Refractory iron ore on-line closed-loop shaft furnace roasting, dry grinding and dry separation technology

A technology for iron ore and roasting is applied in the field of online closed-circuit shaft furnace roasting, dry grinding, and dry separation of refractory iron ore, which can solve the problems of high cost, high grade of magnetic separation tailings, uneven quality of roasted ore, etc. The effect of saving water resources, improving resource utilization, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The +15mm~-100mm Jingtieshan oxidized refractory iron ore with a grade of 32% in Jiujiang Iron and Steel Co., Ltd. is processed as follows: Jingtieshan refractory iron ore mainly contains hematite, siderite, limonite and a small amount of magnetite The ore belongs to refractory weak magnetic iron ore, and the surrounding rocks are iron phyllite and jasper.

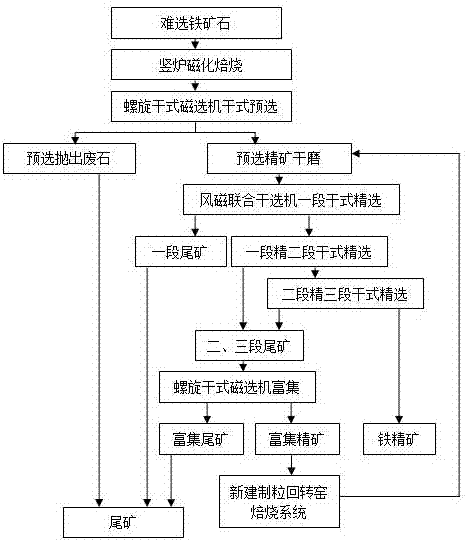

[0023] An on-line closed-circuit shaft furnace roasting dry grinding dry separation process for refractory iron ore, specifically comprising the following steps:

[0024] Step A. +15mm~-100mm Jingtieshan oxidized refractory iron ore is put into the shaft furnace for magnetization roasting, the roasting time is 9 hours, the roasting temperature is 650°C, the roasted ore is cooled to room temperature, the burning loss is 10%, and the roasted ore grade is 35.56 %;

[0025] Step B. Carry out dry pre-selection and discarding of the roasted ore with a spiral dry magnetic separator, the discarding grade is 7%, the discard...

Embodiment 2

[0035] The +15mm~-100mm Jingtieshan oxidized refractory iron ore with a grade of 34% in Jiujiang Iron and Steel Co., Ltd. is processed as follows: Jingtieshan refractory iron ore mainly contains hematite, siderite, limonite and a small amount of magnetite The ore belongs to refractory weak magnetic iron ore, and the surrounding rocks are iron phyllite and jasper.

[0036] An on-line closed-circuit shaft furnace roasting dry grinding dry separation process for refractory iron ore, specifically comprising the following steps:

[0037] Step A. +15mm~-100mm Jingtieshan oxidized refractory iron ore is put into the shaft furnace for magnetization roasting, the roasting time is 9 hours, the roasting temperature is 650°C, the roasted ore is cooled to room temperature, the burning loss is 10%, and the roasted ore grade is 37.78 %;

[0038] Step B. Carry out dry pre-selection and discarding of the roasted ore with a spiral dry magnetic separator, the discarding grade is 7.5%, the disca...

Embodiment 3

[0048] The +15mm~-100mm Jingtieshan oxidized refractory iron ore with a grade of 35% in Jiujiang Iron and Steel Co., Ltd. is processed as follows: Jingtieshan refractory iron ore mainly contains hematite, siderite, limonite and a small amount of magnetite The ore belongs to refractory weak magnetic iron ore, and the surrounding rocks are iron phyllite and jasper.

[0049] An on-line closed-circuit shaft furnace roasting dry grinding dry separation process for refractory iron ore, specifically comprising the following steps:

[0050] Step A. +15mm~-100mm Jingtieshan oxidized refractory iron ore is put into the shaft furnace for magnetization roasting. The roasting time is 9 hours, the roasting temperature is 650°C, the roasted ore is cooled to room temperature, the burning loss is 9.5%, and the roasted ore grade is 38.46 %;

[0051] Step B. Carry out dry pre-selection and discarding of the roasted ore with a spiral dry magnetic separator, the discarding grade is 7.5%, the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com