Bittern bromine-blowing process

A kind of bittern and process technology, applied in the field of bromine extraction, can solve problems such as no bittern blowing bromine, bromine loss, etc., to avoid environmental pollution and improve the effect of obtaining rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

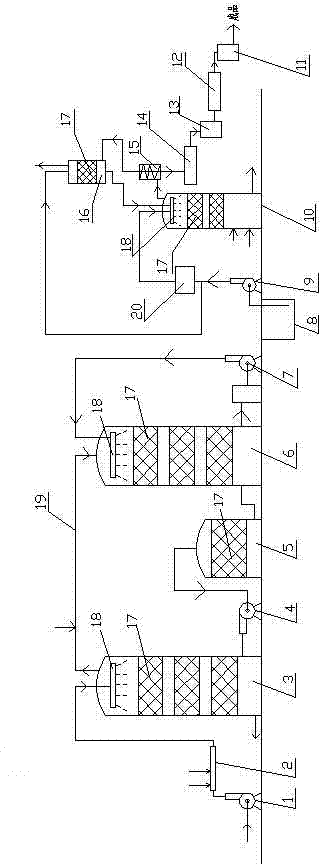

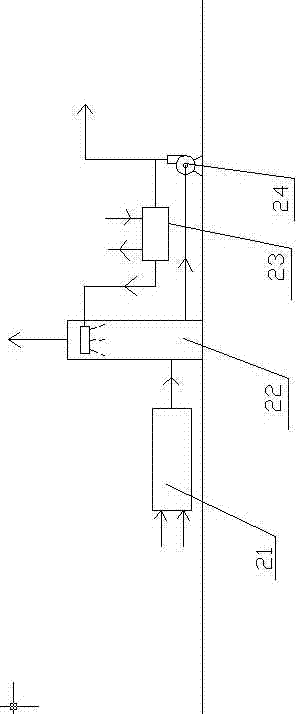

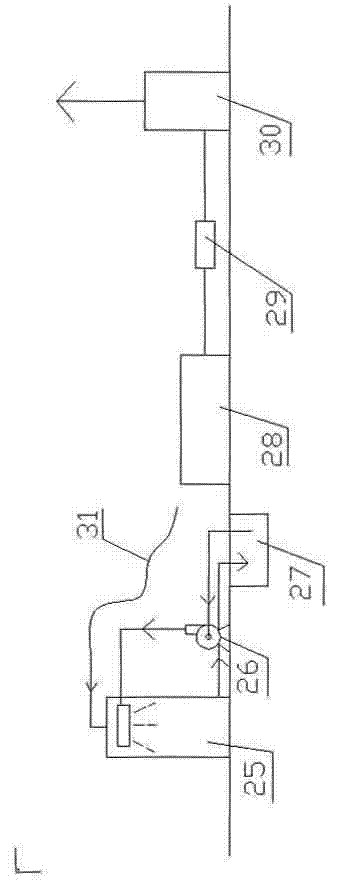

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The invention discloses a high-concentration bittern bromine blowing process. The process adopts the methods of oxidation, blowing, absorption and distillation to extract bromine from bittern (high-concentration bittern is called bittern). The specific process steps are:

[0030] 1) Choose bittern with a bromine content of 1000-2500ppm as the raw material, adjust the ph value with acid liquid before the raw bittern enters the blowing tower, and adjust the ph to 2-3.5 through a mixer;

[0031] 2) Oxidation stage: the bittern is pumped into the high-efficiency gas-liquid and liquid-liquid mixing mixer 2 with the bittern pump 1, the acid concentration is 10-13%, the pH is controlled at 2.0-3.5, and the chlorine mixing rate is 110-130%. In mixer 2, bittern is fully contacted with chlorine gas, and the oxidation rate is above 90%.

[0032] 3) Blow-out stage: the oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com