Method for recycling mixed-acid wastewater generated from metal pickling

A technology for wastewater recovery and metal acid, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, and multi-stage water treatment. It can solve the problems of non-renewable utilization, waste of metal resources, and difficulty in recycling. The effect of saving the dosage and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

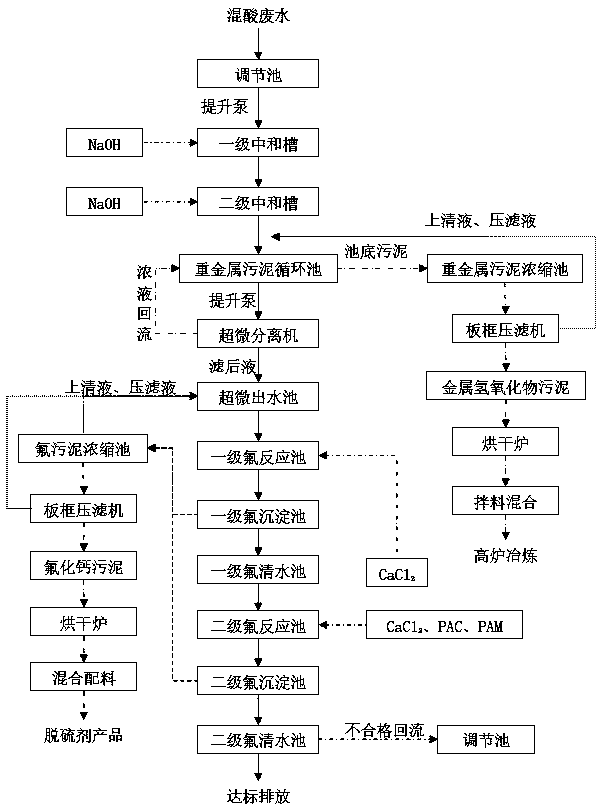

[0046] Adopt the method of the present invention to process the pickling mixed acid waste water discharged from the cold rolling workshop section of a certain stainless steel factory, concrete operation is as follows:

[0047] First, the pickling and mixed acid wastewater discharged from the cold rolling section of a stainless steel factory was introduced into the regulating tank, and the total iron in the wastewater was measured to be 3000mg / L, the concentration of chromium ions was 300mg / L, the concentration of nickel ions was 90mg / L, and the concentration of fluorine ions was 1400mg / L. PH between 1 and 2;

[0048] Then the pickling and mixed acid wastewater is lifted from the adjustment tank to the neutralization tank through the pump. The neutralization tank is divided into two stages, and liquid alkali is added to each stage to adjust the pH. The pH control point of the first-level neutralization tank is: 5--6; The PH control point of the secondary neutralization tank is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com