Deep treatment method and system for solid-containing oil-containing low-concentration heavy metal wastewater

A low-concentration heavy metal, advanced treatment technology, applied in water/sewage multi-stage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Material properties

[0069](1) Low-concentration heavy metal wastewater containing solids and oil: The cold coke wastewater discharged from an oil refinery has a solid particle content of 600 mg / L, an insoluble oil content of 179 mg / L, and heavy metal ions of chromium, tin, nickel, and copper of 0.92 mg / L, 1.6mg / L, 1.2mg / L, and 1.0mg / L, all exceeded the standard. The waste water treatment capacity of the side line experiment is 1m 3 / h, temperature 65°C.

[0070] (2) Separation and adsorption medium: The fluidized bed separator group uses modified carbon ball particles with a particle size of 0.5mm-1.0mm as the separation medium; the heavy metal ion adsorption tower uses self-made EMAH-1 adsorbent with a particle size of 0.3-1.2 mm.

[0071] 2. Process flow

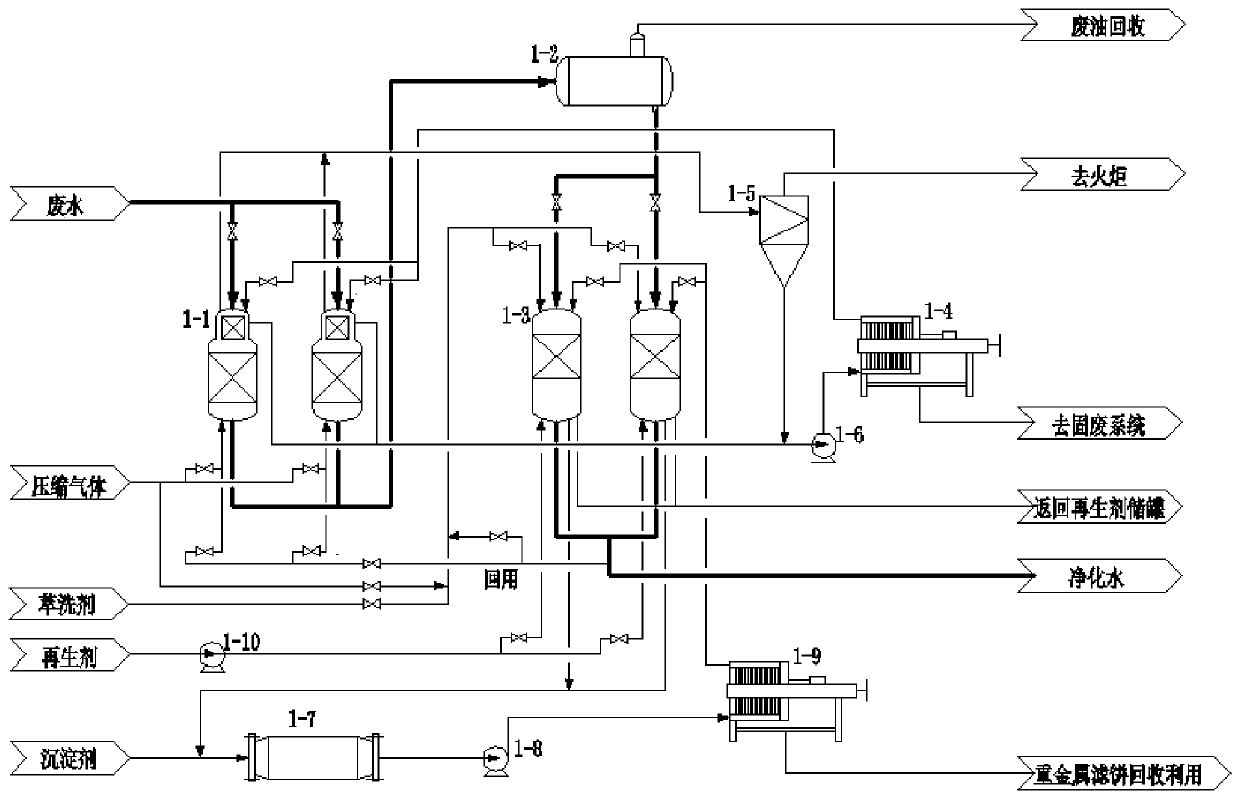

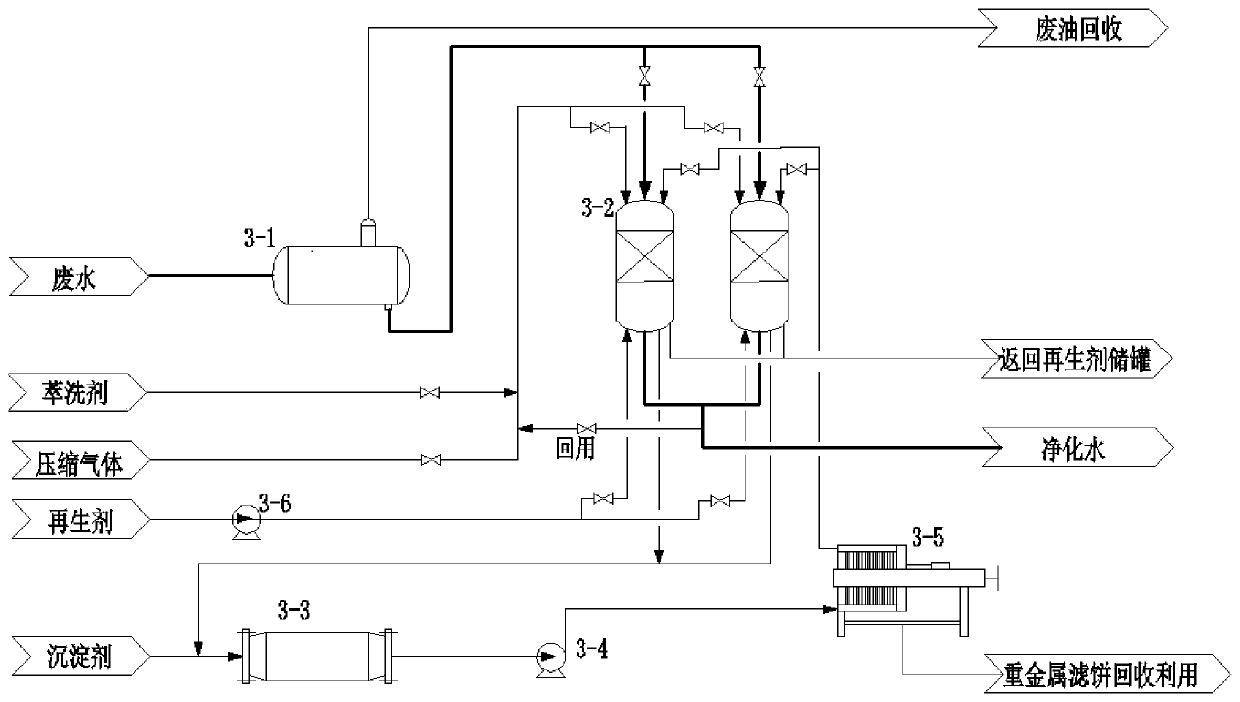

[0072] In view of the characteristics of high solid content and oil content in wastewater, select as attached image 3 Process flow shown. The wastewater first passes through the fluidized bed separator to...

Embodiment 2

[0077] 1. Material properties

[0078] (1) Heavy metal wastewater with low concentration of solids: The content of suspended solids in the desulfurization effluent wastewater of a catalytic cracking unit in a chemical plant is 117mg / L, and the oil content is less than 5mg / L, including nickel (0.5mg / L), copper ( 0.79 mg / L), selenium (0.31mg / L) and three heavy metal ion concentrations exceeded the discharge limit value stipulated in the "Integrated Wastewater Discharge Standard" DB 31 / 199-2018. The waste water treatment capacity of the side line experiment is 1m 3 / h, the temperature is about 50°C.

[0079] (2) Separation medium and heavy metal ion adsorbent: the fluidized bed separator adopts modified quartz sand particles with a particle size of 0.5 mm to 1.0 mm; the heavy metal ion adsorption tower uses self-made R17E adsorbent with a particle size of 0.3 mm to 1.2 mm.

[0080] 2. Process flow

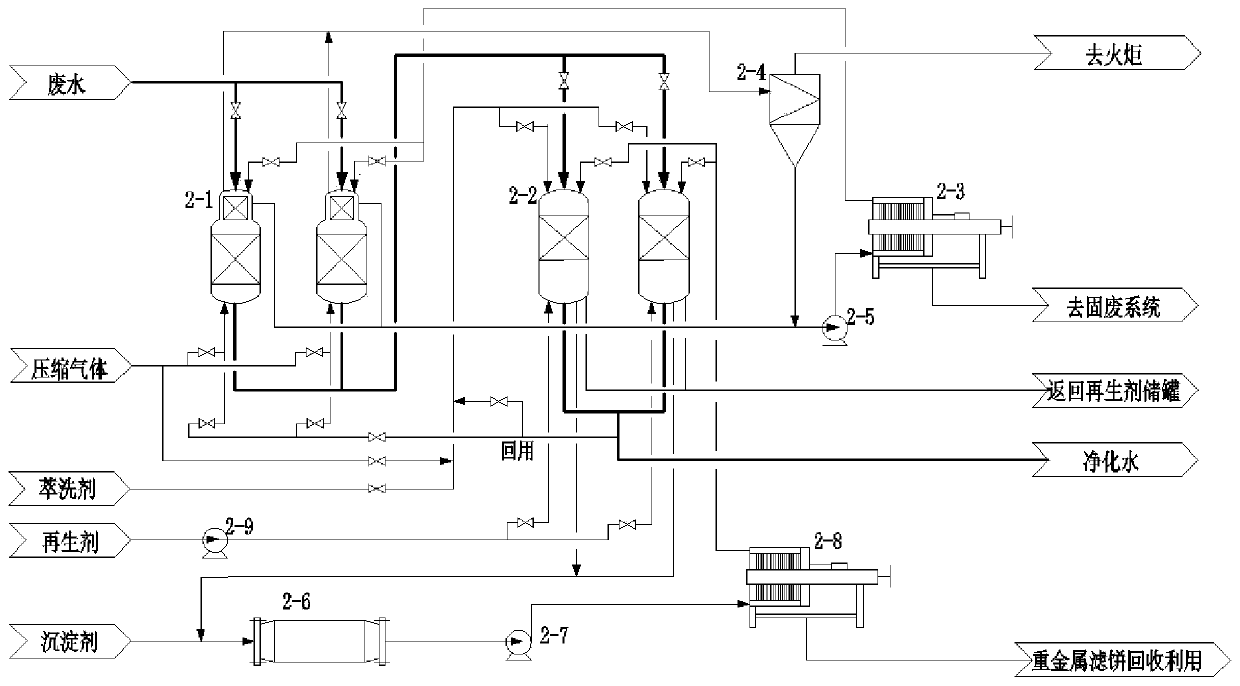

[0081] In view of the characteristics of low oil content and high solid conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com