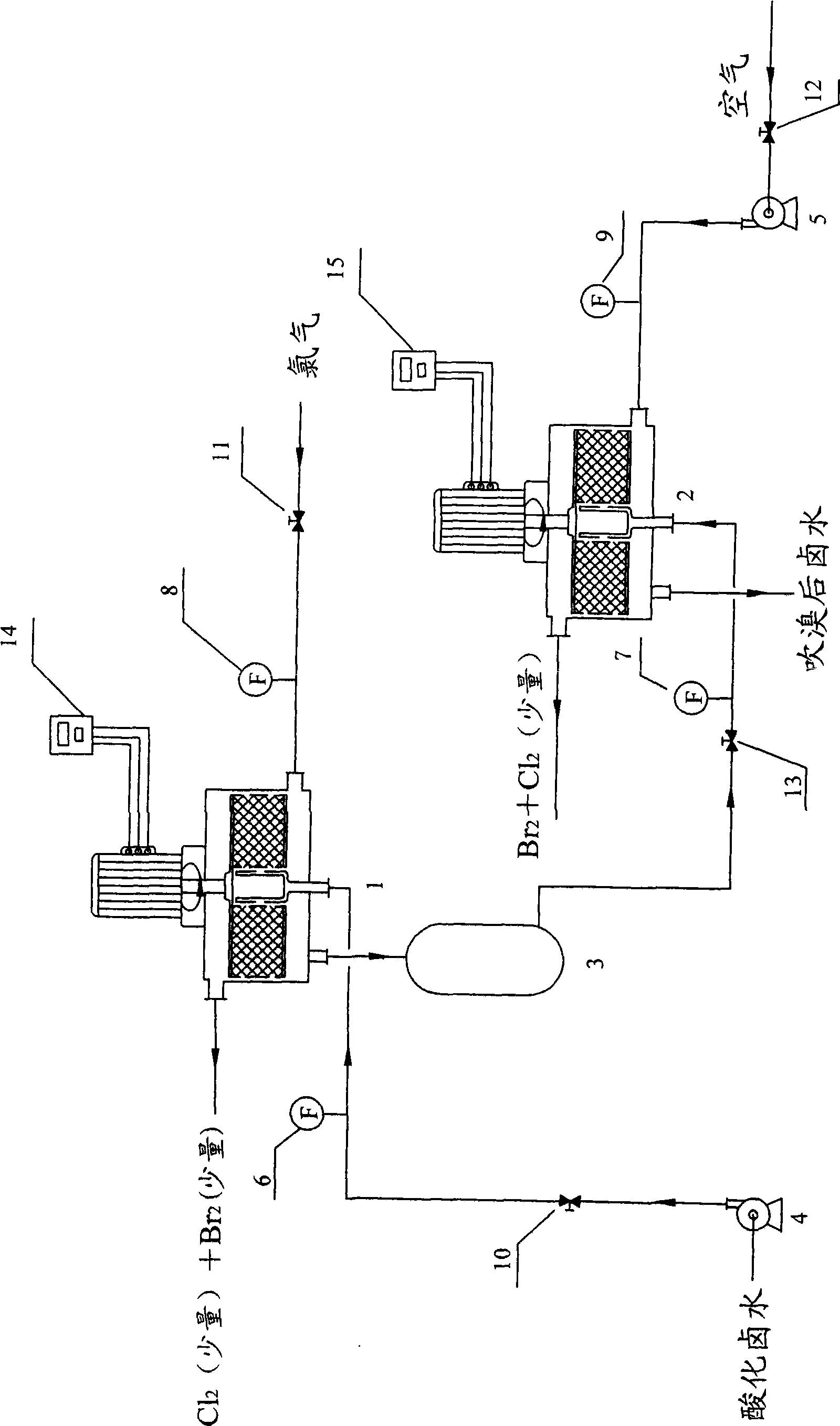

Oxidation and blowout technological process and apparatus for bittern bromine process

A process method and brine technology, applied in the field of bromine extraction from brine, can solve the problems of waste of energy and resources, large consumption of chlorine, low yield of bromine, etc., to reduce corrosion, reduce floor space, and improve oxidation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

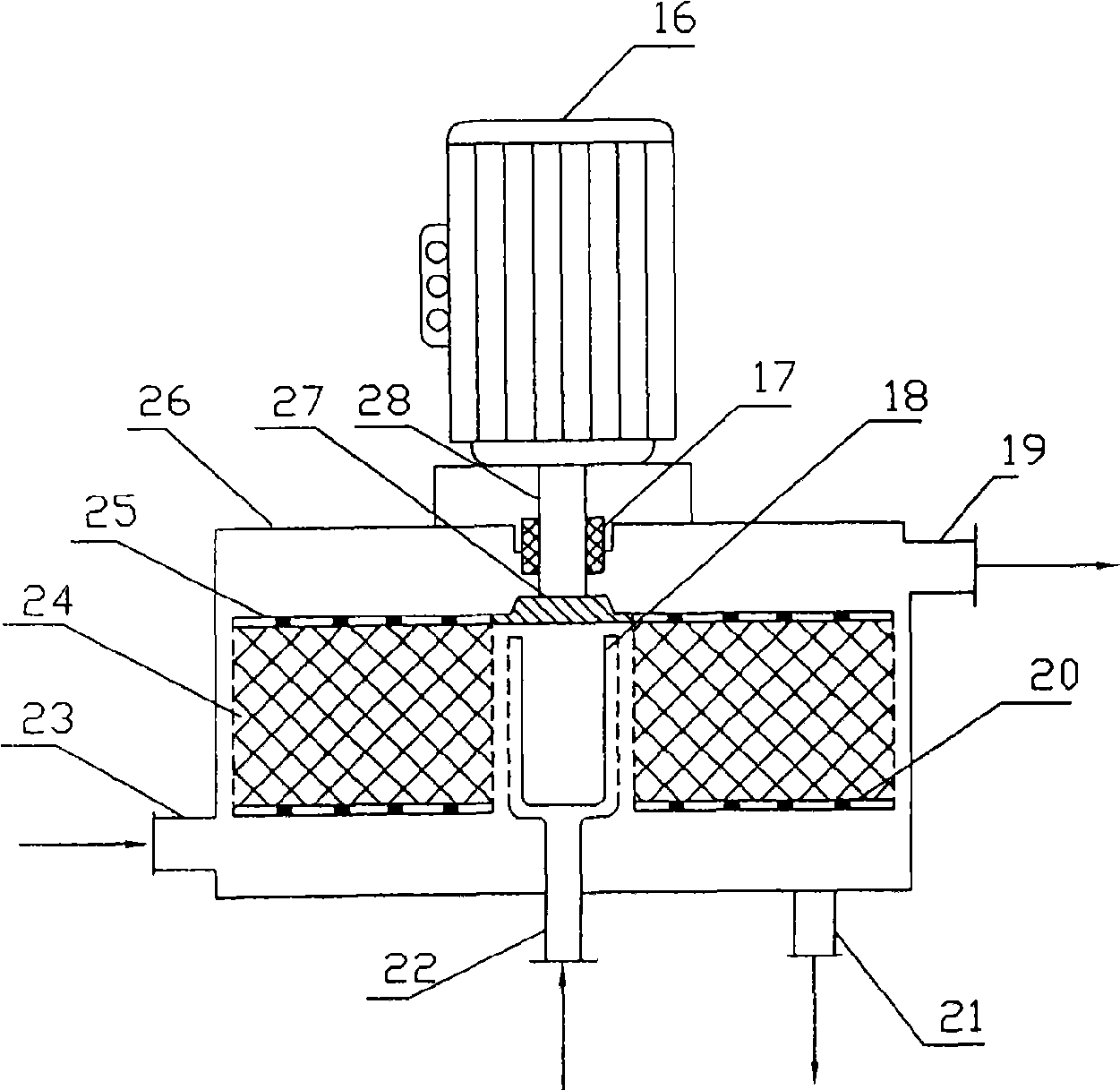

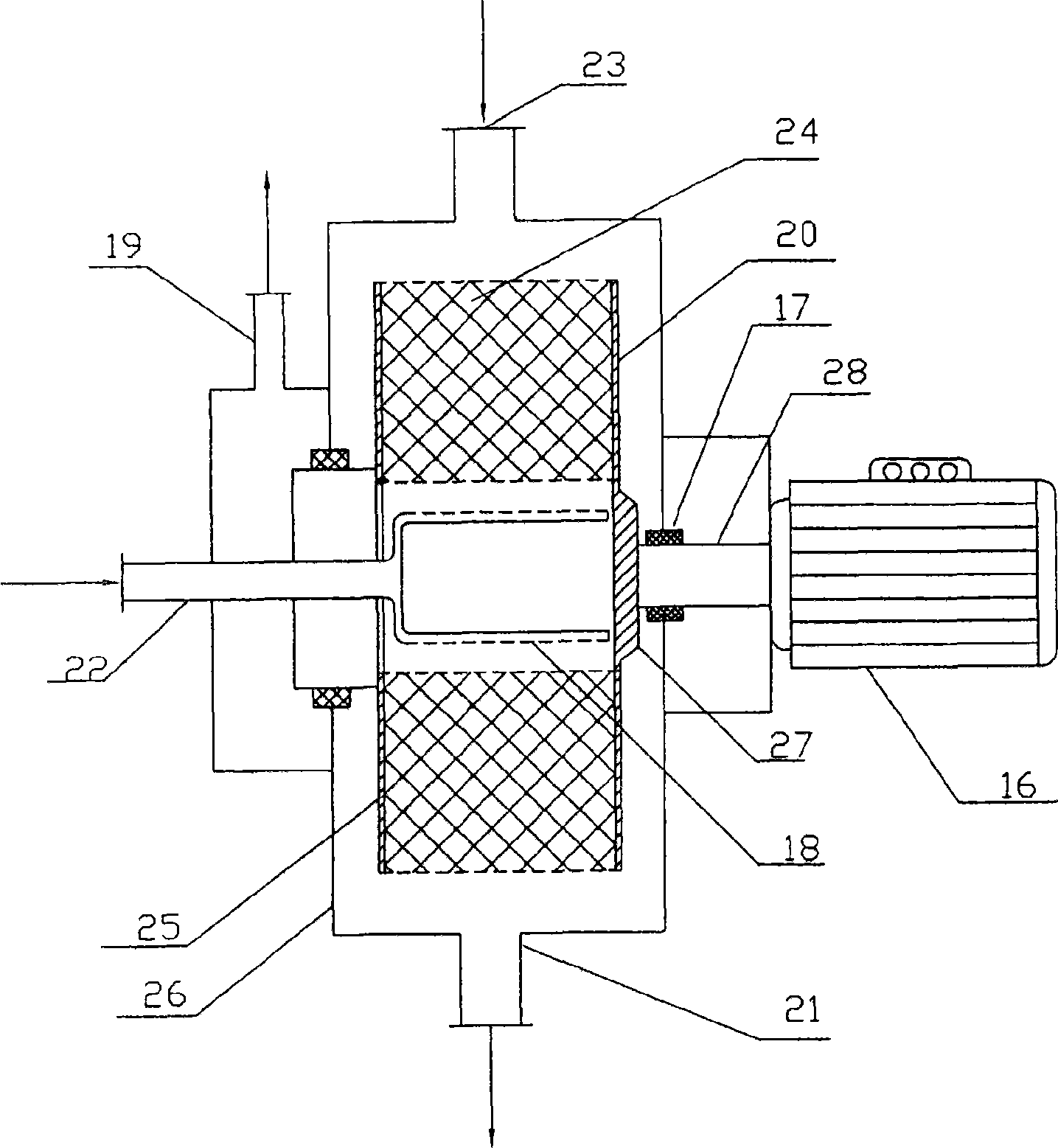

[0036] Embodiment 1: The bromine content of brine is 50mg / L, and its main equipment: two rotating packed beds are respectively made of stainless steel wire mesh packing, and the shells and storage tanks of the two rotating packed beds are made of polytetrafluoroethylene. The gas-liquid contact mode is cross-flow.

[0037] Adjust the pH value of the raw brine to 3 with dilute sulfuric acid. Turn on the rotary packed bed I, control its speed at 400r / min through the frequency converter I, and the chlorine distribution rate at 120%. The acidified brine contacts with chlorine gas in the packing layer, and an oxidation reaction occurs; the oxidizing solution stays in the storage tank for a period of time to be brominated. After the ions are completely oxidized at a specific chlorine distribution rate, turn on the rotating packed bed II, control its speed at 800r / min through the frequency converter II, and then turn on the fan to control the gas-liquid ratio at 50m 3 / m 3 ; The oxi...

Embodiment 2

[0038] Embodiment 2: The bromine content of the brine is 350mg / L, and its main equipment: two rotating packing beds are respectively made of stainless steel wire mesh packing, and the shells and storage tanks of the two rotating packing beds are made of stainless steel. The gas-liquid contact mode is cross-flow.

[0039] Adjust the pH value of the raw brine to 3.2, turn on the rotary packed bed I, control its rotating speed at 600r / min through the frequency converter I, and the chlorine distribution rate at 130%, the acidified brine contacts with chlorine gas in the packed layer, and an oxidation reaction occurs; the oxidation solution After staying in the storage tank for a period of time, turn on the rotating packed bed II, control its speed at 1000r / min through the frequency converter II, and then turn on the fan to control the gas-liquid ratio at 300m 3 / m 3 ; The oxidizing solution is in contact with the air in the filler to complete the mass transfer process and blow ou...

Embodiment 3

[0040] Example 3: The bromine content of the brine is 250mg / L, and its main equipment: two rotating packed beds are respectively made of stainless steel wire mesh packing, and the shells and storage tanks of the two rotating packed beds are made of stainless steel and polytetrafluoroethylene respectively. The gas-liquid contact mode is countercurrent.

[0041] Adjust the pH value of the raw brine to 3.3, turn on the rotary packed bed I, control its rotating speed at 800r / min through the frequency converter I, and the chlorine distribution rate at 110%, and the acidified brine contacts with chlorine gas in the packed layer, and an oxidation reaction occurs; the oxidation solution After staying in the storage tank for a period of time, turn on the rotating packed bed II, control its speed at 600r / min through the frequency converter II, then turn on the fan, and control the gas-liquid ratio at 200m 3 / m 3 ; The oxidizing solution is in contact with the air in the filler to compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com