Patents

Literature

131results about "Bromine/hydrogen-bromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste Treatment and Energy Production Utilizing Halogenation Processes

InactiveUS20090028767A1Reduce needEfficient processingPhotography auxillary processesElectrolysis componentsCelluloseEngineering

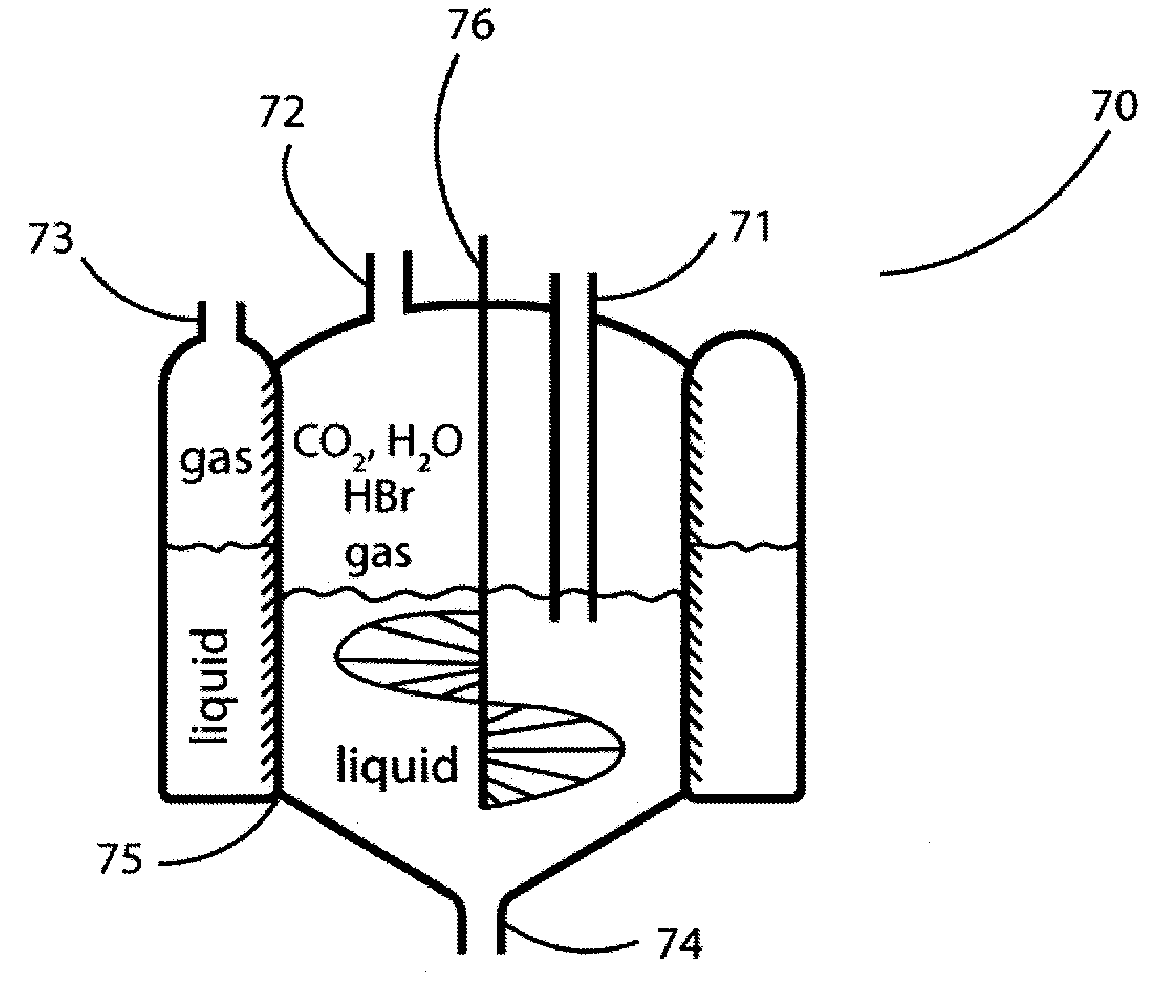

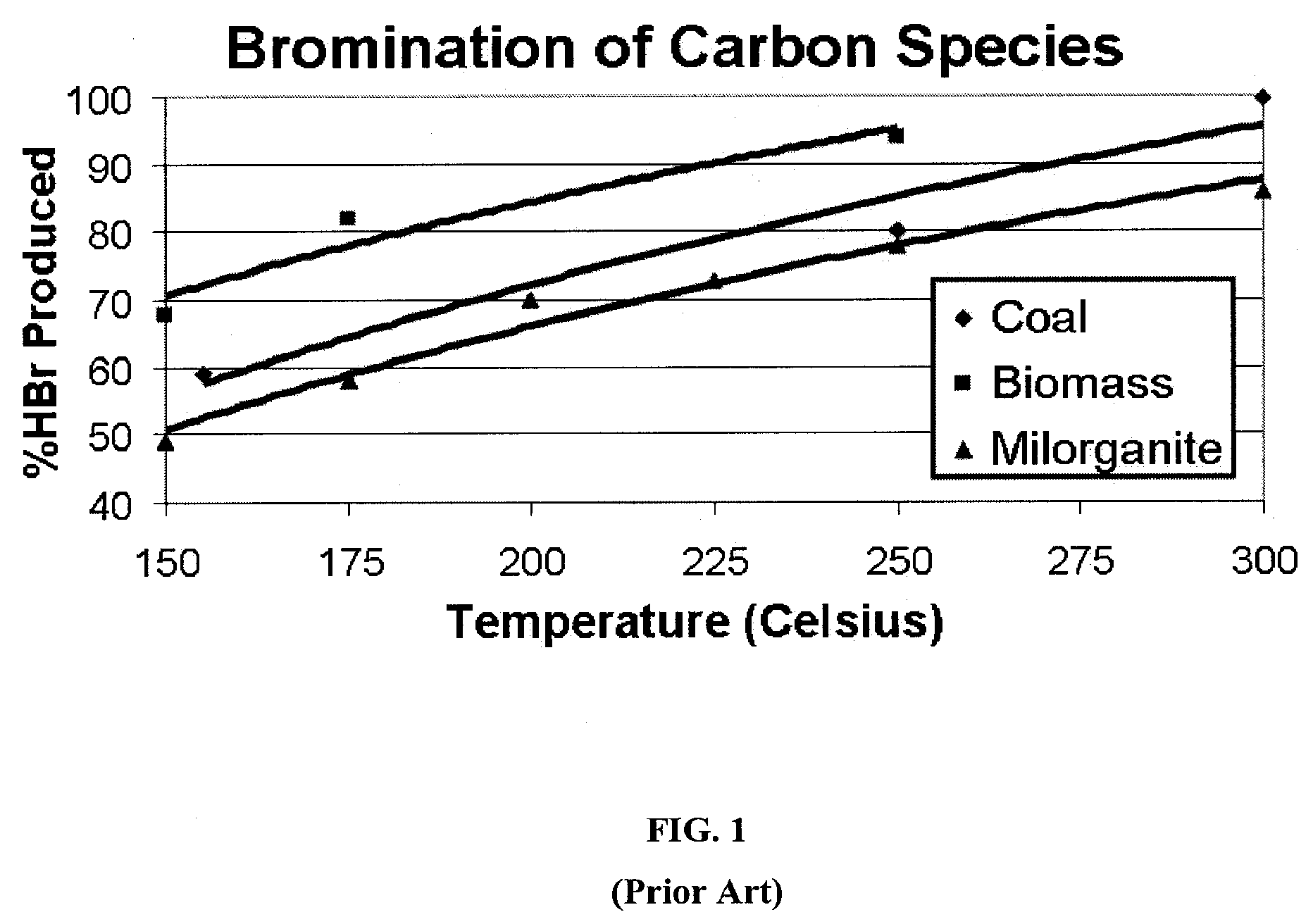

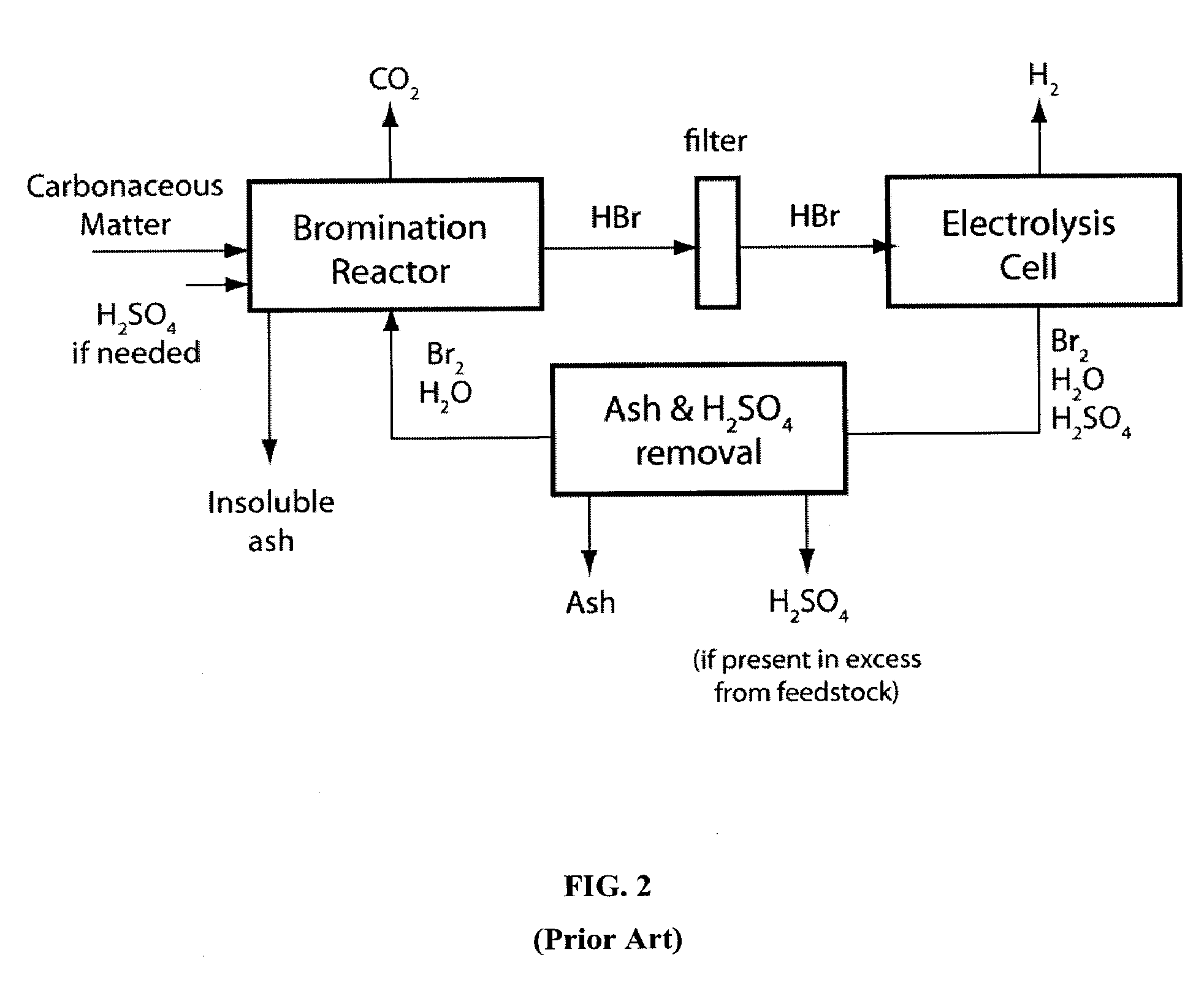

A method for generating energy and / or fuel from the halogenation of a carbon-containing material and / or a sulfur-containing chemical comprises supplying the carbon-containing material (e.g., coal, lignite, biomass, cellulose, milorganite, methane, sewage, animal manure, municipal solid waste, pulp, paper products, food waste) and / or the sulfur-containing chemical (e.g., H2S, SO2, SO3, elemental sulfur) and a first halogen-containing chemical to a reactor. The carbon-containing material and / or the sulfur-containing chemical and the halogen-containing chemical are reacted in the reactor to form a second halogen-containing chemical and carbon dioxide, sulfur and / or sulfuric acid. The second halogen-containing chemical is dissociated (e.g., electrolyzed) to form the first halogen-containing chemical and hydrogen gas (H2). The first halogen-containing chemical can be Br2 and the second halogen-containing chemical can be HBr. Any carbon dioxide formed during reaction can be directed to a prime mover (e.g., turbine) to generate electricity. Any ash and / or sulfur formed can be removed. In some cases a sulfur-containing chemical can be supplied to the reactor with the carbon-containing material.

Owner:SRT GROUP

Comprehensive utilization method for bittern

InactiveCN101691239ARealize closed loopSimple process controlCalcium/strontium/barium carbonatesIodineSimple componentChemistry

The invention relates to a comprehensive utilization method for bittern, which belongs to the technical field of salt chemical engineering. The bittern is a liquid mineral product, and is rich in multiple elements such as potassium, sodium, lithium, boron, bromine, iodine and the like; and at present, in the prior domestic bittern development and utilization, some simple components or components with high additional value in the elements are extracted, and the un-extracted components are discharged along with old bittern to be abandoned so as to cause serious waste of resources and pollute the environment. Through reasonable combination of processes of removing H2S from the bittern, settling magnesium, settling calcium and preparing calcium carbonate, preparing potassium-sodium mixed saltthrough primary salt preparation and secondary salt preparation, extracting potassium chloride through flotation, extracting boron, iodine, bromine, rubidium and cesium through acidification, preparing rubidium chloride and cesium chloride, extracting lithium and the like, the method implements step-by-step ordered extraction of main components; the toil yield of several main components reaches over 95 percent; and the method has the advantages of mutually exclusive loss in component extraction, implementation of closed cycle of processes, no mother liquor discharge, simple process control, low cost, high yield, environmental protection and the like.

Owner:DAZHOU HENGCHENG ENERGY GROUP

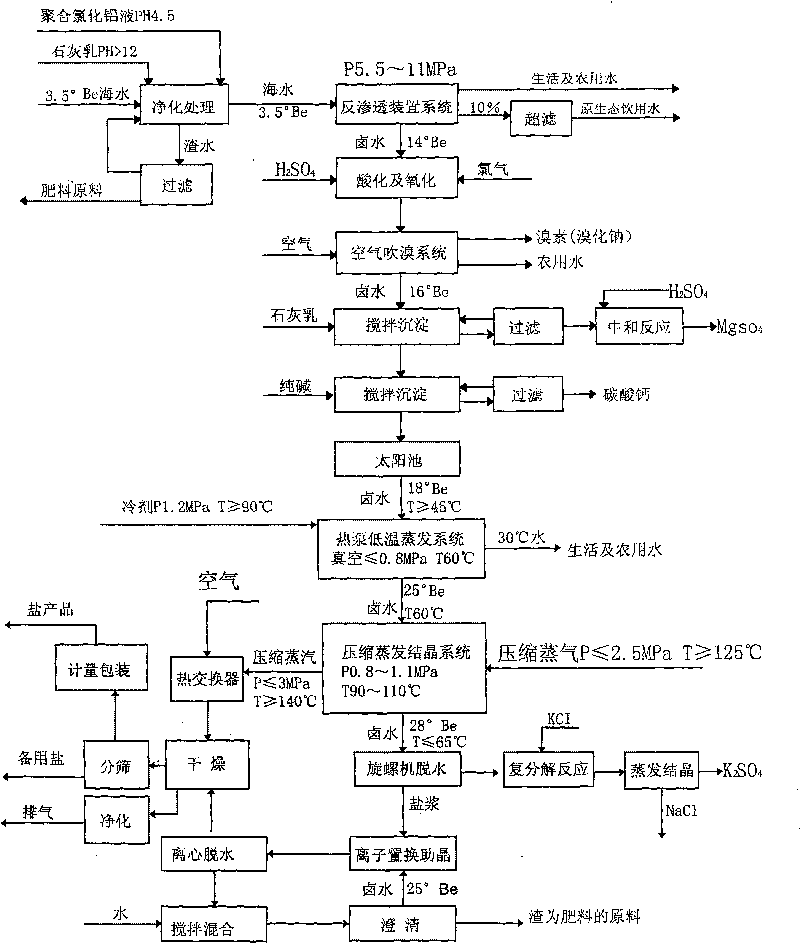

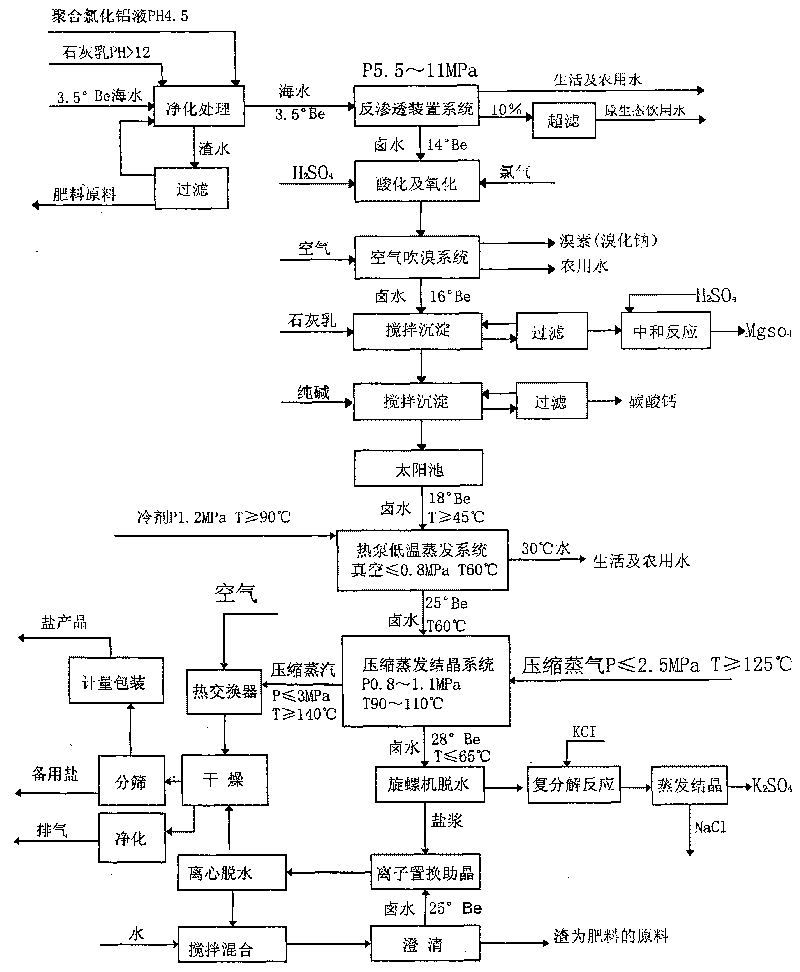

Technique for desalting sea water, making salt and comprehensively using by-products thereof by utilizing wind energy, solar energy and heat pump technologies

ActiveCN101704560AIncrease volumeAchieve balanceGeneral water supply conservationEnergy inputWater desalinationSolar pond

The invention relates to a technique for desalting sea water, making salt and comprehensively using by-products thereof by utilizing wind energy, solar energy and heat pump technologies, the main procedures comprise desalting sea water, air-blowing bromine, removing impurities for clarification, heating solar pond and storing halogen, evaporating for concentration, compressing and crystallizing for salt making, brine chemical engineering, etc. the invention desalts sea water, makes salt and comprehensively uses by-products thereof by utilizing wind energy, solar energy and heat pump technologies, organically combines sea water desalting, salt making and comprehensive use of dregs and waste liquor, takes wind energy, solar energy and other renewable energy resources as main energy sources, changes sea salt production from drying on beach in the open air manually to mechanized and automated operation, puts an end to the backward state of sea salt enterprises, can save energy consumption and reduce pollution, can save investment by about 50% and occupied area by 95%, not only lowers production cost, but also recovers 35m<2> of fresh water by producing one ton of salt, thus protecting fresh water resource.

Owner:ZHANJIANG NONGHAI TECHNOLOGY CO LTD

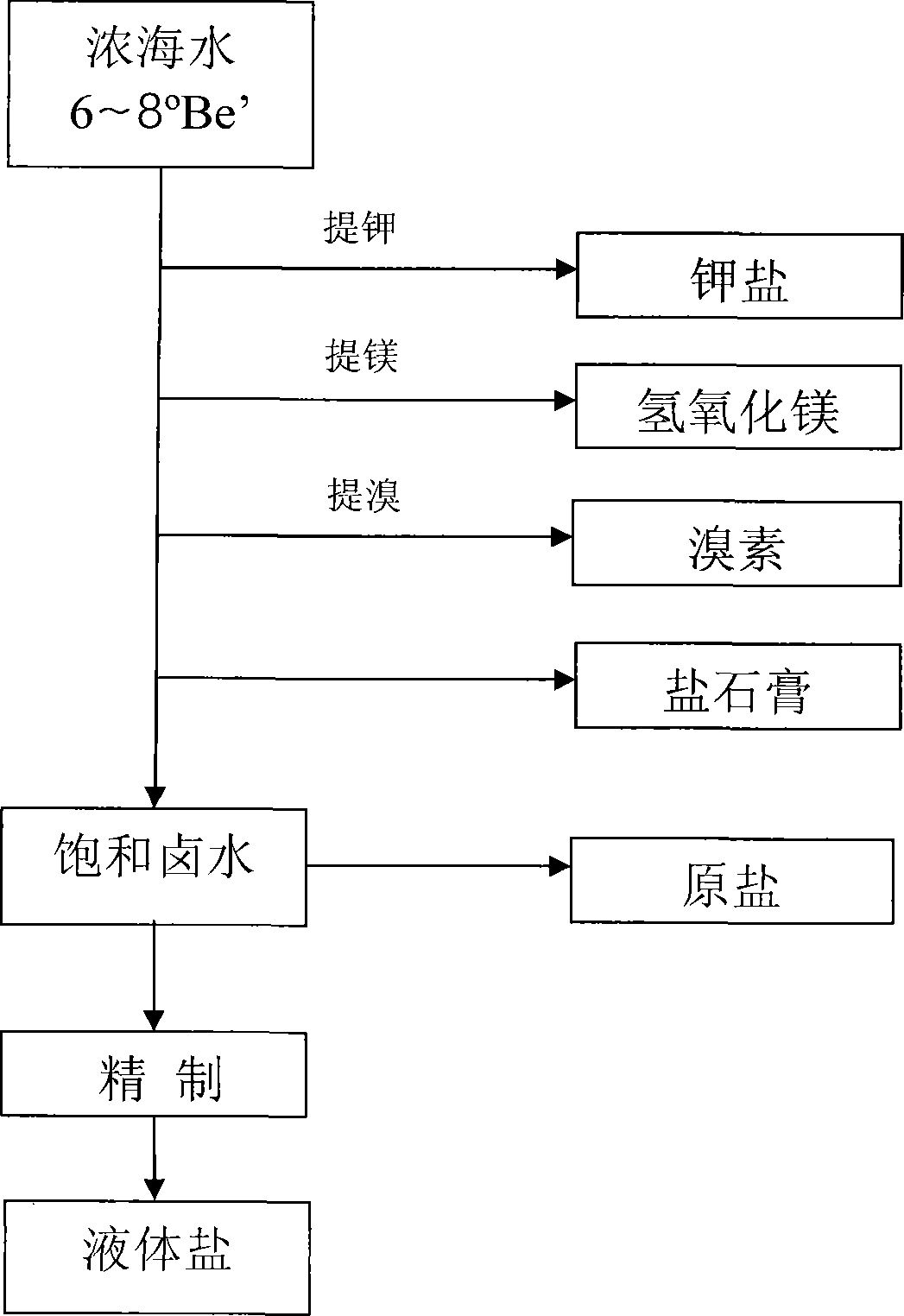

Thick seawater comprehensive utilization technique after seawater desalination

InactiveCN101234767AReduce evaporation resistanceIncrease productionCalcium/strontium/barium sulfatesBromine/hydrogen-bromideBromineEvaporation

The invention provides a process for comprehensively utilizing desalinated seawater after desalination, including the following steps: the desalinated seawater is collected and potassium is extracted; magnesium is extracted; evaporation concentration is carried out and bromine is extracted; marine gypsum is extracted; salt is made with the desalinated seawater; the desalinated seawater is refined to produce liquid salt. The steps for extracting the potassium, magnesium and bromine of the invention can be inter-modulated. The process has the advantages that: Ca<2+> in saturated brine treated by the process is reduced by 85.21-94.29 percent, Mg<+2> is reduced by 51.22-63.98 percent, SO4<2-> is reduced by 85.57-93.82 percent, Br<-> is reduced by 75 percent, k<+> is reduced by 70 percent, Na<+> is increased by 3.06-5.86 percent and Cl<-> is increased by 7.96-9.38 percent. As ingredient of the brine changes, impendence of the brine evaporation is reduced; yield and quality of the sea salt are improved. The process for producing solar salt can not only effectively utilize chemical resource in the desalinated seawater but also greatly improve the yield and quality of the sea salt product. Bittern quantity of the brine is greatly reduced; if the produced saturated brine is refined, the liquid salt can be produced to directly supply an alkali plant for sintering the alkali.

Owner:TIANJIN CHANGLU HAIJING GRP CO LTD

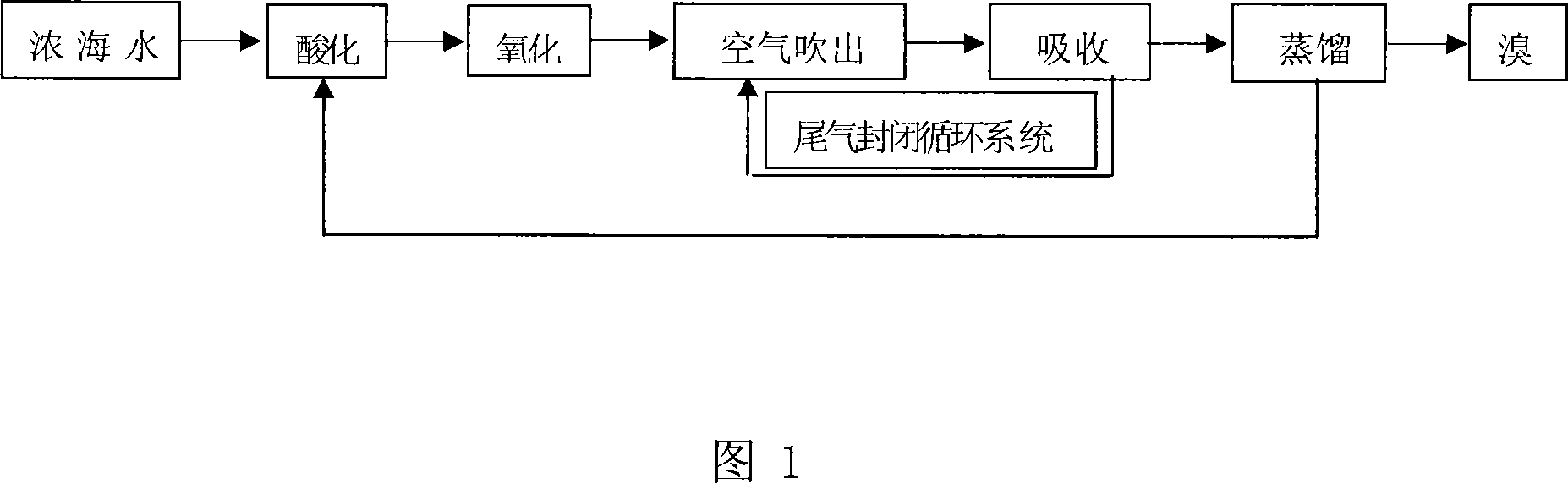

Technology process for producing bromide using concentrated seawater

ActiveCN101045529AIncrease acquisition rateFacilitate desorptionBromine/hydrogen-bromideWater desalinationProcess equipment

Owner:天津海晶科技发展有限公司

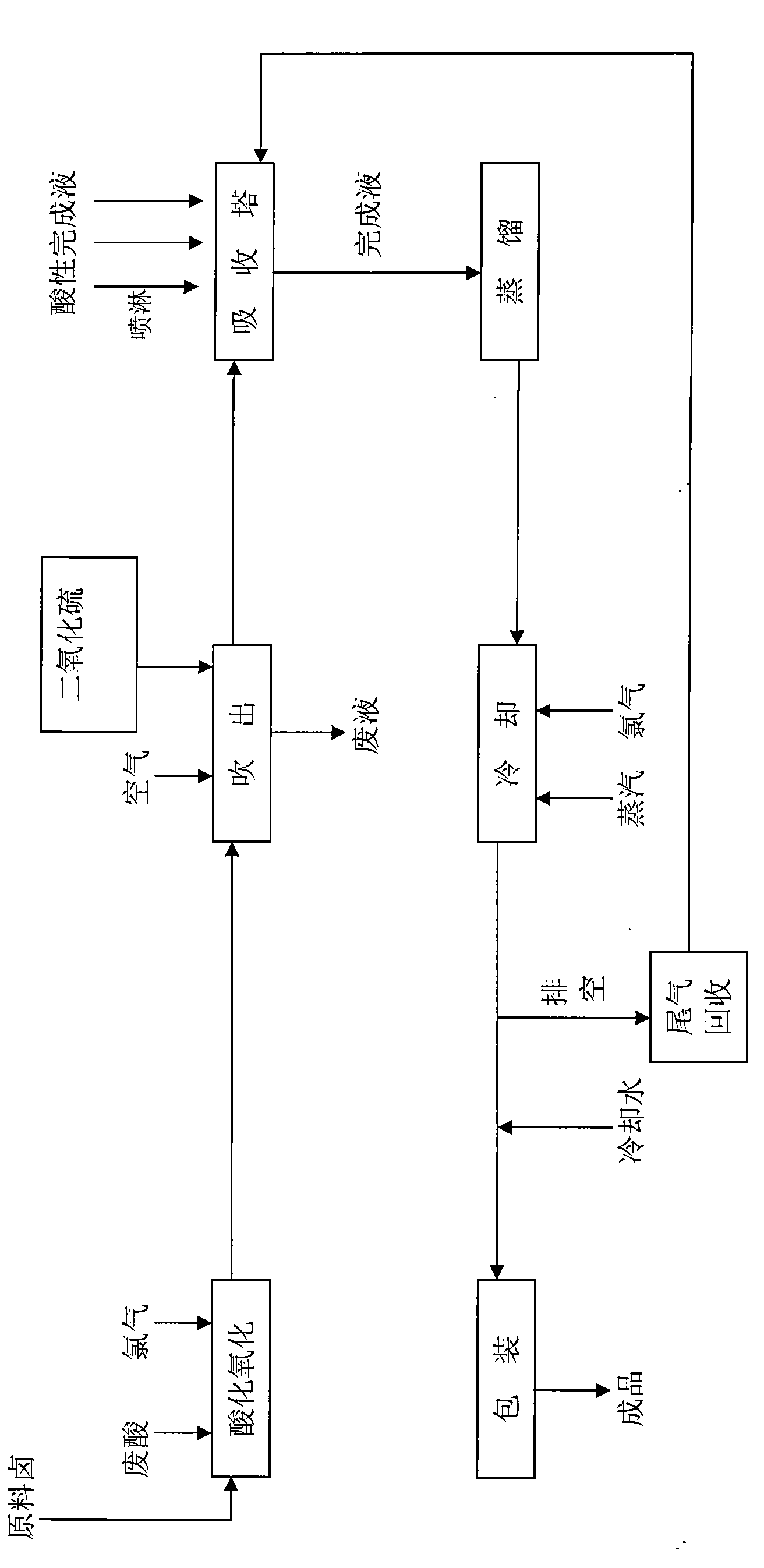

Bittern bromine-blowing process

The invention discloses a bittern bromine-blowing process comprising oxidation, blowout, absorption and distillation. A blowout tower and a mixer are used in the process. The process comprises the steps of selecting bittern of which the bromine content is 1000-2500ppm as a raw material, and adjusting the pH value to 2-3.5 before the bittern raw material is fed into the blowout tower; and performing a bittern oxidation stage and a blowout stage on the bittern, then feeding the bittern into an absorption tower to perform concurrent flow gas liquid contact with absorption completed liquid, and performing absorption operation, wherein the bromine content of the absorption completed liquid is 80-100g / L. The bromine is extracted from the mother solution (bittern) of sea salt production by adopting the oxidation and blowout method, and the blowout tower and the mixer are used in the process, so that the bromine extraction process is scientific, the yield of the bromine is 2.5 times that of a water vapor distillation method, and the power consumption of the process is 60% of that of an intermediate bittern bromine-blowing process. The total extraction rate is over 85%. The process initiates the process equipment parameters of high bromine content, high viscosity and high specific gravity raw material condition, and is used for design and production.

Owner:唐山三友盐化有限公司

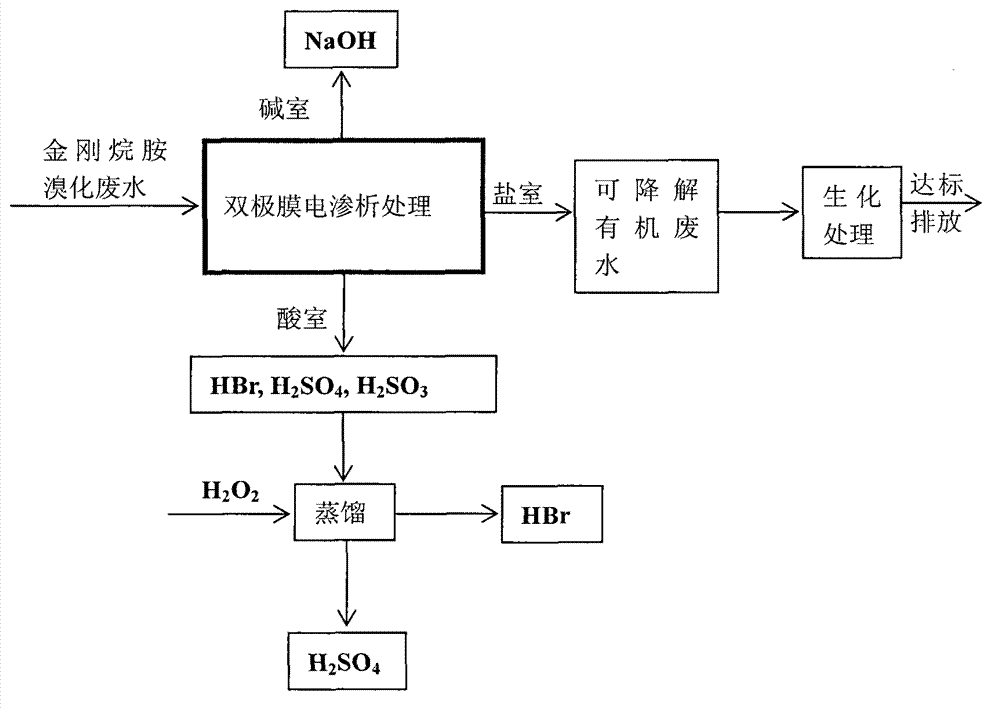

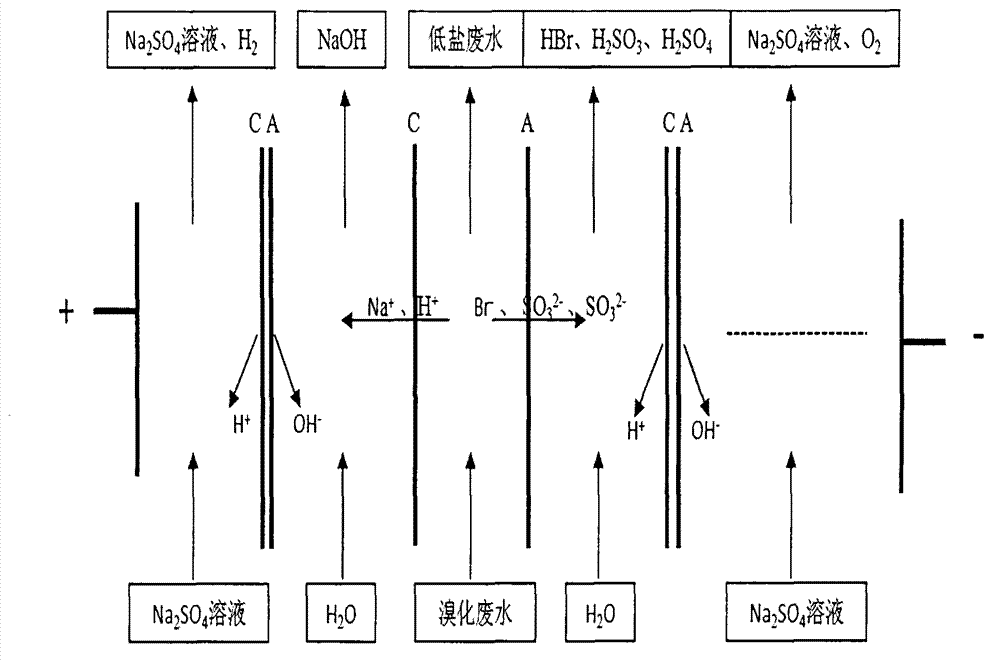

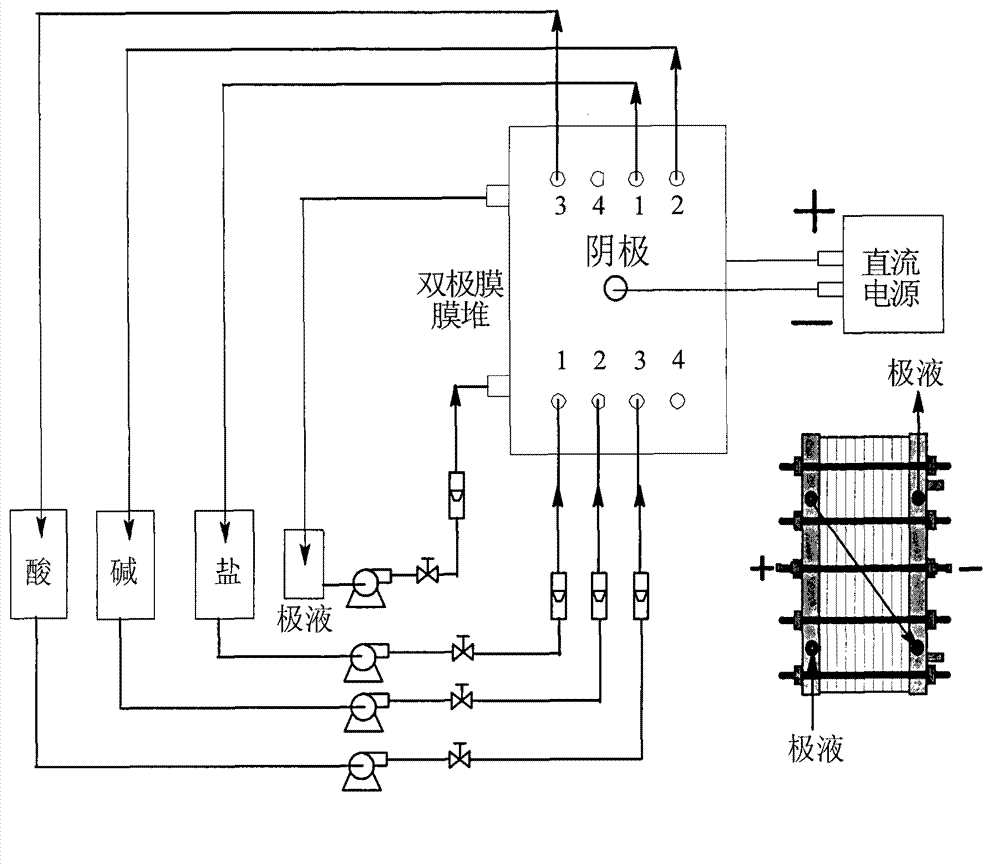

Process for treating amantadine bromination waste water and mineral acid and alkali recycling through bipolar membrane electrodialysis process

InactiveCN103073131AHas recycling valueGood governanceGeneral water supply conservationDispersed particle separationDesalinationBromine

The invention relates to a process for treating amantadine bromination waste water and mineral acid and alkali recycling through a bipolar membrane electrodialysis process, which comprises the following steps: firstly, filtrating bromination waste water through micropore filtration film; then pumping the bromination waste water into a salt chamber of the bipolar membrane electrodialysis device, pumping tap water into an acid chamber and an alkali chamber of the bipolar membrane electrodialysis device, and pumping Na2SO4 solution into electrode liquid of the two ends of the bipolar membrane electrodialysis device; and finally, starting the bipolar membrane electrodialysis device and recycling the acid and the alkali. According to the invention, a bipolar membrane electrodialysis technology is used for the treatment of degradation-resistant amantadine bromination waste water, and realizes the recycle of the mineral acid and the alkali in waste water. The process has the following advantages: bromine irons in waste water containing bromine can be removed, the desalination rate is higher than 95 percent, the hydrogen ion concentration is decreased from 2.95 mol / L to 0.003 mol / L below, and avoids secondary contamination; the process enables the degradation-resistant pharmaceutical wastewater to become biochemical degradable organic wastewater, and emits qualified waste water after the biochemical treatment; and the control effectiveness is good, the operation is convenient, and the process has a favorable application prospect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for recycling bromine from bromine-containing wastewater of brominated butyl rubber

InactiveCN103613071AReduce usageLow costMultistage water/sewage treatmentBromine/hydrogen-bromideN-dodecaneTurbidity

The invention relates to a method for recycling bromine from bromine-containing wastewater of brominated butyl rubber, which comprises the following steps: pretreatment: feeding the bromine-containing wastewater of brominated butyl rubber into an air flotation device, adding a coagulant to remove large colloidal particle matters and organic pollutants, and filtering so that the turbidity of the output water is lower than the preset value; acidification: adding hydrochloric acid or sulfuric acid into the filtered bromine-containing wastewater to adjust the pH value to 3-5; oxidation: adding an oxidizing agent into the acidified bromine-containing wastewater for oxidation to generate bromine; extraction: adopting n-dodecane as an extraction agent, adding n-dodecane into the oxidized bromine-containing wastewater, and extracting bromine from an aqueous phase to an n-dodecane phase; liquid separation: performing liquid separation on the two-phase solution added with the extraction agent, wherein the upper layer is an oil phase, and the lower layer is an aqueous phase; separating the aqueous phase from the oil phase, recycling the oil phase, and discharging the aqueous phase. By adopting the method provided by the invention, the bromine recycling cost is greatly reduced, and better economic benefits are obtained.

Owner:ZHEJIANG SHUANGYI ENVIRONMENTAL PROTECTION TECH DEV

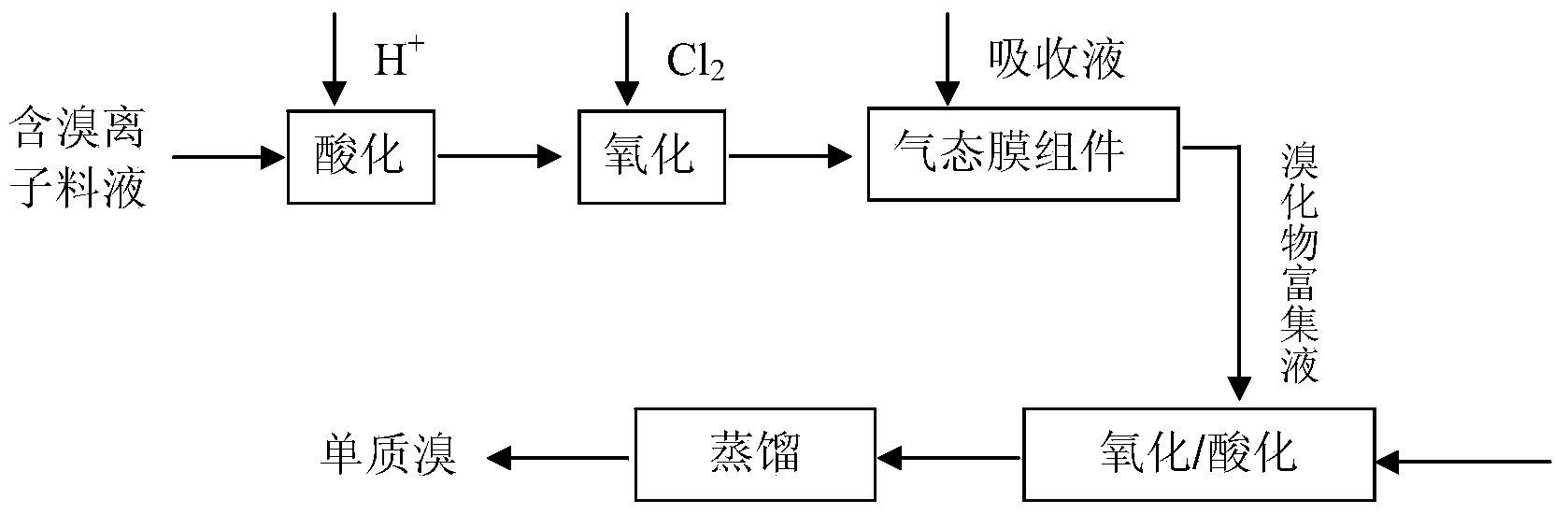

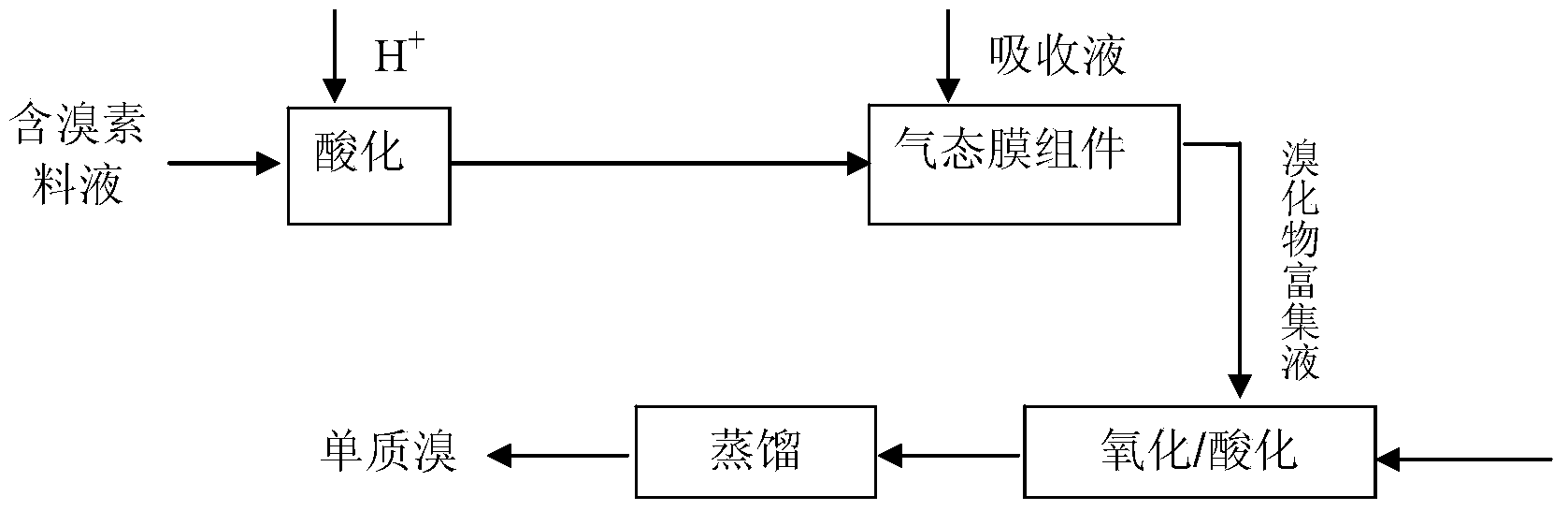

Method for preparing/gathering bromine from bromine-containing feed liquid or waste water

The invention relates to a method for preparing / gathering bromine from bromine-containing feed liquid or waste water. The method comprises the following steps of: (1) acidification or acidification oxidation of the bromine-containing feed liquid or waste water, namely regulating the pH value of the bromine-containing feed liquid or waste water to 3-4, wherein the bromine contained in the acidified feed liquid or waste water exists in a bromine form; (2) bromine extraction in the separation process of a gaseous film, namely carrying out bromine extraction treatment by introducing the bromine-containing feed liquid or waste water which is formed after the acidification or the acidification oxidation into a gaseous film assembly to obtain a bromide-containing gathered solution; (3) post treatment, namely carrying out the post treatment on the gathered solution, and distilling to obtain elemental bromine. According to the method, a polytetrafluoroethylene or polytetrafluoroethylene hollow fiber microporous film assembly is adopted as a bromine extraction core device, and the film assembly has the advantages of oxidation resistance and long service life. The method disclosed by the invention has the advantages of low energy consumption, high bromine mass transfer efficiency and high bromine recovery rate in a process flow, simple equipment, convenience for operation and low operating cost, can be widely applied to the bromine extraction of the bromine-containing feed liquid with various concentration ranges and various scales.

Owner:TIANJIN PURESEA SPRING MEMBRANE TECH CO LTD

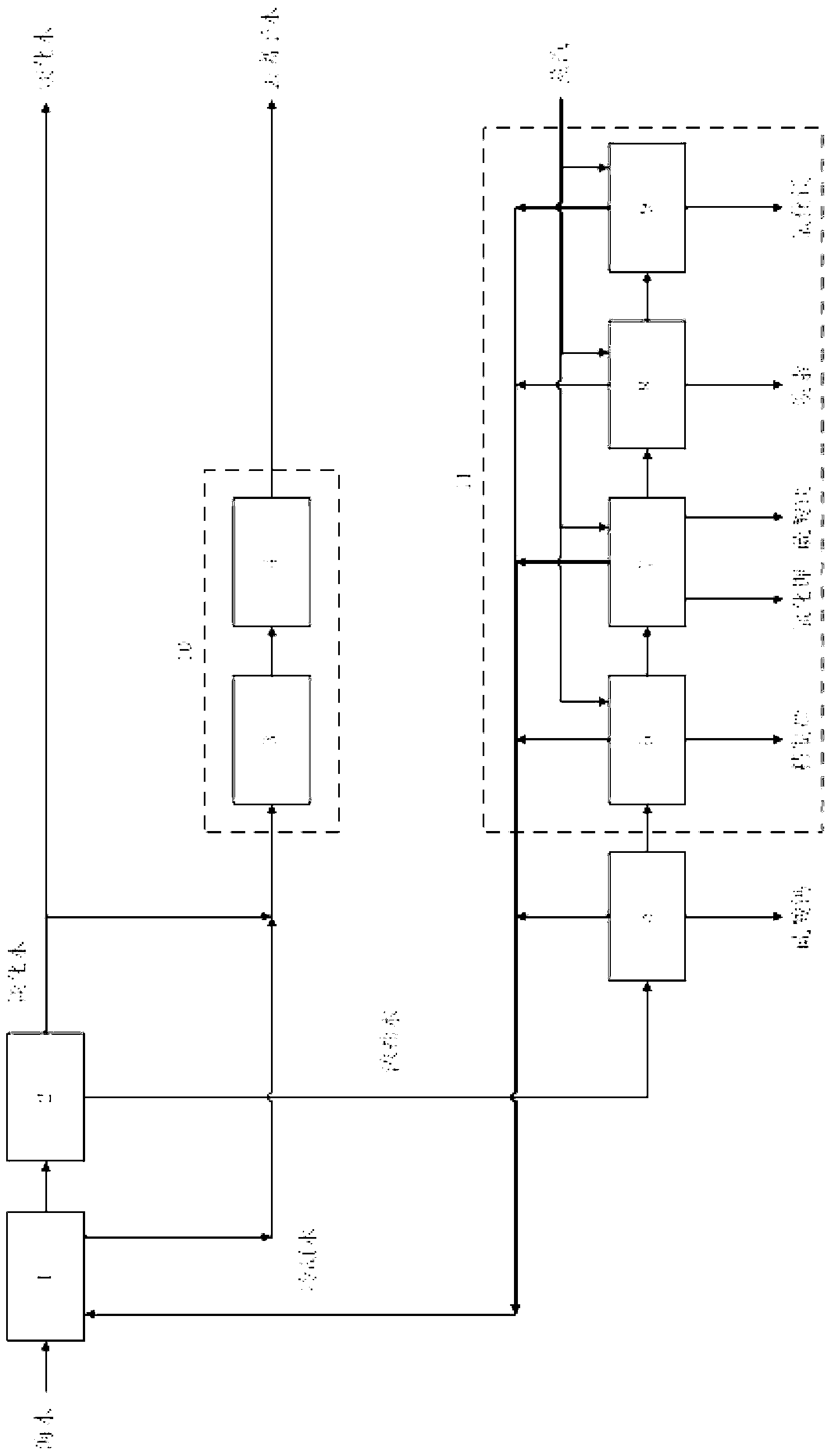

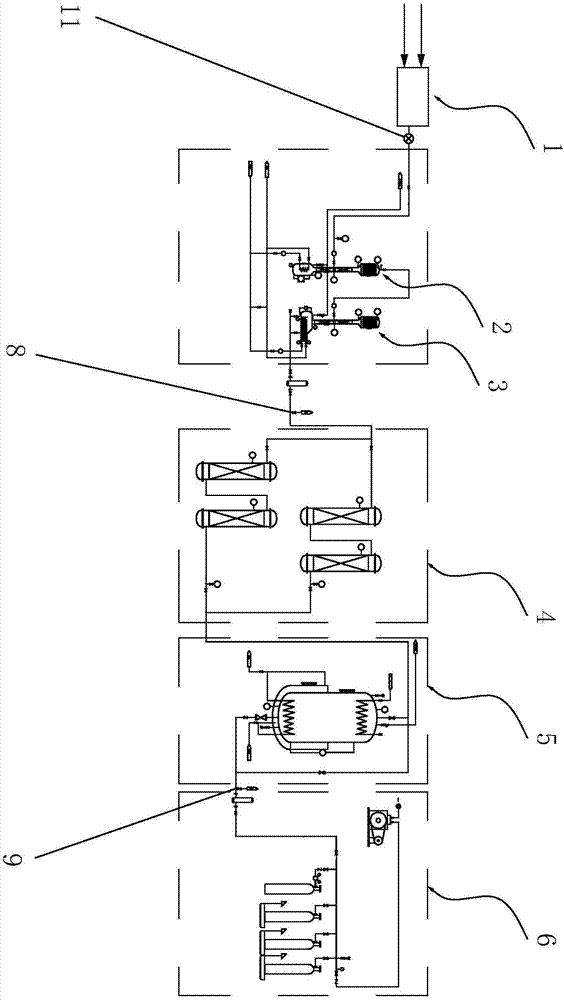

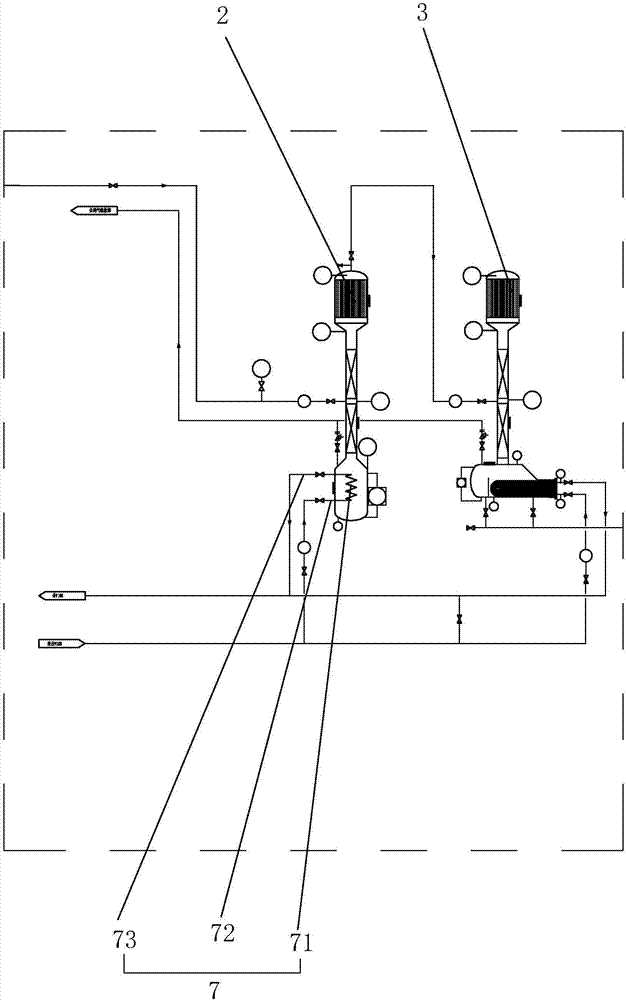

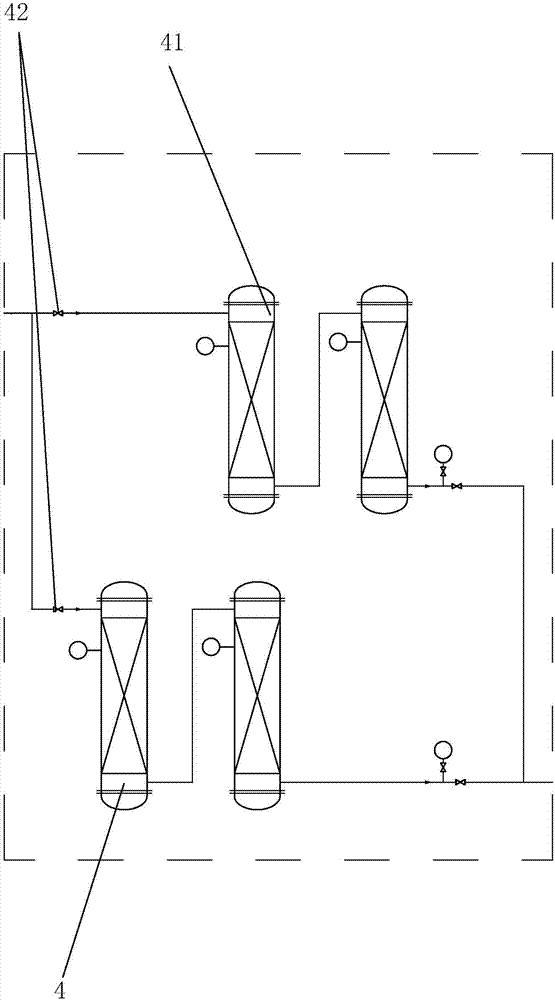

Seawater desalination, resource comprehensive utilization and zero discharge processing system

InactiveCN103253818ASave energyCreate pollutionGeneral water supply conservationSeawater treatmentUF - UltrafiltrationSeawater

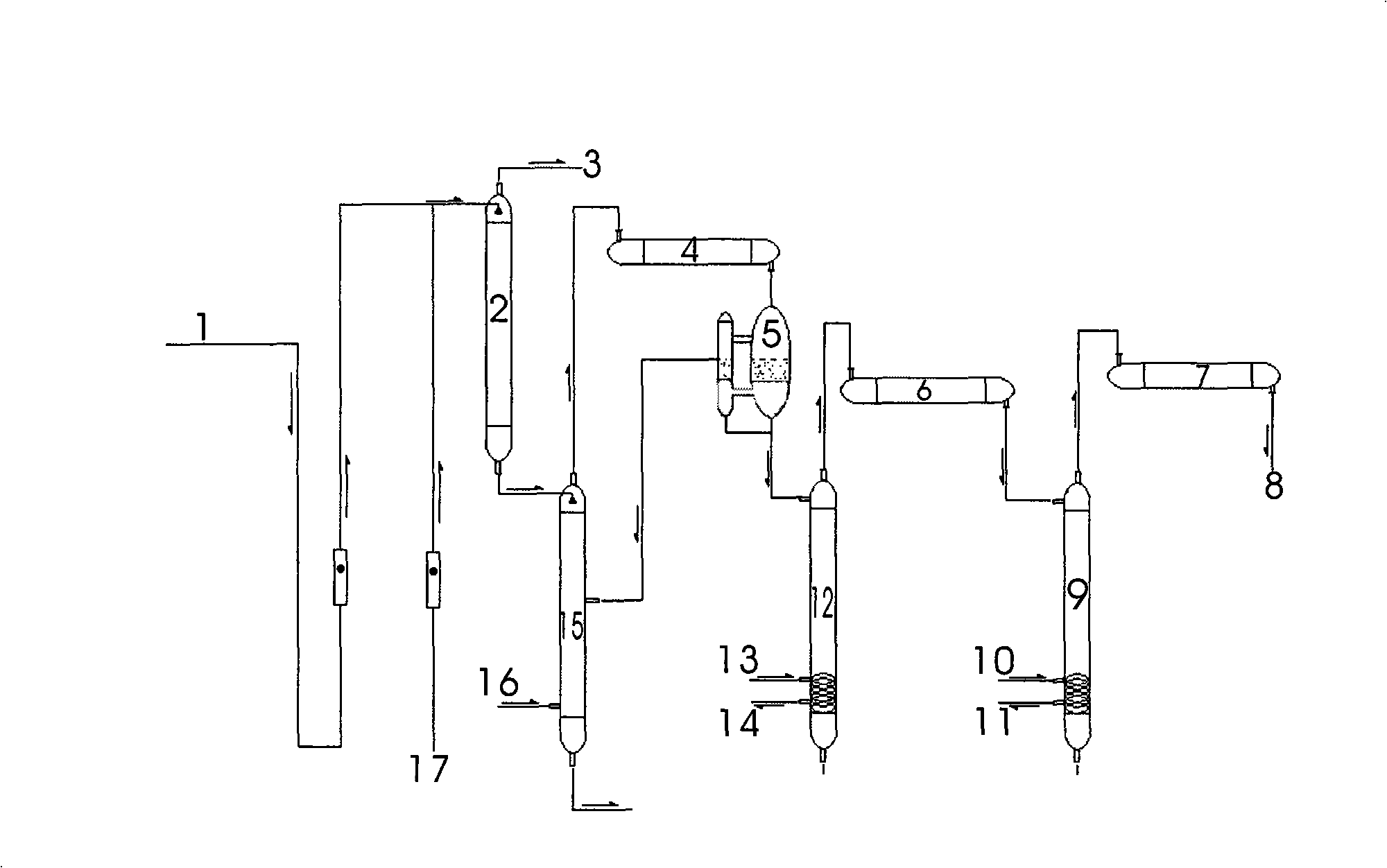

The invention discloses a seawater desalination, resource comprehensive utilization and zero discharge processing system. The system comprises an ultrafiltration (UF) system, a seawater reverse osmosis (SWRO) system, a deionized water processing system, namely an UPW system, a mechanical compression system capable of preventing scaling and a salt manufacturing and salt chemical engineering system, wherein the UF system is used for generating pure seawater; the SWRO system is used for generating desalted water and concentrated seawater; the concentrated seawater can be produced into calcium sulfate, sodium chloride, potassium chloride, magnesium sulfate, bromine, magnesium chloride and steam condensed water by virtue of the mechanical compression system and the salt manufacturing and salt chemical engineering system; and the steam condensed water and a part of desalted water flow into the UPW system to generate deionized water. According to the processing system, the relevant projects of seawater desalination, energy source utilization, industrial salt manufacturing and salt chemical engineering are organically combined, so that reasonable allocation and utilization of resources are realized, and the aims of energy conservation, emission reduction, circular economy and zero discharge are fulfilled.

Owner:金逹行有限公司

Method for extracting bromine by industrial wastewater rich in Br-

InactiveCN102556972AReduce manufacturing costProductiveWater/sewage treatmentBromine/hydrogen-bromideElectrolysisHypochlorite

The invention discloses a method for extracting bromine by industrial wastewater rich in Br-, and is characterized in that bromine is obtained by electrochemical oxidation, blow-out, and collection of industrial wastewater which is pretreated by purification and is rich in Br-; in the electrochemical oxidation, an electrolytic tank is partitioned into a cathode chamber and an anode chamber by an ion exchange membrane; the anode electrolyte is an aqueous solution which is rich in Br- and is obtained by purification treatment of the industrial wastewater rich in Br-; the cathode electrolyte is an acid solution with a pH of 1-4; the temperature of the electrolytes is controlled at 25-45 DEG C; the current density is 0.01-0.1 A / cm2; or a constant voltage is 0.5-6.0 V; after electrolytic balance is reached, the anode electrolyte is removed, and bromine is obtained by air blow-out, condensation, gas-liquid separation, and water-bromine separation. The method of the invention overcomes the disadvantages of bromine preparation by traditional oxidation process through chlorine, hypochlorite, and the like; the method is applicable to the treatment of industrial wastewater with a bromide ion concentration of 0.02-11.5 mol / L, and the process is simple and environment-friendly.

Owner:HUAIBEI NORMAL UNIVERSITY +2

Method for recovering bromine from pure terephthalic acid (PTA) waste water

InactiveCN102923663AReduce consumptionReduce adverse effectsOrganic compound preparationMultistage water/sewage treatmentDistillationBromine

The invention relates to a method for recovering bromine from pure terephthalic acid (PTA) waste water. The method includes oxidation, distillation and dilution for recovering. By means of the method, more than 90% of bromine ion can be distilled from the PTA waste water and then returned back to a PTA device for use, so that consumption of catalyst bromine is greatly reduced.

Owner:绍兴汉青环保科技有限公司

Method for treating profenofos synthetic wastewater by using hydrogen peroxide

InactiveCN101525195ASimple processImprove stabilityMultistage water/sewage treatmentNature of treatment waterHydrogen-Ion ConcentrationsPhosphoric acid

The invention relates to a method for treating profenofos synthetic wastewater by using hydrogen peroxide, which comprises the following steps: after a proper amount of sulphuric acid is added to the wastewater to regulate the acidity of the wastewater, the hydrogen peroxide is added to the wastewater for heating reaction, bromide ions are oxidized into bromine, other organic matters are oxidized, the bromine is separated from the wastewater, and the wastewater from which the bromine is separated is neutralized; the temperature of oxidation reaction is 0 to 105 DEG C, sulphuric acid, hydrochloric acid, nitric acid, phosphoric acid or a mixture of the same can be added to the wastewater, the proper amount of acid is added for regulating the acidity of the wastewater until the concentration of hydrogen ions is 0.01 to 10.0 mol / L, the concentration of the hydrogen peroxide is 7 to 50 percent, the mol ratio of the hydrogen peroxide to the bromine in the wastewater is from 1:0.5-1:4, the hydrogen peroxide is added to the wastewater for reaction of 0.5 to 5.0 h, the wastewater introduced by a connecting pipe of a wastewater overhead tank and the hydrogen peroxide introduced by a connecting pipe of a hydrogen peroxide overhead tank are collected into an oxidation tower to for oxidation reaction, the upper end of a distillating tower is connected with a condensator by a pipeline, and a fine bromine output pipe is arranged after the condensation of the product of the oxidation reaction through a primary rectifying tower and a secondary rectifying tower. The invention has simple integral technology, good stability, high reliability and low operating cost.

Owner:吴秀玲

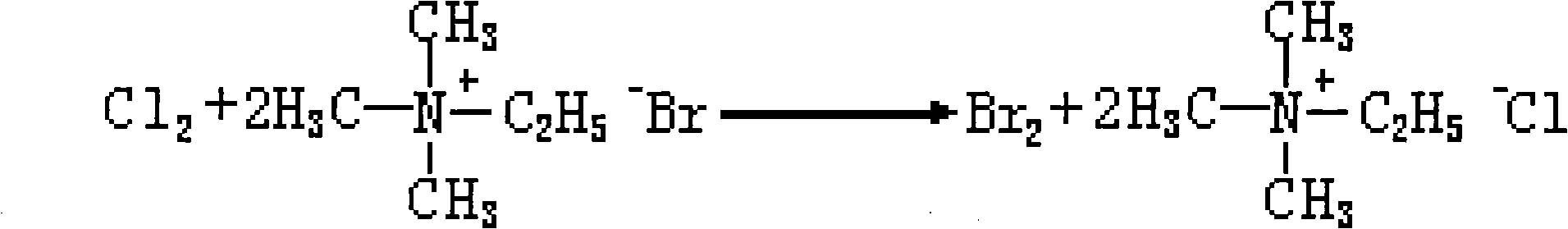

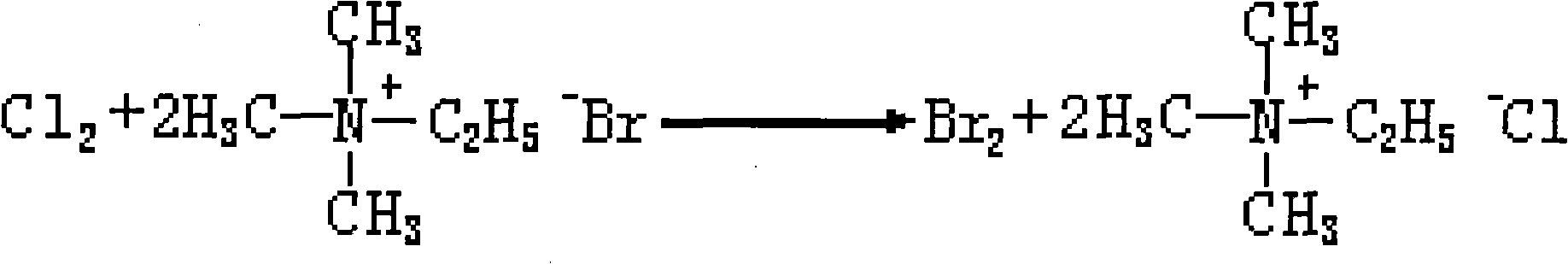

Process for treating waste water in chlorfluazuron synthesis

InactiveCN101274795AGroup 5/15 element organic compoundsBromine/hydrogen-bromideBromineEconomic benefits

The invention provides a method for treating profenofos synthetic wastewater. A certain amount of chlorine is led into the wastewater produced in the synthesis process of profenofos, bromide ion in the wastewater is replaced by bromine and trimethyl ethyl ammonium chloride is generated, the generated bromine is separated with the wastewater, and then the wastewater after the bromine is separated is used for preparing the trimethyl ethyl ammonium chloride. The method can be used for treating the waste water produced in the synthesis process of the profenofos to recover valuable resource, thereby having better social and economic benefits.

Owner:王永昌

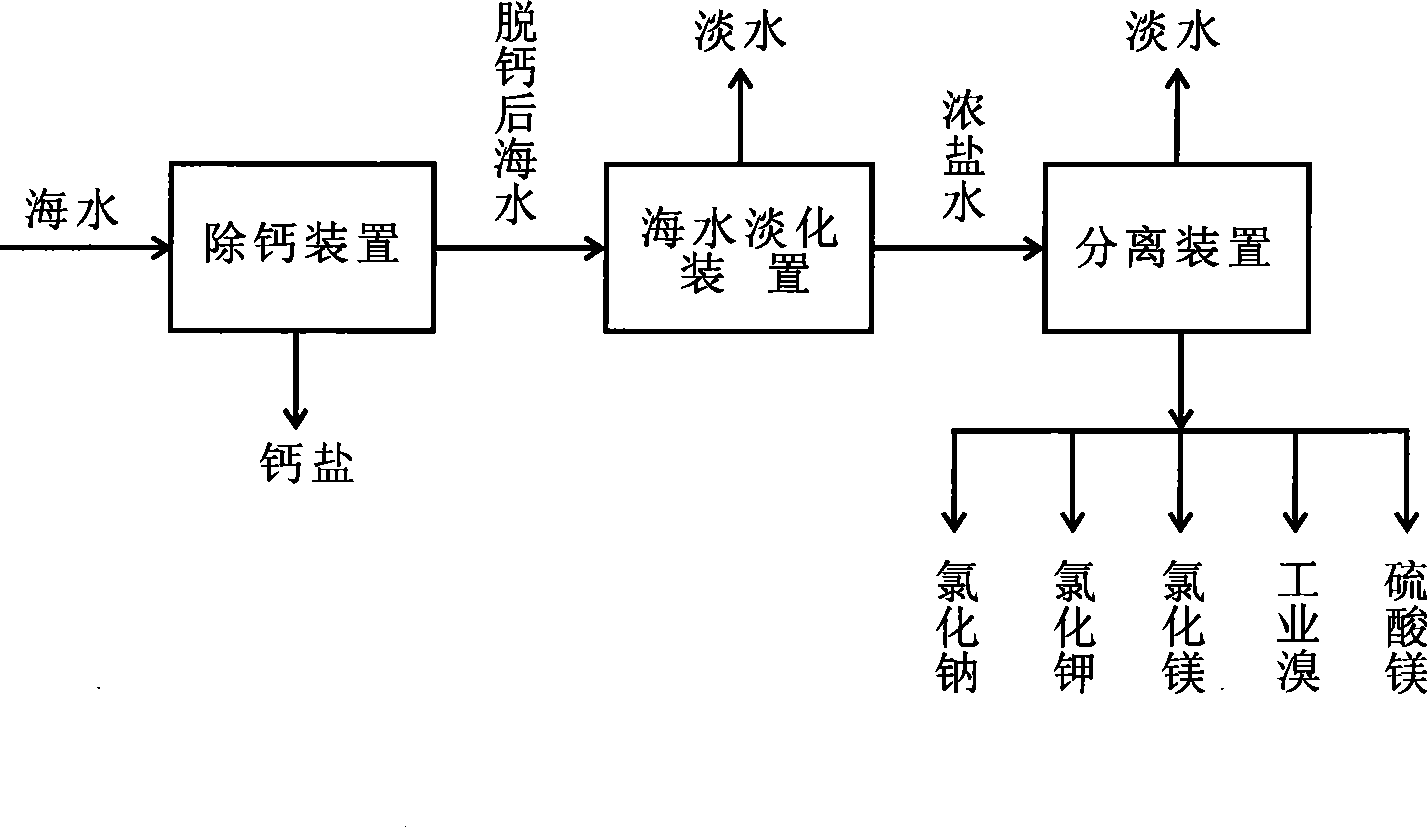

Sea water calcium-removing concentration utilization method

InactiveCN101381147AAvoid pollutionIncrease water production ratioGeneral water supply conservationSeawater treatmentWater desalinationSaline water

The invention relates to a method for calcium removal and condensation utilization of seawater, which relates to utilization of the seawater. The method comprises a seawater desalting plant and a seawater separating device, wherein the seawater desalting plant adopts the technique of multiple-effect evaporation, and the water generation ratio of the seawater desalting plant reaches more than 20; and the front end of the seawater desalting plant is provided with a calcium removal device which absorbs more than 95 percent of calcium ions in the seawater after directly contacting the seawater. After adoption of the method, reduction of the equipment efficiency caused by calcium scale formed by calcium salt in the seawater during the desalting process is avoided, and simultaneously the water generation ratio of the desalting plant is improved; and strong brine obtained finally can be further separated, so as to obtain chemical products such as sodium chloride, potassium chloride, magnesium chloride, industrial bromine, magnesium sulfate and so on, thereby the method improves the utilization rate of the strong brine and avoids waste and environmental pollution caused by exhaustion.

Owner:吴宗生

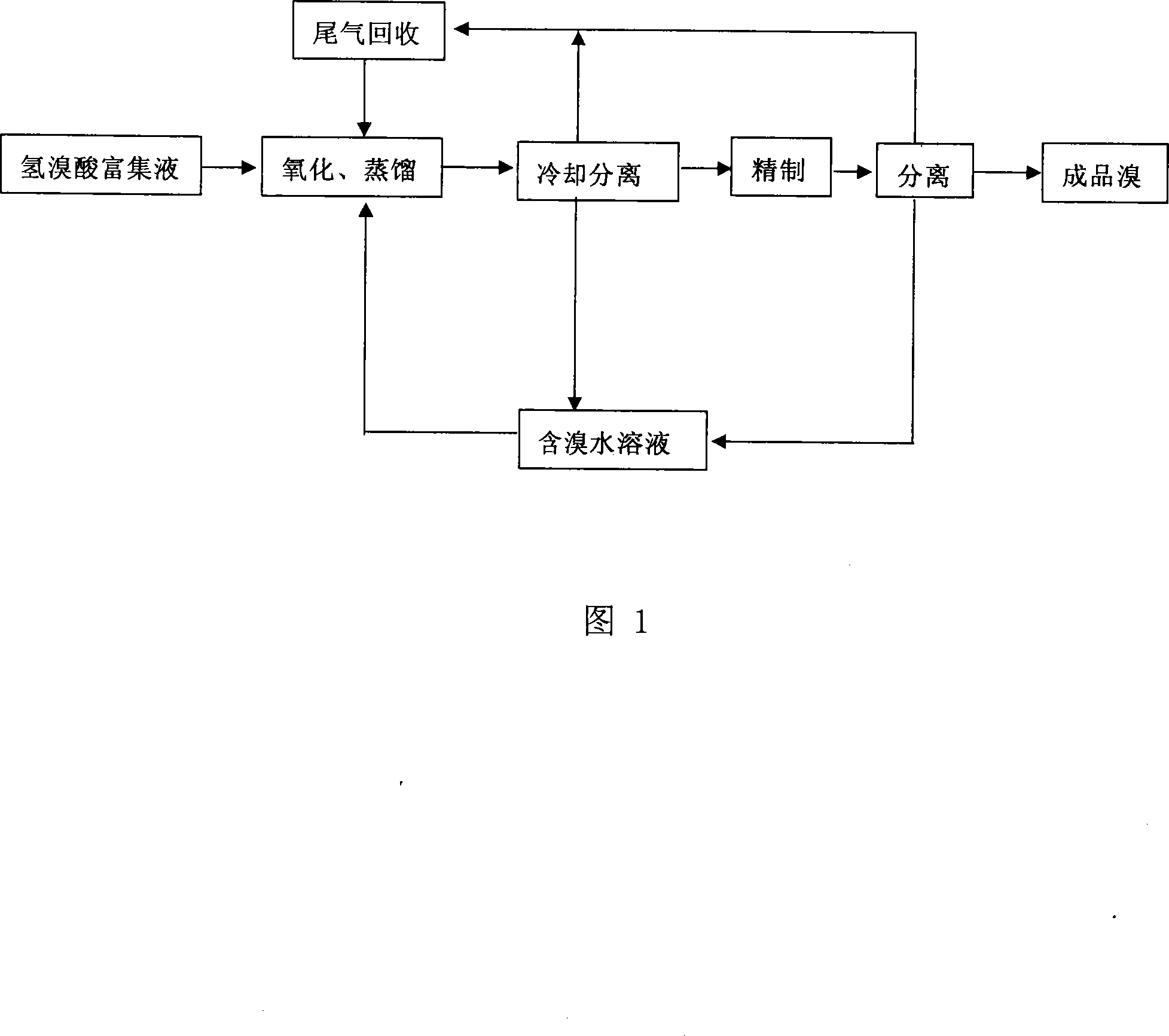

Technology for coarse bromine purifying using hydrobomic acid enriched liquid

A process for preparing high-purity bromine from the hydrobromic acid-enriched liquid includes such steps as oxidizing-distilling, pre-heating, refining, separating and recovering the tailing gas.

Owner:天津海晶科技发展有限公司

Method for extracting bromine from chloride-calcium type oil field water

InactiveCN101613085AHigh yieldHigh purityMultistage water/sewage treatmentWater/sewage treatment by neutralisationSulfite saltBromine

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

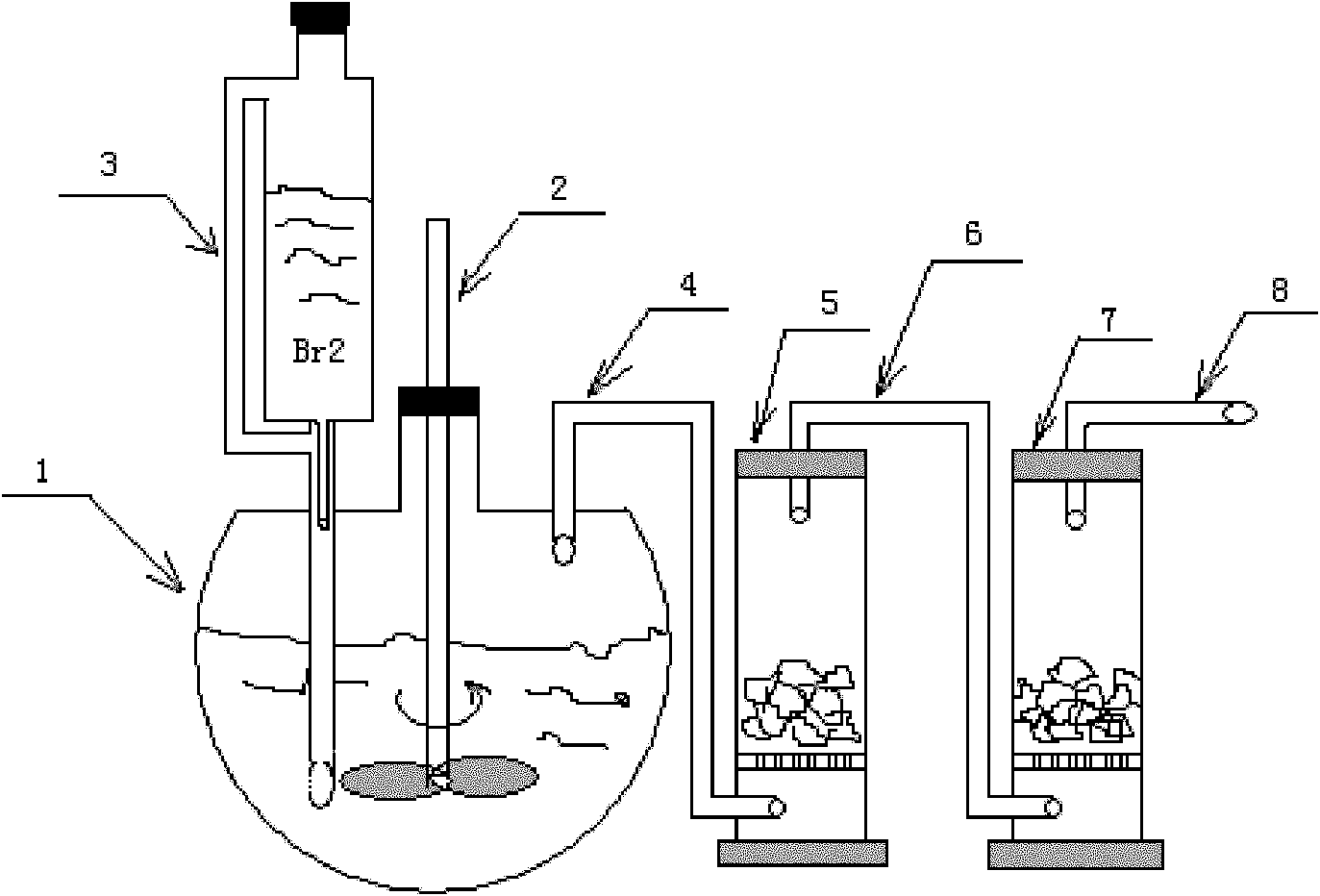

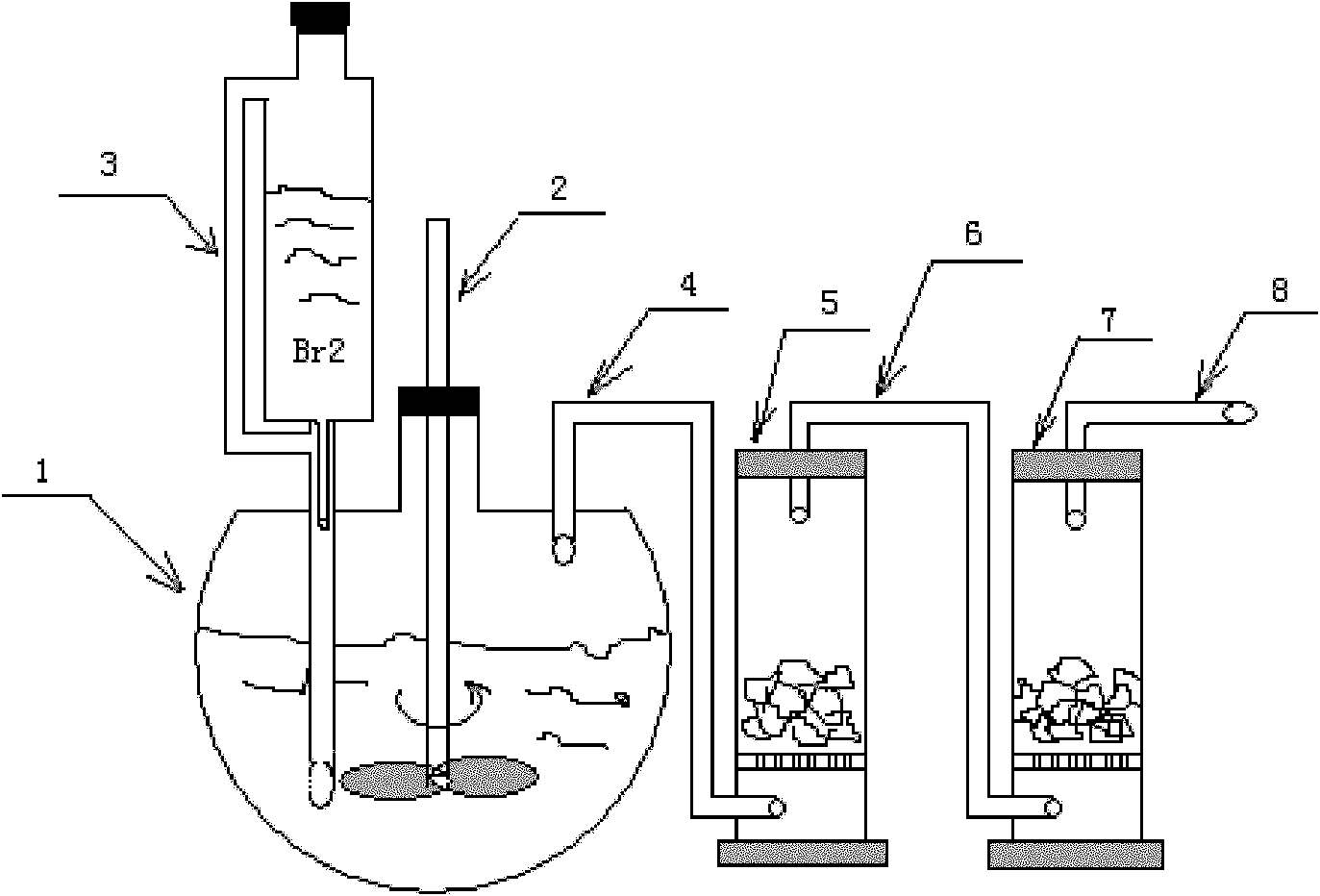

Preparation method of bromine hydride gas and generating device thereof

InactiveCN102001627AIncrease profitRaw materials are cheap and easy to getBromine/hydrogen-bromidePhosphorous acidBromine

The invention relates to a preparation method of bromine hydride gas and a generating device thereof in the field of medicaments, fine chemicals, chemical agents and the like. The preparation method of the bromine hydride gas is characterized by comprising the following steps of: selecting red phosphorus, concentrated hydrobromic acid and bromine according to the weight ratio of the red phosphorus to the concentrated hydrobromic acid to the bromine of 1:3.5-4.5:6-7; putting the red phosphorus and concentrated hydrobromic acid into a reaction vessel, stirring at the room temperature; dropping the bromine into a reactor from a constant pressure dropping liquid device; treating the generated bromine hydride gas in a bromine removing tower and a drying tower, namely leading out dried bromine hydride gas; and filtering kettle bottom solution in the reactor to remove unreacted red phosphorus, and depressurizing to remove the bromine hydride so as to obtain a byproduct of phosphorous acid. The preparation method has the advantages of low-price and readily-available raw materials, mild condition and simple device.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

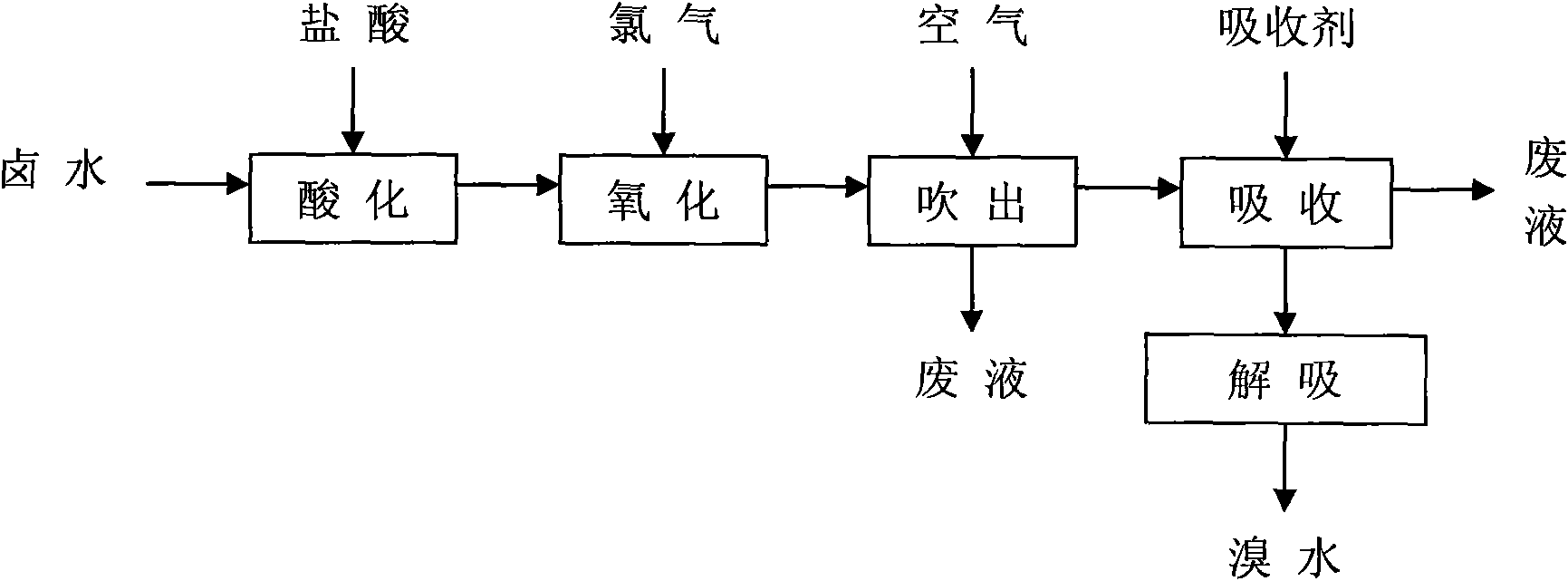

Processing method for extracting bromine from brine by composite blowing and absorbing method

ActiveCN104229739AAdjust the throughput in timeReduce consumptionChlorine/hydrogen-chlorideBromine/hydrogen-bromideBromineDistillation

The invention discloses a processing method for extracting bromine from brine by a composite blowing and absorbing method, and the method comprises the following steps of: (1) accessing chlorine into acidized brine, and preparing into oxidized brine after reaction; (2) downward spraying oxidized brine from a stripping tower top, upwardly blowing from the bottom of the stripping tower to its top by a fan to allow air to be fully contacted with oxidized brine so as to analyze free bromine diffused into air, and blowing bromine-containing air from the stripping tower top; (3) conveying bromine-containing air into an absorbing tower, spraying it with spraying liquid to form absorption liquid containing hydrobromic acid, and discharging the absorption liquid from the absorbing tower; (4) conveying absorbing liquid into a distillation tower, accessing chlorine to react with hydrobromic acid in absorbing liquid so as to generate chlorine hydride and free bromine, reacting chlorine hydride into hydrochloric acid in a wet condition, discharging hydrochloric acid from the distillation tower bottom, evaporating free bromine to form bromine steam, and cooling the bromine steam to prepare into bromine. The method is simple in steps and high in bromine extraction rate.

Owner:SHANDONG TIANYI CHEM

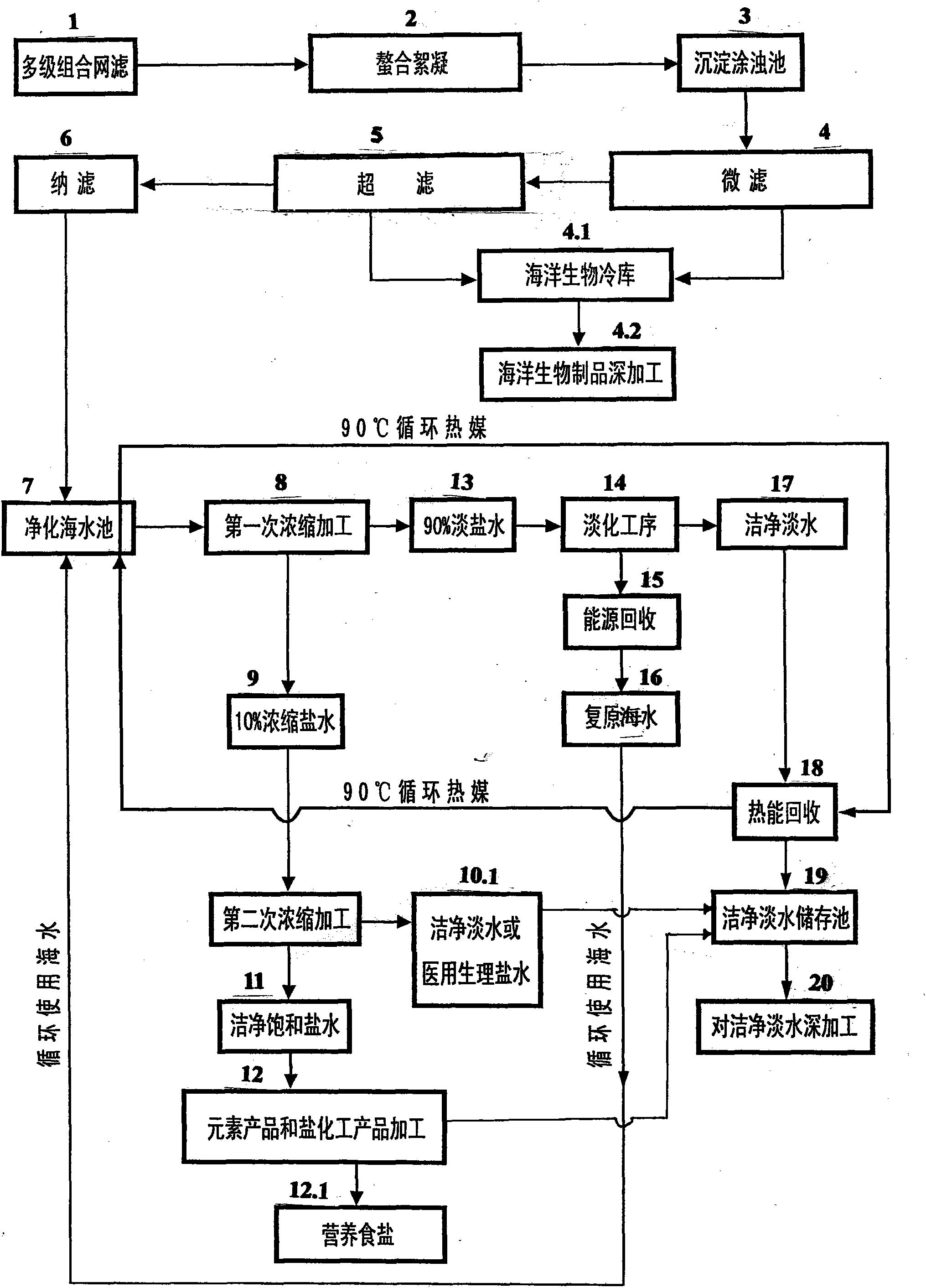

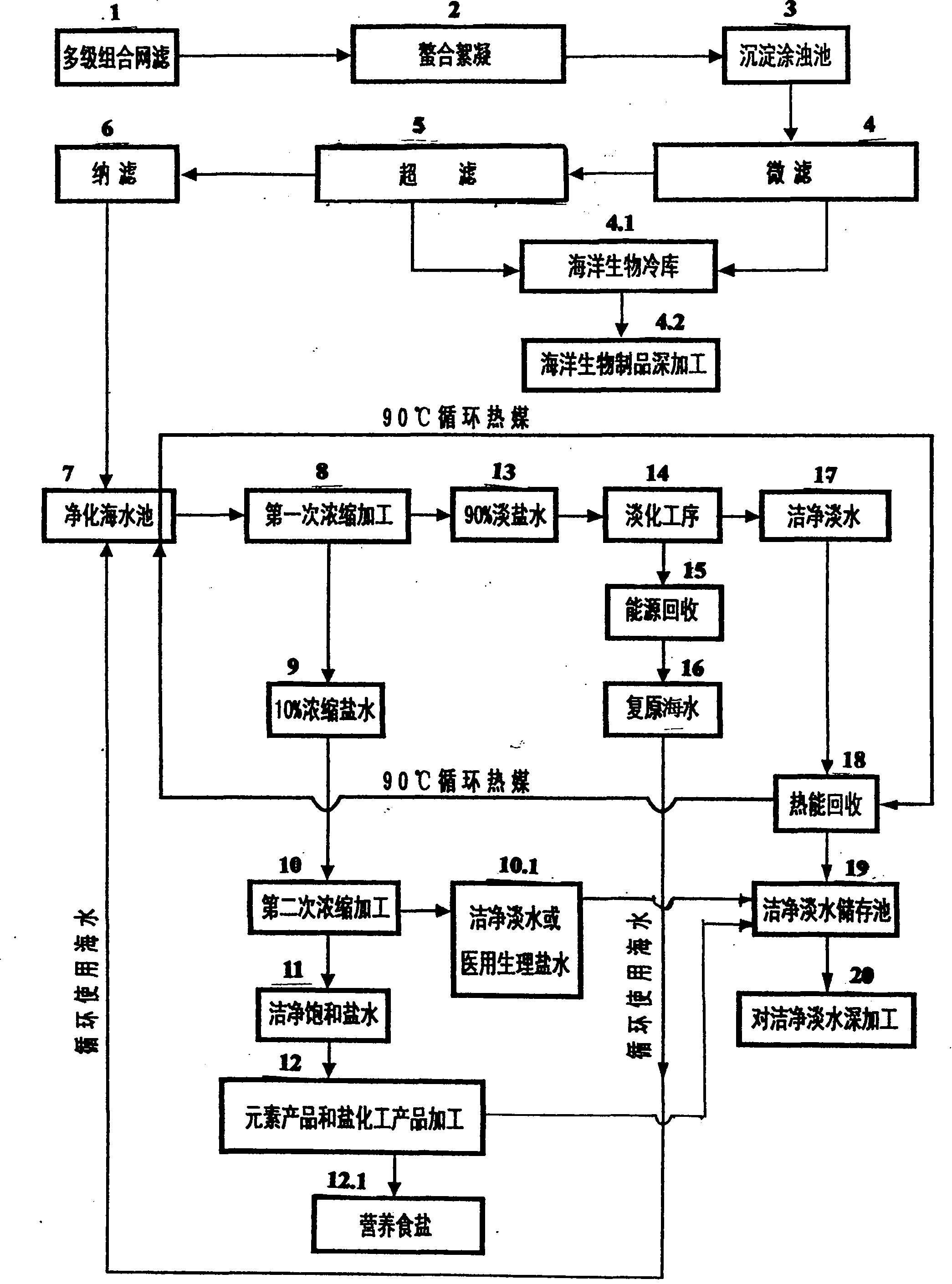

Ecological optimization production process for all-seawater industry

InactiveCN101786738AEnhance physical fitnessEliminate fearSeawater treatmentMagnesium chloridesChemical industryMedical product

The invention aims to provide an 'ecological optimization production process for the all-seawater industry', which is characterized by realizing 100 percent comprehensive utilization of the seawater by the optimization production process which 'circularly extracts and continuously processes the seawater to produce the following three major compound products: marine bio-foods and marine medical products, marine element products and salt chemical products and clean fresh water products. The optimization production process initially provides marine organism pharmaceutical sources for human, eliminates and changes the traditional salt chemical industries and the traditional seawater desalination industries into industrial chain type comprehensive-utilization compound industries with a plurality of salt chemical products rather than the original single products or a fewer varieties of products and supplies cheap and sustainable clean fresh water resources to human beings. The all-seawater-industrial ecological optimization production process has the advantages of reaching zero emission, completely eliminating the ocean pollution caused by 'residual metamorphic seawater', eliminating domestic wastes and realizing ecological environmental protection production.

Owner:葛文宇

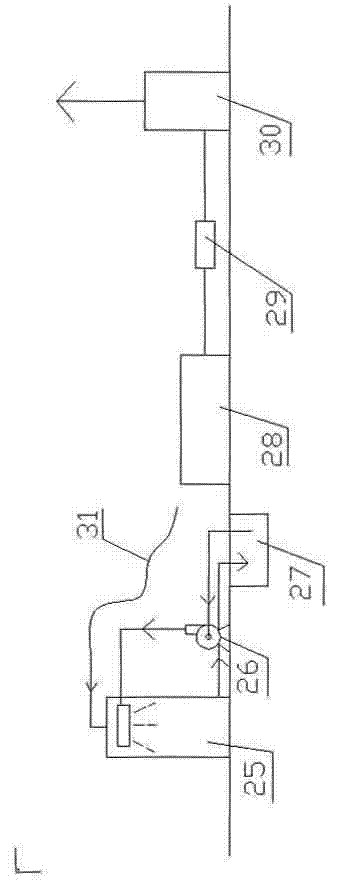

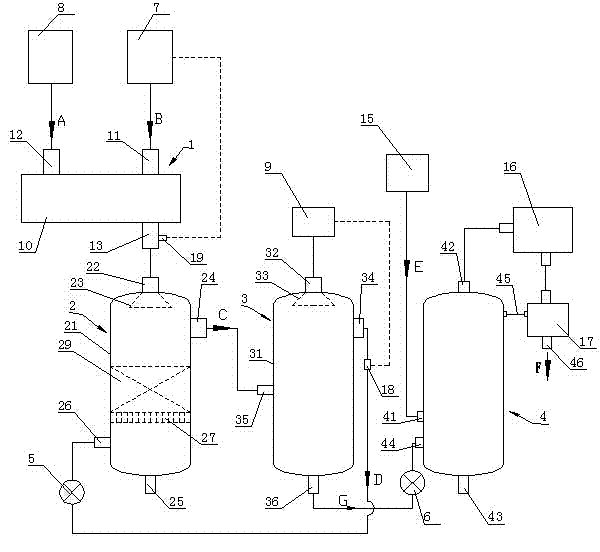

Hydrogen bromide purification technology

ActiveCN107352511AImprove the degree of purificationEasy to adjustBromine/hydrogen-bromideLiquid nitrogen coolingGas cylinder

The invention discloses a hydrogen bromide purification technology. The purification technology is characterized in that a primary rectifying tower, a secondary rectifying tower, an adsorber, a material storage tank and a gas cylinder inflating device are arranged in sequence, the primary rectifying tower and the secondary rectifying tower are both provided with liquid nitrogen cooling devices which conduct refrigeration, and the aims of high purification degree and application on industrial production are achieved.

Owner:绿菱电子材料(天津)有限公司

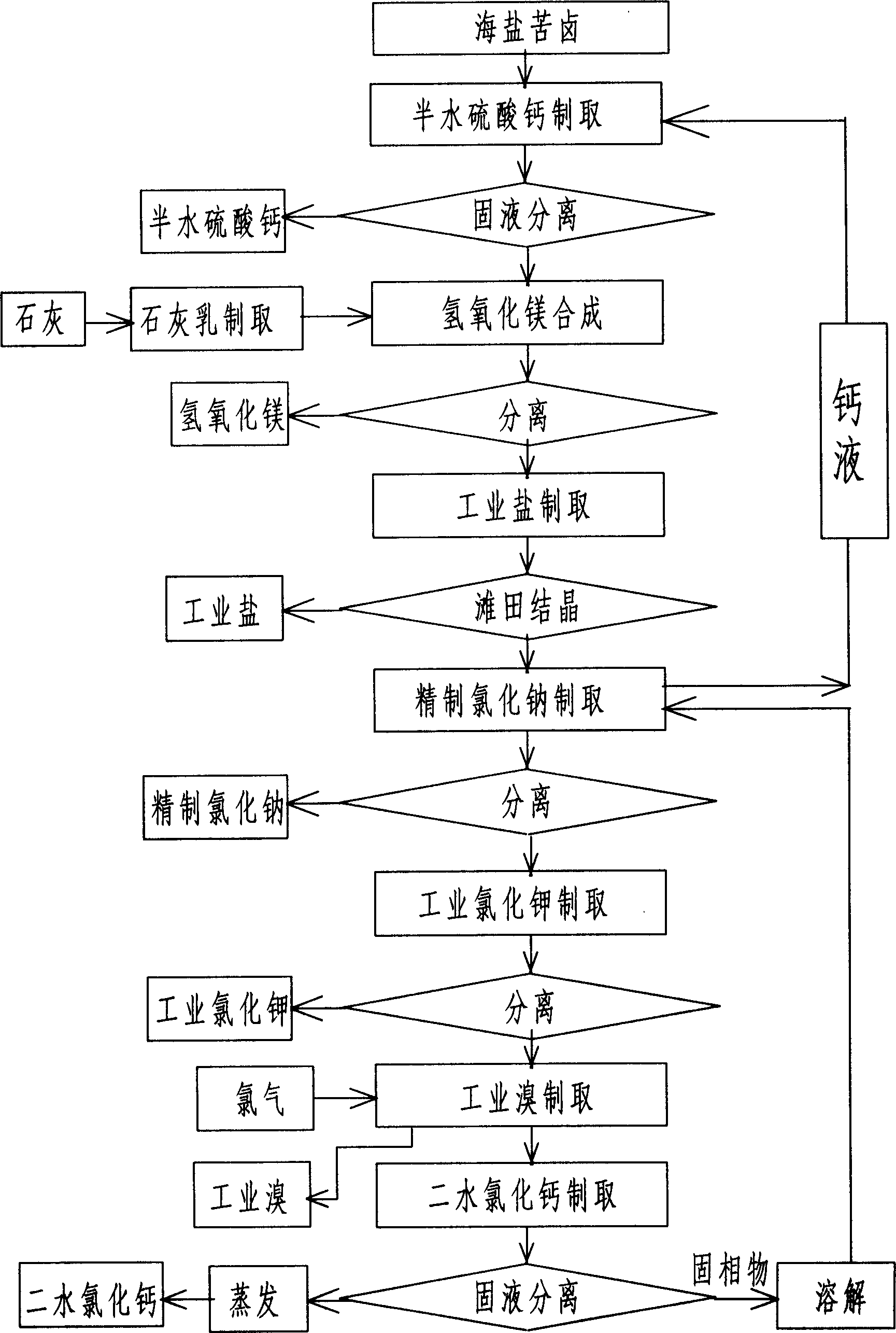

Comprehensive utilization method of sea salt bittern

InactiveCN1903729AReduce energy consumptionSolve the problem of developing fewer productsCalcium/strontium/barium chloridesCalcium/strontium/barium sulfatesPotassiumEvaporation

The present invention relates to a comprehensive utilization method of bittern. Said method uses bittern as raw material and adopts the following steps: making the bittern undergo the processes of mixing reaction with calcium liquor, synthesis reaction with lime cream, evaporation concentration crystallization, four-step evaporation, aerifying chlorine, filtering and removing impurity and solid-liquid separation, etc, so as to make the bittern into several products of hemi-hydrate calcium sulfate, magnesium hydroxide, industrial salt, potassium chloride, industrial bromine and dehydrate calcium chloride.

Owner:杨秀文

Method for extracting bromine from bromine-containing wastewater

InactiveCN103613073ALow costReduce usageMultistage water/sewage treatmentBromine/hydrogen-bromideN-dodecaneBromine

The invention relates to a method for extracting bromine from bromine-containing wastewater, which comprises the following steps: pretreatment: filtering the bromine-containing wastewater so that the turbidity of the filtered bromine-containing wastewater is lower than the preset value; acidification: adding hydrochloric acid or sulfuric acid into industrial wastewater containing bromide ions to adjust the pH value of the industrial wastewater to 3-5; oxidation: adding an oxidizing agent into the acidified industrial wastewater for oxidation to generate bromine; extraction: adopting n-dodecane as an extraction agent, and extracting bromine from an aqueous phase to an n-dodecane phase; liquid separation: performing liquid separation on the two-phase solution added with the extraction agent, wherein the upper layer is an oil phase, and the lower layer is an aqueous phase; separating the aqueous phase from the oil phase; rectification: rectifying the n-dodecane and bromine solution obtained by the liquid separation so that bromine is separated from n-dodecane to obtain a bromine product. In the method provided by the invention, bromine is extracted by a solvent extraction process; compared with the traditional technology, the use of steam is greatly saved, the cost of whole bromine extraction is remarkably reduced, and better economic benefits are obtained.

Owner:ZHEJIANG SHUANGYI ENVIRONMENTAL PROTECTION TECH DEV

Secondary bromine-extracting method by using waste water from bromine-extracted brine

ActiveCN1884045AReduce miningIncrease productionWater/sewage treatment by neutralisationWater/sewage treatment by heatingLiquid wasteBromine

The invention discloses a second bromine-extracting method in the waste water, which comprises the following steps: acidifying; oxidizing; desorbing; adsorbing. The invention can extract 55-70 percent 40ppm-80ppm bromine in the waste liquid through first extraction, which improves total extracting rate by over 90 percent.

Owner:山东昌邑灶户盐化有限公司

Method for treating wastewater produced by methylation reaction in metribuzin synthesis

InactiveCN101445304AReduce processingReduce pollutionMultistage water/sewage treatmentNature of treatment waterRefluxBromine

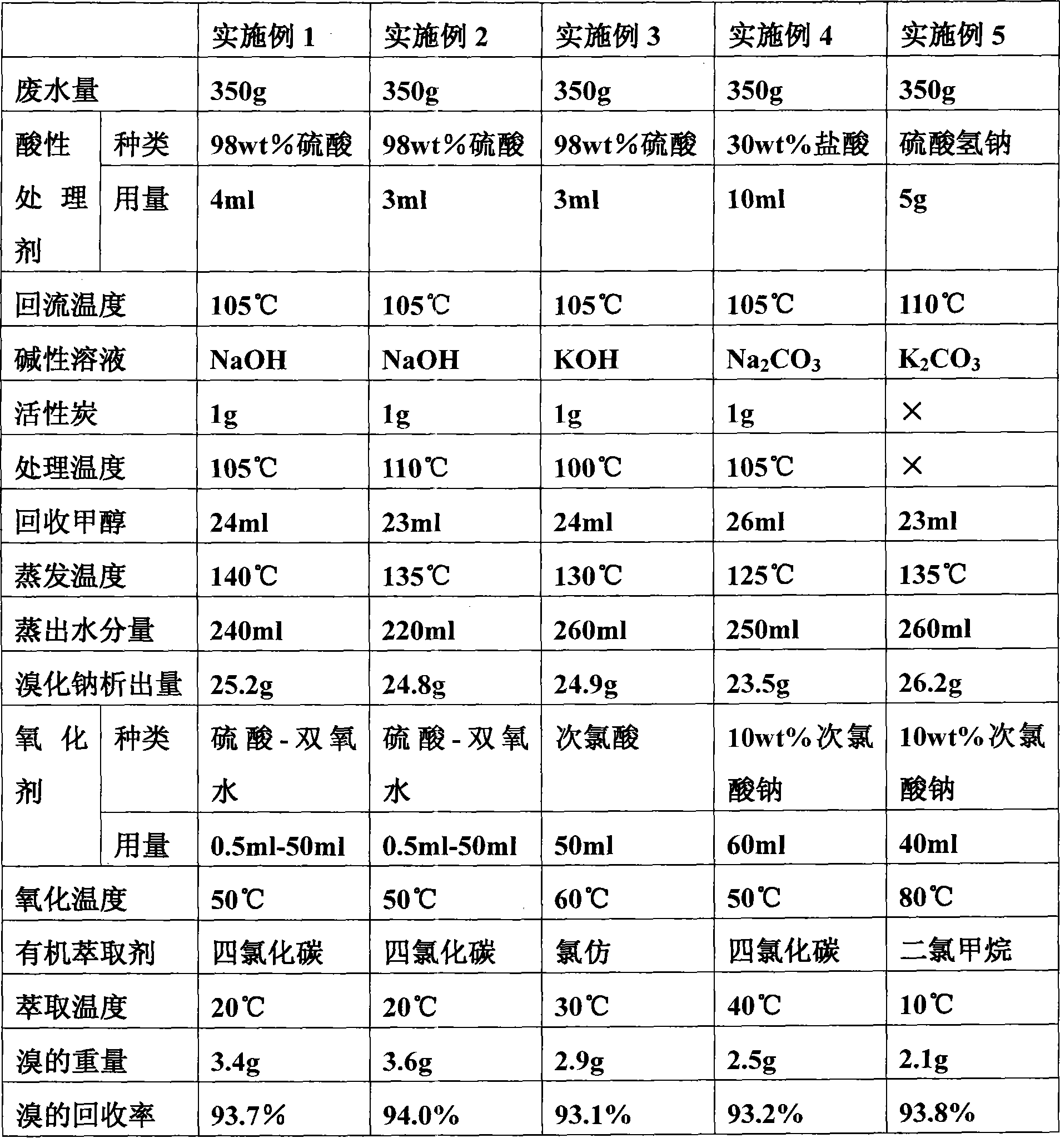

The invention discloses a method for treating wastewater produced by methylation reaction in metribuzin synthesis. In the method, the wastewater produced by the methylation reaction in the metribuzin synthesis is added with an acidic treating agent, and the obtained mixture is heated to 90 DEG C-120 DEG C and refluxed for deodorization and decolorization; and volatile gas in the wastewater and gas produced in the reflux are absorbed by alkaline solution for deodorization. Methanol in the wastewater is recovered by a batch distillation method. Residual liquid is heated to 100 DEG C-150 DEG C for evaporation, and then the residual liquid is naturally cooled by stirring until sodium bromide crystal is separated out. Filtrate is oxidized by an oxidant at the oxidation temperature of 50 DEG C-80 DEG C. A system is cooled to 10 DEG C-40 DEG C, and bromine in the system is extracted by an organic extractant, thus obtaining organic phase extracting solution with the bromine. The method helps solve the problem of treating methylated wastewater in metribuzin production, and reduce environmental pollution and production cost, the recovery rate of the bromine reaches more than 93%, and the method has good use value, and is simple and feasible.

Owner:JIANGSU HUAYI GARMENT CO LTD +1

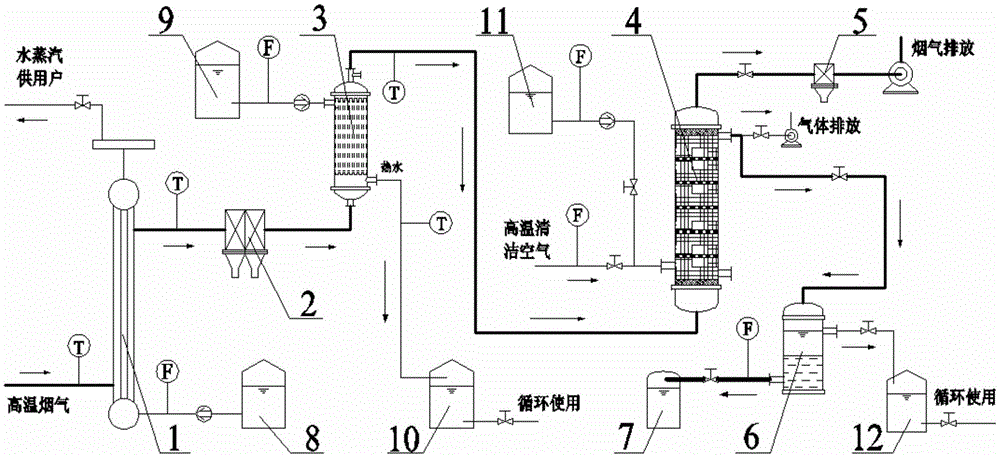

Method and system for treating electronic scrap smoke

ActiveCN104383801AAchieve desulfurizationAchieve dehalogenationDispersed particle separationBromine/hydrogen-bromideBrominePhysical chemistry

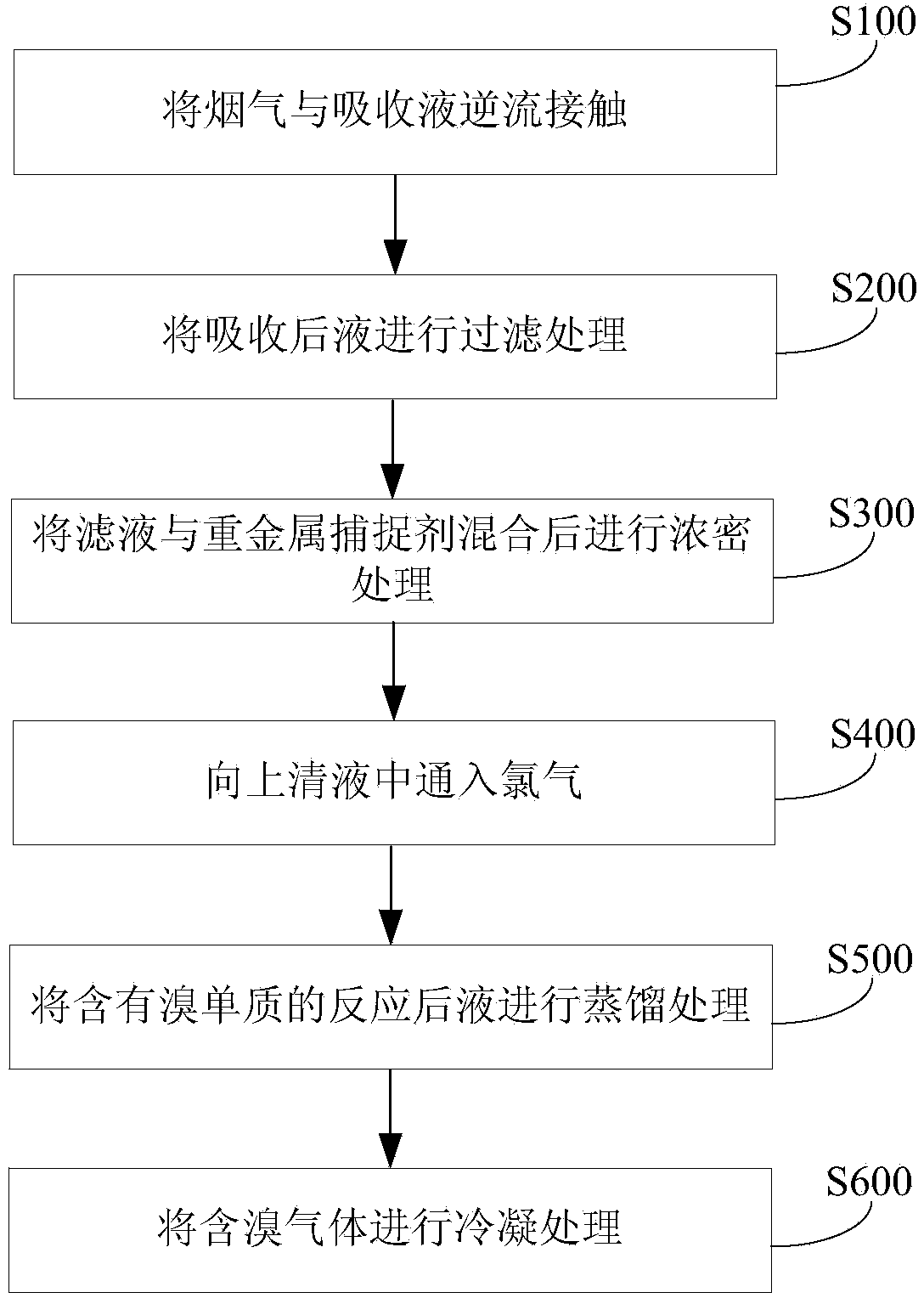

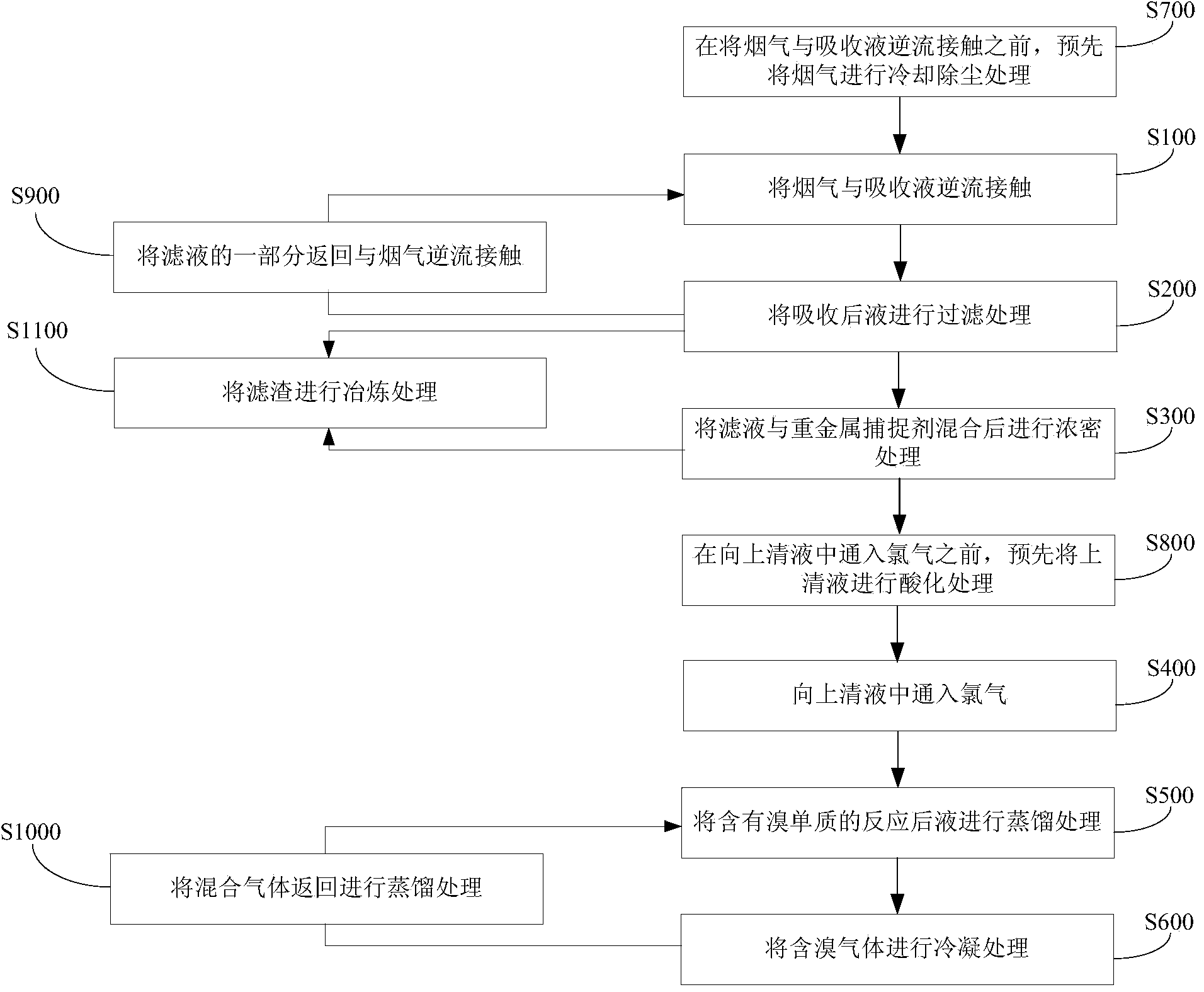

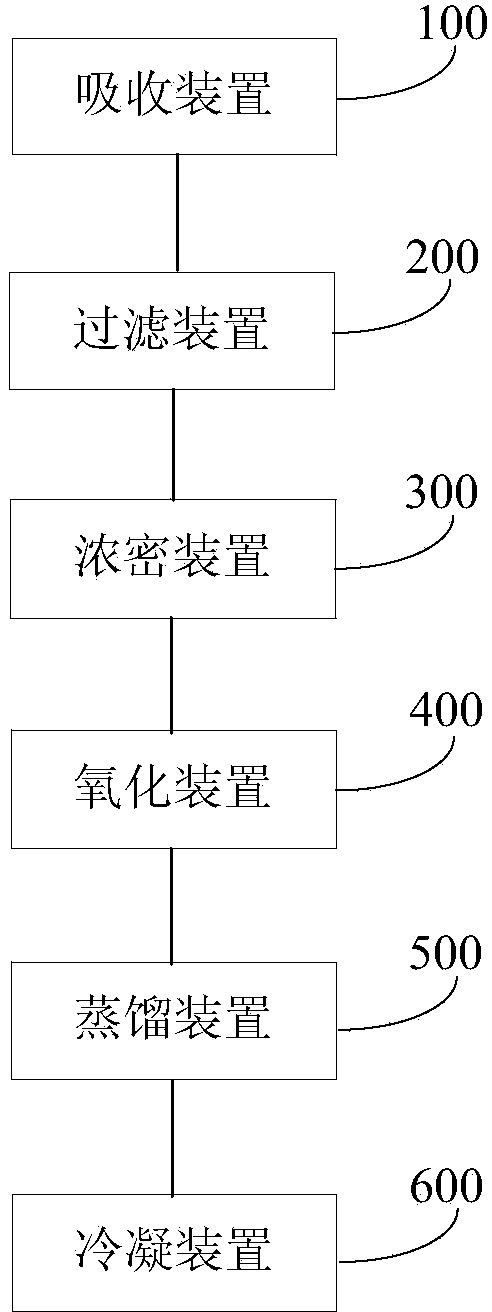

The invention discloses a method and a system for treating electronic scrap smoke. The method comprises the following steps: (1) performing countercurrent contact between smoke and absorption liquid so as to obtain purified smoke and absorbed liquid; (2) filtering the absorbed liquid so as to obtain filtrate and filter residue; (3) mixing the filtrate with a heavy metal capture agent, and performing concentration treatment so as to obtain supernatant and filter residues containing heavy metals; (4) introducing chlorine into the supernatant, oxidizing bromide ions in the supernatant into molecular bromine, so as to obtain a reaction solution containing the molecular bromine; (5) distilling the reaction solution containing the molecular bromine so as to obtain bromine-containing gas; and (6) condensing the bromine-containing gas so as to obtain a bromine product and mixed gas. According to the method, the electronic scrap smoke can be effectively purified, the purified smoke can meet the national environmental protection standard, the bromine element can be efficiently recovered, the bromine extraction rate is over 90 percent, and the purity of the bromine product is over 99 percent.

Owner:CHINA NERIN ENG

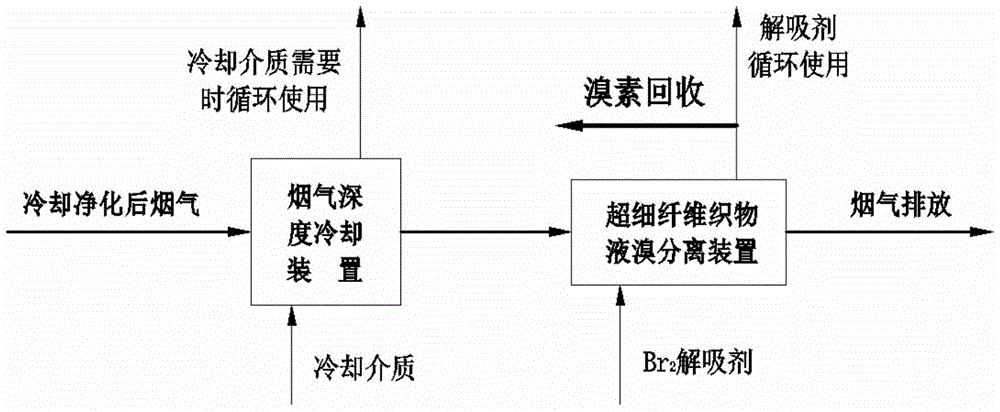

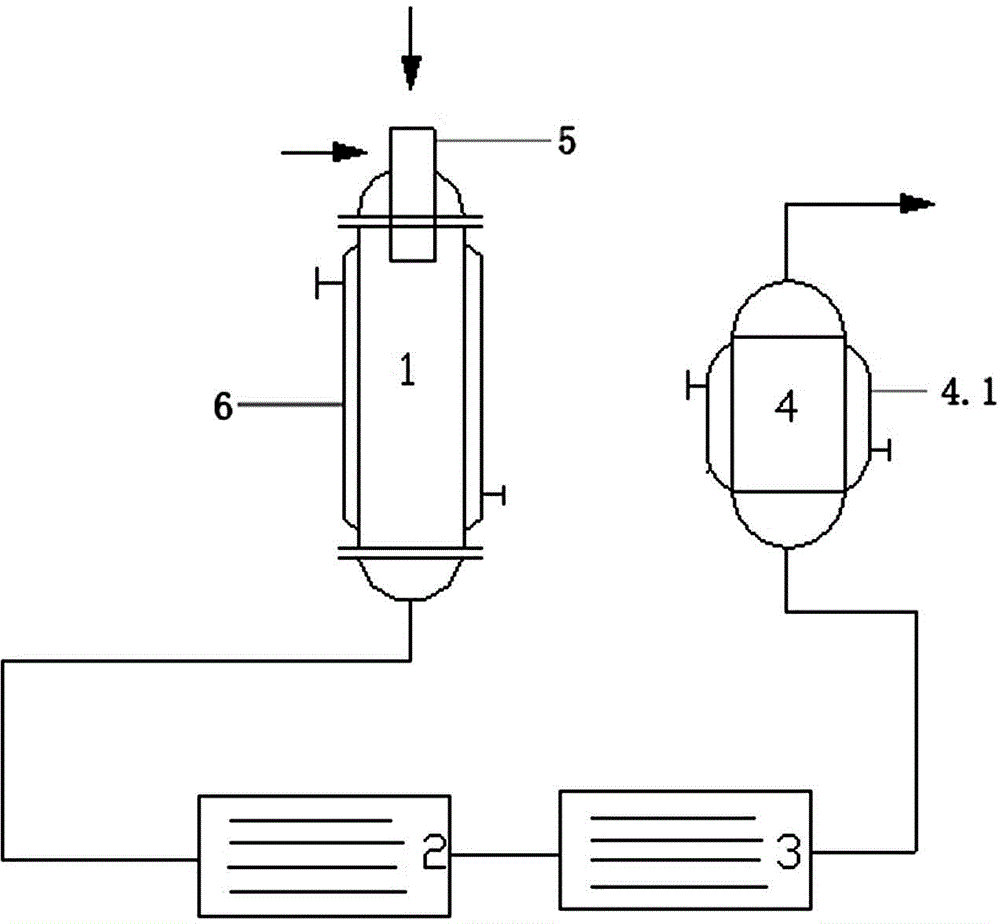

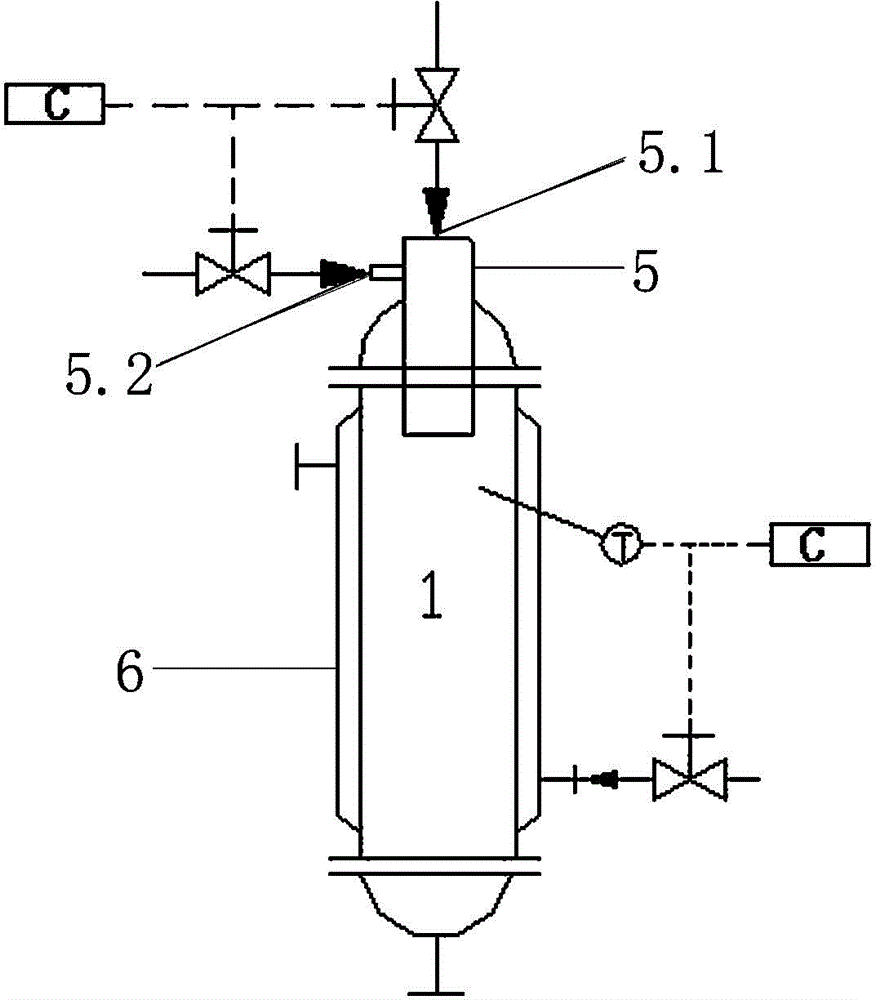

Method for separating and recycling Br2 in flue gas in after-burning area

ActiveCN106881003ANo need to worry about cloggingImprove separation efficiencyDispersed particle separationBromine/hydrogen-bromideFiberDesorption

The invention discloses a method for separating and recycling Br2 in flue gas in an after-burning area by using superfine fiber fabric. The method comprises steps like adsorption separation of the Br2 in the flue gas, desorption of adsorbed Br2 and separation of a desorption agent, and can finally obtain bromine. According to the invention, the principle of the superfine fiber fabric to adsorb the Br2 is different from the principle of a traditional adsorbent; the weight of adsorbed Br2 can be far beyond 30% of the weight of Br2; adsorption is performed at a low temperature, and the Br2 in the flue gas is easier to be extracted; the superfine fiber fabric material has strong corrosion resistance, so the service life is long, and less waste is generated in the process of application; and waste superfine fiber fabric can be treated by incineration. Compared with a traditional adsorption separation and recycling method, the method provided by the invention has high separation and recycling efficiencies and low operation cost, hardly generates new wastes, and realizes unity of environmental benefits and economic benefits.

Owner:ZUNYI NORMAL COLLEGE

Composition and method for enhanced sanitation and oxidation of aqueous systems

ActiveUS7922933B2Inactivation rate can be enhancedEfficient regenerationHeavy metal active ingredientsBiocideChlorine dioxideNeutral ph

This invention relates to a method for enhanced sanitation and oxidation of aqueous solutions at aquatic facilities. The method provides a means for the in-situ generation of chlorine dioxide from dilute solutions of chlorite anions at near neutral pH, and enhanced inactivation rates of microbiological organisms including cryptosporidium.

Owner:TRUOX

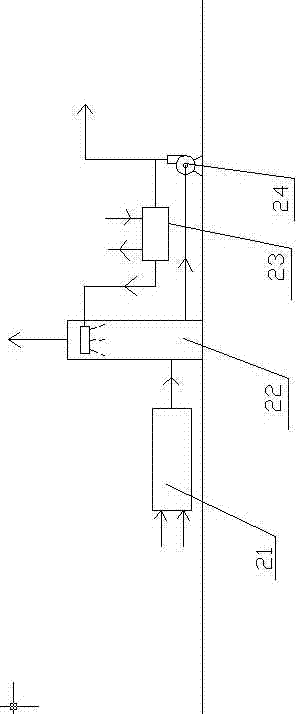

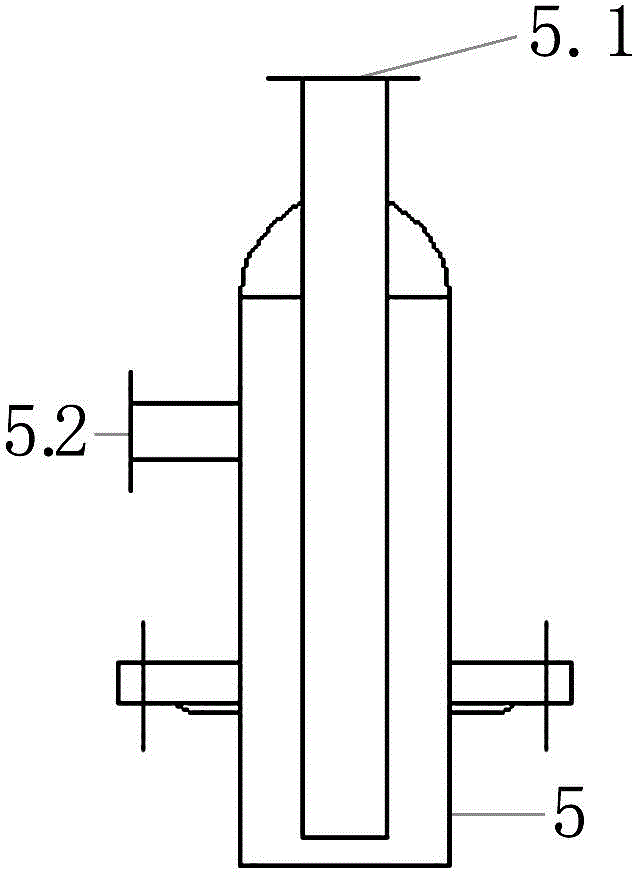

Combined hydrogen bromide generating device and technology

InactiveCN104891441AConducive to requirements such as measurement and storageMeet the needs of industrialized mass productionBromine/hydrogen-bromideSteel jacketSorbent

The invention belongs to the fields of pharmaceutical chemical and production technology. To solve the problems, such as short life, insufficient strength, leaking liability of harmful gas, and low bearing pressure, of a hydrogen bromide generating device in the prior art, provided is a combined hydrogen bromide generating device and technology. The device comprises a combustor, the bottom of which is connected to one side of a condenser; the other side of the condenser is connected to an adsorption bed; and the end part of the adsorption bed is connected to a hydrogen bromide storage tank. The top part of the combustor is provided with a quartz glass nozzle; the cavity of the combustor is externally provided with a steel jacket; and cooling water passes through the steel jacket. An ignition source of the combustor is an electronic igniter. An adsorbent of the adsorption bed is active carbon. The hydrogen bromide storage tank is provided with an explosion-proof membrane. The inner cavity of the combustor, the condenser, and the hydrogen bromide storage tank are made from glass enamel. The device is bromine-resistant or hydrogen bromide-resistant, is beneficial for carrying out a reaction and meeting requirements of subsequent metering storage of hydrogen bromide gas, and satisfies the requirement of industrial mass production. The service life of the device is better prolonged; the technical condition is easy to control; and the product yield and purity are improved.

Owner:SHANXI HENGYI NEW MATERIAL TECH SERVICE

Method for recovering bromine tail gas and chlorine gas in bromine production

InactiveCN101659398AIncrease profitReduce throughputChlorine/hydrogen-chloride purificationBromine/hydrogen-bromideBromineDistillation

The invention relates to a method for recovering bromine tail gas and chlorine gas in bromine production, which is characterized by using acid liquor as an absorbing agent to absorb the chlorine gas and the bromine in a tail gas. The method has the following advantages: the utilization rate of chlorine is improved by effectively dissolving part of the chlorine in a complete solution by absorbing the tail gas with an absorption complete solution, and saving the introduction amount of the chlorine gas for oxidization when the complete solution enters a distillation tower, and such item can save200,000 yuan of financial resources each year; a bromine finished product is effectively recovered, wherein the bromine content in the emptied bromine vapor reaches up to 98.8 percent, the emptied bromine vapor is completely kept in the complete solution by an absorption tower, the bromine finished product is formed through distillation and cooling, and only such item saves about 400,000 yuan of financial resources; and the problems of environmental pollution are solved by absorbing the tail gas with the complete solution, and absorbing the tail gas with an alkali lye at the absorption tail end so as to achieve the zero release of chlorine and bromine of the emptied tail gas.

Owner:天津长芦汉沽盐场有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com