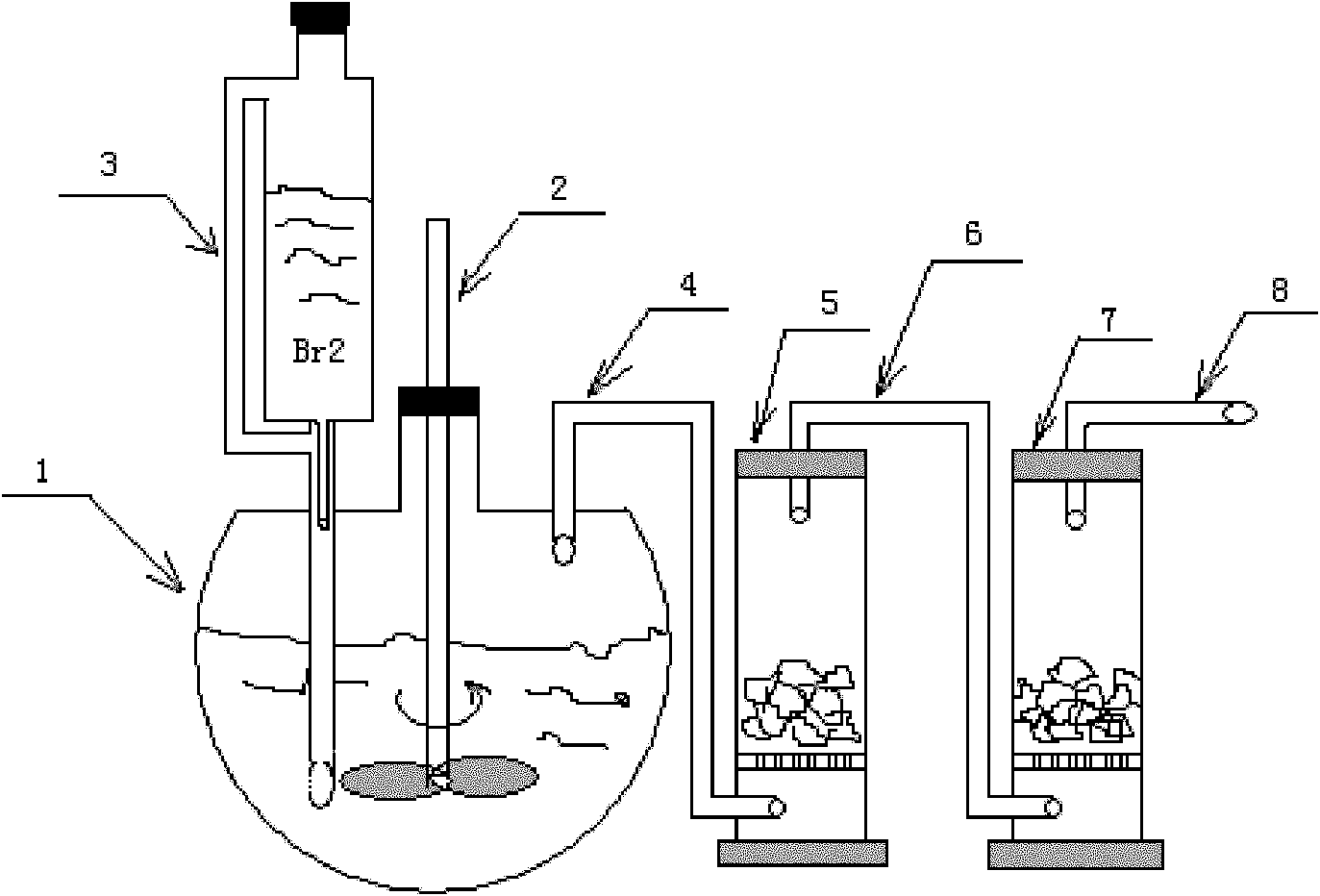

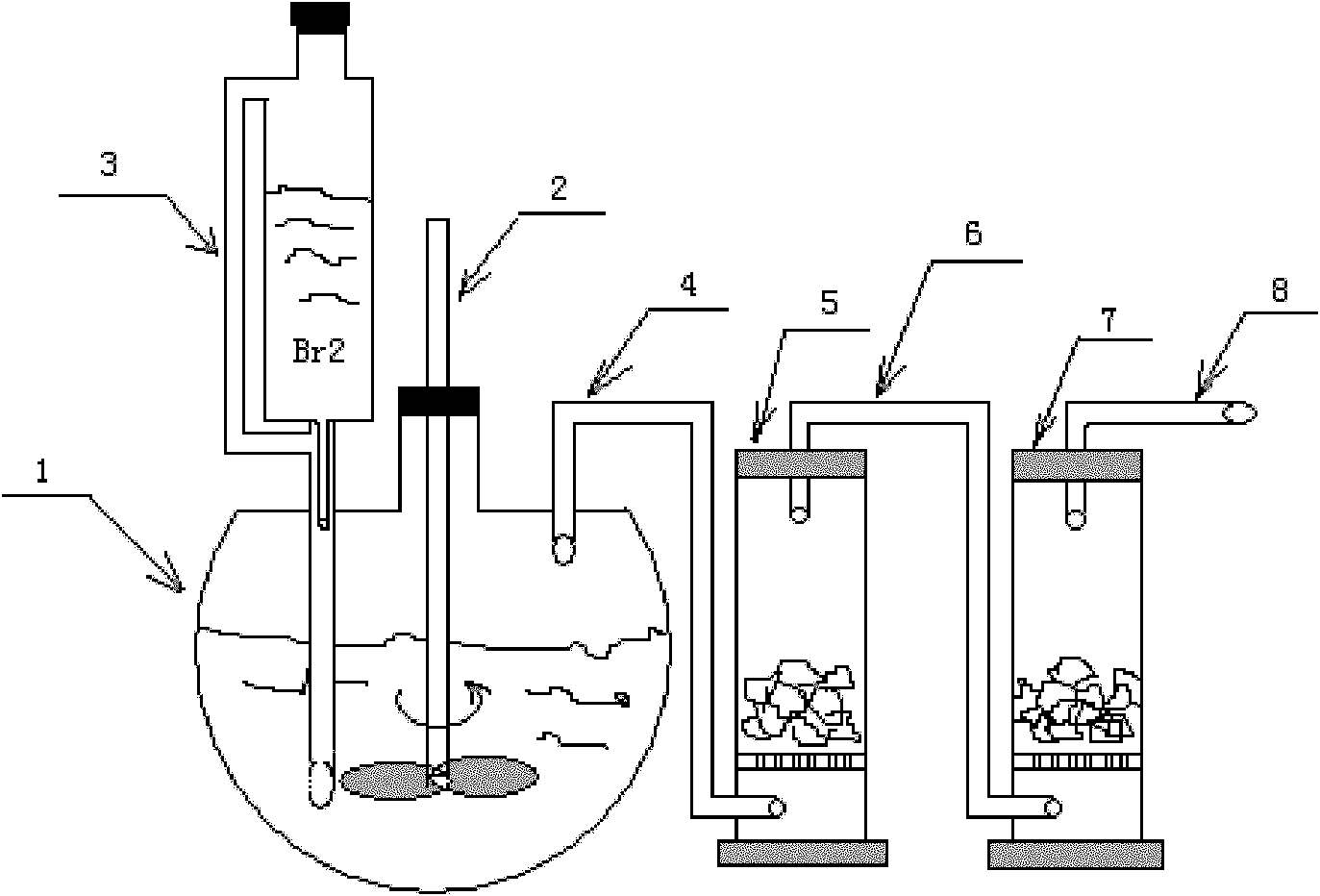

Preparation method of bromine hydride gas and generating device thereof

A technology for generating device and hydrogen bromide, applied in directions such as bromine/hydrogen bromide, can solve the problems of difficult reaction conditions, severe reaction exotherm, difficult gas separation, etc., and achieves easy control of reaction conditions and high bromine utilization rate. , the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 10g red phosphorus and 40g concentrated hydrobromic acid are placed in the reaction vessel, concentrated hydrobromic acid is a commercially available product, stirred at room temperature, and dripped in the reactor from a constant pressure dripping device (the dripping end is located below the liquid level) Add 70g of bromine, that is, hydrogen bromide gas is released, and the produced hydrogen bromide gas passes through the bromine removal tower and the drying tower to export dry hydrogen bromide gas. The production rate of hydrogen bromide can be controlled by the drop rate of bromine.

[0020] The bottom liquid in the reactor is filtered to remove unreacted red phosphorus (recycling), and then hydrogen bromide is removed under reduced pressure to obtain 25 g of by-product phosphorous acid.

Embodiment 2

[0022] 50g red phosphorus and 225g concentrated hydrobromic acid are placed in reaction vessel, the concentration of concentrated hydrobromic acid is 40~48wt%, stir at room temperature, from constant pressure dripping device (drip end is positioned at liquid level below) to reaction container Add 300g of bromine dropwise into the container, and hydrogen bromide gas will be released, and the generated hydrogen bromide gas will be exported to dry hydrogen bromide gas through the bromine removal tower and the drying tower. The production rate of hydrogen bromide can be controlled by the drop rate of bromine.

[0023] The still bottom liquid in the reactor was filtered to remove unreacted red phosphorus (recycling), and then hydrogen bromide was removed under reduced pressure to obtain 110 g of by-product phosphorous acid.

Embodiment 3

[0025] 500g red phosphorus and 1750g concentrated hydrobromic acid are placed in reaction vessel, the concentration of concentrated hydrobromic acid is 40~48wt%, stir at room temperature, from constant pressure dripping device (drip end is positioned at below liquid level) to reaction container Add 3250g of bromine dropwise into the container, and hydrogen bromide gas will be emitted, and the produced hydrogen bromide gas will be exported to dry hydrogen bromide gas through the bromine removal tower and the drying tower. The production rate of hydrogen bromide can be controlled by the drop rate of bromine.

[0026] The still bottom liquid in the reactor was filtered to remove unreacted red phosphorus (recycling), and then hydrogen bromide was removed under reduced pressure to obtain 1180 g of by-product phosphorous acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com