Patents

Literature

58results about How to "Has recycling value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

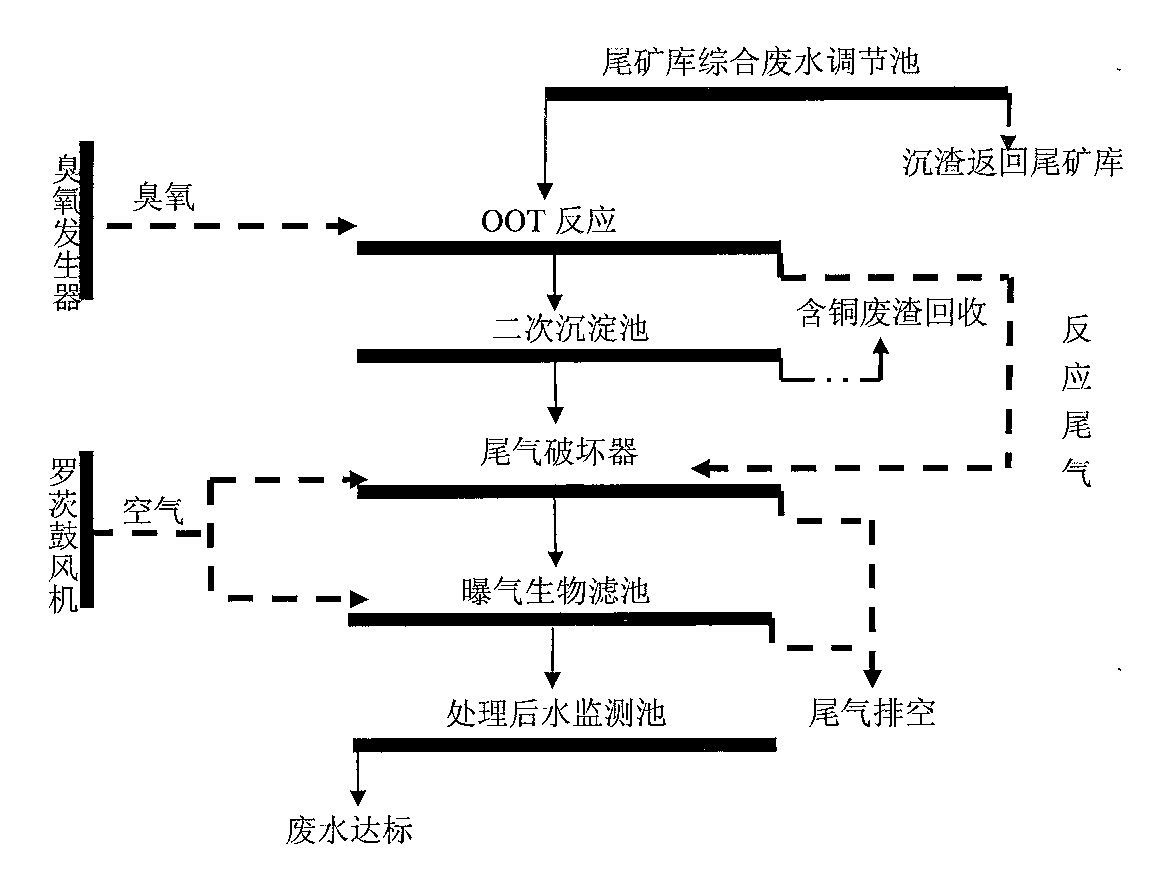

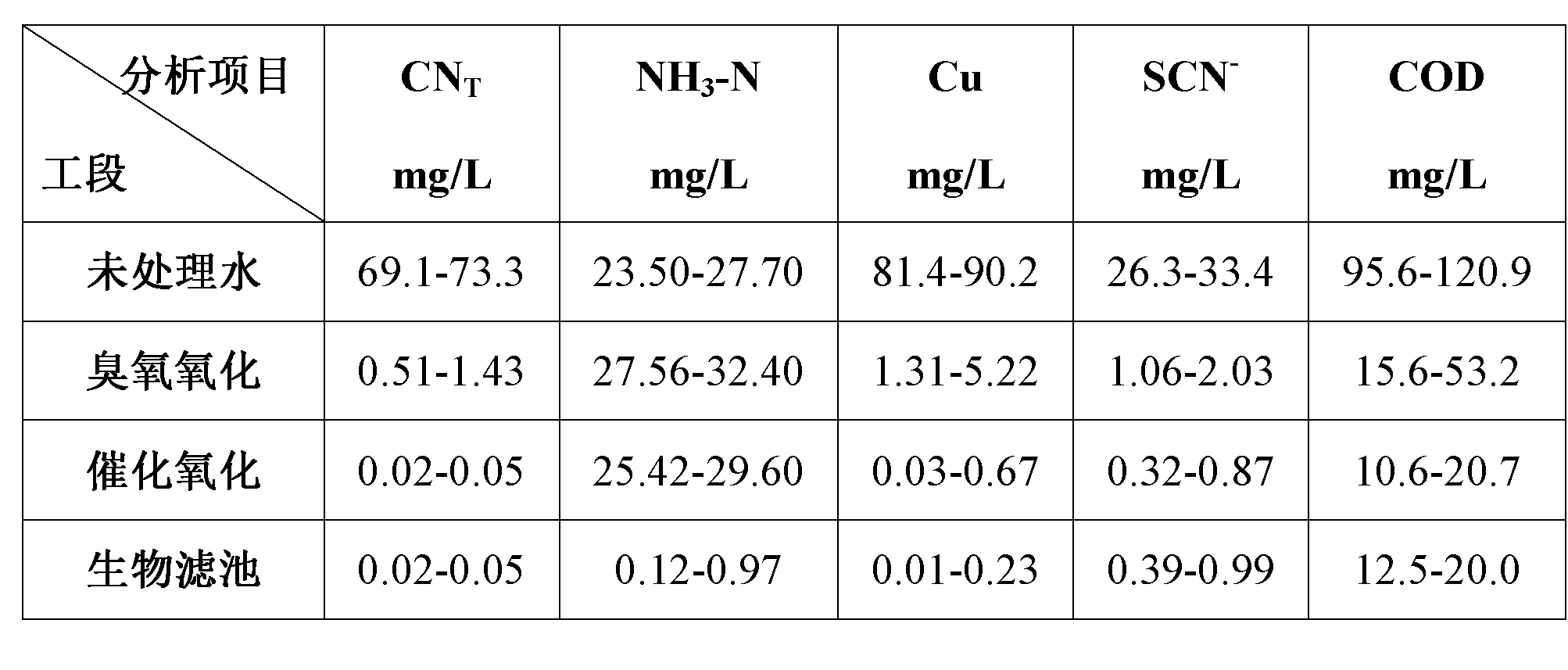

Deep treatment method for cyanide-containing waste water of tailings pond in gold industry

InactiveCN103253834AGood processing effectReduce processing costsMultistage water/sewage treatmentChemistryHeavy metals

The invention discloses a deep treatment method for cyanide-containing waste water of a tailings pond in the gold industry. The process adopts an ozone oxidation method, a catalytic oxidation method and a biological treatment method to collectively deeply treat the cyanide-containing waste water of the tailings pond in the gold industry. Through the combination of the three methods, a good treatment effect on the cyanide, thiocyanate, arsenic and heavy metals is good, the content of the cyanide after being treated is less than or equal to 0.05mg / L, the content of ammonia and nitrogen after being treated is less than 1mg / L, and other pollutants after being treated can meet the requirement of the ground surface water grade-B water quality standard. The method is used for treating the cyanide-containing waste water of the tailings pond in the gold industry, the treatment effect on the cyanide, the COD, As and heavy metals is good, the heavy metals such as the gold and silver as well as other metal resource can be recovered, and the secondary pollution caused by the ammonia and nitrogen can be avoided. By adopting the deep treatment method for the cyanide-containing waste water of the tailings pond, a good environment, a good economic benefit and a good social benefit can be achieved.

Owner:CHANGCHUN GOLD RES INST

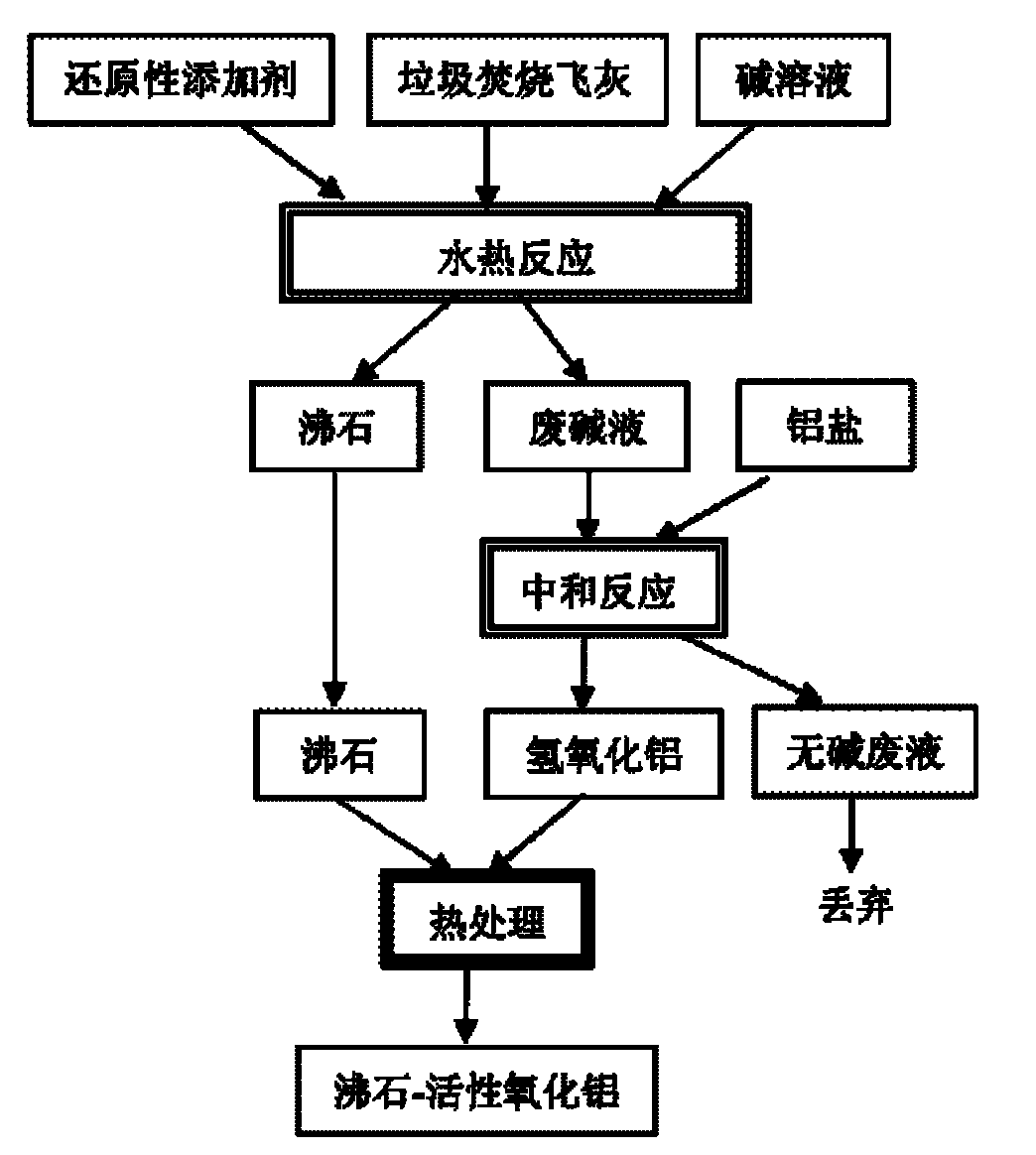

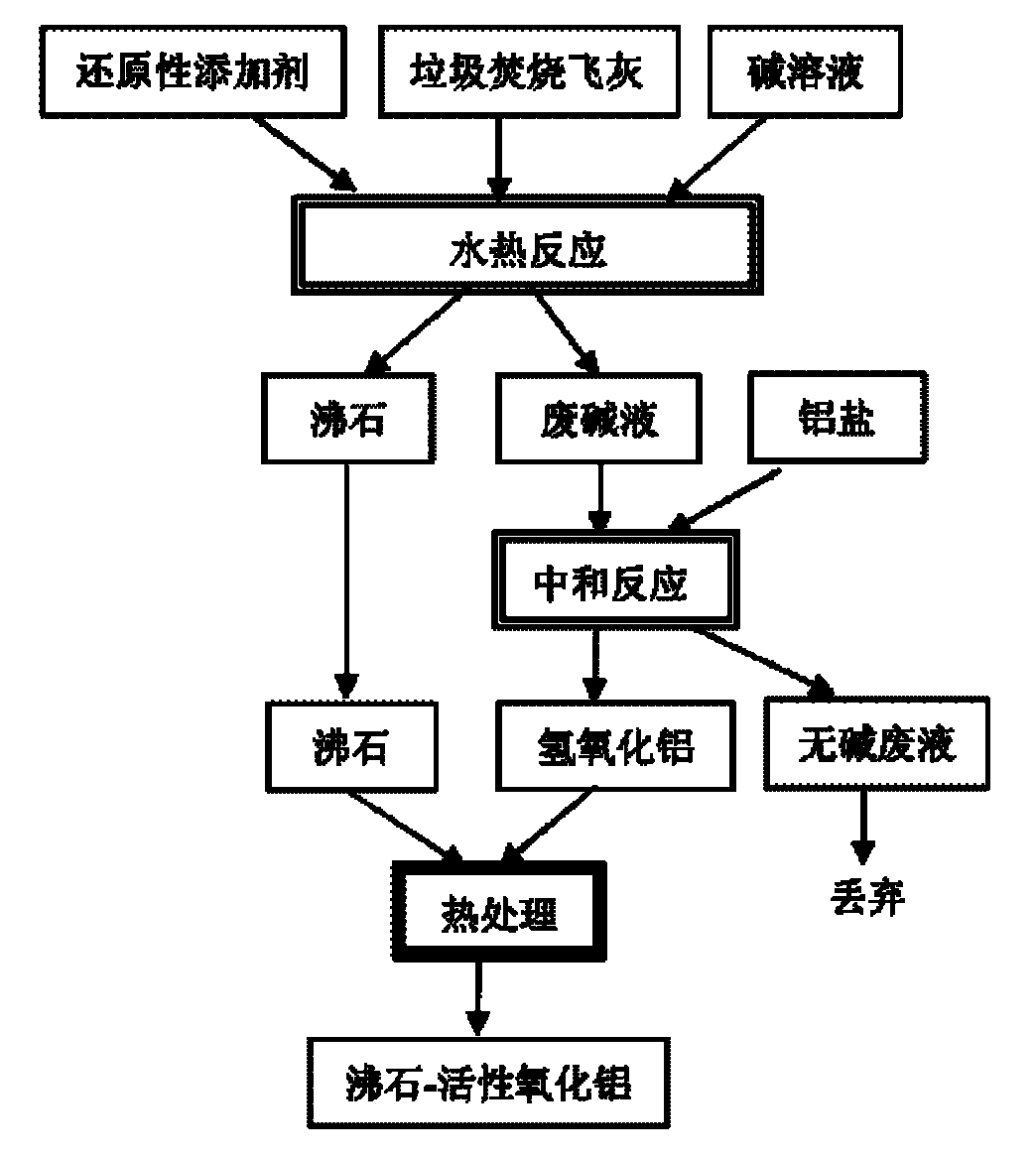

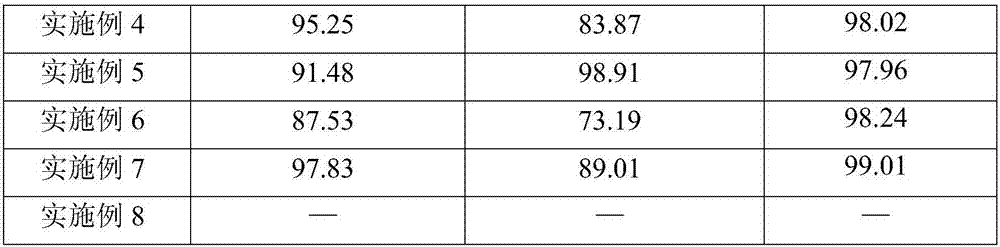

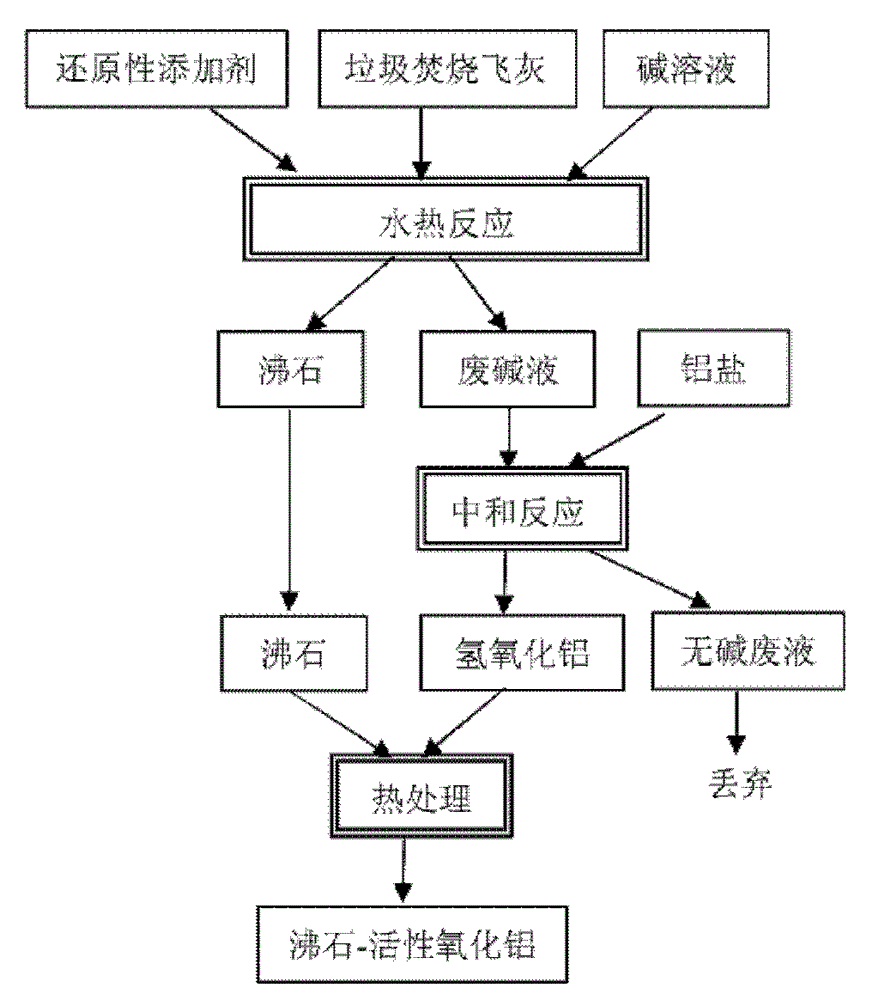

Heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash

InactiveCN102206757AWith resource recyclingAchieving harmlessnessOther chemical processesSolid waste disposalSorbentWater soluble

The invention relates to a heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash in the technical field of treatment for environmental protection. After an alkali solution and hydrazine substances are added to the MSWI fly ash and heated, and a water-soluble aluminum salt solution is further dripped; finally, after solid and liquid separation is conducted, heat treatment is carried out on an obtained solid phase to obtain a zeolite-active alumina compound absorbant; and the absorbant is put into sewage full of heavy metal to absorb and recycle the heavy metal. In the preparation process of the absorbant provided by the invention, dioxin in the MSWI fly ash is decomposed and removed; the MSWI fly ash is recycled as resources, and the heavy metal in the MSWI fly ash and the heavy metal in the sewage are recycled as the resources; and because the dioxin is decomposed and removed and the heavy metal is also extracted, the recycling method provided by the invention is safer and more reliable compared with the traditional treatment manner.

Owner:SHANGHAI JIAO TONG UNIV

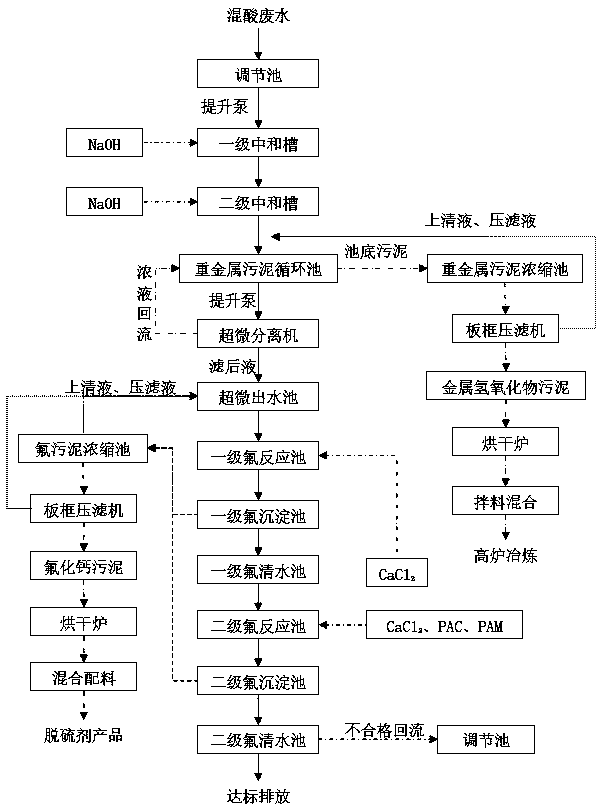

Method for recycling mixed-acid wastewater generated from metal pickling

InactiveCN108218025AImprove water qualityReduce dosageSludge treatment by de-watering/drying/thickeningTreatment involving filtrationSludgeFiltration

The invention discloses a method for recycling metal hydroxide sludge, generated after liquid alkali neutralization, and calcium fluoride sludge resources, generated after calcium chloride solution adding, from mixed-acid wastewater generated from steel industry pickling. The method mainly comprises the steps: subjecting the mixed-acid wastewater to reduction, then, adding liquid alkali, and carrying out concentrating by an ultramicro separator and press filtration by a press filter, so as to recycle metal hydroxide sludge (with the solid content of 50%); adding calcium chloride to produced water of the ultramicro separator, and then, carrying out precipitating, concentrating and pressure filtration, thereby recycling calcium fluoride sludge (with the solid content of 50%). According to the method, valuable metal ions and calcium fluoride sludge can be recycled from pickling mixed-acid wastewater, harmful dangerous solid wastes are not generated, the waste is changed into the valuable,the economic benefit of sewage treatment is improved, and the treatment cost is reduced.

Owner:YIXING XINDE ENVIRONMENTAL PROTECTION TECH

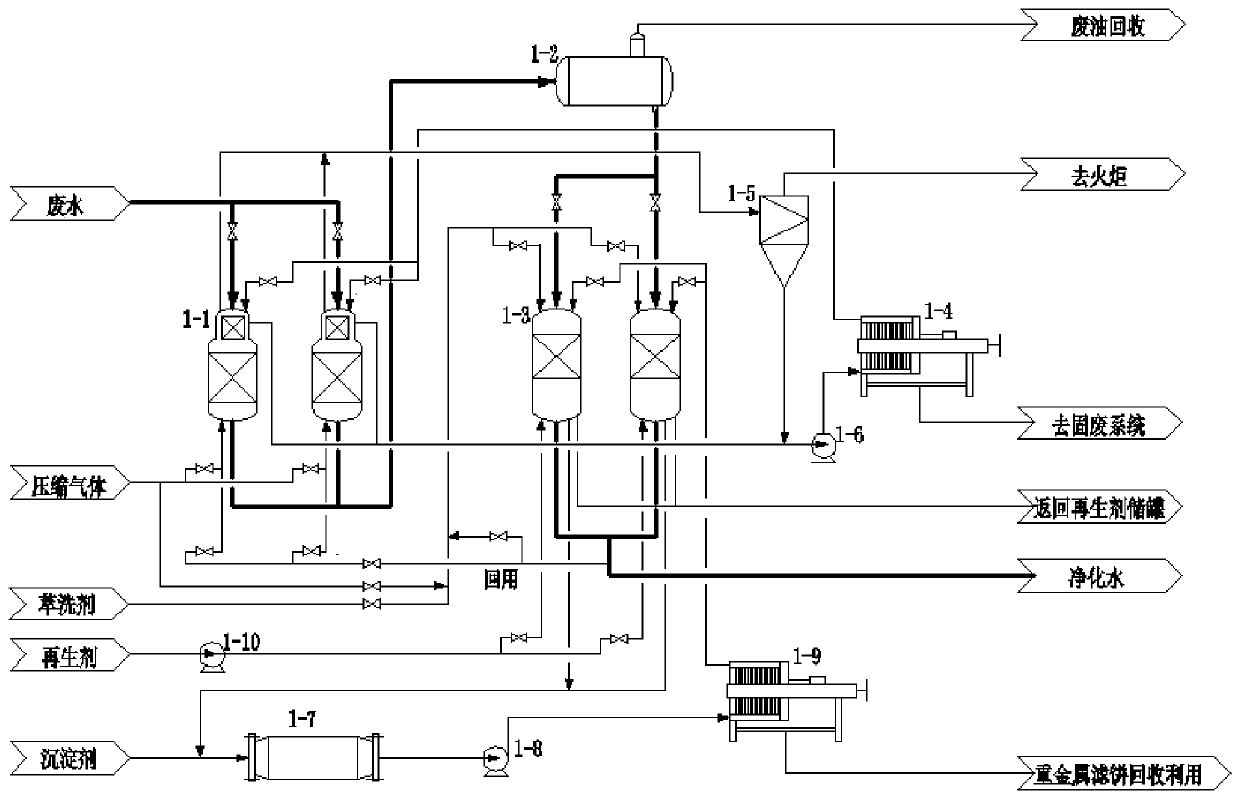

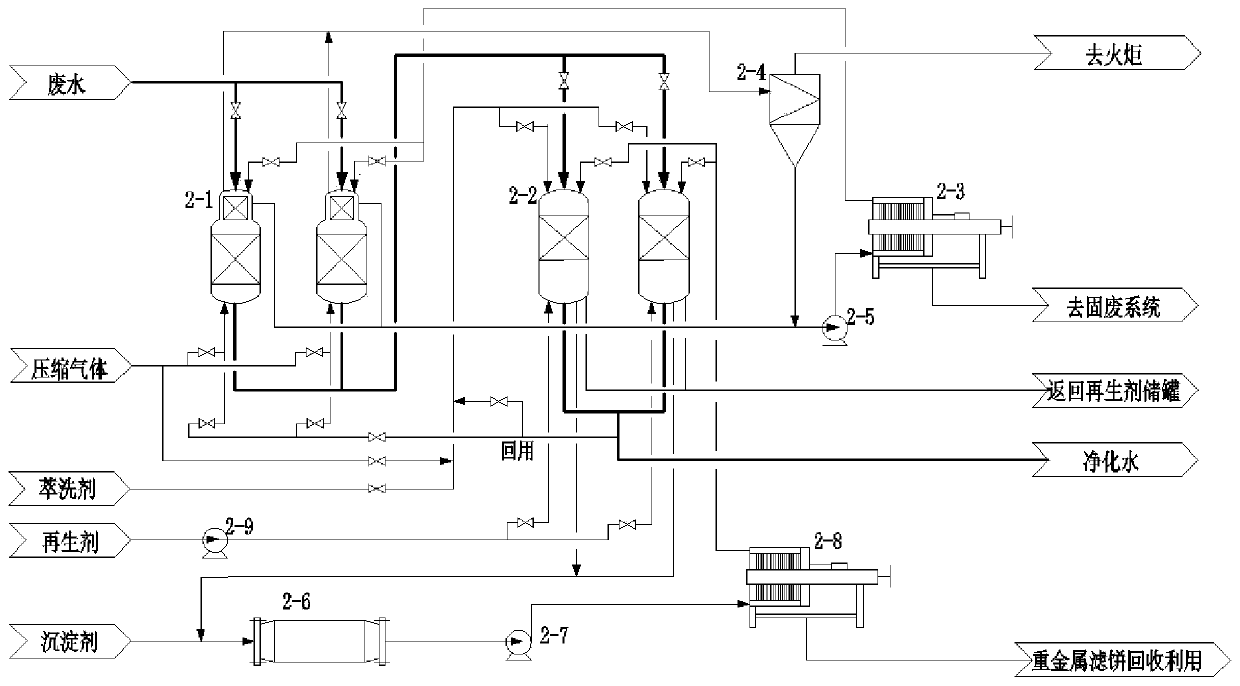

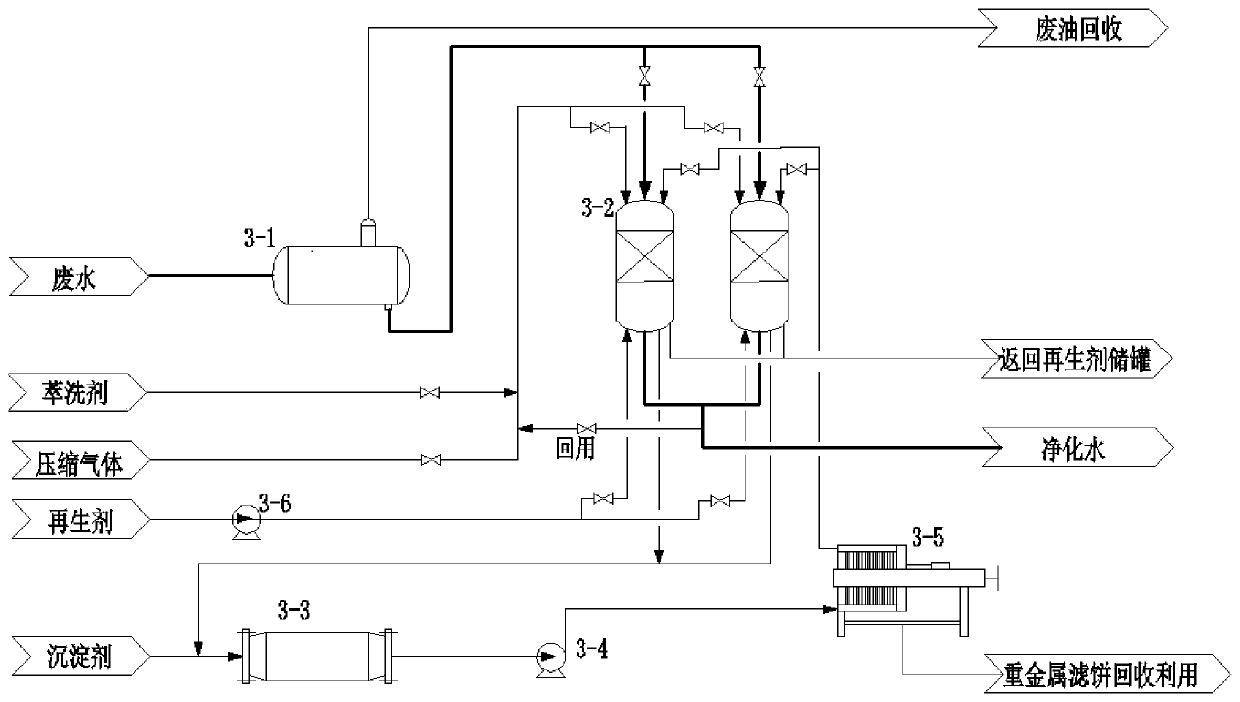

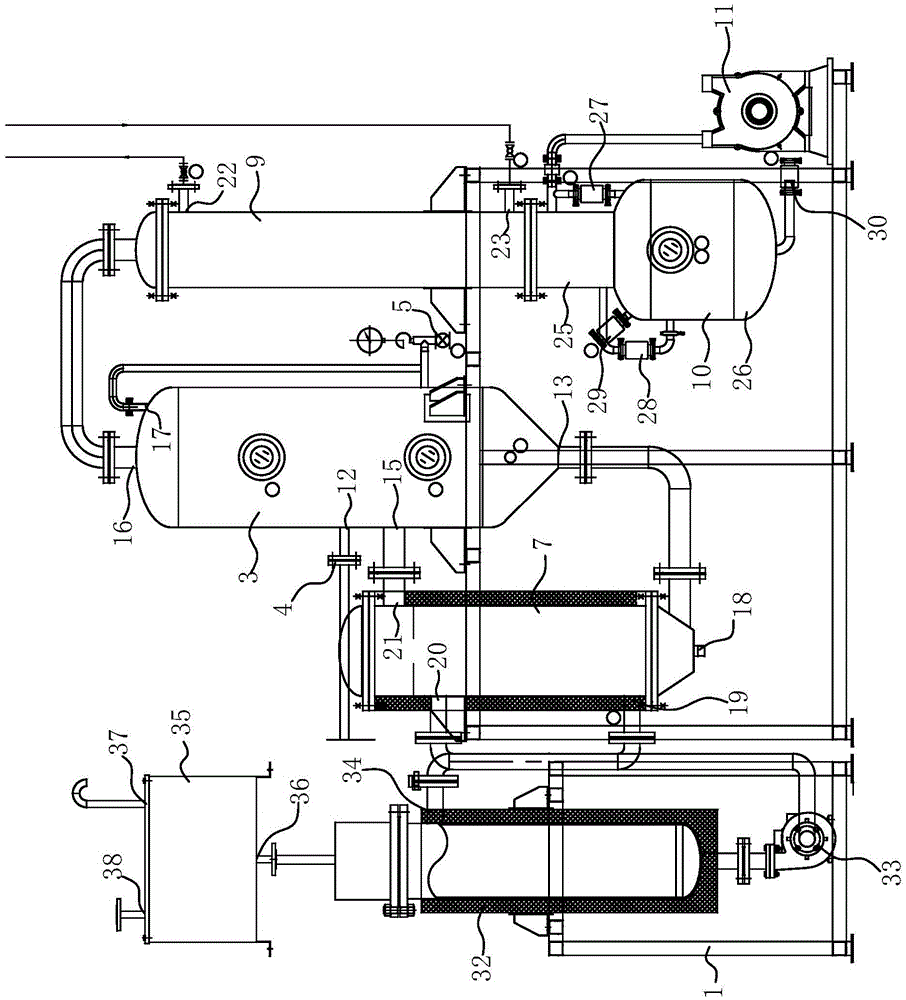

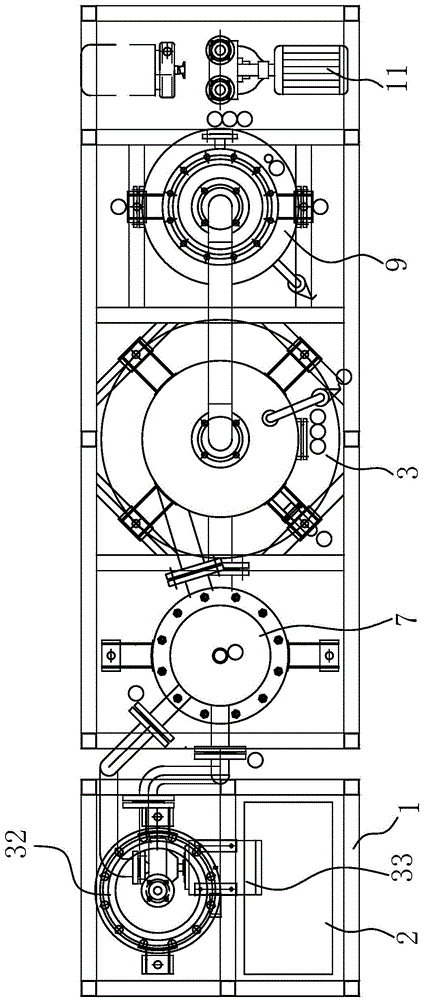

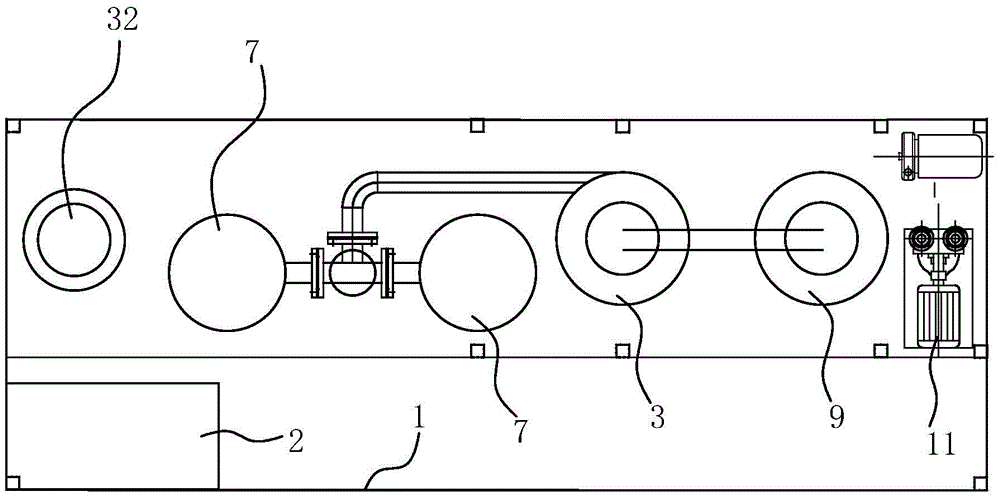

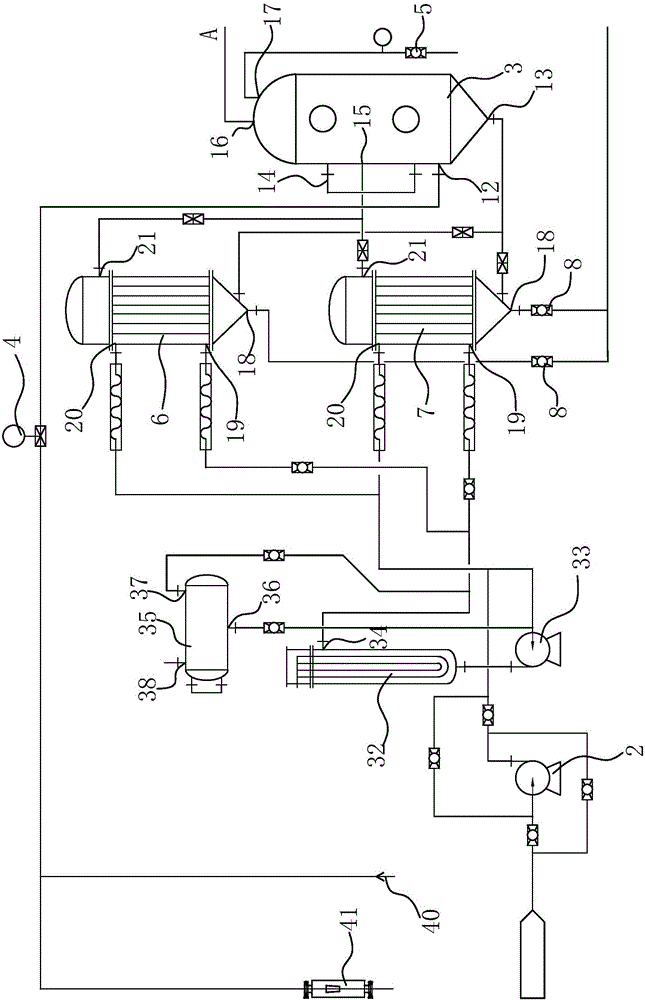

Deep treatment method and system for solid-containing oil-containing low-concentration heavy metal wastewater

InactiveCN110282767AAchieve recyclingSimple ingredientsWater contaminantsTreatment involving filtrationLiquid wasteFiber

The invention relates to the field of wastewater treatment in environment protection, in particular to a treatment method and system for solid-containing oil-containing low-concentration heavy metal wastewater. The method comprises the steps that firstly, a separator with a deep filtering boiling bed is used for removing soil particles in the wastewater; then, a fiber coalescence filter is used for controlling and removing soil in the wastewater and oil wrapped by a micro emulsion state; finally, a heavy metal ion adsorption tower is used for deeply removing an ion-state heavy metal pollutant in the wastewater, so that water discharging reaches the related emission standard. The whole treatment system only discharges the wastewater which reaches the standard, and no other waste liquid is discharged. According to the method, the heavy metal pollutant in the solid-containing oil-containing wastewater of the industries such as oil refining, power plants and electroplating can be deeply removed, and the water quality of the discharged wastewater reaches the related emission standard.

Owner:EAST CHINA UNIV OF SCI & TECH

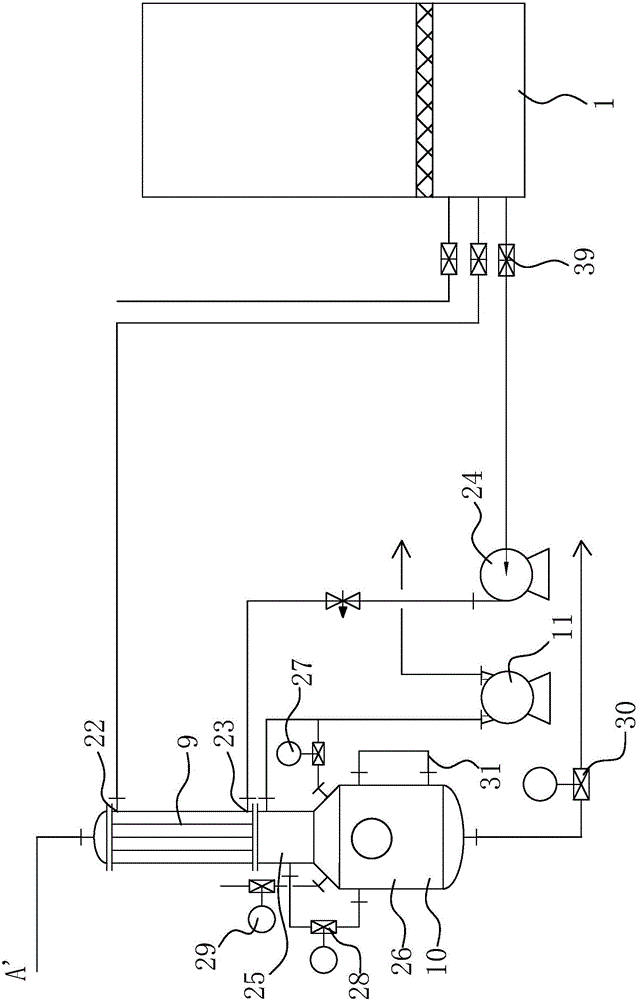

Chemical nickel waste liquid integrated processing system

ActiveCN105601016ARealize resource reuseSolve resource reuseWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteCooling tower

Disclosed is a chemical nickel waste liquid integrated processing system. The chemical nickel waste liquid integrated processing system is characterized in that solid-liquid separation can be performed on chemical nickel waste liquid, and the system comprises an evaporation device, a cooling tower, a conduction oil circulating device, an electric control cabinet and an automatic control unit; the evaporation device comprises a steam-liquid separator, a feeding electric valve, an emptying valve, a heating chamber, a condenser, a water storage tank and a vacuum pump; the water storage tank is composed of a first tank body and a second tank body. The chemical nickel waste liquid integrated processing system is high in integration degree, small in occupied area and capable of safely, stably and effectively removing phosphorus, nickel and COD in chemical nickel waste liquid, no secondary pollution is generated, and the processed chemical nickel concentrated solution has the recycling value.

Owner:苏州市东方环境工程有限公司

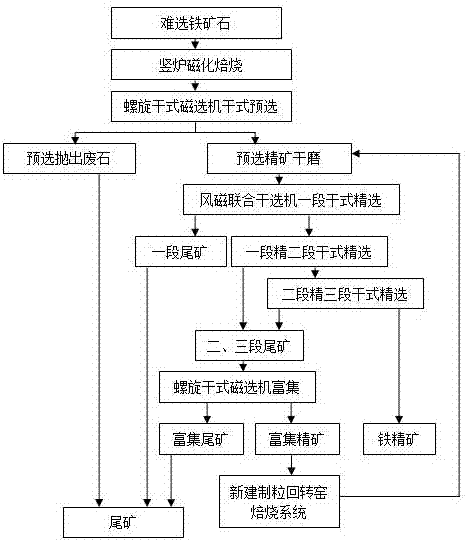

Refractory iron ore on-line closed-loop shaft furnace roasting, dry grinding and dry separation technology

ActiveCN107377204ARaise the gradeHas recycling valueProcess efficiency improvementMagnetic separationIronstoneResource utilization

The invention discloses a refractory iron ore on-line closed-loop shaft furnace roasting, dry grinding and dry separation technology which comprises the following steps that oxidized refractory iron ore with the size fraction being +15 mm to -100 mm is subjected to magnetizing roasting through a shaft furnace, and the roasted ore is cooled to the normal temperature; the roasted ore is subjected to dry-type pre-separation and discarded through magnetic pulleys; after discarding is finished, the roasted ore is subjected to dry grinding and dry separation, specifically, dry grinding is conducted till the ore with the size fraction being -0.074mm accounts for 70-80%; a panel wind magnetism combination dry separator is adopted for three-stage dry-type concentration; after two-stage and three-stage tailings are enriched by a spiral dry-type magnetic separator, the enriched tailings, one-stage concentration tailings and discarded waste ore are discharged by qualified tailings, and the grade is controlled to be 10% or below; the enriched concentrate is returned to a newly-built granulating rotary kiln roasting system for closed-loop magnetizing roasting; and concentrate after three-stage concentration is final qualified concentrate, and the grade reaches 60% or above. According to the refractory iron ore on-line closed-loop shaft furnace roasting dry grinding and dry separation technology, aiming at solving the problem of the high grade of shaft furnace magnetizing roasting ore magnetic separation tailings of refractory iron ore with different size fraction ranges, iron resources in the tailings are recovered in an on-line closed-loop mode, and the resource utilization rate is increased.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

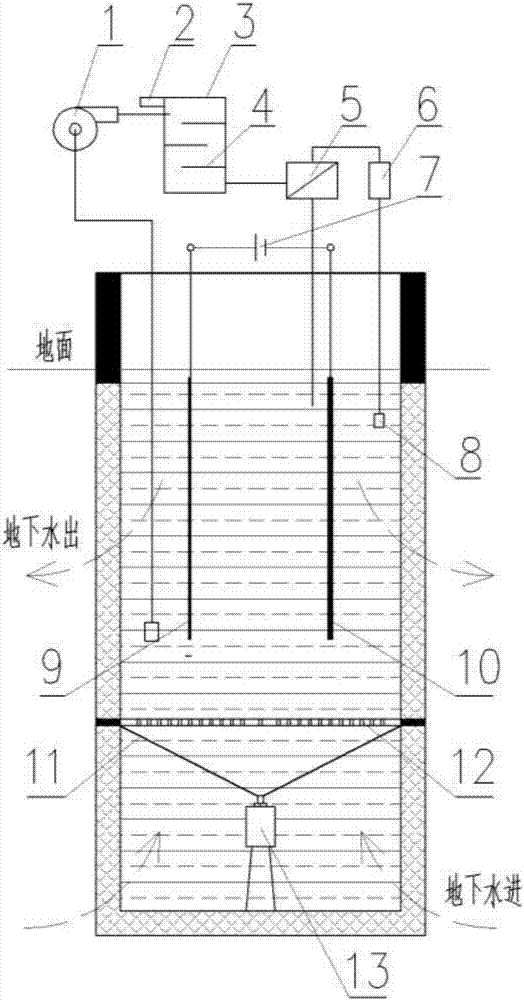

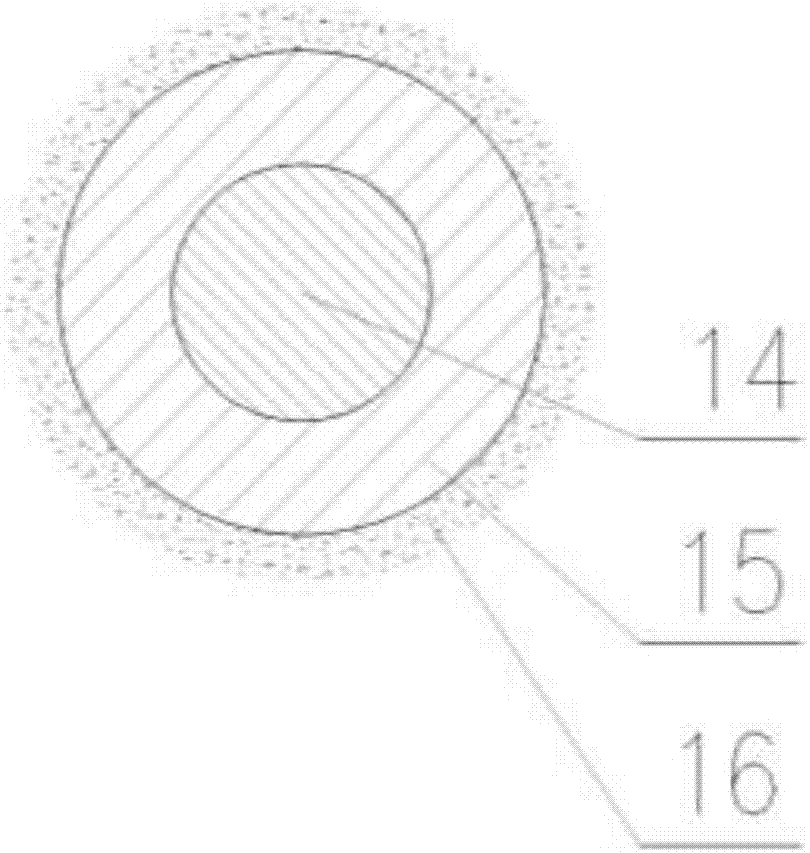

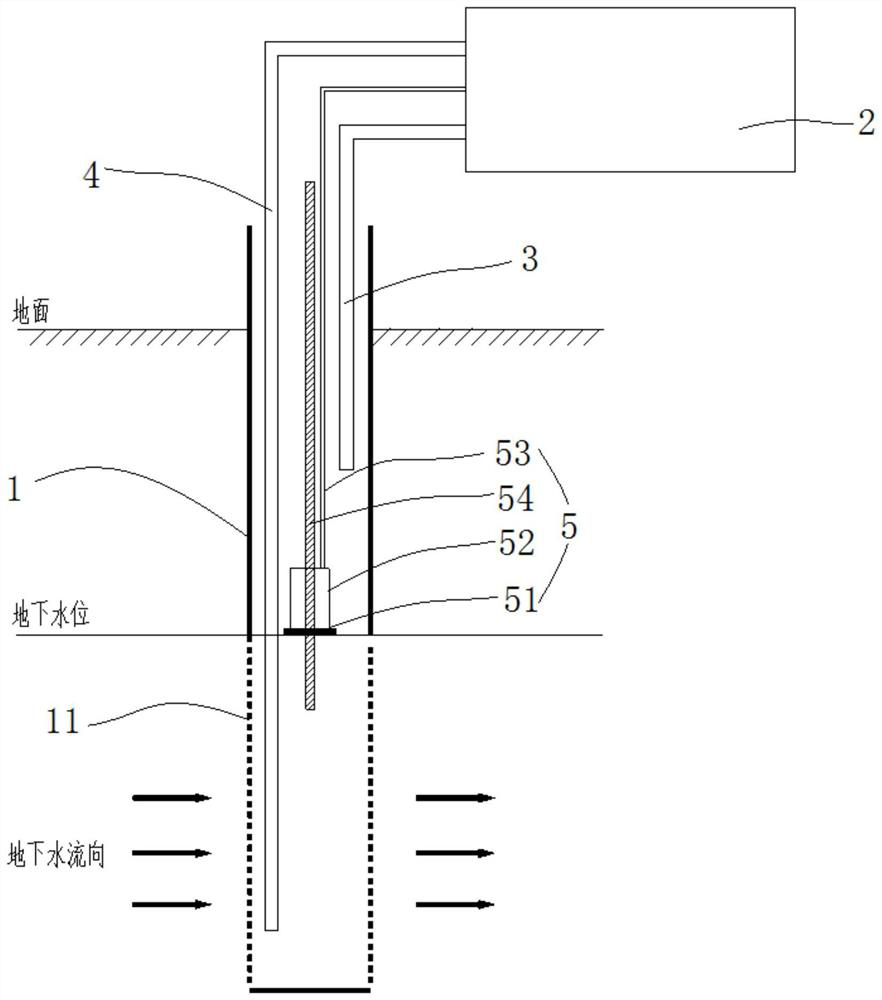

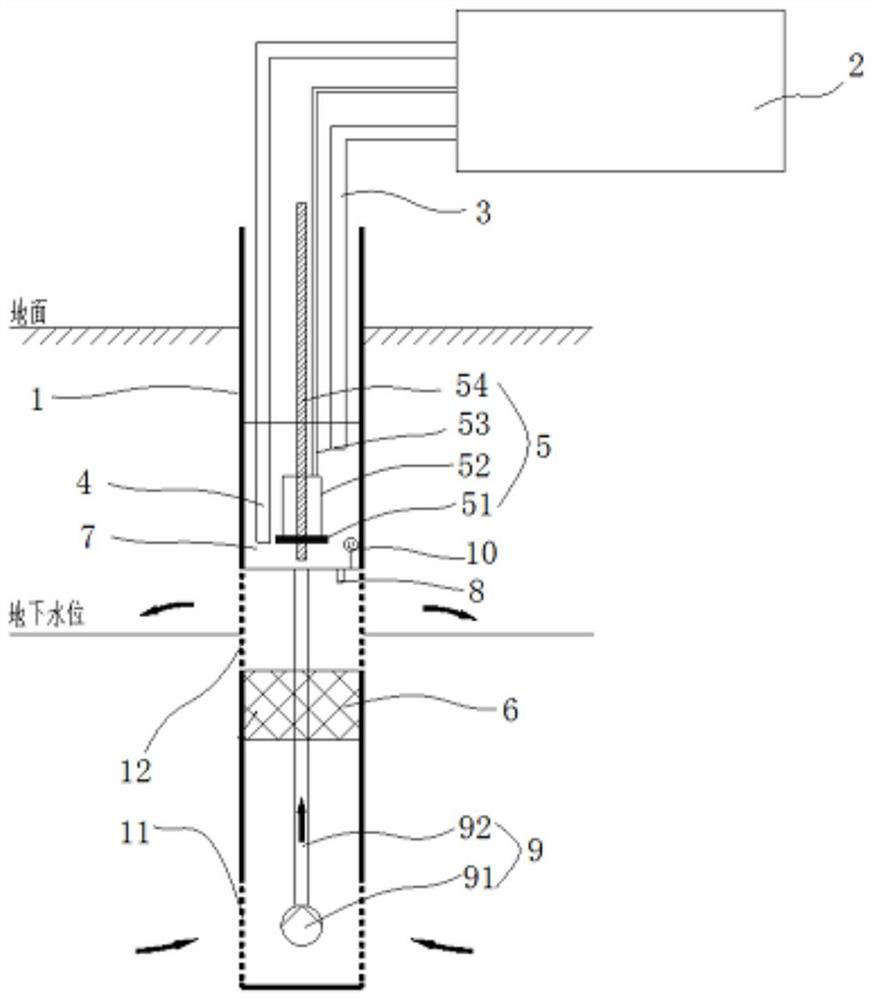

Method and equipment for near in-situ removal of heavy metal ions from groundwater

ActiveCN107352703AImprove stabilityHigh recycling valueWater contaminantsMultistage water/sewage treatmentEngineeringMetal electrodes

The invention relates to a process for removing heavy metal ions from groundwater. According to the process, a pumping well is arranged, the bottom portion of the pumping well is provided with a submersible pump, the pumping well is divided into an upper layer and a lower layer by a separation plate, the outlet of the submersible pump is arranged at the central outlet of the separation plate, groundwater directly enters from the bottom portion of the well or enters through the submersible pump, and in the pumping well, an iron plate is used as an anode, and a cathode is a composite electrode comprising a metal selected from iron, platinum and copper or carbon and Fe3O4; iron is used as an anode, a composite electrode prepared from a metal electrode or carbon and Fe3O4 is used as a cathode; a voltage is applied between the anode and the cathode prepared from the composite electrode, the groundwater directly enters from the bottom portion of the well or enters through the submersible pump, the anode iron is dissolved, and the iron ions enter the water; the Fe3O4 in the cathode can adsorb heavy metals in the water; the groundwater treated by the anode and the cathode flows upward and is mixed while the magnetic Fe3O4 particles returned from an aging device are added; and the water is sufficiently mixed and reacts in a ferrite precipitation reactor, and the heavy metal ions in the groundwater are removed under the actions of flocculation, net catching and adsorption.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

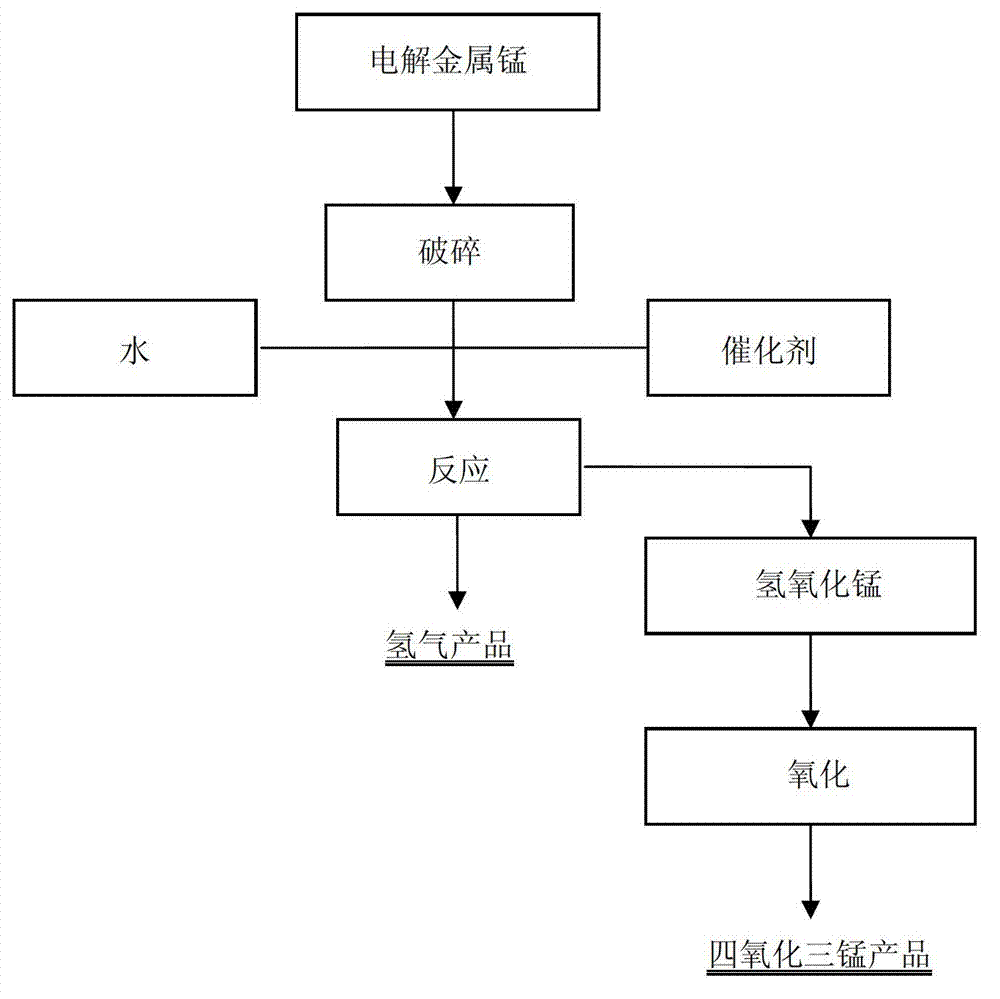

Method for preparing hydrogen in process of producing trimanganese tetroxide from electrolytic manganese metal

InactiveCN103241711ADoes not affect the production processSolve the safety hazards of flammable and explosiveHydrogen productionManganese oxides/hydroxidesElectrolysisReaction temperature

The invention relates to a method for preparing hydrogen in process of producing manganous-manganic oxide through electrolytic manganese metal and belongs to the field of chemical metallurgy. The preparation method comprises the following steps: crushing the electrolytic manganese metal in the process of producing the manganous-manganic oxide by taking the electrolytic manganese metal as a raw material, reacting the electrolytic manganese metal with water to generate manganese hydroxide under specific conditions under the catalytic action of a catalyst, and releasing the hydrogen, wherein the specific reaction conditions in the process of preparing the hydrogen are that the crushing particle size of the electrolytic manganese metal is less than 150 microns, the addition amount of the catalyst is 5-15g of catalyst added into each 1000g of electrolytic manganese metal, the reaction temperature is controlled to be 40-90 DEG C, and the PH value of the reaction process is controlled to be 6-12. The manganese hydroxide generated through the reaction is prepared into a manganous-manganic oxide product through other oxidation processes, and the hydrogen concentration of the hydrogen released from the reaction can reach 80-90 percent, and the hydrogen becomes a final gas product. The added catalysts are ammonium chloride, ammonium sulfate, hydrochloric acid, manganese chloride and oxalic acid and also comprise two or more catalysts.

Owner:湖南特种金属材料有限责任公司宁乡分公司

Resin glass fiber formula and resin glass fiber type tile prepared by same

The invention discloses a resin glass fiber formula and a resin glass fiber type tile prepared by same. The formula comprises the following components in part by weight: 50-70 parts of resin glass fiber powder, 10-30 parts of PP semi-cured sheet leftover material and 10-30 parts of epoxy resin, wherein the particle size of the resin glass fiber powder is 60-100 meshes, the copper content of the resin glass fiber powder is less than 3 % and the water content of the resin glass fiber powder is less than 15 %. The resin glass fiber type tile is prepared by using the following components in parts by weight: 50-70 parts of resin glass fiber powder, 10-30 parts of PP semi-cured sheet leftover material and 10-30 parts of epoxy resin, wherein the particle size of the resin glass fiber powder is 60-100 meshes, the copper content of the resin glass fiber powder is less than 3 % and the water content of the resin glass fiber powder is less than 15 %.

Owner:清远市宏保环保科技有限公司

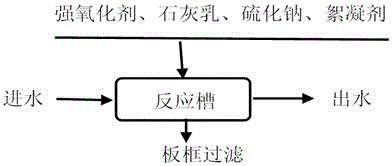

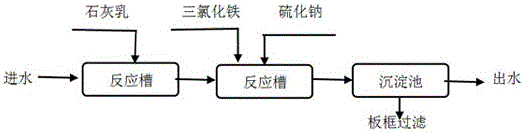

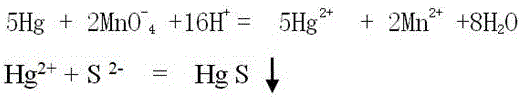

Technology for removing mercury in contaminated acid wastewater

InactiveCN105948314AReliable operationHigh removal rateWater contaminantsTreatment involving filtrationField testsEnvironmental chemistry

The invention discloses a technology for removing mercury in contaminated acid wastewater. The method specifically comprises the following steps of pumping contaminated acid wastewater produced in a sulfuric acid dynamic wave scrubbing process into a reaction tank, adding a strong oxidant KMnO4, then adding lime milk for reaction, and then adding sodium sulphide for reaction; adding a flocculating agent, namely polyacrylamide into ore pulp after mercury removal, pumping the liquid into a plate and frame filter after the reaction to obtain filter liquor and filter residues, wherein the content of Hg in the obtained filter liquor is detected to be less than 0.03mg / L, and the content of the mercury in the filter residues is 0.264 to 20.33 percent, and collecting the filter residues. By adopting the technology provided by the invention to treat contaminated acid produced in the sulfuric acid dynamic wave scrubbing process of the lead and zinc smelting industry to remove the Hg, the wastewater discharging reaches the standard, the operation is simple and reliable, and a production field test result shows that the novel technology is feasible technically. By using the technology in production practice for two years, the problem that the Hg in the contaminated acid produced by lead and zinc smelting does not reach the standard is thoroughly solved. By adopting the technology provided by the invention to remove the mercury, the fact that the Hg of discharge water is less than or equal to 0.03mg / L is guaranteed, and a method through which the discharge reaches the standard is realized.

Owner:BAIYIN NONFERROUS GROUP

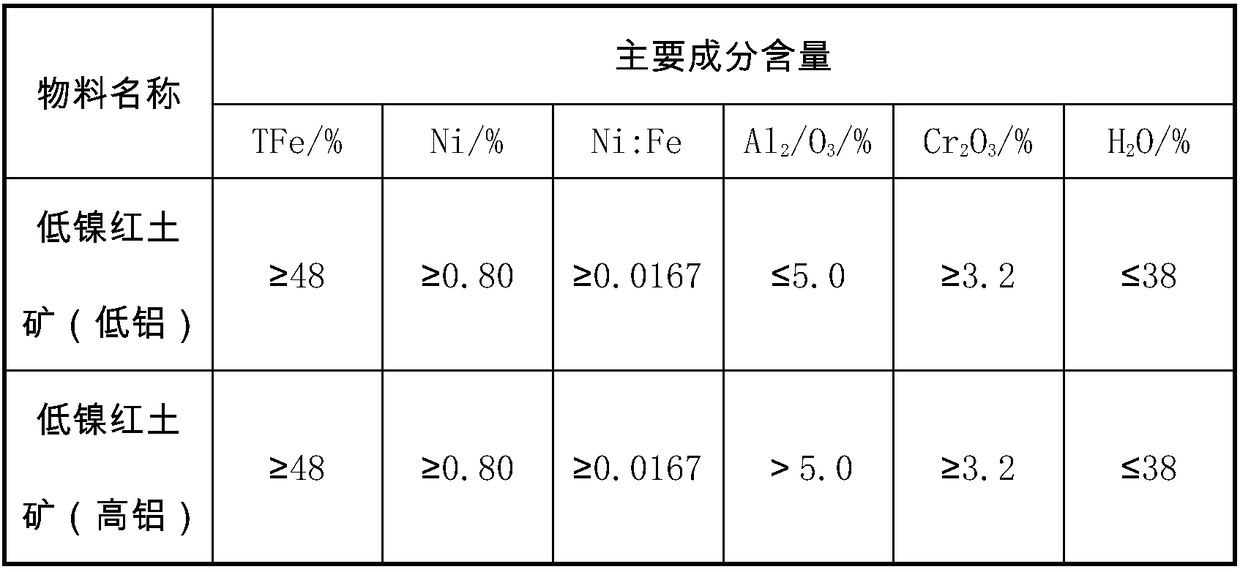

Method for smelting chromium-containing ferronickel through laterite nickel ore

The invention discloses a method for smelting chromium-containing ferronickel through laterite nickel ore. Nickel sulphide ore, a chromium-containing material and stainless steel smelting waste slag with a certain proportion are added into the laterite nickel ore, a rotary kiln pre-reduction-electric furnace process is adopted for smelting, a chromium-containing ferronickel product is used for producing 300-series austenitic stainless steel, the nickel sulphide ore and the chromium-containing material can serve as a part of a nickel source and a chromium source to improve the nickel and chromium grade in an alloy smelting product, other components in the nickel sulphide ore and the chromium-containing material are matched with multiple components in other stainless steel smelting waste slag to serve as a slag forming constituent to adjust the furnace slag smelting property, the reduction condition of chromium oxides can be improved, and separation of metal and slag can be reinforced. The method can improve the chromium grade and the chromium recycling rate in the ferronickel product, the smelting energy consumption can be greatly reduced, multiple metallurgical waste slag in the stainless steel production process can be sufficiently used, secondary resource recycling can be achieved, enterprise production cost is reduced, and the environment pollution brought by the metallurgical waste slag can be removed.

Owner:CENT SOUTH UNIV

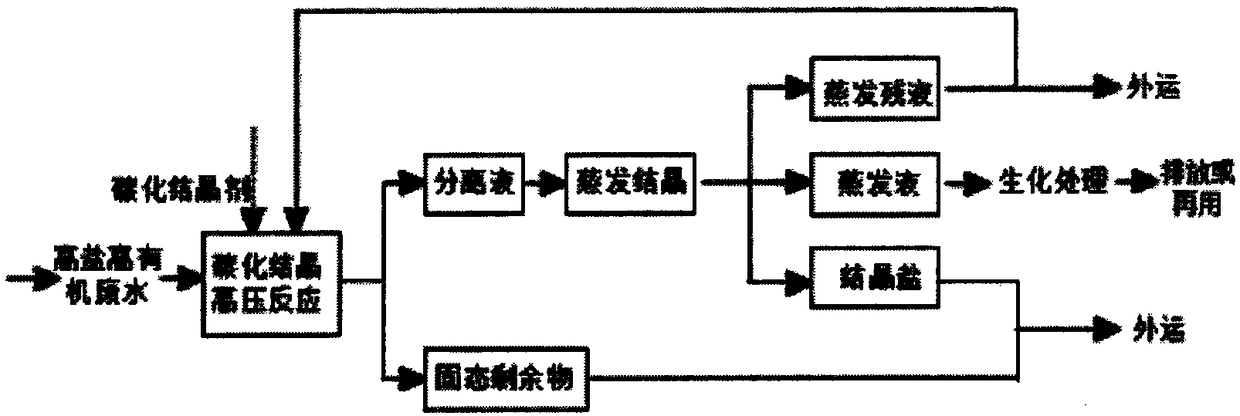

Carbonization and crystallization method for treating high-salt high-organic waste water

ActiveCN108558102AMild reaction conditionsShorten the timeWater treatment compoundsWater contaminantsHigh concentrationOrganic acid

The invention discloses a carbonization and crystallization method for treating high-salt high-organic waste water. The method is characterized in that a metal salt carbonization and crystallization agent containing organic acid and inorganic acid is prepared; the high-salt high-organic waste water is added into a reaction still, the metal carbonization and crystallization agent is added into thereaction still, the liquid is stirred and mixed, and after the liquid is uniformly mixed, the reaction still is closed; the reaction still is heated to a predetermined temperature, the constant temperature carbonation reaction is conducted, the liquid is stirred constantly, after the reaction is finished, the reaction still is cooled to the indoor temperature, and the mixture in the reaction stillis subjected to solid-liquid separation to obtain separating liquid; the separating liquid is subjected to evaporative crystallization treatment to obtain evaporated liquid, salt and high-concentration evaporated residual liquid. The method utilizes the hydrothermal carbonization technology with mild reaction conditions, short reaction time, strong adaptability and lower energy consumption to pretreat the waste water, organic concentration is reduced, therefore the evaporative crystallization effect of the high-salt high-organic waste water is improved, and subsequent biotreatment loading anddifficulty degree of up-to-standard discharge or cyclic utilization of condensed fluid are reduced.

Owner:DONGHUA UNIV

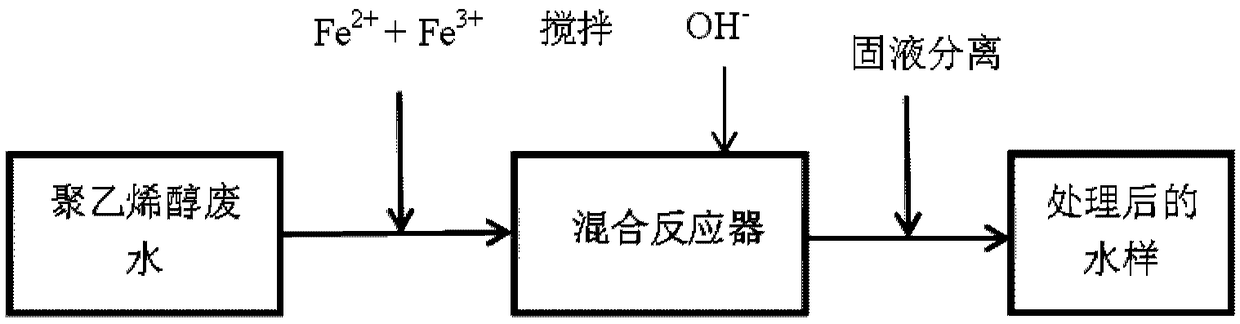

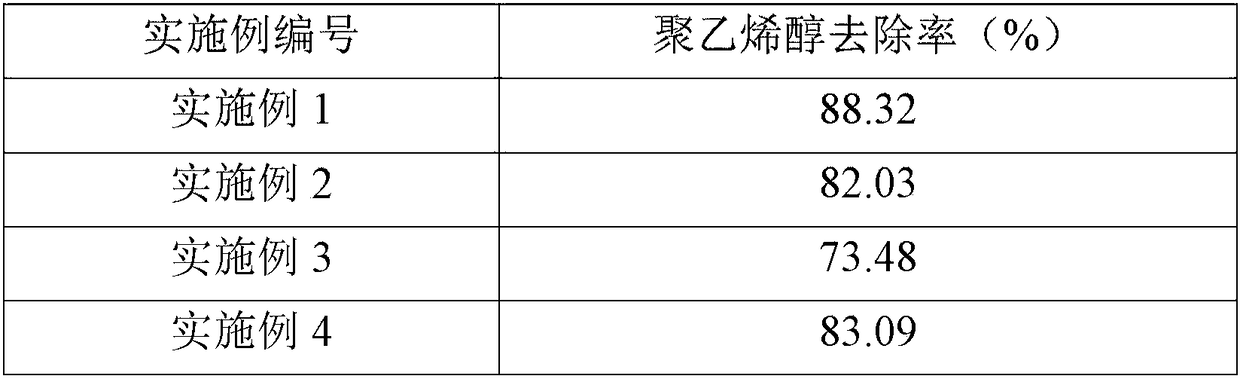

Method for treating wastewater containing polyvinyl alcohol

ActiveCN108503010ATo achieve the purpose of removing polyvinyl alcoholHas recycling valueWater contaminantsWater/sewage treatment by reductionChemistryPVA - Polyvinyl alcohol

The invention relates to a method for treating wastewater containing polyvinyl alcohol. The method comprises the following steps: adding Fe<2+> and Fe <3+> into the wastewater containing the polyvinylalcohol, and evenly stirring, wherein the molar ratio of the Fe<2+> to the Fe <3+> is 1 to 2; then, adjusting the pH value of mixed liquid, and carrying out solid-liquid separation after a reaction is finished. Compared with the traditional polyvinyl alcohol wastewater treatment method, the method, provided by the invention, for treating the wastewater containing the polyvinyl alcohol has the advantages of high removal efficiency, short needed time and simpleness in operation, and enables final precipitate to be easily recycled.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

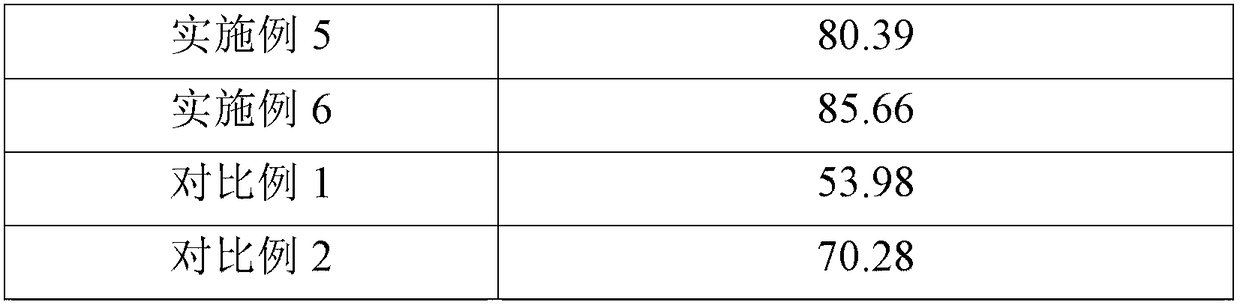

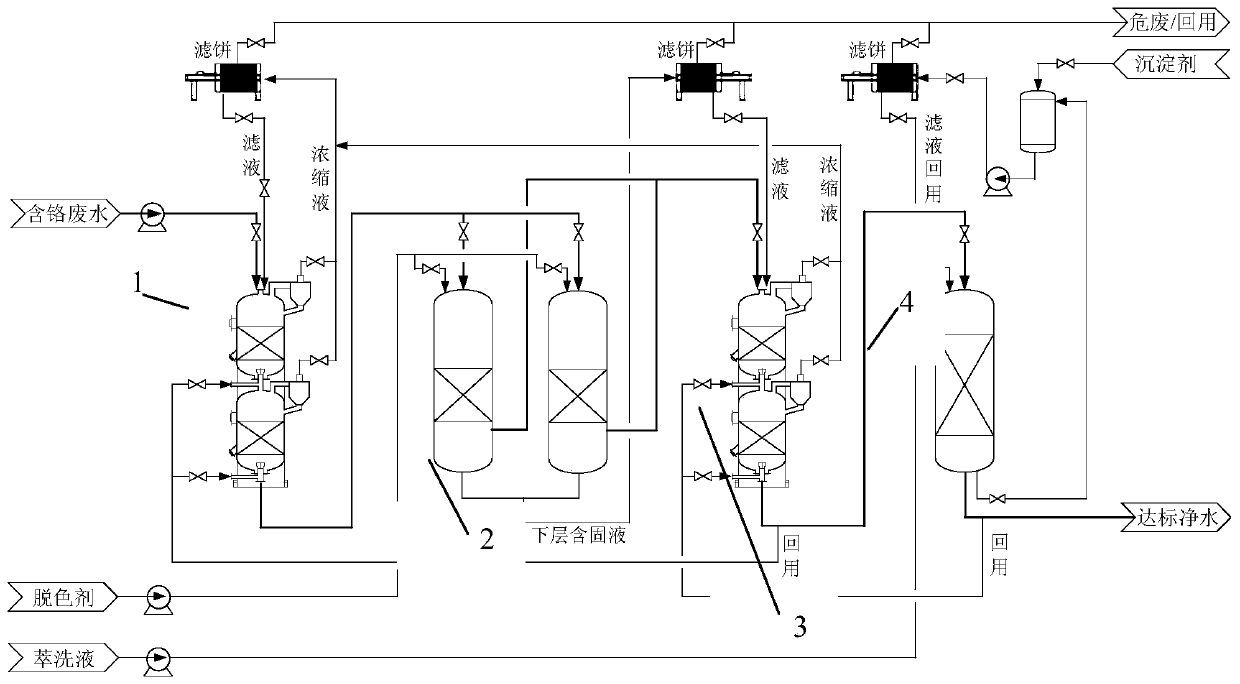

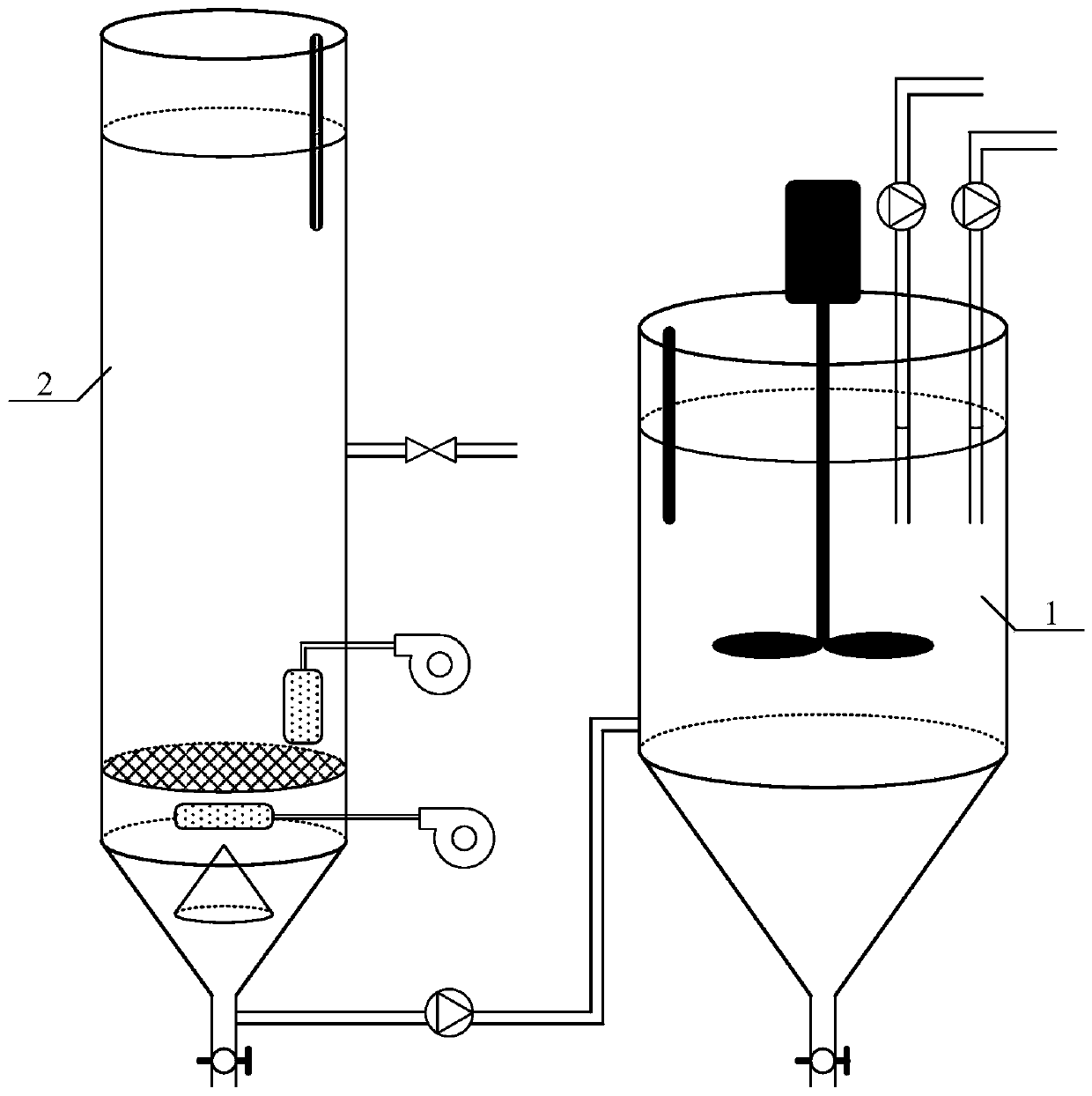

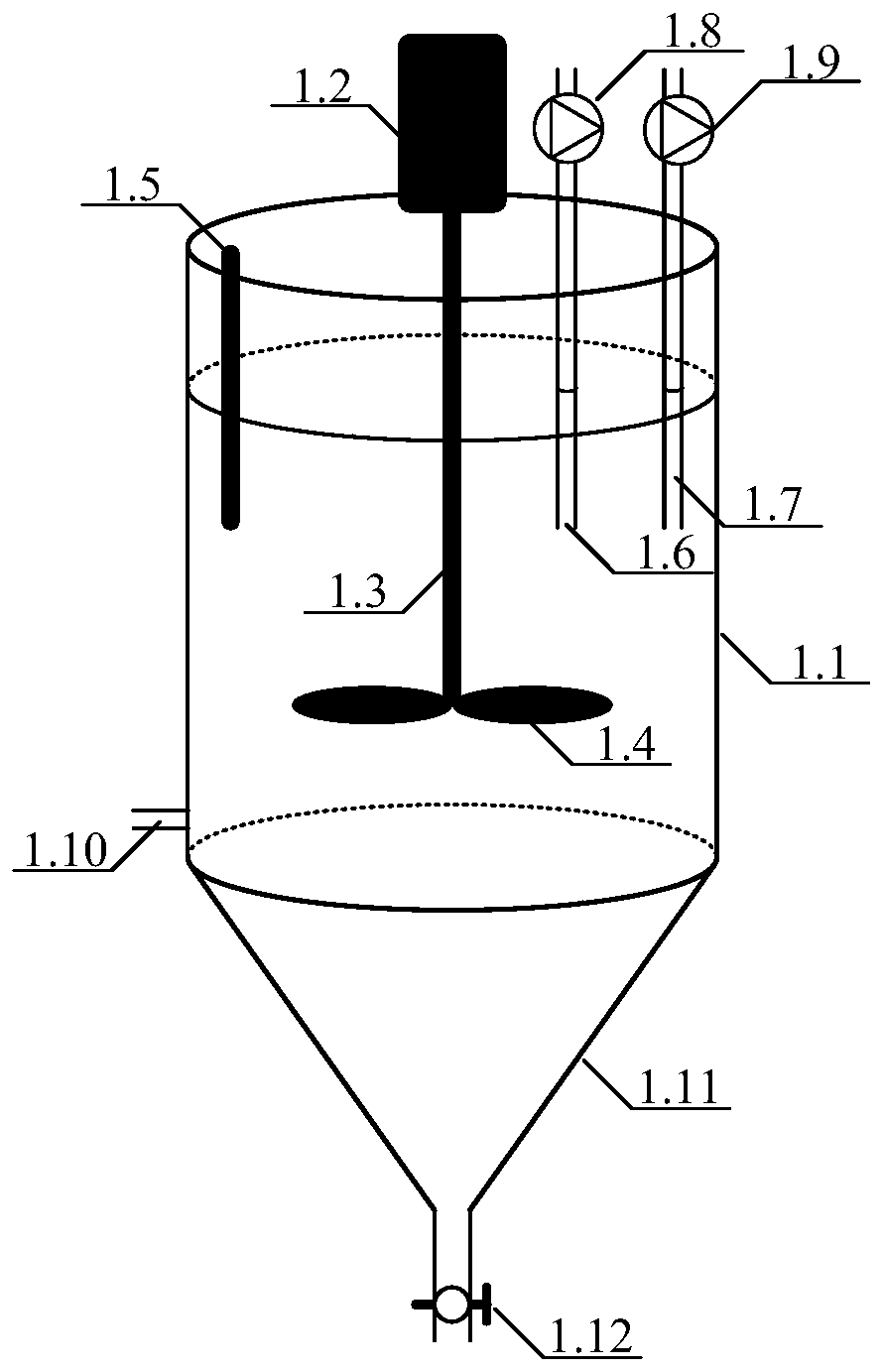

System and method for removing heavy metal chromium, dyes and short wool fibers in leather wastewater

ActiveCN111423013ASolve the problem of purificationEmission reductionSludge treatmentWater treatment compoundsPapermakingWastewater

The invention relates to an advanced treatment system and method for leather wastewater containing heavy metals, dyes and short wool fibers. The method comprises the following steps: firstly, deeply removing the short wool fibers and other impurity solid particles in the leather wastewater by using a particle bed separator; then adding a decolorizing agent to decompose dye molecules in the wastewater; then, removing solid particles generated by a decoloration reaction by using a deep interception filtering tower; and finally, carrying out in-depth removal of heavy metal chromium ions, dye molecules and fragments thereof in the wastewater by using a dual-functional adsorption tower so as to allow effluent to meet reuse requirements or related discharge standards and greatly reduce the discharge amount of chromium-containing hazardous wastes. The treatment method and system can realize synchronous deep removal of heavy metals, dyes and fibers in wastewater produced in the industries of leather, textile, printing and dyeing, papermaking and the like, effluent quality meets reuse requirements, and the effluent reaches relevant national and local discharge standards in China.

Owner:EAST CHINA UNIV OF SCI & TECH

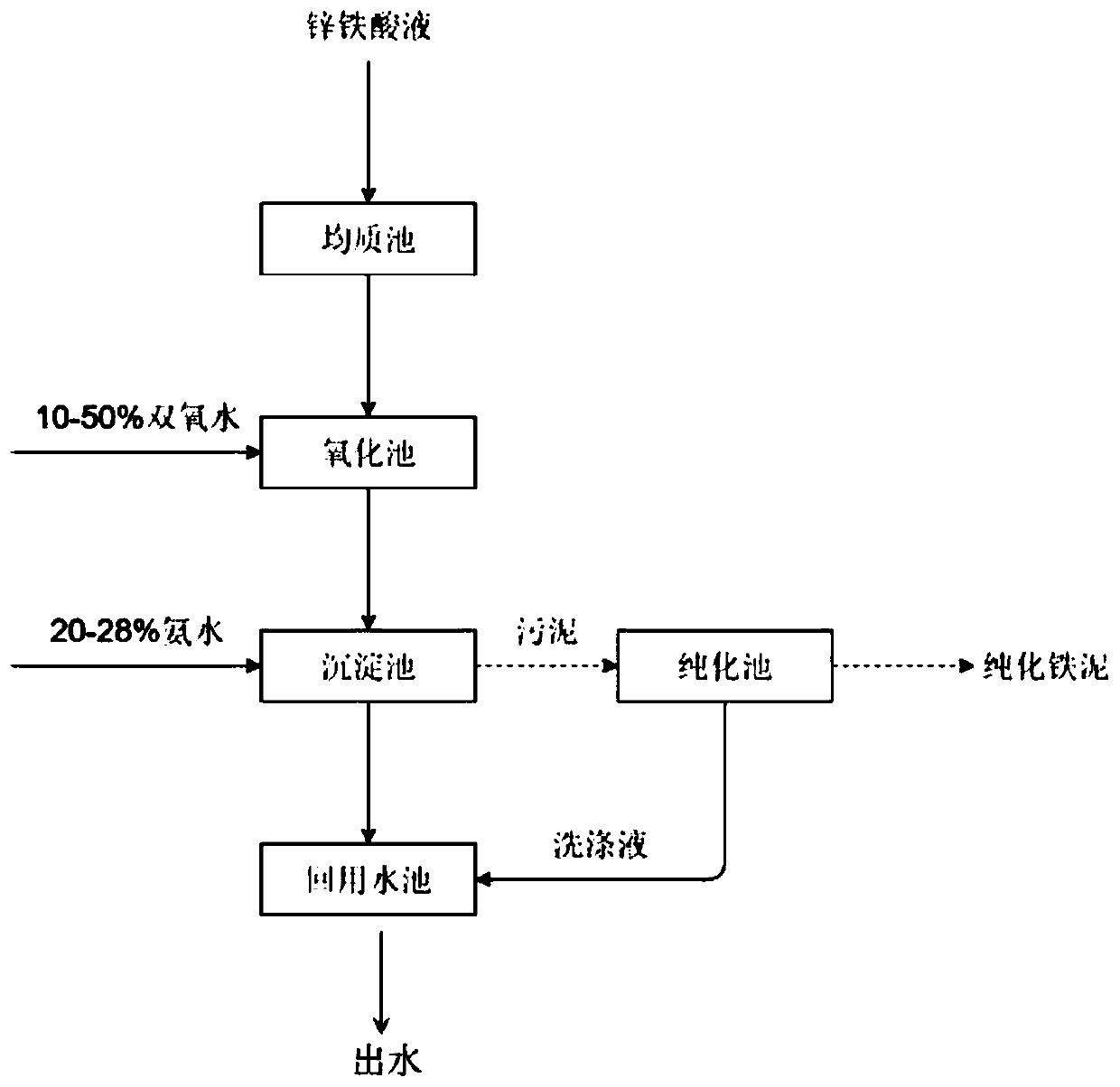

Method for recycling zinc ferrite solution

PendingCN111320300AReduce lossesHas recycling valueWater contaminantsMultistage water/sewage treatmentZinc ferriteHydrogen peroxide

The invention belongs to the field of waste liquid recycling, and provides a method for recycling a zinc ferrite solution. According to the method, hydrogen peroxide or ozone is added into the zinc ferrite solution, so that the hydrogen peroxide or ozone and metal in the zinc ferrite liquid form Fenton and a Fenton-like reaction to generate OH., and low-valent iron ions in the zinc ferrite solution are oxidized into ferric ions while various organic matters in the zinc ferrite liquid are oxidized. The ammonia water is added to adjust the pH value, ferric ions are made to generate ferric hydroxide, and finally iron mud is obtained through precipitation. The steps of stirring and washing are carried out on the iron mud by adopting a hydrochloric acid solution, zinc ions are washed, and the iron mud is purified, so that the iron mud has a certain recovery value, and meanwhile, zinc lost due to mud-water separation is reduced. The recycled water composed of a supernatant and the washing liquid meets the requirement for matching and recycling of the plating assistant agent, and discharging is not needed. Therefore, according to the method for recycling the zinc ferrite solution, zinc recycling is achieved, iron mud is recycled, and two purposes are achieved at a time.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

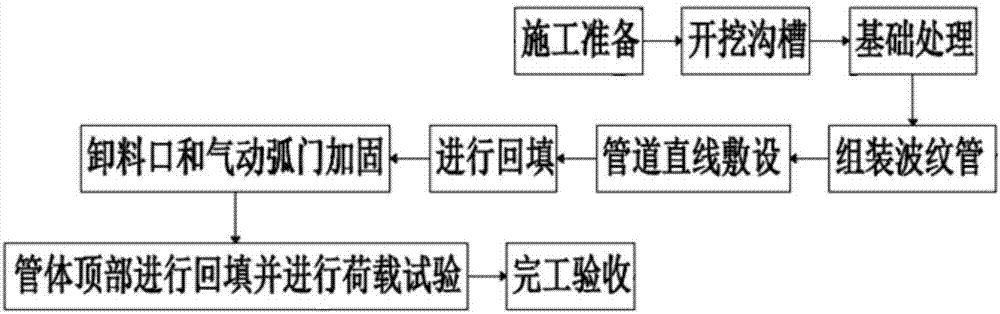

Construction method of replacing sealing-tape machine concrete gallery in gravel system with corrugated pipe

ActiveCN107269930AShort installation periodOccupies a small construction sitePipe laying and repairEngineeringWork in process

The invention provides a construction method of replacing a sealing-tape machine concrete gallery in a gravel system with a corrugated pipe. The construction method comprises the following steps of construction preparation, ditch excavation, foundation treatment, corrugated pipe assembly, pipeline linear laying, backfill, reinforcement of a discharging opening and a pneumatic segment gate, backfill of pipe body top and load test and completion test. The construction method has enough strength and tenacity, so that certain material accumulation load and foundation settlement deformation can be borne; the assembly construction period is short; the construction method is not limited by climate conditions; prefabricated semi-products produced by factories are assembled on site, so that construction site occupation is small; backfill can be rapidly performed after assembly to form a material bin platform; the construction method is not limited by the coagulation period of concrete; a site can be provided for other operation in advance; operation personnel are fewer; used transfer materials are fewer; construction cost is low; and after construction is finished, the metal corrugated pipe can be recycled for repeated utilization, so that a certain recycle value is provided.

Owner:SINOHYDRO BUREAU 9

Resin glass fiber formulation and flowerpot made thereby

The invention discloses a resin glass fiber formulation and a flowerpot made thereby. The resin glass fiber formulation comprises the following components in part by weight: 80-95 parts of resin glass fiber powder and 5-20 parts of epoxide resin, wherein the resin glass fiber powder has the copper content of smaller than 5%. The resin glass fiber flowerpot is made from the following components in part by weight: 80-95 parts of resin glass fiber powder and 5-20 parts of epoxide resin, wherein the resin glass fiber powder has the copper content of smaller than 5%. Due to characteristics of the resin glass fiber powder, the flowerpot made from the resin glass fiber powder as a raw material has the characteristics of water resistance, corrosion resistance, moth resistance, acid and alkali resistance, aging resistance, light weight (compared with a clay flowerpot), low probability of breakage and the like; and a small amount of heavy metal exists in the resin glass fiber powder, so that during slow release of the heavy metal, the color and luster of a flower can be more bright and beautiful and the flowering phase can be prolonged.

Owner:清远市宏保环保科技有限公司

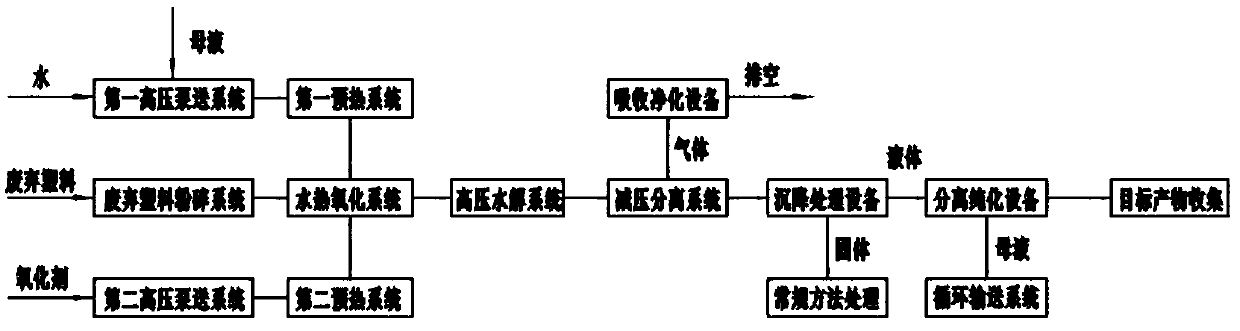

Hydrothermal treatment device and method for waste plastics

The invention discloses a hydrothermal treatment device and method for waste plastics. The hydrothermal treatment device comprises a hydrothermal oxidation system, a high-pressure hydrolysis system, awaste plastic smashing system, a mixture pumping system and an oxidizing agent pumping system, wherein the hydrothermal oxidation system is used for performing partial oxidation reaction on the wasteplastics; the high-pressure hydrolysis system is used for further hydrolyzing a product obtained after the oxidation reaction performed by the hydrothermal oxidation system; the waste plastic smashing system is used for smashing the waste plastics and conveying the smashed waste plastics to the hydrothermal oxidation system; the mixture pumping system is used for pumping a water and mother liquormixture to a first preheating system from a first high-pressure pumping system and conveying the preheated mixture to the hydrothermal oxidation system; the oxidizing agent pumping system is used forpumping an oxidizing agent to a second preheating system from a second high-pressure pumping system and conveying the preheated oxidizing agent to the hydrothermal oxidation system. According to thedevice and the method for adopting water as a degradation agent to perform partial oxidation and hydrolysis treatment sequentially under high temperature and high pressure conditions, the waste plastics can be degraded in the relatively simple hydrothermal system.

Owner:ZUNYI NORMAL COLLEGE

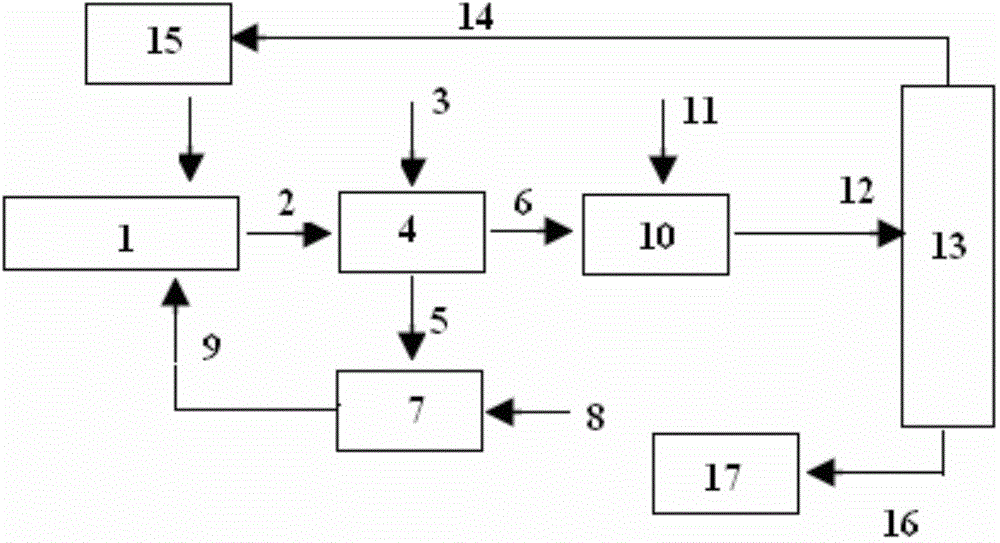

Method and device for recovering ammonia nitrogen from oxidative dehydration catalyst preparation wastewater

InactiveCN105731702AHas recycling valueReduce manufacturing costMultistage water/sewage treatmentChemical recyclingHigh concentrationDistillation

The invention relates to a method and a device for recovering ammonia nitrogen from oxidative dehydration catalyst preparation wastewater. The method comprises the following steps: high-concentration wastewater produced in oxidative dehydration catalyst preparation is treated with gaseous carbon dioxide, such that zinc ions form a precipitate, zinc ammonia complex ion-form ammonia nitrogen is converted into ammonium ion ammonia nitrogen, and metal ion impurities are removed; the precipitate is dissolved with nitric acid, and the solution is used as a catalyst preparation raw material; when the weight concentration of the original ammonium nitrate ammonia nitrogen of the high-concentration wastewater and the newly formed ammonium ion ammonia nitrogen reaches 2-6%, alkali is added, such that ammonium salt is converted into ammonia water; with a distillation method, ammonia water is recovered from the top of a distillation tower; the ammonia water with mass concentration higher than 10% is recycled in the catalyst preparation process; in the wastewater obtained at the bottom of the distillation tower, the ammonia nitrogen content is no higher than 50mg / L, and the mass concentration of sodium nitrate is higher than 5%, such that recycling is convenient. With the method provided by the invention, zinc ions can be precipitated, and ammonia nitrogen existing in a form of zinc ammonia complex ion can be converted into ammonium ion ammonia nitrogen. Therefore, a problem of incomplete precipitation caused by that zinc ion precipitation is influenced by zinc ammonia complex ion balance when sodium carbonate is adopted as a precipitation agent is solved.

Owner:PETROCHINA CO LTD

Treatment method of dyestuff wastewater containing heavy metals

InactiveCN107352676AShorten the timeQuickly achieve the purpose of removalWater contaminantsTreatment involving filtrationFerrous saltsResource recovery

The invention discloses a treatment method of dyestuff wastewater containing heavy metals. The method comprises under a stirring condition, adding Fe<2+> into to-be-processed dyestuff wastewater which contains heavy metals and adjusting the pH value to a range of 4-10, performing a reaction for 1-15 min, and performing solid-liquid separation. The method provided by the invention requires an extremely short time for treating the dyestuff wastewater, and can rapidly reach a goal of removal. The method uses a ferrite method for metallic oxide generation, and can effectively remove dyestuffs and the heavy metals in the wastewater at the same time. The generated metallic oxides have a certain recovery value, so that costs can be recovered and resource recovery and reuse can be realized. The purity requirement of Fe<2+> used by the method is not high, and heavy metal wastewater which is rich in Fe<2+> can be used to replace added ferrous salts to realize using waste to treat waste, so that treatment cost is reduced greatly. The method has a very simple reaction condition, can be performed at normal temperature under a common pressure, and has a simple and convenient operation.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Simple, convenient and efficient boron oxide coated high-nickel ternary positive electrode material and preparation method thereof

InactiveCN110729466AHas recycling valueEasy to separate and recycleCell electrodesPhysical chemistryBoron oxide

The invention belongs to the technical field of lithium batteries and provides a simple, convenient and efficient boron oxide coated high-nickel ternary positive electrode material and a preparation method thereof. In a preparation process, liquid pentaborane is added; and the liquid pentaborane is easy to directly and fully mix with a material, the problem that a solvent needs to be treated in wet coating is not required to be considered; the pentaborane can be quickly hydrolyzed to release heat when meeting water on the surface of the material, so that an oxide coating layer can be formed inan extremely short time; long-term sintering is not needed, and therefore, production efficiency is improved; the surface temperature of the material can be increased to meet a coating requirement when the boron oxide coating layer is formed, and therefore, a user does not to worry about insecure coating caused by insufficient temperature; and in addition, the boiling point of the pentaborane isonly 60 DEG C, the pentaborane which does not participate in a reaction is in a gaseous state when the reaction is finished, and therefore, the pentaborane is very easy to separate and recover from the material, and reaction byproduct hydrogen also has a recovery value.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Ultraviolet-resistance Song brocade fabric and preparation process thereof

PendingCN108691059AHas recycling valueImprove functionalityProtective fabricsMulti-ply fabricsFiberPolyester

The invention discloses an ultraviolet-resistance Song brocade fabric and a preparation process thereof. The fabric comprises a surface layer and an inner layer, the surface layer is formed by the weft-and-warp interweaving of natural mulberry silk yarns, the inner layer is formed by the weft-and-warp interweaving of ultraviolet-resistance polyester staple fiber yarns, and the ultraviolet-resistance polyester staple fiber yarns are formed by the spinning of ceramic fine powder doping with polyester polymer, wherein the surface layer and the inner layer are connected by connecting weft yarns through uniformly arranged interweaving points. The ultraviolet-resistance Song brocade fabric has higher ultraviolet shielding rate.

Owner:DING SHENG SILK

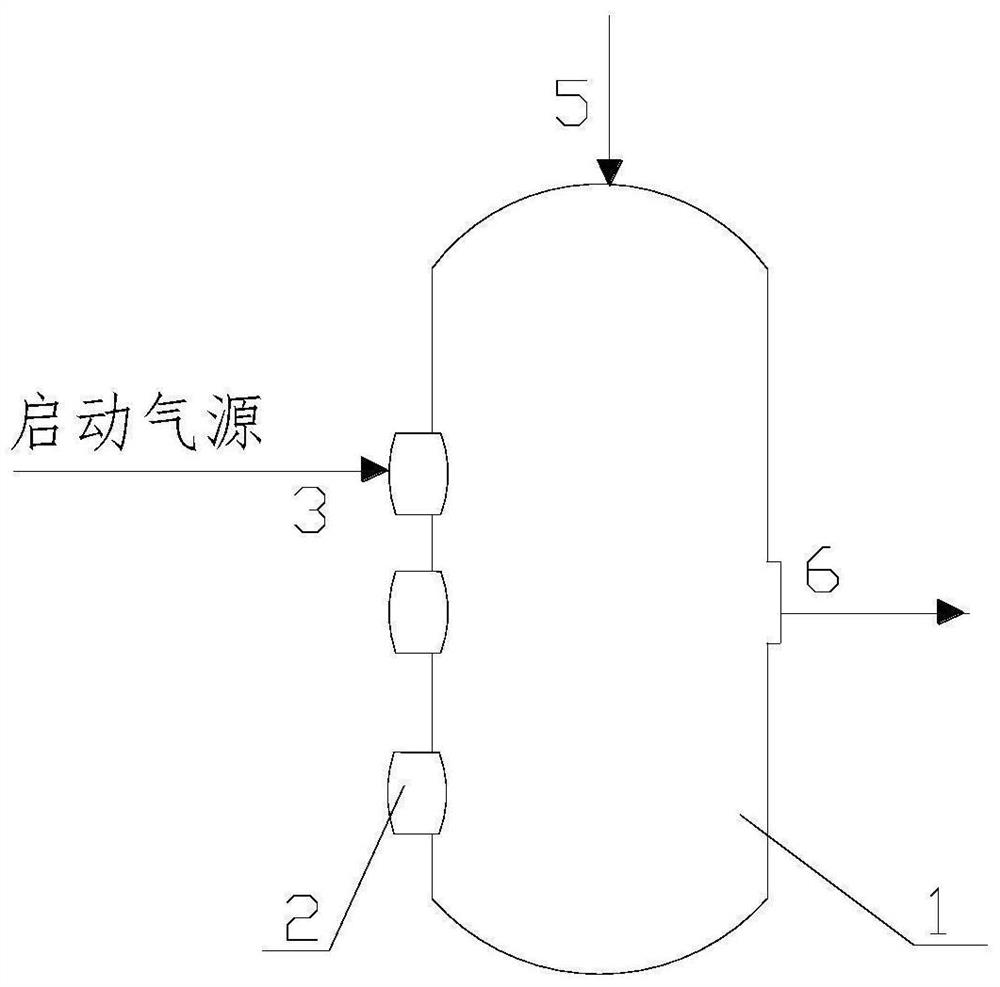

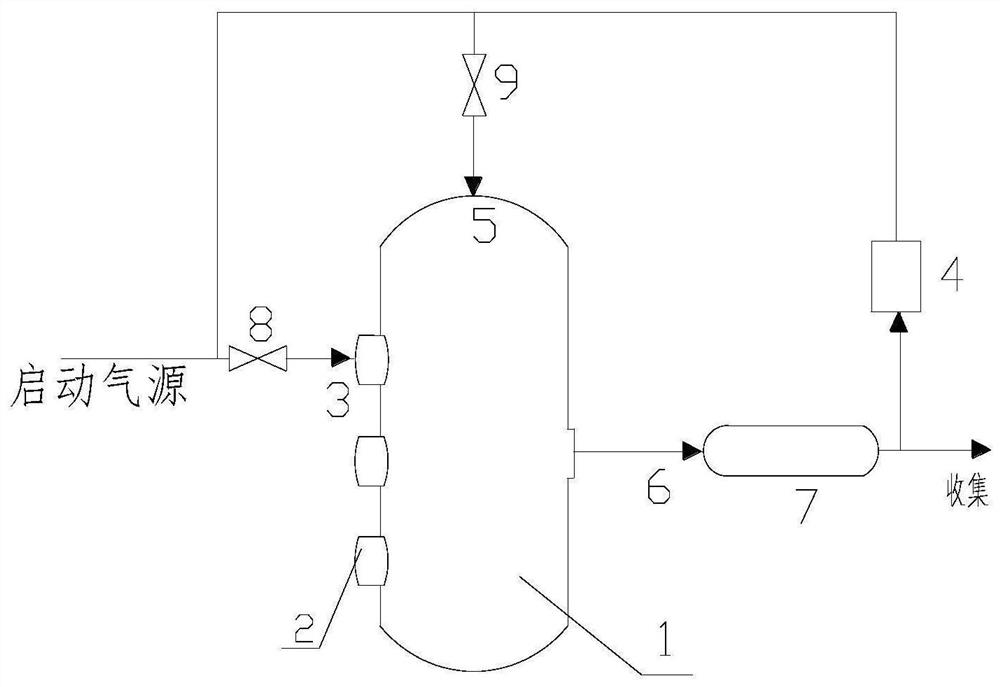

Plasma hot-blast stove and gas recycling device based on plasma hot-blast stove

PendingCN112629015AMeet high temperature requirementsMany choicesAir heatersThermodynamicsHot air oven

The invention belongs to the technical field of heating equipment, and relates to a plasma hot-blast stove and a gas recycling device based on the plasma hot-blast stove. The plasma hot-blast stove comprises a stove body and plasma generators arranged on a stove body shell; the plasma generators communicate with an inner cavity of the stove body, and a temperature-adjusting gas source inlet and a hot air outlet are formed in the stove body; starting gas source inlets communicating with the inner cavity of the stove body are formed in the plasma generators; and the starting gas source inlets communicate with a starting gas source pipeline. The gas recycling device based on the plasma hot-blast stove comprises the plasma hot-blast stove and an industrial kiln. The industrial kiln is connected with the hot air outlet and is connected with the temperature-adjusting gas source inlet and the starting gas source inlets through a cooling and purifying device. The equipment is high in thermal power, high in output temperature and wide in gas source selection range, and the production cost is reduced; a production system is high in gas content and has recovery value; and the heat source temperature is controllable, gas is recycled, and resources are saved.

Owner:陕西翼飞航智能科技有限公司

Heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash

InactiveCN102206757BWith resource recyclingAchieving harmlessnessOther chemical processesSolid waste disposalSorbentWater soluble

Owner:SHANGHAI JIAOTONG UNIV

Resin glass fiber formula, and resin glass fiber tile produced therethrough

The invention discloses a resin glass fiber formula, and a resin glass fiber tile therethrough. The formula includes, by weight, 50-70 parts of resin glass fiber powder, 10-30 parts of PP prepreg scrap and 10-30 parts of epoxy resin; and the particle size of the resin glass fiber powder is 60-100 meshes, the copper content of the resin glass fiber powder is less than 3%, and the water content of the resin glass fiber powder is less than 15%. The resin glass fiber tile is produced from, by weight, 50-70 parts of the resin glass fiber powder, 10-30 parts of the PP prepreg scrap and 10-30 parts of the epoxy resin; and the particle size of the resin glass fiber powder is 60-100 meshes, the copper content of the resin glass fiber powder is less than 3%, and the water content of the resin glassfiber powder is less than 15%.

Owner:YANCHENG TIANSHUN MACHINERY TECH CO LTD

Fully-automatic and continuous chemical nickel liquid waste treatment system

ActiveCN105712558ARealize processingSolve processing problemsWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteCooling tower

The invention provides a fully-automatic and continuous chemical nickel liquid waste treatment system. The fully-automatic and continuous chemical nickel liquid waste treatment system is characterized in that the chemical nickel liquid waste treatment system can conduct solid-liquid separation on chemical nickel liquid waste and comprises evaporation equipment, a cooling tower, heat conduction oil circulation equipment and an automated control unit; the evaporation equipment comprises a vapor-liquid separator, a feeding electric valve, an emptying valve, a first heating chamber, a second heating chamber, concentrated liquid discharge valves, a condenser, a water storage tank and a vacuum pump; in the work state, the first heating chamber and the second heating chamber work by turns and do not work simultaneously; the water storage tank is composed of a first tank body and a second tank body; the heat conduction oil circulation equipment comprises a heating groove and a heat conduction oil circulation pump; the automated control unit comprises a heat conduction oil heating control module, a temperature sensor, a feeding control module, a first sensor, a condensate water discharging control module and a second sensor. By means of the chemical nickel liquid waste treatment system, phosphorus, nickel and COD in chemical nickel liquid waste can be effectively removed.

Owner:苏州市东方环境工程有限公司

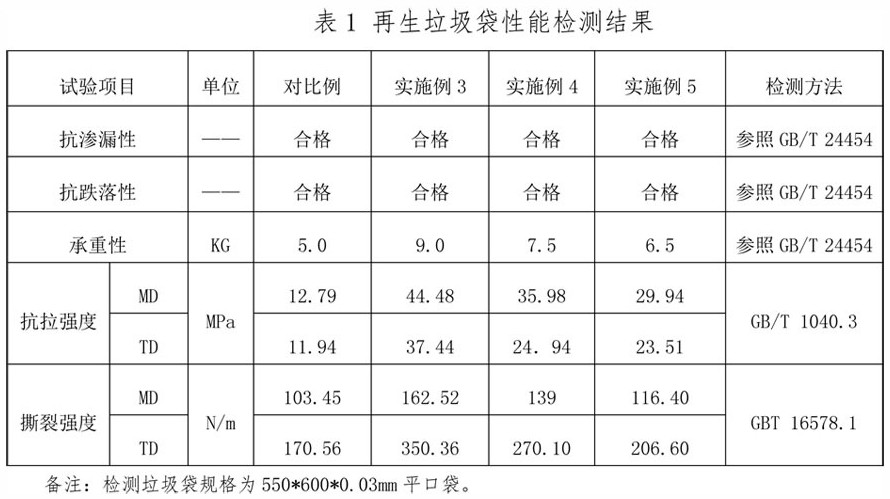

Regenerated garbage bag prepared from waste plastics and preparation method thereof

PendingCN113265096ASolve pollutionAchieve recyclingLinear low-density polyethyleneLow-density polyethylene

The invention discloses a regenerated garbage bag prepared from waste plastics and a preparation method thereof. The garbage bag is prepared from the following materials in parts by mass: 30-70 parts of regenerated high-density polyethylene; 0-40 parts of high density polyethylene; 0-20 parts of regenerated low density polyethylene; 0-20 parts of low density polyethylene; 10 -30 parts of linear low density polyethylene; 0-8 parts of color master batch; and 1-5 parts of an opening master batch. The regenerated garbage bag is prepared from the waste plastics in the household garbage, so that the recycling of waste plastic resources is realized, the problems of plastic pollution and plastic resource consumption can be solved to a certain extent, and certain environmental friendliness is realized; and meanwhile, the waste plastic raw materials are wide in source and low in price, so that the cost is low and the waste plastic raw materials are easily accepted by the market when used for preparing regenerated garbage bags.

Owner:CHINA TIANYING +1

In-situ remediation system and method for perfluorinated compound polluted underground water

ActiveCN114380380AReduce disturbanceReduce energy consumptionWater contaminantsWater/sewage treatmentIn situ remediationActive agent

The invention discloses an in-situ remediation system and method for groundwater polluted by perfluorinated compounds, the system comprises a plurality of groundwater wells and an overground remediation device, and a plurality of water inlets are formed in the well walls of the groundwater wells located in the area below the groundwater level; a chemical injection pipe, an aeration pipe and a foam extractor which are connected with the overground repairing device are further arranged in the underground water well, the lower portion of the aeration pipe is inserted below the underground water level, and the foam extractor is arranged on the underground water surface in a floating mode and conveys collected foam into the overground repairing device; the method comprises the following steps: quantitatively injecting a surfactant with high affinity with a perfluorinated compound into each underground water well; aeration is conducted on underground water through the aeration pipe, and foam is formed at the water level of the underground water well; foam is collected by the floating foam extractor and pumped into the overground repairing device to be processed into liquid, a large amount of underground water does not need to be pumped, disturbance to the environment is small, energy consumption is small, a large amount of auxiliary facilities and processing materials are omitted, and cost is greatly reduced.

Owner:森特士兴环保科技有限公司

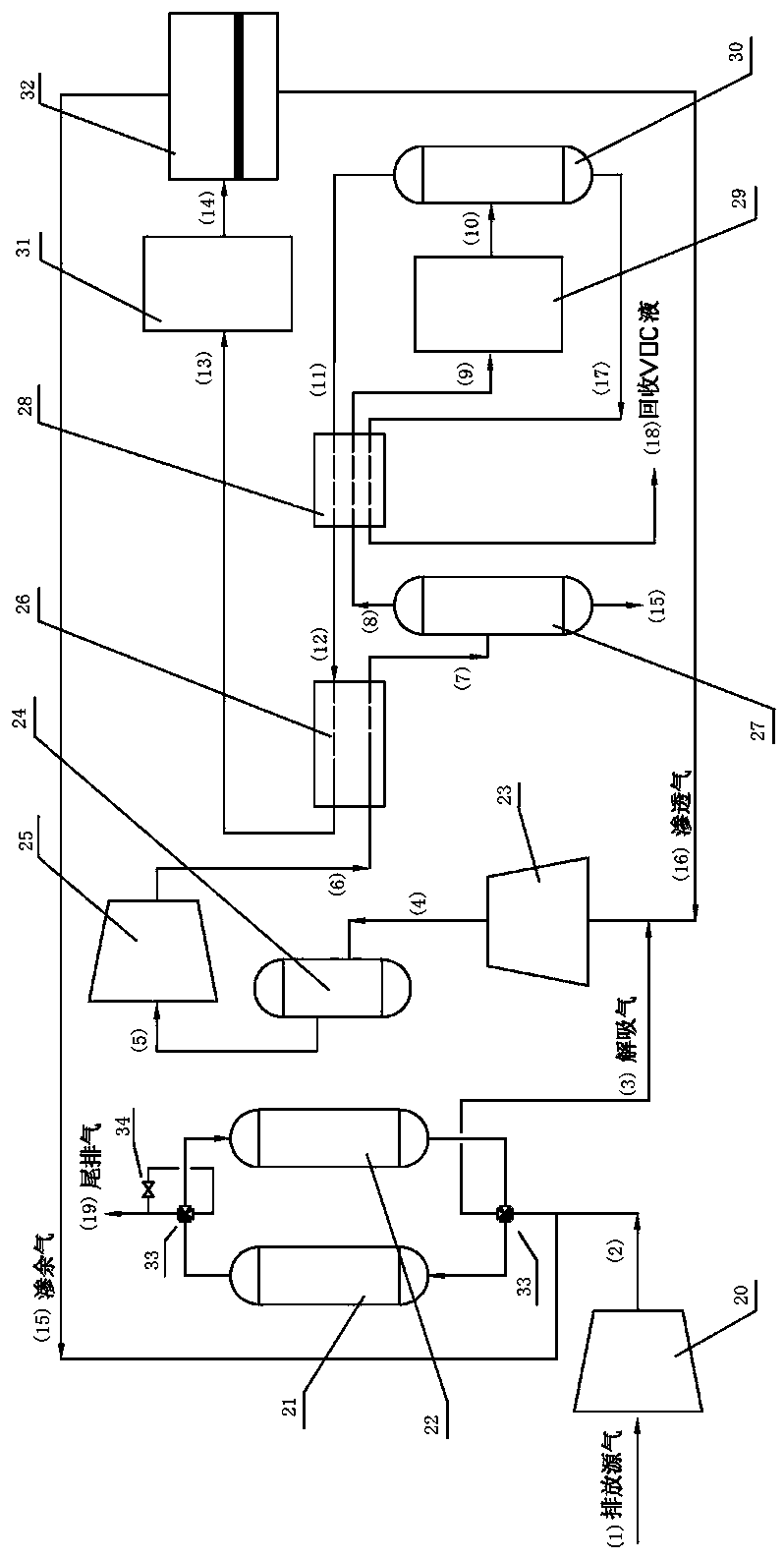

Waste gas treatment system for VOCs recovery

PendingCN110755994AImprove recyclingHas recycling valueGas treatmentDispersed particle filtrationEnvironmental chemistryEnvironmental geology

The invention discloses a waste gas treatment system for VOCs recovery. An adsorption technology, a membrane separation technology and a condensation combination technology are applied; a membrane separation technology is innovatively applied to treat desorbed gas of adsorption equipment; by exerting the concentration effect of membrane separation on VOCs components, not only is the recovery of VOCs by a condensation process enhanced, but also the VOCs concentration of residual gas is lower than the VOCs concentration of discharged raw material gas and is mixed with the discharged raw materialgas to enter adsorption equipment, so that the tail gas emission of the adsorption equipment more easily meets the environmental protection requirement. The adsorption equipment is double-tank type adsorbable / desorbable regeneration equipment, a vacuum desorption regeneration process replaces a traditional steam desorption regeneration process, and the problem that water-soluble VOCs are recovered into a solution and then separated is solved.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

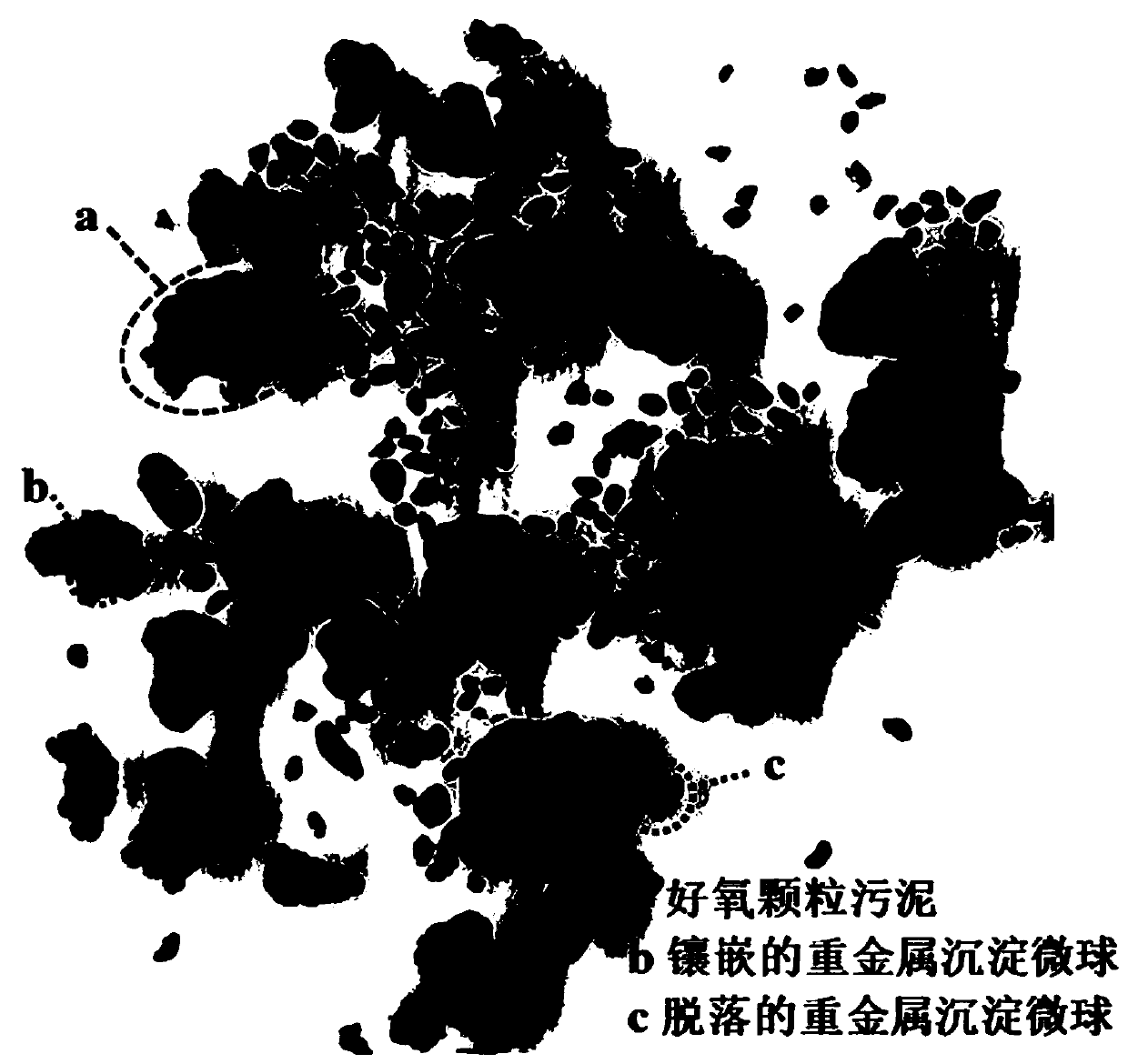

Device and method for removing and recovering cationic heavy metals in organic acid wastewater by using aerobic granular sludge

ActiveCN109704454APromote degradationReduced bioavailabilityTreatment using aerobic processesWater contaminantsSludgeMicrosphere

The invention discloses a device and a method for removing and recovering cationic heavy metals in organic acid wastewater by using aerobic granular sludge. The device comprises an adjusting tank anda reaction tank, wherein the adjusting tank comprises a pH electrode of the adjusting tank, an alkali liquid inlet pipe, a stirring motor, a stirring rod, a stirring paddle and an adjusting tank waterinlet pipe; the reaction tank comprises a pH electrode of the reaction tank, a solenoid valve, a first aeration head, a separation screen, a second aeration head, a precipitation disturbance preventer and a reaction tank water inlet pipe, and the adjusting tank water outlet pipe is connected with the reaction tank water inlet pipe. When the reaction tank is in normal operation, the second aeration pump is used for aeration; at that end of the reaction, a first aeration pump is turned on in a pulse mode for aeration, so that the heavy metal precipitation microspheres formed on the surface of the aerobic granular sludge are dropped, and the precipitation microspheres are separated through a separation sieve and collected in a sludge hopper of the reaction tank, thereby realizing the recovery of heavy metal from the wastewater. The invention can simultaneously remove organic matter and heavy metals in wastewater, and effectively recover heavy metals therein.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com