Process for treating waste water in chlorfluazuron synthesis

A technology for wastewater treatment and profenofos, which is applied in the direction of reducing water/sewage treatment, chemical instruments and methods, bromine/hydrogen bromide, etc. Good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014]

[0015] 3Na 2 CO 3 +3Br 2 →5NaBr+NaBrO 3 +3CO 2 ↑

[0016] 5NaBr+NaBrO 3 +3H 2 SO 4 →3Br 2 +3Na 2 SO 4 +3H 2 o

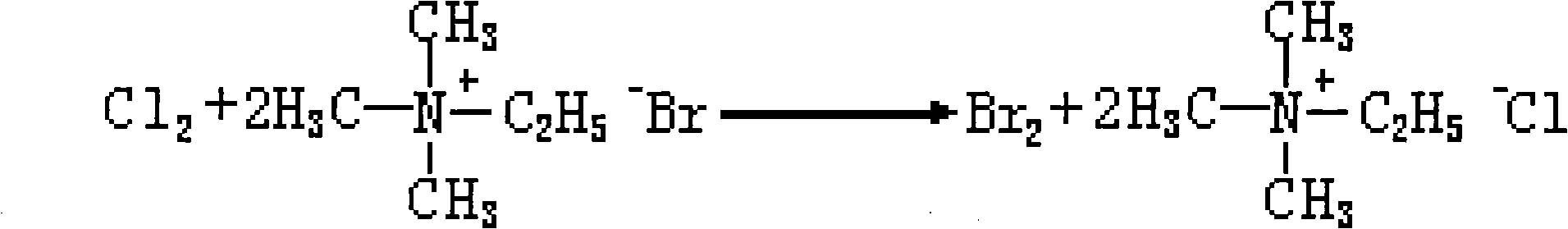

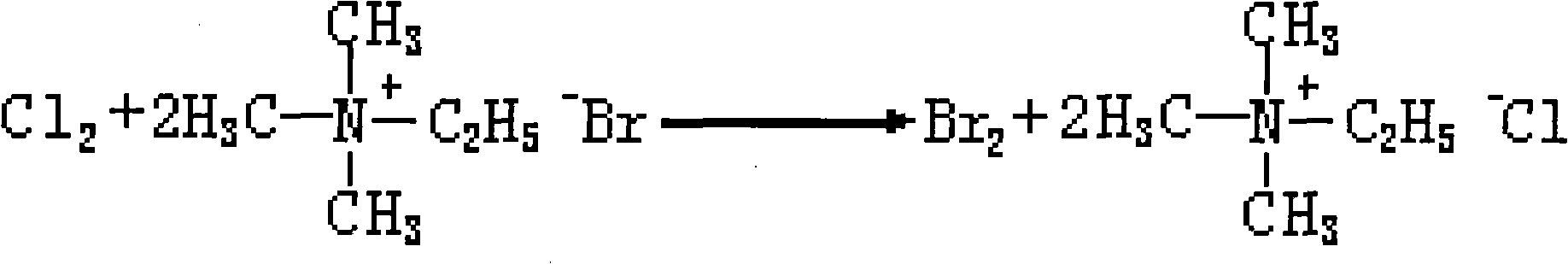

[0017] Introduce quantitative chlorine gas into the waste water to prepare bromine, and then extract trimethylethylammonium chloride from the water after separating bromine, and the chemical reaction equation is as above.

[0018] Add 2500kg of waste water into a 3000L glass-lined reactor, stir at room temperature, feed chlorine gas at a flow rate of 60kg / h, the weight of chlorine gas is 156kg, and continue to react for 0.5h after the chlorine feeding is completed.

[0019] Add 800kg of 30% sodium carbonate solution to the 1000L glass-lined bromine absorption reaction kettle and start stirring, add 800kg of 30% sodium carbonate solution to the tail gas absorption tank; the waste water after chlorine flow is blown by air with a flow rate of 50L / min Bubble, and heat up at the same time until the temperature reaches 105°C, keep bubbling at this ...

Embodiment 2

[0024]

[0025] The bromine is prepared by feeding quantitative chlorine gas into the waste water, the chemical reaction equation is as above, and then trimethylethylammonium chloride is extracted from the water separated from the bromine.

[0026] Add 2500kg of waste water into a 3000L glass-lined reactor, stir at room temperature, feed chlorine gas at a flow rate of 60kg / h, the weight of chlorine gas is 156kg, and continue to react for 0.5h after the chlorine feeding is completed.

[0027] Cooling water is passed into the glass condenser, and steam is passed into the jacket of the 3000L glass-lined reactor. Bromine enters the condenser along with the water vapor, and flows into the water separation receiver after condensation. The bromine sinks to the bottom of the receiver. , the condensed water is returned in the still, until the water in the still turns yellow and the condensed water that evaporates also becomes substantially colorless, the bromine in the water separati...

Embodiment 3

[0030] The waste water flows into the upper port of the oxidation tower at a flow rate of 300L / h from the high level tank, and the chlorine gas flows in from the lower part of the oxidation tower at a flow rate of 350L / h (0.2MPa). The tower is blown out by the water vapor from the lower part of the distillation tower, and enters the condenser together with a part of the water vapor. After condensation, it becomes a liquid and enters the bromine water separation bottle, and the separated and settled crude bromine enters the rectification tower from the bottom of the bromine water separation bottle. , the saturated bromine water returns to the distillation tower, and the crude bromine obtains refined bromine after secondary rectification, and the waste water discharged from the distillation tower enters the trimethyl ethyl ammonium chloride extraction device, and the trimethyl ethyl ammonium chloride extraction device is prepared according to the method of embodiment 1 and 2 Ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com