Method for treating profenofos synthetic wastewater by using hydrogen peroxide

A technology of hydrogen peroxide and profenofos, which is applied in the field of using hydrogen peroxide to treat profenofos synthetic wastewater, can solve problems such as high chemical oxygen consumption, unpleasant odor, environmental pollution, etc., and achieves simple overall process, high reliability, and operating costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one: intermittent production bromine

[0023] Add 640kg of 30% sodium carbonate solution to the 1000L glass-lined bromine absorption reactor and start stirring, add 640kg of 30% sodium carbonate solution to the tail gas absorption tank, add 2000kg of waste water to the 3000L glass-lined reactor, and add 265kg of 92.5% to the reactor Concentrated sulfuric acid and 300kg of 27.5% hydrogen peroxide to make it react, the reaction time is 3.0h, heated to 105±5°C and blowing air, the vertical condenser is fed with cooling water, continue to maintain the distillation temperature until there is basically no bromine in the air 1. Until the wastewater turns light yellow, cool down to 50±5°C, neutralize it with 30% sodium hydroxide, add 20kg sodium thiosulfate, and discharge it to the wastewater treatment pool.

[0024] Pass cooling water into the jacket of the 1000L glass-lined bromine absorption reaction kettle, slowly drop 92.5% sulfuric acid from the elevated tank, ...

Embodiment 2

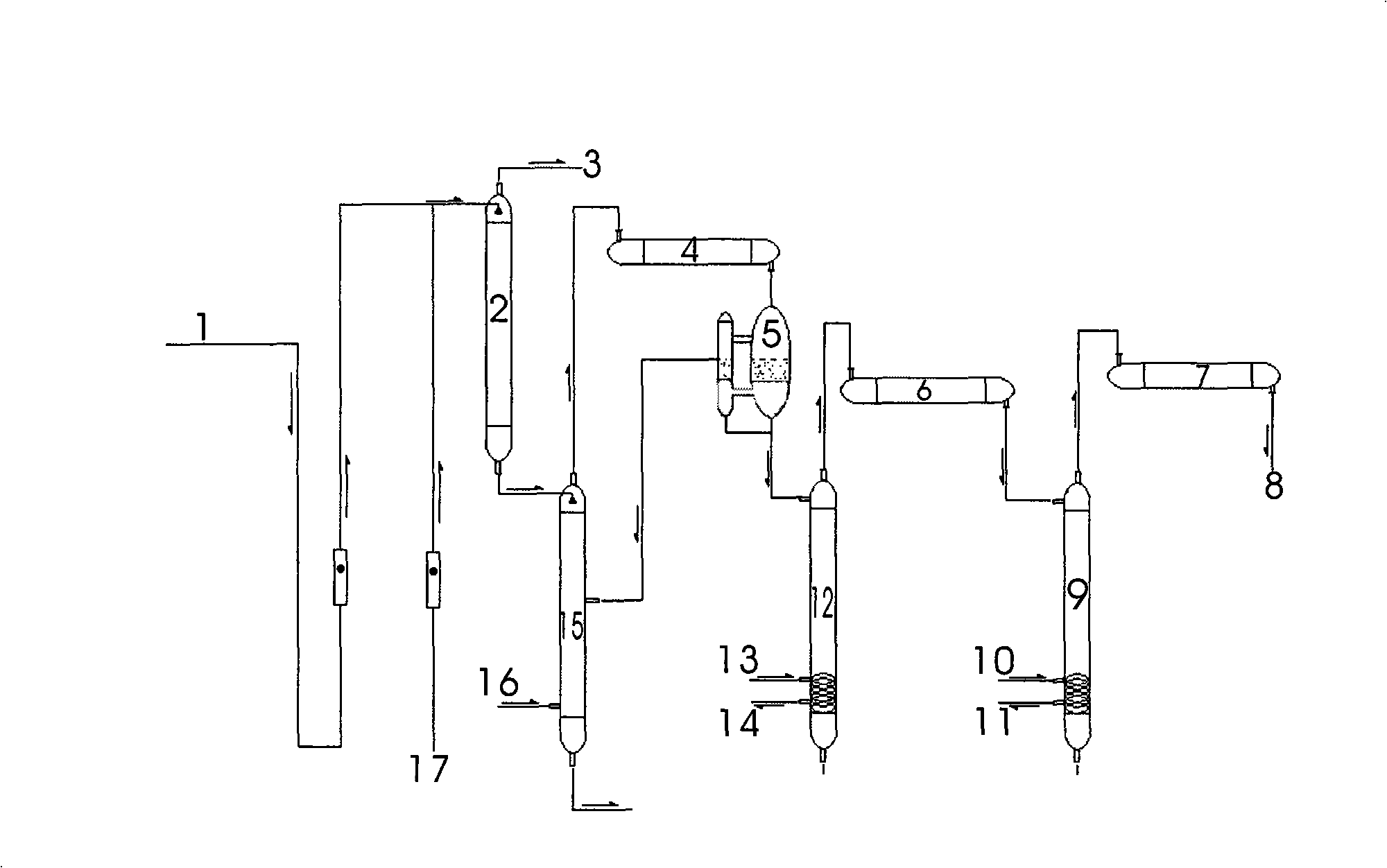

[0026] Embodiment two: continuous production of bromine

[0027] The waste water flows into the upper port of the oxidation tower 1 at a flow rate of 300L / h from the high level tank, and the hydrogen peroxide flows in from the upper port of the oxidation tower 1 at a flow rate of 250L / h. Tower 2 is blown out by the water vapor from the lower part of the distillation tower, and enters the condenser together with a part of the water vapor. After condensation, it becomes a liquid and enters the bromine-water separation bottle 4, and the separated and settled crude bromine enters a bromine-water separation bottle from the bottom of the bromine-water separation bottle. Stage rectification tower 5, saturated bromine water returns to distillation tower 2, enters secondary rectification tower after the bromine of primary rectification is condensed, obtains refined bromine after rectification again, and the waste water discharged from distillation tower is neutralized to neutral.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com