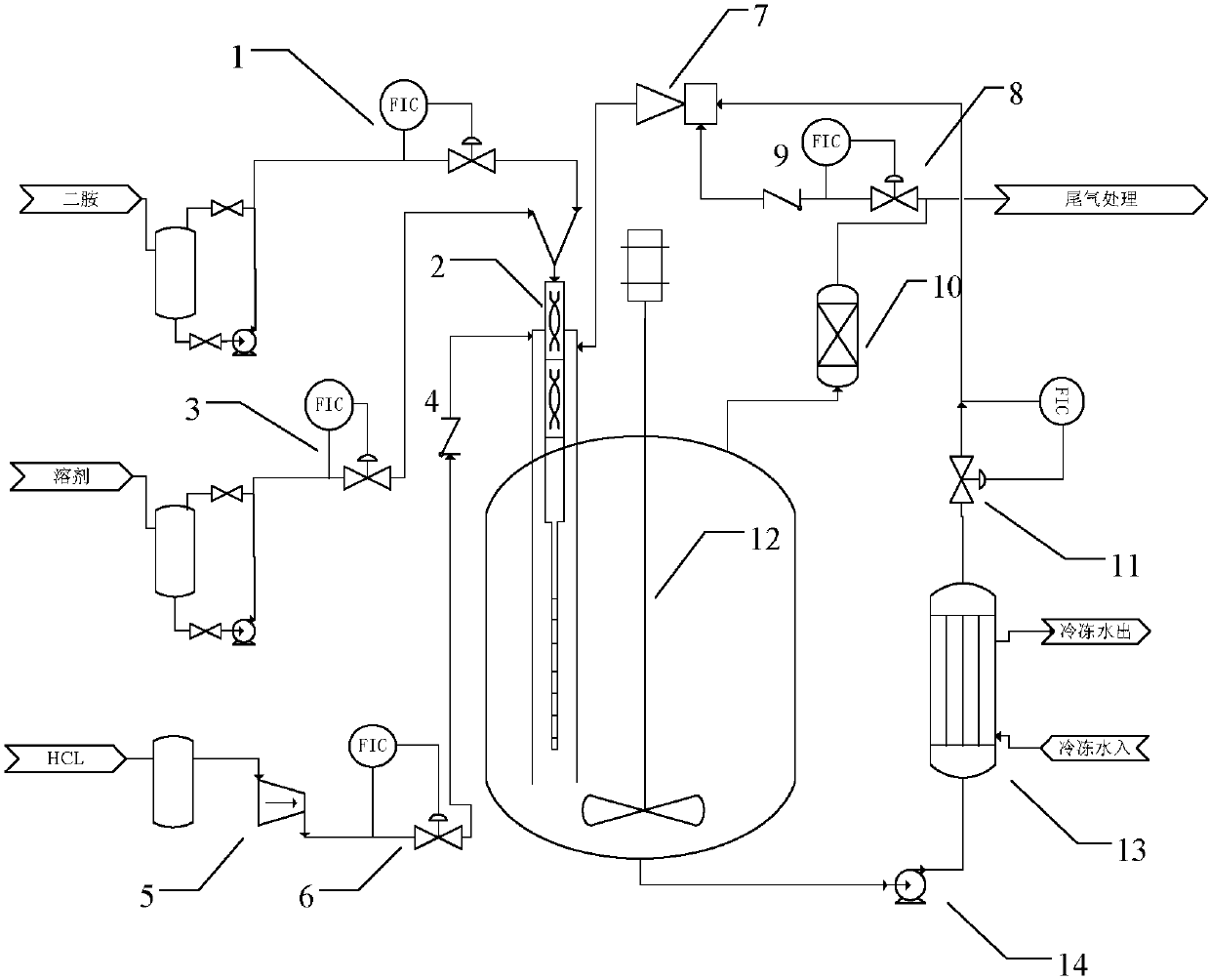

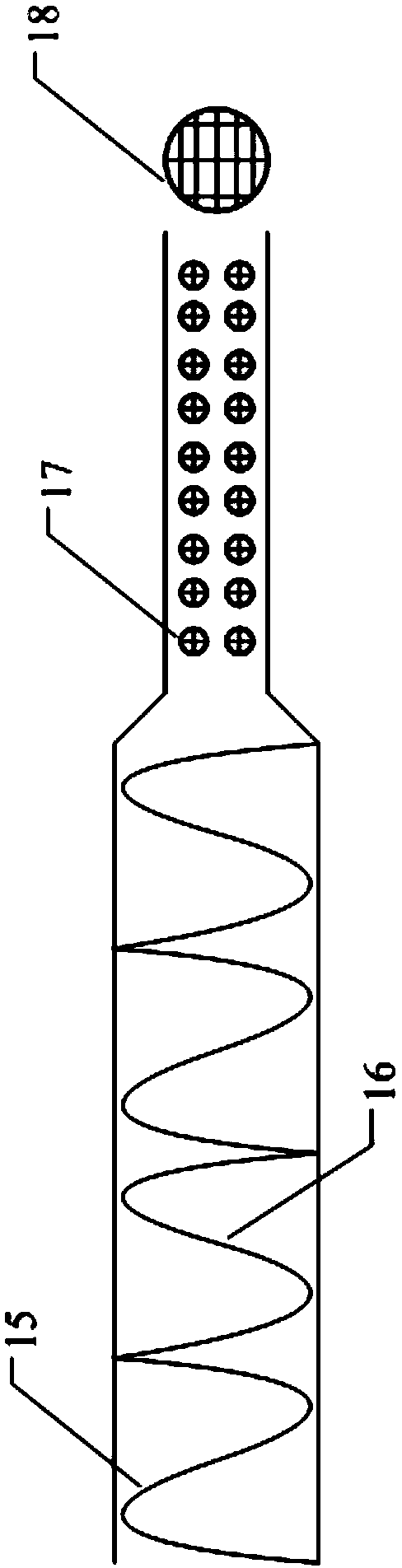

[0079]The inner diameter of the thick part of the mixer is 5cm. There are 3 sets of left-handed helical plates and right-handed helical plates. The helical plates are twisted 270°, and the length of each helical plate is 5cm. The inner diameter of the small diameter part is 4cm, the length is 30cm, and there are evenly distributed holes on the pipe wall of the small diameter part. The diameter of the holes is 1.2mm, and the opening rate is 14%. It is 90cm. The inner diameter of the outer tube of the mixer is 10 cm, the distance h between the top of the outer tube and the top of the inner tube is 15 cm, and the length of the outer tube is 90 cm. Both inner and outer tubes have a wall thickness of 1mm.

[0080] The volume of the salt-forming reaction kettle is 1000L, and nitrogen gas is first introduced to remove the air and moisture in the reaction kettle. Preload 300kg o-dichlorobenzene as the reaction solvent, and start the reactor stirrer 12 and the reaction circulation pu...

Embodiment 2

[0085] The inner diameter of the thick part of the mixer is 6cm, and there are 5 groups of spiral plates, the spiral plates are twisted 270°, and the length of each spiral plate is 5cm. The inner diameter of the small diameter part is 4cm, and the length is 30cm. There are evenly distributed holes on the pipe wall of the small diameter part. The diameter of the holes is 1mm, and the opening rate is 20%. The total length is 90cm. The inner diameter of the outer tube is 13m, the distance h between the top of the outer tube and the top of the inner tube is 20cm, and the length of the outer tube is 100cm. Both inner and outer tubes have a wall thickness of 1mm.

[0086] The volume of the salt-forming reactor is 1000L, and the air and moisture in it are removed by passing nitrogen gas. Preload 300kg o-dichlorobenzene as the reaction solvent, and start the reactor stirrer 12 and the reaction circulation pump 14. Turn on the HCl compressor 5, control the outlet absolute pressure t...

Embodiment 3

[0091] The inner diameter of the thick part of the mixer is 8cm. There are 5 groups of left-handed helical plates and right-handed helical plates. The helical plates are twisted 270°, and the length of each helical plate is 5cm. The inner diameter of the small diameter part of the inner tube is 5cm, and the length is 30cm. There are evenly distributed holes on the wall of the small diameter part. The diameter of the holes is 0.8mm, and the opening rate is 18%. The total length of the inner tube is 100cm. The inner diameter of the outer tube is 14cm, the distance h between the top of the outer tube and the top of the inner tube is 30cm, and the length of the outer tube is 110cm. Both inner and outer tubes have a wall thickness of 1mm.

[0092] The volume of the salt-forming reactor is 1000L, and the air and moisture in it are removed by passing nitrogen gas. Preload 300kg o-dichlorobenzene as the reaction solvent, and start the reactor stirrer 12 and the reaction circulation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com